EX7100 Technical Manual – VHF Fan Assembly

VHF EX7100 Fan Box (Type 8057)

1.0 General

A Fan Box has been designed to assist with the cooling of the PA Heatsink cast ing f or the

VHF EX7100 product range.

The Fan Box consists of a metal enclosur e with two (2) fan assemblies that f its over (and

is bolted to) the existing PA Heatsink. DC Supply for the fans is provided by the existing

DC input socket on the rear of the EX7100 Terminal.

1.0.1 Date of release

All VHF EX7100 Terminals produced aft er 1 May 2001 will include the Fan Box (Product

Code 61-8057-00002). It will be factory-fitted during the manufacturing process.

1.0.2 Terminal Mounting Considerations

The Fan Box fits snugly around the existing PA Heatsink casting and does not adversely

affect the overall width or depth of the EX7100 Terminal but does

affect the height .

The top of the Fan Box will be approximately 40mm above the top cover of t he EX7100

Terminal. However, as it is recommended that a gap of at least 2U (89mm) is left

above/below the EX7100 Terminal and any other equipment, this additional height should

not become a problem for standard 19” Rack mounting.

2.0 Removal Instructions

The following sections detail the steps necessary to rem ove the Fan Box to allow access

to the PA Heatsink casting.

2.0.1 Tools required

> M5 Short Arm Hex Wrench

> Medium sized insulated flat-blade screwdriver

2.0.2 Procedure

1) It is necessary to isolate the EX7100 Term inal f rom any mounting shelf prior to removal of

the Assembly.

(Depending on the leng ths of any antenna, telephone or DC power cables, it will probably

be necessary to remove these to allow unobstructed Terminal access)

2) Switch off the DC supply to the Terminal (if not already removed) and place the Terminal

on a clean, flat surface.

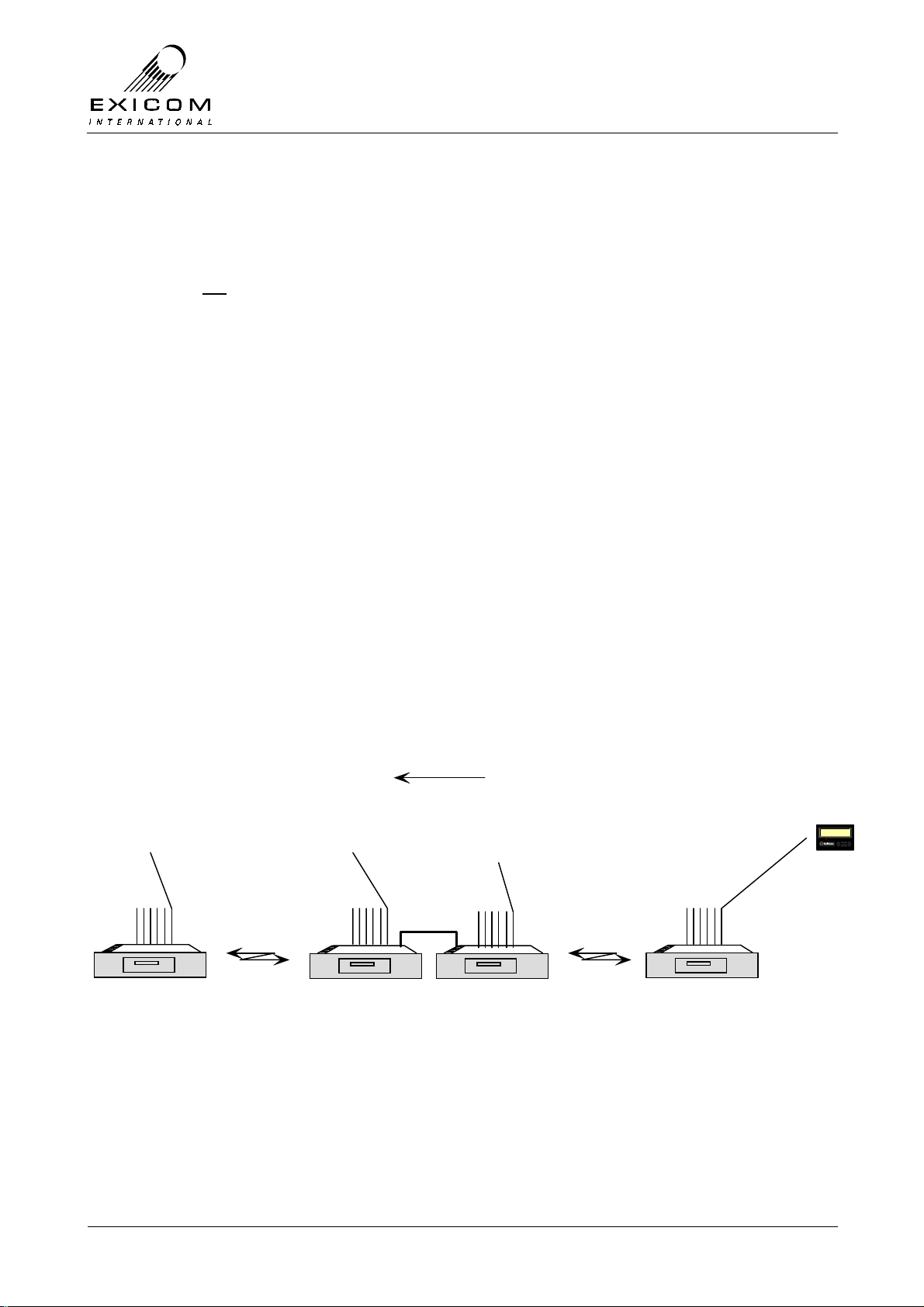

3) Refer to Figure 1 (overleaf) and remove the 2x M6 socket cap screws and washers from

the Fan Box Assembly using the Short arm Hex wrench. The removed screws and

washers should be put to one side for future r eplacem ent.

©2001 Exicom Technologies (1996) Ltd VHF Fan-1 Issue 0 – May 2001

EX7100 Technical Manual – VHF Fan Assembly

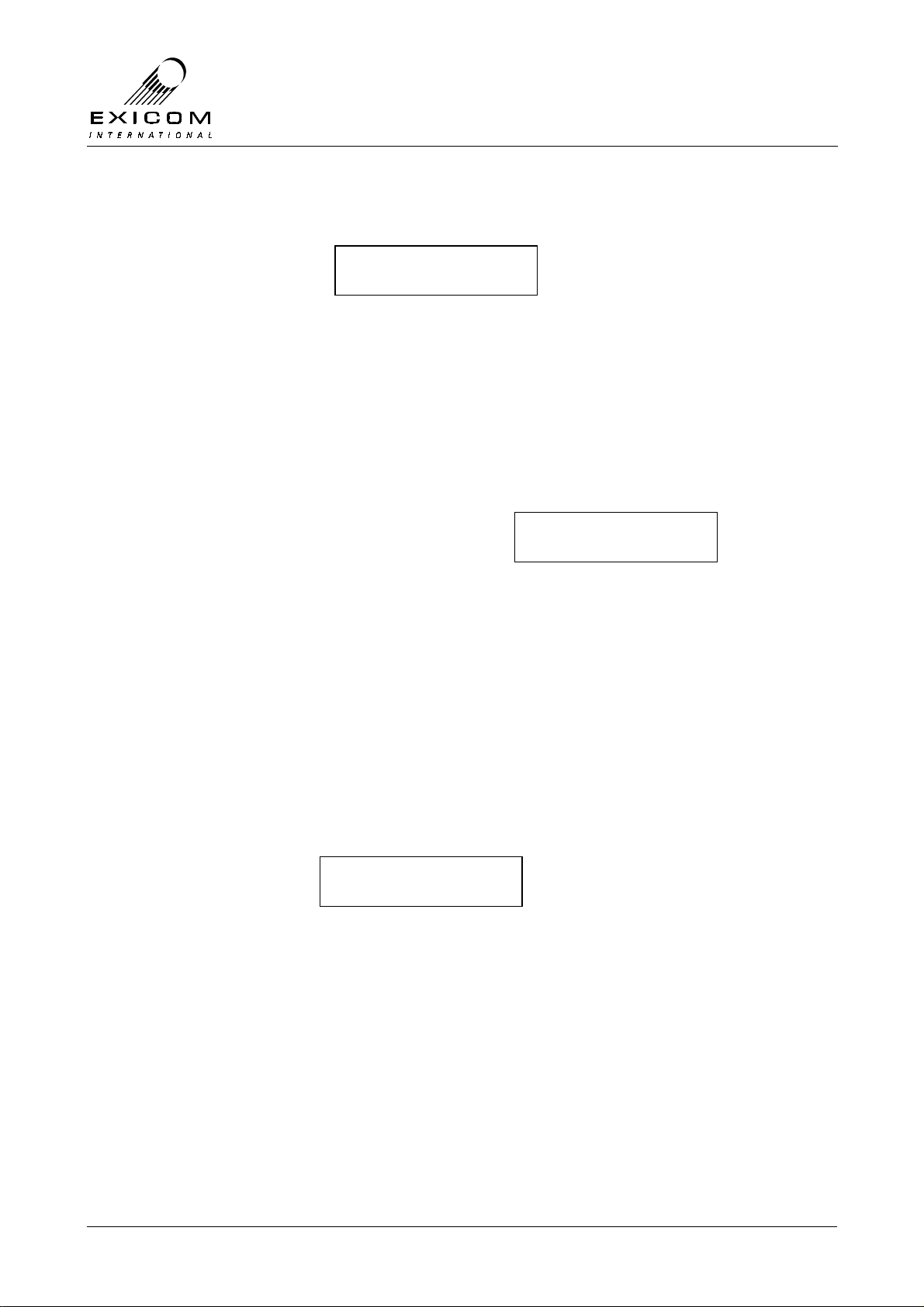

Figure 1: Assembly connected to the EX7100 Terminal

4) Remove the Fan Box DC supply cable from the rear of the EX7100 Terminal, taking

careful note of the existing wire connections f or future re-assembly (the BROWN wire is

connected to the +ve input and the BLUE wire is connected to the –ve input)

5) Carefully remove the Fan Box Assembly from the EX7100 Terminal. Access is now

available to the PA Heatsink casting.

6) Refer to Section 7 of t he EX7100 Technical Manual for further infor mation regarding the

replacement of the Heatsink casting and/or the PA Assembly.

7) Reverse the above-mentioned steps as required t o r e- assem b le t he Fan Box.

©2001 Exicom Technologies (1996) Ltd VHF Fan-2 Issue 0 – May 2001

EX7100 Technical Manual - Mandatory Regulations

The following information outlines the mandatory regulations governing the installation

and operation of the Exicom EX7100 digit al radio link.

Adherence to this information is necessar y to ensure regulatory compliance.

1.0 General Requirements

This equipment shall be configured only with those assemblies as specified in the

Technical Manual and shall only be mounted as instructed.

1.0.1 Danger

The Modem/Controller module contains a lithium bat ter y. Ther e is a danger of explosion if

the battery is incorrectly replaced. Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according t o the manufacturers instructions. Do not recharg e,

disassemble or incinerate.

Mandatory Regulations

1.0.2 Warning

This equipment must only be installed and maintained by service personnel.

1.0.3 Access to the Equipment

The EX7100 digital radio link should be installed in a location or environment that

prevents unauthorised access.

1.0.4 Equipment Port and Connector Classifications

The EX7100 digital r adio link contains various ports and connectors t hat are classified as

either Safety Extra Low Voltage (SELV) or T elecommunication Network Voltage (TNV) as

follows:

SELV TNV

> DC Power Input

> G.703 (3x ports)

> I/O

> Sync Data

> Line Interface Module Connector

> Control

> LMS

> Front Panel Test Pin Sockets

Connect SELV circuits on this equipment

only

to other SELV compliant circuits as

defined in AS/NZS 3260 and IEC950.

