Exhausto VEX260H Original Instructions Manual

VEX260H

with rotary heat exchanger and EXact control system

Product information........................................Chapter 1 + 6

Mechanical assembly.....................................Chapter 2 + 3

Electrical installation.......................................Chapter 4

Maintenance...................................................Chapter 5

MIO-TS-DUCT temperature sensor

MIO-TS-ROOM , temperature sensor

MIO-CO2-DUCT, CO2-sensor

MIO-RH humidity sensor

pieces, HMI control panel

pieces, MPT-DUCT constant pressure control

MXCU control for external cooling unit

pieces, MIO-PIR motion sensor

MIO-CO2-ROOM, CO2-sensor

Closing damper, LS400x80024, (LSA exhaust)

Closing damper, LS400x80024, (LSF outdoor)

Closing damper, LSR400x80024, with

spring-return (LSFR outdoor)

The following accessories are supplied

separately:

Unit supplied with (factory fitted):

Compact filter FP

pieces, Fire thermostat, BT40

pieces, Fire thermostat, BT50

pieces, Fire thermostat, BT70

Filter bag FB

HCE external heating coil (electrical)

HCW external heating coil (water)

Trim damper and blowout zone,TB260

Prod.order no.:

Sales order no.:

Original instructions

3003434-2014-04-14

VEX260_EXact

EXHAUSTO A/S

Odensevej 76

DK-5550 Langeskov

Tel. +45 65 66 12 34

Fax +45 65 66 11 10

exhausto@exhausto.dk

www.exhausto.dk

1. Product information

1.1. Model overview......................................................................................................5

Model overview..........................................................................................................5

1.2. Terms used in these instructions........................................................................7

1.3. Application.............................................................................................................8

1.4. Location requirements..........................................................................................8

1.4.1. Spatial requirements........................................................................................8

1.4.2. Requirements for underlying surface...............................................................9

1.4.3. Requirements for duct system.........................................................................9

1.5. Description...........................................................................................................10

1.5.1. The VEX unit design......................................................................................10

1.6. Principal dimensions...........................................................................................14

VEX260, V1.............................................................................................................14

VEX260, V2.............................................................................................................15

2. Handling

2.1. Unpacking............................................................................................................16

2.2. Transport..............................................................................................................16

2.2.1. Weight............................................................................................................16

2.2.2. The VEX sections' principal dimensions........................................................17

2.2.3. Internal transport with reduced weight...........................................................17

3. Mechanical assembly

3.1. Installing the unit.................................................................................................20

3.1.1. Removal and assembly instructions .............................................................20

4. Electrical installation

4.1. Electrical installation...........................................................................................23

5. Maintenance

5.1. Operating readings via the HMI panel...............................................................24

5.2. Maintenance chart...............................................................................................24

5.3. Service..................................................................................................................25

5.3.1. Filter replacement..........................................................................................25

5.3.2. Servicing and cleaning...................................................................................25

6. Technical data

6.1. Weight, corrosion class, temperature range, etc.............................................27

6.2. Compact filters.....................................................................................................29

6.3. Bag filters.............................................................................................................30

6.4. Capacity diagram.................................................................................................31

6.4.1. Unit with compact filter...................................................................................31

6.4.2. Unit with bag filter..........................................................................................32

6.5. Ordering spare parts...........................................................................................32

6.6. EC Declaration of Conformity.............................................................................33

3003434-2014-04-14

2/34

Symbols, terms and warnings

Prohibition symbol Failure to observe instructions marked with a prohibition symbol

may result in serious or fatal injury.

Danger symbol Failure to observe instructions marked with a danger symbol may

result in personal injury and/or damage to the unit.

Scope This instruction manual is for use with EXHAUSTO VEX-type air handling units.

Please refer to the product instructions regarding accessories and extra equipment.

The instructions must be fully observed to ensure personal safety and to protect the

equipment and ensure its correct operation. EXHAUSTO A/S accepts no liability for

accidents caused by equipment not used in accordance with the manual’s instructions and recommendations.

Supply air/extract

air

These instructions use the following terms as given in DS447-2013:

● Supply air (air blown in)

● Extract air (air removed)

● Outdoor air

● Exhaust air

Left/Right The term R for Right, indicates the supply air is to the right of the cooling unit, as

seen from the operating side. The term L for Left, indicates the supply air is to the

left.

Front page: Accessories

The front page of the instruction manual contains a checklist, detailing the accessories delivered with the VEX unit.

NB When retrofitting EXHAUSTO accessories, please update the checklist on the

front page.

