Page 1

SCR SERIES CHARGERS

SCR SERIES CHARGERS

Section 93.30

2011-11

JA0133-00

INSTALLATION & OPERATING

INSTRUCTIONS

FOR

SCR & SCRF SERIES

BATTERY CHARGER

WITH

THREE PHASE INPUT

I & O MANUALS

I & O MANUALS

Page 2

SCR/SCRF SERIES BATTERY CHARGER SPECIFICATIONS

MODEL No.

1

SERIAL No.

SMART PART No.

(items A-F req’d)

SMART

Pos.

PART

DWG#

CODE

U UNFILTERED DC OUTPUT

F

A

E

1 120 Vac - 60 Hz INPUT (SINGLE PHASE ONLY)

2

3

4

B

5

6

7

0

F REDUNDANT DC FUSE PROTECTION (F1 / F2)

B

C

C

1 EJ0450 1 MANUAL FLOAT / EQUALIZE SWITCH

2

3

4

D

5

6

0

2% 2% ACCURACY 3.5in ANALOG DC METERS

1%

SB

E

DM EJ0895 1 0.1% ACCURACY 3.5in LED DIGITAL DC METERS

CM

P STANDARD (COLOR-CODED PVC) WIRING

F

H CB0002 SWITCHBOARD INSULATION SYS. (#-CODED) WIRING

A EJ0085 7 AC POWER FAILURE ALARM & INDICATOR LIGHTS

G

C CUSTOM AC FAILURE ALARM

C1 EJ0837 1 CASM PC BOARD w/ ONE (1) FORM-C CONTACTS

C2 EJ0837 1 CASM PC BOARD w/ TWO (2) FORM-C CONTACTS

H

HL EJ0083 7 HIGH / LOW DC VOLTAGE ALARM & IND. LIGHTS

ZC EJ0127 1 CHARGER FAILURE ALARM (NO Adc) & IND. LIGHTS

HZ 7 / 5 HLVA / CFA & IND. LIGHTS (EJ0083 & EJ0127)

S EJ0094 4 GND. DET. SWITCH FOR DC VOLTMETER INDICATION

J

L EJ0089 5 GND. DET. IND. LIGHTS w/ GROUND & LAMP TEST

R EJ0086 4 GND. DET. RELAYS w/ RESET SWITCH & IND. LIGHTS

K

F EJ0133 1 PARALLEL CHGR OPERATION w/ 2% LOAD SHARING

L

H EJ0592 1 HIGH DC VOLTAGE CHARGER SHUTDOWN

R EJ0141 1 COMMON ALARM RELAY CONTACTS

M

B

C

D

D

N

D EI5033 1 DRIP SHIELDS - STYLE-3 CABINET (EB0123)

D

D

GENERAL SPECIFICATIONS: ADDITIONAL FEATURES / OPTIONS / NOTES:

Regulation: + or - 0.5% no-load to full-load

Regulation: + or - 0.5% for + or - 10% AC line variation

Regulation: + or - 1% for combined load, line & temp. variations

Ambient Temperature Range: 0º C to 50º C

Relative Humidity: up to 95% without condensation

Altitude: up to 1,000m above sea level

EJ0093

EJ0097

EJ0869

EJ0131

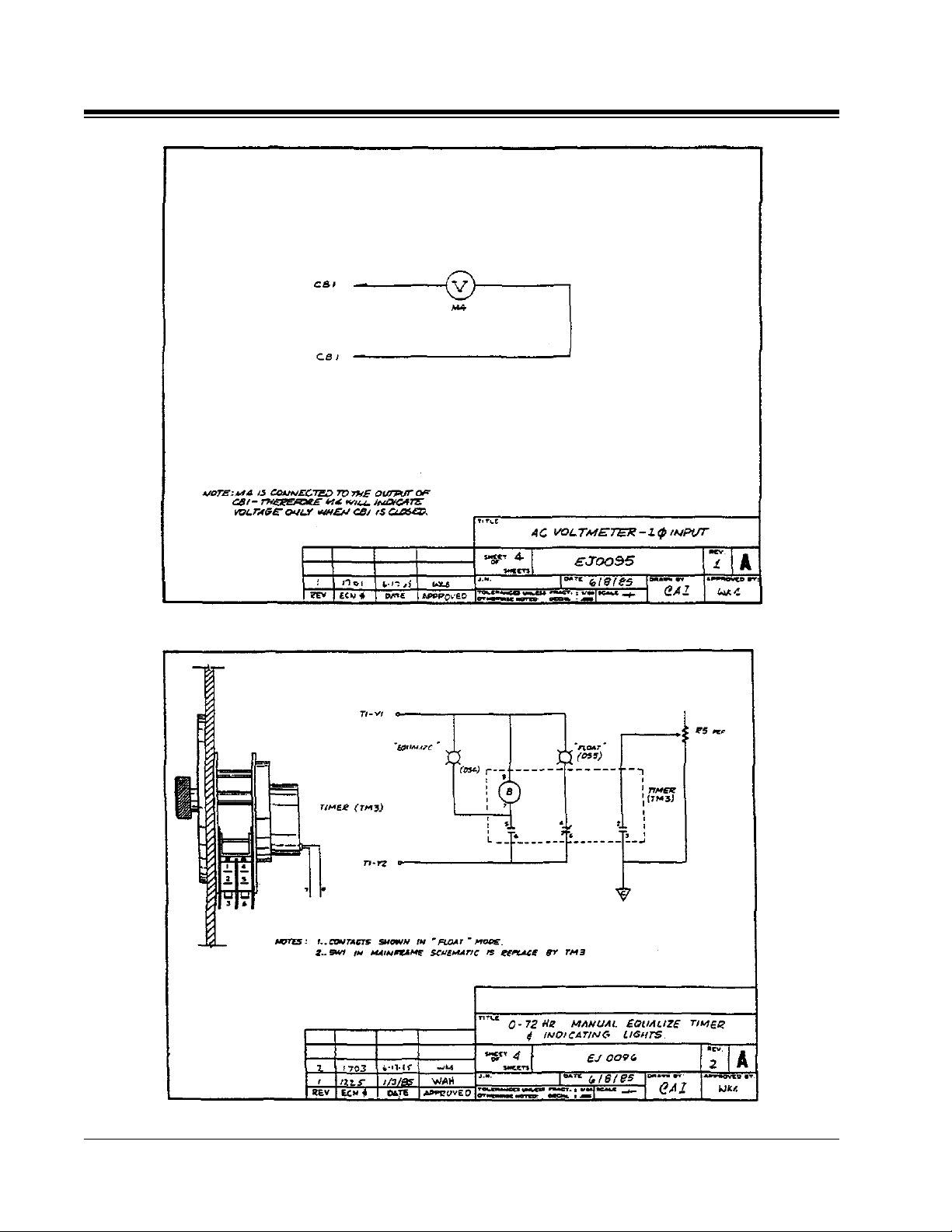

EJ0096

EJ0141

EJ0967

EI5030/31

EI5032

EI5034

EI5035

1

CORE (BB####) A B C D E F G H J K L M N

SHT

#

FILTERED DC OUTPUT (30 mV RMS w/BATTERY)

BATTERY ELIMINATOR DC OUTPUT FILTERING

208/240 Vac - 60 Hz INPUT

220/240 Vac - 50/60 Hz INPUT (SINGLE PHASE ONLY)

380/416 Vac - 50/60 Hz INPUT (THREE PHASE ONLY)

480 Vac - 60 Hz INPUT

120/208/240 Vac - 60 Hz INPUT (SINGLE PHASE ONLY)

208/240/480 Vac - 60 Hz INPUT

Vac Hz INPUT (CUSTOM)

STANDARD DC CIRCUIT BREAKER (F1 / CB2)

CUSTOM DC PROTECTION

4

MANUAL FLOAT / EQUALIZE SWITCH & IND. LIGHTS

5

0-72 HR. MANUAL EQUALIZE TIMER

2

MAN. EQUALIZE TIMER w/ F/E SWITCH & IND. LIGHTS

1

AC FAILURE AUTO-EQUALIZE TIMER & IND. LIGHTS

4

0-72 HR. MANUAL EQUALIZE TIMER & IND. LIGHTS

CUSTOM EQUALIZATION

1% ACCURACY 3.5in ANALOG DC METERS

1% ACCURACY 4.5in SWITCHBOARD DC METERS

CUSTOM DC METERS

2

COMMON ALARM RELAY CONTACTS w/ BUZZER

1

COMMON ALARM BUZZER FOR CASM PC BOARD

1 DRIP SHIELDS - STYLE-1A/1B CABINET (EB0220/221)

1

DRIP SHIELDS - STYLE-2 CABINET (EB0222)

1

DRIP SHIELDS - STYLE-4 CABINET (EB0163)

1

DRIP SHIELDS - STYLE-5 CABINET (EB0198)

DESCRIPTION (X) DWG#

SHT

#

EJ0088 4 GROUND DETECTION INDICATOR LIGHTS

EJ0095

EJ0120

EJ0121 4 2% ACCURACY 3.5in AC VOLTMETER (3PH)

EJ0123

EJ0134

EJ0135

EJ0137

EJ0138

EJ0143

EJ0145

EJ0155 1 HIGH-LOW AC VOLTAGE ALARM & INDICATOR LIGHTS

EJ0439

EJ0615

EJ082X 1 INTERNAL TEMPERATURE COMPENSATION (PB/NICD)

EJ1123

EJ1165

EJ1234

EJ1247

EJ1303

EJ1398

EJ5005 1 0-72 HR. MAN. EQ. TIMER & IND. w/ REMOTE EQ.

