Page 1

THESE INSTRUCTIONS TO BE SHIPPED WITH BATTERY AND TO BE DELIVERED TO USER

PLEASE READ BEFORE PLACING BATTERIES IN SERVICE

MOTIVE POWER VALVE REGULATED

LEAD ACID (VRLA) BATTERIES

INSTALLATION AND OPERATING INSTRUCTIONS

1. RECEIVING BATTERIES

Immediately upon receipt of shipment, examine the outside

of the packing for signs of rough handling before accepting

battery from carrier. If there is evident damage, the receipt

should be signed and both copies (carrier’s and receiving

copies) marked “Shipment Received Damaged”. The carrier

should be called immediately and asked to make a “Carrier’s

Inspection for Damage Report”.

If “concealed” damage is later detected, the carrier should

be called immediately and requested to make a “Carrier’s

Inspection for Concealed Damage Report”. After inspection

by the carrier, arrangements should be made with the local

representative to have the battery repaired before placing it

in service.

BEFORE PLACING BATTERIES IN SERVICE,

REVIEW AND ADHERE TO THE

SAFETY GUIDELINES (ITEM 7).

2. PLACING IN SERVICE

All ELEMENT®batteries must be given an equalizing charge

prior to their use. To accomplish this, connect the battery to

an approved GNB

the automatic charge control terminates.

®

charger and commence charging until

3. CHARGING

The charger must be matched to the battery with respect to

voltage and ampere-hour capacity. The charger must be an

approved GNB

voltage-constant current profile that has automatic charge

control features and a nominal finish rate of 2 amps per 100

ampere-hours of rated capacity. The constant voltage

portion of the curve is 2.37 volts per cell. Under no

circumstances should you attempt to remove the safety

relief-valve vent cap. Such removal shall void the battery’s

warranty and seriously impair battery performance.

OPPORTUNITY CHARGING IS NOT PERMITTED, EXCEPT IN

APPROVED AGV APPLICATIONS.

USE OF ANY CHARGERS OTHER THAN APPROVED GNB

CHA RGERS CAN RESULT IN PERMANENT BATTERY

DAMAGE. CONTACT YOUR LOCAL GNB

POW ER REPRESENTATIVE TO VERIFY PRO PER

CHARGING.

®

charger with a constant current-constant

®

INDUSTRIAL

®

4. COOL DOWN

When the battery reaches an 80% depth of discharge,

disconnect battery from the lift truck and connect to an

approved GNB

charge in eight hours or less. Once the charge is complete,

the battery must be allowed to cool down for eight hours. At

a minimum, the battery must be allowed to cool down for a

time period equal to the time period spent on charge.

®

charger. The battery will normally reach full

BAT TERY REQUIRES COOL DOWN PER IOD

FOLLOWING A CHARGE EQUAL IN TIME TO

CHARGE PERIOD. FAILURE TO ALLOW FOR

COOL DOWN WILL SHORTEN BATTERY LIFE.

5. EQUALIZING CHARGE

Each cell of a ELEMENT®battery ma y have slight

differences in uniformity of construction and content. These

slight differences cause some cells to take less charge than

the other cells in the battery. To bring the cells with a lower

state of charge up to the same level as the others, the

battery is given an “equalizing charge”. The battery should

be given an equalizing charge after 50-100 hours of

operation. If you are unsure of battery use hours, give the

batteries an equalize charge every two weeks.

6. AGV CHARGING

The battery/charger systems are “BALANCED” on each

AGV application to maintain a design operating “STATE OF

CHARGE” within the battery. This state of charge is

dependent on such factors as:

• AMP-HOUR USED

• CHARGE TIME ALLOWED

• CHARGE CURRENT

Any plant operations that will cause these factors to deviate

significantly from the original design could cause sufficient

battery/charger imbalance affecting the battery life and

performance. Plant deviations such as:

• Plant Shutdowns • Extended Testing

• Duty Cycle Change • Vacations

have the poten tial to cau se these imbalances. In

general, when opportunity charging is being used, any nonoperational period of greater than 24 hours should be

controlled to prevent extended battery charging. This can

be accomplished in an AGV application by using the vehicle

P O S T T H E S E I N S T R U C T I O N S I N

B A T T E R Y M A I N T E N A N C E A R E A .

Page 2

INSTALLATION AND OPERATING INSTRUCTIONS (continued)

supervisory controls. GNB recommends a 7 hours on-charge17 hours off-charge control for these 24-hour periods.

7. SAFETY

• Warning: Risk of fire, explosion, or burns. Do not disassemble,

heat above 38 degrees Celsius, or incinerate.

• Wear appropriate safety equipment when working around

electrically live batteries.

• The ELEMENT

®

battery can emit hydrogen gases under

some abnormal charging conditions. Whenever possible,

charge in a well-ventilated area and keep open flames

away from batteries. Howe ver, n orma l ware house

ventilation is adequate for normal ELEMENT

®

usage.

• Lift batteries with a hoist, crane, lift truck, or similar

equipment; move batteries on trucks, conveyors, or rollers.

Make sure equipment is of ample strength and properly

installed. Be sure to place a rubber mat or similar

insulating material across tops of batteries without covers

when handling. This will prevent accidental shorts.

• Disconnect battery from the truck when performing

maintenance and repair on motor or electrical system.