Warnings:

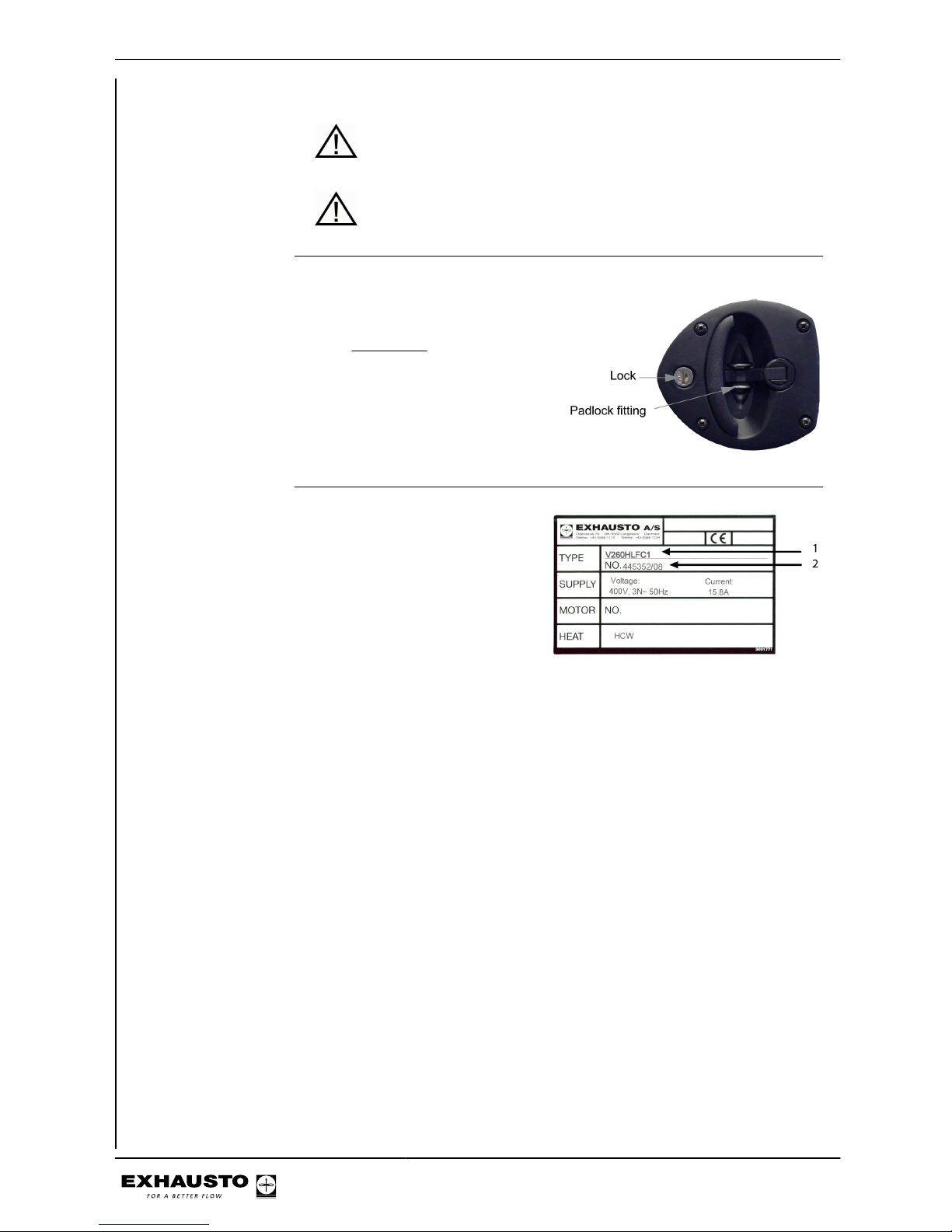

Opening the unit Do not open the service doors before the supply voltage has been

disconnected at the isolation switch and the fans have stopped.

The isolation switch is positioned on the left side of the connection box on top of the unit.

3003434-2014-04-14

3/34

Prohibited The VEX unit is not to be used to transport solid particles or in

areas where there is a risk of explosive gases.

No duct connection If one or more of the spigots is not connected to a duct: Fit a

protective net to the spigots with a maximum mesh width of 20

mm (in accordance with EN294).

Lock the air handling unit during operation

The VEX unit must always be locked

during operation:

● Use the cylinder lock in the handle. Remember to remove the

key from the lock.

● Or use a padlock. Use the handle’s built-in padlock fixture

Information plate The VEX unit information plate

shows:

● VEX model type (1)

● Unit production no. (2)

NB: Have the production number ready at all times when contacting EXHAUSTO

A/S.

