Page 1

®

INSTALLATION

&

OPERATING

INSTRUCTIONS

SECTION 93.10 2013-05

Page 2

YOUR GNB REPRESENTATIVE

SALESPERSON

TELEPHONE

LOCATION

GNB SERVICE ASSISTANCE

1-800-241-4895

Page 3

INDEX

SECTION 1

1.0 General Information . . . . . . . . . . . . . . . . . . . .1

SECTION 2

2.0 Safety Precautions . . . . . . . . . . . . . . . . . . . . .1

SECTION 3

3.0 Receipt of Shipment . . . . . . . . . . . . . . . . . . .1

3.1 Concealed Damage . . . . . . . . . . . . . . . . . . . .2

3.2 Electrolyte Levels . . . . . . . . . . . . . . . . . . . . . .2

SECTION 4

4.0 Storage Prior to Installation . . . . . . . . . . . . . .2

4.1 Storage Location . . . . . . . . . . . . . . . . . . . . . .2

4.2 Parts and Accessories . . . . . . . . . . . . . . . . . .2

4.3 Storage Interval . . . . . . . . . . . . . . . . . . . . . . .2

4.4 Dry Charged Batteries . . . . . . . . . . . . . . . . . .2

SECTION 5

5.0 Rack Assembly . . . . . . . . . . . . . . . . . . . . . . .2

SECTION 6

6.0 Unpacking and Handling . . . . . . . . . . . . . . . .2

SECTION 7

7.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .3

7.1 Battery Location . . . . . . . . . . . . . . . . . . . . . . .3

7.2 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . .3

7.3 Temperature Variation . . . . . . . . . . . . . . . . . .3

7.4 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . .3

7.5 Placement of Cells . . . . . . . . . . . . . . . . . . . . .3

7.6 Connecting Cells . . . . . . . . . . . . . . . . . . . . . .4

7.7 Completing Installation . . . . . . . . . . . . . . . . .6

Page

ECTION 12

S

12.0 Cell Voltage Variation . . . . . . . . . . . . . . . . . .10

12.2 Cell Voltage Variation–Damp Covers . . . . . .11

12.2 Cell Voltage–Temperature Correction . . . . .11

12.3 Correction Factor . . . . . . . . . . . . . . . . . . . . .11

SECTION 13

13.0 Pilot Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

SECTION 14

14.0 Records . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

SECTION 15

15.0 Water Additions . . . . . . . . . . . . . . . . . . . . . .12

15.1 Water Purity . . . . . . . . . . . . . . . . . . . . . . . . .12

SECTION 16

16.0 Tap Connections . . . . . . . . . . . . . . . . . . . . .12

SECTION 17

17.0 Temporary Nonuse . . . . . . . . . . . . . . . . . . .12

SECTION 18

18.0 Battery Cleaning . . . . . . . . . . . . . . . . . . . . .12

18.1 Styrene Acrylonitrile Containers with

Butadiene Styrene Covers . . . . . . . . . . . . . .12

18.2 Polycarbonate Containers and Covers . . . .12

SECTION 19

19.0 Connections . . . . . . . . . . . . . . . . . . . . . . . . .13

19.1 Connection Resistance . . . . . . . . . . . . . . . .13

19.2 Retorquing Connections . . . . . . . . . . . . . . .13

19.3 Connection Resistance Measurement . . . . .14

Page

SECTION 8

8.0 Initial Charge . . . . . . . . . . . . . . . . . . . . . . . . .7

8.1 Constant Voltage Method . . . . . . . . . . . . . . .7

8.2 Initial Charge-Electrolyte Levels . . . . . . . . . .7

SECTION 9

9.0 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

9.1 Floating Charge Method . . . . . . . . . . . . . . . .7

9.2 Float Charge-Float Voltages . . . . . . . . . . . . .7

9.3 Voltmeter Calibration . . . . . . . . . . . . . . . . . . .8

9.4 Cycle Method of Operation . . . . . . . . . . . . . .8

9.5 Recharge . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SECTION 10

10.0 Equalizing Charge . . . . . . . . . . . . . . . . . . . . .8

10.1 Equalizing Frequency . . . . . . . . . . . . . . . . . .8

10.2 Equalizing Charge Method . . . . . . . . . . . . . .9

10.3 Equalizing Individual Cells . . . . . . . . . . . . . . .9

10.4 Equalizing Charge—Electrolyte Levels . . . . .9

SECTION 11

11.0 Specific Gravity . . . . . . . . . . . . . . . . . . . . . . .9

11.1 Hydrometer Readings . . . . . . . . . . . . . . . . .10

11.2 Correction for Temperature . . . . . . . . . . . . .10

11.3 Correction for Electrolyte Level . . . . . . . . . .10

11.4 Specific Gravity Range . . . . . . . . . . . . . . . .10

TABLES

TABLE A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

TABLE B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

TABLE C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

TABLE D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

TABLE E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

STATIONARY BATTERY MAINTENANCE

REPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

FIGURES

FIGURE 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

FIGURE 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

FIGURE 2A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

FIGURE 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

FIGURE 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

FIGURE 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

FIGURE 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

FIGURE 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

FIGURE 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

FIGURE 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

FIGURE 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Page 4

SECTION 1

1.0 General Information

D. When preparing electrolyte, always pour acid into water,

NEVER

will result in excess heat and violent chemical reaction

which may cause serious injury to personnel.

water into acid. Failure to follow this precaution

Caution! Before proceeding with the unpacking, handling,

installation and operation of this lead-acid storage battery,

the following general information should be reviewed together with the recommended safety precautions.

A lead-acid battery is an electro-chemical device containing

e

lectrolyte which is a dilute solution of sulfuric acid and

water. This electrolyte is corrosive and can cause injury.

L

ead-acid batteries, when installed, are capable of high volt-

age which can cause electrical shocks to personnel.

All lead-acid batteries, in the course of normal operation,

generate gases which could be explosive.

Stationary batteries (when installed) are usually on float

charge continually, unless on discharge in the event of AC

failure, or on recharge following a discharge.

SECTION 2

BATTERY WARNING STATEMENT

DANGER

HIGH VOLTAGE

High voltages are present on most battery systems.

Exercise caution and REMOVE ALL METAL

OBJECTS FROM PERSON when working on or

around battery.

EXPLOSIVE GASES

Gases produced by battery can be explosive. DO NOT

SMOKE, USE AN OPEN FLAME, CREATE AN ARC

or SPARKS IN VICINITY OF BATTERY. WEAR EYE

PROTECTION.Personnel should discharge static

charges from their person to ground before working on

battery. Ventilate well in an enclosed space and when

charging.

ACID BURNS

Battery contains SULFURIC ACID WHICH CAN

CAUSE SEVERE BURNS. Avoid getting in eyes, on

skin,or on clothing.In case of contact, flushimmediately and thoroughly with clean water. OBTAIN MEDICAL

ATTENTION.

2.0 Safety Precautions

A. Wear rubber apron, gloves and safety goggles (or face

shield) when handling, installing, or working with batteries. This will help prevent injury due to splashing or

spillage of sulfuric acid.

E. If electrolyte comes into contact with skin or clothing,

immediately wash with water and neutralize with a solution of baking soda and water. Secure medical treatment. If electrolyte comes into contact with the eyes,

wash or flush with plenty of clean water. Secure medical

treatment immediately.

F. Exercise care when handling cells. When lifting straps

and strap spreaders are provided, use them with appropriate mechanical equipment to safely handle cells and

avoid injury to personnel.

G. Promptly neutralize and remove any electrolyte spilled

when handling or installing cells. Use a baking soda/water

solution (1 lb. per gallon of water) to prevent possible

injury to personnel.

H. Make sure that all battery connections are properly pre-

pared and tightened to prevent possible injury to personnel or failure of system.

I. Familiarize personnel with battery installation, charging

and maintenance procedures. Restrict access to battery

area, permitting trained personnel only, to reduce the

possibility of injury.

J. Whenever possible, when making repairs to charging

equipment and/or batteries, interrupt AC and DC circuits

to reduce the possibility of injury to personnel and damage to system equipment. This is particularly important

with high voltage systems (110 volts and above).

K. When maintaining a connected battery string, care

must be taken to prevent a build-up of static charge.