©1999 Exicom Technologies (1996) Ltd Regulations-1 Issue 0 – October 2000

Connect TNV circuits on this equipment

only

to other TNV compliant circuits as

defined in AS/NZS 3260 and IEC950

EX7100 Technical Manual - Mandatory Regulations

1.0.5 Telecom Safety Earth

The wire used for saf et y eart hing should be a minimum of 4mm2 and should preferably be

directly connected to an earthing stak e dr iven into t he ground

Refer to Section 2.8 of t he Technical Manual for specific instructions

2.0 Country-specific Regulations

The following sections detail any regulations that may be required by specific countries

and/or territories.

2.0.1 New Zealand Regulation - PTC 200

• “The grant of a Telepermit for any item of terminal equipment indicates only that

Telecom has accepted t hat the it em complies with minimum conditions f or connection

to its network. It indicates no endorsement of the product by Telecom, nor does it

provide any sort of warranty. Above all, it provides no assurance that any item will

work correctly in all respects with another item of Telepermitted equipment of a

different make or model, nor does it imply that any product is compatible with all of

Telecom’s network services.”

• “This equipment m ay not provide for the eff ective hand-over of a call to another device

connected to the same line.”

• “IMPORTANT NOTICE

Under power failure conditions, this device may not operate. Please ensure that a

separate telephone, not dependent on local power, is available for emergency use.”

• “Use of pulse dialling, when this equipment is connected to the same line as other

equipment, may give rise to bell tinkle or noise and may also cause a false answer

condition. Should such problems occur, the user should NOT contact the Telecom

Faults Service.”

• “Devices designed to respond to particular ringing cadences may not respond when

used with this equipment.”

• In the event of any problem with this device, it is to be disconnected and a CPE item

connected to one of its terminal ports m ay be connected directly in its place. T he user

should then arrange for the product to be repair ed. Should the matter be reported to

Telecom as a wiring fault, and the f ault be proven to be due to this product, a call-out

charge will be incurred.”

• “Note that the receive audio line level must not be more than 3dB higher than the

transmit audio line level. (for typical installations using short telephone cable lengths, it

is recommended that the receive audio line level is set for –3dBm)”

• “The maximum number of parallel CPE devices that can satisfactorily be operated on

a single port is two (2)”

• “This unit should be powered from a supply that is compliant with AS/NZS3260 and is

SELV compliant”

©1999 Exicom Technologies (1996) Ltd Regulations-2 Issue 0 – October 2000

EX7100

TECHNICAL

MANUAL

©1999 Exicom Technologies (1996) Limited

All rights reserved. This publication is copyrig ht.

No part of this work may be reproduced or copied in any form or by any means (electrical,

mechanical, photocopying, microfilm ing, recording or otherwise) without the written permission

of Exicom Technologies (1996) Ltd, Private Bag 50912, Porirua, New Zealand.

Confidentiality

This document contains confidential information which belongs to Exicom Technologies (1996)

Limited. All information is supplied to you in confidence on the basis that it must not be used by

you (except for product evaluation purposes) or disclosed to any person without Exicom

Technologies (1996) Limited’s prior written consent.

Any breach of the above obligation may be restrained by legal proceedings seeking remedies

including injunctions, damages and costs.

Disclaimer

Exicom Technologies (1996) Limited constantly seeks to improve quality and performance.

Therefore, specif ications and configurations are subject t o change without notice.

