Page 1

ELEMENTSERIES

INDUSTRIAL BATTERY CHARGERS

INSTALLATION & OPERATING

INSTRUCTIONS

Page 2

Page 3

TABLE OF CONTENTS

SAFETY PRECAUTIONS .......................................................................................................................... 1

CHARGER SPECIFICATIONS ................................................................................................................. 3

INSTALLATION PROCEDURE ................................................................................................................ 4

CHARGER ELECTRICAL INSTALLATION ........................................................................................... 7

CHARGER CONTROLS AND USER INTERFACE............................................................................. 10

OPERATING PROCEDURE............................................................................................................. .... ... 12

CHARGER MENUS .................................................................................................................................. 15

TROUBLESHOOTING.............................................................................................................................. 20

APPENDIX.................................................................................................................................................. 26

Page 4

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 1

SAFETY PRECAUTIONS

BEFORE ATTEMPTING TO OPERATE THE CHARGER, PLEASE READ THIS GUIDE CAREFULLY.

SAVE THESE INSTRUCTIONS – This guide contains important instructions for Element

High

Frequency series product line that shall be follow

ed during installation and maintenance of the charger.

Only qualified personnel should install, operate, or service this equipment.

WARNINGS:

¾WARNING Risk of High Voltages – Lethal voltages are present within the charger enclosure

whenever the ac line is energized and/or the battery/load is connected. The heatsinks and other

internal components present the risk of electric shock.

¾WARNING Risk of Improper Grounding – The charger must be connected to an ac power supply

incorporating an earth/ground. The grounding conductor must be of a size equal to or larger than

the line (phase) conductors.

¾WARNING Risk of Explosive Gases – Working in the vicinity of a lead-acid battery is dangerous.

Batteries generate explosive gases during charging and discharging. To reduce the risk of battery

explosion, follow these safety instructions as well as those published by the battery manufacturer.

¾WARNING Protect Eye and Skin – Wear safety goggles and skin protection while installing your

battery charger or working in the vicinity of lead-acid batteries.

¾To reduce the risk of injury, only charge rechargeable lead-acid batteries. Charging other battery

types may cause damage and result in personal injury.

CAUTIONS:

¾Risk of electric shock from stored energy. Wait at least two minutes after de-energizing the ac

line and disconnecting the battery/load before removing the cover.

¾Risk of electric shock and/or electric energy - high current levels. Do not touch un-insulated

battery, connectors or terminals. All tools should be adequately insulated to avoid the possibility of

shorting connections. Inspect cables often for damage to the insulation. Replace cracked or worn

cables immediately.

¾Risk of fire or explosion from gases vented by batteries. Be sure to discharge static electricity

from tools and technician by touching a grounded surface in the vicinity of the batteries. To prevent

damage to the connectors and reduce the risk of explosion due to arcing, connect or disconnect the

battery plug only when the charger output is off. ALWAYS press the STOP pushbutton before

unplugging the battery to prevent arcing.

¾Risk of electrical component failure due to improper connection. If the charger is incorrectly

wired to input or output devices, or wiring is not in accordance with local safety codes and

standards, the unit is at risk of being destroyed.

Page 5

¾Risk of electrical component failure due to improper installation. To prevent damage from

overheating, proper airflow must be ensured. Do not restrict fan inlets or exhaust outlets. Do not

mount the charger in a confined space or where the exhaust air will recirculate.

¾There are no user serviceable parts within the charger enclosure. If service is required, contact the

local GNB Industrial Power service representative.

¾The charger is NOT for outdoor use. Do not expose the charger to rain or snow.

¾Do not disconnect the battery while under charge.

IMPORTANT:

¾Follow the battery manufacturer's published instructions when installing, charging and servicing

batteries.

¾These instructions assume a certain level of competence by the installer and/or user. The following

practices and codes contain relevant information, and should be consulted for safe handling,

installation, testing, and maintaining deep cycle batteries. Applicable state and local codes must be

followed.

xNESC, National Electric Safety Code, ANSI C2-1993 (or latest revision). Copies may be

obtained by writing:

The Institute of Electrical and Electronics Engineers, Inc.

th

345 East 47

Street, New York, NY 10017, USA

xNEC National Electrical Code NFPA-70 (or latest version) available from: National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269

xFederal Codes:

29CFR1926.441 "Safety Requirements for Special Equipment"

29CFR1910.151(c) "Medical Services and First Aid"

29CFR1910.305(j) "Wiring Methods, Components and Equipment"

STD 1-8.2(e) "OSHA Standing Directive"

xEMC Compliance:

This device complies with Part 15 section 103 of FCC Rules as a digital device used exclusively

as a power system in public utilities or industrial plants.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may

cause undesired operation.