EJ5012

EJ5087

EJ5007 -00 WHITE CHARACTERS ON BLACK BACKGROUND

EJ5007 -10 BLACK CHARACTERS ON WHITE BACKGROUND

X

JH0002 -09 PARTS DATA PACKAGE PER MFG. SWITCHBOARD

X

JH0002 -07 COPY OF TEST DATA PER NEMA PE5-1985

JH0003 CUSTOM DRAWING PACKAGE CAD DISK

JH0002

JH0002

JH0002 -01 BURN-IN OR HEAT-RUN HOURS

JH0002

JH0004 -01 EXPORT PACKING PER FS0001-00

JH0004

JH0004

4

4

4

4

4

4 / 5

4

4

5

1

1

2

1

1

1

1

1

1

1/2

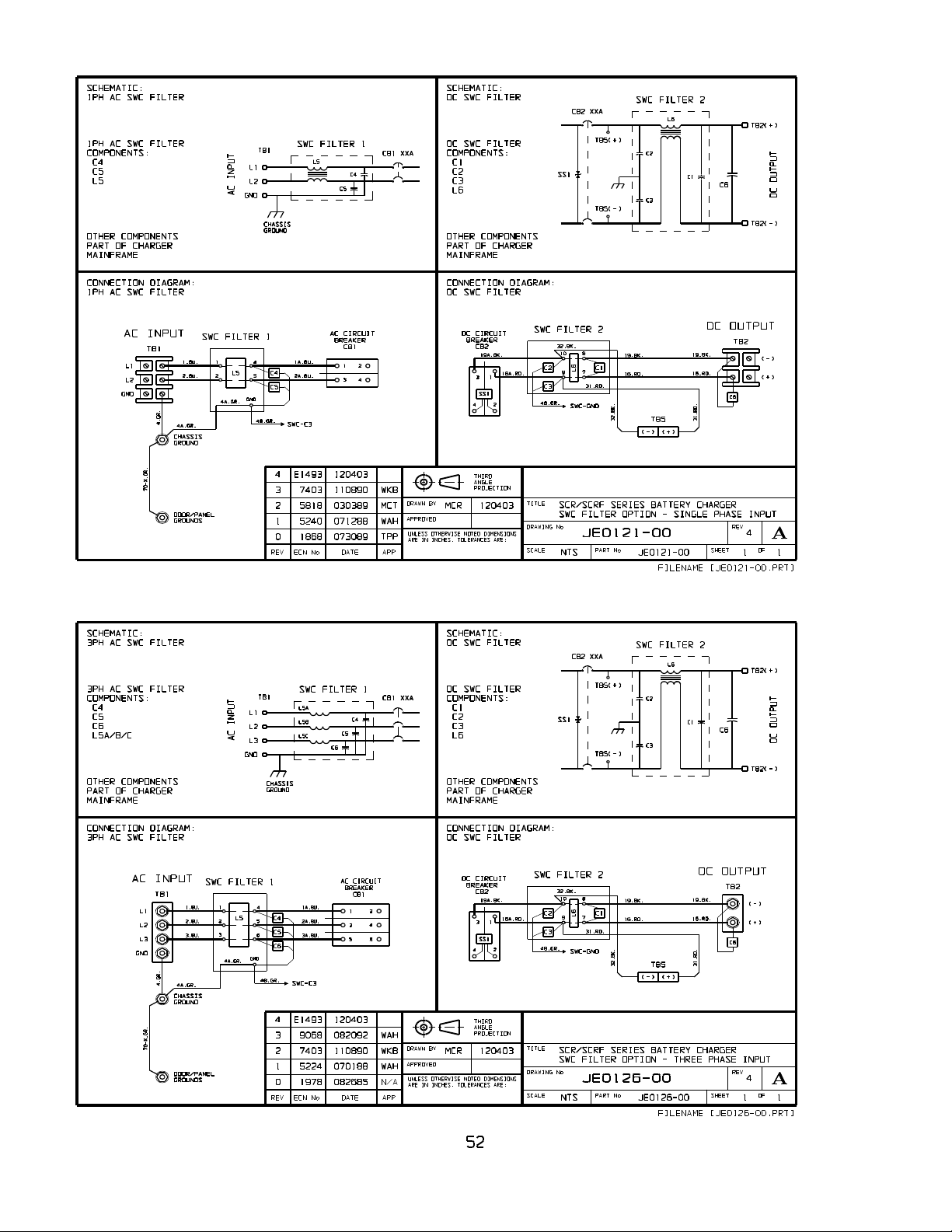

SURGE WITHSTAND FILTER (SWC) PER IEEE-472

200 kAIC AC FUSING (1PH - 2-POLE / 3PH - 3-POLE)

AC DC CKT BKR AUX CONTACTS

COPPER GROUND BUS BAR w/ LUG(S)

FUNGUS PROOFING PER CA0004-00

SPECIAL NEMA CABINET TYPE

in RELAY RACK MOUNTING ASSY.

SPECIAL (FLOOR / WALL) MOUNTING ASSY.

CUSTOM TAG PLATE

ENGRAVED FUNCTIONAL NAMEPLATES

EXTRA INSTRUCTION MANUALS

-06

-03

-00

-05

-10

INPUT VOLTAGE

FLOAT VOLTAGE

EQUALIZE VOLTAGE

1 - Serial Number and Core (BB####) calculated by factory

DESCRIPTION

2% ACCURACY 3.5in AC VOLTMETER (1PH)

BATTERY DISCHARGE ALARM & IND. LIGHT

COMMON ALARM BUZZER

2% ACCURACY 3.5in AC AMMETER (1PH)

2% ACCURACY 3.5in AC AMMETER (3PH)

CURRENT LIMIT ALARM & IND. LIGHT (1PH / 3PH)

0-CENTER DC AMMETER FOR BATT/LOAD MONITOR

END OF DISCHARGE ALARM & INDICATOR LIGHT

CABINET HEATER STRIPS

OVER-TEMPERATURE ALARM w/ (BUZZER / IND.)

DC POWER ON INDICATOR LIGHT

4-20 mA TRANSDUCER Adc Vdc

HIGH AC RIPPLE ALARM w/ INDICATOR LIGHT

AC INPUT LIGHTNING ARRESTOR (1PH / 3PH)

VENT FAN CONTROL RELAY & IND. (FROM EQUALIZE)

BATTERY OPEN ALARM & IND LIGHT

EXTERNAL TEMP COMPENSATION PROBE (PB/NICD)

0-999 HR. MAN. EQUALIZE TIMER w/ SW & IND. LIGHTS

AUXILIARY CONTACTS (TB15-AUX) ON CASM (EJ0837)

kAIC AC kAIC DC CIRCUIT BREAKERS

CERTIFIED TEST DATA PER NEMA PE5-1985

CERTIFICATE OF CONFORMANCE

IN-HOUSE INSPECTION BY OUTSIDE PERSONNEL

CUSTOM PACKING

EXTENDED WARRANTY PER JF5001-00

JF0026-00

Vac

Vdc

Vdc

Page 3

IMPORTANT SAFETY INSTRUCTIONS

1) Before using the battery charger, read all instruction and cautionary markings on:

A) battery charger, B) battery, C) equipment connected to charger and battery

2) This manual contains important safety and operating instructions, and therefore should be filed

for easy access.

3) Do not touch any insulated parts of the battery charger, especially the input and output connections,

as there is the possibility of electric shock.

4) During normal operation, batteries may produce explosive gas. NEVER smoke, use an open flame,

or create arcs in the vicinity of the charger or battery.

5) Maintain at least 1ft (0.3m) clearance from all obstructions on all sides of the battery charger.

6) Keep area in front of battery charger clear for at least 4ft (1.3m).

7) Connect or disconnect the battery only when the battery charger is off to prevent arcing or burning.

8) De-energize all AC and DC inputs to the battery charger before servicing.

9) Do not operate battery charger if it has been damaged in any way. Refer to qualified service

personnel only.

10) Do not disassemble battery charger. Only qualified service personnel should attempt repairs.

Incorrect reassembly may result in explosion, electrical shock, or fire.

11) Do not install the battery charger outdoors, or in wet or damp locations unless specifically ordered

for that environment.

12) Remove all jewelry, watches, rings, etc. before proceeding with installation.

PLEASE READ AND FOLLOW

ALL SAFETY INSTRUCTIONS

i

Page 4

TABLE OF CONTENTS

Page No.