Product code: 61-8031-00002

EX7100 Technical Manual - Contents

Contents

Page

List of Figures

1 Introduction

1.1 General 1-1

1.2 Configuration 1-2

1.2.1 64 kbit/s digital “pipe” 1-2

1.2.2 Six low bit rate voice/fax/data channels 1-2

1.3 About this Manual 1-3

1.4 Terminology 1-3

1.5 EX7100 Specifications 1-4

1.5.1 System Parameters 1-4

1.5.2 Power, Mechanical and Environmental 1-4

1.5.3 Multi-channel Voice and Data Multiplexer 1-5

1.5.4 Data Channel 1-6

1.5.5 System Management 1-6

1.6 System Planning 1-7

2 Installation of Antenna and Equipment

2.1 General 2-1

2.2 Antenna Sites 2-1

2.3 Mounting the Antenna 2-2

2.3.1 Antenna Polarisation 2-2

2.3.2 Antenna Direction 2-3

2.3.3 Antenna Cable Grounding Kits 2-3

2.4 Positioning the EX7100 Terminal 2-4

2.5 Mounting the Terminal in the Rack 2-5

2.6 Cable Connections 2-5

2.6.1 General 2-5

RF Connection 2-5

DC Power Input 2-7

2.7 Terminal Type Specific Connections 2-8

2.7.1 Digital Data Terminal Connections 2-8

Synchronous Data V.35 2-8

ix

©1999 Exicom Technologies (1996) Limited i Issue 2 - May 2001

EX7100 Technical Manual - Contents

Page

G.703 2-8

2.7.2 Exchange Terminal Connections 2-8

2.7.3 Subscriber Terminal Connections 2-9

2.8 Earthing the Terminal 2-9

2.9 Other Rear Panel Connections 2-9

2.9.1 Control 2-10

2.9.2 LMS 2-10

2.9.3 I/O 2-10

External Site Alarms 2-10

2.9.4 RF 2-10

2.10 Powering Up the Terminal 2-11

2.10.1 General 2-11

2.10.2 Procedure 2-11

2.11 Final Antenna Alignment 2-12

2.11.1 General 2-12

2.11.2 Alignment Sequence 2-12

3 Configuring the Terminal

3.1 General 3-1

3.2 Using the Keypad 3-1

3.3 The User Interface Menu 3-2

3.4 Changing Parameters 3-2

3.4.1 Universal Parameters 3-3

Passwords 3-3

Changing the Time and Date 3-5

Operating Mode 3-5

Link ID 3-6

Terminal Descriptor 3-7

Changing the RF Channel Increment 3-7

Changing the Local Transmitter Frequency 3-8

Changing the Local Receiver Frequency 3-10

Transmitter RF Power Level 3-11

Interface Type 3-11

3.4.2 Data Terminal Parameters 3-12

Tx Data Clock Synchronisation 3-12

Sync Data Polarity 3-13

3.4.3 Exchange Terminal Parameters 3-14

Operating Mode 3-14

Channel Set-up 3-14

Payphone Metering Frequency 3-15

Transmit Audio Line Level 3-16

©1999 Exicom Technologies (1996) Limited ii Issue 2 - May 2001

EX7100 Technical Manual - Contents

Page

Receive Audio Line Level 3-16

3.4.4 Subscriber Terminal Parameters 3-17

Ringer Frequency 3-17

Line Termination Impedance 3-17

Payphone Metering Frequency 3-18

Transmit Audio Line Level 3-19

Receive Audio Line Level 3-19

Telephone Loop Current 3-20

4 Monitoring and Diagnostics

4.1 General 4-1

4.2 Monitoring the EX7100’s Operation 4-1

4.2.1 RF Parameters 4-1

4.2.2 Power Supply Parameters 4-2

4.2.3 Framer Parameters 4-3

4.3 Monitoring a Remote Terminal 4-3

4.3.1 Setting up a Test Link 4-4

4.3.2 Closing the Test Link 4-5

4.3.3 Changing Operating Frequencies Remotely 4-5

4.4 EX7100 Internal Alarms 4-7

4.4.1 Acknowledging an Alarm 4-8

4.4.2 Setting Alarm Priorities 4-8

4.4.3 Link Up Time Alarm 4-9

4.4.4 Low RSSI Alarm 4-10

4.5 Diagnostic Tools 4-10

4.5.1 System Align Mode 4-10

4.5.2 Digital Loopbacks 4-11

Local Loopback 4-12

Remote Loopback 4-12

Enabling Digital Loopbacks 4-12

4.5.3 Analogue Loopbacks 4-13

Local Loopback 4-13

Remote Loopback 4-13

Enabling Analogue Loopbacks 4-14

4.6 Bit Error Rate Testing 4-14

4.6.1 General 4-14

4.6.2 BER Testing an EX7100: End-to-End 4-15

4.6.3 BER Testing an EX7100: Round-Trip 4-17

4.6.4 BER Testing an EX7100: Local Interface 4-17

4.7 Networking EX7100 Terminals 4-18

4.7.1 General 4-18

4.7.2 Interconnection of Local Terminals 4-18

©1999 Exicom Technologies (1996) Limited iii Issue 2 - May 2001

Page

4.7.3 Accessing Bussed Terminals 4-19

EX7100 Technical Manual - Contents

5 Troubleshooting the EX7100

5.1 General 5-1

5.2 Configuration Issues 5-1

6 EX7100 Top and Bottom Cover Removal

6.1 Procedure 6-1

7 Module Descriptions

7.1 General 7-1

General (Non-RF) Modules 7-1

RF Modules 7-1

Line Interface Modules 7-1

7.2 Power Supply Module Type 2964 7-3

7.2.1 General 7-3

7.2.2 Testing and Fault Diagnosis 7-4

General 7-4

Accessing the Power Supply 7-5

Diagnosis 7-5

7.2.3 Alignment 7-7

7.2.4 Module Replacement Procedure 7-7

7.3 VHF Transmitter Module Type 8027 7-9

7.3.1 General 7-9

7.3.2 Testing and Fault Diagnosis 7-10

General 7-10

Accessing the VHF Transmitter Module 7-11

Diagnosis 7-11

7.3.3 Alignment 7-13

Re-tuning of the VHF Transmitter Module 7-13

Carrier Null 7-13

7.3.4 VHF Transmitter Module Replacement Procedure 7-14

7.4 UHF Transmitter Module Type 8053 7-15

7.4.1 General 7-15

7.4.2 Testing and Fault Diagnosis 7-16

General 7-16

Accessing the Transmitter Module 7-17

Diagnosis 7-17

7.4.3 Alignment 7-19

Re-tuning of the Transmitter Module 7-19

Carrier Null 7-20

©1999 Exicom Technologies (1996) Limited iv Issue 2 - May 2001

EX7100 Technical Manual - Contents

Page

7.4.4 UHF Transmitter Module Replacement Procedure 7-20

Replacement of the Type 8044 Sub-Module 7-20

Removal of the Transmitter Module 7-22

7.5 VHF RF Power Amplifier Module Type 8028 7-23

7.5.1 General 7-23

7.5.2 Testing and Fault Diagnosis 7-24

VHF RF Power Amplifier Module Testing 7-24

7.5.3 Alignment 7-27

7.5.4 VHF RF Power Amplifier Replacement Procedure 7-27

7.6 UHF RF Power Amplifier Module Type 8048 7-28

7.6.1 General 7-28

7.6.2 Testing and Fault Diagnosis 7-29

UHF RF Power Amplifier Module Testing 7-29

7.6.3 Alignment 7-32

7.6.4 UHF RF Power Amplifier Replacement Procedure 7-32

7.7 VHF Receiver Module Type 8029 7-34

7.7.1 General 7-34

7.7.2 Testing and Fault Diagnosis 7-34

General 7-34

Accessing the VHF Receiver Module 7-35

Diagnosis 7-35

7.7.3 Alignment 7-37

Module Re-tuning 7-37

Receiver Maintenance Adjustments 7-38

7.7.4 VHF Receiver Replacement Procedure 7-38

7.8 UHF Receiver Module Type 8054 7-40

7.8.1 General 7-40

7.8.2 Testing and Fault Diagnosis 7-40

General 7-40

Accessing the UHF Receiver Module 7-40

Diagnosis 7-41

7.8.3 Alignment 7-43

Module Re-tuning 7-43

Receiver Maintenance Adjustments 7-44

7.8.4 UHF Receiver Replacement Procedure 7-44

Removal of the Type 8055 Front-End Module 7-44

Removal of the Receiver Module 7-46

7.9 VHF Duplex Filter Module Type 8013 7-47

7.9.1 General 7-47

VHF Connections 7-47

VHF Mounting 7-47

©1999 Exicom Technologies (1996) Limited v Issue 2 - May 2001

EX7100 Technical Manual - Contents

Page

7.9.2 Testing and Fault Diagnosis 7-48

General 7-48

Checking RF Connectors 7-48

7.9.3 Alignment 7-48

VHF Module Re-tuning 7-48

7.9.4 VHF Duplex Filter Replacement Procedure 7-50

7.10 UHF Duplex Filter Module Type 8045 7-51

7.10.1 General 7-51

UHF Connections 7-51

UHF Mounting 7-51

7.10.2 T esting and Fault Diagnosis 7-52

General 7-52

Checking RF Connectors 7-52

7.10.3 Alignment 7-52

BRBP Filter Adjustment (HPF) 7-54

BPBR Filter Adjustment (LPF) 7-54

Duplex Filter Adjustment (HPF) 7-54

7.10.4 Duplex Tuning / Perform ance checks 7-55

7.10.5 UHF Duplex Filter Replacem ent Procedure 7-56

7.11 Modem/Controller Module Type 2966 7-57

7.11.1 General 7-57

7.11.2 T esting and Fault Diagnosis 7-58

General 7-58

Accessing the Modem/Controller 7-58

Diagnosis 7-58

7.11.3 Alignment 7-60

7.11.4 Modem/Controller Module Replacement Procedure 7-60

7.12 Front Panel Module Type 2994 7-61

7.12.1 General 7-61

7.12.2 T esting and Fault Diagnosis 7-62

7.12.3 Alignment 7-63

7.12.4 Module Replacement Procedure 7-63

7.13 Line Interfaces Type 2971 and Type 2967 7-64

7.13.1 General 7-64

Isolated Power Supply Module Type 2990 7-64

Four wire + E & M Interface Type 8022 7-64

7.13.2 T esting and Fault Diagnosis 7-66

General 7-66

Accessing the Line Interface Module 7-66

Diagnosis 7-66

7.13.3 Alignment/Re-tuning 7-67

©1999 Exicom Technologies (1996) Limited vi Issue 2 - May 2001

Page

7.13.4 Line Int erf ace Replacement Procedure 7-68

7.14 Isolated Power Supply Type 2990 7-69

7.14.1 General 7-69

7.14.2 Description 7-69

7.14.3 T esting and Fault Diagnosis 7-69

Accessing the Isolated Power Supply Module 7-70

Diagnosis 7-70

EX7100 Technical Manual - Contents

8 EX7100 Repeater Configuration

8.1 General 8-1

8.2 Installation 8-1

8.3 Terminal Interconnections 8-1

G.703 Interconnect 8-1

Control Interconnect 8-2

8.4 Software Configuration 8-2

8.5 Remote Monitoring 8-2

Appendix A Connector Pi n Infor mation

A.1 LMS A-1

A.2 Control A-1

A.3 G.703 A-2

A.4 Synchronous Data A-2

A.5 Input/Output A-3

A.6 Line Interface A-4

A.7 Sync Data (DB15) to V.35 (M34) Interface Cable A-6

Appendix B Options

B.1 Line Terminating Frame B-1

Primary Lightning Protection B-1

B.2 ELMS (Exicom Link Management System) B-2

©1999 Exicom Technologies (1996) Limited vii Issue 2 - May 2001

EX7100 Technical Manual - Contents

This page intentionally left blank

©1999 Exicom Technologies (1996) Limited viii Issue 2 - May 2001

EX7100 Technical Manual - List of Figures

List of Figures

Page

1.1 Typical BER curve 1-9

2.1 Antenna Polarisation 2-2

2.2 Antenna Direction 2-3

2.3 UHF Duplexer Connections 2-6

2.4 External Alarms 2-10

2.5 EX7100 Front Panel Display - Initialisation Test 2-11

2.6 EX7100 Front Panel Display - Idle State 2-11

2.7 EX7100 Front Panel Display - Order Specified Terminal Descriptor 2-11

2.8 Antenna Alignment 2-12

3.1 EX7100 Front Panel Display and Keypad 3- 1

3.2 EX7100 Front Panel Display - RSSI Reading 3-2

4.1 Two Terminal Link 4-3

4.2 Two Terminal Link with Repeater Terminal 4-3

4.3 Digital Loopback Configurations 4-11

4.4 Analogue Loopback Configurations 4-13

4.5 End-to-end Bit Error Rate Test 4-15

4.6 Round-trip Bit Error Rate Test 4-15

4.7 Local Interface Bit Error Rate Test 4-15

4.8 Networking EX7100 Terminals 4-18

4.9 Three Terminal Bussed Site 4-18

7.1 EX7100 Terminal with Top Cover Removed 7-2

7.2 VHF EX7100 Terminal with Bottom Cover Removed 7-2

7.3 UHF EX7100 Terminal with Bottom Cover Removed 7-3

7.4 Power Supply Block Diagram 7-4

7.5 Power Supply Fault Diagnostic Tree 7-6

7.6 VHF RF Module Connection Block Diagram 7-9

7.7 VHF Transmitter Module in place within an EX7100 Terminal 7-10

7.8 VHF Transmitter Module Fault Diagnostic Tree 7-12

7.9 UHF RF Module Connection Block Diagram 7-15

7.10 UHF Transmitter Module in place within an EX7100 Terminal 7-16

7.11 UHF Transmitter Module Fault Diagnostic Tree 7-18

©1999 Exicom Technologies (1996) Limited ix Issue 2 - May 2001

EX7100 Technical Manual - List of Figures

Page

7.12 Location of Loop Volts adjustment CV101 7-19

7.13 VHF RF Power Amplifier Module in Place within an EX7100 Terminal 7-23

7.14 VHF PA Module Test set-up 7-25

7.15 Bottom Cover Screws for VHF PA Removal 7-26

7.16 Heat Sink Screws for VHF PA Removal 7-26

7.17 UHF RF Power Amplifier Module in Place within an EX7100 Terminal 7-28

7.18 UHF PA Module Test set-up 7-30

7.19 Bottom Cover Screws for UHF PA Removal 7-31

7.20 Heat Sink Screws for UHF PA Removal 7-31

7.21 VHF Receiver Module in Place within Terminal 7-34

7.22 VHF Receiver Module Fault Diagnostic Tree 7-36

7.23 UHF Receiver Module in Place within Terminal 7-40

7.24 UHF Receiver Module Fault Diagnostic Tree 7-42

7.25 Location of Loop Volts adjustment CV101 7-43

7.26 VHF Duplex Filter Adjustment Locations 7-49

7.27 UHF Duplex Filter Adjustment Locations 7-53

7.28 Modem/Controller Block Diagram 7-57

7.29 Modem/Controller in Place within Terminal 7-57

7.30 Modem/Controller Fault Diagnostic Tree 7-59

7.31 Front Panel Block Diagram 7-61

7.32 Front Panel Fault Diagnostic Tree 7-62

7.33 Six Channel Line Interface Connection Block Diagram 7-64

7.34 Subscriber Line Interface in Place within Terminal 7-65

7.35 Exchange Line Interface in Place within Terminal 7-65

7.36 Six Channel Line Interface Fault Diagnostic Tree 7-67

8.1 EX7100 Repeater 8-1

©1999 Exicom Technologies (1996) Limited x Issue 2 - May 2001

EX7100 Technical Manual - Introduction

1.1 General

The EX7100 is a unique digital radio primarily designed to meet the requirements of

customers who require thin route communications, especially in remote and rural

locations, but also in urban areas where digital linking is required. It is an ideal solution

where copper wires are too expensive or difficult to install.

The EX7100 is a 64kbit/s dig ital radio that operates within a 25kHz RF channel. It has a

number of unique features including:

> On-demand operation,

> Automatic fax and modem data detection ( with inter nal multiplexer installed),

1

Introduction

> G.703 and Synchronous Data interface (V.35) t o connect to external devices,

> An optional internal six circuit, voice/fax/data, multiplexer,

> High system gain with 2 W att or 10 Watt power amplifier options,

> Inherent security through proprietary digital encoding,

> Robust design to operate in a variety of environmental condit ions.

1.2 Configuration

The EX7100 is a point to point, line of sight system available in two configurations as

detailed below:

1.2.1 64 kbit/s digital “pipe”

The 64kbps single channel config uration uses G.703 and/or synchronous data interfaces

(V.35), for connection to external OEM multiplexers, bridges, routers, LAN’s, etc. The

actual transmitted bit rate including system overheads is 68 kbit/ s, allowing a full 64 kbit/s

for the user.

This congifuration is also used to provide a full duplex repeater option, based on two

terminals back-to-back at G. 703 inter f ace. A r epeater enables t he user t o gr eatly increase

the distance between the end terminals

©1999 Exicom Technologies (1996) Ltd 1-1 Issue 2 - February 2001

EX7100 Technical Manual - Introduction

1.2.2 Six low bit rate voice/fax/data channels

With the addition of an internal multiplexer/line interface card the EX7100 provides six,

low bit rate, voice/fax/data channels.

This option is designed to replicate six individual standard wireline telephone circuits and

caters for both 2-wire and 4-wire + E&M (with additional card) telephone operation. Line

drivers and ringers are integral to t he card, allowing telephone equipment to be situated

up to 5 kilometres fr om the terminal when used with external lightning protection.

Most equipment normally connected to telephone lines may be connected to each

channel of the EX7100, including payphone (12/16 kHz meter pulse or line reversal),

electronic funds transfer terminals, G3 fax and data traf fic at up to 9600bps.

Note that provision of voice/fax data tr affic requires external telephone modems at each

location. Modem/Fax data rate is limited to 9600bps.

The six-channel version of the EX7100 is available in two configur ations:

Exchange Terminal

Provides connection for six telephone circuits (either 2-wire or 4-wire +E&M) from the

PSTN. Using two exchange terminals, t he link may be config ured in software for Point-t oPoint Data terminal operation, providing six 9600bps data channels with 4-wire + E&M

interface.

Subscriber Terminal:

Provides connection for Subscriber equipment (2-wire), such as telephones, facsimile,

modem, etc.

Note: The telephone interface circuit boards within these terminals are specific to each

terminal type, i.e. an Exchange terminal cannot be linked as a Subscriber terminal,

or vice versa.

©1999 Exicom Technologies (1996) Ltd 1-2 Issue 2 - February 2001

EX7100 Technical Manual - Introduction

1.3 About this Manual

This Manual contains all the information necessary to enable installation and configurat ion

of an EX7100 as well as module and fault diagnosis information.

1.4 Terminology

The following terms and abbreviations are used throughout this manual:

BER Bit Error Rate,

BERT Bit Error Rate Test,

DSP Digital Signal Processing,

ESN Electronic Serial Number,

LCD Liquid Crystal Display

LED Light Emitting Diode,

LMS Link Management System,

LTF Line Terminating Frame,

MDF Main Distribution Frame,

PA Power Amplifier

POTS Plain O ld Telephone System

PSTN Public Switched Telephone Network

PSU Power Supply Unit,

RSSI Receive Signal Str ength Indication,

TCXO Temperature Controlled Crystal Oscillat or ,

VSWR Voltage Standing Wave Ratio.

This manual refers to “Exchange Terminal” and “Subscriber Terminal” however the

installation instructions apply equally to non-telephone, or Dat a, systems.

