Page 1

®

FLX200 SERIES

INDUSTRIAL BATTERY CHARGERS

INSTALLATION & OPERATING

INSTRUCTIONS

Page 2

TABLE OF CONTENTS

TITLE Page

1. Important Operating Instructions 2

2. Introduction 3

3. Receiving Instructions 3

4. Location and Installation of Charger 3

5. Stacking 3-4

6. AC Electrical Supply 5-9

6.1 Branch Circuit Protection 5

6.2 AC Voltage Connections 9

6.3 Ground Connection 9

7. DC Output 10

8. Fault and Display Codes 10

9. Options 10

9.1 JIC Switch 10

9.2 Momentary Remote and Stop Operation 10

10. FLX200 Standard Charger Operation 11

11. Charger Functional Description 12

11.1 LED Descriptions 12

11.2 Display 12

11.3 Pause Push Button 12

11.4 Smart Start Stage 12

11.5 Auto Balance 13

11.6 Equalize Stage 13

11.7 Equalize Pushbutton 13

11.8 Low Battery Override/Recovery 13

11.9 Delayed Start of Charge 14

11.10 Battery Cooldown Operation Stage 14

11.11 Refresh Charge 14

11.12 Charge Time 15

11.13 Incorrect Battery Limits 15

11.14 Charge Cycle Reset 15

11.15 AC Power Failure 15

12. Maintenance 15

Appendix A Fault Codes 16

Appendix B FLX200 Troubleshooting 17

Appendix C Single Phase Technical Data 18

Appendix D Three Phase Technical Data 19

Appendix E Circuit Diagrams 20-25

Appendix F Cabinet Dimensions 26

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

1

Page 3

FLX200 SERIES INDUSTRIAL BATTERY CHARGERS

1. IMPORTANT OPERATING AND SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

a) Before using the battery charger, read all the instructions in addition to the

CAUTION, WARNING, and DANGER marking s on the charger, battery, and all

the associated equipment.

b) Do not touch un-insulated parts of the DC output connector or the battery

terminals, as there is a possibility of electric shock.

c) Connect or disconnect the battery plug only when the charger output is off.

ALWAYS press the PAUSE pushbutton before unplugging the battery to

prevent arcing or burning.

d) If the battery is unplugged during charging, the charger will indicate “F18”. To

restart the charger, plug in the next battery. Do not connect the next battery

before you see indication “- - - -” or “F18”.

e) Only qualified personnel should operate or service this equipment.

f) De-energize all AC and DC po wer connections before servicing this unit . If injury

does occur, apply the prescribed treatment for electrical shock and obtain

medical attention immediately.

g) The charger is NOT for outdoor use. Do not expose the charger to rain or snow.

h) This charger is factory set to charge lead-acid batteries only. The operating

environment should not contain any materials that may cause corrosion or

contamination that would degrade the performance of a charger.

i) Do not operate this unit if it has received a sharp blow, been dropped or

otherwise damaged. Take it to a qualified GNB Industrial Power service center.

j) Do not disassemble the charger. Have the charger examined by an GNB

Industrial Power service representative or local qualified service facility. Incorrect

re-assembly of the charger may result in an explosion, electric shock or fire.

k) The charger profile is set at the factory for a charger DC cable length of 9 ft and a

battery DC cable length of 25 in. If DC cable lengths are adjusted, please

contact your local GNB Industrial Power service representative.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

2

Page 4

1. INTRODUCTION

The GNB® FLX200 battery chargers are fan cooled, solid state, microprocessor

controlled, SCR regulated chargers designed to make battery charging simple. They

are factory set to charge flooded lead-acid batteries, but an upgrade can be

purchased from a GNB Industrial Power service representative to enable the charger

™

to service ELEMENT

valve regulated lead-acid batteries. The charger has a

comprehensive self-checking diagnostic program to control all charger functions,

monitor the quality of charge and check its own safety conditions. Large easy to read

LEDs, two button keypad and LED display report on the charger and battery status.

2. RECEIVING CHARGER

Examine the charger thoroughly before using, to make sure that no parts have been

loosened or damaged during shipment. Check the contents of the package against

the delivery slip before disposing of the shipping package. If any shipping damage or

partial loss is found, file a claim with the carrier without delay and take any necessary

steps to protect your rights. Before installing, check that the charger nameplate data

corresponds to the packing slip and to the model specified on the original sales

order. The FLX200 chargers are delivered on skids for easy handling using a forklift

truck.

3. LOCATION AND INSTALLATION OF CHARGER

Proper installation is important in order to achieve good charger performance and

long trouble free operation and to prevent damage to the charger and batteries. The

charger should be located in a clean, cool, normal ambient room temperature

(between +32

o

F/0oC and 104oF/40oC), dry and well-ventilated area. In order to permit

free air flow for convection cooling allow four inches minimum between the charger

and any wall, six inches from other equipment, and never store anything beneath or

on top of the charger.

4. STACKING

The following recommendations should be taken into consideration when stacking

these units:

a) The base unit should be secured to the floor or a solid base using appropriate

bolts and with accordance to local building codes and regulations.

b) These units can be stacked to a maximum 3 high.

c) If a lifting sling is used, the sling should be placed under the unit where the base

plate is located to avoid damage to the units.

Lifting Sequence is as follows: a) Secure the base unit to the floor or solid base. T he bolts can be accessed and

secured from the underside of the unit at the front and rear or from inside the unit

where the large holes are located directly above mounting holes (see appendix G

for mounting hole locations). When accessing the mounting holes from the

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

3

Page 5

inside, it is recommended you use a long handle hexagon key or screwdriver with

the hexagon key inserted. This will allow you to go t hrough the base plate to the

bolts, which are located on the flange.

b) Remove the bolts from the top cover of the base unit, but do not discard these,

as they will be required to fix the two units together.

c) Use an appropriate lifting sling to lift the second unit on to the base unit, inch the

second unit over the base unit and align the holes before resting the second unit

on top.

d) Secure the two units together using the bolts removed from the top cover of the

base unit. Use the access between the two units or inside the second unit using

the tools as recommended above.

e) If stacking three high, use the above procedure for stacking the third unit.

WARNING: THESE PROCEDURES MUST BE FOLLOWED EXACTLY TO AVOID

INJURY OR RISK OF ELECTRIC SHOCK.

WARNING: TO REDUCE THE RISK OF FIRE, INST ALL BATTERY CHARGER ON A

FLOOR OF NON-COMBUSTIBLE MATERIAL SUCH AS STONE, BRICK,

CONCRETE OR METAL. IF THIS IS NOT AVAILABLE, A FLOOR

PLATE OF AT LEAST 1.43mm GALVANIZED OR 1.6mm UNCOATED

STEEL EXTENDED AT LEAST 150mm BEYOND THE EQUIPMENT ON

ALL SIDES MUST BE INSTALLED.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

4

Page 6

5. AC ELECTRICAL SUPPLY

The charger must be connected to either a single phase or three phase, 60 Hertz

(± 2%) AC power source. Three phase chargers cannot be powered with a single

phase source.