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 2

Page 6

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 3

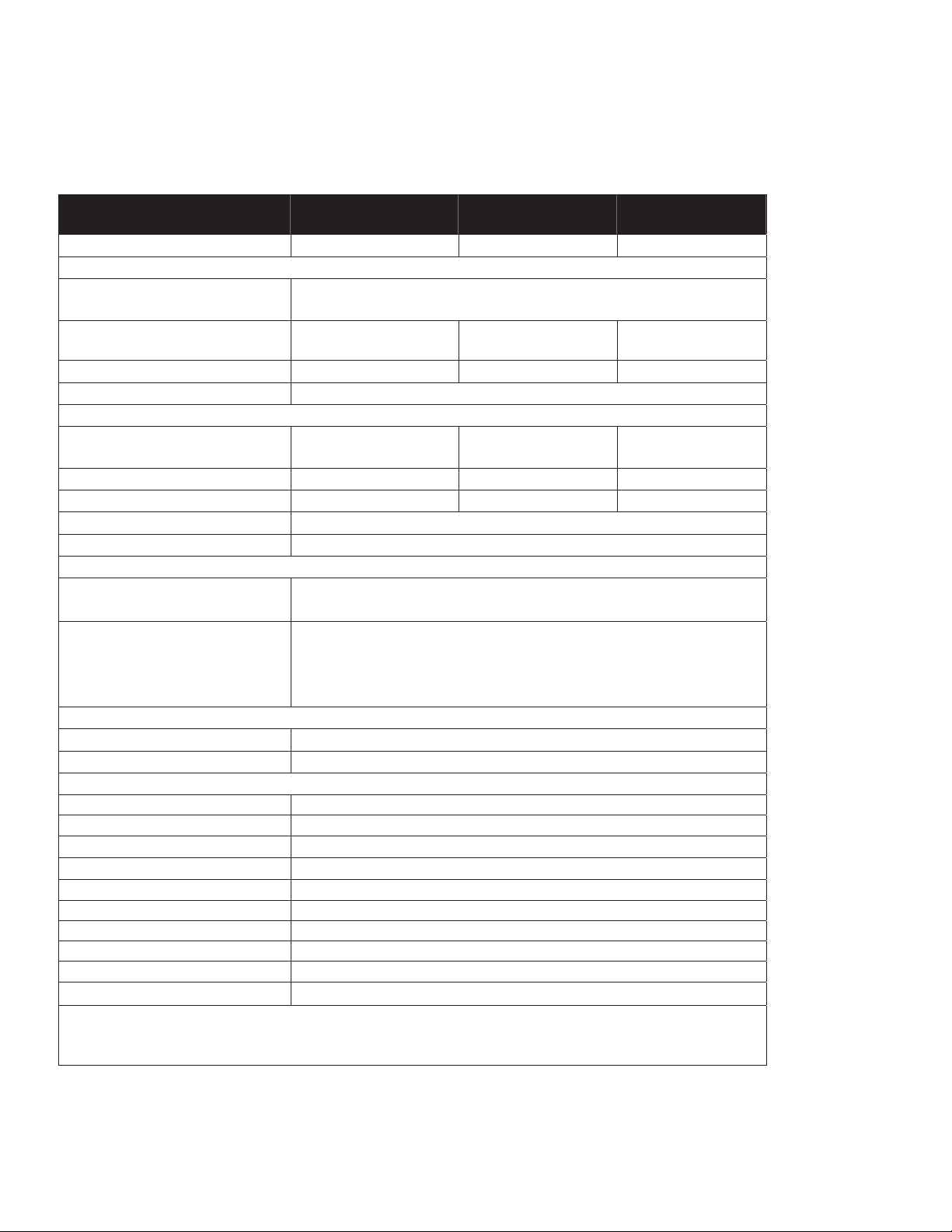

CHARGER SPECIFICATIONS

The Elementsystem specifications are listed below.

LMT-06kW-48-xxxS LMT-10kW-48-

xxxT

LMT-10kW-80-

xxxT

Nominal VA Ratings 48V / 150A

48V / 250A 80V / 120A

Input Specs.

Voltage 480VAC, 3-phase +10% Delta Connection with Earth

Ground

Current (nominal) 8.3A rms / phase

13.8A rms /

phase

13.8A rms /

phase

AC Circuit Size 15A

20A 20A

Power Factor 0.96 (Active Power Factor Correction)

Output Specs.

Voltage 48V Nom. /

62.5V Max.

48V Nom. /

62.5V Max.

80V Nom. /

110V Max.

Current 150A Max.

250A Max. 120A Max.

Power 6 kW Max.

10 kW Max. 10 kW Max.

Pk-Pk Voltage Ripple < 1%

Efficiency (typical) 92% at Full Load

Protection

Input ¾Under voltage

¾Over Voltage

Output ¾Over Current

¾Over Voltage

¾Over temperature

¾Battery reverse polarity protection

Operating Conditions

Ambient Temperature 0 – 40oC

Humidity 10-90% RH non-condensing

Interface

Communication Isolated RS-232 (Ethernet optional)

User Interface LCD/Keypad, RS-232, IR with a PDA (Palm Pilot)

Cooling Forced air (fans)

Mechanical

Dim. WxDxH 29"x8.5"x28"

Weight ~ 98 lb

Output Cabling 2/0 cables

Output Connectors SBX w/aux. contacts or Euro Connector

Auxiliary Contacts Interface with 5kȍbattery thermistor (optional)

Certifications UL and cUL Listed

Note: Design and/or specifications are subject to change without notice. If questions arise,

contact your local sales representative for clarification.