This danger is particularly significant when the worker is

electrically isolated, ie. working on a rubber mat or an

epoxy painted floor or wearing rubber shoes. Prior to

making contact with the cell, discharge static electricity by touching a grounded surface. Wearing a

ground strap while working on a connected battery string

recommended.

is not

NOTE: If the foregoing precautions are not fully understood,

clarification should be obtained from your nearest GNB representative. Local conditions may introduce situations not

covered by GNB Safety Precautions. Here again, contact the

nearest GNB representative for guidance with your particular

safety problem; also refer to applicable federal, state, and

local regulations as well as industry standards.

B. Prohibit smoking. Keep flames and sparks of all kinds away

from vicinity of storage batteries as liberated or entrapped

hydrogen gas in the cells may be exploded,causing injury to

personnel and damage to cells.

C. Never place metal tools on top of cells, since sparks due to

shorting across cell terminals may result in an explosion of

hydrogen gas in or near the cells. Insulate

protect against shorting.

tool handles to

SECTION 3

3.0 Receipt of Shipment

Immediately upon delivery by the carrier, examine for possible damage caused in transit. Damaged packing material or

staining from leaking electrolyte would indicate rough handling.

1

Page 5

If such conditions are found, make description notation on

delivery receipt before signing. If cell damage is found, request

an inspection by the carrier and file a damage claim. Also notify local

GNB representative of action taken.

3.1 Concealed Damage

Storage beyond the above stated periods can result in sulphated plates which can be detrimental to battery life and

performance.

he battery should be given its initial charge (see Section

T

8.0) before the end of the above stated storage intervals and

repeated for each additional storage interval.

Shortly after receipt (within 15 days), examine all cells for concealed damage. Pay particular attention to packing material

exhibiting damage or electrolyte staining. Perform examination

prior to installation and disposal of packing materials. Cells with

electrolyte levels more that 1/2" below top of plates have suffered probable permanent damage due to plate exposure to air.

If this condition or other cell damage is found, request an inspection by the carrier immediately and file a concealed damage

claim. Examine cells for container damage, misaligned elements, broken plates, or any other visible damage.

3.2 Electrolyte Levels

Cells are shipped with electrolyte levels about 1/8" below the

high level line. During shipment, the levels drop due to the loss

of gases from internal cell components. The amount of drop in

level will vary with each type of cell. Electrolyte levels, when

received, may range from the high level line to slightly below the

low level line. If this condition exists, make no addition of electrolyte or water at this time (see Section 8.2). If certain cells

have low electrolyte levels, with less than 1/2" of plates exposed

to air, add battery grade sulphuric acid of the same specific gravity as the remaining cells; thus bringing low level cells up to the

average level of other cells.

SECTION 4

4.0 Storage Prior to Installation

If permanent installation is deferred for an extended time

eriod, the battery may be temporarily connected and main-

p

tained on a floating charge (see Section 9).

Failure to charge in accordance with the above can void the

battery's warranty.

4.4 Dry-Charged Batteries

For batteries shipped dry-charged, follow special handling

and preparation instructions supplied as well as appropriate

sections of this Manual.

SECTION 5

5.0 Rack Assembly

Assembly of the battery rack should be completed in accordance with the GNB drawing and/or instructions included

with the rack.

SECTION 6

6.0 Unpacking and Handling

Most cells are packed in individual corrugated cartons.

Some smaller size cells are packed in a master carton containing 2 (two) or 3 (three) cells. Cartons are shipped on

wood pallets.

4.1 Storage Location

If the battery is not to be installed at the time of the receipt, it is

recommended that it be stored indoors in a cool, 60°F (15.6° C)

to 90° F (32° C), clean, dry location. Do not top load pallets or

possible cell damage may occur. Storage or transport of flooded

lead-acid batteries at temperatures exceeding 120°F (49°C) can

cause detimental effects on plastic components and battery

state of health which may void warranty.

4.2 Parts and Accessories

Prior to planned installation of battery, the separately packaged

parts and accessories should be opened and checked against

shipping invoice for completeness. Discovery of missing or

incorrect parts during installation may cause delays resulting

from reordering and shipment of replacements. Store parts in

safe location to prevent loss.

4.3 Storage Interval

For batteries shipped wet, fully-charged, the following storage

intervals from date of shipment to date of installation and initial

charge should not be exceeded:

Lead-Antimony Types:

Three (3) Months

Lead Calcium Types:

Six (6) Months

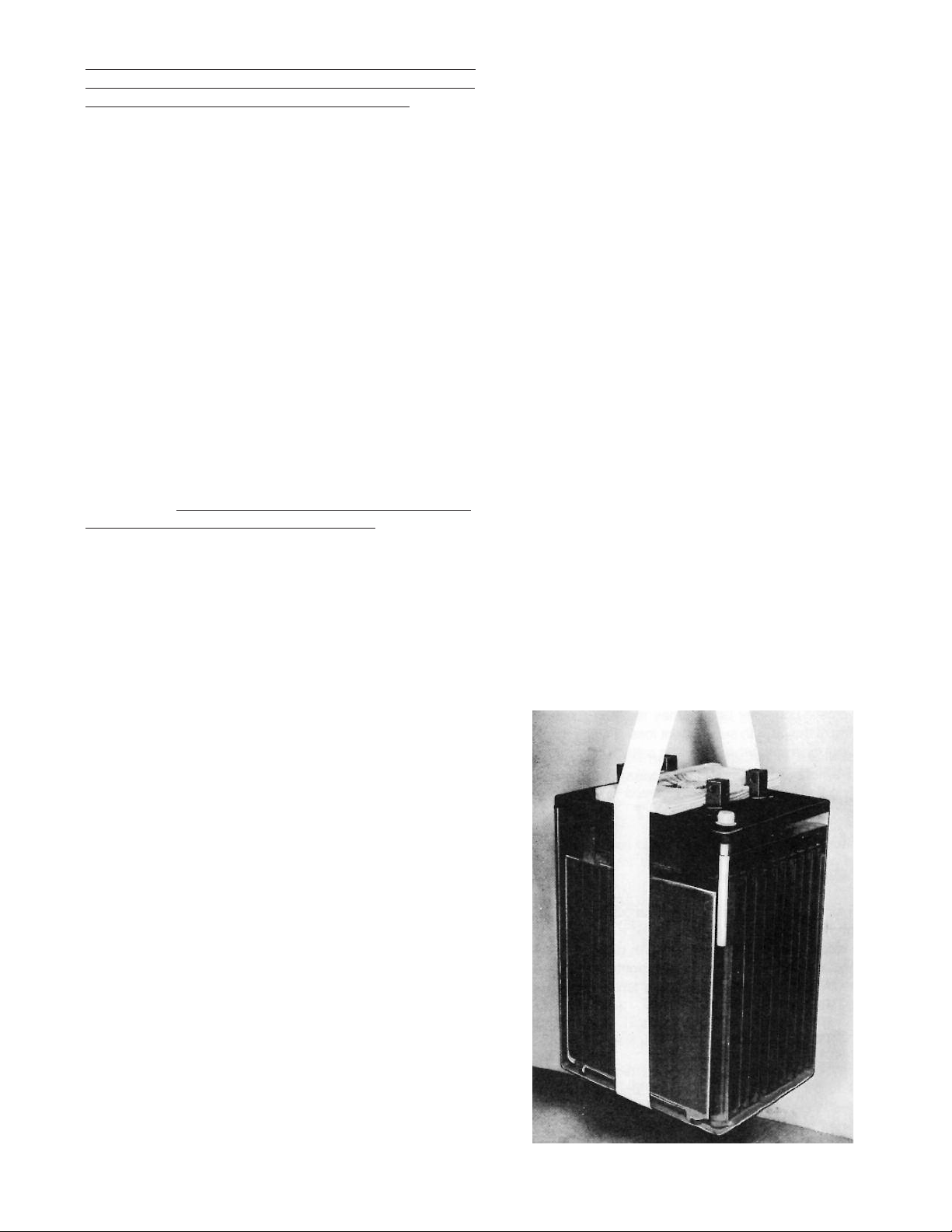

Figure 1

2

Page 6

Remove material holding cartons to pallets, exercising care

when cutting banding material to prevent injury. If individual

cells are to be moved to another location, do not remove carton at this time. Exercise caution if using a two-wheeled

hand truck and, to prevent spillage of electrolyte, do not tilt

cell more than 25 degrees from vertical. When cells have

been brought to the installation sight, remove carton sleeve

and top corrugated spacers.

7.3 Temperature Variation

The location of rack arrangement should result in no greater

than 5°F (2.78°C) variation in cell temperatures in a series

string at any given time. If a greater variation is found, steps

should be taken to correct the condition. When uniform cell

temperature is maintained, the need for equalizing charges

may be eliminated or reduced in frequency.