The following transformer options are available:

TABLE 1 – TRANSFORMER OPTIONS

Single phase Three phase

120/208/240 VAC 60Hz* 208/240/480 VAC, 60Hz*

208/240/480 VAC, 60Hz* 240/480 VAC, 60Hz*

240/480 VAC, 60Hz* 480 VAC, 60Hz

600 VAC, 60Hz 600 VAC, 60Hz

*Only the AC input wire configuration for multi-input chargers can be changed

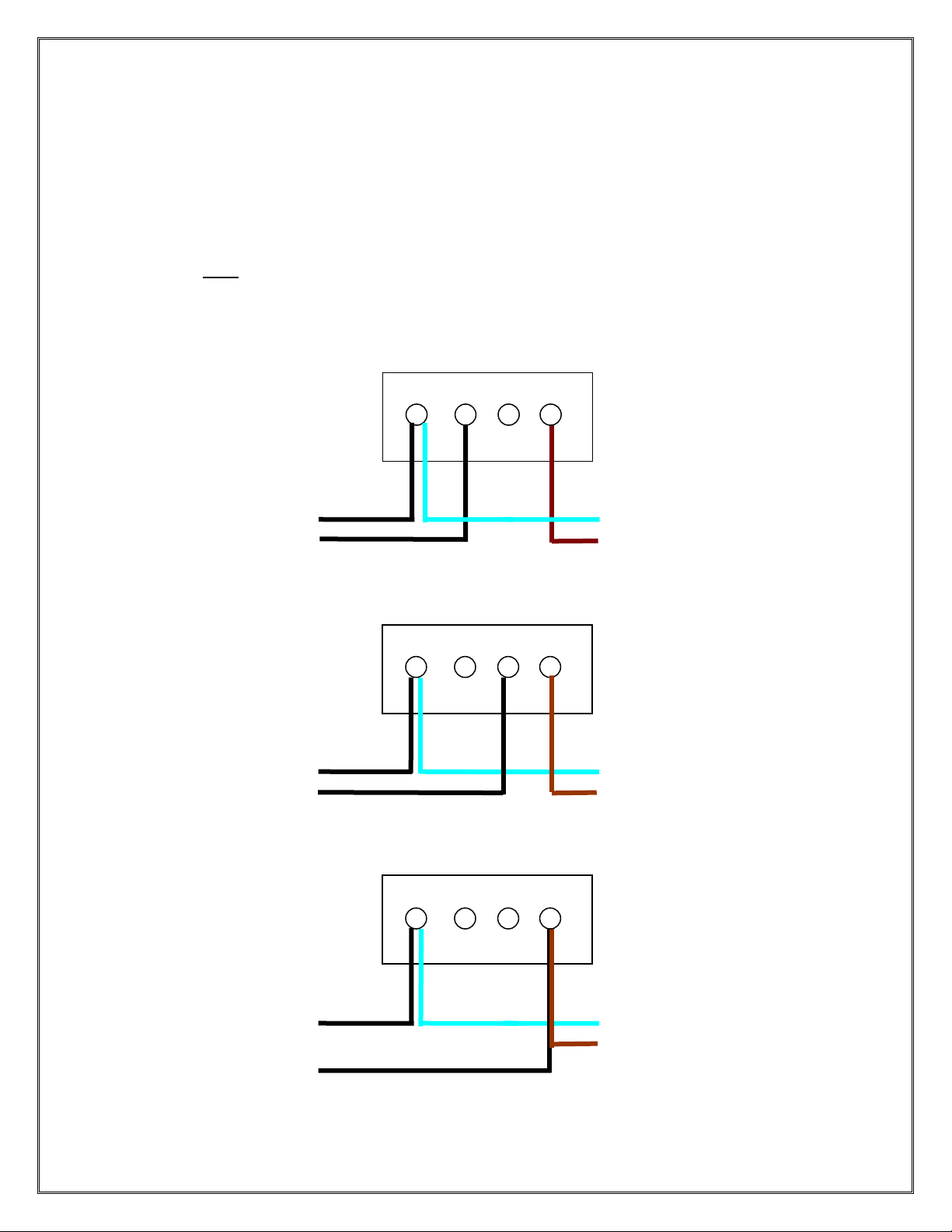

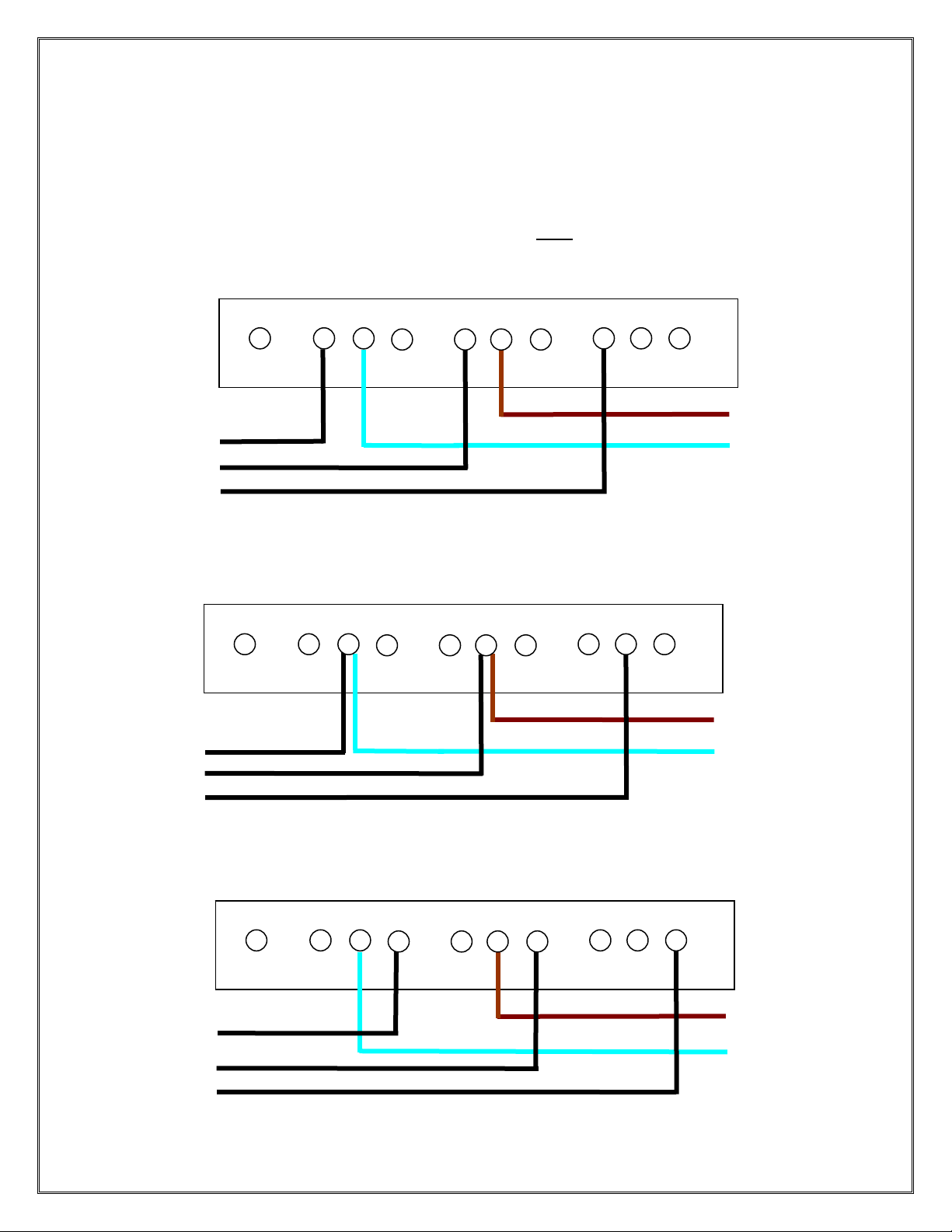

Follow Figure 1 (page 6) for single-phase input with 120/208/240 VAC transformers,