3003434-2014-04-14

4/34

1. Product information

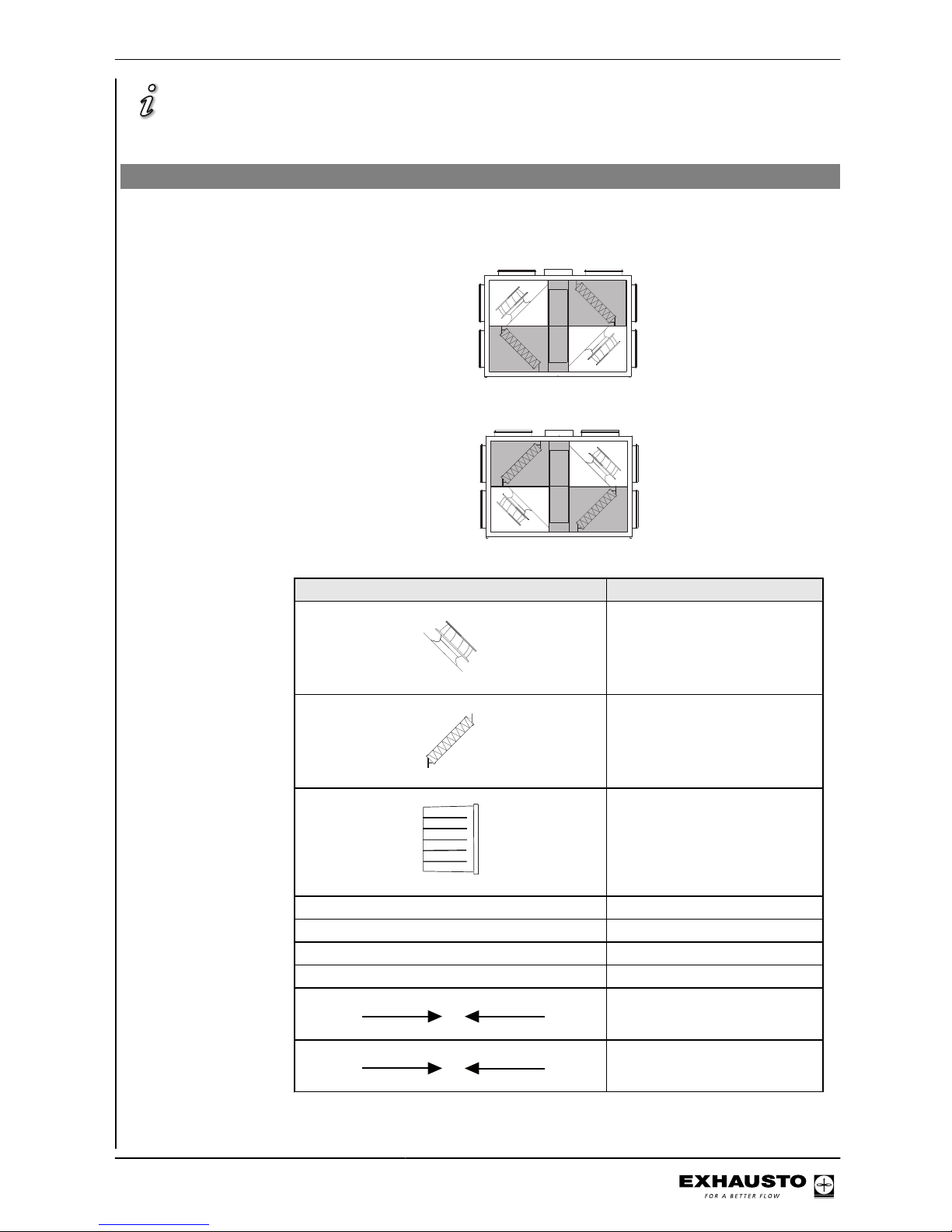

1.1 Model overview

Model overview

Positioning of fan,

motor (M) and frequency converter

(FC)

Fan placement 1 (V1)

RD12178-01

M2

FC2

M1

FC1

Fan placement 2 (V2)