SCR/SCRF BATTERY CHARGER SPECIFICATIONS (JF0026-00).......................... (inside front cover)

IMPORTANT SAFETY INSTRUCTIONS ................................................................................................i

TABLE OF CONTENTS......................................................................................................................ii-iii

SECTION II - INSTALLATION AND OPERATION

1. Safety Notice......................................................................................................................................................2

2. Application.........................................................................................................................................................2

3. Installation..........................................................................................................................................................2

4. Placing Charger in Service.................................................................................................................................3

5. Adjustments of Float & Equalizing Charge .......................................................................................................3

6. Manual Equalize Timer......................................................................................................................................3

7. Maintenance .......................................................................................................................................................4

8. Normal Performance ..........................................................................................................................................4

9. Description of Operation....................................................................................................................................5

a. Power Transformer........................................................................................................................................5

b. Rectifier Section............................................................................................................................................5

c. Control Module .............................................................................................................................................5

d. Filter Section .................................................................................................................................................5

SECTION III - TROUBLESHOOTING

1. CAUTION Notice .............................................................................................................................................6

2. Troubleshooting Procedure ................................................................................................................................6

3. Testing of Components ......................................................................................................................................6

a. External Circuit Wiring.................................................................................................................................6

b. Power Transformer (T1)................................................................................................................................7

c. Circuit Breakers (CB1 / CB2) .......................................................................................................................7

d. Surge Suppressors (SS1 / SS2 / SS3 / SS4)...................................................................................................7

e. Rectifier Diodes (CR4 / CR5 / CR6).............................................................................................................7

f. SCR Diodes (SCR1 / SCR2 / SCR3).............................................................................................................8

g. Control Module (A1).....................................................................................................................................8

h. Current Sensing Resistor (SH1) ....................................................................................................................9

j. DC Voltmeter (M2).......................................................................................................................................9

k. DC Ammeter (M1)......................................................................................................................................10

m. Filter Capacitors (C1 / C2)..........................................................................................................................10

n. Internal Wiring ............................................................................................................................................10

SECTION IV - SYSTEM ADJUSTMENTS

1. Voltage Adjustments and Response.................................................................................................................11

a. Float Adjustment .........................................................................................................................................11

b. Equalize Adjustment...................................................................................................................................12

2. Current Limit Response and Adjustment.........................................................................................................13

a. Checks and Adjustments .............................................................................................................................13

b. Checks to Make if Malfunctioning..............................................................................................................13

ii

Page 5

Page No.

SECTION V - CUSTOMER OPTIONS

1. Ground Detection Circuits (EJ0088 / EJ0089 / EJ0094 / EJ0086) ..................................................................14

2. AC Power Failure Alarm Relay (EJ0085)....................................................................................................... 15

3. Three Phase AC Input Voltmeter (EJ0121) / Three Phase AC Input Ammeter (EJ0135)............................... 15

4. High and Low DC Voltage Alarm Relays (EJ0083) ..................................................................................15-16

5. Charger Failure Alarm Relay (EJ0127)........................................................................................................... 16

6. Battery Discharging Alarm Relay (EJ0120)....................................................................................................16

7. Equalize Timers (EJ0097 / EJ0096 / EJ0869 / EJ0131 / EJ0084) ...................................................................17

8. Common Alarm Buzzer (EJ0123) ...................................................................................................................18

9. Common Alarm Relay (EJ0141) .....................................................................................................................18

10. Float and Equalize Indicating Lights (EJ0093) ...............................................................................................18

11. Parallel Charger Operation with 2% Forced Load Sharing (EJ0133)..............................................................18

12. Zero-Center DC Ammeter for Battery/Load Monitoring (EJ0138).................................................................19

13. High DC Voltage Charger Shutdown with Alarm Relay (EJ0592)................................................................. 19

14. End of Discharge Alarm Relay (EJ0143) ........................................................................................................ 19

15. Current Limit Alarm Relay (EJ0137) ..............................................................................................................20

16. Cabinet Heater Strips (EJ0145) ....................................................................................................................... 20

17. High and Low AC Voltage Alarm Relays (EJ0155) .......................................................................................20

18. Over-Temperature Alarm Relay (EJ0439)....................................................................................................... 20

19. Combined Alarm-Status Monitor "CASM" PC Board Assembly (EJ0837).................................................... 21

SECTION VI - COMPONENT DESCRIPTIONS

1. Component Description - SCR/SCRF Series Battery Charger Mainframe (Three Phase Input)................22-23

2. Component Description - SCR/SCRF Series Battery Charger Options (Single Phase / Three Phase).......24-26

SECTION VII - TABLES / DIAGRAMS / FIGURES

Table A - Troubleshooting Chart..........................................................................................................................27

Diagram - SCR/SCRF Series Battery Charger: Mainframe Schematic - 3PH Input (JE5078 -00) .......................28

Figure 1 - Component Layout for Control Module - 3PH SCR/SCRF Battery Charger (GK0048).....................29

Diagram - Schematic: Control Module 3PH Battery Charger (EH0467).............................................................30

Figure 2 - Typical Waveforms 3PH Control Module / 3PH Anode Firing PC Board Schematic (EH0617) .......31

Diagram - Power Transformer (T1) Schematics - 3PH SCR/SCRF Series (EH0553).........................................32

Diagram - Remote Alarm Terminal Block Legend for TB3 and TB15 (EH0423-00)..........................................33

SECTION VIII - OPTION SCHEMATICS

Option Page No. Option Page No. Option Page No. Option Page No.

EJ0083......................34 EJ0096.......................38 EJ0134.......................43 EJ0155......................47

EJ0084......................34 EJ0097.......................39 EJ0135.......................43 EJ0439......................48

EJ0085......................35 EJ0120.......................39 EJ0137 (1PH)..............44 EJ0592...................... 48

EJ0086......................35 EJ0121.......................40 EJ0137 (3PH)..............44 EJ0837...................... 49

EJ0088......................36 EJ0123.......................40 EJ0138.......................45 EJ0826......................50

EJ0089......................36 EJ0127.......................41 EJ0141.......................45 EJ1895......................50

EJ0093......................37 EJ0131.......................41 EJ0141 (w/buzzer)........46 EJ1234......................51

EJ0094......................37 EJ0133 (schematic).......42 EJ0143.......................46 EJ1398...................... 51

EJ0095......................38 EJ0133 (wiring) ...........42 EJ0145.......................47 SWC filter.................52

SECTION IX - REPLACEMENT PARTS

Electrical Ratings and Replacement Parts - SCR/SCRF Series Battery Charger (3PH Mainframe)...............53-56

Replacement Parts - SCR/SCRF Series Battery Charger Options (1PH/3PH)................................................57-61

SECTION X - MANUAL SPECIFICATIONS (document control information)

Document Number / Revision Information.......................................................................................................... 62

On-Line Availability Note....................................................................................................................................62

Parts List / Drawing Notes.................................................................................................................................... 62

iii

Page 6

SECTION II

INSTALLATION AND OPERATION

1. SAFETY NOTICE

CAUTION! READ “IMPORTANT SAFETY INSTRUCTIONS” ON PAGE i.

There are dangerous voltages within the battery charger cabinet!

a. Only qualified personnel should attempt to adjust or service this equipment.

b. Refer to instruction manual for service procedures and CAUTION notes.

2. APPLICATION

Specifications: The silicon controlled rectifier is designed to maintain a system voltage within + or -

0.5% of the set value without exceeding its rated output current. It will maintain + or - 0.5% with input

voltage variations 10% above or below the rated input AC voltage and with 5% frequency variations.

The charger is designed, primarily, to operate only when connected to a battery load. It can be

operated as a battery eliminator into a resistive load up to full rated output at increased ripple. Filtered type

chargers will have a ripple content less than 30 mV RMS under steady state conditions with the charger

connected to a battery having an 8-hour Amp-Hour rating of at least 4 times the full load current rating of

the charger. Other connected loads such as DC-to-DC power supplies or inverters, may put ripple on the

battery appreciably above 30 mV.

Unfiltered chargers should not be used with critical loads such as communication systems, amplifiers

and instrumentation systems, but should only be used for non-critical applications such as engine cranking.

This charger can be used on any number of lead-acid, nickel-cadmium, or nickel-iron cells as long as

the desired float and/or equalize voltages are within the range of the charger.

3. INSTALLATION

a. Location: Select a clean, dry location for the charger. It may be located in the battery room, but not

over the battery, and must be mounted upright. The openings for ventilation in the top, bottom and sides of

the cabinet should not be obstructed, as they provide convection cooling and ventilation. Ambient

temperatures between 32° F and 122° F, and elevations up to 3,300 feet above sea level, will not affect the

performance of the charger. Operation at higher temperatures, or at higher elevations, is possible if the

ampere output is de-rated in accordance with published information, and if the charger is custom ordered for

these operating ambient conditions.

b. Wire Sizes AC: Wire sizes for the AC wiring may be selected by consulting the data on the

nameplate for input amperage. Local electrical or NEMA standards should dictate appropriate wire size.