Page 7

INSTALLATION PROCEDURE

I. Charger Inspection

1. Upon receipt of the Element charger, verify that the shipping information (packing list)

matches the charger rating (label on the side of the charger).

2. Upon receipt of the Element charger, ensure that there is no physical damage to the

chassis, the LCD/keypad, the E-Stop/Disconnect switches, or the AC/DC cables. If you

notice any damage, inform the shipping carrier and/or GNB Industrial Power.

Do not install or operate the unit if it has received a sharp blow, been dropped or

otherwise damaged.

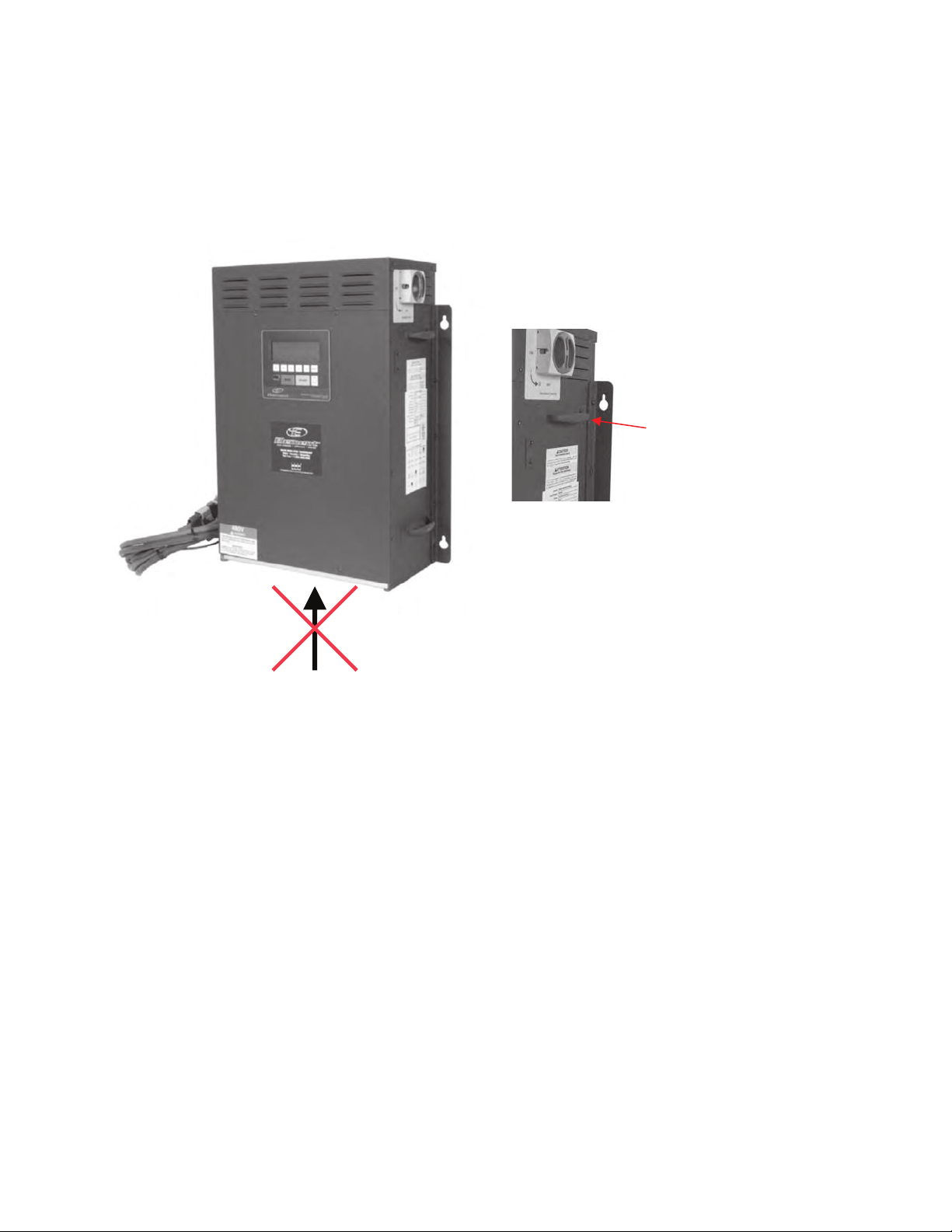

II. Charger Physical Installation

1. Ensure that the charging area is well ventilated, dry, and adequately clean.

2. Do not restrict airflow to the bottom air filter or top cover. Leave at least 1 ft spacing

between the sides of the charger and any adjacent walls or barriers and 2 ft spacing

between the bottom of the charger (air filter) and the floor / any mounting brackets.

3. Use a cardboard sheet as a template to mark the locations for the hardware on the wall.

4. Drill and install the hardware needed to mount the charger on the wall.

5. Lift the charger and mount it on the wall using the installed hardware (Figure 1).

Use ¼-20 hardware with lock washers to secure the charger to wall.