RD12179-01

M1

FC1

M2

FC2

Elements Description

RD12767-01

Fan

RD12763-01

Compact filter

RD12762-01

Bag filter

1,1,A or B Extract air spigot

1,2,A or B Exhaust air spigot

2,1,A or B Outdoor air spigot

2,2,A or B Supply air spigot

1

1

Air direction, extract air

2

2

Air direction, supply air

3003434-2014-04-14

Product information

5/34

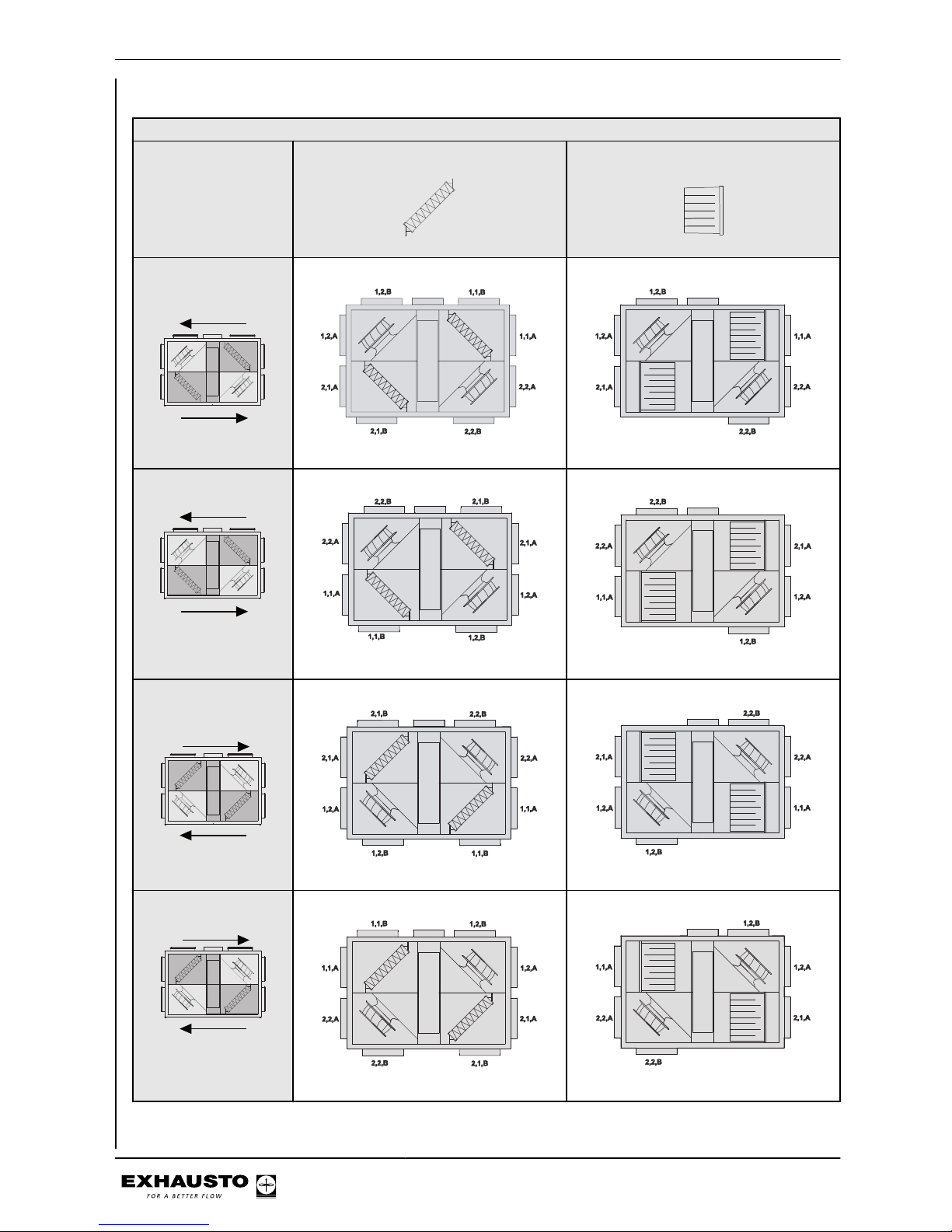

Optional spigot positioning in relation to fan placement and filter type

Fan placement and

airflows

Compact filters

RD12763-01

Bag filters

RD12762-01

Fan placement 1,

Right

RD12178-01

1

2

RD12979-01

RD12980-01

Fan placement 1, Left

RD12178-01

1

2

RD12981-01

RD12982-01

Fan placement 2,

Right

RD12179-01

2

1

RD12983-01

RD12984-01

Fan placement 2, Left

RD12179-01

2

1

RD12985-01

RD12986-01

3003434-2014-04-14

Product information

6/34

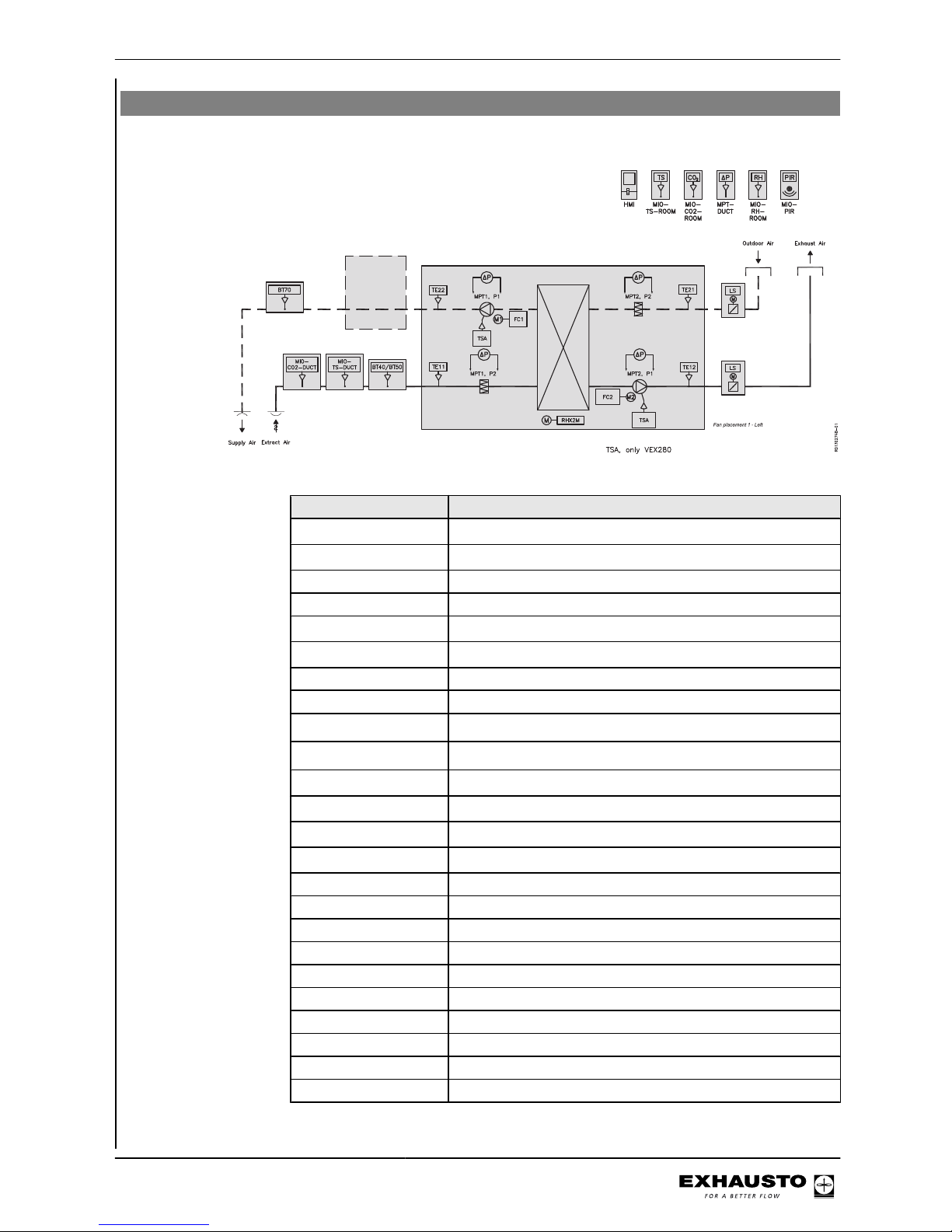

1.2 Terms used in these instructions

The simplified diagram shows a VEX unit with LEFT fan placement.

Component Function

BT40/BT50

1)