Figure 2 (page 7) for single-phase input with 208/240/480 transformers or Figure 3

(page 8) for three-phase input transformers.

Use the 208/240/480 diagram for the 240/480 transformers. The 208 tap will be

eliminated from the charger as a selection.

A qualified electrical contractor should perform this adjustment.

6.1 BRANCH CIRCUIT PROTECTION

The charger comes with an internal supplementary protective device rated to

accommodate the highest possible current and voltage for that model.

CAUTION: TO REDUCE THE RISK OF FIRE, USE ONLY ON CIRCUITS PROVI DED

WITH BRANCH CIRCUIT PROTECTION CONSISTENT WITH THE

CURRENT INDICATED ON THE FRONT PANEL-RATING LABEL AND

IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE,

ANSI/NFPA 70.

.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

5

Page 7

L 0

N

L

0

L L N

FIGURE 1: 120/208/240 VAC, SINGLE-PHASE INPUT

WARNING: IM PROPER WIRE AND JUMPER CONNECTION MAY CAUSE SEVERE

DAMAGE TO THE CHARGER AND BATTERY

NOTE: Live connection ‘L’ Must be connected to the breaker. The mains input are the

only user configurable connections. The blue and brown PCB connections must

be altered from factory setting.

NOT

120 VAC 60Hz CONFIGURATION (120/208/240VAC INPUT)

120

208

120

120

208

208

Mains Input

(Black)

(Black)

Mains Input

(Black)

(Black)

N

L

208 VAC 60Hz CONFIGURATION (120/208/240VAC INPUT)

0

N

L

240VAC 60Hz CONFIGURATION (120/208/240VAC INPUT)

240

240

240

PCB

(Blue)

(Brown)

PCB

(Blue)

N

(Brown)

Mains Input

(Black)

(Black)

N

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

PCB

(Blue)

(Brown)

6

Page 8

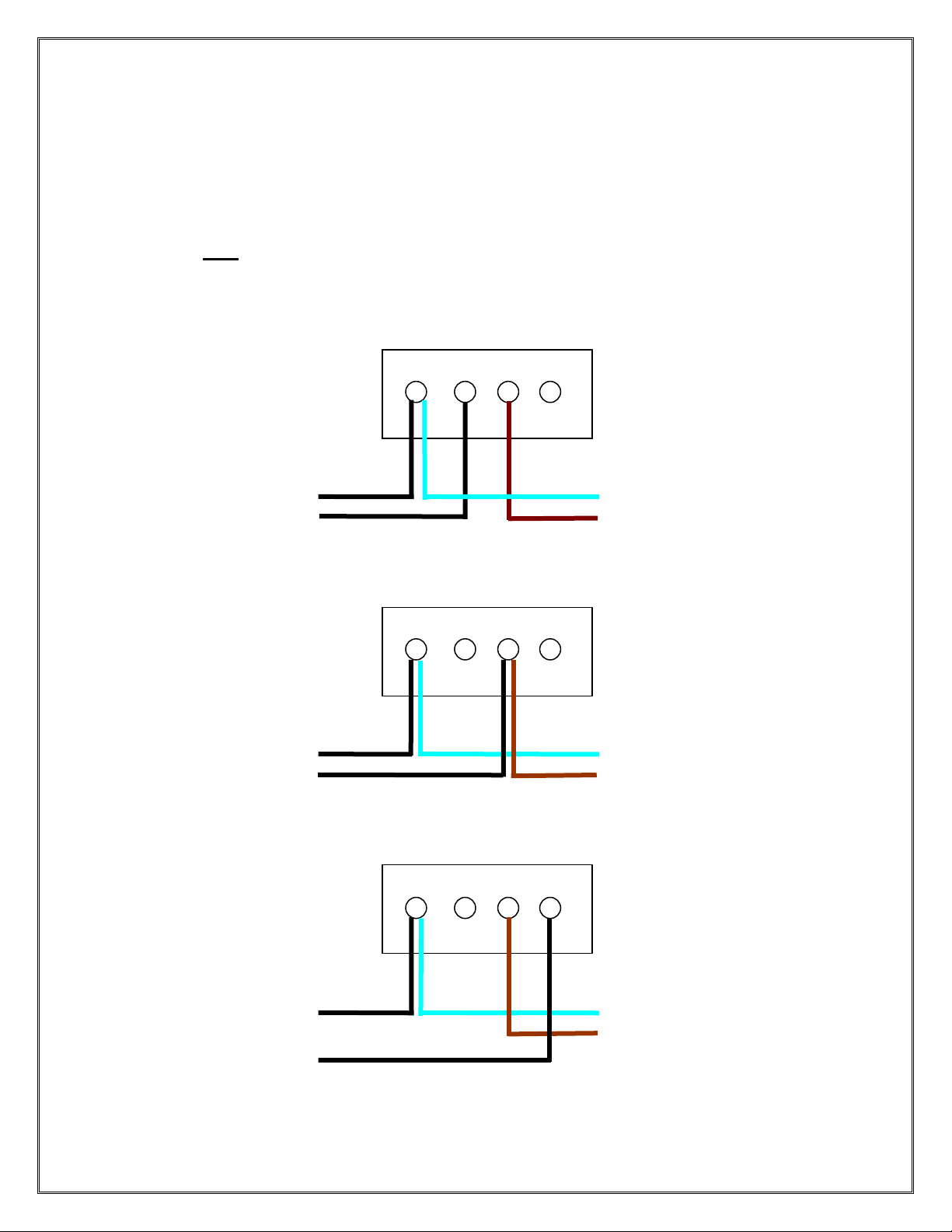

FIGURE 2: 208/240/480 VAC, SINGLE-PHASE INPUT

L 0

N

L L N

0

L L N

WARNING: IM PROPER WIRE AND JUMPER CONNECTION MAY CAUSE SEVERE

DAMAGE TO THE CHARGER AND BATTERY

NOTE: Live connection ‘L’ Must be connected to the breaker. The mains input are the

only user configurable connections. The blue and brown PCB connections must

be altered from factory setting.