Most codes specify that the AC wiring size must match the current rating of the input circuit breaker or

fuses.

c. Wire Sizes DC: The size of the charger leads should be selected to (a) carry the charger (ampere)

current rating, and also (b) provide less than 0.5 volt total drop at rated current in the loop or leads between

the charger and battery terminals. Choose the larger wire size that meets conditions (a) and (b). Do not

undersize. It is good practice to keep the DC leads as short as possible and to keep them together as a pair to

obtain low inductance. Likewise, it is good practice to avoid sharp bends and to run both DC leads together

if run in conduit.

d. Input Power: These chargers are nominal 208V, 240V, 480V (60 Hz) or 380/416V (50 Hz) AC

three phase. If the AC input data as supplied with the charger does not agree with the AC supply voltage at

the installation site, do not connect the charger to the AC line. The AC voltage must be within +/- 10% of

the rated input voltage of the charger. If not, consult your power company or the battery charger

manufacturer. These three phase input power chargers are not phase rotation sensitive, and thus any

combination of three phase input AC wiring may be used.

2

Page 7

4. PLACING CHARGER IN SERVICE

a. With the AC and DC breakers OFF and the system in float mode, install the charger making AC

and DC connections, as described in Section II, 3, and in accord with local regulations as they apply.

b. After connecting the lead from the positive (+) battery terminal to the positive (+) terminal on the

charger and the lead from the negative (-) battery terminal to the (-) terminal on the charger, observe the

voltmeter. It should read the correct polarity and be approximately the battery open circuit voltage (this is

2.0 volts per cell for lead-acid batteries and 1.2 volts per cell for nickel cadmium batteries). For example, a

60-cell lead-acid battery should read about 2 x 60 cells = 120 volts. This is a check to indicate that all cells

are in a true series (none connected in reverse). The open circuit voltage should be about 8% to 10% below

the rated float voltage.

c. The charger can now be energized, by first closing the DC breaker to supply voltage for the control

circuits then closing the AC breaker. Set the charger to “float”. The AC power ON pilot light should light,

and the ammeter should indicate charger output current. It is to be expected that the meter may show up to

110% current rating of the charger; the 110% being the factory setting of the current limit control.

d. The factory preset float voltage adjustment value is listed on the inside front cover. When this

value is reached, the charger ammeter should show a slow decrease in current, eventually down to a

stabilized value. Please note that whenever a charger is in a current limit condition, the output voltage is

automatically reduced to a value below the set float or equalize voltage. The voltage will not increase to

normal value until the battery’s state of charge increases, causing the charger current to decrease to a value

equal to or less than the rated current.

e. The factory preset equalize voltage value is also listed on the inside front cover. Assuming this is

as desired, the Float/Equalize switch may be switched to “Equalize”, to check the charger performance at

this voltage value. If a Manual Equalize Timer (option) has been included, turn it clockwise to activate the

equalize charger mode. The charger ammeter may again go up to current limit until the equalizing charger

voltage is reached. The length of time required to reach this level depends on the state of charge of the

battery, and the ampere rating of the charger versus the battery Ampere-hour rating.

f. With the charger operating at the desired float and equalizing voltage values, the system can be

considered installed and ready for service.

5. ADJUSTMENTS OF FLOAT & EQUALIZING CHARGE (also see Section IV, 1)

a. Each adjustment is made by means of a potentiometer with a slotted shaft for a screwdriver. The

potentiometers are front-panel mounted and appropriately marked. A lock nut on each potentiometer is

provided and should be tightened after the proper adjustment is completed. This prevents any accidental

mis-adjustments of the settings. The voltage response may be slow if a rise in voltage adjustment is desired,

because the battery state of charger and connected load must be considered. Turning the shaft clockwise will

raise the voltage, and turning counter-clockwise will lower the voltage.

b. Since accuracy of measurement is important when setting float and equalizing voltages, a

precision portable VoltOhmmeter with at least 1% accuracy is recommended for these DC measurements. A

conventional VoltOhmmeter or analyzer such as the Simpson Model 260 is also satisfactory, but is not as

accurate.

c. Any setting of the float voltage or equalizing charger voltage should not be considered final until

the ammeter shows less than charger rated current, and voltage does not change after several hours of

operation.

6. MANUAL EQUALIZE TIMER (OPTIONAL)

a. This timer is provided to obtain a charge up to 72 hours, at a slightly higher value than the

ordinary float voltage. The timer may be used for recharging older batteries, or for a freshening charge on

new batteries. For a detailed explanation of operation see Section V (Customer Options).

3

Page 8

7. MAINTENANCE

a. This charger is designed to require a minimum of maintenance. There are no rotating parts except

in the optional timer and all components have a nominally indefinite life with no expected aging effect. It

should be kept clean, dry and checked periodically to make sure all connections are tight. If necessary, dry

air may be used to blow dust out of the interior. In the event of any irregular operation, examine, and tighten

if necessary, all internal and external connections and check circuits for continuity (see schematic diagram

on page 28). If the difficulty cannot be remedied, contact the manufacturer.

8. NORMAL PERFORMANCE

a. Assuming that the charger has been operating in the float position, an indication of normal

performance can be obtained by setting the FLOAT/EQUALIZE switch in the equalize position (turn timer

off zero). Increased charge current will show on charger ammeter until the battery reaches the equalize

voltage. At this point the current should slowly decrease.

b. If the charger has been operating in the equalize voltage position, turn SW1 to FLOAT (turn the

timer manually to zero). The charger will indicate zero or little output current until the float voltage is

reached. At this point, the current should increase slowly to the system load value, (the battery is now

“floating” across the line with approximately equal input and output currents).

c. When operating normally, the current limit control will limit the maximum charger output current

to approximately 110% of the rated charge current. In case of a high DC current demand, the current limit

control will keep the charger output within safe values without tripping the DC circuit breaker or the AC

breaker.

4

Page 9

9. DESCRIPTION OF OPERATION

There are four major sections of the SCR three-phase charger, which work together to produce

stable, regulated, filtered output. The functions of these four sections may be described as follows.

a. The Power Transformer (T1): This section includes T1 and its associated input

protection. Its purpose is basically to supply an AC voltage of the proper magnitude and capacity to the

rectifier section. It also supplies various other voltages used by the control unit and accessories. It is

connected to an AC source by means of a circuit breaker.

b. The Rectifier Section: This section consists mainly of the voltage regulating silicon

controlled rectifiers and the power rectifier diodes. It accepts the AC voltage from the transformer, rectifies

this voltage to DC, and controls the voltage’s magnitude so that the charger output is regulated at all times.

The firing angle of the SCRs is controlled by the action of the control module. Both the SCRs and the diodes

are protected from AC and DC surge voltages by means of the metal-oxide varistor surge suppressors.

c. The Control Module: This printed circuit board generates the three-phase phase-fired gate

signals that turn on the SCR diodes in response to the charging requirements of the battery load. The output

voltage of the charger is monitored by the voltage feedback circuit and advances or retards the phase angle

of the trigger pulses so that the output voltage is maintained essentially constant. This is accomplished by

comparing a small portion of the output voltage to a stable voltage reference. An error signal is created

proportional to the differential voltage. This error signal is then used to alter the phase angle of the SCR gate

trigger pulses in order to correct the output voltage. The load current is also monitored by the circuit so that

when its value exceeds an arbitrary value (110% rated current) the system is “phased back” to limit the

output current to no more than 110% of its rated value.

d. The Filter Section:

(1). Depending on the application, the charger may be unfiltered. In this case, one

filter choke, L1, is utilized not for filtering but for phase correction of the highly leading current-voltage

condition created by the batteries during the charging pulses. The batteries represent a very large capacitor in

shunt with a resistive load. This creates out-of-phase current problems for the SCR diodes causing nonuniform triggering problems particularly at low load currents. The single filter choke corrects this condition

and also aids the ratio of average current to RMS current flowing in the circuit.

(2). For filtered units, the objective is to remove the charging ripple at the battery

terminals. To accomplish this a "T" or "double-L" section filter consisting of inductors L1 and L2 and

capacitors C1 and C2 are used. C1 and C2 may consist of one or more individual capacitors. The degree of

filtering required dictates whether the "T" or "double-L" configuration is used. The "double-L" section filter

is normally used to reduce the ripple to 0.06% of nominal output voltage when the charger is operated as a

filtered eliminator.

5

Page 10

SECTION III

TROUBLESHOOTING

1. CAUTION NOTICE

Before troubleshooting, always isolate and de-energize the charger by opening the AC circuit breaker

(CB1) and the DC circuit breaker (CB2). This avoids the possibility of high short circuit current damaging

the charger, tools, test equipment, or injuring personnel. NOTE: Circuit breaker terminals (CBx), printed

circuit boards (Ax) and terminals/terminal blocks (TB1, TB2, TB3, TB5 & TB15) have dangerous voltage

across them, even when both circuit breakers are open. After isolating the charger, check that the voltage

across the filter capacitors (C1/C2) is zero. Once charged, they will take several minutes to discharge if

bleeder resistor (R1) is open. If DC circuit breaker (CB2) is not provided, remove the DC fuses (F1/F2) in

order to isolate the charger from the battery. AFTER LOCATING THE CHARGER PROBLEM,

ALWAYS DE-ENERGIZE ALL AC AND DC CHARGER INPUTS AT THE POWER SOURCE

BEFORE SERVICING.