• Open, or “break” battery circuit before attempting repairs

to charging plug or receptacles.

• Familiarize yourself with batteries and rules for charging

and handling. Contact your local GNB representative for

information.

• Assign battery and charger care to properly trained

personnel. Review your company safety regulations, and

familiarize yourself with industry and government

guidelines (OSHA, ANSI, etc.) to help reduce personnel

accidents and equipment damage.

8. OPERATION

Batteries are rated in ampere-hour and are selected to

perform a specific workload within an established period of

time. Increasing the work load or time period could result in

over discharging, thus shortening battery life. In general, all

lead-acid batteries should not be discharged to more than

80% of its six-hour rated capacity. ONE BATTERY IS

REQUIRED PER TRUCK PER EIGHT-HOUR SHIFT. If a

lift interrupt is used or installed on the lift truck, a minimum

interrupt voltage of 1.86 VPC (under load), 2.02 VPC (open

circuit) multiplied by the number of cells, should be set to

avoid overdischarge of the battery.

ADJUST LIFT INTERRUPT SETTING ON LIFT TRUCK TO

A MINIMUM INTERRUPT VOLTAGE OF 1.86 VPC (UNDER

LOAD), 2.02 VPC (OPEN CIRCUIT) MULTIPLIED BY THE

NUMBER OF CELLS FOR ELEMENT

®

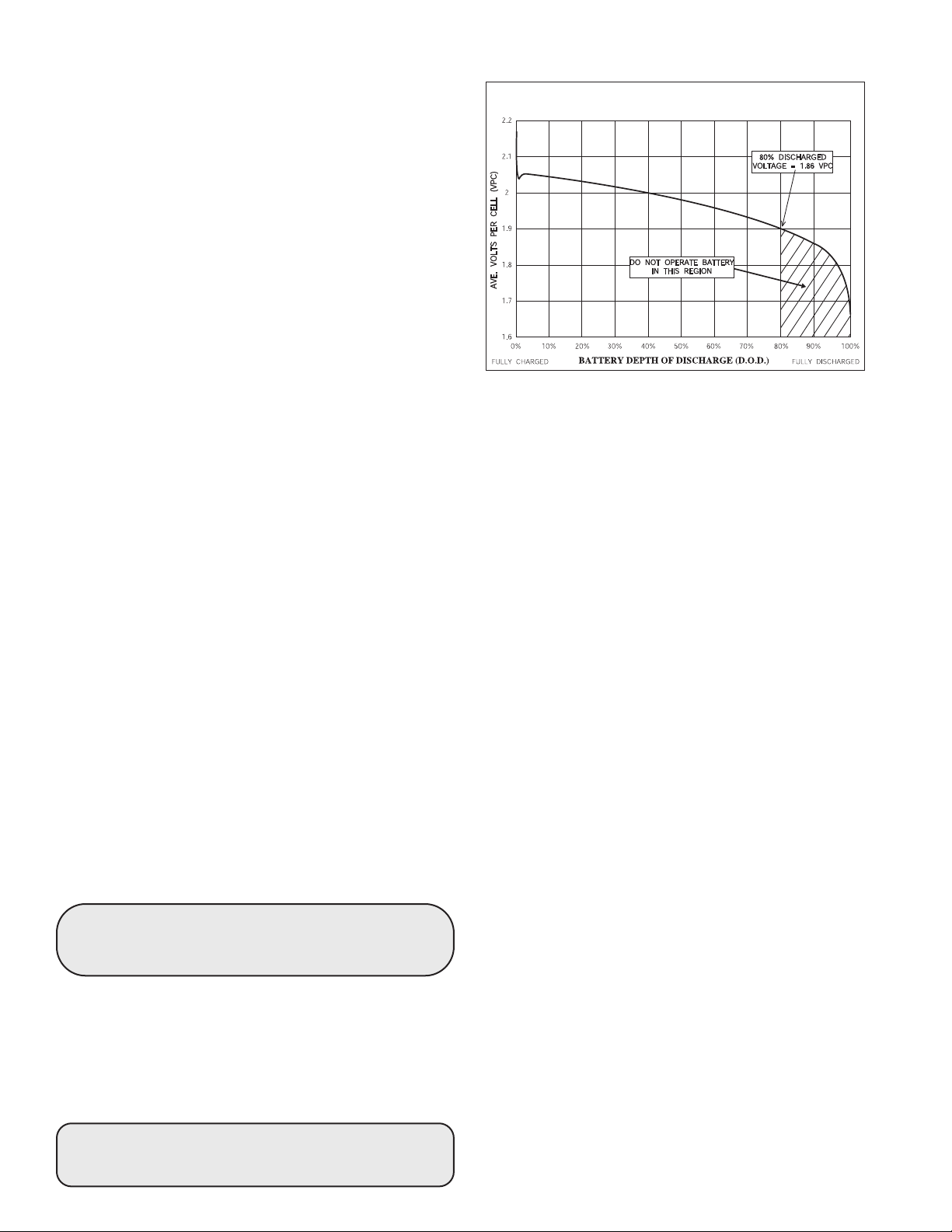

Since ELEMENT

is a VRLA battery, it’s state of charge cannot

be approximated by specific gravity. However, average cell

voltage (Volts per Cell) with the battery under load can be used

to approximate the battery depth of discharge as shown in

Figure 1. Alternatively, the battery at 80% depth of discharge

will have an open circuit voltage equal to 2.02 VPC multiplied

by the number of cells in the battery.