Figure 1: Charger installation

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 4

Page 8

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 5

CAUTION: When installing, do not lift the unit from the middle of the lower cover as this

may damage the filter. To reduce potential for filter damage, lift the charger using the

lifting handles mounted on either side of the charger chassis (see Figure 2).

Figure 2: Charger lifting instructions

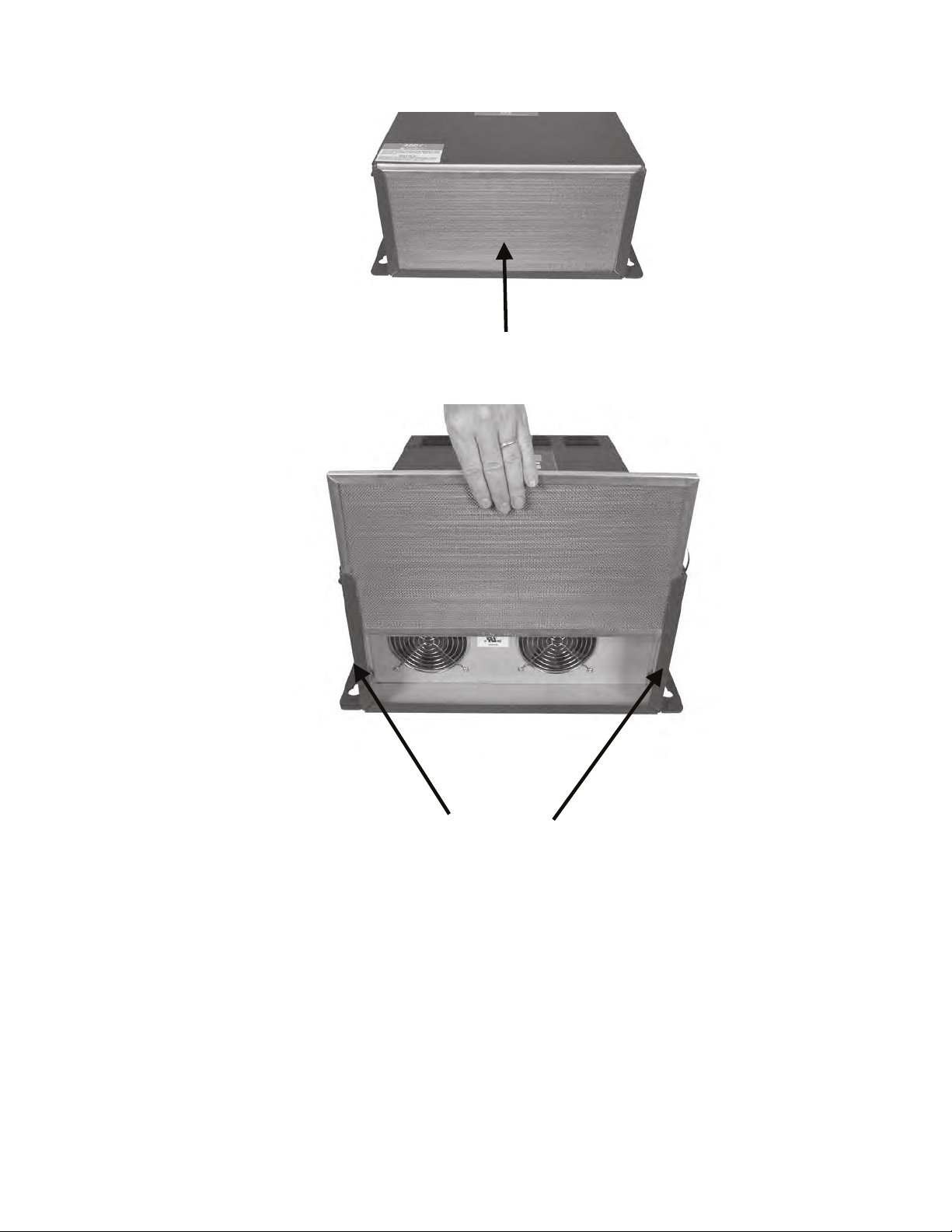

III. Installing / Removing Air Filter

The charger is equipped with an air filter located in the lower cover of the unit. The air

filter needs to be checked on a regular basis and cleaned if needed.

ATTENTION: To clean the filter, use soap and water; dry thoroughly before

installing.

To remove the filter, hold the open end of the filter and slide out. To re-install, slide the

filter into the lower cover guide and push in until fully inserted (Figure 3).

Lifting

Handles

Page 9

Air filter

Filter Guides

Figure 3: Installing / Replacing Air Filter

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 6

Page 10

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 7

Charger Electrical Installation

1. Verify proper AC line voltage and current ratings per the charger specifications as listed on the

label on the side of the unit (see table below for proper AC line ratings).

