Page 1

THESE INSTRUCTIONS TO BE SHIPPED WITH BATTERY AND TO BE DELIVERED TO USER

L

E

A

D

R

E

TU

R

N

RECYCLE

PLEASE READ BEFORE PLACING BATTERIES IN SERVICE

FLOODED FLAT-PLATE

MOTIVE POWER BATTERIES

INSTALLATION AND OPERATING INSTRUCTIONS

1. SAFETY

1.1 Follow your company’s Safety Instructions when

working with or near industrial truck batteries. Observe

the caution label affixed to the battery. Thoroughly

familiarize yourself with industry and government

guidelines (OSHA, ANSI) for charging, handling, and

maintaining industrial batteries.

1.2 Assign battery and charger care to properly trained

personnel.

1.3 This battery contains sulfuric acid electrolyte. Avoid

contact with skin, eyes, or clothing. Wear rubber

apron, gloves, boots, and goggles or face shield when

handling, checking, filling, charging or repairing

batteries.

1.4 Keep water readily available for flushing spilled

electrolyte from eyes or skin. Use plain water only and

obtain medical attention immediately. Special deluge

showers and eye wash basins are required.

1.5 Batteries produce hydrogen and oxygen gas during

charge. Keep open flames away. Do not check

electrolyte level with a cigarette lighter or match. Use

a flashlight or permanent lights. Switch on/off away

from the top of the battery. Do not smoke or create

sparks.

1.6 Lift batteries with a certified/approved hoist, crane, lift

truck, or similar equipment. Move batteries with trucks,

conveyors, or rollers. Be sure to place a rubber mat or

similar insulating material across the tops of coverless

batteries when handling. Make sure equipment is of

ample strength and properly installed.

DO NOT USE CHAIN OR WIRE ROPE SLINGS.

1.7 Never lay metal tools, such as wrenches or

screwdrivers, on top of a battery.

1.8 Disconnect the battery from the truck when performing

maintenance and repair on motor or electrical system.

1.9 Open or “break” the battery circuit before attempting

repairs to the charging plug or receptacles.

1.10 Apply a strong neutralizer, such as baking soda or

soda ash, when electrolyte is spilled on the floor.

Check local regulations regarding the disposal of

neutralized waste.

2. RECEIVING BATTERIES

Immediately upon receipt of shipment, examine the outside

of the packing for signs of rough handling before accepting

the battery from the carrier. Wet spots on the shipping pallet

may be an indication of leaking jars broken in shipment.

f there is evidence of damage, the receipt should be signed

I

and both copies (carrier’s and receiving copies) marked

“Shipment Received Damaged”. The carrier should be called

immediately and asked to make a “Carrier’s Inspection for

Damage Report”.

If “concealed” damage is later detected, the carrier should be

called immediately and requested to make a “Carrier’s

Inspection for Concealed Damage Report”. After inspection

by the carrier, arrangements should be made with the local

GNB Industrial Power representative to have the battery

repaired before placing it in service.

BEFORE PLACING BATTERIES IN SERVICE,

REVIEW AND FOLLOW THE SAFETY

GUIDELINES LISTED IN ITEM 1. SAFETY.

3. PLACING IN SERVICE

Verify that the battery weight meets or exceeds the minimum

truck weight requirements. Allow the battery to cool or warm

to room temperature before charging or adding water. Make

sure the battery charger is properly matched to the battery.

Use a charger with automatic charger termination controls.

GNB Industrial Power recommends the use of a GNB

®

SCR

charger.

Remove the vent caps from each cell and check to see that

the electrolyte level is above the plates. If it is obvious that

the electrolyte has spilled out of any cells, replace it with

electrolyte of the same specific gravity as found in the other

cells of the battery. Replace the vent caps and give the

battery a freshening charge until there is no increase in

specific gravity for three hydrometer readings taken at one

hour intervals.

During shipment of the battery, low temperatures and/or

normal shock and vibration often results in a drop in the

electrolyte level. If the level is below the plates, recheck it

after 3 hours of charging. If the level remains below the

plates, add water or electrolyte to the proper level at the end

of charging.

Following the first month of service, the battery should

reach its normal operating specific gravity of 1.305 ± 0.005

at 77°F (25°C).

IF BATTERIES ARE NOT IN USE, KEEP THEM

CHARGED. CHECK THE SPECIFIC GRAVITIES

MONTHLY AND GIVE A FRESHENING CHARGE

(3 OR 4 HOURS AT THE FINISH RATE) IF THE

GRAVITIES HAVE FALLEN 0.030 OR MORE;

OTHERWISE GIVE A FRESHENING CHARGE

EVERY THREE MONTHS.

P O S T T H E S E I N S T R U C T I O N S I N

TH E BATT E RY M AI N T EN A N CE A R EA .

Page 2

4. OPERATION

Batteries are rated in ampere-hours (Ah) and are selected to

perform a specific workload within an established period of

time. Increasing the workload or time period could result in

over discharging, thus shortening battery life. Limit

discharging of the battery (to 80% or less) so that specific

gravities do not go below 1.180. If truck operation results in

only partial discharges (40% or less) and specific gravities

are 1.230 or more at the end of the shift, recharging may be

eferred and the battery used for another shift, providing the

d

workload is not expected to increase. Hydrometer readings

and experience will determine the frequency of charge

intervals under these circumstances.

A battery should always be recharged immediately following a

complete discharge. Never allow it to remain in a discharged

condition, otherwise, permanent damage may result.

A battery is designed to be operated as follows:

8 hours discharge

8 hours charge

8 hours cool-down or rest designed and built

Flooded flat-plate motive power batteries are designed and

built to deliver 80% of their rated capacity at 77°F (25°C.)