©1999 Exicom Technologies (1996) Ltd 1-3 Issue 2 - February 2001

EX7100 Technical Manual - Introduction

1.5 EX7100 Specifications

1.5.1 System Parameters

Frequency Bands (MHz)

(Other bands to follow)

RF Frequency Stability

Available Digital Bandwidth

Channel Data Rate

138-174, 400-520

240-270, 335-400, 800-900, 1400

± 1.5 ppm

64 kbit/s

68 kbit/s

RF Bandwidth

Digital Interface

Duplexer

25kHz

G.703 or V.35 synchronous

VHF: Internal Notch Type

UHF: External Notch Type + Band Pass

Frequency Selection

Channel Selection

Maximum Transmitter power @

duplexer output (PEP)

Synthesiser in 5.0 or 6.25kHz steps

Via front panel LCD or external ter m inal

UHF > +31 to +40 dBm (1.25 to 10 W) variable

> +24 to +33 dBm (0.25 to 2 W) variable

VHF > +31 to +40 dBm (1.25 to 10W) variable

> +24 to +30 dBm (0.25 to 1 W) variable

Duty Cycle

Emission Designator

Receive Sensitivity 10-3 BER

100% @ 60 °C ambient, < 3000 feet AMSL

18K4D1WET

< -105 dBm (<1.3 µV) @ Rx input

1.5.2 Power, Mechanical and Environmental

Ambient Operating Temperature

Humidity

Size of basic system (H x W x D)

-10 °C to +60 °C

up to 95% relative humidity, 0 °C to +45 °C,

non-condensing

VHF: (3U) 135 mm x 483 mm x 425mm

UHF: (4U) 175 mm x 483 mm x 425 mm

1

1

Weight

Physical Mounting

Line Lightning Protection

Approx. 15 kg

Rack Mount

Secondary Lightning Protection

1

425mm depth dimension measured from front panel handle to end of rear panel bracket. Additional depth allowance

may be required to cater for connecting cables etc.

©1999 Exicom Technologies (1996) Ltd 1-4 Issue 2 - February 2001

EX7100 Technical Manual - Introduction

Power Supply

1

10.8 - 30 VDC and 30 - 60 VDC, positive or

negative earth for 12/24/ 48 VDC power

systems

Power Consumption

Standby, 64 kbit/s config uration 35 W

Standby, 6 Ch. configuration 40 W

Tx 10 Watt, 64 kbit/s configuration

Typical 65 W

Maximum 100 W

Tx 10 Watt, 6 Ch. Configuration

Typical 85 W

Maximum 120 W

Tx 2 Watt, 64 kbit/s configuration

Tx 2 Watt, 6 Ch. configuration

(2 W figures above TO BE ADVISED)

1.5.3 Multi-channel Voice and Data Multiplexer

Purpose

Integral Multiplexer Interface

Number of Channels used

Exchange/Subscriber Line

Connections

Voice Quality

For data and low bit rate voice options

Proprietary

Up to six low bit rate voice/data/fax

Via 50-way CHAMP connector

Near toll quality - MOS

(64 kbit/s PCM MOS = 4.2, 32 kbit/s ADPCM

MOS = 3.8)

3

= 3.9

2

2

Voice Compression

Audio Frequency Response

Line Interfaces

MP-MLQ @ 6.3 kbit/s (ITU-T G 723.1)

300 to 3400 Hz typical

2-wire, 600Ω/900Ω/complex, 4-wire + E&M

(optional)

Telephone Interface (2-Wire)

2-wire, 600Ω/900Ω/complex, maximum DC

loop resistance 1500Ω, 50 V DC supply

Rx/Tx Line Levels 2 Wire

4 Wire

Line Drive Current

Payphone Interface

Fax and data detection

Fax Speed

Data Speed

1

Refer to Section 2, page 2-6 for IMPORTANT WARNINGS re the power supply

2

6 Channel Tx power consumption is maxi mum with 6 channels operational with 25 mA loop current and no ringing

3

MOS = Mean Opinion Score as defined by ITU-T Rec. P80 and tested by AT&T Study Group 15

-15 dBm to +3 dBm

-15 dBm to +3 dBm or –11 dBm to +7 dBm

25 or 45 mA selectable

12/16 kHz meter pulse and line reversal

Automatic

G3 up to 9.6 kbit/s

Up to 9.6 kbit/s with telephone modems

©1999 Exicom Technologies (1996) Ltd 1-5 Issue 2 - February 2001

EX7100 Technical Manual - Introduction

1.5.4 Data Channel

Data Interfaces

Data Rate

Connections G.703 - 75 ΩΩΩΩ

G.703 - 120 ΩΩΩΩ

Synch. Data

1.5.5 System Management

Basic Front Panel Metering

Configuration

System management Standard

Inter-site Communications

Communications and Signalling

data channel

Monitoring of site security or other

alarms

Channel Selection

G.703 or V.35 synchronous

64 kbit/s

BNC Connectors

DB15 Connector

DB15 Connector to standard V.35 connectors

on extender cable

1

LCD digital with bar graph and test points for

connection of external voltmeter

Menu driven 16x2 LCD with six button control

or via RS485 connection to external PC

Proprietary

RS485 communications with daisy-chain

capability

1000 bit/s (not user accessible)

Six I/O Ports

Via front panel LCD or external ter m inal

System Management Functions

-3

• BER alarm set 10

adjustable

to 10-5

• Loopback on each line (6

channel)

• Repeater mode • 64 kbit/s loopback, local/remote

• Set link active excess alarm time • Set individual Receiver and

Transmitter RF frequencies

• Adjust transmit power level • Antenna alignment mode

• Audio line levels

Alarms

-3

• BER set 10

to 10-5 adjustable • Low input voltage

• Low receive signal level • Synth lock fail

• Link up time • External alarms

• Tx high VSW R and low power • Lost modem lock

• Internal voltage rail fault • Link fail alarm

• Over Temperature (UHF 10 W) •

Digital and Analogue Meter Tests and Bar Graph

• Receive signal levels • DC input voltage

• Current consumption • Internal voltage rails

• Tx Heatsink temperature

1

DB15 connector has a proprietary pin-out, refer to Appendix A sections A.3 and A.4 for details

©1999 Exicom Technologies (1996) Ltd 1-6 Issue 2 - February 2001

EX7100 Technical Manual - Introduction

1.6 System Planning

Digital Radio link planning is a complex procedure req uiring a study of each site and the

path between each site. Exicom T echnologies is able to assist in system planning if this is

required.

Specialist software packages are used by Radio System Engineers to determine path

losses and sources of interfering signals that may affect the reliability of the radio link.

(Unlike an FM signal, a digital radio signal is suscept ible to interf erence and f ades, similar

to those found on television broadcast systems)

The EX7100 is capable, under ideal circumstances, of providing communications over

paths of more than 50 kilom et r es.

However, the following considerations must be taken into account, which will assist in

determining the maximum link dist ance and system r eliability:

> Operating frequencies

> Free Space loss

> Terrain effects: Absorption and Reflection losses

> Antenna gain and position

> Cable losses

> Transmit power

> Receiver sensitivity

> Required fade margin

Further to these considerations, the system designer must be aware of factors at each

site, which may affect the reliabilit y of the radio link. These f act ors include:

> Access to a reliable power source.

> Antenna height.

> Access to a suitable grounding system.

> Lightning and surge protect ion

> Other radiating and receiving systems using t he site

©1999 Exicom Technologies (1996) Ltd 1-7 Issue 2 - February 2001

EX7100 Technical Manual - Introduction

This page intentionally left blank

©1999 Exicom Technologies (1996) Ltd 1-8 Issue 2 - February 2001

EX7100 Technical Manual - Introduction

1.00E-02

1.00E-03

1.00E-04

BER

1.00E-05

1.00E-06

VHF/UHF E X 7100 at

'nominal' operating

temp range

VHF/UHF E X 7100 at

'extreme' operating

temp range

-10 to +45 C

-30 to +60 C

1.00E-07

-108 -107 -106 -105 -104 -103 -102 -101 -100 -99 -98 -97 -96 -95

Receive level (dBm )

Figure 1.1: Typical BER curve

©1999 Exicom Technologies (1996) Ltd 1-9 Issue 2 - February 2001

EX7100 Technical Manual - Introduction

This page intentionally left blank

©1999 Exicom Technologies (1996) Ltd 1-10 Issue 2 - February 2001

EX7100 Technical Manual - Installation of Antenna and Equipment

Installation of Antenna and Equipment

2.1 General

2

Although EX7100 Radio Link terminals can be installed in any order, the following

sequence should be followed to ensure that minimum t im e is spent on installation.

> Install Exchange antenna (Section 2.3),

> Mount the Exchange terminal (Sections 2.4 and 2.5),

> Connect power, antenna and interface cables to the Exchange t er m inal (Section 2.6),

> Configure and test Exchange ter m inal ( Sect ion 3) ,

> Repeat the above steps for the installation of the Subscriber antenna, Subscriber

terminal and cabling (Sections 2.3 to 2.6 inclusive and Section 3) ,

> Final antenna alignment at Subscriber site ( Sect ion 2.11),

> Final antenna alignment at Exchange site (Section 2. 11) .

THIS EQUIPMENT MUST ONLY BE INSTALLED AND

MAINTAINED BY SERVICE PERSONNEL

WARNING

> Establish a test link to confir m oper at ion of system (Sections 4.3.1 and 4.3.2),

Note: Ensure that the correct terminal is dispatched to the appropriate site (Terminal

information can be found on a label on the side of the packing box).

2.2 Antenna Sites

Antenna sites for the EX7100 installat ion should have been chosen as part of the system

planning process (Refer to Section 1.6). If they have not been selected, contact your

Exicom International Supplier.

Radio path planning is a highly technical procedure and should only be performed by a

qualified person.

©1999 Exicom Technologies (1996) Ltd 2-1 Issue 2 - February 2001

EX7100 Technical Manual - Installation of Antenna and Equipment

2.3 Mounting the Antenna

The antenna should be mounted high enough so that it is in "line-of-sight" with the

antenna at the other radio site (antenna heig ht may have been determined during system

planning). The antenna should be placed at least 10 m etres (VHF) or 3.5 metres (UHF)

from any metallic or conductive objects to avoid possible impaired operation of the

EX7100 link and fastened securely to protect against the effect s of strong winds.

When mounting the antenna, ensure it is pointing in the correct direction with the correct

polarisation. Final adjustments to t he antenna direction are made af ter both terminals are

installed. Refer to Section 2. 11 " Final Antenna Alignment".

2.3.1 Antenna Polarisation

The site plan should include details of antenna polar isation. If it doesn't, use t he following

information as a guide:

The antenna may be mounted with either vertical or horizontal polarisation. Figure 2.1

shows an antenna mounted with vertical polarisation (top) and horizontal polarisation

(bottom). In general, either polarisation can be used although each antenna must

identical polarisation.

have

Note: Vertical antenna polarisation is prefer red if the r adio link is to be used over a body

of water such as a lake or sea.