AC Line Ratings for Element Chargers

Charger Model AC Voltage AC Current

Disconnect Circuit

(@125%)

LMT-06kW-48V

480VAC 3

(±10%) & GND

8.3 A nominal 15 A

LMT-10kW-48V-250A

LMT-10kW-80V-120A

480VAC 3

(±10%) & GND

13.8 A

nominal

20 A

2. Verify that the main power and emergency stop switches on the unit are in the off (stop)

positions.

3. Figure 4) then push out one of the knockouts on the top cover to pass the AC conduit through.

The AC & GND wire connections are shown in

4. Figure 5.

5. Connect the input 480VAC power cable to the three pole AC block terminals marked ABC

(Figure 6). Connect the GND wire to the terminal marked GND as shown in Figure 7.

6. Note that the unit is not phase rotation sensitive, but noted here to avoid confusion.

7. Verify the line and ground connections of the outlet or junction box (4-Wire Delta – No

Neutral).

CAUTION: Verify that input and output wiring adheres to all local safety codes and standards.

THE UNIT IS NOW READY FOR OPERATION.

Page 11

Figure 4: Removing top cover

Figure 5: AC wire connections

AC Knockouts

480VAC

3

GND

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 8

Page 12

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 9

Figure 6 : Making AC wire connections

Figure 7: Connecting GND wire

Page 13

Charger Controls and User Interface

The charger main disconnect is located on the upper right side of charger. The user interface panel is

located on the front of the charger (see Fig. 8).

1- Main

2 -LCD /

Keypad

Disconnect

Power Switch

Fig. 8: Charger Controls

The following is a brief description of the charger controls:

1. Main Disconnect Switch: This is a padlock type disconnect switch that should be in the OFF

position and padlocked before any panels or drawers are removed. It disconnects AC power

from all parts of the system.

2. LCD/Keypad Assembly: The main user interface for viewing and displaying operation and fault

messages as well as programming the charger.

¾The disconnect switch action is rotational where turning the switch clockwise will move the switch to

the ON position (arrow pointing up) while turning the switch counter clockwise will move the switch

to the OFF position (arrow pointing to the left) as shown in Fig. 9.

Fig. 9: Disconnect and Stop Switch Actions

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 10

Page 14

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 11

¾The LCD/Keypad assembly shown in Figure 10 encompasses:

o A 4x20 character LCD for operation and fault message display

o A 1x6 push button keypad with separate START and STOP push button

o Two status LEDs for run (OK) and Fault indication

o A serial RS-232 connector and an IR window

Fig. 10: LCD/Keypad and User Interfaces

¾The status LEDs indicate the charger status, namely OK (Green LED lit) for normal operation, Fault

(Red LED lit) when a fault trips (Fig. 11). For faults and troubleshooting, refer to the

troubleshooting section of this manual.

Fig. 11: Charger status LEDs

OK LED

FAULT LED

LCD

RS-232

IR

Status

LEDs

Page 15

OPERATING PROCEDURE

I. Turning on the Unit

1. Connect charger to truck’s battery using DC connectors.

2. Energize the AC Mains.

3. Energize the side panel AC input main disconnect switch (RED). Verify that the LCD display

is lit and displays the “Connect Battery” screen shown below.

Battery Voltage Setting

Charger Maximum Current

4 8 V 2 0 0 A

0 7 / 1 9 / 0 7 1 2 : 0 0 : 0 0

C O N N E C T B A T T E R Y

D I S P L A Y

If the LCD is not lit, if the above message is not displayed, or the fans are not operating,

perform the following:

A. Turn off the unit (de-energize the disconnect switch)

B. Ensure proper AC wiring

C. Ensure the main AC disconnect (wall) is energized

D. Verify fuses in main AC junction box (wall)

E. If wiring and fan operation check OK proper and the problem persists, contact GNB

Industrial Power.

Note: The LCD will display the battery voltage and the maximum current settings on the first line,

namely 48V and 250A for a 10kW ELEMENT

charging system.

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 12

Page 16

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 13

II. Starting a Charge Cycle

1. Connect the truck’s battery to the charger. Once the battery is detected, the LCD message

will change to “Push Start to Begin Cycle”.

4 8 V 2 0 0 A

0 7 / 1 9 / 0 7 1 2 : 0 0 : 0 0

P U S H S T A R T T O

B E G I N C Y C L E

If the above message is not displayed, the battery may not have been detected. Make sure

that the battery cables are connected properly and verify that the auxiliary contacts are

proper and making good contact. Once a battery is connected, the above message will be

displayed.

2. To start the charger, press the START button. A STARTING CHARGE screen will appear

for few seconds as shown below.

S T A R T I N G C H A R G E

E X I T

3. The charge cycle will start and the following screen showing the charging operation will be

displayed.

M M C H A R G E H H : M M : S S

V : X X X . X A : X X X X

T : X X X F A H : X X X X

E F 5 2 %

“MM” indicates the active charging mode, which can be Trickle, CC, CV, Finish, or Equalize.

The Charge Timer, Battery Voltage, Current, Temperature, and returned Amp-Hours will all

be displayed. Also, the battery state of charge is shown at the bottom of the screen.