5. TEMPERATURE

In the operation of motive power lead acid batteries, the

electrolyte temperature must not exceed 110°F (43°C). If the

battery is continuously operated at or above this

temperature, the service life of the battery will be severely

diminished. Under normal operating conditions, battery

electrolyte temperature should be maintained between

60-100°F (15-38°C). Following charging, the battery should

be allowed to cool-down or rest approximately 8 hours prior

to another discharge cycle.

If a battery is ever

temperature before charging or discharging. If a battery

consistently operates at high tempertures greater than

100°F (38°C), contact your local GNB Industrial Power

representative for service.

hot to the touch, allow it to cool to room

6. CHARGING

When recharging a fully discharged battery, the starting

charge rate may be 3 to 5 times higher than the finish charge

rate indicated on the battery nameplate. The charge rate

should taper down to the finish rate by the time the battery is

85% charged and may be even lower when fully charged.

High “on charge” temperatures or frequent need for water

additions are indications of overcharging. Short running

times and/or low end-of-charge specific gravities may

indicate inadequate recharge. Consult your local GNB

Industrial Power representative on specific charging

problems.

The ampere-hour rating of the charger applied to the battery

should be within 10% of the ampere-hour rating of the battery.

DO NOT INTERMITTENTLY CHARGE,

"OPPORTUNITY CHARGE", OR SHORT CYCLE

THIS BATTERY, UNLESS IT HAS BEEN DESIGNED

AND APPROVED FOR SUCH APPLICATION.

• TEMPERATURE… Under normal operating conditions,

the electrolyte temperature shall be between 60-100°F

(15-37°C). Operating temperature above 100°F will

reduce the battery’s service life. Operating temperature

below 60°F results in less capacity and special charging

s required.

i

• WATER ADDITIONS… Add water at the end of

the charging period when the battery is fully charged

nd the charger has tapered to its finish rate. See

a

Item 9.

• EQUALIZE… Once a week for heavy

pplication (e.g., 80% daily discharge) to once a

a

month for light duty application (e.g., less than

50% daily discharge).

DEPTH OF DISCHARGE… Do not discharge

•

the battery below 80% of the rated capacity.

Over discharging shortens the battery life and voids

the warranty.

• CLEANING… Keep the top of the battery clean

and dry. See Item 8.

• PREVENTIVE MAINTENANCE SCHEDULE…

WEEKLY

• Check electrolyte levels (see water additions).

• Equalize charge (heavy use application).

MONTHLY

• Record electrolyte specific gravities.

• Equalize charge (light use application).

• Inspect the cables and charging plugs.

• Clean the top of the cells.

SEMI-ANNUAL

• Inspect the charger. Confirm proper output voltage

and current. Check for external damage, frayed

cables, or worn connectors.

• Clean the exterior of the battery.

TROUBLE SIGNS

• Battery temperature rises more than 25°F (14°C)

during a normal charge.

• Open circuit cell voltages vary by 0.15 volts or more

and specific gravity varies by 0.020 or more during

equalizing.

• The top of the battery is always wet or one cell

requires excessive water.

8. MAINTENANCE CLEANING

The top of the battery should be kept clean and dry. Keep

the vent caps in place during use and charging. Remove

them only to observe electrolyte levels, make water

additions, take temperatures, or take specific gravity

readings with a hydrometer. If the battery requires cleaning,

contact your local GNB Industrial Power servicing

representative. The solution used to clean and neutralize the

outside of the batteries should be disposed of in an

environmentally safe manner.

7. MAINTENANCE

• KEEP RECORDS… Showing specific gravities,

equalizing, charging, temperature, and voltages

on a monthly basis. These records are required

to maintain your warranty.