THE ELEMENT®BATTERY SHOULD NOT BE

DISCHARGED BELOW 1.86 VPC (UNDER LOAD), 2.02

VPC (OPEN CIRCUIT) (80% DEPTH OF DISCHARGE)

®

BATTERIES

IGURE 1 - ELEMENT

F

®

ISCHARGE CURVE

D

9. BATTERY DISCHARGE ALARM/MONITORS

Your ELEMENT®battery is equipped with a Battery Discharge

Alarm to protect your ELEMENT

An intermittent 80-db alarm will start to sound whenever the

battery's voltage drops to or below the alarm reference

voltage for a fixed period of time. The alarm will stop if and

when the battery's voltage recovers to above the alarm

reference voltage within a fixed period of time. The battery is

at 80% depth of discharge when the alarm sounds

continuously. As soon as the alarm begins to sound

continuously, the battery should be completely recharged

using an approved charger and proper charging procedures.

Batteries may be equipped with monitoring devices by GNB.

Damage to or tampering with these devices shall void all

warranties. Any addition of monitoring devices affixed to the

battery, not authorized in writing by GNB, shall void all

warranties.

®

battery from over-discharge.

10. 48 VOLT ELEMENT®BATTERIES

Your 48 volt ELEMENT®battery may be equipped with an

active cooling system. This will be evident by two fan

cutouts on the battery cover and by "81" at the end of the

battery part number. The following special considerations

apply:

1. The fans will only operate when the battery is on charge

or during the cool-down period (at or above fully charged

open circuit voltage). The fans will not operate when the

battery is plugged into the lift truck. If the fans continue

to operate when the battery is plugged into the lift truck,

contact your local GNB service representative

immediately at 1-888-563-6300.

2. 48 volt ELEMENT

cooling system must be removed from the lift truck for

charging, and have a minimum of 6 inches of clearance

on all sides of the battery for proper airflow.

Deviations from the proper operating instructions for 48 volt

ELEMENT

®

batteries will void the warranty. Additional

information and assistance can be obtained by contacting

your local sales representative by calling 1-888-563-6300.

®

batteries equipped with the active

Page 3

11. TEMPERATURE

Normal operating conditions shall be between 60°F and

100°F. Operating temperature above 100°F will reduce the

attery’s service life. Operating temperature below 60°F

b

results in less capacity and special charging is required.

12. MAINTENANCE

Because this is a ELEMENT®battery, there is little to do

regarding maintenance operations. The top of the battery

should be kept clean and dry and may be washed to remove

any accumulated foreign matter. In the unlikely event of an

accidental contamination with electrolyte or lead, contain the

spill and notify your local GNB representative who is

equipped to handle any environmental concerns. Spill kits

are available from the GNB Parts Center by calling (800)

634-4462.

CES INSTRUCTIONS DOIVENT ETRE EXPEDIEES AVEC LA BATTERIE ET FOURNIES A L’UTILISATEUR.

Never attempt to add water to the battery - it has been

designed to function without any such additions over its

entire life. As previously noted, any attempt to remove the

vent caps shall void the warranty.

13. CHANGES IN OPERATIONS

If any time after initial purchase you have changes to your

operating conditions, such as extended shifts, increased

loads or other changes that alter your initial purchase

onditions, please contact your local GNB representative

c

immediately to ensure you are properly equipped and are

not affecting the life of the battery.

14. SERVICE

Additional information and assistance can be obtained by

contacting your local sales representative or in the USA call

toll free 1-888-563-6300.

À LIRE AVANT DE METTRE LA BATTERIE EN SERVICE.

BATTERIES D'ACCUMULATEUR À FORCE MOTRICE AU

PLOMB-ACIDE À RÉGULATION PAR SOUPAPE (VRLA)

INSTALLATION ET UTILISATION

1. RÉCEPTION DES BATTERIES

Immédiatement après avoir reçu une livraison et avant

d’accepter la batterie du transporteur, vérifier que l’extérieur

de l’emballage n’a aucun signe de manutention abusive. S’il

y a évidence de dommage, il faut signer le récépissé et

marquer “Livraison reçue endommagée” sur les deux

copies, celle du transporteur et celle de réception. Il faut

appeler transporteur immédiatement et demander un

“Rapport d’inspection de dommage par le transporteur.”

Si des avaries non apparentes sont découvertes plus tard, il

faut appeler le transporteur immédiatement et lui demander

de faire un “Rapport d’inspection par le transporteur d’avaries

non apparentes.” Après inspection par le transporteur, il faut

faire des arrangements avec le représentant local pour faire

réparer la batterie avant de la mettre en service.

IL F AUT EXAMINER ET RESPECTER LES

DIRECTIVES DE SÉCURITÉ (ARTICLE 7) AVANT

DE METTRE DES BATTERIES EN SERVICE.

2. MISE EN SERVICE

Toute batterie ELEMENT®doit recevoir une charge

d’égalisation avant d’être mise en service. Pour cela, brancher

la batterie sur un chargeur GNB

jusqu’à la fin automatique du cycle.