DO NOT LIFT CELLS BY THEIR TERMINAL POSTS.

Support the cells from the bottom when handling and

unpacking. In general, units weighing less than 75 pounds

are handled manually, being supported from the bottom.

After removal of outer carton and top spacers, the cell should still

be resting in the bottom corrugated tray. This tray is designed to

be easily broken away to permit positioning of a lifting strap

under the cell with a minimal amount of cell tilting.

A lifting strap and a strap spreader are furnished for use with

mechanical lifting devices, when cells weigh 75 pounds or

more. See Figure 1 which shows typical positioning of strap

and spreader. Large cells are provided with 2 lifting straps

and a special spreader for stability in handling during installation.

Always use lifting straps and spreaders, when provided,

together with suitable mechanical lifting devices to prevent

injury to personnel or damage to cells.

Platform lifts of adequate capacity to handle cell weights and

dimensions may be used provided they are stable and capable of reaching needed heights and used on smooth and

level floor conditions.

Never slide cells across rough surfaces as severe scratching

of plastic container bottom may result in stressing and rupturing of the jar with subsequent loss of electrolyte. At all

times, exercise care when handling cells to prevent scratching of plastic jars and covers.

SECTION 7

7.0 Installation

7.1 Battery Location

It is recommended that the battery be installed in a clean,

cool, dry location. Cells should not be exposed to heating

units, strip heaters, radiators, steam pipes or sunshine

through a window. Any of these conditions can cause a serious electrolyte temperature variation among cells within a

battery (see Section 7.3).

7.2 Temperature

A battery location having an ambient temperature of 75°F

(24°C) to 77°F (25°C) will result in optimum battery life.

Batteries operated in high ambient temperatures will result

in reduced life. Therefore, for longer life and ease of maintenance, locations having cooler ambient temperatures are

recommended. The normal battery operating temperatures

are between 60°F (16°C) and 90°F (32°C).

7.4 Ventilation

In the operation of lead-acid battery whether it be on initial

charge, float charge, equalizing charge or recharge following

a discharge, hydrogen and oxygen gases are produced.

This results from electrolysis of the water portion of the electrolyte by the charging current.

Ventilation should be provided in the battery room or area to

prevent hydrogen, liberated from the cells in service, from

exceeding a 1% concentration. Concentrations above this

percentage can result in an explosive mixture, which could

be ignited by sparks from adjacent electrical equipment as

well as accidental sparks or open flames introduced by personnel. All air moved by ventilation in the battery room or

area should be exhausted into the outside atmosphere and

should not be allowed to recirculate into other confined

areas.

7.5 Placement of Cells

It is assumed at this point that the battery rack has been

assembled. Study the rack layout and wiring drawings to

determine proper location of the positive and negative terminals of the battery; this will establish correct positioning of

the initial cell on each rack row. Cells are normally installed

with plate edges perpendicular to rack length.

Measure and mark the center of the rack stringer length.

Determine the number of cells to be placed in each row.

When an odd number of cells are in the row, place the center of the initial cell at the center point of the rack stringer

length.

When an even number of cells are in the row, locate the initial cells so that the center of the space between the cells

coincides with the center mark of the stringer length.

To minimize friction of cells when transferring from platform

lift to the rack rails or for positioning of cells, talcum powder

may be used on the platform surface or plastic rack strips to

ease movement.

CAUTION!

DO NOT USE ANY OTHER TYPE OF

LUBRICANT SUCH AS GREASE OR OIL AS

THEY MAY CONTAIN MINERAL SPIRITS

WHICH CAUSE CRAZING AND CRACKING

OF THE PLASTIC JAR MATERIAL.

DO NOT USE METAL RODS, SCREWDRIVERS, ETC. THROUGH POST HOLES

TO LATERALLY MOVE CELLS AS CELL

SHORTING AS WELL AS DAMAGE TO THE

POST SEALS COULD OCCUR.

3

Page 7

When installing cells on the rack, start at the lower step or

ier for stability and safety reasons.

t

Place cells on the rack so that the positive terminal (marked

“+”) of each cell adjoins the negative terminal (marked “-”) of

the next cell. The standard spacing between cells is 1/2” at

the top of the jars.

On cells using stainless steel bolts, washers and nuts, make

ure a washer is placed between the bolt head and connec-

s

tor as well as between the nut and connector with the rolled

edge against the connector. Never install washers between

the connector and the cell post. (See figure 2A).

Adjacent cells should not touch; nor should any cell contact

the metal rack supports or metal cable conduits. Check for

proper alignment and 1/2” spacing between cells. Adjust

cell position where necessary. This should be completed

before installation of intercell connectors.

Use two 1/2” thick pieces of plywood cut to cell width and 1”

higher than jar height to expedite positioning of cells. Space

cells by placing one piece between the first cell positioned

and the next cell. In positioning the third cell, use the second piece of plywood for spacing. The first piece is removed

and used for the next cell placement, etc.

The cell post surfaces have a coating of NO-OX-ID grease

or approved equal applied at the factory. Do not remove any

grease from posts. Re-coat any surfaces that may have

been exposed during handling of cells.

Also closely examine factory coated post contact surfaces

for presence of foreign substances which may have been

introduced through handling or construction activity in the

installation area. If the foregoing is noted, remove the NOOX-ID grease or approved equal with paper wipers and

apply a new coating. Also inspect posts for corrosion. If corrosion is found, clean posts with brass suede brush or plastic scouring pad and re-grease.

CAUTION!

WHEN INSTALLING TERMINAL HARDWARE

DO NOT PERMIT ANY ITEMS TO FALL INTO

CELL. IF SUCH MATERIAL REMAINS IN THE

CELL, CONTAMINATION WILL RESULT,

REQUIRING REPLACEMENT OF THE CELL.

As intercell connectors are installed, adjust them to a level

position and finger tighten hardware.

After all connectors are installed, the hardware should be

tightened using insulated tools as outlined in the following

illustration. (Figure 2):

QUANTITY AND THICKNESS

OF INTERCELL CONNECTORS TORQUE (INCH LBS).

1/8” or 1/4” (D cells only) 100

1/8” (M & N cells) 100

CAUTION!

FAILURE TO OBSERVE ABOVE PROCEDURE

MAY IMPAIR INTEGRITY OF ELECTRICAL

CONNECTION AND CELL PERFORMANCE.

7.6 Connecting Cells

Refer to the cell arrangement drawing to determine the

quantity, size, and correct positioning of the intercell connectors. On the “N” type cells using 1 1/4” wide connectors,

the bolt holes are located off-center. Position the connector

so that the lesser dimension faces downward on the cell

post.

Gently clean contact surfaces only of the lead plated intercell connectors, terminal plates and cable lugs using a brass

suede brush or 3M Scotch Brite scouring pad. Caution: Do

not use powered wire brush or course abrasives, as lead

plating may be removed exposing copper.

As contact surfaces of posts and connectors are cleaned,

apply a thin coating of NO-OX-ID grease or approved equal

to these surfaces only.

Starting at center of the cell row, install connectors per

wiring diagram and cell arrangement drawing furnished with

the battery.

1/4” or two 1/8” (M & N cells) 150

1/4” (PDQ, N & H cells) 150

Figure 2

Torque both the bolt head and the nut of stainless steel

hardware to their prescribed torque values. Torquing only

one side of either combination will not provide the desired

tightness.

Re-torque stainless steel hardware 4 to 6 hours after initial

torquing to allow for initial relaxation of connection components.

Complete connecting of cells by installing necessary interrow, inter-tier or inter-rack cable connectors. Do not

connect

battery to charger at this time.

Take and record connection resistances (See Section 19.0)

of cell to cell and cell to terminal (including inter level and

load connections). This is particularly important on high rate

applications. Remake any connection that has a value more

than 10% or 5 u Ω, whichever is greater.

Re-check to be certain that the cells are connected positive

(+) to negative (-) throughout the battery string. Measure

the total voltage at the battery terminals. The voltage should

be equal to the number of cells times the voltage of one of

the cells. Example: 60 cells times 2.05 volts = 123 volts.

4

Page 8

5

Page 9

ELECTROLYTE

ITHDRAWAL

W

UST CAPS

D

Figure 4Figure 3

7.7 Completing Installation

Explosion Resistant Vents

Certain cell sizes may have been shipped with GNB PreVent™ vent/filling funnels in place. These vents have flexible

plastic caps installed for shipping purposes. These caps may

be removed and discarded, or they may be left in place if the

battery environment is dusty. (See Figure 3)

Other cell sizes are supplied with Pre-Vents which are not

shipped in place. A standard screw-type vent is used for shipping purposes. If Pre-Vent units were specified, they would have

been packed separately with other accessories. Remove the

screw-type shipping vents one-at-a-time and install a Pre-Vent

unit before charging. Discard the shipping vent.