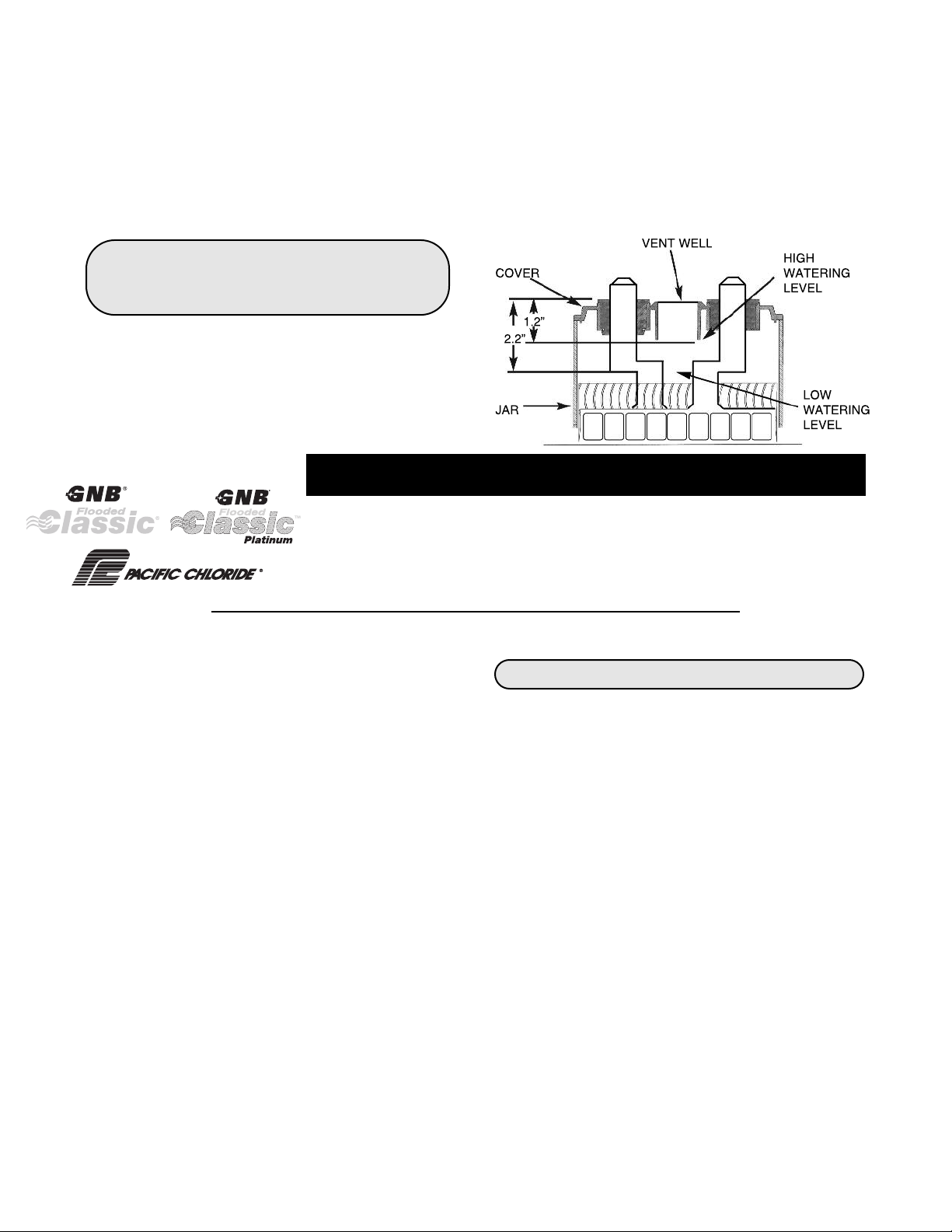

9. WATER ADDITIONS

Maintain electrolyte levels above the plates, but no higher

than 1/8" from the bottom of the cell cover vent well. Check

the electrolyte level weekly, or as necessary depending on

battery use prior to charging. If the level is not visible (below

Page 3

the plates) add just enough water to cover it and then

proceed with charging the battery. Otherwise, defer watering

the battery until the end of the charging period when the

battery is fully charged and the charger has tapered to its

finish rate. At that time, add enough water to bring the

electrolyte level to between 1.2-2.2” of the top of the cover.

Always use distilled water or water that is known to be free

f abnormally high amounts of impurities. Contact your local

o

GNB Industrial Power representative if you are not sure of

your water quality.

BATTERIES MUST BE VISUALLY INSPECTED

PER THE ABOVE SCHEDULE EVEN WITH THE

USE OF A WATERING SYSTEM.

10. SERVICE AND PARTS

Your local GNB Industrial Power sales representative has

more information regarding the full range of maintenance

and repair service available. GNB Industrial Power can also

supply all of your battery, charger, and accessory device

replacement part needs. For more information in the U.S.A.

LEA ANTES DE PONER LAS BATERÍAS EN SERVICIO ESTAS INSTRUCCIONES

DEBEN INCLUIRSE CON LA BATERÍA Y ENTREGARSE AL USUARIO

and Canada, call 1-888-563-6300. All others, please contact

our local GNB Industrial Power battery sales

y

representative.

11. RECYCLING

U.S. Federal and State Regulations require that lead acid

batteries be handled and disposed of in compliance with

trict guidelines. GNB Industrial Power offers disposal

s

service for lead acid batteries. Call 1-888-438-5865 to

arrange a pick-up or to get additional information.

VENT WELL

COVER WATERING

1.2”

2.2”

JAR WATERING

HIGH

LEVEL

LOW

LEVEL

BATERÍAS INUNDADAS DE PLACAS

PLANAS PARA FUERZA MOTRIZ

INSTRUCCIONES DE INSTALACIÓN Y OPERACIÓN

1. SEGURIDAD

1.1 Siga las instrucciones de seguridad de la compañía al

trabajar con baterías de montacargas industriales o en

sus proximidades. Observe la etiqueta de precaución

pegada en la batería. Familiarícese completamente con

las normas industriales y gubernamentales (OSHA, ANSI)

para cargar, manipular y mantener baterías industriales.

1.2 Asigne el cuidado de las baterías y de los cargadores

a personas capacitadas.

1.3 Esta batería contiene electrolito a base de ácido

sulfúrico. No permita contacto con la piel, los ojos o la

ropa. Lleve puesto un delantal de goma, guantes,

botas y gafas o máscara al manipular, comprobar,

llenar, cargar o reparar baterías.

1.4 Tenga a mano agua para lavar el electrolito derramado

de los ojos o en la piel. Use agua corriente solamente y

procure atención médica de forma inmediata. Se

requieren duchas de lluvia artificial y lavabos para los

ojos según sea necesario.

1.5 Las baterías desprenden hidrógeno y oxígeno

gaseosos durante su carga. No acerque las baterías a

las llamas abiertas. No compruebe el nivel de electrolito

con un encendedor o un fósforo. Use una linterna o

luces permanentes. Encienda y apague lejos de la parte

superior de la batería. No fume ni produzca chispas.

1.6 Levante las baterías con un torno, grúa, montacargas

o equipo similar certificado/aprobado. Mueva las

baterías en camiones, transportadores o rodillos.

Asegúrese de poner una estera de goma o materiales

aislantes similares encima de las baterías sin tapas al

manipularlas. Cerciórese de que los equipos tengan una

amplia resistencia y que estén bien instalados.