2. TROUBLESHOOTING PROCEDURE

a. When a charger is not operating properly, the cause must be determined by checking various

components until the fault is located.

b. The major components do not have to be checked in the order as listed in Section II, 9, since a charger

may exhibit a number of difficulties, each with different symptoms. In many cases, failure of one

component may cause another component or part to fail. Therefore, the following paragraphs treat major

components, functional circuits and parts individually (or by symptom). Together with serviceability

measurements and tests, the faulty part or component should be located.

c. Most of the following checks can be performed with an oscilloscope, a VoltOhmmeter (similar to a

Simpson Model 260) and an SCR tester.

d. Consult the trouble-shooting chart in Table A on page 27. When using the table, first locate the fault

symptom observed (in the left hand column) then follow the sequence for checking components in the

numerical order listed (1, 2, 3 etc.) for that particular symptom. Follow this sequence until the trouble is

located. After correcting the trouble, check the charger for normal performance as described in Section II, 8.

e. In addition to those symptoms listed in Table A, the following procedure should be followed for any

condition:

• Check voltage of the AC supply to insure that it is within 10% of the value of the

specified input voltage.

• Examine charger for any evident loose or improper connections, particularly at the

control unit, transformer and input/output terminal board.

• Check continuity of battery circuit by comparing voltage at charger terminals with total

of cell voltages.

• Check accuracy of voltmeter and ammeter on the charger.

3. TESTING OF COMPONENTS

a. External Circuit Wiring

1. When no line voltage exists between TB1 input terminals (L1 to L2 , L2 to L3 & L3 to L1), check

the AC line back to source.

2. With no output, or a low output, the external DC wiring may be at fault. Check the wiring

between charger and battery to see that it is properly installed. Make certain that terminals are tight and

clean, and that the DC wiring is free from grounds. The total operating voltage drop in the loop or leads

between the charger and battery terminals should never exceed 0.5 volt (at rated charge current), and

preferably should be kept considerably below this limit by using a sufficiently large wire size.

6

Page 11

b. Power Transformer (T1)

1. With the AC and DC circuit breakers open or OFF, open the cabinet and carefully check the line voltage

across line terminals on TB1, terminals (L1 to L2, L2 to L3 & L3 to L1). If no AC voltage is indicated, refer to

Section III, 3, a, 1. Check the wiring connections to ascertain that the unit has the proper primary tap connections for

the line voltage indicated. Turn on the AC circuit breaker (CB1). Check that the voltage at the primary is the same as

that of the line. If this is not the case, CB1 or the wiring between it and T1 is open. In this case, proceed with checks

under Section III, 3, c, 1.

2. Check AC secondary voltage on T1 (see Table B below for expected voltage values). If secondary voltages

are much less than indicated or not balanced, then either T1 is at fault or the power regulating devices (SCR1, SCR2

or SCR3) are faulty.

TABLE B - SECONDARY VOLTAGE OF TRANSFORMER T1

Expected Voltages (AC) Leads or Locations

Approximately equal to float voltage X1 to X2, X2 to X3 and X3 to X1

Note: The "X" of Table B voltages should be measured as they terminate on the full-wave bridge

components. All other voltages may be measured at the end of the transformer leads. Where power

rectifier fuses are employed in the larger power chargers (see custom diagrams and parts list), these

fuses should also be checked, and replaced if unserviceable.

120 Vac Y1 to Y2, Y2 to Y3 and Y3 to Y1

c. Circuit Breakers (CB1/CB2)

1. AC Circuit Breaker (CB1): When an AC voltmeter of suitable range is connected between leads L1-L2, L2L3 & L3-L1 and indicates line voltage, but does not indicate when connected to the output terminals of CB1 when

closed, the circuit breaker is probably defective. De-energize the AC supply to the charger and remove the leads to the

circuit breaker. Use a volt-ohmmeter to check for continuity between the circuit breaker terminals with breaker

manually closed. Zero resistance should be indicated if the unit is operative. If unit checks OK, check performance by

measuring the AC voltage drop across each pole of the breaker. This voltage should be under 0.1 volt when the load

current is normal. If a higher voltage drop is found, replace the breaker.

2. DC Circuit Breaker (CB2): When the DC circuit breaker is suspected of being inoperative or at fault, a

similar test to that made for the AC breaker will determine the operating condition of the breaker.

3. If the polarity protection diode (CR1) is shorted, the battery will discharge into CR1, which will trip the DC

circuit breaker (CB2). Check CR1 with an ohmmeter (both polarities) for a shorted condition and replace if required.

d. Surge Suppressors (SS1/SS2/SS3/SS4)

1. The metal-oxide varistor (MOV) type of surge suppressor is used throughout these battery chargers instead

of the older selenium type. This is done for personnel safety. When a selenium device fails and arcs or burns, toxic

selenium fumes are given off, which are very poisonous if inhaled. The MOV type has a much sharper limiting

“knee” characteristic, and performs a better protection function. If an MOV surge suppressor fails during a highenergy transient, it may explode. This is an obvious failure and the part must be replaced.

2. If the suppressor is shorted, an ohmmeter check will indicate continuity. When the suppressor shows an

infinite resistance in both directions measured with it disconnected from the charger and has a normal appearance it

can be presumed to be in good operating condition.

e. Rectifier Diodes (CR4/CR5/CR6) - also see Section III, 3, f

1. In lower current three phase chargers, these diodes are part of an SCR-diode module, in which the SCR and

diode of each leg are contained in an assembly mounted on an electrically insulated heatsink plate. Three connections

(plus one SCR gate terminal) are available for checking. In higher current three phase chargers, individual diodes and

SCRs are used instead of modules. Check the diode portion of each bridge leg by disconnecting one terminal and

measuring the forward and reverse resistance in either of two ways:

a) Using an ohmmeter, use the Rx1 scale for the forward resistance. This should show approximately 5 to

10 ohms. The reverse resistance should be up in the thousands of ohms (probably 50,000 or more) measured with a

higher scale of the meter.

b) Connect the diodes in series with a 6 or 12-volt lamp across a DC source of the same voltage. The lamp

must require at least one-quarter Ampere. The lamp should light with nearly full brilliance with current flowing in the

forward direction and not at all in reverse. If it lights in both directions, the diode is shorted. If in neither direction, the

diode is open.

7

Page 12

2. Note that semiconductors usually short in pairs in bridge circuits, seldom as single units, and it is rare that

all six semiconductors in a bridge are found defective. When diodes fail it usually is because of surge voltages.

Therefore, surge suppressors (SS1, SS2, SS3 & SS4) should also be checked to determine that they are operative

(refer to Section III, 3, d).

f. SCR Diodes (SCR1/SCR2/SCR3) - also see Section III, 3, e

1. These devices are either part of the SCR-diode modules or are individual components as described in

Section III, 3, e above. Power regulating devices (SCR1, SCR2 & SCR3) are silicon-controlled rectifiers, which

cannot be checked using the same method as used with rectifier diodes by forward and reverse resistance checks,

since the SCR will always show a high resistance until triggered.

2. The operation of the SCR can be checked with an oscilloscope. The control module assembly (A1)

produces the gate-firing voltage signal. The oscilloscope should be GROUND ISOLATED for these tests. This is

normally done, using a line isolation transformer, in which the secondary that powers the oscilloscope is

UNGROUNDED. Alternatively, a battery-powered portable oscilloscope can be used. The gate signal may be

checked on the control module (see Section III, 3, g) or where the twisted-pair trigger leads terminate on the SCRdiode module. The same signal should appear at both points. Absence of the signal indicates that the control module is

defective, not the SCR (see Section III, 3, g).

3. If the charger AC input breaker (CB1) trips immediately, and a shorted SCR is suspected, a simple check

with an ohmmeter can be made. Turn off CB1 and CB2. Connect to the anode and to the cathode, and adjust to the

direct reading scale of the ohmmeter. If a low resistance is observed, reverse the leads and again check the resistance.

If this reading is also low, the SCR is shorted and should be replaced.

4. An SCR can also be checked for operation with a Simpson Model 260 volt-ohmmeter. With the black lead

in common and red lead in +, put polarity switch to + DC. Connect the red lead to the anode and the black lead to the

cathode. The meter should now indicate high resistance above 50,000 ohms (when on the R x 10,000 scale). With the

leads connected as above, set the function switch to R x 1 and touch the gate to the anode. This should fire the SCR

and give a reading of approximately 5-20 ohms. This shows the SCR has been turned on. On very small SCRs, this

reading will hold after removing the gate lead. This is latched-on and can be unlatched by opening the cathode lead.

Larger SCRs will not stay on with the current available with Simpson meter. The Simpson may not have enough

current to gate or turn on extremely large SCRs (400 amp and up).

5. If the charger output is too high, unplug the control module and turn on the charger. With no gate signals

the charger should have zero output. If there is still current output, one or both SCRs are defective.

6. The above checks can be used to confirm that a suspected SCR is indeed bad. However, occasionally an

SCR might check OK in all these tests and still break down or fail in the charger circuit during normal operation. Any

SCRs suspected should be replaced.

g. Control Module PC Board Assembly (A1)

One preliminary note that should be kept in mind: The action of the overall feedback circuit controls the

battery charger output voltage so that the feedback voltage from the slider of “FLOAT ADJUST” potentiometer (R3)

to the control module board matches the 6.4 volt reference voltage on the module. Measure this voltage and if it is not

approximately 6.4 volts the feedback circuit or related circuits are not functioning. Proceed as follows using the

GROUND ISOLATED oscilloscope described in Section III, 3, f, 2 above. Make the following tests in the order

shown.