4. To stop the charge cycle, press the STOP button. A CHARGE CYCLE STOPPED screen

will appear as shown below.

Page 17

C H A R G E C Y C L E S T O P P E D

B Y U S E R

Pressing the STOP button for the second time will stop the charger completely and the unit

will default to the Charger Idle screen. If necessary, it is now safe to disconnect the charger

from the battery. Pressing the START button from the CHARGE CYCLE STOPPED screen

will resume the charge cycle and the screen will again display the Charger Operation

screen.

5. Once the charge cycle has completed, the following screen will be displayed.

C Y C L E H H : M M : S S

C O M P L E T E

T E M P : X X X F A H R S : X X X X

E X I T

The elapsed charging time, the battery temperature in degrees F, and the total retuned

amp-hours will be displayed.

It is now safe to disconnect the battery from the charger.

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 14

Page 18

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 15

CHARGER MENUS

Users can access various menus of the charger to view charge history, charger lifetime operational

history, charger settings, charger model and serial number as well as activate a recovery cycle for a

sulfated battery.

The charger menus can be accessed when the charger is idle, i.e. when the “Connect Battery” or the

“Push Start to Begin Cycle” screens are displayed. Pushing the function key “F” will display the

charger “Main Menu” while pushing the up/down (q/r) keys allows scrolling between the various menus

of the charger.

I. Charge Cycle History

1. With the “Connect Battery” or the “Push Start to Begin Cycle” screens are displayed,

push the function key “F”. The “Charge History” menu will first appear.

M A I N M E N U :

C H A R G E H I S T O R Y

E X I T E N T E R

Pressing the “EXIT” key will exit the charger menus while pressing the “ENTER” key will access

the selected menu.

2. Push the ENTER key to access the charge cycle history. The charger can hold up to 100

charge cycles which can be displayed (Note that the first cycle will be cycle 0 and the last

will be cycle 99). The last charge cycle is displayed first. Note that the charger will only

save the last 100 charge cycles.

C H # 9 9 0 7 / 1 9 / 0 7 0 4 : 2 0

V O L T : 5 8 . 6 H R S : 0 3 : 2 1

T E M P : 9 8 F A H R S : 5 6 2

The above screen will display the following:

CH#XX: Charge cycle number

01/01/05: Start date of the charge cycle

04:20: Start time of charge cycle

VOLT: Battery end of charge voltage

HRS: Duration of charge cycle

TEMP: Maximum battery temperature recorded

AHRS: Amp-hours returned

Page 19

3. Pressing the left/right (/) keys will display the second screen of the charger history.

C H # 9 9 0 7 / 1 9 / 0 7 0 4 : 2 0

A C T I V A T E D P R O F I L E S :

T R C C C V F I E Q

S T A T E : X X X X X X X X X X X X X X

The second screen lists additional relevant information about the charge cycle including:

ACTIVATED

PROFILES: Lists the profiles that were activated during that cycle.

STATE: Shows whether the cycle completed successfully or interrupted by the user

or due to a fault.

The ACTIVATED PROFILES allows users to check whether certain profiles were activated

during certain times (e.g. equalize cycles on the preset days). The STATE field lists the state of

the charge when the cycle was terminated. The following messages may appear:

COMPLETED: Cycle completed successfully

STOPPED: Cycle stopped by user

XX FAULT # Y: Charger fault with drawer # Y

If a fault took place, the reference to the drawer number allows quick identification of a problem

or faulty drawer.

4. Pressing the up/down (q/r) keys allows scrolling between the various charge cycles saved.

II. ACTIVE PROFILES

While in the Main Menu, press the up/down (q/r) keys until the Charge Profiles screen appears.

A C T I V E P R O F I L E : P 0

P 0 : T R C C C V Z P

P 1 : T R C C C V F I E Q Z P

The Active Profile screen shows the charger’s active profile as well as the profiles 0 and 1

settings. For each profile, the programmed charge modes are listed. Refer to the charger

programming section for further details.

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 16

Page 20

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 17

III. Charger Lifetime History

While in the Main Menu, press the up/down (q/r) keys until the Lifetime Summary screen

appears.

M A I N M E N U :

L I F E T I M E S U M M A R Y

E X I T E N T E R

Pressing the “ENTER” key will access the selected menu. The charger lifetime operational

summary screen will then appear.

F I R S T C H A R G : 0 7 / 1 9 / 0 7

C H R G H O U R S : 1 2 3 4

A M P H O U R S : 1 2 3 4 5

K W H O U R S : 1 2 3 4

The above variables allow users to verify charger usage since installation and compare usage of

a specific charger versus others in the vicinity or in the plant.

IV. CHARGER MODEL AND SERIAL NUMBER

While in the Main Menu, press the up/down (q/r) keys until the Charger Model screen appears.

M O D E L : P C H G - L V - 6 0 0 4 8

M F G I D : 2 0 0 5 0 1 0 0 0 1

M F G D A T E : 0 7 / 1 9 / 2 0 0 7

R E V I S I O N : 1 . 1 0

The charger model number, ID, manufacturing date and firmware revision are shown for

reference.