®

approuvé et faire la charge

3. CHARGE

La tension et la capacité du chargeur doivent correspondre

à celles de la batterie. Le chargeur doit être un chargeur

approuvé par GNB

constantes, avec des fonctions de commande de charge

automatique et une intensité finale de 2 A par 100 Ah de

capacité nominale. La portion de tension constante de la

courbe est de 2,37 volts par cellule.

LA CHARGE D’OCCASION DES BATTERIES EST

INTERDITE SAUF DANS LE CAS DES APPLICATIONS

AGV APPROUVÉES.

L’UTILISATION DE TOUT CHARGEUR AUTRE

QU’UN CHARGEUR APPROUVÉ PAR GNB PEUT

CAUSER DES DOMMAGES PERMANENTS DE LA

BATTERIE. CONTACTER LE REPRÉSENTANT

LOCAL DE GNB POUR VÉRIFIER LA PROCÉDURE

DE CHARGE APPROPRIÉE.

®

avec une tention et une intensité

CES INSTRUCTIONS DOIVENT ÊTRE AFFICHÉES

DANS L’AIRE D’ENTRETIEN DES BATTERIES

Page 4

Il ne faut pas essayer, pour une raison quelconque,

d’enlever le capuchon d’évent de sécurité. Une telle dépose

annule la garantie de la batterie et diminue sérieusement la

erformance de la batterie.

p

4. REFROIDISSEMENT

Quand la batterie est déchargée de 80 %, la débrancher du

chariot élévateur et la brancher à un chargeur GNB

approuvé. Normalement, la batterie atteint pleine charge en

moins de huit heures. Quand la charge est terminée, il faut

permettre à la batterie de se refroidir pendant huit heures.

Au minimum, la batterie doit se refroidir pendant une période

aussi longue que celle de charge.

LA BATTERIE DOIT SE REFROIDIR PENDANT UNE

PÉR IODE AUS SI LONGUE QUE CELLE DE

CHARGE. L’ABSENCE DE REFROIDISSEMENT

DIMINUE LA LONGÉVITÉ DE LA BATTERIE.

5. CHARGE D’ÉGALISATION

Les cellules des batteries ELEMENT®peuvent être

légèrement différentes les unes des autres. À cause de ces

légères différences de construction et de contenu, certaines

cellules acceptent moins bien la charge que d’autres. La

batterie doit être soumise à une charge d’égalisation pour

amener toutes les cellules au même niveau de charge. Il

faut soumettre la batterie à une charge d’égalisation après

50 à 100 heures de service. En cas de doute sur la durée de

service de la batterie, il faut la soumettre à une charge

d’égalisation toutes les deux semaines.

6. CHARGE DE CHARIOTS AUTOMATIQUES

Le système de batterie et de chargeur est équilibré pour

chaque application de chariot automatique pour maintenir un

« ÉTAT DE CHARGE » dans la batterie. Cet état de charge

dépend des facteurs suivants :

• LA QUANTITÉ D’ÉLECTRICITÉ UTILISÉE (A/h);

• LA DURÉE DE CHARGE ALLOUÉE;

• L’INTENSITÉ DU COURANT DE CHARGE.

Toute exploitation qui permet à ces facteurs de dévier

suffisamment de la réalisation initiale peut causer un

déséquilibre important de la batterie et du chargeur qui peut

affecter la longévité et la performance de la batterie. Les

déviations d’exploitation suivantes peuvent causer ces

déséquilibres :

• Fermeture d’usine

• Changement du cycle d’utilisation

• Essais prolongés

• Vacances

En général, quand la charge d’occasion est utilisée, il faut

surveiller toute période de non-utilisation de plus de 24

heures pour éviter une décharge excessive de la batterie.

Pour accomplir cela dans une application de chariot

automatique (AGV), il est possible d’utiliser les commandes

de surveillance du véhicule. GNB recommande une période

de charge de 7 heures et une période de décharge de 17

heures pour toute tranche de 24 heures.

7. SÉCURITÉ

• Attention: Risque d'incendie, d'explosion ou de brûlures.

Ne pas démonter, chauffer à plus de 38 degrés Celsius,

ou incinérer.

• Il faut porter de l’équipement de protection approprié

pendant le travail sur les batteries électriquement actives.

®

• Da ns certaines conditions de charge, les batteries

ELEMENT

®

peuvent émettre de l’hydrogène. Dans la

mesure du possible, il faut charger les batteries dans un

ndroit bien ventilé et maintenir toute flamme à l’écart des

e

batteries. L a ventilation normale d’un entrepôt e st

généralement adéquate pour l’utilisation normale des

batteries ELEMENT

®

.

• Il faut soulever les batteries avec un palan, une grue, un

chariot élévateur ou de l’équipement similaire. Il faut

transporter les b atte ries avec des chariots, des

transporteurs ou des rouleaux. Il faut s’assurer que

l’équipemen t est suffisamment robuste et in stallé

correctement. Pendant la manutention, il faut prendre soin

de mettre un tapis en caoutchouc ou en matière isolante

similaire sur les batteries couvercle. Ceci évite les courtscircuits accidentels.

• Il faut débrancher la batterie pendant l’entretien ou les

réparations du moteur ou du circuit du véhicule.

• Il faut ouvrir ou débrancher le circuit des batteries avant

toute tentative de réparation sur les prises ou réceptacles

de charge.

