Exhausto VEX200 series, EXact2 VEX240 series, EXact2 VEX250 series, EXact2 VEX260 series, EXact2 VEX270 series Basic Instructions

...

EXact Control System

Basic instructions for the VEX200 series

EXHAUSTO

OK

EXHAUSTO

Esc

OK

Original instructions

3003246-2014-05-21

EXact_VEX200

EXHAUSTO A/S

Odensevej 76

DK-5550 Langeskov

Tel. +45 65 66 12 34

Fax +45 65 66 11 10

exhausto@exhausto.dk

www.exhausto.dk

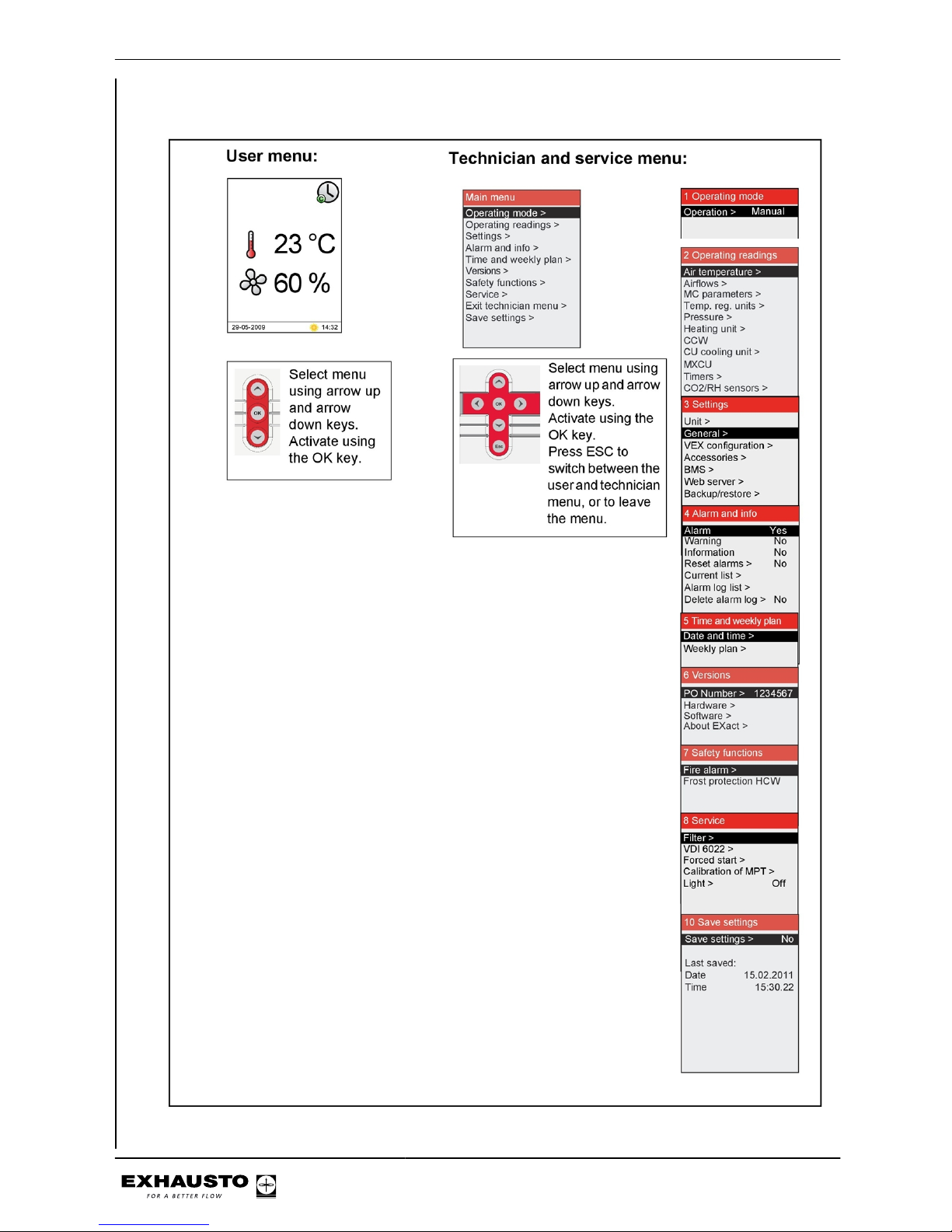

Menu structure

3003246-2014-05-21

2/100

Symbols and software version

Symbols used in these instructions...........................................................................5

Software version...........................................................................................................5

Software version .......................................................................................................5

2. User mode

2.1. HMI panel................................................................................................................6

2.2. Display icons..........................................................................................................7

3. Operation, access codes and selecting language

3.1. Using the HMI panel..............................................................................................9

3.1.1. Using keys within the menus...........................................................................9

3.2. Access codes for technician and service menus.............................................10

3.3. IMPORTANT when servicing..............................................................................11

3.3.1. Auxiliary service panel...................................................................................12

Menu 3.2 - Selecting language..................................................................................13

Menu 3.2.1 - Setting date and time............................................................................13

Menu 3.2 - Reset settings...........................................................................................13

Menu 3.2 - Reload database.......................................................................................14

Menu 3.6 - Web server................................................................................................14

Menu 3.7 - Backup/restore.........................................................................................15

4. Starting unit operation

4.1. Getting started.....................................................................................................16

Start configuration....................................................................................................17

Menu 3.4 - Accessories...........................................................................................18

Menu 3.4 Connecting heating and cooling units .....................................................19

Menu 3.5 BMS.............................................................................................................20

Menu 3.5 - BMS.......................................................................................................20

4.3. What is an indoor air quality level?...................................................................20

Menu 1 - Selecting operating mode..........................................................................21

Menu 3.1.1 - Operating settings - Air regulation......................................................21

Menu 3.1.1 - Operating settings Balance................................................................23

Menu 3.1.1.5 Regulators ........................................................................................24

Menus 3.1.1.1.1 to 3.1.1.1.4 Configuring the selected indoor air quality levels....25

Menu 3.1.1.1.x - Air set point ..................................................................................25

Menu 3.1.1.1.x - Temperature set point ..................................................................25

Menu 3.1.1.1.x - Absolute / Relative temperature ..................................................25

Menu 3.1.1.1.x - Cooling relative start ....................................................................26

Menu 3.1.1.1.x - Heating relative start ....................................................................26

Menu 3.1.1.1.x - Cooling absolute start ..................................................................26

Menu 3.1.1.1.x - Heating absolute start ..................................................................27

Generally on temperature regulation ......................................................................27

Menu 3.1.8 - Temperature limits..............................................................................27

Menu 3.1.1.1.x - Supply air regulation, absolute ....................................................29

Menu 3.1.1.1.x - Room temperature regulation, absolute ......................................30

Menu 3.1.1.1.x - Supply air regulation, relative ......................................................31

Menu 3.1.1.1.x - Room temperature regulation, relative ........................................33

Menu 3.1.1 - Operation settings - Temperature regulation.....................................35

Compensation.............................................................................................................36

Menu 3.1.2 - Air compensation..................................................................................36

Menu 3.1.2.1 - CO2 compensation .........................................................................37

Menu 3.1.2.2 - Humidity compensation of airflow ...................................................38

Menu 3.1.2.3 - Airflow reduction .............................................................................38

Menu 3.1.2.4 - Outdoor compensation of airflow ....................................................39

Menu 3.1.3 - Temperature compensation.................................................................40

Outdoor air temperature compensation (menu 3.1.2.1) ..........................................40