NOT

208 VAC 60Hz CONFIGURATION (208/240/480V INPUT)

208

240

Mains Input

(Black)

(Black)

Mains Input

(Black)

(Black)

N

L

240 VAC 60Hz CONFIGURATION (208/240/480V INPUT)

208

0

N

480 VAC 60Hz CONFIGURATION (208/240/480V INPUT)

240

480

480

PCB

(Blue)

(Brown)

PCB

(Blue)

(Brown)

208

240

Mains Input

(Black)

(Black)

N

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

480

PCB

(Blue)

(Brown)

7

Page 9

N

N

N

FIGURE 3: 208/240/480 VAC, THREE-PHASE INPUT

WARNING: IMPROPER WIRE AND JUMPER CONNECTION MAY CAUSE SEVERE

DAMAGE TO THE CHARGER AND BATTERY

NOTE: The blue and brown PCB connections must NOT

208VAC 60 Hz CONFIGURATION (208/240/480V INPUT)

be altered from factory setting.

Mains Input

(Black)

(Black)

(Black)

Mains Input

(Black)

(Black)

(Black)

L1

L2

L3

L1

L2

L3

N

N

208

240VAC 60 Hz CONFIGURATION (208/240/480V INPUT)

208

240

480VAC 60 Hz CONFIGURATION (208/240/480V INPUT)

480

240

480

208 208

208 208

480

480

240240

480

PCB

(Brown)

L

(Blue)

240240

480

PCB

(Brown)

L

(Blue)

208

480

240

208 208

Mains Input

(Black)

(Black)

(Black)

L1

L2

L3

N

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

480

240240

480

PCB

(Brown)

L

(Blue)

8

Page 10

6.2 AC VOLTAGE CONNECTIONS

To connect the input AC voltage, route the AC conduit through the knockout hole

provided. Continue the AC wiring to the breaker terminals L1 (N) and L2 (L) (single

phase input) or L1, L2, and L3 (three phase input). For proper connection, torque the

screws to approximately 25 inch-pounds.

6.3 GROUND CONNECTION

It is a requirement to ground the chassis while the charger is connected to AC power.

The charger comes with a threaded M6 hole, clearly marked on the chassis. To

ensure good continuity, keep the contact area clean.

WARNING: DO NOT OPERATE THE UNIT WITHOUT PROPER GROUNDING.

IMPROPER GROUNDING CAN RESULT IN THE RISK OF AN ELECTRIC

SHOCK.

CAUTION: USE MINIMUM 75°C WIRING FO R SUPPLY CONNECTIONS. GROUND

THE CHARGER PROPERLY USING THE THREADED M6 HOLE (G ND)

PROVIDED. USE COPPER-CLAD ALUMINUM, ALUMINUM OR

COPPER CONDUCTORS ONLY.

After electrical connection is completed, the charger is ready for operation.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

9

Page 11

6. DC OUTPUT

The DC charging cable has a commonly used battery plug or receptacle. The polarity

of the charger plug must be the same as the battery connector. The BLACK DC

cable must be connected to the battery negative terminal (-) and the RED DC cable

must be connected to the battery positive terminal (+). The charger will not operate in

a reversed polarity condition. The DC output fuse is a "fast-acting" fuse used to

protect the power semiconductors of a charger.

NOTE: Use only identical replacement fuses available f rom your GNB Industrial Power

service representative. The DC fuse must be replaced with a fast acting f use

capable of protecting semiconductors. See Appendix C and D for correct fuse

sizes.

7. FAULT AND DISPLAY CODES

Refer to Appendix A and B (on pages 16 and 17) for a complete list of fault codes.

8. OPTIONS

9.1 JIC SWITCH ASSEMBLY

All FLX200 battery chargers can come with a f actory installed JIC switch assembly

option for extra operator protection. In the "OFF" position, the door can be opened

but only AC power at the input of the switch is present while everything downstream

is dead. In the "ON" position, AC power is supplied to the charger but the door

cannot be opened.

9.2 MOMENTARY REMOTE STOP OPERATION

The FLX200 charger has a complete remote control option, which can be factory

installed or field retrofitted. Contact your local GNB Industrial Power representative

for more details.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

10

Page 12

10. FLX200 STANDARD CHARGER OPERATION

CHARGE CONDITION

I1 A A,V,Ah,t,Ph Y*

CONSTANT VOLTAGE A/ #StSt A,V,Ah,t,Ph Y

I2 A A,V,Ah,t,Ph Y

COOL DOWN PERIOD CooL / rt A,V,Ah ,t ,tr G*

TERMINATION rEdy A,V,Ah,t,tr G

TERMINATION/ FAULT CODE rEdy / F A,V,Ah,T,tr R*, G

REFRESH CHARGE A / rEFr A,V,Ah,t,tr G, Y

DISPLAY

DEFAULT

FUNCTION BUTTON DISPLAY SELECTION LED

SETTING EQUALISE EqAL for 5 seconds then default display

EQUALISE CHARGE A / EqAL A,V,Ah,t,tr G*, Y

AUTO BALANCE StSt / A StSt / V A,V,Ah,t,tr G

Lobt CHARGE PERIOD Lobt / A A,V,Ah,t Y*

Lobt OFF PERIOD Lobt / V A,V,Ah,t

CRITICAL FAULT CODE F

NONE CRITICAL FAULT CODE F Charge continues R*

DELAYED START OF CHARGE dELy / rt

Charge

stage

R

A = Output current

V = Volts per cell

Ah = Returned ampere hours

t = Time of recharge

F = Fault code, display will alternate with the two codes

Ph = Phase of charge i.e. 1, 2 and 3

StSt = Smart start

Cool = Cool down period

LoBt = low battery override

/ = Display will alternate with the two-displayed information

rt = Remaining time

tr = Termination method, tr1 = dv/dt, tr2 = I2 entered 3.5 hour timer operated

* = flashing LED.

NOTE: In LoBt, StSt, Equalise and Termination charge function display will only be displayed for 10 seconds, not

permanently.

# Display if due to smart start.

R: Red = Fault, flashing red is a none critical fault.

Y: Yellow = Current f l owing, flashing yellow when < 2.37VPC.

G: Green = charge complete.

tr3 = Constant voltage stage entered 3.5 hour timer operated, tr4 = di/dt.

tr5 = Smart Start, tr6 = Autobalance timeout

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

11

Page 13

11. CHARGER FUNCTIONAL DESCRIPTION

11.1 LED Descriptions

LED Description

Yellow Flashing High Rate Current

Yellow Solid 80% Charged

Green Flashing Cool Down

Green Solid Charge Complete

Red Fault – See page 16 for codes

11.2 DISPLAY

The display by default shows the charging current during the charge cycle. The

display may be changed to show voltage, time or Amp-Hours by pressing the

FUNCTION button. The display may show additional messages as the charge cycle

progr esses or a fault occurs.