• Il faut se familiariser avec les batteries et les règlements de

charge et de manutention. Le représentant local de GNB

peut fournir des renseignements supplémentaires.

• Des personnes avec une formation appropriée doivent être

responsables des batteries et du chargeur.

Il faut étudier les règles de sécurité de l’entreprise et se

familiarise r avec les dir ectives indus trielles et

gouvernementales pour aider à réduire les accidents qui

causent des blessures et endommagent l’équipement.

8. UTILISATION

La capacité des batteries est donnée en ampères-heure.

Les batteries sont sélectionnées pour exécuter une tâche

spécifique pendant une période déterminée. L’augmentation

de la demande ou de la durée peut causer une décharge

excessive, diminuant ainsi la longévité de la batterie. En

général, une batterie au plomb ne doit pas être déchargée

de plus de 80% de sa capacité nominale de 6 heures. IL

FAUT UNE BATTERIE PAR CHARIOT ELEVATEUR PAR

EQUIPE DE HUIT HEURES. Si un dispositif d’interruption

de service est utilisé ou installé sur le chariot élévateur, il

doit être réglé à une valeur minimale de 1.86 V (en charge),

2.02 V (à vide) multipliée par le nombre d cellules, afin

d’éviter une décharge excessive de la batterie.

POUR LES BATTERIES ELEMENT®, IL FAUT RÉGLER LE

DISPO S ITIF D’INTERRUP TION DE S E RVICE DU

CHARIOT ÉLÉVATEUR À UN MINIMUM DE 1.86 V (EN

CHARGE), 2.02 V (À VIDE) MULTIPLIÉ PAR LE NOMBRE

DE CELLULES.

Puisque la batterie ELEMENT

n'est pas possible de déterminer sa charge par sa densité. Il

®

est une batterie VRLA, il

Page 5

est cependant possible d'utiliser la tension moyenne par

cellule pour déterminer la profondeur de décharge, comme

montré sur la Figure 1. Alternativement, la profondeur de

écharge de 80% aura une tension en circuit ouvert égal à

d

2.02 V par cellule multipliée par le nombre de cellules.

UNE BATTERIE ELEMENT®NE DOIT PAS ÊTRE

DÉCHARGÉE À UNE TENSION INFÉRIEURE À 1.86 V

EN CHARGE), 2.02 V (À VIDE) (DÉCHARGE DE 80%)

(

IGURE 1 – COURBE DE DÉCHARGE DES BATTERIES ELEMENT

F

DÉCHARGE DE 80%

TENSION = 1.90 V PAR CELLULE

IL NE FAUT PAS UTILISER

LA BATTERIE DANS CETTE

ZONE

TENSION MOYENNE PAR CELLULE (V)

OMPLÈTEMENT CHARGÉE DÉCHARGE DE LA BATTERIE COMPLÈTEMENT DÉCHARGÉE

C

®

9. SURVEILLANCES/ALARME DE

DÉCHARGE DE BATTERIE

Votre batterie ELEMENT®est équipée d'une alarme de

décharge destinée à la protéger contre une décharge

excessive. Une alarme intermittente de 80 dB commence à

retentir chaque fois que la tension de batterie baisse au

niveau ou sous la tension de référence d'alarme pendant

une période déterminée. L'alarme s'arrête si et quand la

tension de batterie revient au-dessus de la tension de

référence au bout d'une période déterminée. La batterie est

déchargée à 80% lorsque l'alarme retentit sans interruption.

Dès que l'alarme commence à retentir sans interruption, il

convient de recharger complètement la batterie à l'aide d'un

chargeur homologué en appliquant les procédures de

chargement appropriées.

Les batteries peu vent être équipées de sy stème de

surveillance par GNB. Tout dommage ou altération infligée

aux systèmes annule les garanties. Tout ajout de système

de surveillance à la batterie qui ne serait pas approuver par

écrit par GNB annule également les garanties.

10. BATTERIES ELEMENT®, 48 VOLTS

La batterie ELEMENT®de 48 volts peut être équipée d’un

système de refroidissement actif. Une telle batterie se

reconnaît à la pré senc e de deux découpures pou r

ventilateurs sur le couvercle de batterie et par celle du

chiffre « 81 » à la fin de son numéro de pièce. Les points

particuliers suivants doivent être pris en considération:

1. Les ventilateurs ne fonctionnent que lorsque la batterie

est en cours de recharge ou pendant la période de

refroidissement (à une tension égale ou supérieure à la

tension de repos de la batterie complètement rechargée).

Les ventilateurs ne fonctionnent pas lorsque la batterie

est branchée au chariot transporteur. Si les ventilateurs

continuent à fonctionner lorsque la batterie est branchée

dans le chariot, pr endr e conta ct immédiatement

avec le représentant local de GNB en appelant le

1-888-563-6300.

2. Les batteries ELEMENT

®

de 48 volts équipées d’un

système de refroidissement actif doivent être dégagées

d’au moins 15.24 cm tout autour lorsqu’elles sont

déposées du chariot élévateur pour être rechargées afin

de garantir une circulation d’air correcte.

L’inobservation des instructions d’utilisation correcte des

batteries ELEMENT

®

de 48 volts annule la garantie. Il est

possible d’obtenir des informations complémentaires et toute

assistance auprès du représentant local en appelant le

1-888-563-6300.