Other cell types are supplied with separate explosion resistant vents installed at time of shipment. Separate plastic filling funnels are supplied along with this type vent. These

funnels also have flexible plastic shipping caps. Here again,

these may be removed and discarded or left in place if environment is dusty.

The Pre-Vent assembly and other explosion resistant vents

are designed to prevent external sparks or flames from igniting and exploding internal cell gases. (See Figure 4).

Electrolyte Withdrawal Tubes

Certain calcium cells are equipped with two electrolyte withdrawal tubes which are installed in the diagonal corners of

the cell. These permit the taking of specific gravity readings

at a point about one-third from the top of the plates. (See

Section 11.1). Refer to Figure 3.

A flexible shipping cap and shipping plug is installed on each

withdrawal tube. The cap may be removed and discarded

after neutralizing or left in place as dust covers. The red plug

should be discarded.

Plastic Numerals

(See Page 16)

Plastic cell numerals and battery terminal polarity labels are

provided for 12-cell batteries of 40 ampere hours and over.

The positive terminal cell is usually designated as cell #1 in

the series string.

Battery-to-Charger Connection

The positive (+) terminal of the battery should be connected

to the positive (+) terminal of the charger and the negative

(-) terminal of the battery to the negative (-) terminal of the

charger.

CAUTION!

BEFORE DISPOSING OF FLEXIBLE PLASTIC

CAPS OR SCREW-TYPE SHIPPING CAPS,

NEUTRALIZE ANY ELECTROLYTE ON THEM

IN A BAKING SODA - WATER SOLUTION TO

PREVENT INJURY TO ANYONE HANDLING

THESE DISCARDED ITEMS.

Battery Warning Statement and Nameplate

(See Page 1)

A nameplate is shipped with the parts for each battery system. It has a peel-off backing to allow mounting on or near

the battery. Nameplate information should be completed by

the installer at the time of the initial charge and start of battery operation. The installer must make the contents of the

Battery Warning Statement known to all personnel in the

vicinity of the battery.

6

Page 10

SECTION 8

8.0 Initial Charge

Batteries lose some charge during shipment as well as during

the storage period prior to installation. The battery should be

installed and given its initial charge as soon after receipt as

possible. At the completion of initial charge, record voltage

and specific gravity of each cell while still on charge and retain

records for future reference per Section 14.0.

8.1 Constant Voltage Method

Constant voltage is the principal method to give the initial

charge, as most modern chargers are of the constant voltage design. In addition, some systems have equipment with

voltage limitations making the use of constant current charging undesirable.

Determine the maximum voltage that may be applied to the

system equipment. The voltage divided by the number of

cells connected in series will establish the maximum voltage

per cell that may be used.

Establish whether the battery is of lead-antimony or leadcalcium construction by referring to type on cell name plate

and compare this with the proper

For lead-antimony types, refer to Table A and for lead-calcium types refer to Table B to obtain various voltages and

associated time periods recommended. Select the highest

voltage the system will allow, to perform the initial charge in

the shortest period of time.

The recommended time periods are considered minimum.

Raise the voltage to the maximum value permitted by the

system equipment. When charging current has tapered and

stabilized (no further reduction for 3 hours), charge for the

hours shown in the appropriate table and for the battery temperature, at the time of stabilization, until the lowest cell volt

age ceases to rise.

started during the latter 10% of the applicable time period to

determine lowest cell in battery.

Recommended Voltages and Time Periods

NOTE: Time Periods listed in tables A and B are for cell

Cell Volts

2.24 200 —

2.27 150 —

2.30 120 —

2.33 90 146

2.36 75 129

2.39 60 97

2.42 — 73

2.45 — 54

2.49 — 36

2.50 — 30

temperatures from 70°F (21°C) to 90°F (32°C). For temperatures 55°F (13°C) to 69°F (20.5°C) double the number of

hours. For temperatures 40°F (4°C) to 54°F (12°C) use four

times the number of hours.

Monitoring of cell voltages should be

INITIAL CHARGE

TABLE A

Lead-Antimony Types

Time-Hrs. Time-Hrs

1.215 1.250

sp. gr. sp. gr.

GNB sales literature.

TABLE B

Lead-Calcium Types

Time-Hrs. Time-Hrs. Time-Hrs.

1.215 1.250 1.300

Cell Volts

2.24 444 ——

.27 333 ——

2

2.30 210 ——

2.33 148 333 —

2.36 100 235 400

2.39 67 160 267

2.42 48 108 182

2.45 38 73 125

2.48 36 55 83

2.50 32 44 60

sp. gr. sp. gr. sp. gr.

8.2 Initial Charge — Electrolyte Levels

During the initial charge, there will be an increase in the

electrolyte levels and they may go above the high level mark.

(See Section 3.2). This is due to gases, that were lost during

transportation or standing in storage, being restored to the

cells. Do not remove any electrolyte even though levels

may be above high level. When battery is placed on floating

charge (See Section 9.2). the electrolyte levels should return

close to the high level line.

Removal of electrolyte during the initial charge with subsequent restoration with water of levels which have fallen following placement on float charge mode could result in variations or sub-normal specific gravity values.

SECTION 9

-

9.0 Operation

9.1 Floating Charge Method

In this type of operation, the battery is connected in parallel

with a constant voltage charger and the critical load circuits.

The charger should be capable of maintaining the required

constant voltage at battery terminals and also supply a normal connected load were applicable. This will then sustain

the battery in a fully charged condition and also make it

available to assume the emergency power requirements, in

the event of an AC power interruption or charger failure.

9.2 Float Charge — Float Voltages

The following are the float voltage ranges recommended for

the various types of batteries. Select any “volts per cell”

value within the range listed that will result in the series

string having an average volts per cell equal to that value.

Do not interchange voltage ranges from one type to another.

7

Page 11

TABLE C

Recommended Float Voltages

Lead-Antimony Types:

Nominal 1.215 sp. gr. 2.15 to 2.17 VPC

Nominal 1.250 sp. gr. 2.19 to 2.23 VPC

Lead Calcium Types:

Nominal 1.215 sp. gr. 2.17 to 2.25 VPC

Nominal 1.250 sp. gr. 2.23 to 2.33 VPC

ominal 1.300 sp. gr. 2.28 to 2.37 VPC

N

Modern constant voltage output charging equipment is recommended for the floating charger method of operation of

GNB stationary type batteries. This type of charger, proper-

ly adjusted to the recommended float voltages, together with

adherence to recommended maintenance procedures, will

assist in obtaining consistent serviceability and optimum life.

After the battery has been given its initial charge (see

Section 8.0), the charger should be adjusted to provide the

recommended float voltage (see Table C) at the battery terminals. For example, a 60-cell lead antimony battery should

have 130 volts maintained at its terminals. . . 60 cells x 2.17

volts per cell (V.P.C.) = 130 volts.

When the cell voltage reaches 2.33, the charge rate should

be reduced to the normal finish charge rate. The finish

charge rate is defined as amperes

to 5% of the cell’s 8-hour capacity in ampere hours. For

example, if the cell has an 8-hour capacity of 1680 AH, its

finish rate is 84 amperes. The charge should be stopped

when the specific gravity is ten (.010) points below the normal fully charged value.

The battery is now available for the next discharge requirement. The battery should be given an equalizing charge

monthly by continuing the regular charge until there is no

increase in specific gravity of the pilot cell for three hours.

when using the finish charge rate.

equal in numerical value

9.5 Recharge

All batteries should be recharged as soon as possible following a discharge (within 8 hours). With constant voltage

chargers, this will be accomplished automatically. However,

to recharge in the shortest period of time, raise the charger

output voltage to the highest value which the connected system will permit. Do not exceed those voltage values listed in

Table D or Table E on page 9.

Do not use voltages for lead-antimony types higher than

shown in table C, as excessive water consumption and

reduced battery life will result.

Lead-calcium types may be floated at any of the voltage values (Table C) shown for a particular nominal specific gravity. Use the lower VPC value in the appropriate nominal specific gravity group, where system equipment voltage limitations will not permit higher values. The use of higher VPC

values may make it unnecessary to give an equalizing

charge. However, the use of higher float voltages where

high ambient temperatures prevail may result in reduced

battery life.