11.3 PAUSE PUSH BUTTON

This PAUSE push button will halt the charge cycle. The battery can then be safely

unplugged for up to 10 minutes. If the battery is still connected after this time, the

charger will continue with the present charge cycle.

11.4 SMART START STAGE

The charger begins the charge cycle at the high rate current and continues until the

gassing voltage is reached. If the time to reach the gassing voltage level is equal t o

or less than 2 minutes, then the charge cycle will be suspended and a battery

voltage test to determine if the battery was in a sulphated or heavily discharged

condition will be instigated.

During the suspension, the decay in battery voltage is monitored. At this time, the

display will show VPC only. If the battery voltage decays quickly the battery is

determined to be sulphated and the charger will continue to Stage 1 High Rate or I1

current level with a ‘sulphated battery’ fault set. If the battery voltage does not fall

quickly, the charger will terminate and Auto Balance stage will be entered.

If the time to reach the constant voltage level is greater then 2 minutes and less than

45 minutes, the gassing voltage is maintained until the current level is equal to the

Finish Rate or 32% of the maximum output current. Charge will then terminate and

Auto Balance stage will be entered.

When the constant voltage stage U1 is entered then the display shows ‘StSt’

alternating with current.

When the Auto Balance stage is entered, the green LED will be illuminated and the

display will show ‘StSt’. The FUNCTION button can select charge information.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

12

Page 14

11.5 AUTO BALANCE

The charger maintains a current equal to 32% of the maximum output that is

activated by voltage, on at 2.15VPC and off at 2.35VPC with a time limit of 2 hour if

2.35VPC is not reached.

When current is flowing, amps will be displayed and the yellow LED will be

illuminated. When no current is flowing, the display will show ‘StSt’. The FUNCTION

button can select charge information. The green LED will remain illuminated.

11.6 EQUALIZE STAGE

Equalize charge consists of 3.5 hours at 32% of the maximum output current with a

voltage limit.

The following table summarizes the action taken when Equalize is set manually

during different charge modes…

Charge Mode Action

During recharge Equalize active after termination

After charge termination Equalize active immediately

Smart Start termination Equalize active after termination

11.7 EQUALIZE PUSHBUTTON

Equalize charge can be enabled/disabled, when the FUNCTION button is depressed

> 5 second at anytime whilst a battery is connected. Only one equalize charg e per

recharge cycle is permitted. The equalize charge can be set in the service mode to

be initiated at ‘x’ number of cycles. X = 0 to 255.

CAUTION: DO NOT EQUALIZE MORE OFTEN THAN REQUIRED BY THE

CONDITION OF THE BATTERY, AS SPECIFIED IN THE BATTERY

MAINTENANCE INSTRUCTIONS. EXCESSIVE EQUALIZING MAY

DAMAGE THE BATTERY.

11.8 LOW BATTERY OVERRIDE/RECOVORY

11.8.1 CONFIGURATION

There is the ability to manually override the lo w ‘Incorrect Bat tery’ threshold of

1.70 VPC, down to a minimum of 1.00 VPC - the level at which the charger will

recognize a battery connection. This is achieved by holding the FUNCTION

push button for 5 seconds when the incorrect battery fault has been detected.

11.8.2 OPERATION

If ‘Low Battery Override’ has been enabled and a battery (voltage > 1.00 VPC)

is connected to the charger, the charger will pass current at 75% of maximum

current output the charger rated output current level.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

13

Page 15

If less than 3.0VPC, current will flow for 5 minutes and the charge will be

suspended for 5 minutes. The cycle is repeated until the battery voltage is

greater than 1.70 VPC at the end of the 5-minute rest period.

If the battery voltage is greater than 1.70 VPC at the end of the 5-minute rest

period, the battery recovery mode will cease and charge will start from stage 1

with smart start disabled.

If 3.0 VPC is reached within the 5 minutes of charge, the charge will be

suspended equal to the ‘on’ time, maximum of 5 minutes. During this period

the display will show ‘Lobt’. During the 5-minute off period the display will

show the battery volts per cell alternating with ‘Lobt’.

11.9 DELAYED START OF CHARGE

A charge delay can be set in the service mode. The time is 0 to 48 hours in 1-hour

steps; this is permanently set for every charge cycle.

The display will show ‘dELy’ and alternate with the time remaining before charge

starts.

11.10 BATTERY COOLDOWN OPERATION STAGE

The cool down period begins after charge termination and is equal to the time spent

on charge.

During the cool down period, the green LED will flash and the display will show

‘CooL’ alternating with the remaining cool down time. The FUNCTION button can

select charge information and display this momentarily.

Once the cool down period is complete, the charger will illuminate the green LED

and enter the refresh stage.

If the battery is disconnected before completion of the cool down period, the

countdown will cease and the display will show F19.

If equalize is activated during cool down, the cool down timer will be suspended until

Equalize is complete, whereupon the cool down timer countdown will resume.

11.11 REFRESH CHARGE STAGE

The Refresh Charge activates every 24 hours after the standard charge cycle, if the

battery remains connected to the charger. The Refresh Charge stage lasts for 10

minutes and consists of Finish Rate or 32% of the maximum output current.

The 24-hour refresh delay starts after termination of recharge or Equalize. During

the refresh off period the display will show ‘rEdy’. The green LED will remain

illuminated. The FUNCTION button can select charge information.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

14

Page 16

During the 10-minute Refresh Charge per iod the display will toggle between ‘rEFr ’

and the output current. The yellow LED is illuminated and t he green LED will remain

illuminated and the FUNCTION button can select charge status.

The charger will remain in the Refresh Charge stage until the battery is

disconnected.

11.12 CHARGE TIME

The amount of time a battery charges will vary depending on the depth of discharge

(DOD). Once the battery has reached 80% charged, the cycle will be terminated after

3.5 hours or less if terminated by dV/dt. Normal charge cycles will average about 8

hours total.

11.13 INCORRECT BATTERY LIMITS

Incorrect battery detection limits will be < 1.70 VPC and > 2.25 VPC (off charge). If

the battery voltage comes within this window the charger will automatically

commence charging.

11.14 CHARGE CYCLE RESET

A charge cycle is reset when a battery is disconnected and a battery is reconnected.

11.15 AC POWER FAILURE

If the AC power fails during a charge cycle, the charger will resume t he cycle at the

point of termination as soon as AC power is restored.