Figure 2.1: Antenna Polarisation

©1999 Exicom Technologies (1996) Ltd 2-2 Issue 2 - February 2001

EX7100 Technical Manual - Installation of Antenna and Equipment

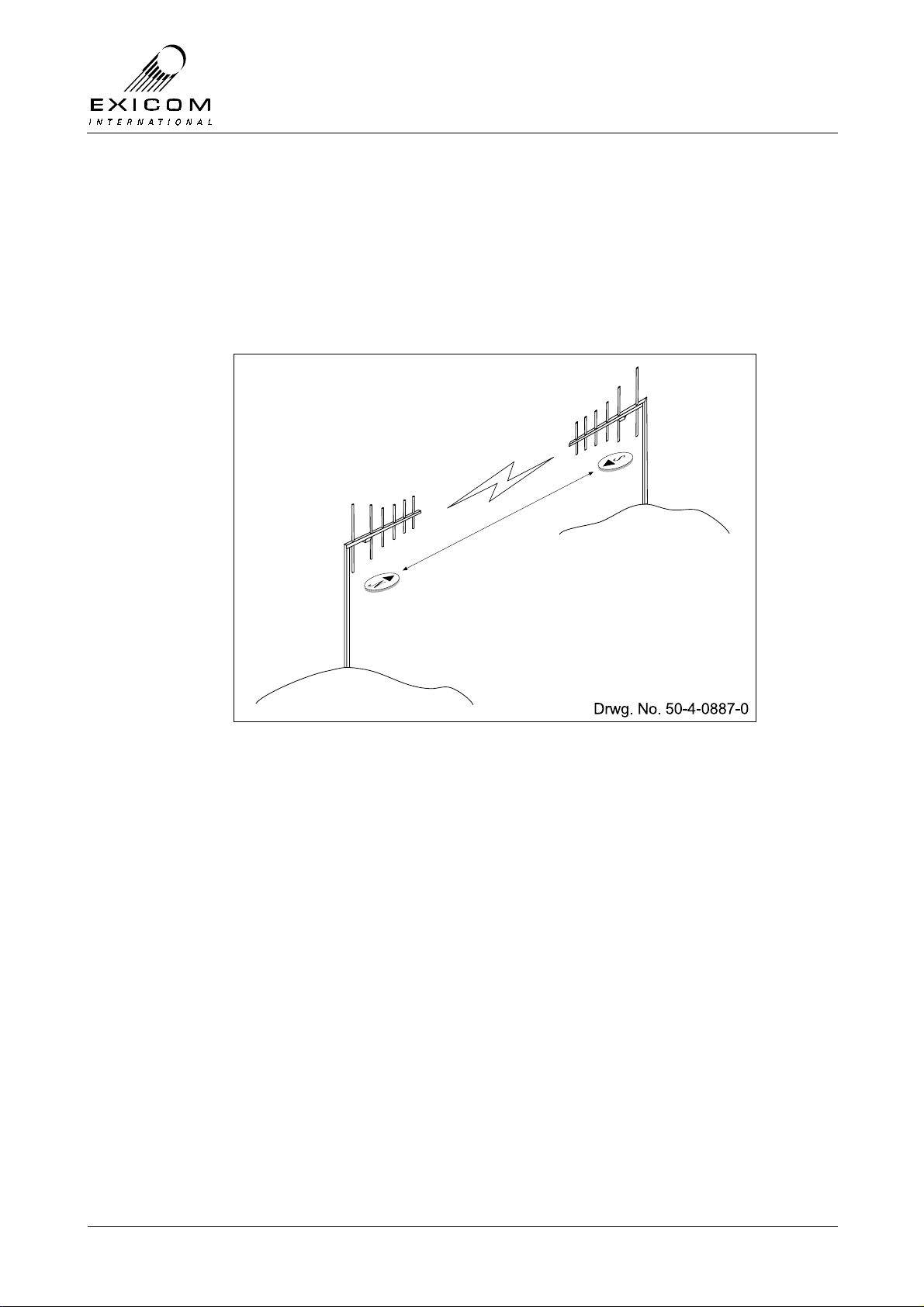

2.3.2 Antenna Direction

The site plan should include details of antenna direction. If it doesn't, use the following

information as a guide:

Refer to a map with the antenna sites marked. The antennas must point towards each

other in a straight line for the link to operate eff ectively. Take a compass bearing of each

antenna as shown in Figure 2.2. This is the direction the antenna should point towards

when mounted.

Figure 2.2: Antenna Direction

2.3.3 Antenna Cable Grounding Kits

To assist with lightning protection, coaxial cable grounding kits should be used at each

site. Grounding of the cable is recommended at the tower top, tower bottom and at the

entrance to the equipment shelter .

A range of grounding kits are available. Contact your Exicom International Supplier for

details.

©1999 Exicom Technologies (1996) Ltd 2-3 Issue 2 - February 2001

2.4

f

EX7100 Technical Manual - Installation of Antenna and Equipment

Positioning the EX7100 Terminal

Before deciding on the position of the terminal, consider the following:

> The antenna coaxial cable should be as short as practical to m inimise transmission

losses,

> The EX7100 requires good ventilation to allow generated heat t o escape. Although

the maximum temperature environment f or the EX 7100 is +60°C, lower temperatur es

will assist with trouble-free operation, as is the case with most elect r onic equipment,

Always allow a gap of at least 2U

1

(89mm) above/below the terminal and any other

equipment,

> The EX7100 should be mounted close to a source of power, telephone wires (if

required) and the antenna cable. Note: Ensure that sufficient room for any cables

(including adequate bend radius etc) is present prior to positioning the terminal

> Access to a good earth is essential (separate t o m ains ear t h) r efer to Section 2.8,

> It may be necessary during the installation process (or subsequent servicing) to

access the rear panel of the term inal. Sufficient room should therefore be provided

around the terminal to allow access to any connections (such as the RS485 port that

may be used for PC control during test ing and set-up).

2

Ensure that the equipment racks are stable and capable o

supporting the weight of the EX7100 terminal before

equipment installation. Note t hat unsecur ed rack s may tip over,

causing damage to equipment or personal injury

WARNING

1

One U = 44.5 mm or 1 ¾ inch

2

Terminal depth of 425mm is measured from front panel handle to end of rear panel bracket. Additional

depth allowance may be required to cater for connecting cables etc.

©1999 Exicom Technologies (1996) Ltd 2-4 Issue 2 - February 2001

EX7100 Technical Manual - Installation of Antenna and Equipment

2.5 Mounting the Terminal in the Rack

The EX7100 is compatible with the industry standard 19" rack system and occupies 3U1

(VHF) or 4U (UHF) of vertical space.

> Attach the handles to the EX7100 front panel using the handle kit supplied.

> Attach the front panel to t he r adio t erminal using the six screws supplied.

> Mount the terminal to the r ack using the f our front panel mounting points. Due to the

weight of the EX7100 terminal (approx. 15 kg), it is highly recommended that the

terminal be supported with the use of angled side rails. These rails are commonly

found in 19” racking systems (but are not

> Ensure that the terminal’s chassis ground is connected to the equipment rack’s

ground via the chassis earth screw terminal. (Refer to Section 2.8)

included with EX7100 terminals).

2.6 Cable Connections

2.6.1 General

Cable configuration is dependent on the variant of the terminal being installed, i.e. Data,

Exchange, or Subscriber. (Refer t o section 1.2)

However, there are some generic connections required, r egardless of variant type:

> The RF connection,

> The power supply connection,

> The earth connection.

RF Connection

VHF system

cable to the N-type socket mark ed ‘ANT’.

UHF system:

antenna’s coaxial cable to the N-type antenna socket on the lid of the terminal. If the

duplexer leads have been disconnected from RF connectors on the rear panel, it is

important they are reconnected correctly.

The connector marked thus: is connect ed to the Transmitter. (RF out) .

: The VHF EX7100 uses an internal duplexer Connect t he antenna’s coaxial

The UHF EX7100 uses an externally mounted duplexer. Connect the

The connector marked thus: is connect ed t o the Receiver. (RF in).

1

One U = 44.5 mm or 1 ¾ inch

©1999 Exicom Technologies (1996) Ltd 2-5 Issue 2 - February 2001

EX7100 Technical Manual - Installation of Antenna and Equipment

If the terminal’s transmitter frequency is higher t han it’s receiver frequency, the RF output

connector should be connected to the high-pass side of the duplexer.

If the terminal’s tr ansmitter frequency is lower than it’s receiver frequency, the RF output

connector should be connected to the low-pass side of the duplexer.

Figure 2.3 below shows the RF connections for a UHF duplexer.

Tx or Rx Tx or RxA ntenna

1234567

BRBP

Band Reject

Band Pas s

Filte r

(H PF)

A B C

High

4 Cavit y Duplex filter

D E F G

adjustment

High pass

Figure 2.3: UHF Duplexer Connections

Low

BPBR

Band Pas s

Band Reject

Filter

(LPF)

H I J

adjustment

low pass

A suitable lightning arrestor must

be installed at all

times in the coax cable between the EX7100 terminal

and the antenna.

©1999 Exicom Technologies (1996) Ltd 2-6 Issue 2 - February 2001

EX7100 Technical Manual - Installation of Antenna and Equipment

The arrester must have a direct earth connect ion and must be mounted at either the base

of the antenna mast or where the coax cable enters the building. For further detail on

mounting the antenna, refer to the documentation that accompanies it.

Note: Ensure that any coaxial connectors exposed to the weather are adequately

protected with suitable weatherproof t ape that com pletely seals the connect or f rom

moisture.

DC Power Input

The EX7100 terminal is supplied with two variants of internal power supply:

> 10.8 VDC – 30 VDC Input

> 30 VDC – 60 VDC Input

If the terminal is to be powered by an existing DC power supply, ensure the voltage

supplied by the power supply system falls within one of the ranges detailed above.

Note: The terminal has a built-in sensing circ uit and will not operate if t he supply voltage

or polarity is incorrect.

NOTICE

Supply power to this equipment must be provided via an approved

power supply whose output voltages are in accordance with the

Safety Extra Low Voltages (SELV) limits as specified in IEC950.

Failure to operate this equipment with this type of power supply

would void safety approvals

DC Input cabling should be capable of carrying 15 Am ps @ 12V, 7.5 Amps @ 24V, and

4.0 Amps @ 48V. The maximum

Note: The terminal requires an external fuse (not supplied

permitted voltage drop in the cable is 200mV.

) within the DC Input cabling.

Fuse ratings vary depending on the nominal DC input voltage used:

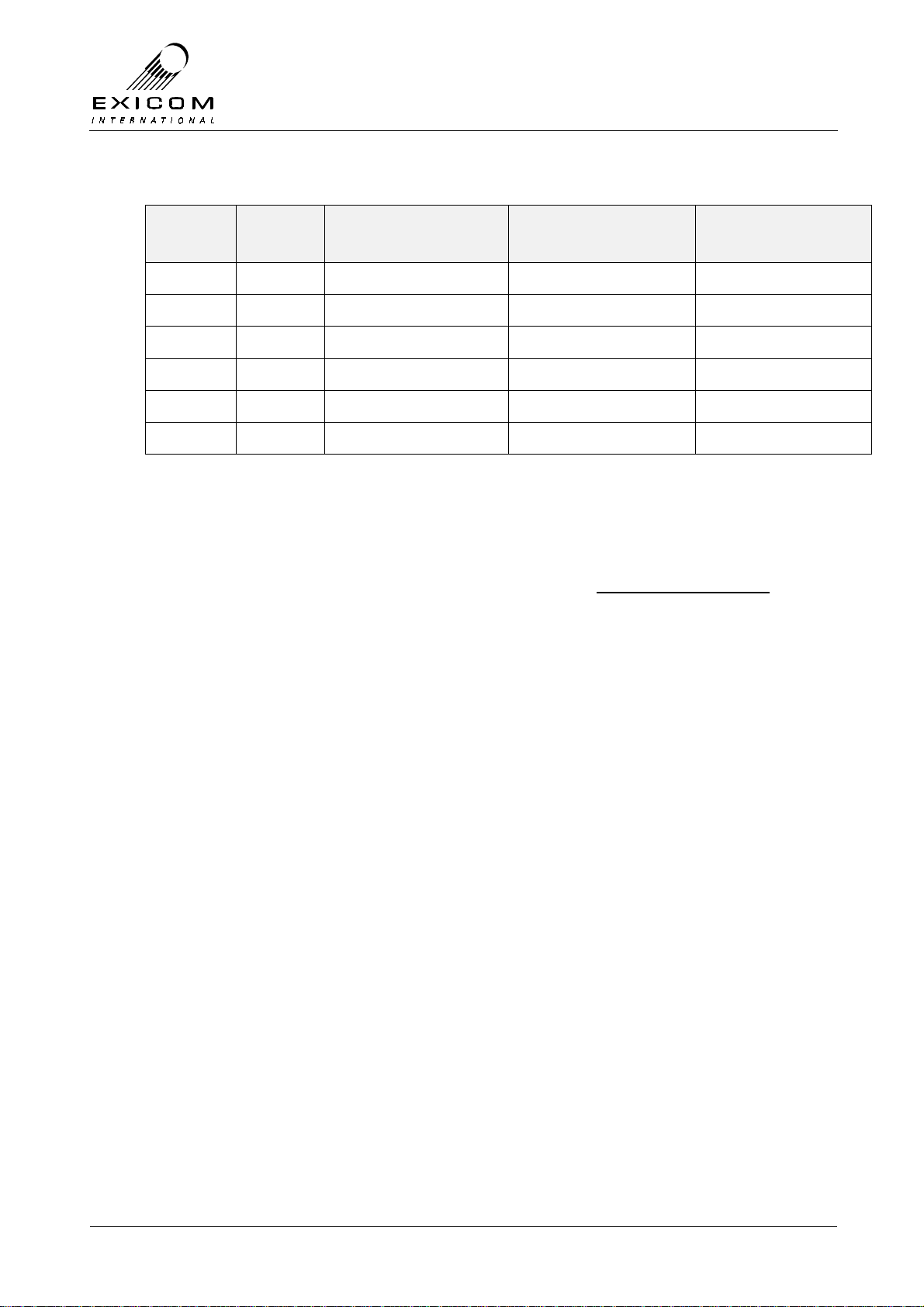

Nominal DC Input Voltage Fuse Rating

12 V DC 60 Amp HRC type

24 V DC 30 Amp HRC type

48 V DC 20 Amp HRC type

HRC fuses should be used with a minimum current breaking capacity of 5000

Amps (as lead acid batteries are likely to be used to back up the DC supply)

©1999 Exicom Technologies (1996) Ltd 2-7 Issue 2 - February 2001

EX7100 Technical Manual - Installation of Antenna and Equipment

Connect the power supply cable to the 3-way connector marked ‘- GND +’. The DC input

lines on this connector are floating and have no power connection to the chassis ground

(neither the positive nor the negative term inal is connected to the EX7100 chassis). This

enables the EX7100 to be powered from either a positive or negative ground supply.