11. TEMPÉRATURE

En service, la température normale de la batterie doit être 16

et 38°C (60 et 100°F). Une température de service

supérieure à 38°C (100°F) réduit la longévité de la batterie.

Une température de service inférieure à 16°C (60°F) diminue

le rendement de la batterie et il faut une charge spéciale.

12. ENTRETIEN

Dans la mesure où il s'agit d'une batterie ELEMENT®, il y a

peu de choses à faire du point de vue de l'entretien. Il faut

maintenir le dessus de la batterie propre et sec. Pour éliminer

toute accumulation de saleté, laver le dessus de la batterie.

Dans le cas peu probable de contamination accidentelle avec

de l'électrolyte ou du plomb, maîtriser le renversement et

avertir le représentant local GNB qui est équipé pour traiter

les questions environnementales. Les kits de renversement

sont disponibles auprès du Centre des Pièces GNB en

appelant le (800) 634-4462.

Il ne faut jamais essayer d’ajouter de l’eau à la batterie. Elle

a été conçue pour fonctionner sans ajout d’eau. Toute

tentative de dépose des bouchons d’évent annule la

garantie (voir ci-dessus).

13. CHANGEMENTS DE SERVICE

Si, après la mise en service initiale, il faut changer les

conditions d e ser vice, postes prolongés, charges

supplémentaires ou autres changements qui modifient les

termes d’achat initiaux, contacter le représentant local de

GNB pour vérifier que l’équipement est adéquat et que la

longévité des batteries n’est pas affectée.

14. SERVICE

Pour obtenir des renseignements supplémentaires ou de

l’assistance, contacter le représentant local ou, aux

États-Unis, appeler le numéro gratuit 1-888-563-6300.

Page 6

POR FAVOR, LEA ESTA INFORMACIÓN ANTES DE HACER FUNCIONAR LAS BATERÍAS

ESTAS INSTRUCCIONES DEBEN SER ENVIADAS CON LA BATERÍA Y ENTREGADAS AL USUARIO

BATERÍAS ÁCIDAS REGULADAS POR

VÁLVULAS PARA PRODUCIR FUERZA MOTRIZ

INSTRUCCIONES DE INSTALACIÓN Y FUNCIONAMIENTO

1. AL RECIBIR LAS BATERÍAS

l recibir el paquete, examine inmediatamente el exterior del

A

mismo viendo si muestra signos de haber sido maltratado,

antes de aceptar el paquete del portador. Si hay daños

aparentes, el recibo debe ser firmado y ambas copias (la del

portador y la de quien recibe el paquete) deben ser marcadas

con la frase “Envío recibido dañado”. Se debe llamar

inmediatamente a la empresa de transporte y pedir que

hagan un “Reporte de inspección de daños por el portador”.

Si más tarde se descubren daños no evidentes, se debe

llamar inmediatamente a la empresa de transporte y solicitar

que haga un “Reporte de inspección de daños ocultos por el

portador”. Después de esta inspección, se deben hacer los

arreglos necesarios con un representante local para

substituir la batería antes de utilizarla.

ANTES DE UTILIZAR LA BATERÍA, LEA Y SIGA

LAS DIRECTRICES DE SEGURIDAD (PUNTO 7).

2. ANTES DE UTILIZARLA

Todas las baterías ELEMENT®deben recibir una carga

igualizadora antes de su uso. Para esto, conecta la batería

a un cargador aprobado GNB®y comience a cargar hasta

que termine el control de carga automática.

3. CARGA

El cargador debe ser un cargador aprobado GNB® con un

perfil de corriente constante corriente-constante voltajeconstante que tenga control de carga automática y una tasa

de acabado nominal de 2 amperios por 100 amperio-horas

de capacidad nominal. La parte de voltaje constante de la

curva es 2.37 voltios por elemento.

No debe, bajo ninguna circunstancia, tratar de retirar la tapa

de ventilación de la válvula de seguridad. De hacerlo,

quedaría anulada la garantía de la batería y se perjudicaría

gravemente su funcionamiento.

4. ENFRIAMIENTO

Cuando la batería alcance un 80% de profundidad de

descarga, desconéctela del carro elevador y conéctela a un

cargador aprobad o GNB

alcanzará la carga completa en ocho horas o menos. Una

vez terminada la carga, se debe dejar enfriar la batería

durante ocho horas. Como mínimo, se debe dejarla enfriar

durante un período igual al tiempo que pasó cargándose.

®

. Normalmente , la ba terí a

LA BATERÍA REQUIERE UN PERÍODO DE

ENFRIAMIENTO DESPUÉS DE UNA CARGA IGUAL

A LA DURACIÓN DEL PERÍODO DE CARGA. DE NO

DEJAR QUE SE ENFRÍE, SE REDUCIRÁ LA

DURACIÓN DE LA BATERÍA.

5. CARGA DE IGUALIZACIÓN

Cada elemento de la bate ría ELEMENT®puede ser

ligeramente diferente a los demás en uniformidad de

construcción y contenido. Estas ligeras diferencias causan

que algunos elementos acepten menos carga que otros en

la batería. Para llevar los elementos a un estado de carga

más bajo, hasta el mismo nivel que los demás, se da a la

batería una “carga de igualización”. La batería debe recibir

una carga de igualización después de 50 – 100 horas de

operación. Si no está seguro de las horas de uso de la

batería, dé una carga de igualización a la misma cada dos

semanas.