12. MAINTENANCE

The charger requires minimum maintenance. ENSURE THE CHASSIS IS SECURELY

GROUNDED per the local/federal Electrical Code. Do not allow excessive dust to

accumulate on the components inside. Blow out with clean compressed air when

necessary. The chargers are designed with a breaker and fuse for t he AC input and DC

output respectively. Should this fuse fail or breaker trip, the cause must be determined

before they are corrected or replaced. Never replace the fuse or breaker with one of a

higher capacity than the one originally fitted.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

15

Page 17

APPENDIX A – FAULT CODES

CODE STATUS DESCRIPTION

F01 N Over discharged battery (<1.90vpc after 30 seconds of charge)

F02 N Deep discharged battery (<1.90vpc after 30 seconds of charge > 1.90vpc)

F03 N Sulphated battery

F04 S Charger over heating

F05 S Mains failed during charge

F06 R No output current

F07 C Incorrect battery < 1.70

F07 (+Y led on) C Incorrect battery > 2.25

F09 C Bulk charge time-out

F10 C Second stage time-out (Profile Dependant)

F11 C Incorrect Mains Frequency

F12 C Control hardware (MCU)

F13 S Thermistor fault

F16 S Battery overheating (if temp probe fitted)

F17 C Auto balance charge time-out

F18 C Battery disconnected without pausing charge

F19 C Battery disconnected in cool do wn peri od

Key: C = critical fault Ö charge stopped Ö fault code displayed permanently

S = suspend fault Ö charge suspended until criteria fulfilled Ö fault code displayed permanently

R = retry fault Ö charge retries after 20 s econds Ö fault code disp lay alternating with stan dard

display

N = non-critical fault Ö charge continues Ö fault code dis pl a y alterna tin g with sta ndar d dis p lay

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

16

Page 18

APPENDIX B – FLX200 TROUBLESHOOTING

SYMPTOM

No Display No AC Power Check Input Power. Check Breaker. Mains fuse on Control Board

POSSIBLE

CAUSE

EXPLANATION / ACTION

Deeply

F01

F02

F03 Sulphated Battery

F04

F05 Mains Failure Electrical Supply failure during charge. (Power Cut)

F06

F07

F09 Battery Failure

F10

Discharged

Battery

Over Discharged

Battery

Charger

Overheating

No Output

Current

Incorrect Battery Make sure the battery voltage matches the charger voltage.

Low Voltage

<1.70 vpc

High Voltage

>2.25 vpc

Second Stage

Time-Out

Battery Voltage less than 1.9 volts per cell initially but rose above this

level within the first minute. Check battery condition and Equalize.

Battery less than 1.9 volts per cell after the first minute of charge. Check

battery condition and Equalize

Make sure your battery gets a full charge every cycle. Check battery

condition and Equalize.

Check Fan for operation on initial power up. Ensure adequate

ventilation. Contact your local

Check DC Fuse, SCRs. Connection to Battery.

Check battery voltage with a voltage meter. Make sure battery voltage

matches charger. Battery may require servicing.

Check battery voltage with a voltage meter. Make sure battery voltage

matches charger.

Battery did not reach gassing volts within the time limit.

Check battery for low voltage. Confirm charger capacity is correctly

matched to battery. Check battery condition.

Contact your local

I2 limit not reached within time limit. Check battery condition.

Contact your local

GNB Industrial Power representative.

GNB Industrial Power representative.

GNB Industrial Power representative.

F11

F12

F13

F17

F16

F18

F19

Incorrect Mains

Frequency

Board

Failure

Temperature

Sensor Failure

Auto Balance

Stage Time Out

Battery

Overheating

Battery

Disconnection

Battery

Disconnection in

Cool Down

Check the mains supply.

Contact your local

Contact your local

Check battery condition.

Check battery for High Temperature. Allow battery to cool. Check battery

condition. Confirm charger capacity is correctly matched to battery

Press the PAUSE button before disconnecting the battery.

Allow the battery to cool before use.

GNB Industrial Power representative.

GNB Industrial Power representative.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

17

Page 19

APPENDIX C – SINGLE PHASE TECHNICAL DATA

SINGLE PHASE MAXIMUM AC AMPS (RMS) SHIPPING DATA

FLX or SCR Amp DC DC 120 208 240 480 600 Cabinet WEIGHT

Model Numbers Hour Volts Amps VAC VAC VAC VAC VAC Size Lbs KG

200-06-260S1 260 12 40 11.7 6.7 5.8 2.9 M4 79 36

200-06-475S1 475 12 75 21.9 12.6 10.9 5.5 M4 97 44

200-06-600S1 600 12 95 27.7 16 13.9 6.9 M4 101 46

200-06-865S1 865 12 135 16.2 19.7 9.8 M4 125 57

200-06-965S1 965 12 150 25.2 21.9 10.9 M4 154 70

200-09-475S1 475 18 75 17 14.7 7.3 M4 114 52

200-09-600S1 600 18 95 21.5 18.6 9.3 M4 119 54

200-09-865S1 865 18 135 30.5 26.4 13.2 M4 143 65

200-09-965S1 965 18 150 33.9 29.4 14.7 M4 178 80

200-12-260S1 260 24 40 19.7 11.4 9.8 4.9 3.9 M4 95 43

200-12-475S1 475 24 75 21.3 18.4 9.2 7.4 M4 134 61

200-12-600S1 600 24 95 27 23.4 11.7 9.3 M4 145 66

200-12-750S1 750 24 115 32.6 28.3 14.1 11.3 M4 163 74

200-12-865S1 865 24 135 38.3 33.2 16.6 13.3 M4 169 77

200-12-965S1 965 24 150 42.6 36.9 18.4 14.8 M4 198 90

200-18-260S1 260 36 40 16 13.8 6.9 5.5 M4 136 62

200-18-475S1 475 36 75 29.9 25.9 13 10.4 M4 158 72

200-18-600S1 600 36 95 37.9 32.9 16.4 13.1 M4 163 74

200-18-750S1 750 36 115 45.9 39.8 19.9 15.9 M5 216 98

200-18-865S1 865 36 135 46.7 23.3 18.7 M5 238 108

200-24-260S1 260 48 40 20.6 17.8 8.9 7.1 M5 132 60

200-24-475S1 475 48 75 38.6 33.4 16.7 13.4 M5 198 90

200-24-600S1 600 48 95 48.9 42.4 21.2 16.9 M5 242 110

*DC FUSE MUST BE A FAST ACTING FUSE CAPABLE OF PROTECTING SEMICONDUCTORS.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