NO USE ESLINGAS DE CADENA O CABLE METÁLICO.

1.7 No ponga nunca herramientas metálicas, tales como

llaves o destornilladores encima de una batería.

1.8 Desconecte la batería del montacargas al efectuar las

tareas de mantenimiento y reparación en el motor o en

el sistema eléctrico.

1.9 Abra o “rompa” el circuito de la batería antes de tratar

de hacer reparaciones en el enchufe o en los

receptáculos de carga.

1.10 Aplique un neutralizador fuerte, tal como bicarbonato

ódico o cenizas de sosa, cuando se derrame electrolito

en el suelo. Consulte las regulaciones locales en lo que

se refiere a la evacuación de desechos neutralizados.

2. RECEPCIÓN DE BATERÍAS

Inmediatamente después de recibir el envío, examine la

parte de fuera del paquete para ver si hay indicios de

manipulación brusca antes de aceptar la batería del

transportista. La aparición de lugares húmedos en la paleta

de envío puede ser una indicación de que hay fugas debido

a vasos rotos durante el envio.

Si hay daños evidentes, el recibo debe ser firmado y ambos

ejemplares (tanto del transportista como del receptor) deben

marcarse con las palabras “despacho recibido con daños”.

El transportista debe llamar inmediatamente y solicitar la

redacción de un “Informe de inspección de daños del

transportista”.

Page 4

Si más adelante se descubren daños “ocultos”, se debe

llamar inmediatamente al transportista y se le debe solicitar

que redacte un “Informe de inspección del transportista para

er si hay daños ocultos”. Después de la inspección por parte

v

del transportista, se deben hacer arreglos con el

representante local de GNB Industrial Power para reparar la

batería antes de ponerla en servicio.

ANTES DE PONER LAS BATERÍAS EN SERVICIO,

REVISE Y SIGA LAS NORMAS DE SEGURIDAD

INDICADAS EN EL COMPONENTE 1. SEGURIDAD.

3. PUESTA EN SERVICIO

Verifique que el peso de la batería cumpla o exceda los

equisitos de peso mínimo del montacargas. Deje que la

r

batería se enfríe o se caliente a la temperatura ambiente

antes de cargar o echar agua. Asegúrese de que el

cargador de la batería se adapte completamente a la

batería. Use un cargador con controles de terminación

automáticos del cargador. GNB Industrial Power

recomienda el empleo de un cargador GNB

®

SCR.

Retire las tapas de ventilación de cada célula y comprobar

que el nivel del electrolito está por encima de las placas. Si

es evidente que se ha derramado electrolito de cualquier

celda, reemplácelo por electrolito del mismo peso específico

como el encontrado en las otras celdas de la batería. Vuelva

a poner las tapas de ventilación y recargue la batería hasta

que no aumente la densidad relativa para las tres lecturas

de hidrómetro tomadas en intervalos de una hora.

Durante el despacho de la batería, las bajas temperaturas y

el impacto y las vibraciones normales producen a menudo

una disminución del nivel de electrolito. Si el nivel está por

debajo de las placas, vuelva a comprobar que después de 3

horas de carga. Si el nivel se mantiene por debajo de las

placas, se añade agua o electrolito hasta el nivel adecuado

al final de la carga.

Tras el primer mes de servicio, la batería debe alcanzar su

densidad relativa de operación normal de 1.305 ± 0.005 a 25°C.

SI NO SE USAN BATERÍAS, MANTÉNGALAS

CARGADAS. COMPRUEBE MENSUALMENTE LOS

PESOS ESPECÍFICOS Y RECARGUE (3 Ó 4 HORAS A LA

VELOCIDAD FINAL) SI LAS DENSIDADES DISMINUYEN

30 PUNTOS (0.030) O MÁS, DE LO CONTRARIO

RECARGUE CADA TRES MESES.

4. OPERACIÓN

Las baterías se clasifican en amperios-hora (Ah) nominales

y se seleccionan para realizar una carga de trabajo

específica dentro de un período establecido. El aumento de

la carga de trabajo o del período puede producir una

descarga excesiva, acortando así la duración de la batería.

Limite la descarga de la batería (a un 80% o menos) de

modo que los pesos específicos no sean inferiores a 1.180. Si

la operación del montacargas produce solamente descargas

parciales (40% o menos) y las densidades relativas son 1.230

o mayores al final del turno, la recarga puede demorarse y la

batería puede usarse en otro turno siempre y cuando no se

espere que aumente la carga de trabajo. Las lecturas del

hidrómetro y la experiencia dictará la frecuencia de los

intervalos de carga en estas circunstancias.

La batería siempre debe recargarse inmediatamente

después de una descarga completa. No la deje nunca en

estado descargado, ya que de lo contrario se pueden

roducir daños permanentes.

p

Una batería está diseñada para operar de la forma

siguiente:

8 horas de descarga

8 horas de carga

8 horas de enfriamiento o reposo

Las baterías inundadas de placas planas para fuerza motriz

están diseñadas y construidas para suministrar el 80% de su

capacidad nominal a 25°C.

5. TEMPERATURA

En la operación de baterías plomo-ácido de tracción, la

temperatura del electrolito no debe exceder de 43°C. Si se

hace funcionar la batería de modo continuo a esta

temperatura o a una temperatura superior a la misma,

disminuirá en gran medida la duración de la batería. En

condiciones de operación normales, la temperatura del

electrolito de la batería debe mantenerse entre 15°C y 38°C.

Después de la carga, se debe dejar que la batería se enfríe

o repose aproximadamente durante 8 horas antes de otro

ciclo de descarga.