Fire thermostat, 40°C/50°C (extract air)

BT70

1)

Fire thermostat 70°C (supply air)

FC1 Frequency converter 1

FC2 Frequency converter 2

HMI

1)

Control panel

LS

1)

Closing damper, outdoor/exhaust air

M1 Fan motor, 1

M2 Fan motor, 2

MIO-CO2-DUCT

1)

CO2 sensor, duct

MIO-CO2-ROOM

1)

CO2 sensor, room

MIO-PIR

1)

PIR sensor

MIO-RH-ROOM

1)

Humidity sensor

MIO-TS-ROOM

1)

Temperature sensor, room

MIO-TS-DUCT

1)

Temperature sensor, extract air (external)

MPT1, P1 Airflow control, supply air

MPT1, P2 Filter monitor, extract air

MPT2, P1 Airflow control, extract air

MPT2, P2 Filter monitor, outdoor air

MPTDUCT Pressure transmitter, constant pressure regulation

RHX2M Control unit for the rotary heat exchanger

TE11 Temperature sensor, extract air

TE12 Temperature sensor, exhaust air

TE21 Temperature sensor, outdoor air

TE22 Temperature sensor, supply air

3003434-2014-04-14

Product information

7/34

Component Function

TSA Overheating

1)

Accessory. See checklist on the front page of these instructions.