6. CARGA de AGV (Vehículo Guiado

Automáticamente)

Los sistemas batería/cargador son “EQUILIBRADOS” en

cada aplicación AGV para mantener un “ESTADO DE

CARGA” operativo de diseño dentro de la batería. Este

estado de carga depende de factores como:

NO SE PERMITE LA CARGA DE OPORTUNIDAD

EXCEPTO EN APLICACIONES APROBADAS POR AGV.

EL USO DE CUALQUIER CARGADOR QUE NO SEA

UN GNB®CARGADOR APROBADO PUEDE CAUSAR

DAÑOS PERMANENTES A LA BATERÍA. LLAME A SU

REPRESENTANTE LOCAL DE GNB PARA VERIFICAR

EL MÉTODO DE CARGA ADECUADO.

PONGA ESTAS INSTRUCCIONES EN LUGAR VISIBLE

EN EL ÁREA DE MANTENIMIENTO DE LA BATERÍA.

• AMPERIOS-HORA UTILIZADOS

• TIEMPO DE CARGA PERMITIDO

• CORRIENTE DE CARGA

Cualquier operación de la planta que cause que estos

factores se desvíen considerablemente del diseño original,

podría causar suficiente desequilibrio batería/cargador para

afectar la duración y e l rendi mien to de la batería.

Desviaciones de la planta como:

• Paradas de la planta

• Cambio del ciclo de funcionamiento

Page 7

• Pruebas prolongadas

• Vacaciones

ienen el potencial de causar estos desequilibrios. En

t

general, cuando se uti lice la carga cuan do haya

oportunidad, cualquier período sin funcionamiento de más

de 24 horas debe ser controlado para impedir la carga

prolongada de la batería. En una aplicación AGV esto se

puede lograr utilizando los controles de vigilancia del

vehículo. GNB recomienda un control de 7 horas cargando y

17 horas no cargando para estos períodos de 24 horas.

7. SEGURIDAD

• Advertencia: Riesgo de i ncen dio, e xplo sión o

quemaduras. No desarme, caliente a más de 38 grados

centígrados, ni la incinere.

• Lleve equipo de seguridad apropiado cuando trabaje con

baterías eléctricas activas.

• La batería ELEMENT

®

puede emitir gases de hidrógeno

bajo algunas condiciones anormales de carga. Siempre

que sea posible, cargue la batería en un área bien

ventilada y manténgala alejada de las llamas. Sin

embargo, la ventilación normal es adecuada para el uso

normal de la batería ELEMENT

®

.

• Levante las baterías con una cabria, una grúa, un carro

elevador o equipo similar; mue va la batería sobre

camiones, transportadores o rodillos. Cerciórese de que el

equipo tenga la fuerza adecuada y esté bien instalado.

Cerciórese de colocar una capa de caucho o material

aislante similar encima de la parte superior de las baterías

sin cubiertas cuando las esté manipulando. Esto impedirá

cortocircuitos accidentales.

• Desconecte l a batería del carr o cuando efectúe

operaciones de mantenimiento y reparación en el motor o

el sistema eléctrico.

• Abra o “rompa” el circuito de la batería antes de tratar de

efectuar reparaciones en enchufes o receptáculos de

carga.

• Familiarícese con las baterías y las reglas para cargarlas

y manejarlas. Llame a su representante local de GNB si

desea información.

• Asigne el cuidado de la batería y del cargador a personal

adecuadamente capacitado.

Revise los reglamentos de seguridad de su compañía y

familiarícese con las pautas de la industria y el gobierno

(OSHA, ANSI, etc.) para reducir los accidentes personales y

los daños al equipo.

8. FUNCIONAMIENTO

Las baterías s e clas ific an en amperio-hora y son

seleccionadas para realizar una carga de trabajo específica

dentro de un período de tiempo establecido. De aumentar la

carga de trabajo o el período de tiempo, se podría provocar

una descarga excesiva, lo cual reduciría la duración de la

batería. En general, todas las baterías de acumuladores de

plomo no deben descargarse más del 80% de su capacidad

nominal para seis horas. SE REQUIERE UNA BATERIA

POR CARRO POR TURNO DE OCHO HORAS. Si se utiliza

o se instala un interruptor de elevación en el carro elevador,

se debe establecer un voltaje mínimo de interrupción de

1.86 VPC [voltios por elemento] (bajo carga), 2.02 VPC

(circuito abierto) multiplicado por el número de elementos,

para evitar la descarga excesiva de la batería.

JUSTE EL REGLAJE DE INTERRUPCIÓN DE

A

ELEVACIÓN DEL CARRO ELEVADOR A UN VOLTAJE

MÍNIMO DE INTERRUPCIÓN DE 1.86 VPC [voltios por

elemento] (BAJO CARGA), 2.02 VPC (CIRCUITO

ABIERTO) MULTIPLICADO POR EL NÚMERO DE

LEMENTOS PARA LAS BATERÍAS ELEMENT

E

®

Puesto que la batería ELEMENT

es una batería VRLA, no

®

.

se puede aproximar su estado de carga por el peso

específico. No obstante, se puede utilizar el voltaje

romedio por elemento (voltios por elemento) con la batería

p

cargándose para aproximar la descarga de la batería como

se muestra la Figura 1. Alternativamente, la batería para

una descarga del 80% tendrá un voltaje de circuito abierto

igual a 2,02 VPC multiplicado por el número de elementos

de la batería.