Si en cualquier momento

la batería se calienta demasiado

como para no poder tocarla, deje que se enfríe a la

temperatura ambiente antes de cargar o descargar. Si una

batería opera de manera uniforme a altas temperaturas

mayores que 38°C, póngase en contacto con su

representante local de GNB Industrial Power para efectuar su

servicio.

6. CARGA

Al recargar una batería completamente descargada, la

velocidad de carga inicial puede ser de 3 a 5 veces mayor que

la velocidad de carga final indicada en la placa de identificación

de la batería. La velocidad de carga debe disminuir

gradualmente hasta la velocidad final en el momento en que la

batería esté cargada un 85% y puede ser incluso inferior cuando

esté completamente cargada. Las altas temperaturas “en carga”

o la necesidad frecuente de agregar agua son indicaciones de

una carga excesiva.

Los tiempos de funcionamiento cortos y las densidades relativas

bajos pueden ser indicativos de una recarga inadecuada.

Consulte con su representante local de GNB Industrial Power en

lo que se refiere a problemas de carga específicos.

La capacidad nominal de amperios-hora del cargador aplicado

a la batería debe ser igual a la capacidad nominal de amperioshora de la batería ±10%.

NO CARGA INTERMITENTE, "CARGA DE LA

OPORTUNIDAD”, O CICLO CORTO ESTA BATERÍA,

MENOS QUE HAYA SIDO DISEÑADO Y APROBADO

PARA SU APLICATIÓN.

7. MANTENIMIENTO

• MANTENIMIENTO DE REGISTROS… Mantenga

registros mensuales de densidades relativas,

compensación, carga, temperatura y voltajes. Estos

registros son necesarios para mantener la garantía.

Page 5

• TEMPERATURA… Condiciones de operación

normales, la temperatura del electrolito debe estar

comprendida entre 15°C y 37°C. La temperatura de

operación por encima de 37°C reducirá la duración de

la batería. La temperatura de operación inferior a 15°C

roduce menos capacidad y requiere una carga

p

especial.

• ADICIONES DE AGUA… Agregue agua al final de

período de carga cuando la batería esté completamente

cargada y el cargador haya disminuido gradualmente

su velocidad hasta la velocidad de carga final. Vea el

apartado 9.

• COMPENSE… Una vez por semana para aplicaciones

de servicio pesado (por ejemplo, descarga diaria del

0%) a una vez al mes para aplicaciones de servicio

8

ligero (por ejemplo, descarga diaria menor del 50%).

• PORCENTAJE DE DESCARGA… No descargue la

batería a menos del 80% de la capacidad nominal. La

descarga excesiva acorta la duración de la batería y

anula la garantía.

• LIMPIEZA… Mantenga limpia y seca la parte de arribe

de la batería. Vea el apartado 8.

PROGRAMA DE MANTENIMIENTO PREVENTIVO…

SEMANAL

• Compruebe los niveles de electrolito (vea adiciones

de agua).

• Compense la carga (aplicación de servicio pesado).

MENSUAL

• Registre los pesos específicos del electrolito.

• Compense la carga (aplicación de servicio ligero).

• Inspeccione los cables y los enchufes de carga.

• Limpie la parte de arriba de las celdas.

SEMIANUAL

• Inspeccione el cargador.

• Limpie el exterior de la batería.

INDICIOS DE PROBLEMAS

• La temperatura de la batería sube más de 14°C

durante una carga normal.

• Los voltajes de las celdas de circuito abierto varían

0.15 voltios o más y el peso específico varía 0.020 o

más durante la compensación.

• La parte de arribe de la batería está siempre mojada o

una de las celdas requiere un exceso de agua.

8. LIMPIEZA DE MANTENIMIENTO

La parte superior de la batería debe conservarse limpia y

seca. Mantenga todas las tapas de la batería colocadas

durante el uso y la carga. Quite solamente para observar los

niveles de electrolito, agregar agua, medir temperaturas o

densidades relativas con un hidrómetro. Si es necesario

limpiar la batería, póngase en contacto con su representante

de servicio local de GNB Industrial Power. La solución

usada para limpiar y neutralizar el exterior de las baterías

debe desecharse de una manera que sea segura para el

medio ambiente.

9. ADICIONES DE AGUA

Mantener los niveles de electrolitos por encima de las

lacas, pero también que no supere el 1/8 "de la parte

p

inferior de la abertura cubierta de la celda. Compruebe

semanalmente el nivel de electrolito antes de la carga, o

según sea necesario dependiendo del uso de la batería. Si

el nivel no es visible (por debajo de las placas), agregue

suficiente agua para cubrirlo y luego proceder con la carga

de la batería. De lo contrario, demore la adición de agua a

la batería hasta el final del período de carga cuando la

batería esté completamente cargada y el cargador haya

isminuido gradualmente su velocidad de carga hasta la

d

velocidad final. En ese momento, agregue agua suficiente

para hacer que el nivel de electrolito esté a una distancia

comprendida entre 30 y 56 mm con respecto a la parte de

arribe de la tapa. Use siempre agua destilada o agua que no

tenga cantidades de impurezas anormalmente elevadas.

Póngase en contacto con su representante local de GNB

Industrial Power si no está seguro de la calidad del agua.

SE DEBEN INSPECCIONAR VISUALMENTE

LAS BATERÍAS SEGÚN EL PROGRAMA

ANTERIOR INCLUSO CON EL USO DE UN

SISTEMA DE ADICIÓN DE AGUA.

10.SERVICIO Y PIEZAS

Su representante de ventas local de GNB Industrial Power

dispone de más información referente a la gama completa

de servicios de mantenimiento y reparación disponibles.