1.3 Application

Comfort ventilation EXHAUSTO VEX is used for comfort ventilation tasks. Operating temperature range

for the unit – see section "Technical data".

Prohibited uses The VEX unit is not to be used to transport solid particles or in areas where there

is a risk of explosive gases.

1.4 Location requirements

Positioning The air handling unit is designed for indoor fitting. The air handling unit can be

ordered for outdoor installation (accessory Outdoor, OD).

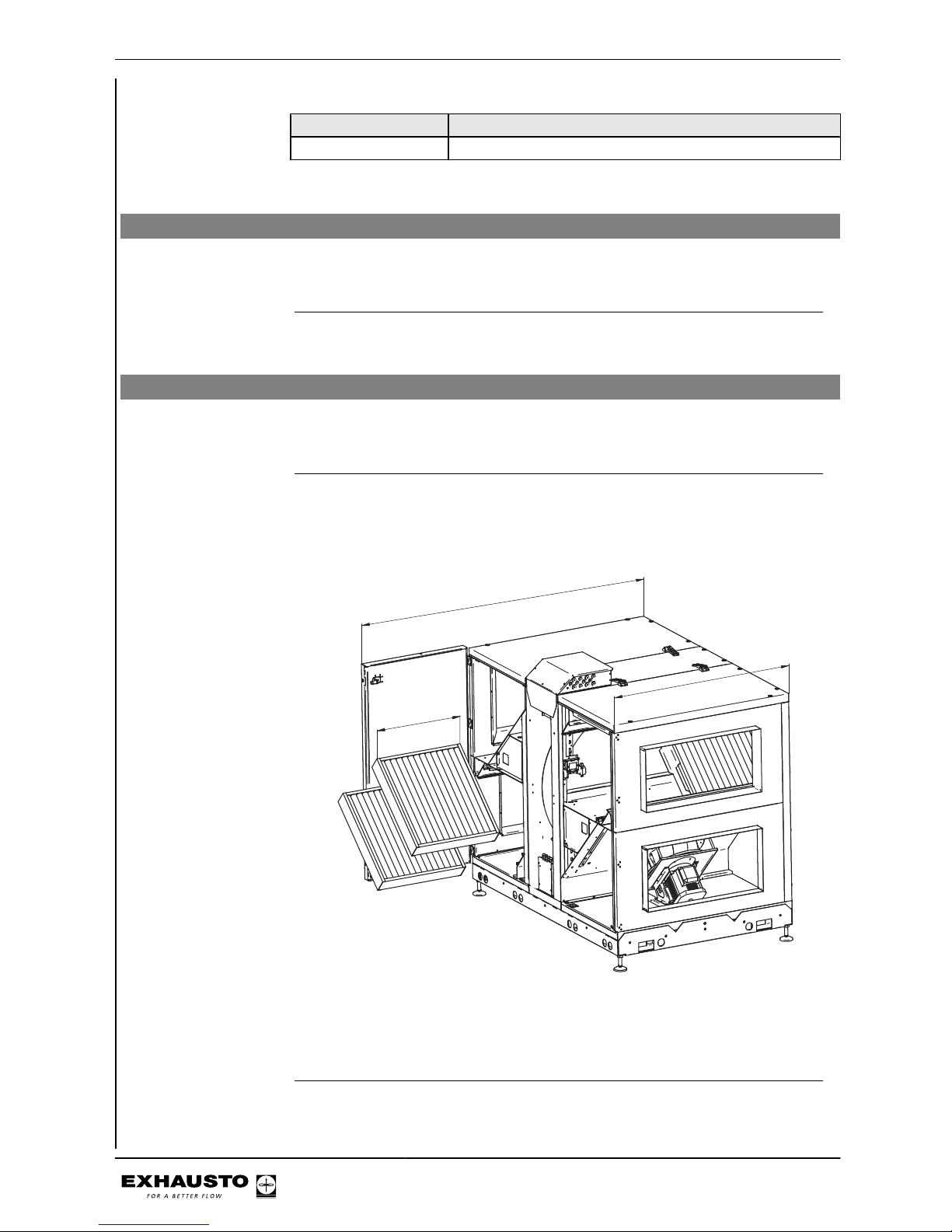

1.4.1 Spatial requirements

The drawing below indicates how much space is needed for servicing, replacing filters,

cleaning, etc.

A

1

2

1

0

1

9

2

5

RD11635-01

Compact filter: A = 575 mm

Bag filter: A = 592 mm

NB: A free height of at least 200 mm is required above the unit’s connection box.