Summertime compensation (menu 3.1.2.2) ............................................................41

Menu 3.1.4 + Menu 8.1 - Filter (monitoring in case of pressure) ............................41

Menu 3.1.4 + Menu 8.1 - Filter (monitoring with hour counter) ...............................42

Menu 3.1.5 - Night-time cooling ..............................................................................42

Menu 3.1.6 - Cold recovery.....................................................................................45

Menu 3.1.7 - Fan limits............................................................................................45

3003246-2014-05-21

3/100

Menu 3.1.8 - Temperature limits for supply air and room........................................45

Room temperature limits..........................................................................................46

Menu 3.1.9 - Cooling/heat pump unit ......................................................................46

Menu 5 - Time and weekly plan.................................................................................47

Menu 5.1 - Date and time........................................................................................47

Menu 5.2 - Weekly plan ..........................................................................................48

Menu 7 - Safety functions..........................................................................................49

Menu 7.1 - Fire alarm..............................................................................................49

Menu 7.2 - Frost protection of HCW .......................................................................50

5. Operation

Menu 2 - Operating readings.....................................................................................52

Menu 2.1 - Air temperatures ...................................................................................52

Menu 2.1.1 - Set points for regulators ....................................................................53

Menu 2.2 - Airflows .................................................................................................53

Menu 2.3 - Motor controller parameters (MC parameters) .....................................53

Menu 2.4 - Temperature regulating units ................................................................54

Menu 2.5 - Pressure................................................................................................54

Menu 2.6 - Heating coil ...........................................................................................54

Menu 2.7 - Cooling/heat pump unit .........................................................................55

Menu 2.8 - CCW cold water coil .............................................................................55

Menu 2.9 - CU cooling unit......................................................................................55

Menu 2.10 - MXCU external cooling unit.................................................................55

Menu 2.11 - Hour counters......................................................................................56

Menu 2.12 - CO2/RH sensors (if mounted).............................................................56

Menu 6 - Versions.......................................................................................................56

Menu 8 - Service.........................................................................................................57

Auxiliary service panel.............................................................................................58

Menu 8.2 - VDI 6022................................................................................................59

Menu 8.3 - Forced start ..........................................................................................59

Menu 8.3.1 Fans......................................................................................................59

Menu 8.3.2 Recovery...............................................................................................59

Menu 8.3.3 Heating unit...........................................................................................60

Menu 8.3.4 Cooling unit...........................................................................................60

Menu 8.3.5 Dampers and relays..............................................................................60

Menu 8.4 - Calibrating MPT.....................................................................................60

6. Alarms

6.1. Alarms and info (Menu 4)....................................................................................62

6.2. Reset alarms........................................................................................................62

6.3. Alarm display – causes of errors.......................................................................62

6.4. List of alarms.......................................................................................................64

Appendix 1 - Simplified diagrams

Simplified diagrams....................................................................................................90

Simplified diagrams for unit with chiller ...................................................................90

VEX240-250-260-270L fan placement 1 ................................................................90

VEX240-250-260-270L fan placement 1 ................................................................90

VEX240-250-260-270L fan placement 2 ................................................................91

VEX240-250-260-270L fan placement 2 ................................................................91

VEX280L fan placement 1 ......................................................................................92

VEX280R fan placement 1 .....................................................................................93

VEX280L fan placement 2 ......................................................................................94

VEX280R fan placement 2 .....................................................................................95

Appendix 2 - Temperature resistance table

Temperature resistance table DC95..........................................................................96

3003246-2014-05-21

4/100

Symbols and software version

Symbols used in these instructions

Prohibition symbol Failure to observe instructions marked with a prohibition symbol

may result in serious or fatal injury.

Danger symbol Failure to observe instructions marked with a danger symbol may

result in personal injury and/or damage to the unit.

Software version

Software version

These instructions are for use with the following version:

AHUC: 3.2.0.0

HMI: 3.2.0.0

3003246-2014-05-21

Symbols and software version

5/100

2. User mode

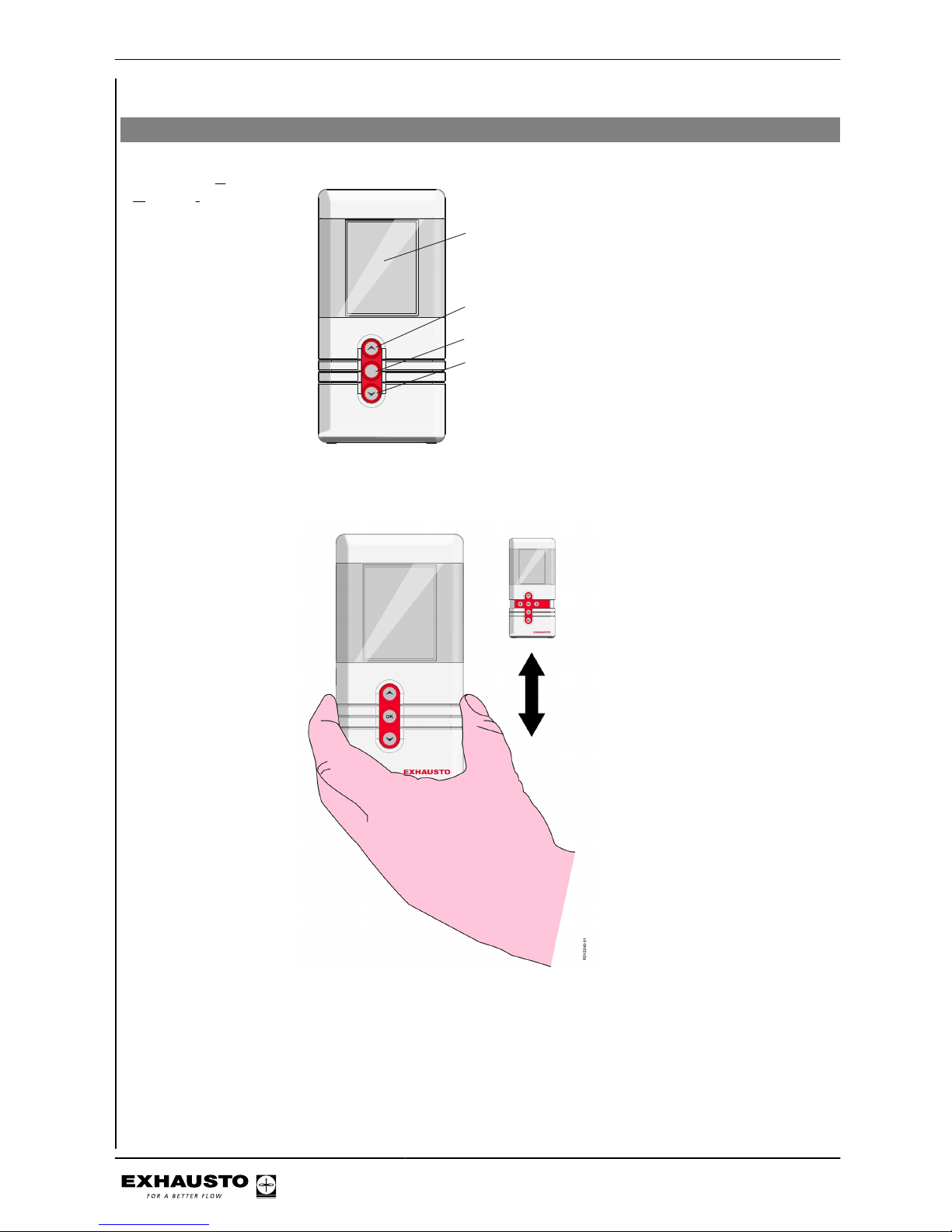

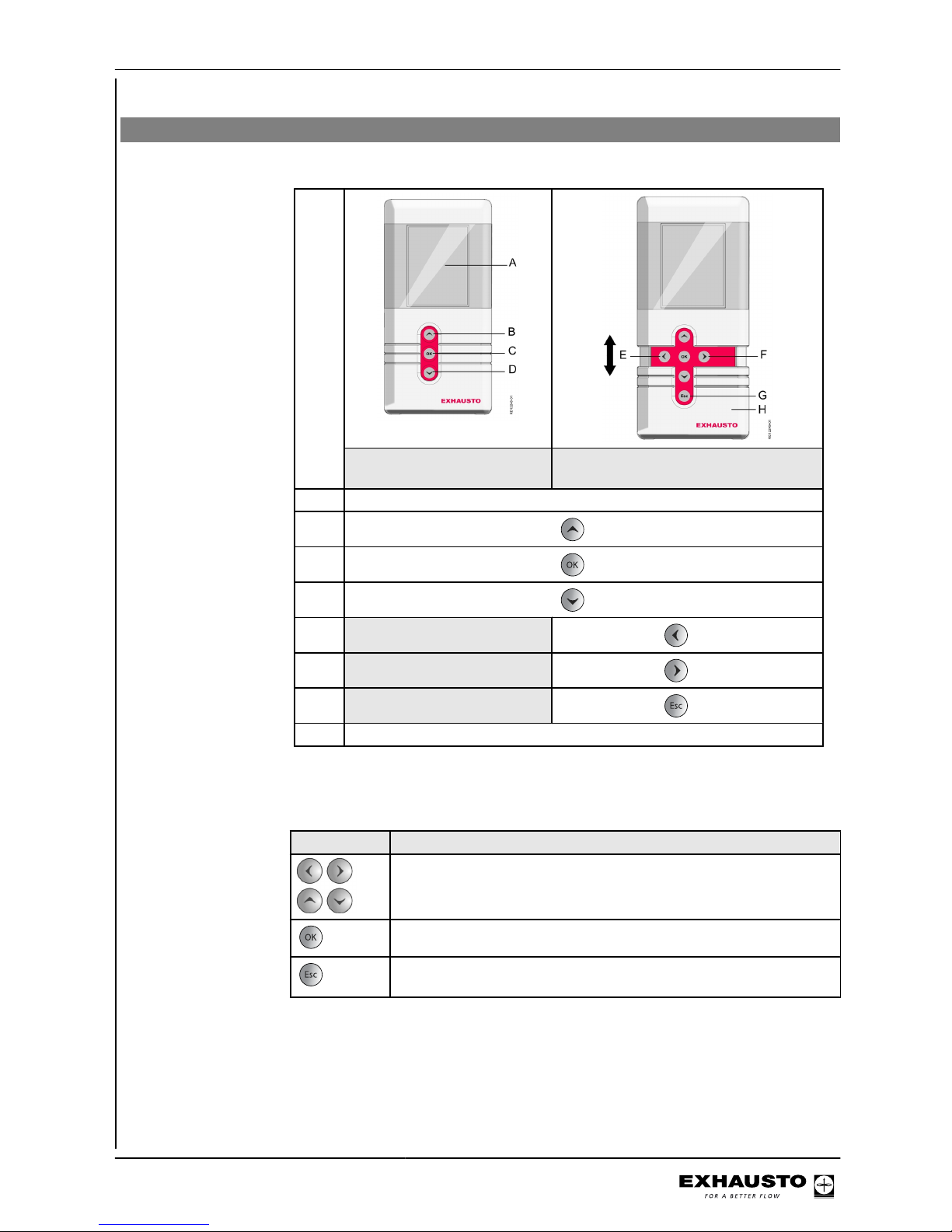

2.1 HMI panel

HMI panel - Human

Machine Interface

panel

mode

EXHAUSTO

OK

RD12248-01

Display

Browse menu or

set value

Activate menu/confirm key

Browse menu or

set value

If the front cover is extended, push it back in. The extra keys are for service technician use only.

3003246-2014-05-21

User mode

6/100

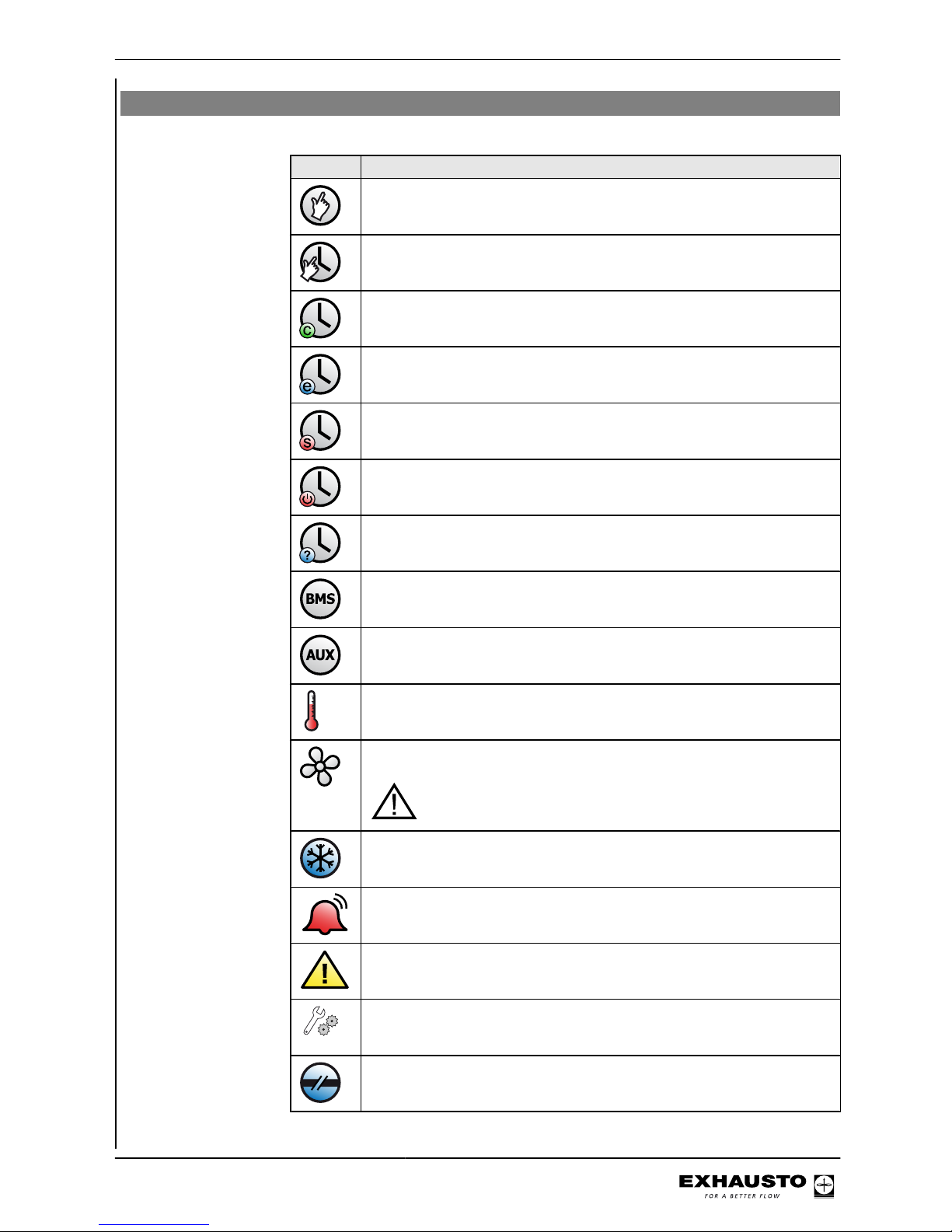

2.2 Display icons

Icon Description

Manual operation

Timer overridden until next changeover in the timer schedule

Timer, current indoor air quality level is comfort

Timer, current indoor air quality level is economy

Timer, current indoor air quality level is standby

Timer, VEX has stopped

Timer, no changeover times defined in timer schedule

BMS-controlled operation

Externally-controlled operation

Set point for temperature shown in °C

Set point for ventilation shown as percentage: 0% = no ventilation OFF =

Unit is switched off - timer function cannot start up unit

BMS or Web server-controlled system overrides the OFF function. This means the system may start up even if set to OFF