V. RECOVERY CYCLE FOR SULFATED BATTERIES

One of the unique features of this charger is the ability to activate a long safe recovery cycle for

sulfated batteries. This can be easily done by accessing the recovery cycle screen and starting a

recovery cycle for a given battery.

1. While in the Main Menu, press the up/down (q/r) keys until the Recovery Cycle for

Sulfated Battery screen appears.

Page 21

M A I N M E N U :

R E C O V E R Y C Y C L E F O R

S U L F A T E D B A T T E R Y

E X I T E N T E R

Pressing the”ENTER” key will access the selected menu. The user will then be prompted to enter

the battery voltage, charge current, and required cycle time.

N O M I N A L B A T T E R Y

V O L T A G E

4 8 V

E X I T E N T E R

Pressing the up/down (q/r) keys will change the battery voltage setting (24V/36V/48V). Select the

correct voltage then press the “ENTER” key. The recovery charge current setting screen will then

appear.

R E C O V E R Y C H A R G E

C U R R E N T

1 0 A

E X I T E N T E R

Pressing the up/down (q/r) keys will change the recovery charge current setting in 5 A

increments. Recommended recovery charge current rates are 3A-5A / 100 Ahrs.

Select the correct value then press the “ENTER” key. The recovery charge timer screen will then

appear.

R E C O V E R Y C H A R G E

T I M E R

1 2 : 0 0

E X I T E N T E R

Pressing the up/down (q/r) keys will change the charge timer setting. The recommended charge

timer setting is 12-24 hours. Longer recovery cycles may be needed as necessary.

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 18

Page 22

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 19

S

elect the correct value then press the “ENTER” key. The recovery charge start screen will then

appear.

P U S H S T A R T

T O B E G I N R E C O V E R Y

E X I T E N T E R

Pressing the “ENTER” key will start the recovery cycle. Once the cycle is completed, the Cycle

Complete message will appear.

Note that the recovery cycle is a separate cycle and activating it does not change the

charger settings.

Page 23

TROUBLESHOOTING

Under normal operation, the Status OK LED (green) is lit. In case of a fault, the Status FAULT LED

(red) is lit. If that occurs, perform the following:

1. Note the fault message that appears on the screen. Make sure to note the second line of the

fault message as it indicates the type of fault. It is important to note the fault message precisely

as that will help identify the cause of the fault so that a fix can be quickly found.

2. Open the charger louvered front door and note if any of the charging drawers has a RED LED light

(upper left corner of the front panel of the charging drawer). The charging drawer(s) with a RED

LED is (are) the one(s) that initiated the fault.

I. Charger Not Operational

When the charger is first turned on, with the main disconnect power switch in the ON (CW) position,

the LCD should be ON with the CHARGER IDLE message displayed.

If the problem persists, perform the following:

A. Turn off the unit. Main disconnect power switch should be in the OFF (CCW) position

B. Ensure proper AC wiring

C. Ensure the main AC disconnect (wall) is energized

D. Verify fuses in main AC junction box (wall)

E. Using an AC voltmeter, verify that the supply voltage for all three phases (AC mains

line to line) matches the specification for the charger and are within the charger

tolerances.

After going through the checklist above, restart the unit once more. If the problem persists, contact

the local GNB Industrial Power service representative.

DO NOT ATTEMPT TO SERVICE THE UNIT.

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 20

Page 24

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 21

II. Charger Faults

1. AC Fault

A C F A U L T :

E X I T

Note that the drawer number that reported the fault is listed on the second line. Also note that

the charging drawer that caused the fault is shown.

Possible Causes:

¾AC line voltage is below/above operational limits (±10%)

¾Internal input stage failure

Troubleshooting:

1. Press the STOP key to revert to the IDLE screen.

2. Open the charger drawer and identify the drawer with a RED LED lit (unit that initiated the

fault).

3. Verify the AC connections to the charger.

4. Restart the charge cycle by pressing the START key.

5. If the fault persists, turn off the charger and contact GNB Industrial Power.

2. Over Voltage or Over Current

O V E R C U R R E N T F A U L T :

E X I T

Page 25

O V E R V O L T A G E F A U L T :

E X I T

Possible Causes:

¾Worn DC cables (open or short)

¾Improper DC cable connections

Troubleshooting:

1. Press the STOP key to revert to the IDLE screen.

2. Verify that the output cables are in good working condition and are properly connected to

the battery.

3. Restart the charge cycle by pressing the START key.

4. If the fault persists, turn off the charger and contact the local GNB Industrial Power service

representative.

3. Over Temperature

O V E R T E M P F A U L T :

E X I T

Possible Causes:

¾Blocked air flow to the charger

¾Failed fan

Troubleshooting:

1. Press the STOP key to revert to the IDLE screen.

2. Allow the charger to cool down

3. Make sure there that there are no airflow restrictions on the sides or bottom of the charger.

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 22

Page 26

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 23

4

. Restart the charge cycle by pressing the START key.

5. If the charger starts with no faults, the fault was likely caused by the build up of heat in the

charger.