18

Page 20

APPENDIX D – THREE PHASE TECHNICAL DATA

THREE PHASE MAXIMUM AC AMPS (RMS) SHIPPING DATA

FLX or SCR Amp DC DC 120 208 240 480 600 Cabinet WEIGHT

Model Numbers Hour Volts Amps VAC VAC VAC VAC VAC Size Lbs Kg

200-06-475T1 475 12 75 6.1 5.3 2.6 M4 101 46

200-06-600T1 600 12 95 7.7 6.7 3.3 M4 101 46

200-06-750T1 750 12 115 9.3 8.1 4.0 M4 123 56

200-06-865T1 865 12 135 10.9 9.5 4.7 M4 132 60

200-06-965T1 965 12 150 12.1 10.5 5.3 M4 143 65

200-06-1050T1 1050 12 165 13.3 11.6 5.8 M4 163 74

200-06-1200T1 1200 12 185 14.9 13 6.5 M5 246 112

200-06-1450T1 1450 12 225 18.2 15.8 7.9 M5 299 136

200-12-475T1 475 24 75 11 9.7 5 4.2 M4 134 61

200-12-600T1 600 24 95 13.8 12.2 6.3 5.3 M4 145 66

200-12-750T1 750 24 115 16.7 14.6 7.6 6.4 M4 145 66

200-12-865T1 865 24 135 19.5 17.1 8.9 7.6 M4 180 82

200-12-965T1 965 24 150 21.6 18.9 9.9 8.4 M5 238 108

200-12-1050T1 1050 24 165 23.7 20.7 10.8 9.2 M5 238 108

200-12-1200T1 1200 24 185 26.4 23 12.1 10 M5 288 131

200-12-1450T1 1450 24 225 31.9 27.6 14.7 13 M5 365 166

200-18-260T1 260 36 40 8.4 7.3 3.7 3.4 M4 158 72

200-18-475T1 475 36 75 15.5 13.6 7 6.3 M4 180 82

200-18-600T1 600 36 95 19.5 17.1 8.8 8 M4 180 82

200-18-750T1 750 36 115 23.4 20.6 10.7 9.7 M4 209 95

200-18-865T1 865 36 135 27.3 24.1 12.5 11 M5 275 125

200-18-965T1 965 36 150 30.1 26.6 13.9 13 M5 275 125

200-18-1050T1 1050 36 165 33 29.2 15.3 14 M5 297 135

200-18-1200T1 1200 36 185 36.7 32.5 17.1 16 M5 321 146

200-18-1450T1 1450 36 225 44 39.1 20.8 19 M5 398 180

200-18-1700T1 1700 36 265 45.6 24.5 22 M6 466 212

200-24-475T1 475 48 75 20.4 17.8 9.2 8.4 M5 242 110

200-24-600T1 600 48 95 25.7 22.4 11.6 11 M5 264 120

200-24-750T1 750 48 115 30.9 27 14 13 M5 288 130

200-24-865T1 865 48 135 36.1 31.5 16.4 15 M5 299 136

200-24-965T1 965 48 150 39.9 34.8 18.2 17 M5 304 138

200-24-1050T1 1050 48 165 43.7 38.1 20 18 M5 326 148

200-24-1200T1 1200 48 185 42.4 22.4 21 M5 363 165

200-24-1450T1 1450 48 225 27.1 25 M5 464 211

200-36-475T1 475 72 75 30.1 26.2 13.7 13 M5 330 150

200-36-750T1 750 72 115 45.7 39.7 21 19 M5 352 160

200-36-865T1 865 72 135 46.3 24.6 23 M5 374 170

200-36-965T1 965 72 150 27.3 25 M5 396 180

*DC FUSE MUST BE A FAST ACTING FUSE CAPABLE OF PROTECTING SEMICONDUCTORS.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

19

Page 21

APPENDIX F – CIRCUIT DIAGRAMS

Component No:

CLT6006

For 208V input connect to 208V

connections on T1

For 240V input connect to 240V

connections on T1

For 480V input connect to 480V

connections on T1

2

2

0

4

N

8

0

V

V

bl

2

2

4

4

0

8

0

8

0

V

V

V

DRAWING TITLE:

GNB [UL] 3phase wiring diagram

KEY

L1

L2

L3

L1

L2

L3

OR

2

4

8

0

V

4

2

0

8

4

8

0

0

V

V

V

L1

L2

L3

L1

L2

L3

br

T1

PCB1

gy

bl

bl '1'

bl '0'

16

bl '2'

bl BLUE

bk BLACK

br BROWN

gy GREY

rd RED

wh WHITE

YL/G YELLOW / GREEN

br

CON1

FS1

wh '1'

wh '0'

rd

rd

wh '2'

9101112131415

rd

wh

bl

YL/G

blgybl

1234

bk

12345678

Shunt

FS2

_

bk

DRAWING No: 4 - CMP - 2600 - 01 - WD - E

Drawn by:

Trev Peacock

Trev Peacock 10 12 03

Trev Peacock

Trev Peacock

13 12 02

19 12 03

17 03 04

Checked by:

-

-

-

-

MOD No: REV:

C000007

C000044

C000045

C000068

wh '2'

bl '2'

wh '1'

bl '1'

wh '0'

bl '0'

wh

bl

rd

+

CON 5

If any errors are apparent within this

diagram please inform CMP

engineering.

B

Materials: White Polypropylene 60u PP198 TC

C

D

E

Clear Overlaminate 60u PP20

Adheasive: AP51

Size: A5 (210mm x 147mm)

Text: As shown

Colour: Black on white

CMP Batteries Ltd,

Charger Division,

Unit 2 Pisces,

Mosley Road,

Trafford Park,

Manchester.

M17 1PF.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

20

Page 22

Component No:

CLT6005

For 120V input connect to 120V

connections on T1

For 208V input connect to 208V

connections on T1

For 240V input connect to 240V

connections on T1

For 480V input connect to 480V

connections on T1

1

2

2

0

V

0

0

8

V

V

DRAWING TITLE:

GNB [UL] Single phase wiring diagram Fuse / Breakers

KEY

N

L

OR

N

L

N

OR

L

2

4

0

V

bl BLUE

bk BLACK

br BROWN

gy GREY

rd RED

wh WHITE

YL/G YELLOW / GREEN

YL/G

V

0

bl

OR

2

4

2

0

8

4

8

0

V

0

0

V

V

V

240V

br

PCB1

gy

bl

wh

CON1

rd

rd

FS1

rd

blgybl

br

1234

wh

bl

bk

12345678

T1

CON 5

wh

wh

wh

Shunt

FS2

bl

rd

_

bk

+

DRAWING No: 4 - CMP - 2600 - 02 - WD - E

Drawn by:

Trev Peacock

Trev Peacock

Trev Peacock

Trev Peacock

17 04 03

10 12 03

19 12 03

17 03 04

Checked by:

-

-

-

-

MOD No: REV:

C000007

C000044

C000045

C000068

If any errors are apparent within this

diagram please inform CMP

engineering.

B

Materials: White Polypropylene 60u PP198 TC

C

D

E

Clear Overlaminate 60u PP20

Adheasive: AP51

Size: A5 (210mm x 147mm)

Text: As shown

Colour: Black on white

CMP Batteries Ltd,

Charger Division,

Unit 2 Pisces,

Mosley Road,

Trafford Park,

Manchester.

M17 1PF.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

21

Page 23

Component No:

CLT6006C

Transformer determines voltage

operation. Connect to T1 for 600V

input voltage operation.

DRAWING TITLE:

GNB [UL] 3phase wiring diagram 600V Fuse/Breaker

KEY

bl BLUE

bk BLACK

br BROWN

gy GREY

rd RED

wh WHITE

YL/G YELLOW / GREEN

L1

L2

L3

L1

L2

L3

OR

br

F2

2

4

0

V

6

N

0

0

V

6

6

0

0

0

0

V

V

L1

L2

L3

L1

L2

L3

YL/G

bl

blgybl

wh '0'

CON1

rd

br

1234

FS1

wh

bl

rd

rd

bk

12345678

T1

PCB1

gy

bl

bl '1'

bl '0'

16

CON 5

wh '1'

bl '2'

wh '2'

9101112131415

wh '2'

bl '2'

wh '1'

bl '1'

wh '0'

bl '0'

wh

Shunt

bl

rd

FS2

_

bk

DRAWING No: 4 - CMP - 2600 - 03 - WD - C

Drawn by:

Trev Peacock 01 10 03

Trev Peacock 19 12 03

Trev Peacock 17 03 04

Checked by:

-

-

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

+

MOD No: REV:

A-C000045

C000068

B

C

If any errors are apparent within this

diagram please inform CMP

engineering.