9. ALARMA DE DESCARGA DE LA

BATERÍA/MONITORES

NO SE DEBE DESCARGAR LA BATERÍA ELEMENT

A MENOS DE 1.86 VPC (BAJO CARGA), 2.02 VPC

(CIRCUITO ABIERTO) (80% DE PROFUNDIDAD DE

DESCARGA).

FIGURA 1 – CURVA DE DESCARGA ELEMENT

NO UTILIZAR LA BATERÍA EN

ESTA REGIÓN

VOLTIOS PROM. POR ELEMENTO (VPC)

TOTALMENTE CARGADA PROFUNDIDAD DE DESCARGA DE LA BATERÍA TOTALMENTE DESCARGADA

®

0% DESCARGADA

8

VOLTAJE = 1.90 VPC

Su batería ELEMENT®está equipada con una alarma para

protegerla contra la descarga excesiva. Siempre que el

voltaje de la batería descienda durante un período fijo hasta

el voltaje de referencia de la alarma, o por debajo de la

misma, sonará una alarma intermitente de 80 db. La alarma

cesará cuando el voltaje de la batería se recupere a un nivel

superior al voltaje de referencia de la alarma durante un

período fijo. Cuando la alarma suena continuamente, indica

que la batería está descargada un 80%. Tan pronto como la

alarma comience a sonar continuamente, se debe recargar

completamente la batería utilizando un cargador aprobado y

siguiendo el procedimiento de carga adecuado.

GNB

puede equipar las baterías con dispositivos de

mon itoreo. Los da ños a estos dispositivos o su

manipulación indebida anulará las garantías. Cualquier

adición de dispositivos de monitoreo fijados a la batería,

sin la autorización por escrito de

GNB, anulará las

garantías.

®

Page 8

INSTRUCCIONES DE INSTALACIÓN Y FUNCIONMIENTO (continuación)

A Division of Exide Technologies

10. BATERIAS ELEMENT®DE 48 VOLTIOS

Su batería ELEMENT®de 48 voltios puede tener un sistema

activo de enfriamiento. Si la cubierta de la batería tiene dos

recortes para un ventilador y los dígitos "81" al final del

número de pieza de la batería, esto indica que tiene este

sistema de enfriamiento. En este caso, se aplican las

siguientes consideraciones espaciales:

1. Los ventiladores solamente funcionan durante la carga

de la batería o durante el período de enfriamiento (a, o

por encima, del voltaje de circuito abierto con carga

total). Los ventiladores no funcionarán cuando la batería

esté enchufada en el carro elevador. Si los ventiladores

continúan funcionando cuando la batería está enchufada

en el ca rro elevador, llame inmediatamente a su

representante local de servicio de GNB al número 1-888563-6300.

2. Las baterías ELEMENT

sistema activo de enfriamiento deben ser retiradas del

carro elevador para cargarlas dejando un mínimo de

15.24 cm de separación todo alrededor de la batería para

permitir la circulación de aire apropiada.

Cualquier desviación de las instrucciones de operación

adecuadas para las baterías de 48 voltios ELEMENT

anulará la garantía. Puede obtener información adicional y

asistencia llamando a su representante local de ventas, al

número 1-888-563-6300.

®

de 48 voltios equipadas con

11. TEMPERATURA

Las condiciones normales de operación deben estar entre

16°C y 38°C (60°F y 100°F). Temperaturas de operación de

más de 38°C (100°F) reducirán la duración de la batería.

Temperaturas de operación de menos de 16°C (60°F)

causarán menos capacidad y requerirán carga especial.

12. MANTENIMIENTO

Puesto que se trata de una batería ELEMENT®, requiere

muy pocas operaciones de mantenimiento. Se debe

mantener limpia y seca la parte superior de la batería y

puede lavarse para eliminar cualquier material extraño

acumulado. En el caso improbable de contaminación por

accidente con electrolito o plomo, contenga el derrame y

otifique a su representante local de GNB, que está

n

preparado para resolver cualquier problema

medioambiental. Los juegos contra derrames pueden

obtenerse del Centro de Piezas global de GNB llamando al

(800) 634-4462.

No trate nunca de añadir agua a la batería, ya que ha sido

diseñada para funcionar sin tener que añadir agua durante

toda su vida útil. Como indicamos anteriormente, cualquier

intento de quitar las tapas de ventilación anularían la

garantía.

13. CAMBIOS EN LAS OPERACIONES

Si en cualquier momento después de la compra inicial

ocurriesen cambios en las condiciones de operación, como

turnos prolongados, cargas aumentadas o cualquier otro

®

cambio que altere las condiciones iniciales de compra, le

rogamos que se comunique con su representante local de

GNB inmediatamente para asegurarse de que tiene el

equipo adecuado y de que no está afectando la duración de

la batería.

14. SERVICIO

Puede obtener información y asistencia adicional llamando

a su representante local de ventas o, en los EE.UU.,

llamando gratis al número 1-888-563-6300.

GNB Industrial Power

USA – Tel: 877.462.4636

Canada – Tel: 800.268.2698

www.gnb.com

GB3902 2013-03

Loading...

Loading...