1. If the gate signals were not checked as described in Section III, 3, f, 2, do so at this time. If one or more of

the gate signals are absent when attempting to operate the charger in a normal manner, make the following checks.

Refer to FIGURE 1 on page 29 for component layout and test point locations on the trigger board. See schematic on

page 30 for related circuit diagram.

2. Check DC voltages at test point P10 [+12 VDC, +/- 0.5V]. If zero, check input and output to miniature

transformer TR1 [120V:12V AC] and check DC voltage at IC7, pin 1 [18 VDC]. Replace defective components. If

OK, proceed as follows.

3. Check three phase input voltages at resistors (R1, R2 & R3). The voltage should be 120 VAC between any

two resistors in three phase relationship. If not present, check J1 plug connections and voltages appearing between

terminal pins 1, 3 and 5 (also 120V - three phase).

Note: The following wave form tests must be made using the oscilloscope set with vertical sensitivity set

at 5V/CM and the horizontal time base set at 5mS/CM. Compare the waveforms observed with those

shown in FIGURE 2 on page 31 for the various test points indicated.

8

Page 13

4. Check square wave pattern at test points A1, A2 and A3. Note the 120-degree (5.5 mS) delay between the

three patterns (scope synchronized to the 60 Hz AC line). If A1 pattern is missing, replace IC3. If A2 or A3 is

missing, replace IC4.

5. Check ramp pattern at B1, B2 and B3. Compare with those shown in FIGURE 2. Note that the exact wave

shape depends on the phase angle of SCR gates. The steeper the ramp the earlier in each half cycle the SCR is fired

and the higher the output of the charger. If waveform at B1 or B2 is abnormal or missing replace IC2. If B3 waveform

is missing replace IC1.

6. Check waveform at test points C1, C2 and C3. This comparator pulse generator produces rectangular

waveforms of varying lengths with the leading edge varying in position to a fixed-in-time trailing edge. Compare with

FIGURE 2. If C1 or C2 is missing, replace IC2. If C3 is missing, replace IC1.

7. Check waveform at test point H. This waveform should be a continuous string of very short pulses with

approximately 10V amplitude. This is the picket fence generator output. If missing, replace IC3, IC5 or IC6.

8. Check bursts of picket fence signal at test points D1, D2 and E3. Compare with FIGURE 2. If D1 or D3 is

missing, replace IC4. If D2 is missing, replace IC3.

9. Check amplified picket fence pulse trains at test points E1, E2 and E3. These pulse trains are similar to

those at D1, D2 and D3 of FIGURE 2. If E1 is missing replace Q1 or Q2. If E2 is missing, replace Q3 or Q4. If E3 is

missing, replace Q5 or Q6.

Note: The following check should be made only after completing steps 1 through 9 above. Chargers with

output ratings higher than 150 Adc may be supplied with an Auxiliary Gate Drive PC Board (A14)

triggering the phase-controlled SCRs. The A14 board intercepts the SCR gate lead wiring from the

control module (A1) as shown in drawing EH0617 on page 31. The A14 board converts the “picket

fence” pulse train (waveform similar to D1) from the control module to a DC gating signal for the main

SCRs. The A14 output will be a square wave approximately 1.5 Vdc in amplitude.

10. If a main SCR fails to turn on, trace the gate signal from the control module to A14, and from A14 to the

appropriate SCR. The AC gate signal should be approximately the same magnitude at both input and output of A14. If

an input gate signal has no corresponding output signal, replace A14.

11. If a main SCR fails to turn off, resulting in a high charger output voltage, disconnect SO14 plug from A14

board. If the main SCR now turns off, replace A14. If the main SCR remains on, the main SCR is defective and must

be replaced.

12. Check ripple waveform symmetry of the charger by connecting the oscilloscope ahead of the filter choke

(L1). Connection may be made across the bleeder resistor (R1). With the unit adjusted for about 66% output current,

observe to determine that the 360 Hz ripple pulses are of uniform amplitude. If not, slowly adjust the two balance

adjust potentiometers (R24 & R32) on the trigger board (A1). Note that phase #1 is not adjustable and is used as a

reference. Adjust the two potentiometers for the most uniform pattern yielding the lowest ripple voltage at the output

terminals. This adjustment may also be made using a sensitive AC voltmeter at the charger output terminals, and

adjusting for minimum RMS voltage indication (less than 30 mV for a filtered charger).

h. Current Sensing Resistor (SH1)

1. In light current chargers, the current sensing signal is taken directly across the DC ammeter. In chargers

with 50 Amp or higher output current, the sensing resistor is a meter shunt, which also serves as the shunt for the

panel ammeter. Use a portable precision digital voltmeter and measure the voltage drop across the current sensing

resistor. With a rated current output indicated on the panel ammeter, a nominal voltage drop of approximately 30mV

(in proportion to rated current) should be observed. If the voltage drop is higher or lower than the nominal indication,

replace the ammeter or shunt and recheck the voltage drop.

j. DC Voltmeter (M2)

1. The DC voltmeter is of the 2 percent accuracy type. It is connected across the charger output to the battery

and should indicate regardless of whether or not the charger is operating or the DC breaker is ON. If it does not, use a

precision voltmeter of the 1% accuracy type connected across the meter terminals. An indication on the test meter will

show that the panel meter is open. Check the wiring for an open circuit, or replace meter if circuit wiring is complete.

2. A shorted voltmeter will show no indication. Battery current through a shorted meter will cause a visible

indication such as smoke from burning wire insulation. Disconnect the charger from the battery and AC source and

replace the meter and damaged wiring.

3. If the meter calibration is in doubt, checking against a precision meter will determine if the panel voltmeter

is off calibration more than two percent.

9

Page 14

k. DC Ammeter (M1)

1. The charger DC ammeter is connected in series between the charger output and battery. If open it

will indicate zero, or if shorted, it will also indicate zero. First be certain the connections are tight. If still no

indication, turn CB1 and CB2 breakers to OFF, disconnect the charger ammeter (and/or shunt) and

substitute a precision ammeter of suitable range. Be certain to make solid connections; clip contacts may not

carry sufficient current, or may make poor contact and cause the reading to be inaccurate.

2. A reverse-scale indication of the meter indicates the charger is inoperative or internally shorted,

and that the battery is discharging through the rectifier, or that the meter leads have been reversed. Turn

CB1 and CB2 to OFF and check wiring and meter connections. Then check meter operation, using a 1-1/2

Volt D-cell as the power source. Momentarily touch the D-cell terminals (with proper polarity) to meter

terminals and observe meter deflection.

m. Filter Capacitors (C1/C2) - (filtered chargers only)

NOTE: Capacitors C1 and C2 may consist of one or more parallel-connected capacitor units as

needed by the filtering requirements. C2 normally is used only in chargers with the filtered eliminator

option.

CAUTION: The filter capacitor is on the charger side of the blocking diode (CR2) and is NOT

charged by the battery when CB2 is turned ON. When the charger is turned "OFF" (CB1 opened) the

capacitor will hold a charge until discharged by bleeder resistor (R1). Capacitors C1 and C2 should always

be discharged before servicing in the event the R1 has opened and no longer serves as a bleeder.

1. Before attempting to check the output ripple, it should be determined that in all other respects the

charger is operating normally. Having determined this, the ripple may be checked as follows. Connect a

sensitive AC voltmeter (digital type preferred) to the battery terminals and measure the AC ripple voltage. If

it measures more than 30 milliVolts RMS check the following:

(a). That the battery connected to the output terminals of the charger has an Ampere-hour rating

of at least four times the rated capacity in amperes of the charger.

(b). The ripple is measured at the terminals of the battery.

(c). Check capacitors C1 and C2 as follows: Switch the VoltOhmmeter to the Rx100 scale and

connect the red lead to the capacitor plus terminal (marked by a red dot or plus sign) and the black lead to

the negative terminal. The meter should initially swing up scale toward zero Ohms then come back as the

capacitor charges. A reading of zero Ohms indicates a shorted capacitor while no initial swing means an

open capacitor. Either an open or shorted capacitor should be replaced.

n. Internal Wiring

1. Check internal wiring for obvious mechanical faults or wear. Follow the schematic diagram on

page 28 and check continuity with an ohmmeter to determine open connections. Check wiring against

ground also, and remove any grounds.

10

Page 15

SECTION IV

SYSTEM ADJUSTMENTS

1. VOLTAGE ADJUSTMENTS AND RESPONSE

When abnormal output voltage exists (or no output current is present), and the previous checks in

Table A on page 27 “VOLTAGE ADJUST INEFFECTIVE” have been made without locating the fault,

switch the AC breaker (CB1) to OFF. Switch the DC breaker (CB2) to OFF or disconnect the battery and

proceed as follows:

Check the battery with a portable voltmeter of one percent accuracy to insure that it is not higher

than the rated float voltage. For proper operation, the open circuit voltage of the battery must be slightly

lower than the rated float voltage. If the battery voltage is higher than the float voltage range, check the

number and type of cells connected to the charger making certain the proper number and type of cells are

not exceeded. Close the DC breaker (CB2) or connect charger to battery. Close the AC breaker (CB1). If

battery voltage is now within the float voltage range or is slightly lower and some output current exists,

proceed with Section IV, 1, a, 2 below.