9.3 Voltmeter Calibration

Panel and portable voltmeters used to indicate battery float

voltages should be accurate at the operating voltage value.

The same holds true for portable meters used to read individual cell voltages. These meters should be checked

against a standard every six months and calibrated when

necessary.

9.4 Cycle Method of Operation

This method is recommended for lead antimony type cells

Lead-calcium cells should not be cycle operated.

only.

In cycle operation, the degree of discharge will vary for various applications. Therefore, the frequency of recharging

will also vary. The recharge is conducted by manually starting the charge, generally using the normal finish rate. The

amount of charge necessary depends on the number of

ampere hours discharge. If a shorter recharge period is

desired, higher charge rates equal to the eight-hour rate of

discharge may be used when the battery is more than 25%

discharged and the cell voltage on charge is below 2.33

volts.

SECTION 10

10.0 Equalizing Charge

An equalizing charge is a special charge given a battery

when non-uniformity in voltage or specific gravity has developed between cells. It is given to restore all cells to a fully

charged condition using a charging voltage higher than the

normal float voltage and for a specified number of hours, as

determined by the voltage used.

Non-uniformity of cells may result from low floating voltage

due to improper adjustment of the charger or a panel voltmeter which reads incorrect (higher) output voltage. Also,

variations in cell temperatures greater than 5°F (2.78°C) in

the series string at a given time, due to environmental conditions or rack arrangement, can cause low cells.

10.1 Equalizing Frequency

The following guidelines cover lead-antimony and leadcalcium types. Recommendations not applying to all types

will be so designated.

A.

An equalizing charge should be given quarterly or as

required by conditions in the following paragraphs (Note:

lead-calcium types at nominal 1.215 sp. gr. floated 2.20

V.P.C., to 2.25 V.P.C., nominal 1.250 sp. gr. floated at 2.27

V.P.C. to 2.33 V.P.C. and nominal 1.300 sp. gr. floated at

2.31 V.P.C. to 2.37V.P.C. may not require equalizing charges).

B. Equalize when the temperature corrected specific grav-

ity of the pilot cell (or any cell for the quarterly reading)

is more than 10 points below its full charge value. (See

Section 11.2)

C. Equalize when the floating voltage of the pilot cell (or

any cell for the quarterly reading) is below 2.13 volts

(nominal 1.215 sp. gr.), 2.18 volts (nominal 1.250 sp.

gr.) and 2.23 volts (nominal 1.300 sp. gr.) or more than

.04 volts below the average for the battery.

8

Page 12

D. Equalize to complete a recharge of the battery in a min-

imum length of time following an emergency discharge.

E. If accurate quarterly records are maintained (See

Section 14.0) and the individual cell voltages and teperature corrected specific gravities show no increase

instead from the previous quarterly readings, equalizing

ay be deferred. (See Section 11.2)

m

F. Equalize once a year even though preceding conditions

did not require. (Lead-calcium types floated p er paragraph A, may not

require annual equalizing).

10.2 Equalizing Charge Method

Constant voltage charging is the preferred method for giving

an equalizing charge. Determine the maximum voltage that

may be applied to system equipment. This voltage, divided

by the number of cells connected in series, will establish the

maximum voltage per cell that may be used to perform the

equalizing charge in the shortest period of time.

For lead-antimony types, refer to Table D and for lead-calcium type, refer to Table E to obtain various voltage and associated time period recommended.

The recommended time periods below are considered mini

Raise the voltage to the maximum value permitted by

mum.

the system equipment. When charging current has tapered

and stabilized (no further reduction for three hours), charge

for the hours shown in the appropriate table and for the battery temperature, at the time of stabilization, until the lowest

cell voltage ceases to rise. Monitoring of cell voltages

should be started during the latter 10% of the applicable

time period to determine the lowest cell in battery.

EQUALIZING CHARGE

Recommended Voltages and Time Periods

NOTE: Time periods listed in Tables D and E are for cell

temperatures from 70°F (21°C) to 90°F (32°C). For temperatures 55°F (13°C) to 69°F (20.5°C) double the number of

hours. For temperatures 40°F (4°C) to 54°F (12°C) use four

times the number of hours.

10.3 Equalizing Individual Cells

When only a few cells in a battery require equalizing, and

system voltage limitations do not permit raising the battery

voltage up to a recommended equalizing voltage, a separate

voltage regulated charger may be used on the affected cells.

The charger must have complete AC line isolation and

should be paralleled across the below normal cell. Select

the equalizing voltage values listed in Tables D or E for the

type cell involved. The hours of equalizing may have to be

increased from listed values before stabilization of cell voltage and specific gravity is achieved, especially where below

normal condition has existed for a prolonged period.

-

WHEN INDIVIDUAL CHARGER IS REMOVED

FROM CELL WHICH HAS BEEN EQUALIZED,

A DROP IN VOLTAGE BELOW THE AVERAGE

STRING VOLTAGE MAY OCCUR. THIS IS

NORMAL, DUE TO THE EXCESS INTERNAL

CELL GASES PRESENT. ASTHESEEXCESS

GASES DISLODGE FROM INTERNAL CELL

COMPONENTS, THE CELL VOLTAGE WILL

RISE GRADUALLY, WHICH MAY TAKE FROM

TWO TO FOUR WEEKS.

CAUTION!

TABLE D

Lead-Antimony Types

Time-Hrs. Time-Hrs.

1.215 1.250

Cell Volts

2.24 80 —

2.27 60 —

2.30 48 —

2.33 36 58

2.36 30 51

2.39 24 39

2.42 — 29

2.45 — 26

2.48 — 24

Lead-Calcium Types

Time-Hrs. Time-Hrs. Time-Hr.s

1.215 1.250 1.300

Cell Volts

2.24 222 ——

2.27 166 ——

2.30 105 ——

2.33 74 166 —

2.36 50 118 200

2.39 34 80 134

2.42 — 54 91

2.45 — 36 62

2.48 ——42

sp. gr. sp. gr. sp. gr.

sp. gr. sp. gr.

TABLE E

10.4 Equalizing Charge—Electrolyte

Levels

A battery which has electrolyte levels at the high level line

while on a float and then placed on equalizing charge will

result in a rise in electrolyte above the high level line. This

is a normal condition. DO NOT

levels will return to their former condition when the battery is

returned to normal float. Removal of the electrolyte with

subsequent restoration to proper electrolyte levels by water

addition could result in variations or sub-normal specific

gravity values.

remove any electrolyte as the

SECTION 11

11.0 Specific Gravity

In a lead-acid cell, the electrolyte is a dilute solution of water

and sulfuric acid. Specific gravity is a measure of the weight

of acid in the electrolyte as compared to an equal volume of

water. Therefore, electrolyte with a specific gravity of 1.215

means it is 1.215 times heavier than an equal volume of

water which has a specific gravity of 1.000.

9

Page 13

11.1 Hydrometer Readings

Specific gravity is used in determining a cell’s state of

charge. It decreases as the cell discharges and increases

as the cell is charged; reaching its original value when the

cell is fully charged. Specific gravity is expressed to the third

decimal place (1.215) and is measured by a hydrometer

float enclosed in a glass barrel/rubber bulb syringe. Draw

sufficient electrolyte into the barrels holding the syringe vertical and with no hand pressure on bulb; so that float is freely

floating without touching sides or top of syringe.

The gravity is read on the hydrometer scale at the flat surface of the electrolyte. (See Figure 5).

When taking a hydrometer reading, the base of the hydrometer syringe should be pressed firmly against the tube

opening to prevent back splash of electrolyte. Fill and empty

the hydrometer at least once in each cell before reading.

This will give a more accurate reading of the average electrolyte density.

Never inter-mix usage of hydrometers on lead-antimony or

lead-calcium types as cell contamination will result. Assign

hydrometers for exclusive use on one type only.

11.2 Correction for Temperature

When taking specific gravity readings, corrections must be

made for variations in temperature of the electrolyte. For

each 3°F (1.67°C) in temperature of the electrolyte above

77°F (25°C) add one point (.001) in specific gravity to the

observed hydrometer readings; and for each 3°F (1.67°C) in

temperature below 77°F (25°C) subtract one (.001) in specific gravity from the observed hydrometer reading.

Example:

Reading

Hydrometer Cell Corrected to

Reading Temperature Correction 77°F (25°C)

1.213 sp. gr 68°F (20°C) -.003 points= 1.210 sp. gr.