GNB Industrial Power también puede suministrarle todas las

baterías, cargadores y dispositivos accesorios de repuesto

que necesite. Para obtener información adicional en EE.UU.

y Canadá llame al 1-888-563-6300. Para los demás países

póngase en contacto con su representante de ventas local

de baterías GNB Industrial Power.

11. RECICLAJE

Regulaciones de las autoridades federales y estatales

impiden estrictas normas sobre la manipulación y el

desecho de baterías plomo-ácido. GNB Industrial Power

ofrece un servicio de recuperación de baterías plomo-ácido.

En EE.UU. llame al 1-888-438-5865 para recibir

informaciones sobre este servicio.

HUECO DE VENTILACIˆÓN

TAPA ADICIÓN

30 mm

56 mm

VASO DE AGUE

NIVEL ALTO DE

DE AGUA

BAJO NIVEL

PROTVASO

Page 6

LIRE CES INSTRUCTIONS AVANT DE METTRE LES BATTERIES EN SERVICE

ELLES DOIVENT ACCOMPAGNER LA BATTERIE ET ÊTRE REMISES À L’UTILISATEUR

BATTERIE DE TRACTION A

PLAQUE PLATES

INSTRUCTIONS POUR L’INSTALLATION ET L’EXPLOITATION

1. SÉCURITÉ

1.1 Suivre les consignes de sécurité particulières à votre

entreprise lorsque vous travaillez avec des batteries

industrielles pour chariot élévateur, ou prés de

celles-ci. Observer les recommandations de l’étiquette

de sécurité apposée sur la batterie. Se familiariser à

fond avec les directives de l’industrie et du

gouvernement (OSHA, ANSI) pour la recharge, la

manipulation et l’entretien des batteries industrielles.

1.2 Attribuer la tâche d’entretenir les batteries et les

chargeurs á des personnes ayant reçu une formation

appropriée.

1.3 Cette batterie contient de l’acide sulfurique

(électrolyte). Éviter tout contact avec la peau, les yeux

ou les vêtements. Porter un tablier, des gants et des

bottes de caoutchouc, ainsi que des lunettes de

sécurité ou une visière protège-visage lors de la

manipulation, du remplissage, de la recharge ou de la

réparation de batteries.

1.4 Garder de l’eau à la portée de la main afin de nettoyer

á grande eau l’électrolyte projeté dans les yeux ou sur

la peau. Utiliser uniquement de l’eau pure et appeler

immédiatement un médecin. Des douches spéciales à

grand débit et des cuvettes de rinçage pour les yeux

sont nécessaires.

1.5 Les batteries produisent de l’hydrogène et de l’oxygène

gazeux durant la recharge. Tenir les flammes nues

éloignées. Ne pas vérifier le niveau de l’électrolyte à

l’aide d’un briquet ou d’une allumette. Utiliser une

lampe de poche ou des lumières permanentes.

L’allumer et l’éteindre à l’écart du dessus de la batterie.

Ne pas fumer ou provoquer d’étincelles.

1.6 Soulever les batteries á l’aide d’un treuil, d’une grue,

d’un chariot élévateur, ou d’un équipement similaire

homologué/agréé. Déplacer les batteries à l’aide de

chariots, de convoyeurs ou de rouleaux. S’assurer de

mettre un tapis de caoutchouc (ou matériau isolant

similaire) sur le dessus des batteries sans couvercles

lors de la manipulation. S’assurer que l’équipement est

assez robuste et adéquatement isolé.

NE PAS UTILISER UN TREUIL À

CHAÎNES OU À CORDAGES.

1.7 Ne jamais déposer d’outils en métal, tels que clés ou

tournevis sur le dessus d’une batterie.

1.8 Débrancher la batterie du chariot pour effectuer

l’entretien ou la réparation du moteur ou du système

électrique.

1.9 Ouvrir le circuit de la batterie avant d’entreprendre des

réparations sur les fiches ou les prises de charge.

1.10 Utiliser un neutralisant puissant, tel du bicarbonate ou

du carbonate de soude, si de l’électrolyte a été

déversé sur le plancher. Consulter la réglementation

locale concernant la disposition des déchets de la

neutralisation.

2. RÉCEPTION DES BATTERIES

Dès la réception de la cargaison, examiner immédiatement

l’extérieur des emballages afin de détecter tout signe de

manutention abusive avant d’accepter les batteries

du transporteur. Des taches d’humidité sur la palette

d’expédition peuvent indiquer des fuites provenant de bacs

endommagés durant le transport.

S’il y a des signes de dommages évidents, il faut inscrire la

mention «Cargaison reçue endommagée» sur les deux

copies du connaissement (celle du transporteur et celle du

destinataire), puis signer celles-ci. Il faut communiquer

immédiatement avec le transporteur et exiger qu’il produise

un «Rapport d’inspection du transporteur pour cargaison

endommagée».

Si des dommages «cachés» sont découverts

ultérieurement, il faut communiquer immédiatement avec le

transporteur et exiger qu’il produise un «Rapport

d’inspection du transporteur pour dommages cachés». Suite

à l’inspection par le transporteur, il faut prendre les

dispositions nécessaires avec le représentant de GNB

Industrial Power pour faire réparer la batterie avant de la

mettre en service.

AVANT DE METTRE LES BATTERIES EN

SERVICE, PASSER EN REVUE ET OBSERVER

LES MESURES DE SÉCURITÉ LISTÉES À

LA SECTION 1 SÉCURITÉ.