3003434-2014-04-14

Product information

8/34

1.4.2 Requirements for underlying surface

When fitting the unit directly, the surface must be:

● flat

● level

● hard

● resistant to vibration

1.4.3 Requirements for duct system

Silencers The duct system must be fitted with silencers specified by the Project Manager,

which meet the requirements of the operating area.

Bends A duct bend may be fitted immediately after the unit, because the airflow in the

spigot has a uniformly moderate speed profile, which results in negligible system

pressure loss.

Insulation The duct system must be insulated against:

● condensation

● sound leakage

● heating/cooling losses

Condensation Condensation in the ducts may occur when the exhaust/outdoor air has high hu-

midity. EXHAUSTO recommends a condensation outlet is also fitted at the lowest

point in the ducts.

No duct connection If one or more of the spigots is not connected to a duct: Fit a

protective net to the spigots with a maximum mesh width of 20

mm.

3003434-2014-04-14

Product information

9/34

1.5 Description

1.5.1 The VEX unit design

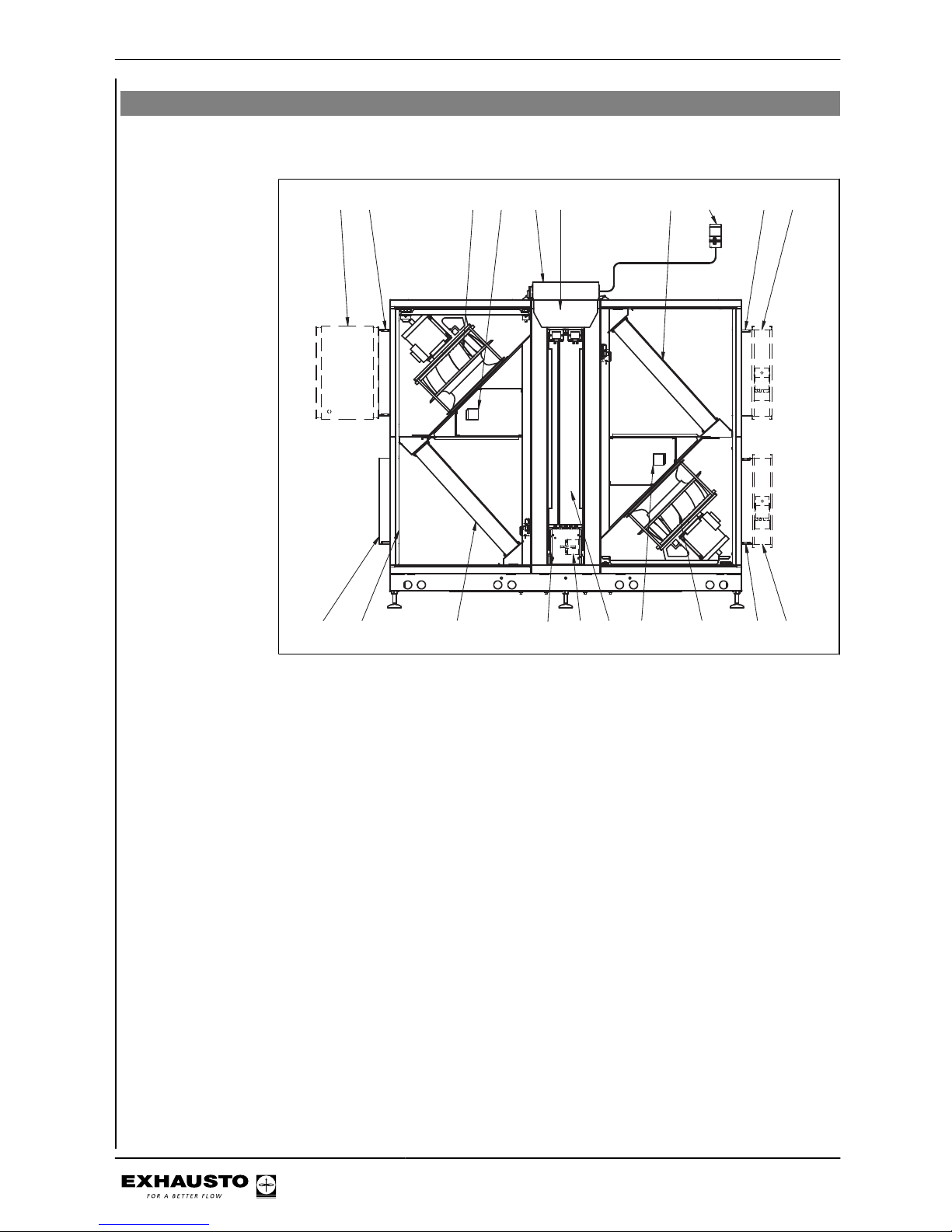

VEX200L - V1 The drawing below illustrates the construction of the unit (without service doors).