If the battery voltage is slightly lower or within the float voltage range, switch the charger to the

equalize mode. If still no output appears, or the potentiometer (R5) does not produce a rise from the

previous value, turn equalize charge control fully clockwise, and if still no voltage rise is obtained or no

output appears, proceed again with the check sequence in Table A trouble-shooting chart. If the voltage

increased or output was obtained when the charger switched, to evaluate proceed with the voltage

adjustments.

a. Float Adjustment

1. Since the charger must be operable for this adjustment, preceding checks in Section IV, 1

above must indicate a serviceable charger. Set switch (SW1) to “FLOAT”. Use a portable voltmeter of

one percent accuracy. Connect the battery supply leads to the battery and close the DC (battery) breaker

(CB2). Set the AC breaker (CB1) to "ON".

2. Since the EQUALIZE and FLOAT potentiometer control settings interact with each other, it is

always necessary to adjust the FLOAT control first and then the EQUALIZE control afterward. Never

finalize a voltage adjustment with the charger output in excess of 100% rated output current.

3. Turn the control clockwise, watching the response on the voltmeter. Clockwise rotation should

cause the charger output current to increase rapidly, while the voltage should rise slowly. The rate of

voltage rise depends upon whether the battery is fully charged, the size of any connected load, and the

size of the charger versus the size of the battery. After getting several volts response in battery voltage

rise, turn the FLOAT control counterclockwise. This should result in a rapid drop in charger output

current and eventually in a slow decrease in battery voltage. Now adjust the voltage for the desired float

setting and tighten the locknut on the potentiometer.

11

Page 16

b. Equalize Adjustment

1. Since the equalize adjustment will not affect the float voltage adjustment and requires a higher

voltage it should always be made after the float voltage is determined. Use a portable voltmeter of one

percent accuracy as in the float adjustment. Set switch (SW1) to “EQUALIZE”. Close the DC (battery)

breaker (CB2). Set the AC breaker (CB1) to "ON".

2. In attempting to set the equalize voltage, one thing must be kept in mind. It will be impossible

to set the equalize voltage if the batteries are in a discharged condition. If fact, they must be at near fullcharge. This is to prevent the charger from going into a current limit condition. Current limit reduces the

charging voltage and no matter if the EQUALIZE potentiometer is increased to a full-clockwise position,

the charger voltage will not increase.

3. Therefore, it is suggested that the batteries be placed on equalize charge for several hours so

that the charger is no longer in current limit. This should be observed using the portable 1% accuracy

voltmeter and the charger panel ammeter. When the charging current falls below the 100% rated value of

charger current, observe the voltage and set carefully for the desired equalize voltage. If, upon

readjustment, the current again goes into current limit wait for the batteries to continue their charge

cycle. Continue this adjustment procedure until the desired voltage is reached and the current is less than

rated current. When the final setting is determined, tighten the lock nut on the EQUALIZE

potentiometer.

12

Page 17

2. CURRENT LIMIT RESPONSE AND ADJUSTMENT

a. Checks and Adjustments: Make certain the charger leads are connected to the battery and that

the panel voltmeter indicates the proper polarity. Switch the DC breaker (CB2) to "ON" and AC breaker

(CB1) to "ON". The "AC ON" indicating light (DS1) should illuminate, indicating power has been

applied. With the charger in float mode, a float voltage charge should be indicated on the panel

voltmeter and the ammeter should show either a charge current, or practically none at all, depending on

the state of battery charge.

1. If the batteries are in a discharged condition, switching to the equalize mode will cause the

charger to automatically go into a current limit condition. If, however, the batteries are fully charged they

probably will not draw current in the current limit range. In order to cause this condition, it will be

necessary to connect additional load to the battery charger or battery bank. This can be resistive elements

or turning on the normal load of the installation. When current limiting is encountered, observe that the

charger voltage will be reduced below its set value by the current limit feedback signal. Observe that as

the current limit condition continues, the voltage will slowly increase as the batteries take on a charge.

Eventually the current will begin to decrease below the current limit value and continue to decrease to a

value less than 100% of rated output current. As the current decreases below 100% of rated output

current, the voltage will become constant at the equalize value and remain so.

2. To check the system response, turn the AC breaker (CB1) to "OFF" to simulate line voltage

failure. Charging current will return to zero on the instrument panel ammeter (M1), and the voltage

should reduce slightly. Place a load on the battery and discharge it heavily for a short period of time until

the voltmeter drops to float value or slightly lower. Return the AC breaker (CB1) to "ON" and observe

that charge ammeter again reads 110% of charge rate and voltage is less than the equalizing level. If

current is greater than, or less than 110% of rated charge, open the cabinet and locate the CURRENT

LIMIT potentiometer on the control trigger PC board (A1). Reference the component layout on page 29

and schematic on page 30. The CURRENT LIMIT is labeled R11 on single-phase control PC boards

(GK0058) and R65 on three-phase control PC boards (GK0048). Adjust this control for 110% charge

current. Repeat the AC circuit breaker (CB1) ON-OFF sequence listed above. If charge rate is still 110%

rated value for which it was set, close the cabinet. Restore the charger to float mode.

b. Checks to Make if Malfunctioning: If all of the above adjustments were attempted and a high

current persists, the current limit circuit on the control trigger board or the ammeter or shunt used for

current sense may be defective. The interconnecting wiring may also be faulty. Make the following

checks to isolate the fault.

1. Turn the current limit control on the control trigger PC Board (A1) to determine if it has any

effect on the high output current reading. This control is the potentiometer labeled R11 on single-phase

control PC boards (GK0058) and R65 on three-phase control PC boards (GK0048). If it does have an

effect, make the adjustment for 110% rated current for a current limit setting as described in paragraph

IV, 2, a, 2 above.

2. If no effect is noted, IC1 on the control trigger PC board (A1) may be defective. If so, replace.

3. Check the voltage generated across the ammeter (M1), or ammeter shunt (SH1) to determine

that sufficient voltage is available at rated current to activate the current-limit feedback amplifier. See

Section III, 2, h. Use a sensitive DC voltmeter and measure the voltage across the ammeter (M1) or

ammeter shunt (SH1). Measure the voltage from the "current limit" pin to the "control circuit reference"

pin, on the plug (SO1) of the control trigger PC board (A1). These pins are respectively pins #1 and #10

on single-phase control boards (GK0058) and pins #6 and #9 on three-phase control boards (GK0048). If

the sense voltage is not present at the control trigger PC board (A1), check the wiring. If the wiring is

satisfactory, proceed with the check sequence listed in Table A trouble shooting chart on page 27.

13

Page 18

SECTION V

SCR/SCRF SERIES BATTERY CHARGER CUSTOMER OPTIONS

The following pages describe customer options available in SCR/SCRF Series battery chargers. The text

describes the basic operational philosophy and theory of operation. Block diagrams (or schematics) for these

options are shown in Section VIII, in numerical order of the "EJ####" specification number.

1. GROUND DETECTION CIRCUITS

Purpose: The purpose of a ground detector circuit is to indicate to the user when either the positive (+)

or negative (-) output terminal of the battery charger (or its connected load) is grounded. This is important

for many applications where a full floating system is required for operation or safety reasons. There are

several methods of indicating a grounded output terminal. These will be outlined below with an explanation

of how each works.

Descriptions:

a. POSITIVE / NEGATIVE GROUND INDICATOR LIGHTS (EJ0088)

The simplest form of a ground detection system is the two-lamp method. This utilizes two lamps of

voltage equal to the battery charger output voltage connected from the positive terminal to ground and from

negative terminal to ground. Under normal conditions, each bulb will have half-voltage applied and glow

dimly at quarter-brilliance. Upon a ground, the lamp indicating the grounded terminal will glow at full

brilliance. The other lamp will go out.

b. POSITIVE / NEGATIVE GROUND INDICATOR LIGHTS W/TEST SWITCH (EJ0089)

This is a variation of “EJ0088” above, so that the two lamps are not continuously connected in the

circuit. A double-pole, double-throw momentary center off switch (SW12) is utilized. Activating the SW12

down will connect the two lamps in series across the battery, with the center attached to chassis ground. This

performs as the two-lamp system (EJ0088) as described above. Activating the SW12 up serves to test the

lamps.

c. GROUND DETECTION SWITCH FOR DC VOLTMETER INDICATION (EJ0094)

This method uses the existing panel DC voltmeter (M2) and two double-throw switches (SW8/SW9)

to utilize the voltmeter in both functions. SW8 establishes the meter function (output voltage or ground

detection) and SW9 switches the voltmeter between (+) or (-) terminals to chassis ground, reversing the

meter polarity to maintain up-scale indications. The voltmeter, used in the ground detection mode, will

indicate the DC voltage potential between the corresponding output terminal and chassis ground. For cases

of partial grounds, the voltmeter will indicate the difference of the terminal DC voltage and the voltage of

the partial ground.

d. GROUND DETECTION ALARM RELAYS (EJ0086) - W/OPTIONAL INDICATOR LIGHTS

This method utilizes two DC relays which monitor the (+) and (-) terminal voltage to chassis ground

and will energize if the opposite polarity terminal is grounded. To insure that the relays will not energize on

half-voltage, when there is no ground present, series resistances are used to reduce the relay pull-in

sensitivity. However, once pulled in by a ground condition, the relays will not drop out when the ground is

removed because the drop out voltage of a DC relay is always less than the pull-in voltage. As a result, a

momentary “RESET” switch (SW3) must be activated to open the relays returning them to the “ready”

condition. Schematic EJ0086 shows the circuit diagram of this method. The panel lamps shown are a user

option that is available for front panel indication. The relay coil voltages, and series resistances will depend

on the output voltage of the battery charger.