The unit is running de-icing (De-ice)

Unit alarm. Contact the service technician who can help reset the alarm.

Icon is also shown in the technician menu

Warning. Contact the service technician who can help reset the warning.

Icon is also shown in the technician menu

Temporarily

in service

Service display connected

External start/stop disconnected. See Electrical Installation Guide for further information

3003246-2014-05-21

User mode

7/100

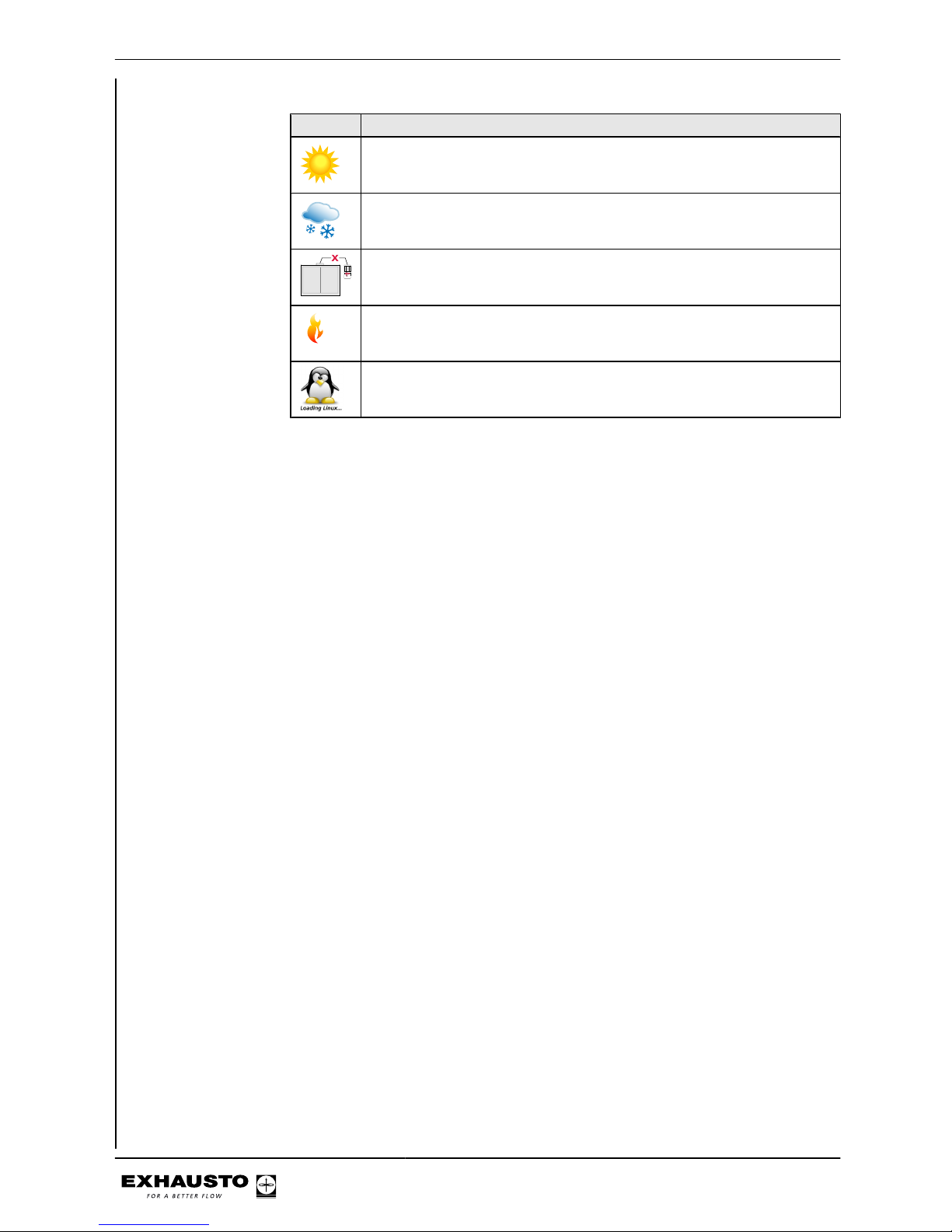

Icon Description

Summertime

Wintertime

No communication on the external BUS or communication between the

VEX and HMI is disconnected

Fire!

Fire alarm. Closed circuit open and the pre-set fire alarm function activated

Startup: Web server accessing database. The icon is displayed until the

HMI panel is ready for use.

3003246-2014-05-21

User mode

8/100

3. Operation, access codes and selecting language

3.1 Using the HMI panel

Keys for user mode

or service mode

HMI panel ready for everyday use

HMI panel ready for service mode

A Display

B

key

C

key

D

key

E

key

F

key

G

key

H Service key cover

3.1.1 Using keys within the menus

Keys Used for...