1.207 sp. gr. 86°F (30°C) +.003 points= 1.210 sp. gr.

1.204 sp. gr. 95°F (35°C) +.006 points= 1.210 sp. gr.

Figure 5

Clean the hydrometer glass barrel and float with soap and

water as required for ease of reading and float accuracy.

When recharging a lead-calcium cell, the specific gravity

reading lags behind the ampere hour input due mainly to the

very low end of charge currents. Mixing of the electrolyte is

slow due to the small amount of gas generated; so the gravity readings do not reflect the actual state of charge. A similar condition exists after water additions. Therefore, meaningful gravity readings can only be obtained at the top of the

cell after an equalizing charge or after six weeks on float.

For this reason, most

trolyte withdrawal tubes to permit sampling of the electrolyte

at a point one third down from the top of the plates. A long

rubber tip on the hydrometer is inserted into the tube to provide an average value of cell specific gravity and a more

accurate indication on the state of the charge.

GNB lead-calcium cells have elec-

11.3 Correction for Electrolyte Level

The loss of water from the electrolyte due to evaporation as

well as conversion of the water to hydrogen and oxygen by

charging current also effects the specific gravity value. For

example: A fully charged cell with a correct high level at

77°F (25°C) will have a nominal specific gravity of 1.215.

When the electrolyte level has been reduced from evaporation and charging by 1/4”, the specific gravity will be approximately 6 points (.006) higher or 1.221@ 77°F (25°C).

Therefore when taking hydrometer readings, the electrolyte

level referenced to the high level line should be recorded for

proper evaluation of the specific gravity value. This applies

when taking a pilot cell reading or for 10% of the cells when

taking a quarterly set of readings.

11.4 Specific Gravity Range

GNB stationary batteries are furnished with a nominal fully

charged specific gravity of 1.215@ 77°F (25°C).

For special applications, nominal specific gravity such as

1.250 or 1.300 @ 77°F (25°C) may be used.

The specific gravity may range± .010 points within a battery

for any of the nominal values @ 77°F (25°C) with the electrolyte level at the high level line and still be considered satisfactory.

SECTION 12

12.0 Cell Voltage Variation

The tabulation on the following page indicates the normal cell

voltage variation that may exist with the battery on float and

no greater than a 5°F (2.78°C) variation in cell temperature.

10

Page 14

NORMAL VOLTAGE RANGE

Average

Type

Lead-Antimony

Nominal 1.215 sp. gr. 2.15 to 2.17 V.P.C. ± .04 V.P.C.

Nominal 1.250 sp. gr. 2.19 to 2.23 V.P.C. ± .04 V.P.C.

Float Voltage Variation

A slight amount of electrolyte may be lost each time a specific

gravity reading is taken, even though it is recommended that all

electrolyte in the hydrometer be returned to the cell after reading. Therefore it is suggested that the pilot cell be changed to

another cell annually to provide a representative specific gravity

indicator for the battery.

Lead-Calcium

Nominal 1.215 sp. gr. 2.17 to 2.25 V.P.C. ± .05 V.P.C.

Nominal 1.250 sp. gr. 2.23 to 2.33 V.P.C. ± .05 V.P.C.

Nominal 1.300 sp. gr. 2.28 to 2.37 V.P.C. ± .05 V.P.C.

12.1 Cell Voltage Variation

Damp Covers

Cell voltage variation can also be the result of damp cell cover

tops. Spilled electrolyte when taking hydrometer readings can

result in parasitic currents paths across the tops of cell covers.

This reduces the float current through the cell resulting in voltage variations. See Section 18.0 - Battery Cleaning —to correct

damp cover condition.

12.2 Cell Voltage Temperature Correction

To properly analyze cell uniformity within the string, cell voltages

should be corrected for cell electrolyte temperature. Cell voltage

variation that may have developed since a previous quarterly set

of readings may be due to cell temperature variations within the

string that may have resulted from a change in ambient conditions. Therefore, correcting cell voltage for cell temperature may

make it unnecessary to apply an equalizing charge which otherwise had been believed necessary. See Section 10.1 Equalizing Frequency.

12.3 Correction Factor

The temperature correction factor for cell voltage equals 0.003

volts for each degree fahrenheit (0.0055V/C°) using a base 77°F

(25°C). The correction is added to the measured cell voltage

above 77°F (25°C) and subtracted below 77°F (25°C).

Example: Measured cell voltage = 2.19V @ 87°F(30.5°C) cell

temperature. Correction = 10°F x .003V (3.5°C x .0055V) =

.03V. Therefore, corrected cell voltage = 2.19V + .03V = 2.22

volts.

If the cell temperature in the example had been 67°F (19°C), the

correction would be .03 volts which is subtracted from the measured voltage of 2.19V. The corrected cell voltage = 2.19V - .03V

= 2.16V.

SECTION 13

13.0 Pilot Cell

A pilot cell is selected in the series string to reflect the general condition of all cells in the battery regarding specific

gravities, float voltage and temperature. It serves as an indicator of battery condition between scheduled overall individual cell readings.

SECTION 14

14.0 Records

A complete recorded history of the battery operation is

required. Good records will also show when corrective

action may be required to eliminate possible charging, maintenance or environmental problems.

Data should be recorded on Stationary Battery Maintenance

Report shown on page 15. Report headings should be filled

in completely on the date of installation.

The following data should be read and permanently recorded for review by supervisory personnel.

A. Upon completion of the initial charge and with the battery

floating at the desired float voltage for one week, read

and record individual cell voltages, connection resistances, specific gravities [corrected to 77°F (25°C)],

ambient temperature plus cell temperatures and electrolyte levels for 10% of the cells. The cell temperature

readings should be from each step or tier of the rack to

reflect temperature range of the battery.

This first set of readings will be the basis for comparison

with subsequent readings to reflect possible operating

problems and the need for corrective action.

B. Monthly - Observe the general appearance and cleanli-

ness of the battery. Record battery terminal voltage.

Check electrolyte levels and adjust if necessary. Check

for cracks in cells and leakage. Note any evidence of corrosion at terminals and connectors. Record pilot cell voltage, specific gravity and temperature.

C. Quarterly - Supplement the monthly inspection and

record keeping with these additional measures. Check

and record the specific gravity and voltage of each cell.

Check and record the electrolyte temperature of one cell

on each level of individual racks.

D. Annual - Supplement quarterly reports with these extra

procedures. Make a detailed visual inspection of each

cell. Tighten all bolted connections to the specified

torque values. Take and record connection resistances

of each cell to cell, cell to terminal, inter-level and load

connections. Remake any connections that are more

than 20% above installation base value. Check integrity

of the rack.

E. Any time the battery is given an equalizing charge (see

Section 10.1), an additional set of individual cell readings

11

Page 15

should be taken after battery has been returned to normal

float for one week. These will serve as an updated basis for

comparison with future readings.

F. Record dates of any equalizing charges as well as total

quantity of water when added. Also record any maintenance and/or testing performed.

The foregoing frequency of record taking may have to

be modified somewhat to suit local requirements.

See Page 16 for Battery nameplate

SECTION 16

16.0 Tap Connections

It is not recommended that tap connections be used on a

battery, as possible unbalance between groups of cells may

result. This can cause overcharging of the untapped group

of cells and undercharging of the tapped cells supplying the

load. This condition can cause unsatisfactory operation and

reduced battery life.

SECTION 17

SECTION 15

15.0 Water Additions

There are two conditions in the operation of batteries which

cause a reduction in the amount of water in the electrolyte,

resulting in a lowering of the electrolyte level. These are

normal evaporation and the conversion of water into hydrogen and oxygen gases by the charging current. These gases

are liberated through the cell vents. Periodically, this water

loss must be replaced with approved or distilled water to

maintain the electrolyte level at the mid point between the

high and low level lines.

If suitability of the local water supply for use in storage batteries is questionable, contact your nearest

tative for instructions regarding procedure for submitting a

sample for analysis. A report will be rendered as to whether

or not the water is suitable.

If water is to be stored in containers they should be clean

and of non-metallic material; such as: glass, hard rubber,

porcelain or plastic.

Infrequently used water lines should be purged to remove

accumulated impurities, thus preventing their introduction

into the battery.

Water additions should be scheduled prior to an equalizing

charge so that mixing with the electrolyte occurs. Also at

unheated installations, arrange water additions when battery temperature is above 50°F (10°C).

Never introduce “battery additives” into a

15.1 Water Purity

The maximum allowable limits of impurities in the water

used in

Distilled water or deionized water satisfying the above

requirements may be used.