14

Page 19

2. AC POWER FAILURE ALARM RELAY (EJ0085) - WITH OPTIONAL INDICATOR LIGHT

Purpose: The purpose of this alarm is to notify the user that the AC input power to the battery charger

has been interrupted. A front panel "AC FAILURE" lamp is optional for local indication. Relay contacts are

provided for remote monitoring.

Description: The principle of operation utilizes the normally closed contacts of an AC relay (K1). K1 is

powered from the AC line at the primary of the transformer (T1). TM1, when energized, holds the normally

closed contacts open disabling the alarm indication. When the AC line fails or the AC circuit breaker (CB1)

is opened for any reason, the alarm contacts will close activating the alarm indicator. EJ0085 shows the

circuit with the optional panel indicator lamp and external relay connections for remote indication. The

indicator lamp must operate from the battery power since the AC line power is not available in an alarm

state. As a result, the indicator light operating voltage must match the battery DC voltage or must utilize a

series-dropping resistor to compensate for the difference in voltage between the battery and indicator lamp.

3. AC INPUT VOLTMETER (EJ0095/EJ0121) AND AMMETER (EJ0134/EJ0135) OPTIONS

Purpose: These options are to permit the user to monitor the input AC line voltage and line current to

the battery charger. This may be done for either single phase or three phase input power.

Descriptions:

a. Single phase AC: EJ0095 shows the connections to the ac voltmeter and EJ0134 shows the

connections to the AC ammeter. The ammeter is usually connected to the AC line via a current transformer

(CT1) if the line current is over 50 Amperes.

b. Three Phase AC: EJ0121 shows the connections to the ac voltmeter and EJ0135 and shows the

connections to the AC ammeter. Both show the connections utilizing a single meter, one to monitor the

three phase-to-phase voltages and one to monitor the three line currents. A two-pole, three position switch

(SW5) is used to switch the voltmeter from phase-to-phase to check all three input voltages. The ammeter

switch (SW6) is a special switch, which shorts all unused current transformer secondaries. Upon changing

switch position, it shorts the current transformer (CT1) secondary in use before transferring the ammeter to a

new position. This prevents very high voltage arcs when the secondary is open circuited.

CAUTION: NEVER OPERATE A CURRENT TRANSFORMER WITHOUT A SECONDARY

LOAD OR SHORT CIRCUIT ACROSS THE SECONDARY TERMINALS.

4. HIGH / LOW DC VOLTAGE ALARM RELAYS (EJ0083) - W/OPTIONAL INDICATOR LIGHTS

Purpose: The HIGH/LOW DC Voltage Alarm (HLVA) provides alarm indication for the DC system in

the event of a malfunction of the battery charger, which causes the battery voltage to rise or drop to a

dangerous level. Relay contacts and optional front panel lamps provide alarm indications.

Description: The HLVA printed circuit board consists of two independent operational amplifier circuits,

one monitoring the battery voltage for a high voltage condition and the other monitoring for a low voltage

condition.

The board obtains its operating voltage (12VDC) from the battery terminals and if required, an

externally mounted dropping resistor (R57).

There are two potentiometers on the HLVA PC board (A2). Viewed from the component side of the

board, the potentiometer near the top-left of the board is the LOW voltage alarm (LVA) threshold

adjustment. The right-hand potentiometer at the top of the board is the HIGH voltage alarm (HVA)

threshold adjustment.

15

Page 20

If it is necessary to adjust the LVA threshold in the field, the user must load the battery bank and allow

the battery voltage to drop while decreasing the float voltage adjustment to the desired cut-off potential. The

LVA potentiometer is then adjusted so that the LVA relay is activated into the low voltage alarm condition.

Note that there is a delay time, up to 30 seconds before the relay operates once the threshold voltage is

reached. It will be necessary to raise and lower the battery voltage several times to ascertain that the

potentiometer setting is correct.

Similarly the battery bank will have to be charged at a high equalize rate in order to set the HVA

threshold. At the equalize rate the charger may go into a current limit condition, depending on the state of

charge, and it may be impossible to reach the desired high voltage alarm voltage. If this is the case, it will be

necessary to substitute a resistive load bank with paralleled capacitance in place of the batteries. Adjust the

output voltage of the charger by using the "EQUALIZE" potentiometer (R5) and then set the HVA

potentiometer accordingly.

It will be noticed that there is an operational delay time and a hysteresis zone (dead zone) between the

drop out voltage and the pull-in voltage of the alarm circuits. This is natural and desirable to prevent

chattering of the relays when the threshold voltage is reached.

The factory preset thresholds for alarm conditions are as follows unless otherwise specified:

LVA 2.00 volts/cell for LEAD ACID

1.14 volts/cell for NICKEL CADMIUM

HVA 2.40 volts/cell for LEAD ACID

1.65 volts/cell for NICKEL CADMIUM

5. CHARGER FAILURE ALARM RELAY (EJ0127) - WITH OPTIONAL INDICATOR LIGHT

Purpose: The Charger Failure Alarm provides an alarm indication whenever the charger output current

decreases to below 2% of rated current for more than 30 seconds. Alarm contacts are wired to TB3 terminals

19, 20 & 21 and an optional front-panel indicator (DS7) is available.

Description: Charger output current is sensed by means of an auxiliary winding on the main inductor

(L1). The CFA PC Board assembly (A3) detects the voltage signal from L1. When the voltage signal

indicates that the current has dropped to below 2%, an on-board relay switches to provide the alarm

indication. When the output current is restored to a value above 2%, the alarm will be automatically reset.

6. BATTERY DISCHARGING ALARM RELAY WITH INDICATOR LIGHT (EJ0120)

Purpose: The Battery Discharging Alarm indicates the condition when the battery is no longer receiving

adequate charging current from the charger and has become a source of current for the load. Alarm

indication is provided by a front panel lamp (DS10) and relay contacts. Alarm contacts are wired to TB3

terminals 22, 23 & 24.

Description: This is accomplished by monitoring the direction of current flow in a DC meter shunt

(SH3) connected in the main battery lead. When this current polarity changes from negative to positive the

alarm circuit is activated.

EJ0120 shows the connection diagram of the alarms. An op-amp voltage comparator senses when the

input signal from SH3 changes from negative to positive polarity. The op-amp output goes “high” and

activates the alarm.

The alarm board derives its power from the battery terminals. If necessary, voltage-dropping resistors are

used to properly match the battery voltage.

16

Page 21

7. EQUALIZE TIMERS

Purpose: Equalize Timers are used to switch the charger into equalize charging mode for a set period of

time, when required by the batteries. "FLOAT" and "EQUALIZE" indicating lights mounted on the

instrument panel can be included with all timers to indicate the charging mode. There are three basic timers

described below. These Equalize Timers replace the standard "FLOAT/EQUALIZE" switch (SW1) featured

in the charger mainframe and referenced elsewhere in this manual.

Descriptions:

a. MANUAL EQUALIZE TIMER (EJ0097), W/LIGHTS (EJ0096), W/LIGHTS & SW (EJ0869)

To operate this 0-72 hour timer, turn the timer control knob (TM1) clockwise to the number of charge

hours desired. This will start an AC clock, driving two cams, which operate two contacts. One contact

provides AC to the clock motor, the other changes the voltage-sensing network to the higher equalizing

voltage. Upon completion of the time period, when the timer control knob reaches "0", the clock motor is

stopped and the voltage-sensing network is returned automatically to the float voltage value. Option EJ0096

features the aforementioned manual equalize timer, along with "FLOAT" and "EQUALIZE" indicating

lights. Option EJ0896 features the aforementioned manual equalize timer and indicator lights, along with a

manual "FLOAT/EQUALIZE" switch.

b. AC LINE FAILURE AUTO-EQUALIZE TIMER WITH INDICATOR LIGHTS (EJ0131)

The Auto-Equalize timer is designed to automatically provide an equalizing cycle when the ac input has

been interrupted longer then 10 seconds. The operation of this equalize timer is as follows. Toggle switch

(SW1) to the "AUTO/EQUALIZE" position, and the battery charger in the "FLOAT" mode: When the AC

power is interrupted for a period longer than 10 seconds and returns, the battery charger is placed in the

"EQUALIZE" charge mode for a pre-selected period of time (0 to 999 hours). The timer, now energized,

displays time remaining and completes the equalize charge period. Once the timer reaches "0" the charger

will switch to the "FLOAT" mode. The timer will shut its self down and remains ready to repeat the