3. MISE EN SERVICE

Vérifier que le poids de la batterie rencontre ou excède le

minimum de poids exigé pour le chariot. Laisser la batterie

refroidir ou se réchauffer à la température ambiante avant de

la recharger ou d’ajouter de l’eau. S’assurer que le chargeur

est de modèle adéquat pour la batterie. Utiliser un chargeur

avec un contrôle automatique de fin de charge. Il est

recommandé par GNB Industrial Power d’utiliser un chargeur

®

GNB

à thyristor.

Retirer les bouchons de ventilation de chaque cellule et

vérifier que le niveau d'électrolyte est au-dessus des

plaques. S’il est évident que de l’électrolyte s’est déversé de

certaines cellules, le remplacer par de l’électrolyte de même

densité que celui des autres cellules de la batterie. Remettre

les bouchons d’aération en place et donner une charge de

restauration à la batterie jusqu’à ce qu’il n’y ait plus

d’augmentation de la densité pour trois lectures de

densimètre consécutives prises à intervalles d’une heure.

Page 7

Lors de l’expédition de la batterie, les basses températures

et/ou les chocs et vibrations normales ont souvent pour effet

une diminution du niveau de l’électrolyte. Si le niveau est en

dessous des plaques, revérifier après 3 heures de charge. Si

le niveau reste en dessous des plaques, ajouter de l'eau ou

de l'électrolyte au niveau approprié à la fin de la charge.

AFFICHER CES INSTRUCTIONS DANS

’AIRE D’ENTRETIEN DES BATTERIES.

L

Après le premier mois d'exploitation, l’électrolyte de la

batterie devrait atteindre sa densité normale d’exploitation,

soit entre 1.305 ± 0.005 à 25°C.

SI LES BATTERIES NE SONT PAS

UTILISÉES, LES MAINTENIR CHARGÉES. VÉRIFIER

LEUR DENSITÉ MENSUELLEMENT

ET LEUR DONNER UNE CHARGE DE

RESTAURATION (3 À 4 HEURES AU TAUX DE FIN

DE CHARGE) SI LA DENSITÉ EST DE 0,030 OU PLUS

SOUS LE NIVEAU NORMAL. AUTREMENT, LEUR

DONNER UNE CHARGE

DE RESTAURATION TOUS LES TROIS MOIS.

4. EXPLOITATION

La capacité des batteries est exprimée en ampère-heures

(Ah) et celles-ci sont sélectionnées pour effectuer une

charge de travail spécifique durant une période de temps

établie. Si la charge de travail ou la période de temps est

prolongée, il peut en résulter une décharge trop profonde, ce

qui réduit la vie utile de la batterie. Limiter la décharge de la

batterie (à 80% ou moins) de façon à ce que les densités ne

descendent pas sous le seuil de 1.180. Si l’exploitation du

chariot n’exige qu’une décharge partielle (40% ou moins) et

que les densités sont de 1.230 ou plus à la fin du quart de

travail, on peut repousser la recharge et utiliser la batterie

pour un autre quart de travail, á condition qu’aucune hausse

de la charge de travail ne soit prévue. Les mesures à l’aide

d’un densimètre et l’expérience permettront de déterminer la

fréquence des intervalles de recharge sous de telles

conditions.

Une batterie doit toujours être rechargée immédiatement

après une décharge complète. Ne jamais la laisser dans un

état de décharge, car cela pourrait causer des dommages

permanents.

Une batterie est conçue pour être utilisée comme suit:

Durée de décharge: 8 heures

Durée de recharge: 8 heures

Durée de refroidissement ou d’arrêt de par la conception

et la fabrication: 8 heures

Les batteries de traction a plaque plates sont conçues et

fabriquées pour produire 80% de leur capacité nominale à

25°C.

5. TEMPÉRATURE

Lors de l’exploitation de batteries au plomb-acide pour

chariot, la température de l’électrolyte ne doit pas excéder

43°C. Si la batterie est continuellement exploitée á cette

température ou au-dessus de celle-ci, la durée de vie utile de

la batterie en sera grandement réduite. Sous des conditions

normales d’exploitation, la température devrait être

maintenue entre 15°C et 38°C. À la suite d’une recharge, on

doit permettre à la batterie de refroidir ou de s’arrêter

pendant environ 8 heures avant de l’utiliser pour un autre

cycle de décharge.

Si ja

mais une batterie est chaude au toucher, la laisser refroidir

à la température ambiante avant de la charger ou de la

décharger. Si une batterie fonctionne continuellement à des

températures dépassant 38°C, s’adresser au représentant GNB

Industrial Power local pour la faire réparer.

. RECHARGE

6

Lors de la recharge d’une batterie complètement déchargée,

le taux de début de charge peut être de 3 à 5 fois supérieur

au taux de fin de charge indiqué sur la plaque signalétique

de la batterie. Le taux de recharge devrait avoir diminué

jusqu’au taux de fin de charge lorsque la batterie est

rechargée à 85%, et pourrait être encore plus bas à pleine

harge. Des températures élevées durant la recharge et/ou

c

la nécessité de fréquentes additions d’eau sont les signes

d’une surcharge. Des périodes de fonctionnement réduites

et/ou des densités trop basses à la fin de la recharge sont

les signes d’une recharge inadéquate. Communiquer avec

votre représentant GNB Industrial Power pour tout problème

spécifique à la recharge.

La capacité en ampère-heures du chargeur relié à la batterie

ne doit pas différer de plus de 10% de celle de cette

dernière.

NE PAS INTERMITTENCE CHARGE, "CHARGE

OPPORTUNITÉ ", OU COURT CETTE BATTERIE,

SAUF S’IL A ETE CONÇU ET HOMOLOGUÉ POUR

UNE TELLE APPLICATION.