GNB stationary batteries shall be as follows:

Total solids 500 ppm

Fixed solids 350ppm

Organic & volatile matter 200ppm

Iron as Fe 4.0 ppm

Manganese as Mn 0.007 ppm

Nitrates as N02 15.0 ppm

Ammonia as NH4 5.0 ppm

Chlorides as CL 25.0 ppm

GNB represen-

GNB battery.

17.0 Temporary Nonuse

An installed battery that is permitted to stand idle for a period of time should be treated in the following manner. With

the battery on normal float, add approved water to cells to

bring electrolyte level to the high level line. Give the battery

an equalizing charge per Section 10.2. Following completion of the equalizing charge, open connections at the battery terminals to separate charger and load circuit from battery.

Every three months for lead antimony and every six months

for lead calcium, temporarily connect battery to charger and

give it an equalizing charge.

To return to normal service, re-connect all open connections, give equalizing charge and then return battery to normal float voltage.

SECTION 18

18.0 Battery Cleaning

CAUTION

DO NOT CLEAN PLASTIC CELL JARS OR

COVERS WITH SOLVENTS, DETERGENTS, OILS OR SPRAY TYPE CLEANERS, AS THESE MATERIALS MAY CAUSE

CRAZING AND CRACKING OF THE PLASTIC MATERIALS

18.1 Styrene Acrylonitrile Containers

with Butadiene Styrene Covers

and PVC Containers and Covers

Periodically, clean cell jars and covers with a water dampened cloth to remove accumulated dust. Cell parts damp

with electrolyte should be neutralized with baking sodawater solution (1 lb. of soda per gallon of water). Apply with

cloth dampened with the solution, making sure none is

allowed to enter the cell. Continue to neutralize until fizzing

action ceases, then wipe area with a water dampened cloth

to remove soda solution. Wipe dry with a clean cloth.

18.2 Polycarbonate Containers

and Covers

Cells with containers and covers made from polycarbonate

plastic should be cleaned ONLY with a WATER dampened

12

Page 16

cloth. Any surface that is damp with electrolyte should be

neutralized with a baking soda—water solution (1 lb. of baking soda per gallon of water). DO NOT USE AMMONIA,

SODIUM HYDROXIDE OR ANY STRONG ALKALIES.

SECTION 19

19.0 Connections

Battery terminal connections should be corrosion free and

tight to provide satisfactory operation while supplying emergency power and when on floating charging.

Visual monitoring of all connections should be made quarterly. When corrosion is observed on any connection, DO

NOT retorque. Retorquing does not improve electrical

integrity but only restores mechanical compression. Any

connection suspected of having corrosion should be disassembled, cleaned and neutralized. All post contact surfaces, intercell connectors, terminal plates, cable lugs and

hardware should be neutralized using a solution of baking

soda (1 lb./gallon water). After allowing to dry, all contact

surfaces should be burnished using 3M Scotch Brite scouring pads or a brass suede brush. Stubborn oxidized coatings on solid lead parts may be removed using a narrow

CAUTION!

1 DO NOT USE POWER WIRE BRUSH AS

THIS MAY REMOVE LEAD PLATING

EXPOSING COPPER OR CAUSE RIPPLING OF LEAD CONTACT SURFACES.

2.. DONOT USE PAINT SCRAPER ON POSTS

WITH COPPER INSERTS. INTERCELL CONNECTORS OR TERMINAL PLATES AS LEAD

PLATING WILL BE REMOVED EXPOSING

COPPER.

paint scraper.

After contact surfaces are burnished, a thin coating of NOOX-ID grease should be applied to all contact surfaces and

hardware. The connectors and hardware should then be

reassembled and torqued per Section 7.6 - Connecting

Cells.

It is important that properly prepared contact surfaces be

coated with a thin film of NO-OX-ID grease to reduce possibility of oxidation or corrosion. Tests reveal that this will also

prevent measurable increase in the connection resistance.

19.1 Connection Resistance

Electrical integrity of connections can be objectively established by measuring the resistance of each connection.

These resistances are typically in the microhm range.

Meters are available which determine connection resistance

in microhms by measuring voltage drop upon the application

of a fixed direct current (DC) through the external cell connections. Some precautions must be observed to get consistent and meaningful values, however, and these are

described in Section 19.3.

Resistance measurements or microhm measurements

should be taken at the time of the installation and annually

thereafter. Initial measurements at installation become the

benchmark values and should be recorded for future moni-

oring of electrical integrity.

t

Specific values of connection resistance vary with cell type,

quantity of connectors, etc. It is important that the benchmark value for all similar

than 10% or 5 microhms, whichever is greater, above the

average resistance of all such connections in the battery. If

any connection resistance exceed the average by more than

10% or 5 microhms, whichever is greater, the connection

should be remade so that an acceptable benchmark value

is established. Benchmark values for connection resistances should also be established for terminal plates, where

used, as well as cable connections. Benchmark values

should preferably be established upon installation. However,

if that was not done, they may be established later provided

the special procedure described below is followed.

Disconnect the battery from the charger and load and disassemble at least

Clean, neutralize and burnish these connection components

as though they had corrosion (See Section 19.0)

Reassemble each connection per Section 7.7 and determine its resistance. Measure the resistance of all similar

connections in the battery. If any connection resistance

exceeds the average of the three remade connections by

10% or 5 microhms, whichever is greater, that connection

should be remade to establish an acceptable benchmark

value.

All benchmark values should be recorded. Annually, all connection resistances should be remeasured. Any connection

which has a resistance value more than 20% above the

benchmark value should be corrected.

Increase in connection resistance of more than 20% above

the recorded benchmark definitely indicates a degrading

connection. Such degradation may be caused by corrosion

(See Section 19.0) or by relaxation in hardware torque

value. If there is no sign of corrosion, the higher resistance

at the connection may be corrected by retorquing (See

Section19.2). If connection resistance is reduced to within

20% of the benchmark value, no further action will be necessary. Failure to restore resistance to an acceptable value

will necessitate reworking the connection.

Maintaining electrical integrity of connections is important

as poor connection will result in reduced battery output and

in extreme cases may cause melted cell posts, circuit interruptions or battery fires.

connections should be no greater

three (3) of the intercell connections.

19.2 Retorquing Connections

Retorquing of connections should be performed annually

(See Section 9, 14) and when connection resistances have

increased to more than 20% over the benchmark.

Retorquing should not be done if visual inspection shows

evidence of corrosion. Retorquing when corrosion is present only restores mechanical compression but will not

improve electrical integrity.

13

Page 17

Tests reveal that a reduction in the original torque value of

30% still provides a functional electrical connection if there

is no corrosion between contact surfaces.

etorquing of connections should always be to the recom

R

mended value (See Section 7.7).

CAUTION!

TOO FREQUENT RETORQUING OF

ONNECTIONS IS NOT RECOMMEND-

C

ED AS THIS WILL RESULT IN DISTORTION OF CELL POSTS, CONNECTORS,

ETC., THUS DEGRADING RATHER

THAN IMPROVING THE CONNECTIONS.

19.3 Connection Resistance

Measurements

Connection resistances are very small, usually in microhms.

Therefore, precautions must be observed so that the measured values are meaningful and not misleading. Different

connector hook-ups require that the measurement technique allows for these differences.