The centre term inal of the DC input connector is connect ed to the EX7100’s chassis and

may be strapped to the side of the DC input t hat is at station ground potential.

2.7 Terminal Type Specific Connections

The EX7100 is supplied as one of three types, Data, Exchange, or Subscriber. (Ref er to

section 1.2). The interface connections to each terminal type are diff er ent.

Connection details for the three t er minal types are as follows:

2.7.1 Digital Data Terminal Connections

The EX7100 provides both synchronous Data, e.g . V.35 and CCIT T G.703 co-dir ectional,

digital interfaces. The terminal automatically detects the presence of a digital interface

card.

Selection of the interf ace req uired is m ade in soft ware using the front panel keypad. Refer

to Section 3.4.1 for configuration details.

Synchronous Data V.35

Once selected, the synchronous Data interface is m ade available on the DB15 connector

labelled ‘SYNC DATA’ on the ter minal’s rear panel. Detailed pin-out information can be

found in Appendix A.4.

Various adapter cables are available to cater for V. 35, RS-232 conversion. Contact your

Exicom International Supplier for det ails.

G.703

Once selected, the G.703 interface is made available on the DB15 connector labelled

‘G.703’ (for detailed pin-out information refer to Appendix A.3) and also on the pair of

BNC connectors labelled ‘G.703’, on the ter m inal’s r ear panel.

The DB15 connector provides a 120 Ohm co-directional interface, whereas the BNC

connectors provide a 75 Ohm co-directional interf ace. It should be noted that the arrows

alongside the BNC connectors indicate the data flow to and from the terminal.

2.7.2 Exchange Terminal Connections

The EX7100 Exchange terminal allows connection of six 2-wire telephone circuits; six 4wire+E&M telephone circuits, or six 4-wire+E&M data circuits (up to 9600bps).

All circuits are connect ed to t he terminal via the 50-way Champ connector, labelled ‘LINE

INTERFACE’, on the terminal’s rear panel. (For detailed pin-out information refer to

Appendix A.6)

The Exchange Terminal may be supplied with a 3 or 10 metre cable that can be plugged

directly into this connector. The other end of this cable should be terminated into the

PSTN’s MDF. Contact your Exicom International Supplier for details.

©1999 Exicom Technologies (1996) Ltd 2-8 Issue 2 - February 2001

EX7100 Technical Manual - Installation of Antenna and Equipment

Note: The EX7100 automatically detects the presence of an Exchange interface card.

The terminal is conf ig ured f or 2-wire or 4-wire+E&M, in software via the f ront panel

keypad. Refer to Section 3.4. 3 for configuration details.

The Exchange terminal may also be soft ware config ured, via the fr ont panel keyboard, as

a point to point Data terminal. Refer to Section 3.4.3 f or configuration details.

2.7.3 Subscriber Terminal Connections

The EX7100 Subscriber terminal provides six 2-wire telephone circuits for connection to

equipment such as telephones, payphones, EFT-POS t erminals, etc.

These circuits are accessed from the terminal via the 50-way Champ connector, labelled

‘LINE INTERFACE’, on the terminal’s rear panel. (For detailed pin-out information refer to

Appendix A.6)

The Subscriber terminal may be supplied with a 3 or 10 metre cable that can be plugged

directly into this connector. The un-terminated end of the cable may be either wired

directly to the user equipment, to an existing MDF, or to Exicom’s optional Line

Terminating Frame (LTF). Contact your Exicom International Supplier for details

Note: The EX7100 automatically detects the presence of a Subscriber inter face card.

The LTF is available with various connector options, as well as optional Primary Lightning

Protection circuitry. Contact your Exicom Int ernational Supplier for fur ther details.

2.8 Earthing the Terminal

The provision of a suitable earth f or the terminal is the responsibility of the installer. The

EX7100 has a screw terminal on the rear panel to connect the t er m inal to earth.

This will assist in preventing damage to the terminal from lightning strikes, particularly

strikes to the telephone cables. Protection from strikes to the antenna system may be

provided by fitting the recommended antenna lightning arrester.

For these protective measures to be effective, the system requires a good earth

connection. Mains earth is not

adequate, nor is a thin wire or any wire with bends or twists

in it.

The best earth connection is using a suitably heavy wire (e.g. >4 mm

connected straight to an earthing stake driven into the ground

If this is not possible, connect the ear t h cable t o the equipment rack ground system .

2.9 Other Rear Panel Connections

2

copper cable)

The EX7100 is f itted with several other rear panel connect ors as detailed below. Some of

these connectors will not be used for all applications, however descriptions of their

functions are detailed below.

Note: Detailed pin-out infor m ation can be found in Appendix A.

©1999 Exicom Technologies (1996) Ltd 2-9 Issue 2 - February 2001

EX7100 Technical Manual - Installation of Antenna and Equipment

2.9.1 Control

A DB9 connector provides access to the internal RS-485 bus for future expansion of the

EX7100, and for back-to-back repeater connection. This connector will allow system

control of externally mounted interface cards that are yet to be developed. The Control

bus is not

user accessible.

2.9.2 LMS

A DB9 connector provides access to the internal RS-485 bus to allow daisy chaining of

multiple terminals and connection to an external Link Management device - ELMS. Refer

Appendix B-2.

2.9.3 I/O

A DB25 connector provides high and low priority alarm outputs, and six input/output

contacts for connection of non-latching externally generated site alarms that are sent

across the radio link when triggered.

Important Note: The I/O port is optically isolated. Details of maximum voltages and

currents are given in Appendix A.5. Failure to comply with this criteria may cause damage

to the I/O port.

External Site Alarms

The EX7100 provides the facility to connect up t o six non-latching external alar m contacts

which, when triggered, are sent across the radio link. Alarms may include: Site door

alarm, site fire alarm , or generator fuel low alarm.

When an external alarm cont act closes, the alarm is sent across the link, via the

engineering channel, and the corresponding output at all intermediate ter m inals ar e

triggered. An external alarm appear s on the front panel along with standard alarms.

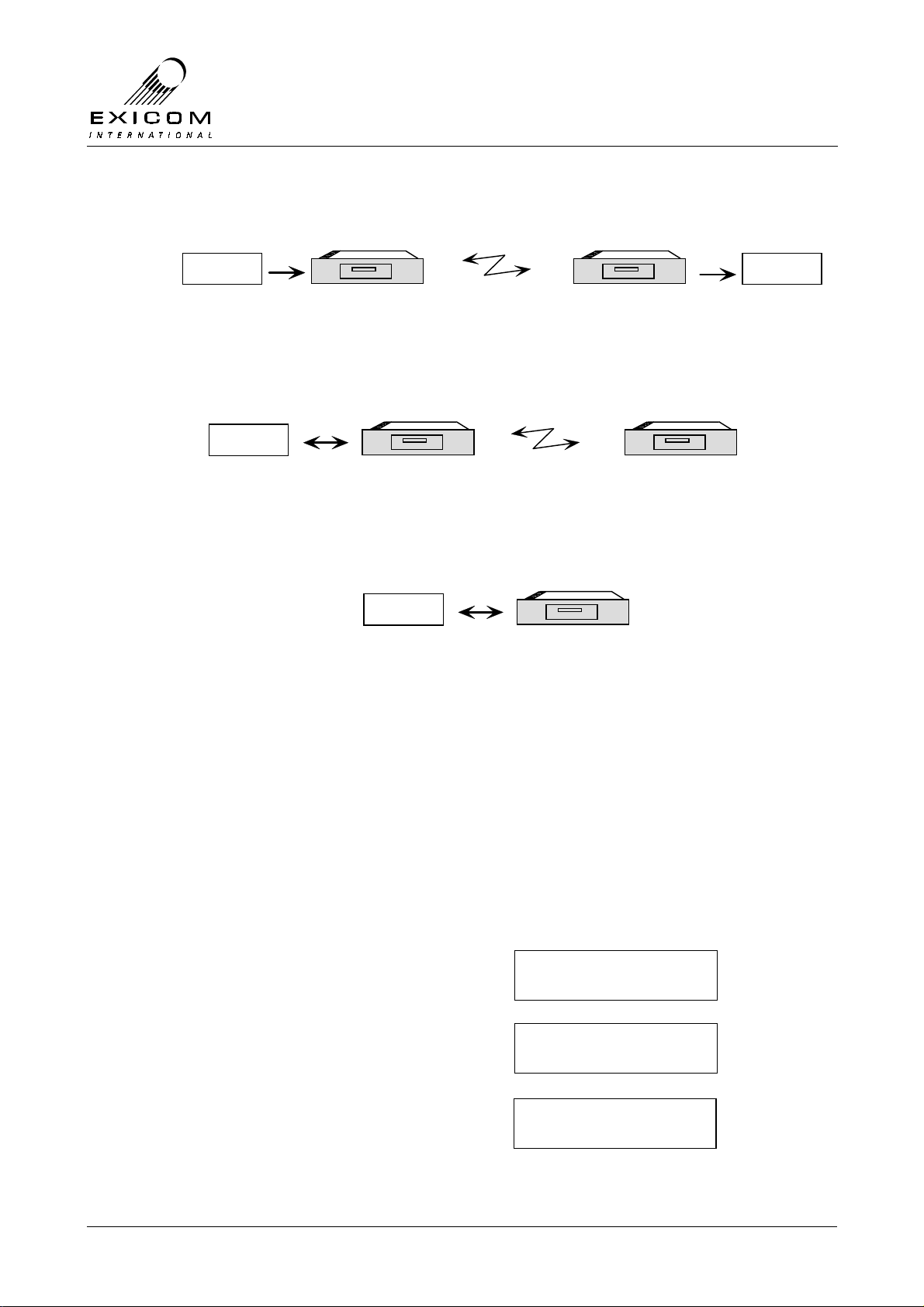

Received

Burgla r Alarm

External output 0

goes low

Burgla r Alarm

External output 0

goes low

I/O

o o

o

o o

o

o o

EX7100

EXICOM

EX7100

EXICOM

2.9.4 RF

Allows connection to an externally mounted Duplexer, if required. (For example, UHF

Duplexer Type 8045)

Transmitted

I/O

o

o

Direction of Alarm

Received

Burgla r Alarm

External output 0

goes low

RS -485

o o

o o

o o

EX7100

EXICOM

o o

o

o o

o

o o

Repeater

Figure 2.4: External Alarms

I/O

EX7100

EX7100EX7100

EXICOM

Burgla r Alarm

External input 0 goes low

External output 0 goes low

o o

o

o o

o

o o

EX7100

EX7100

©1999 Exicom Technologies (1996) Ltd 2-10 Issue 2 - February 2001

EX7100 Technical Manual - Installation of Antenna and Equipment

2.10 Powering up the Terminal

2.10.1 General

Before powering up, ensure that all cables are connect ed correctly and that there is DC

power to the EX7100 terminal. Pay particular attention to the RF cable assembly,

ensuring all connections are tight.