2,1,A

1,2,A

1,1,A

2,2,A

2

35678

9

101112

13 14 1516 17 18 19

20

1

4

RD11702-01

3003434-2014-04-14

Product information

10/34

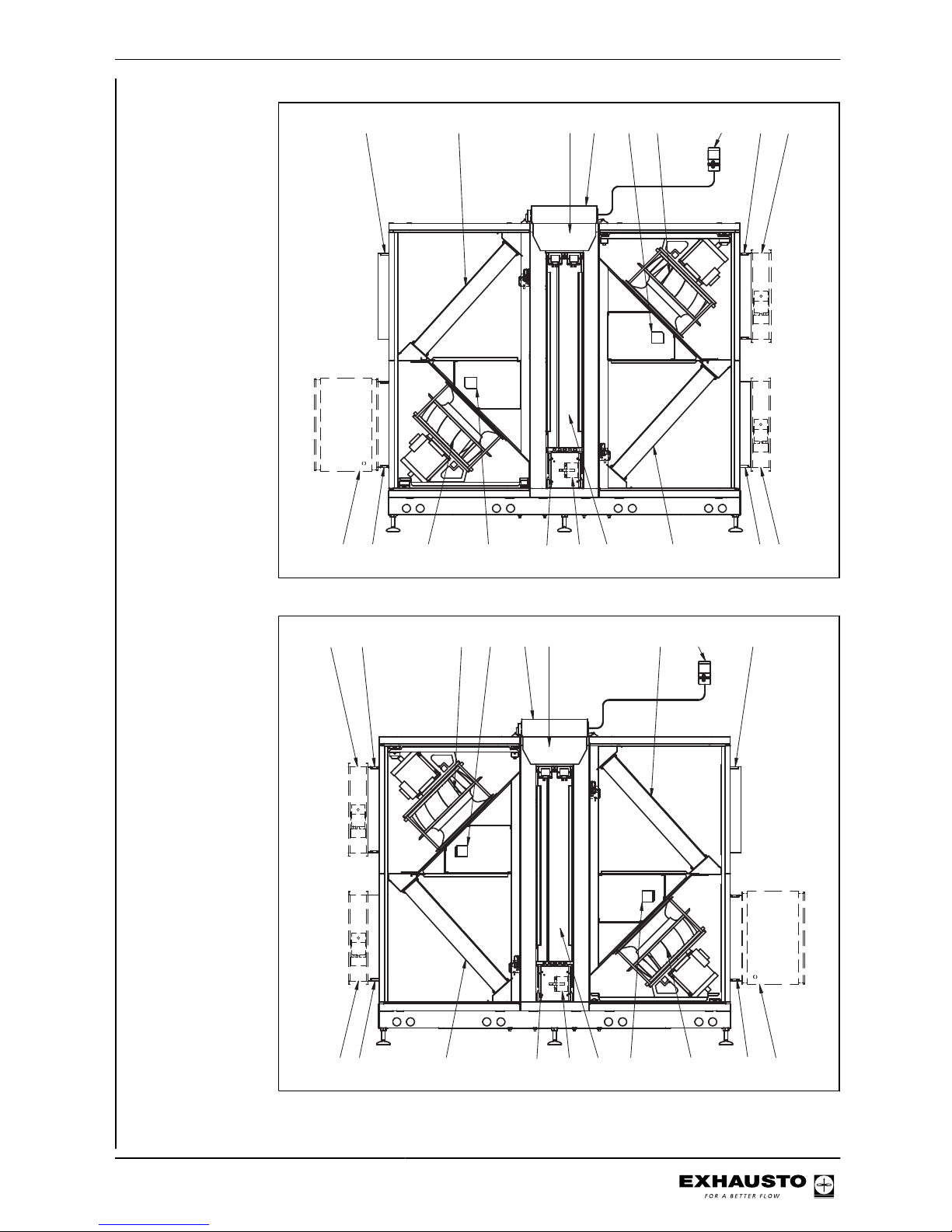

VEX200L - V2

7

2,1,A

1,2,A

1,1,A

2,2,A

13 16 17 8

9

20

3

4155618192012

14 1 2

RD11703-01

VEX200R - V1 The drawing below illustrates the construction of the unit (without service doors).

2,1,A

1,2,A

1,1,A

2,2,A

13161778

9

20

3

4

15

5

6 18 19 20 12

14

12

RD11704-01

3003434-2014-04-14

Product information

11/34

Loading...

Loading...