Navigation and setting values

Confirm key - selecting menu

Change between daily user and technician mode

Exiting a menu without making changes

3003246-2014-05-21

Operation, access codes and selecting

language

9/100

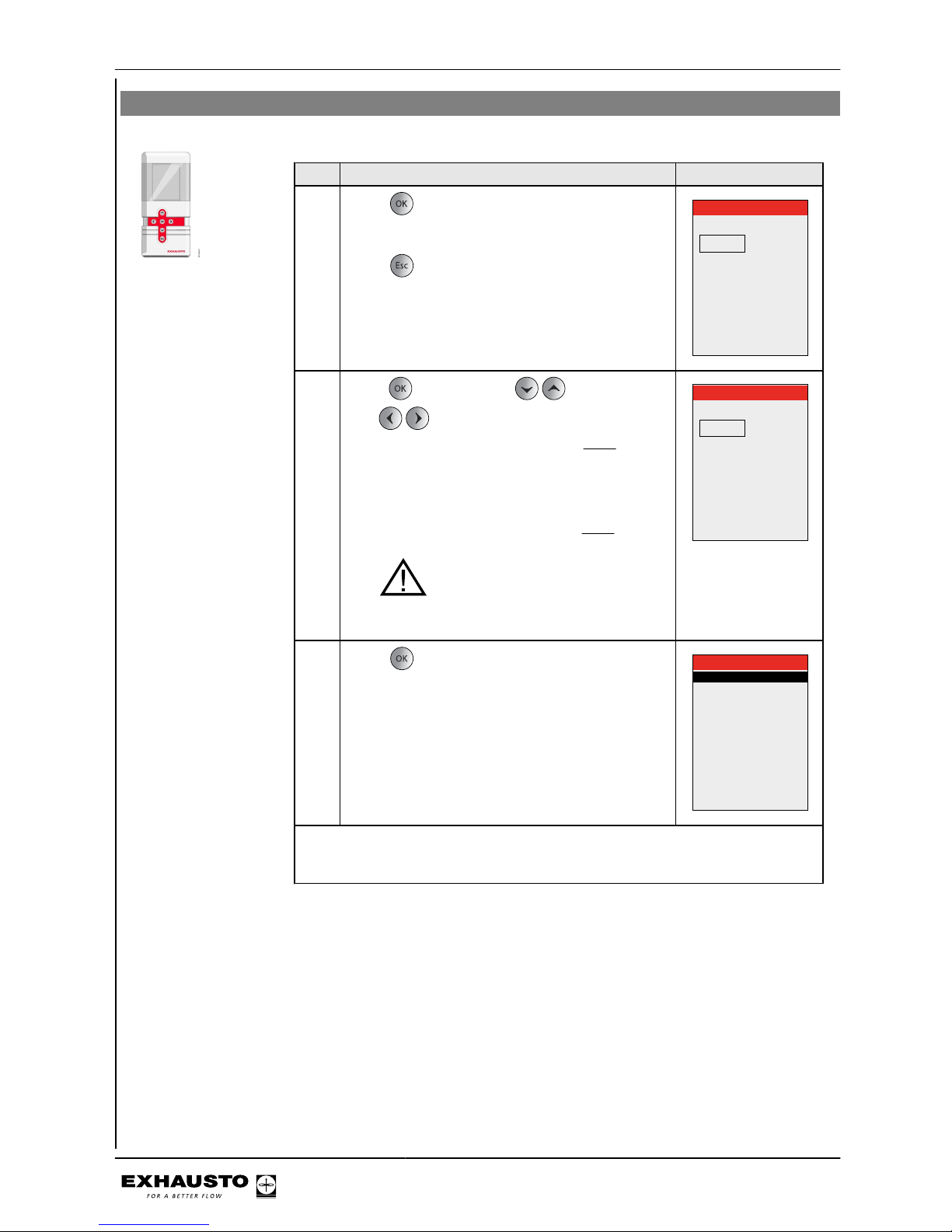

3.2 Access codes for technician and service menus

Step Action The display shows

1

Press for full display brightness (if the display

is in hibernation mode).

Press

Password

0000

2

Press and then press to set the value.

Use to shift to the next digit of the code.

● The code for technician mode is

1111 (some

menus are hidden or read-only). EXHAUSTO

recommends this mode is used for normal

service tasks

● The code for specialist mode is 3142 (full ac-

cess to all menus).

NB: incorrect settings (wrong val-

ues) may have a negative impact on unit

operation in some menus

Password

1111

3

Press to access main menu.

Main menu

Operating mode >

Operating readings >

Settings >

Alarm and info >

Time and weekly plan >

Versions >

Safety functions >

Service >

Exit technician menu >

Save settings >

Note

● Automatically logs out and returns to the user menu if no buttons are pressed

in a 30-minute period.

3003246-2014-05-21

Operation, access codes and selecting

language

10/100

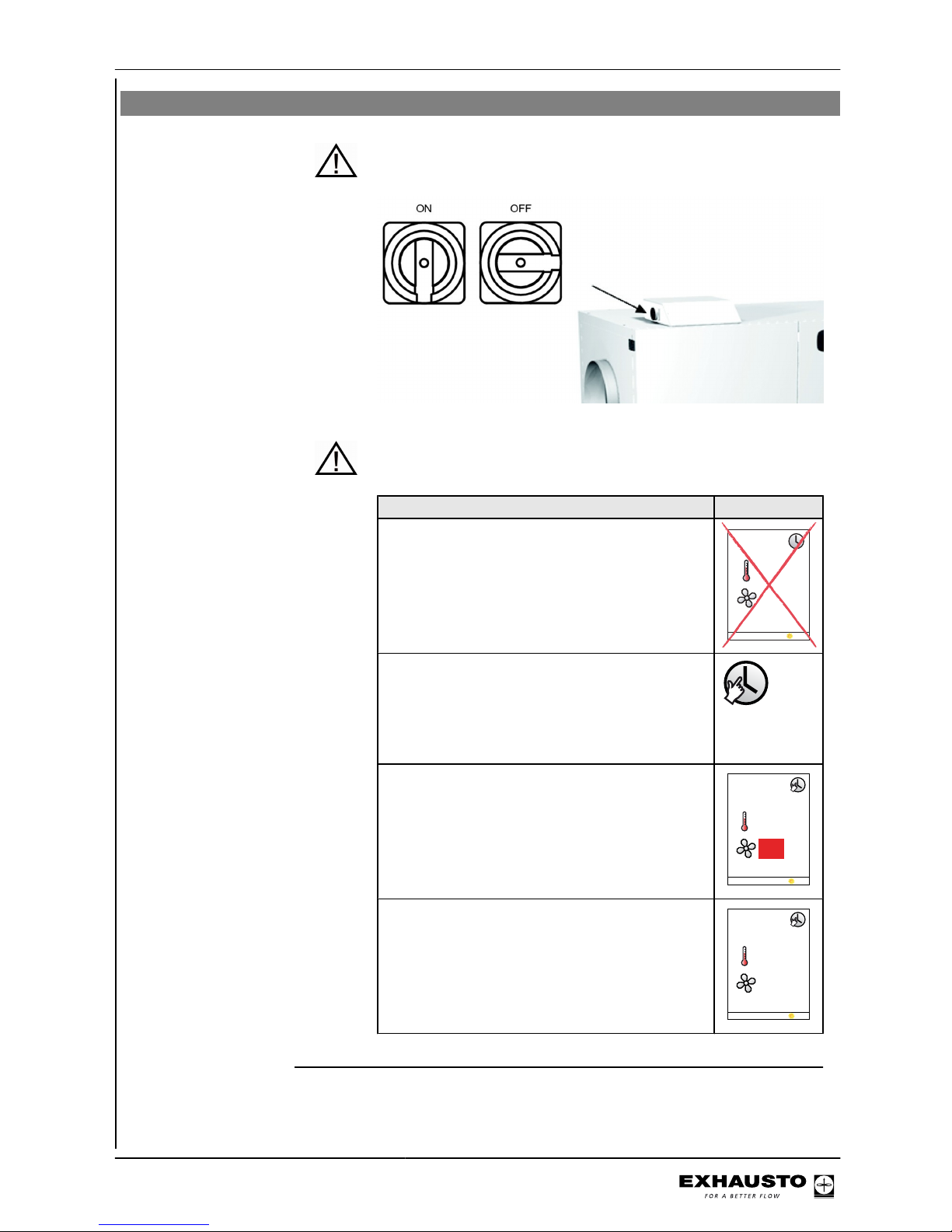

3.3 IMPORTANT when servicing

Do not open the service doors before the supply voltage has been disconnec-

ted at the isolation switch. The isolation switch is positioned on

the left side of the connection box on top of the unit.

Weekly plan It is important to set ventilation to OFF when the weekly plan is

active:

Set ventilation to OFF

NB - If the HMI panel shows 0% (VEX is inactive)

and the unit is operating to a weekly plan when

servicing begins, there is a risk that the program may change via a timer operation and restart the VEX unit.