The EX7100 on/off switch is located on t he r ear panel.

Note: This switch has an interlocking feature that prohibits accidental switch off. To

toggle the switch on or off you must pull the switch gently forward.

2.10.2 Procedure

Turn on the EX7100 terminal with the on/of f switch. The EX7100 will perform an internal

initialisation test, befor e set tling to its idle state.

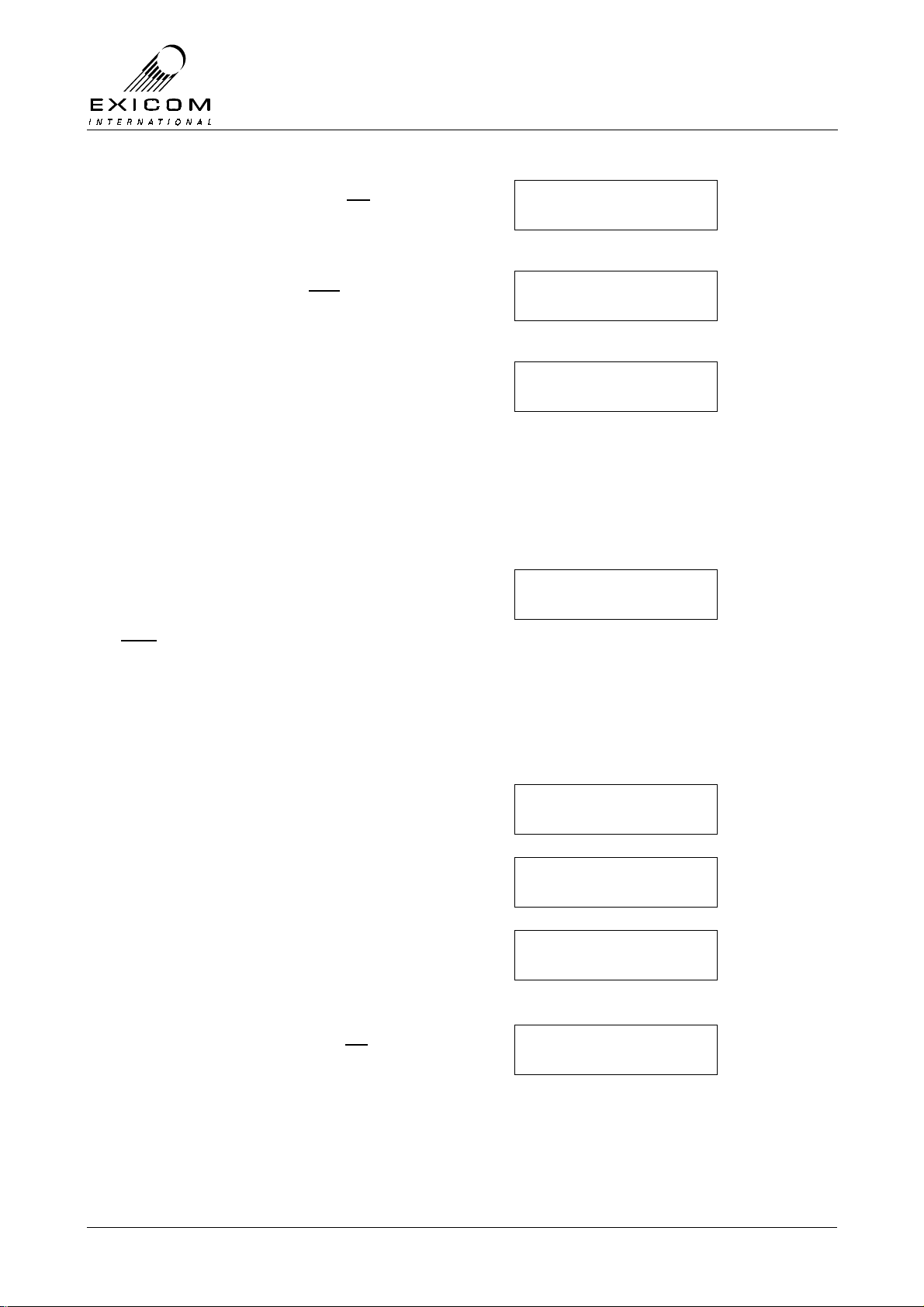

Figure 2.5: EX7100 Front Panel Display - Initialisation Test

In this idle state, the f ront panel LCD will display:

initialising

■■■■■■■■■

Figure 2.6: EX7100 Front Panel Display – Idle State

Exicom EX7100

1 Jan 1210:01

Note: ‘Exicom EX7100’ is the factory default t erminal descriptor. This descriptor can be

any 16 character string , and may be changed at any time (Ref er to Section 3.4.1) .

If this descriptor was specified at time of order, the display will reflect that. For

example:

Figure 2.7: EX7100 Front Panel Display – Order Specified Terminal Descriptor

Exchange no 1

1 Jan 1210:01

If the Operating Mode is configured as ‘100%’ mode, the ‘Tx on’ LED will light and the

system will attempt to establish a link with the remote ter minal. This condition will continue

until a link has been established, indicated by the ‘Rx lock’ LED being lit.

If the Operating mode is configured as ‘on-demand’ the terminal will not turn on its

transmitter until a valid req uest is sent f r om the r elevant user int erf ace, e.g . t elephone of f hook.

©1999 Exicom Technologies (1996) Ltd 2-11 Issue 2 - February 2001

EX7100 Technical Manual - Installation of Antenna and Equipment

It is now recommended that you proceed to Section 3 ‘Configuring the Terminal’, to

ensure that the EX7100 terminal has been configured for your specif ic applicat ion.

2.11 Final Antenna Alignment

2.11.1 General

This part of t he installation req uires t wo people, or one person with an analogue voltm eter

plugged into the terminals front panel monitoring point. The voltmeter leads need to be

long enough for the inst aller t o view the display while rotating the ant enna.

You will also need to refer to Section 3 of this Manual for instructions on using the

EX7100’s front panel.

Do not stand in front of the antenna, as electromagnetic radiation

may be hazardous to your health. Leave at least 1 metre between

the installer and the antenna as shown below

Figure 2.8: Antenna Alignment

2.11.2 Alignment Sequence

1) Set up a Test Link by following the

procedure outlined in Section 4.3.1.

2) Use the up and down arrow keys to

make sure the →→→→ is next to Antenna

Align and then press ‘Enter’

©1999 Exicom Technologies (1996) Ltd 2-12 Issue 2 - February 2001

12345678

→antenna align

EX7100 Technical Manual - Installation of Antenna and Equipment

3) The local terminal’s transmitter will turn

off (Tx LED will go off), allowing the user

to adjust the antenna safely. T he r em ot e

Tx will remain on for up to 60 minutes.

RSSI is now displayed on the screen as

well as on the voltmeter inputs on the

front panel.

4) While one person watches the RSSI

level, the other should move the antenna

direction slightly until the RSSI level is at

its highest. This is the optim um antenna

alignment. Make sure you stand at least

one metre behind the active element

while taking a reading so as not to cause

interference. Tig hten the mounting bolts.

(Note: One person can do both tasks if a

voltmeter with long leads is connected to

the jacks on the front panel.

5) Press ‘Escape’. T he link will restart and

the menu will return to Antenna Align.

Press ‘Escape’ again then use the up

and down arrows to make sure the →→→→ is

next to End Remote Tests and then

press ‘Enter’.

RSSI: -95 DBM

■■■■■■■■■

RSSI: -90 dbm

■■■■■■■■■■■

Start tests

→end remote tests

This completes the installation of the terminal.

Repeat this “Final Antenna Alignment” procedure for the other ter minal.

©1999 Exicom Technologies (1996) Ltd 2-13 Issue 2 - February 2001

EX7100 Technical Manual - Installation of Antenna and Equipment

This page intentionally left blank

©1999 Exicom Technologies (1996) Ltd 2-14 Issue 2 - February 2001

EX7100 Technical Manual - Configuring the Terminal

3.1 General

In many cases, the terminal will have been configured in the factory, however it is

recommended that certain operating parameters be checked and corrected as required

before attempting to set-up a link.

The EX7100 is equipped with a powerful configuration, monitoring, and diagnostic, system

that may be accessed using the six-button keypad and LCD on the f ront panel. The front

panel also has four LED's that indicate the operating status of the terminal, as well as any

alarms being generated by the terminal.

3.2 Using the Keypad

3

Configuring the Terminal

The EX7100 six-button keypad allows the user to scroll through the user interface menu,

and then select, or change, the relevant parameters.

A password is required to allow access to the menu system. This password is ‘1111’, and

cannot be changed

operating parameters. This password may be changed at any time from the Exicom

default value of ‘1234’. Refer to Section 3.4.1 for details.

Direction Buttons

The four direction buttons provide up and down scrolling, as well as moving the cursor left

and right along any particular line.

Example: To change the default second level password from ‘1234’ to ‘2222’

(Refer to Section 3.4.1 for full details):

> Use the right arrow key to position the ↑↑↑↑ under the ‘1’.

> Press the up arrow key once to change the ‘1’ to a 2.

Exicom EX7100

1 Jan 1200.01

. A Second Level password is required to allow amendment of

Figure 3.1: EX7100 Front Panel Display and Keypad

> Press the right arrow key twice to position the ↑↑↑↑ under the ‘3’.

> Press the down arrow key once to change the ‘3’ to a 2.

> Press the right arrow key once to position the ↑↑↑↑ under the ‘4’.

> Press the down arrow key twice to change the ‘4’ to a 2.

> Press ‘Enter’ to accept changes.

©1999 Exicom Technologies (1996) Ltd 3-1 Issue 1 - May 2001

EX7100 Technical Manual - Configuring the Terminal

Note: The user menu is not

a continuous loop. Once the cursor reaches the bottom of the

menu, you must use the up arrow to step back up to the top. Similarly, once the

cursor reaches the top of the menu you must use the down arrow to step back

down.

‘Enter’ Key

The ‘Enter’ key operates the same as a computer keyboard ‘Enter’ key. This will accept

any changes you have made to a parameter, or access the next menu level if available.

This will be indicated by a →→→→ symbol.

‘Escape’ Key

The ‘Escape’ key enables the user to back out of a menu location.

3.3 The User Interface Menu

The 16x2 digit display lets the user see two lines of the menu at once. As the user scrolls

up or down through the menu, the →→→→ symbol will indicate which line will b e selected if the

‘Enter’ key is pressed.

When viewing certain parameters, the LCD will give a numerical reading as well as a

graphical display. For example, an RSSI reading may look like this:

RSSI: -95 DBM

■■■■■■■

Figure 3.2: EX7100 Front Panel Display – RSSI Reading

3.4 Changing Parameters

This section is split into four areas:

Universal Parameters (refer to Section 3.4.1)

This section explains how to check and reconfigure certain oper ating parameters, which

are generic to all EX7100 terminals, whether Data, Exchange, or Subscriber.

Data Terminal Parameters (refer to Section 3.4.2)

This section explains how to check and reconfigure certain oper ating parameters, which

are specific to 64kbps Data terminals only.

Exchange Terminal Parameters (refer to Section 3.4. 3)

This section explains how to check and reconfigure the operation of certain parameters

that are specific to Exchange terminals only.

Note that an Exchange terminal normally connects t o the PST N or a PABX . W hen used in

conjunction with a Subscriber terminal the system provides six replacement telephone

circuits.

©1999 Exicom Technologies (1996) Ltd 3-2 Issue 1 - May 2001

EX7100 Technical Manual - Configuring the Terminal

Two Exchange terminals may also be configured as a 4-wire Point to Point system. In this

mode, the system provides six, 4-wire trunked audio circuits with E & M wire control

signalling.