7. ENTRETIEN

• GARDER DES REGISTRES: Inscrire les densités, les

charges d’égalisation, les recharges, les températures

et les tensions mensuellement. Ces registres sont

nécessaires pour maintenir la validité de votre garantie.

• TEMPÉRATURE: Sous des conditions normales

d’exploitation, la température doit se situer entre 15°C

et 37°C. L’exploitation à des températures au-dessus

de 37°C réduira la durée de vie utile de la batterie.

L’exploitation à des températures au-dessous de 15°C

réduit la capacité et nécessite des conditions de

recharge spéciales.

• ADDITIONS D’EAU: Ajouter de l’eau á la fin de la

période de recharge, quand la batterie est pleinement

chargée et que le courant du chargeur s’est abaissé au

taux de fin de charge. Se référer à la section 9.

• CHARGE D’ÉGALISATION: Donner une charge

d’égalisation entre une fois par semaine pour les

applications de service intense (ex.: décharge

quotidienne á 80%) et une fois par mois pour les

applications de service léger (ex.: décharge quotidienne

à moins de 50%).

• PROFONDEUR DE DÉCHARGE: Ne pas décharger la

batterie à plus de 80% de sa capacité nominale. Les

décharges trop profondes réduisent la durée de vie utile

de la batterie et annulent la garantie.

• NETTOYAGE: Garder le dessus de la batterie propre et

sec. Se référer à la section 8.

Page 8

PROGRAMME D’ENTRETIEN PRÉVENTIF…

A Division of Exide Technologies

•

UNE FOIS PAR SEMAINE

• Vérifier les niveaux de l’électrolyte (voir la section sur

les additions d’eau)

• Donner une charge d’égalisation (applications de

service intense)

UNE FOIS PAR MOIS

• Enregistrer les densités de l’électrolyte

• Donner une charge d’égalisation (applications de

service léger)

• Inspecter les cables, les fiches et les prises de charge

• Nettoyer le dessus des cellules

DEUX FOIS PAR ANNÉE

• Inspecter le chargeur

• Nettoyer l’extérieur de la batterie

INDICATEURS DE PROBLÈMES

• La température de la batterie augmente de plus de

14°C durant une recharge normale.

• Les tensions en circuit ouvert des cellules varient de

0.15 volt ou plus et les densités varient de 0.020 ou

plus durant la charge d’égalisation.

• Le dessus de la batterie est toujours mouillé ou une

cellule requiert une quantité d’eau excessive.

8. NETTOYAGE POUR ENTRETIEN

Le dessus de la batterie doit être maintenue propre et sec.

Garder les bouchons d’aération en place durant

l’exploitation et la recharge. Ne les enlever que pour vérifier

les niveaux d’électrolyte, ajouter de l’eau, prendre des

lectures de température, ou prendre des lectures de densité

á l’aide d’un densimètre. Si la batterie doit être nettoyée,

contacter le représentant GNB Industrial Power local. La

solution utilisée pour nettoyer et neutraliser l’extérieur des

batteries doit être mise au rebut de façon à sauvegarder

l’environnement.

9. ADDITIONS D’EAU

Maintenir les niveaux d'électrolyte au-dessus des plaques,

mais ne dépasse pas 1/8 "à partir du bas de l'évent

couvercle de la cellule ainsi. Vérifier les niveaux d’électrolyte

une fois par semaine, ou au besoin selon l’utilisation de la

batterie avant la recharge. Si le niveau n'est pas visible (cidessous les plaques), ajoutez juste assez d'eau pour le

couvrir, puis procéder à la charge de la batterie. Autrement,

reporter l’addition d’eau jusqu’à la fin de la période de

recharge, lorsque la batterie sera pleinement chargée et que

le courant du chargeur aura diminué jusqu’au taux de fin de

charge. Alors, ajouter assez d’eau pour hausser le niveau

d’électrolyte à une distance de 30 mm à 56 mm du dessus

du couvercle. Toujours utiliser de l’eau distillée ou de l’eau

reconnue comme ne contenant pas de quantités

anormalement élevées d’impuretés. Communiquer avec

otre représentant GNB Industrial Power s’il y a un doute

v

quant à la qualité de l’eau utilisée.

LES BATTERIES DOIVENT ÊTRE INSPECTÉES

SELON L’HORAIRE CI-DESSUS, MÊME SI UN

SYSTÈME DE DISTRIBUTION D’EAU EST UTILISÉ.

10. SERVICE APRÈS-VENTE ET PIÈCES

Votre représentant des ventes de GNB Industrial Power peut

vous fournir plus d’information concernant la gamme

complète des services d’entretien et de réparation

disponibles. GNB Industrial Power peut également fournir

toutes les pièces de rechange nécessaires pour les

batteries, les chargeurs et les accessoires. Pour plus

d’information, aux États-Unis et au Canada, appeler au

1.888.563.6300. Dans tous les autres pays, contacter le

représentant local en batteries GNB Industrial Power.

11. RECYCLAGE

Les règlements fédéraux et des états des États-Unis exigent

que les batteries au plomb-acide usées soient manipulées et

que l’on en dispose selon des directives très strictes. GNB

Industrial Power offre un service d’enlèvement pour les

batteries au plomb-acide. Appeler au 1.888.438.5865 pour

un organiser un enlèvement ou obtenir des informations

complémentaires.

PUITS D’AÉRATION

COUVERCLE DÉAU

30mm

56mm

BAC DÉAU

NIVEAU

MAXI

NIVEAU

MINI

GNB Industrial Power

USA – Tel: 877.462.4636

Canada – Tel: 800.268.2698

www.gnb.com

GB3696 2013-06

Loading...

Loading...