21

0°C%

29-05-2009 14:32

● Log onto technician menu, using password 1111

● Change to manual operation via menu 1

● Change back to user menu

● The icon for manual operation appears in

the right-hand corner of the menu

● Press the OK button twice

● Use the arrow keys to adjust ventilation to

0%

23 °C

%

29-05-2013 14:32

0

● Press OK

● OFF will now appear on the display next to

the ventilation icon

23 °C

29-05-2013 14:32

OFF

3003246-2014-05-21

Operation, access codes and selecting

language

11/100

BMS unit or Web

server

If BMS or Web server controls are used, they could override the

OFF function and the VEX may start up irregularly. To disconnect

the BMS or WEB server connection, you must remove the plug

from the connection board. Refer to the section on the terminal

board in the Electrical Installation Guide.

3.3.1 Auxiliary service panel

If the HMI panel is located far from the VEX, it is recommended that an auxiliary HMI

panel be connected to the VEX in the connection box.

RD12627-02

Auxiliary service panel which

overrides the fixed HMI panel

Fixed HMI-panel

Service panel connector - Exact

3003246-2014-05-21

Operation, access codes and selecting

language

12/100

Menu 3.2 - Selecting language

Unit >

General >

VEX configuration >

Accessories >

BMS >

Web server >

Backup/restore >

3 Settings

3.2 General

Date and time >

Language >

Reset settings >

Reload database >

English

Main menu

Operating mode >

Operating readings >

Settings >

Alarm and info >

Time and weekly plan >

Versions >

Safety functions >

Service >

Exit technician menu >

Save settings >

Step Action

1 Select "Settings"

2 Select "General"

3 Select the required language in line 2 "Language"

4 Return to the main menu and select yes in "Save settings"

Menu 3.2.1 - Setting date and time

Unit >

General >

VEX configuration >

Accessories >

BMS >

Web server >

Backup/restore >

3 Settings

3.2 General

Date and time >

Language >

Reset settings >

Reload database >

English

3.2.1 Date and time

Date > 22-02-2009

Day >

Time >

Wednesday

13:11

Step Action

1 Select "Date and time" to set these parameters in Menu 3.2.1

Menu 3.2 - Reset settings

Selecting "Reset settings" resets the user settings. See the menu guide for details of

which menus are affected.

NB This cannot be reversed and the VEX will restart.

3.2 General

Date and time >

Language >

Reset settings >

Reload database >

English

3003246-2014-05-21

Operation, access codes and selecting

language

13/100

Menu 3.2 - Reload database

Selecting "Reset settings" resets the user settings. See the menu guide for details of

which menus are affected.

Database reloads

Initialising

Loading DB names

Menu 3.6 - Web server

Contact the network administrator for information on the correct IP address, etc. If the

admin password is lost, it can be reset to the factory setting. But note that this cannot

be reversed. See Exact Web server Instructions.

No

> 192.168.001.180

> 255.255.255.000

> 192.168.001.001

80

00:1F:79:00:00:D0

No

3.6 Web server

DHCP >

IP address

Subnet mask

Standard gateway

Port number >

MAC address

Reset password >

3003246-2014-05-21

Operation, access codes and selecting

language

14/100

Menu 3.7 - Backup/restore

It is recommended that a backup copy of the VEX settings is made and saved on a

secure media. See the individual backup guidelines in the diagram:

+

Backup via the HMI panel

● Insert the USB plug in one of the web

server sockets

● Select menu Backup/restore

● It can take up to 20 seconds to establish

the connection to the USB

The backup file can only be saved on a USB

plug. Once the file has been saved it is not

possible to change the file name or type.

The file is named automatically as in this example: backup_20110918.file

Backup via web server

Follow the backup/restore instructions in the

web server guide. The backup file may be

saved on any medium (USB, PC etc.).

A backup file saved via the web server may

be renamed, but the file type cannot be

changed.

NB

If a backup file has been saved from the web

server and then renamed, it cannot be retrieved (restored) via HMI until the name has

been changed back to the standard form, see

"Via HMI panel".

If it is necessary to make backup files for several VEX, it is recommended that each file is

saved on a separate USB flash drive or that

a folder is created for each VEX on which the

backup files can be saved.

3003246-2014-05-21

Operation, access codes and selecting

language

15/100

4. Starting unit operation

The Modbus connectors must not be connected or removed while the

units are powered up. Both Modbus units must be switched off before

making changes, otherwise the units may be damaged.

During commissioning, it may be necessary to work with the control

system boxes open. Components in these boxes must only be touched

with electrically-insulated tools.

Before doing any work on motor controls or motor cables and terminal

boxes, the power supply must be switched off for at least five minutes

to allow the capacitors to discharge.

Before commissioning begins

● Check that the supply voltage is connected

● Set the HMI panel to specialist mode. See section 2.2

4.1 Getting started

From the main menu, follow the steps below to start the commissioning process.

Commissioning

Step Action Menu

1 Configure any external accessories or units (heating or

cooling coils (CCW, MXCU), chiller, sensors, etc.)

3.4

2 Select operating mode - Manual operation is the recom-

mended setting during commissioning

1

3 Set/activate operation settings 3.1

4 Program weekly plan 5.2

5 Set safety function settings 7

6 Select operating mode - change to timer operation if re-

quired

1

The various menu items are explained later in this section.

REMEMBER - Save

settings

After changing menu settings it is always important to return to the main menu to

save your settings by selecting "Save settings" in menu 10 (select yes). If power is

disrupted before the settings are saved, the changes must be re-entered.

Main menu

Operating mode >

Operating readings >

Settings >

Alarm and info >

Time and weekly plan >

Versions >

Safety functions >

Service >

Exit technician menu >

Save settings >

10 Save settings

Save settings >

Last saved:

Date

Time

No

15.02.2011

15:30.22

3003246-2014-05-21

Starting unit operation

16/100

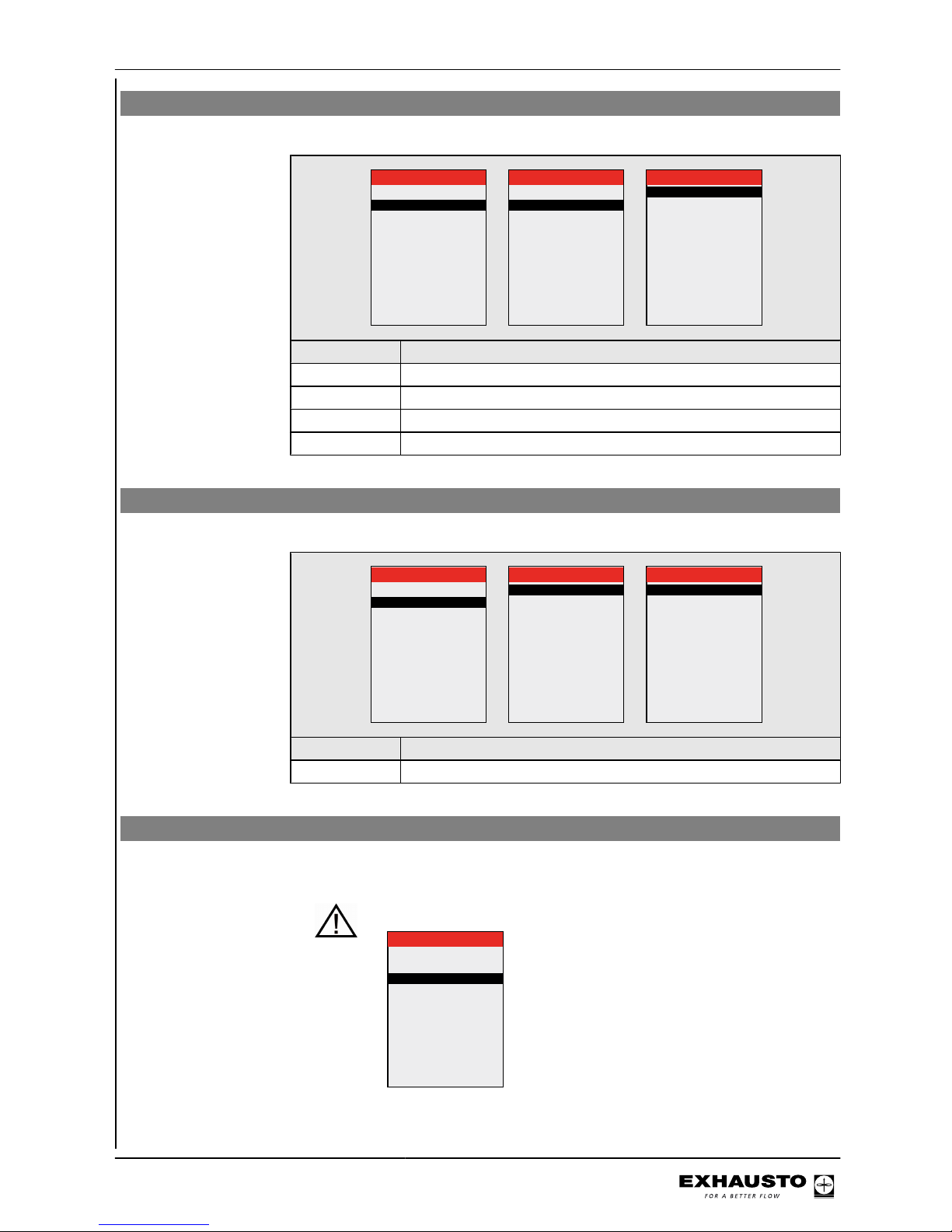

Start configuration

Step Action

1 Check that the correct configuration for the VEX has been selected

at the factory via menu 3.3.

2 Check that all accessories have been configured in menu 3.4

3 If a CO2sensor is installed, check in Menu 3.1.2.1 "CO2compensa-

tion" whether CO2compensation has been activated.

4 If the humidity sensor (RH sensor) has been installed, check that

humidity compensation has been activated in Menu 3.1.2.2 Humidity

compensation.

5 Go to Menu 4.5. Current list, and check whether any units from the

configuration menu are reporting errors. Alarm icon is shown in the

menu bar

6 If a unit is reporting an error but has been correctly configured, check

the installation

3.3 VEX configuration

VEX-type >

VEX-size >

Fan positioning >

Direction >

Rotor type >

Cleaning zone >

Heating coil >

Cooling unit >

200

1

Right

Cond.

None

HCE

Power step HCE >

TS >

BMS >

1

TS Room

None

x40

CCW

PIR > Active

Line in Menu 3.3 Factory-set and

should not be

changed.

Comments

VEX type x

VEX size x

Fan placement x

Direction Adjustable. See section select-

ing Left/Right

Rotor type x

Cleaning zone x

3003246-2014-05-21

Starting unit operation

17/100

Menu 3.4 - Accessories

Ice-detect. >

De-icing method >

Heating coil >

Cooling unit >

Power step HCE >

Filter detect. >

PIR >

TS >

CO2 >

RH >

Dining solution

3.4 Accessories

Pressure

0

MHCE

None

4

Timer

PIR1

TS Room

MIOCO2

None

No

Line in Menu 3.4 Factory-set and

should not be

changed.

Comments

Ice detection method x ● None

De-icing method De-icing not available

● 0

Heating unit Options:

● IHCW (cannot be used for

VEX200)

● MHCE (Electric heating

coil)

● MHCW (Water heating

coil),

● None

Cooling unit Options:

● CH

● MXCU (external cooling

unit)

● CCW (cold water coil)

● CU (EXHAUSTO cooling

unit)

● None

Filter detection x Should only be changed when

sensors for detecting filter soiling are retrofitted. Options:

● Pressure

● Timer

Power step HCE This menu item is only active if

MHCE is selected

PIR Activating PIR sensor. Op-

tions:

● Both (Both MIOPIR and

PIRB connected)

● PIR2 (PIRB connected)

● PIR1 (MIOPIR connected)

● None

When the sensor(s) is/are activated by movement in the

room, the VEX will be overridden and set to comfort level.

Comfort level will be maintained for the time set on the

rear of the sensor (PIRB), after

which the VEX will return to the

previous indoor climate level.

NB: The time interval for MIOPIR is a fixed 10 minutes and

cannot be changed).

3003246-2014-05-21

Starting unit operation

18/100

Line in Menu 3.4 Factory-set and

should not be

changed.

Comments

TS Activation of external tempera-

ture sensor and selection of

type. Options:

● TS DUCT

● TS ROOM

● None

CO2 Activation of CO2 sensor Op-

tions:

● None

● MIOCO2

● CO2B (sensor connected

to AI SPARE)

● BMS

RH Activation of RH sensor. Op-

tions:

● BMS

● RHB (sensor connected to

AI SPARE)

● MIORH

● None

Dining solution

Menu 3.4 Connecting heating and cooling units

Location A heating coil and a cooling unit can be connected to the VEX. The example below

(VEX200) shows the position of the coils in relation to the VEX unit.

RD12313-02

Heating coil - Cooling unit

3003246-2014-05-21

Starting unit operation

19/100

Menu 3.5 BMS

Menu 3.5 - BMS

BMS >

Configuration >

3.5 BMS

None

Line in Menu 3.5 Comments

BMS Activating override control system BMS Op-

tions:

● None

● LON

● Modbus

● MTCP

● BACnet MSTP

● BACnetIP

Configuration Configuration of Modbus and BACnet MSTP.

BMS configuration See detailed description in the instructions for the protocols.

4.3 What is an indoor air quality level?

Example

3.1.1.1.1 Comfort

Air setpoint >

Air setpoint,cool >

Temp. setpoint >

Abs. /Rel. >

Cool rel. start >

Cool abs. start >

Heat rel. start >

Heat abs. start >

60

80

21,0

Relativ

1,0

---

-1,0

---

%

%

°c

K

K

Indoor air quality

level definition

The four indoor air quality levels - Comfort, Standby, Economy and Manual - are

defined in menus 3.1.1.1.1 to 3.1.1.1.4. Parameters such as ventilation and temperature set points and control method for a given indoor air quality level are grouped in a menu, as shown in the example above. The table below shows suggested

settings for each mode:

Indoor climate levels Energy saving People in the

room

Air replacement* Deviation from de-

sired room temperature*

(Ventilation stopped) - No No ventilation No control of room

temperature

Economy Menu

3.1.1.1.3

Large No Low Greatest tempera-

ture deviation permitted*)

Standby Menu 3.1.1.1.2 Small No Low Least temperature

deviation permitted*

Comfort Menu 3.1.1.1.1 None Yes High Precise tempera-

ture

Manual Menu 3.1.1.1.4 Dependent on set-

ting

Yes/No Adjustable Adjustable

3003246-2014-05-21

Starting unit operation

20/100

* Air replacement and temperature deviation set via the HMI panel.

The current indoor air quality level can be controlled in five ways:

● Via a weekly plan, based on the given operating requirements. Set via HMI panel.

● via an HMI panel in the room.