Subscriber Terminal Parameters (refer to Section 3.4.4)

This section explains how to check and reconfigure the operation of certain parameters,

which are specific to Subscriber terminals only.

3.4.1 Universal Parameters

Passwords.

EX7100 is protected by two levels of passwording.

The Low Level password is required to access the front panel menu system and is factory

fixed as ‘1111’. This cannot be changed by the user.

The High (or Second) Level password (required to change important operating

parameters) may be changed from the Exicom factory default setting of ‘1234’ to any fourdigit number.

Note 1: If the high level password is changed and the new password subsequently

forgotten, you will need to contact Exicom for a backdoor password.

Note 2: It is possible to disable either/both passwords as detailed below. It

should be noted however, that disabling the passwords will allow any

unauthorised person to change the terminal’s configuration.

Changing the Second Level Password.

1) From idle, press ‘Enter’

You will be asked to enter the password.

Note

this is the First Level password

which is factory fixed at ‘1111’

Use the arrow keys to enter ‘1111’, then

press ‘Enter’.

(Note: the up and down arrows increase

or decrease the number above the ↑↑↑↑

symbol)

2) Use the up and down arrow keys to make

sure the →→→→ is next to Controller.

Press ‘Enter’

3) Use the up and down arrow keys to make

sure the →→→→ is next to Passwords.

Press ‘Enter’

4) Use the up and down arrow keys to make

sure the → is next to Change Password.

Press ‘Enter’

Password ∗ ∗ 1 ∗

↑

→Controller

RF PARAMETERS

Set Time / date

→passwords

→change password

disable lo p/word

©1999 Exicom Technologies (1996) Ltd 3-3 Issue 1 - May 2001

EX7100 Technical Manual - Configuring the Terminal

4) You will be asked to enter the old Second

Level password. If this is still set to the

factory default value, use the arrow keys

to enter ‘1234’, then press ‘Enter’

5) You will be asked for the new

Second

Level password. Use the arrow keys to

change the old password to the required

new password and press ‘Enter’

6) You will be asked to confirm the new

password. Use the arrow keys to re-enter

the new Password, and press ‘Enter’

7) The new Second Level password is now

set. Press ‘‘Escape’’ until the display

returns to idle.

Disabling the Passwords.

1) From idle, press ‘Enter’

You will be asked to enter the password.

Note

this is the First Level password

which is factory fixed at ‘1111’

Use the arrow keys to enter ‘1111’, then

press ‘Enter’.

(Note: the up and down arrows increase

or decrease the number above the ↑↑↑↑

symbol)

2) Use the up and down arrow keys to make

sure the →→→→ is next to Controller.

Press ‘Enter’

3) Use the up and down arrow keys to make

sure the →→→→ is next to Passwords.

Press ‘Enter’

4) Use the up and down arrow keys to make

sure the → is next to ‘Disable Lo Lvl’, or

‘Disable Hi Lvl’.

Press ‘Enter’

5) You will be asked to enter the old

Second

Level password. If this is still set to the

factory default value, use the arrow keys

to enter ‘1234’, then press ‘Enter’

6) The password has now been disabled. To

re-enable the password, follow the same

process.

Old p/word: 0* * *

↑

New p/word: 0* * *

↑

Confirm p/w: 0***

↑

Password ∗ ∗ 1 ∗

↑

→Controller

RF PARAMETERS

Set Time / date

→passwords

change password

→Disable lo lvl

Old p/word: 0* * *

↑

©1999 Exicom Technologies (1996) Ltd 3-4 Issue 1 - May 2001

EX7100 Technical Manual - Configuring the Terminal

Changing the Time and Date.

The Time and Date should be changed to reflect local settings. Note that the date f ield

follows the UK format: DD/MM/YY.

1) From idle, press ‘Enter’

Use the arrow keys to enter the First Level

password ‘1111’ and then press ‘Enter’.

2) Use the up and down arrow keys to make

sure the →→→→ is next to Controller.

Press ‘Enter’.

3) Use the up and down arrow keys to make

sure the →→→→ is next to Set Time/Date.

Press ‘Enter’

4) The current time and date is displayed. As

in the example at the start of this section,

use the arrow keys to change the time and

date to the required local settings and then

press ‘Enter’

The new time takes effect when the ‘Enter’

key is pressed.

5) Press ‘‘Escape’’ unt il t h e display returns to

idle

Password ∗ ∗ 1 ∗

↑

→Controller

RF PARAMETERS

Operating mode

→set time/date

1201:01 01/01/98

↑

Operating Mode.

Ensure that this parameter is set to either:

> Terminal 100% (link is continually up),

> Terminal On Demand (link is up only with traffic),

> Repeater 100% (terminal configured as a repeater transmitting continually),

> Repeater On Demand (terminal configured as a repeater transmitting only with

traffic).

1) From idle, press ‘Enter’

Use the arrow keys to enter the First Level

password ‘1111’ and then press ‘Enter’.

2) Use the up and down arrow keys to make

sure the →→→→ is next to Controller.

Press ‘Enter’.

3) The screen will read Operating Mode.

Press ‘Enter’

Password ∗ ∗ 1 ∗

↑

→Controller

rf parameters

→operating mode

set Time / date

©1999 Exicom Technologies (1996) Ltd 3-5 Issue 1 - May 2001

EX7100 Technical Manual - Configuring the Terminal

4) Use the up and down arrow keys to

choose the required operating mode and

then press ‘Enter’.

Note that the current setting is indicated by

an asterisk.

5) Press ‘‘Escape’’ unt il t h e display returns to

idle.

Link ID.

The Link ID is the identification number f or the link. There are 99 possible numbers from

1-99. (The factory default setting is 01)

Both terminals in the link must have the same Link ID setting. (If a repeater conf iguration

is used, see Section 8, all

terminals must have the same link ID).

1) From idle, press ‘Enter’

Use the arrow keys to enter the First Level

password ‘1111’ and then press ‘Enter’.

2) Use the up and down arrow keys to make

sure the →→→→ is next to Controller and then

press ‘Enter’.

3) Use the up and down arrow keys until the

→→→→ is next to Change Link ID and then

press ‘Enter’.

4) Use the arrow keys to enter the required

link identification number (0-99)

Note: all term inals in a link must

have the

same Link ID (including repeaters).

Press ‘Enter’ to accept changes.

5) Press ‘Escape’ until the display returns to

idle.

→terminal 100%

term on demand

Password ∗ ∗ 1 ∗

↑

→Controller

rf parameters

Change password

→change Link id

Link id: 01

↑

Terminal Descriptor.

If required, a 16-character description of the terminal can be set. If changed from the

factory default setting, the terminal descriptor will be displayed on the front panel while the

user interface is idle, and will be displayed instead of the ESN when being accessed from

a remote location.

1) From idle, press ‘Enter’

Use the arrow keys to enter the First Level

Password ∗ ∗ 1 ∗

↑

password ‘1111’ and then press ‘Enter’.

2) Use the up and down arrow keys to make

sure the →→→→ is next to Controller.

→Controller

rf parameters

Press ‘Enter’.

©1999 Exicom Technologies (1996) Ltd 3-6 Issue 1 - May 2001

EX7100 Technical Manual - Configuring the Terminal

3) Use the up and down arrows until the →→→→ is

next to Terminal Desc. Press ‘Enter’

4) Use the keypad to set the required

terminal description and then press ‘Enter’.

5) Press ‘Escape’ until the display returns to

idle.

Changing the RF Channel Increment.

The EX7100 provides RF Frequency increments of either 6.25 kHz (Exicom factory default

setting), or 5.0 kHz. Depending on the operating frequencies you require, it may be

necessary to change this setting to the other value.

Example: If your required frequencies are not divisible by 6.25 k Hz you will need to set the

channel increments to 5.0 kHz.

The procedure below is particular to a link at idle. If a link is alr eady established, or you

wish to change the channel increment remotely, the ‘Change Frequency’ command must

be used to action the changes. Refer to Section 4.3.3 for details.

1) From idle, press ‘Enter’.

Use the arrow keys to enter the First Level

password ‘1111’ and then press ‘Enter’.

2) Use the up and down arrow keys to make

sure the →→→→ is next to RF Parameters.

Press ‘Enter’.

3) Use the up and down arrow keys to make

sure the →→→→ is next to Chan Increment.

Press ‘Enter’.

4) An asterisk (*) shows which increment

setting is currently in use. If required, use

the up and down arrow keys to toggle

between the two settings. Press ‘Enter’ to

accept the change.

5) If t he current operating frequencies are

incompatible with the new channel

increment, the terminal will display an

error message. The operating frequencies

will need to be adjusted as required to suit.

6) Press ‘Escape’ until the display returns to

idle.

Change link ID

→terminal desc

Exicom ex7100

↑

Password ∗ ∗ 1 ∗

↑

Controller

→RF PARAMETERS

→chan increment

Tx frequency

→ 5 khz

* 6.25 khz

Error: tx,rx not

On 25khz step

©1999 Exicom Technologies (1996) Ltd 3-7 Issue 1 - May 2001

EX7100 Technical Manual - Configuring the Terminal

Changing the Local Transmitter Frequency.

Ensure the Transmitter is set to operate on the required frequency.

Notes:

- This procedure is specific to a local

transmitter. To change the frequency of a

remote transmitter refer to Section 4.3.3.

- The EX7100’s front panel tuning range is limited. If a frequency change of more

than 100kHz

is required, it will be necessary to manually retune some parts of the

RF Section of the radio. Transmitter module re-tuning instructions are detailed in

Sections 7.3.3 (VHF) and 7.4.3 (UHF). Duplexer module re-tuning instructions are

given in Sections 7.9.3 (VHF) and 7.10.3 (UHF).

In addition, it may be necessary to replace the Duplexer module if a large chang e

in frequency is required. Refer Section 7.9.4 (VHF) and 7.10.5 (UHF).

Reserved Frequencies

- There are a number of internationally agreed frequencies that have been reserved

exclusively for Distress and Safety Communications.

It is therefore necessary to prevent transmission on the reserved frequencies (as

well as the frequencies one channel either side of the reserved frequencies)

Affected VHF frequencies

:

156.525 MHz (± 5 or 6.25 kHz) & 156.800 MHz (± 5 or 6.25 kHz)

Affected UHF frequency

:

406.000 MHz (± 5 or 6.25 kHz)

It is not possible to enter the above frequencies during the Tx frequency change

procedure outlined below (note that this only affects the Tx frequency procedure,

the Rx frequency procedure will allow selection of the frequencies but the

corresponding transmitter cannot be set)

1) The local transmitter must not be

transmitting. Setting the terminal to “Ondemand” operating mode will ensure the

transmitter is idle as long as there is no

data traffic .

From idle, press ‘Enter’

Use the arrow keys to enter the First Level

password ‘1111’ and then press ‘Enter’.

2) Use the up and down arrow keys to make

sure the → is next to Controller.

Press ‘Enter’.

Password ∗ ∗ 1 ∗

↑

→Controller

rf parameters

©1999 Exicom Technologies (1996) Ltd 3-8 Issue 1 - May 2001

EX7100 Technical Manual - Configuring the Terminal

3) Use the up and down arrow keys to make

sure the → is next to Operating mode.

Press ‘Enter’.

4) Use the up and down arrow keys to make

sure the → is next to Term On Demand.

Press ‘Enter’. (The Tx On LED will

extinguish after 10 seconds).

5) Press ‘Escape’ to return to the main menu.

Select RF parameters and press ‘Enter’.

6) Use the up and down arrow keys to make

sure the →→→→ is next to Tx Frequency.

Press ‘Enter’

7) The current frequency setting is displayed.

Press ‘Enter’ to change the frequency.

8) You will be asked for the Second Level

password. Exicom’s factory default is

‘1234’. If the default password does not

give access, see your System Engineer as

the password may have been changed

(refer to Section 3.4.1 for details).

9) The current frequency is displayed. Using

the arrow keys, change the frequency to

the required setting. Press ‘Enter’

(Note: When the cursor is under the least