Materials: White Polypropylene 60u PP198 TC

Clear Overlaminate 60u PP20

Adhesive: AP51

Size: A5 (210mm x 147mm)

Text: As shown

Colour: Black on white

CMP Batteries Ltd,

Charger Division,

Unit 2 Pisces,

Mosley Road,

Trafford Park,

Manchester.

M17 1PF.

22

Page 24

Component No:

CLT6005JIC

For 120V input connect to 120V

connections on T1

For 208V input connect to 208V

connections on T1

For 240V input connect to 240V

connections on T1

For 480V input connect to 480V

connections on T1

1

2

0

0

V

V

DRAWING TITLE:

GNB [UL] Single phase wiring diagram single phase JIC

KEY

N

L

OR

N

L

N

OR

L

2

2

4

0

0

8

V

V

bl BLUE

bk BLACK

br BROWN

gy GREY

rd RED

wh WHITE

YL/G YELLOW / GREEN

N

L

V

0

bl

OR

2

4

2

0

4

0

V

8

8

0

0

V

V

V

240V

br

PCB1

gy

bl

wh

CON1

rd

rd

FS1

rd

blgybl

br

1234

wh

bl

bk

12345678

T1

CON 5

wh

wh

wh

Shunt

FS2

bl

rd

_

bk

DRAWING No: 4 - CMP - 2600 - 04 - WD - C

Drawn by:

Trev Peacock 01 10 03

Trev Peacock

Trev Peacock

01 10 03

17 03 04 - C000068 C

Checked by:

- C000045 B

MOD No: REV:

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

If any errors are apparent within this

diagram please inform CMP

engineering.

A--

Materials: White Polypropylene 60u PP198 TC

Clear Overlaminate 60u PP20

Adheasive: AP51

Size: A5 (210mm x 147mm)

Text: As shown

Colour: Black on white

CMP Batteries Ltd,

Charger Division,

Unit 2 Pisces,

Mosley Road,

Trafford P a rk,

Manchester.

M17 1PF.

23

Page 25

Component No:

CLT6006JIC

DRAWING TITLE:

GNB [UL] 3phase wiring diagram JI C

For 208V input connect to 208V

connections on T1

For 240V input connect to 240V

connections on T1

For 480V input connect to 480V

connections on T1

2

0

N

8

V

2

2

4

0

V

2

4

0

8

8

0

V

V

2

4

4

0

8

0

8

0

V

V

V

T1

bl

KEY

L1

L2

L3

L1

L2

L3

NOTE

ISOLATOR AND

BREAKER MAY

BE COMBINED

bl BLUE

bk BL ACK

br BROWN

gy GREY

rd RED

wh WHITE

YL/G YELLOW / GREEN

OR

L1

L2

4

2

8

4

0

0

V

V

L3

L1

L2

L3

L1

L2

L3

YL/G

br

blgybl

br

PCB1

gy

bl

bl '1'

bl '0'

16

CON 5

bl '2'

CON1

FS1

wh '1'

rd

wh

rd

rd

wh '0'

wh '2'

9101112131415

1234

bl

bk

12345678

Shunt

FS2

_

bk

DRAWING No: 4 - CMP - 2600 - 05 - WD - C

Drawn by:

Trev Peacock 01 10 03

Trev Peacock

Trev Peacock

01 10 03

17 03 04

Checked by:

- C000045 B

- C000068 C

MOD No: REV:

wh '2'

bl '2'

wh '1'

bl '1'

wh '0'

bl '0'

wh

bl

rd

+

If any errors are apparent within this

diagram please inform CMP

engineering.

A--

Materials: White Polypropylene 60u PP198 TC

Clear Overlaminate 60u PP20

Adhesive: AP51

Size: A5 (210mm x 147mm)

Text: As shown

Colour: Black on white

CMP Batteries Ltd,

Charger Division,

Unit 2 Pisces,

Mosley Road,

Trafford Park,

Manchester.

M17 1PF.

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

24

Page 26

Component No:

CLT6006CJIC

Transformer determines voltage

operation. Connect to T1 for 600V

input voltage operation.

DRAWING TITLE:

GNB [UL] 3phase wiring diagram 600V JI C

bl BLUE

bk BLACK

br BROWN

gy GREY

rd RED

wh WHITE

YL/G YELLOW / GREEN

L1

L2

L3

L1

L2

L3

OR

KEY

F2

L1

2

4

0

V

6

N

0

0

V

6

6

0

0

0

0

V

V

L1

L2

L3

br

bl

T1

PCB1

gy

bl

bl '0'

16

CON 5

L1

L2

L3

L2

L3

L1

L2

L3

blgyblbr

CON1

FS1

bl '2'

bl '1'

wh '2'

wh '1'

rd

wh

bl

rd

rd

wh '0'

9101112131415

NOTE

ISOLATOR AND

BREAKER MAY BE

COMBINED

YL/G

1234

bk

12345678

wh '2'

bl '2'

wh '1'

bl '1'

wh '0'

bl '0'

wh

Shunt

bl

rd

FS2

_

bk

DRAWING No: 4 - CMP - 2600 - 06 - WD - C

Drawn by:

Trev Peacock 01 10 03

19 12 03Trev Peacock

Trev Peacock 17 03 04

Checked by:

- C000045

-C

MOD No: REV:

C000068

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

If any errors are apparent within this

diagram please inform CMP

engineering.

A--

Materials: White Polypropylene 60u PP198 TC

B

Clear Overlaminate 60u PP20

Adhesive: AP51

Size: A5 (210mm x 147mm)

Text: As shown

Colour: Black on white

CMP Batteries Ltd,

Charger Division,

Unit 2 Pisces,

Mosley Road,

Trafford Park,

Manchester.

M17 1PF.

25

Page 27

APPENDIX G – DIMENSIONS

CABINET DIM. A DIM. B DIM. C DIM. D DIM. E

Size M4 19.69” 26.65” 16.93” 17.54” 12.99”

Size M5 23.62” 26.65” 20.87” 21.48” 16.93”

Size M6 23.62” 42.00” 23.62” 21.48” 19.69”

Sales • Service • Recycling 888.563.6300 in the USA 800.268.2698 in Canada

26

Page 28

®

SALES – SERVICE - RECYCLING

TOLL FREE

1-888-563-6300 in the USA

1-800-268-2698 in Canada

GNB Industrial Power

A Division of Exide Technologies

U.S.A.- Tel: 888.563.6300

Canada - Tel: 800.268.2698

V19CIL5200ULF 2006-11

www.exide.com

Loading...

Loading...