6. If the fault persists, verify that all fans are operational. If one or more fans are not

operational, switch off the disconnect switch and contact GNB Industrial Power.

4. Battery Disconnected Fault

C H A R G E C Y C L E S T O P P E D

B A T T E R Y D I C O N N E C T E D

E X I T

Possible Causes:

¾Battery cable was disconnected while the charger cycle is active

¾The charger or battery cables are worn out

¾The charger or battery connectors’ contacts are worn out

Troubleshooting:

1. If the battery was intentionally disconnected, press the STOP key to clear the fault message.

2. If the battery was not intentionally disconnected, check the charger and battery cables as

well as the charger and battery connectors’ contacts. Fix or replace worn out contacts /

cables.

3. Press the STOP key to clear the fault message.

4. Restart the charge cycle by pressing the START key.

5. If the fault persists, turn off the charger and contact GNB Industrial Power.

5. Battery Fault: Over Temperature

B A T T E R Y F A U L T : O V E R

B A T T E R Y T E M P E R A T U R E

E X I T

Page 27

Possible Causes:

¾Battery temperature exceeded preset limit

¾Faulty (worn) thermistor

Troubleshooting:

1. Press the STOP key to revert to the IDLE screen.

2. Measure the battery tray temperature. If an elevated battery temperature is detected, do

not re-start the charge cycle.

3. If no elevated battery temperature is detected, verify battery cable connections including the

auxiliary thermistor connections.

4. Restart the charge cycle by pressing the START key.

5. If the fault persists, turn off the charger and contact GNB Industrial Power.

6. Battery Fault: Battery Not Detected (When Battery is Connected)

4 8 V 2 0 0 A

0 1 / 0 1 / 0 5 1 2 : 0 0 : 0 0

C O N N E C T B A T T E R Y

D I S P L A Y

Possible Causes:

¾Battery auxiliary wiring is damaged

¾Charger auxiliary wiring is damaged

Troubleshooting:

1. Verify there is 2k-5k on the thermistor auxiliary contacts (Reading depends on battery

temperature)

2. Verify there is zero on the opposite auxiliary contacts

3. Verify there are no open connections on the charger auxiliary contacts

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 24

Page 28

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 25

8. Charger Timeout Faults

C H A R G E R T I M E O U T :

X X X X X X X X X X X X T I M E R

E X I T

XXXXXXXX: Total Charge Timer

Trickle Charge Timer

CC Charge Timer

CV Charge Timer

Finish Charge Timer

Possible Causes:

¾Programmed timers are incorrect

¾Battery is faulty (shorted cell)

Troubleshooting:

1. Press the STOP key to revert to the IDLE screen.

2. Using the provided Palm software, start the PowerCharge program, tap the Charge Timers

button and tap the scan button on the Charge Timers screen.

3. Verify that the programmed timer values are proper. If not, they may need to be

reprogrammed.

4. Verify battery is in good working condition (no shorted cell)

5. If the fault persists, turn off the charger and contact GNB Industrial Power.

t

RT1

12

W

ire Loop in one

Battery Aux. contact

+Temp Sense

J1

B

attery Aux

1

2

J

4

Charger Aux

1

2

-Temp Sense

Thermistor in one

B

attery Aux. contact

Internal to Charger

J3

Charger Aux

1

2

J2

Batte ry Aux

1

2

Page 29

Appendix

Charging System Block Diagrams

Sales xService xRecycling 888.563.6300 in the USA 800.268.2698 in Canada 26

Page 30

FAN 2

IR

Gate Drive Control

1

2

3

4

GND

Analog Control PCB

1

E

1

2

3

4

5

6

1

2

1

2

3

1

2

+12V

AC3

Input Power Assembly

+12V

Output

Fuse -

300A

L

1

2

3

4

5

6

L

GND

Microprocessor

PCB

Fan Control PCB

30

AC1

EMI

Filter

1

2

Processor Interface

1

2

AC2

1

1

2

3

+12V

30

AC2

1

2

3

4

5

6

FAN 1

1

2

3

4

5

6

-Vout

Boost Control

30 pin

connector

Fan Power

3 Phase

Temp & OC Fault

AC1

Boost Control

LCD

VBAT-

Output

Power

Assembly

1

2

3

4

5

6

7

8

More

+Vout

AC Fuses

25A/600V

F

Fan Power

1

2

3

4

5

6

7

8

OK

DC Bus

T

emp & OC Fault

1

2

3

4

5

6

AC3

1

2

Output Feedback

1

2

123

4

Fault

480VAC

Disconnect

Switch

Charger Idle

RS-232

1

2

3

4

5

6

Gate Drive Control

L

+12V

Key Pad

VBAT+

Battery Charger System Block Diagram

Page 31

Page 32

SALES – SERVICE – RECYCLING

A Division of Exide Technologies

TOLL FREE

1-888-563-6300 in the USA

1-800-268-2698 in Canada

GNB Industrial Power

USA – Tel: 877.462.4636

Canada – Tel: 800.268.2698

www.gnb.com

GB4109 2013-07

Loading...

Loading...