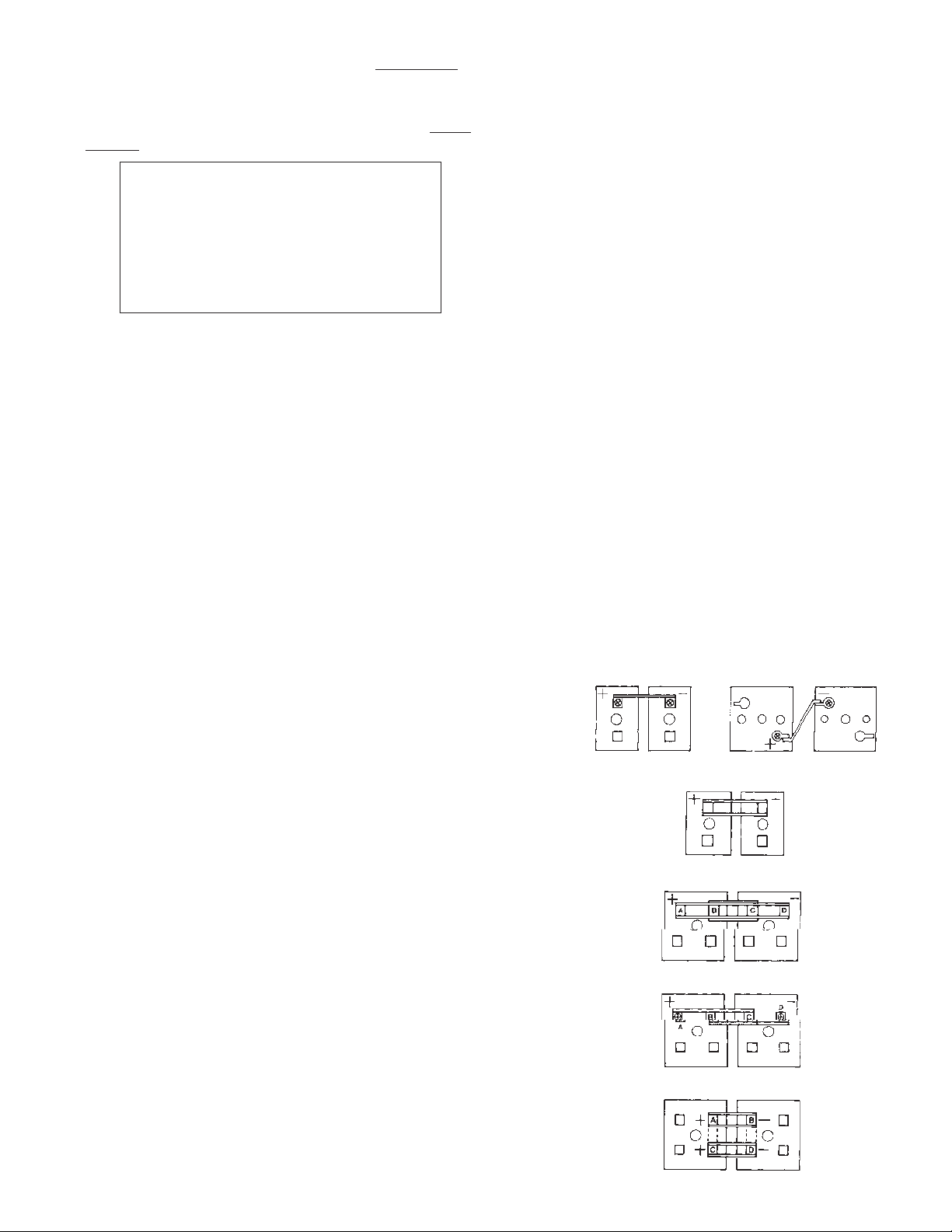

(i) Single Connector Hook-ups. (Figure 6)

When measuring the resistance of single connector hook-ups between adjacent cell posts (or in the

case of flag terminals between multi-cell units), the

probe point locations must be at the same location

for each similar type connection. If the probe part

departs from the center point indicated by “X” in

Figure 6, the measured resistance value can vary

due to either an increase or decrease in the lead

mass included in the measuring points.

When con- ducting subsequent monitoring of

connection resis-tance, it is important that the same

probe point

locations are used so that any measured increase

(or decrease) is a true increase (or decrease) due to

connection degradation and not due to using a different probe point location.

(iv) Four Post,Two Connector Staggered Hook-Ups.

(Figure 9).

C

ells with four post staggered connector hook-ups

r

-

equire two step measurement as described above in

(

iii). In addition, the probe point locations for points A

a

nd D (See Figure 9) must be centered as described

a

bove in (i).

(

v) Four Post, Connector Parallel Hook-Ups.

(

Figure 10)

Cells arranged end-to-end have parallel current paths

above and below the cell covers and require that resistance measurement make allowance for the same. The

current paths above the cover are provided by the connectors and the path under the cover is provided by the

busbars (shown by dotted lines in Figure 10). Most

resistance meters apply 10 amperes DC to the connections being monitored. If this was done between posts

A and B in Figure 10, the current will divide through the

busbars between AB and CD and the resistance value

will be about half of the actual value, provided all connections are good. If the process is repeated for posts

C and D and the two resistance values are compared,

the difference, if any, indicates differences in the two

parallel paths as well as poor connections at the post

connector interfaces. A better and preferred technique

is to apply the 10 amperes DC to posts A and D such

that equal current paths are provided. Then, the differences in readings across AB and CD will reflect connector interface problems in either of the two external

intercell connections. Both intercell connections should

be reworked as described in Section 19.0.

Figure 6 Single connector hook-ups

(ii) Parallel Connector Hook-Ups.

(Figure 7)

Parallel paths exist in this hook-up and measurement of connection resistance include all four connector post interfaces. The location of probe points

is not critical here because of the existence of parallel paths. An increase (decrease) in the lead mass

between post and connector interface on one side is

cancelled by an equal decrease (increase) in the

mass on the opposite side.

(iii) Four Post, Four Connector In-Line Hook-Ups.

(Figure 8)

Cells with four post connector hook ups require two

measurements to monitor all eight post-connector

interfaces. Measurement is made in two steps—

First between points A and C and then between

points B and D. The measured values should be the

same. Values appreciably different (5 micrhoms or

more) require reworking of connections as

described in Section 19.0.

Figure 7 Parallel connector hook-ups

Figure 8 Four post, four connector in-line hook-ups

Figure 9 Four post, two connector staggered post hook-ups

Figure 10 Four post, four connector parallel hook-ups

14

Page 18

A Division of Exide Technologies

GNB Industrial Power

GB-1000F

15

Page 19

STATIONARY BATTERY PLASTIC CELL NUMERAL APPLICATION

A Division of Exide Technologies

To insure proper adhesion of the pressure sensitive plastic

cell numerals, and polarity markings supplied with your GNB

Stationary Battery, the following procedure should be followed:

. Numerals and polarity markings should not be applied

1

until after the cells have been installed on the rack. It is

recommended that they be applied to jar surfaces only,

and not to cell covers or rack rails.

2. Clean the plastic jar surface, in the area where the

numeral is to be located, by using a cloth dampened

with a washing soda solution. Immediately dry the area

using a soft dry cloth to remove residual washing soda.

CAUTION!!

they may cause damage to the plastic jar material.

3. It is a general practice to designate the positive terminal

cell as #1 with succeeding cells in series in ascending

order.

Do not use any solvent type materials as

TYPICAL BATTERY NAMEPLATE

4. Numerals are shipped mounted on a plastic backing

strip. They are easily removed by peeling back the plastic strip. Keep finger contact with adhesive backing on

numeral to a minimum.

. Locate and place numeral on side of jar, being careful

5

that there is no conflict with electrolyte level lines or side

rails of SEISMIC TYPE RACKS. For clean appearance,

exercise care in numeral placement so that all the

numerals are in the same relative position on each cell.

Install polarity markings on the appropriate cells in the

same manner.

6. Following application of cell numerals and polarity markings, use a dry cloth to rub entire surface of each label

to insure proper surface contact.

Note: Design and/or specifications subject to change

without notice. If questions arise, contact your local

sales representative for clarification.

NO. OF CELLS TYPE SERIAL NO.

CAPACITY AMPERE HRS. AT HR. RATE

SPECIFIC GRAVITY

GNB INDUSTRIAL POWER, Aurora, IL 60504

NOTES

16

Page 20

A Division of Exide Technologies

®

GNB Industrial Power –

The Industry Leader.

GNB Industrial Power, a division of Exide Technologies, is a

global leader in network power applications including com-

munication/data networks, UPS systems for computers and

control systems, electrical power generation and distribution

systems, as well as a wide range of other industrial standby

power applications. With a strong manufacturing base in

both North America and Europe and a truly global reach (operations in more than 80 countries) in sales and service, GNB

Industrial Power is best positioned to satisfy your back up

power needs locally as well as all over the world.

GNB Industrial Power

USA – Tel: 888.898.4462

Canada – Tel: 800.268.2698

www.gnb.com

Based on over 100 years of technological innovation the

Network Power group leads the industry with the most recognized global brands such as ABSOLYTE

CLASSIC

SONNENSCHEIN

symbolize quality, reliability, performance and excellence in

all the markets served.

GNB Industrial Power takes pride in its commitment to a better environment. Its Total Battery Management program, an

integrated approach to manufacturing, distributing and recycling of lead acid batteries, has been developed to ensure a

safe and responsible life cycle for all of its products.

®

, MARATHON®, ONYX®, RELAY GEL®,

®

, and SPRINTER®. They have come to

®

, GNB®FLOODED

SECTION 93.10 2013-05

Loading...

Loading...