● via sensor(s) placed in the room or in the extract air duct (e.g. MIO-PIR, MIO-CO2,

MIO-RH, MIO-TS)

● via a PC connected to the integral web server

● via a high-level control system (e.g. BMS unit)

NB The Comfort indoor air quality level is the overriding level. The comfort level

is also activated if a mounted PIR sensor gives a signal (the unit changes from

an energy-saving indoor climate level/OFF).

Menu 1 - Selecting operating mode

1 Operating mode

Operation >

Manual

Select If

Manual The unit is intended to always operate at the same indoor air quality

level (set in Menu 3.1.1.1.4) and operation is controlled manually via

the HMI panel or the Web server

Timer The unit is controlled automatically via a fixed weekly plan

Note during commissioning

EXHAUSTO recommends that the operating mode be set to Manual during commissioning and changed to Timer operation when complete.

NB: for manual When the unit is operating in Manual air quality level, the temperature set point

(Temp. set point) and Air set point values are shown immediately in the user menu.

3.1.1.1.4 Manual

Air setpoint >

Air setpoint,cool >

Temp. setpoint >

Abs. / Rel. >

Cool rel. start >

Cool abs. start >

Heat rel. start >

Heat abs. start >

60

80

21,0

Relativ

1,0

---

-1,0

---

%

%

°c

K

K

2160°C

%

29-05-2009 14:32

Menu 3.1.1 - Operating settings - Air regulation

3.1.1 Operating settings

IAQ. levels >

Air reg. >

Temp. reg. >

Balance >

Regulators >

Supply air

1

1,0

The control method can be selected from the methods shown in the table. Note that

some of these methods require that an optional pressure sensor is fitted in one or

more ducts (MPTDUCT).

3003246-2014-05-21

Starting unit operation

21/100

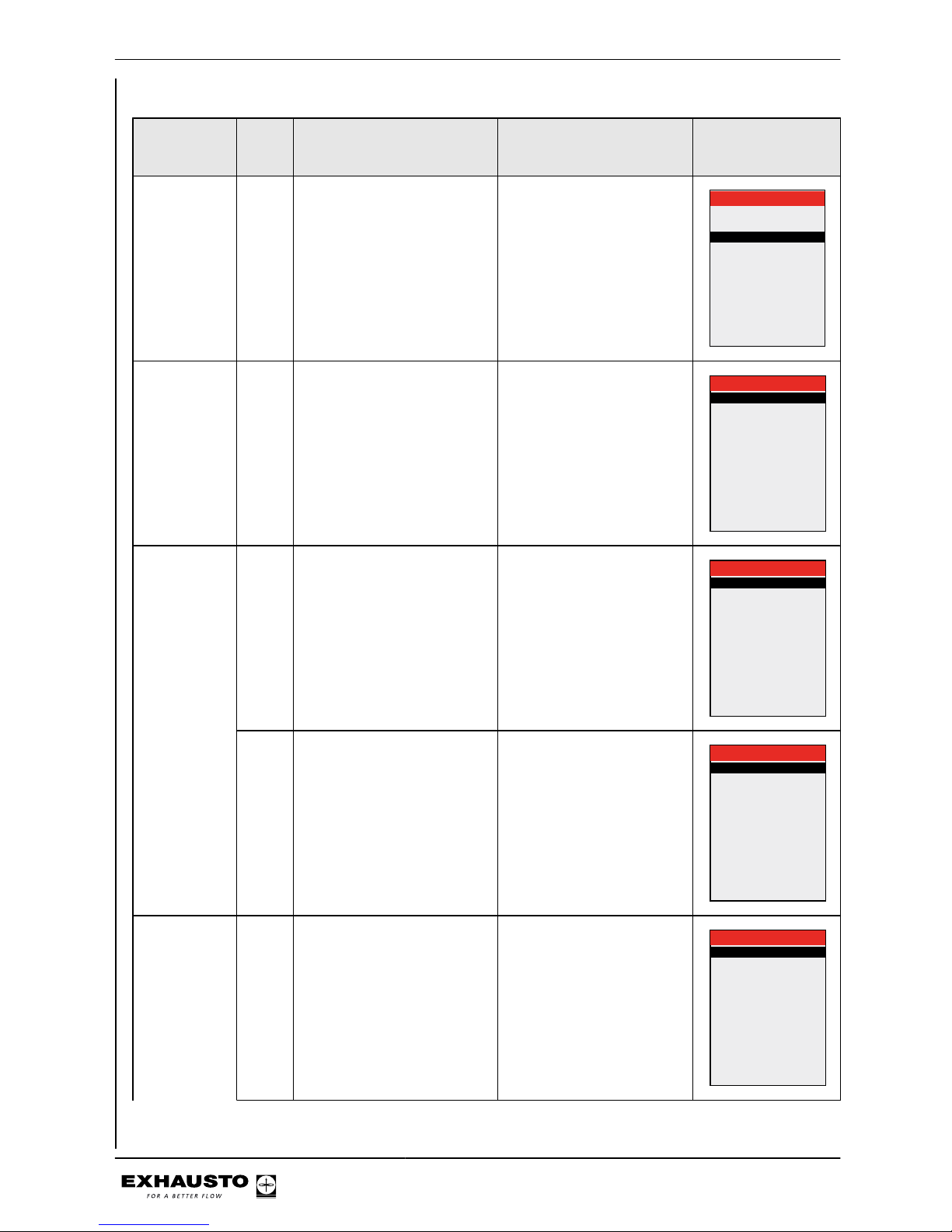

Method Meth-

od no.

(1-8)

Description Following parameters are

set

Menu

Manual control

1 Constant speed

Manual control of fan speed

● Balance

3.1.1 Operating settings

IAQ. levels >

Air reg. >

Temp. reg. >

Balance >

Regulators >

Supply air

1

1,0

Airflow control

2 Constant airflow

Maintains the airflow, compensating for changes in the

ducting system, filter soiling,

etc.

● Extract airflow values

for maximum and minimum ventilation (see

capacity diagram in

VEX instructions)

● Supply air balance relative to extract air

3.1.1.4 Constant airflow

Setp. maks. >

Setp. min. >

Balance > 1,00

10000l/s

0l/s

Constant

pressure regulation of extract air

3 Constant pressure-regulated

extract air with fixed supply air

setting

Requirements:

● MPT-DUCT negative

pressure sensor in the

extract air duct. Available

as an accessory

● Extract airflow values

for maximum and minimum ventilation

● Fixed setting for supply

airflow

3.1.1.4 Constant pressure

Extract air:

Setp. max. >

Setp. min. >

Setp. >

Supply air:

1000Pa

0Pa

0l/s

5 Constant pressure-regulated

extract air with slave-controlled supply air

Requirements:

● MPT-DUCT negative

pressure sensor in the

extract air duct. Available

as an accessory

● Extract airflow values

for maximum and minimum ventilation

● Supply air balance relative to extract air

3.1.1.4 Constant pressure

Extract air:

Setp. max. >

Setp. min. >

Balance >

Supply air:

1000Pa

0Pa

1.00

Constant

pressure regulation of supply air

4 Constant pressure-regulated

supply air with fixed extract air

setting

Requirements:

● MPT-DUCT overpressure sensor in the supply

air duct. Available as an

accessory

● Supply airflow values

for maximum and minimum ventilation

● Fixed setting for extract

airflow

3.1.1.4 Constant pressure

Supply air:

Setp. max. >

Setp. min. >

Setp. >

Extract air:

1000Pa

0Pa

0l/s

3003246-2014-05-21

Starting unit operation

22/100

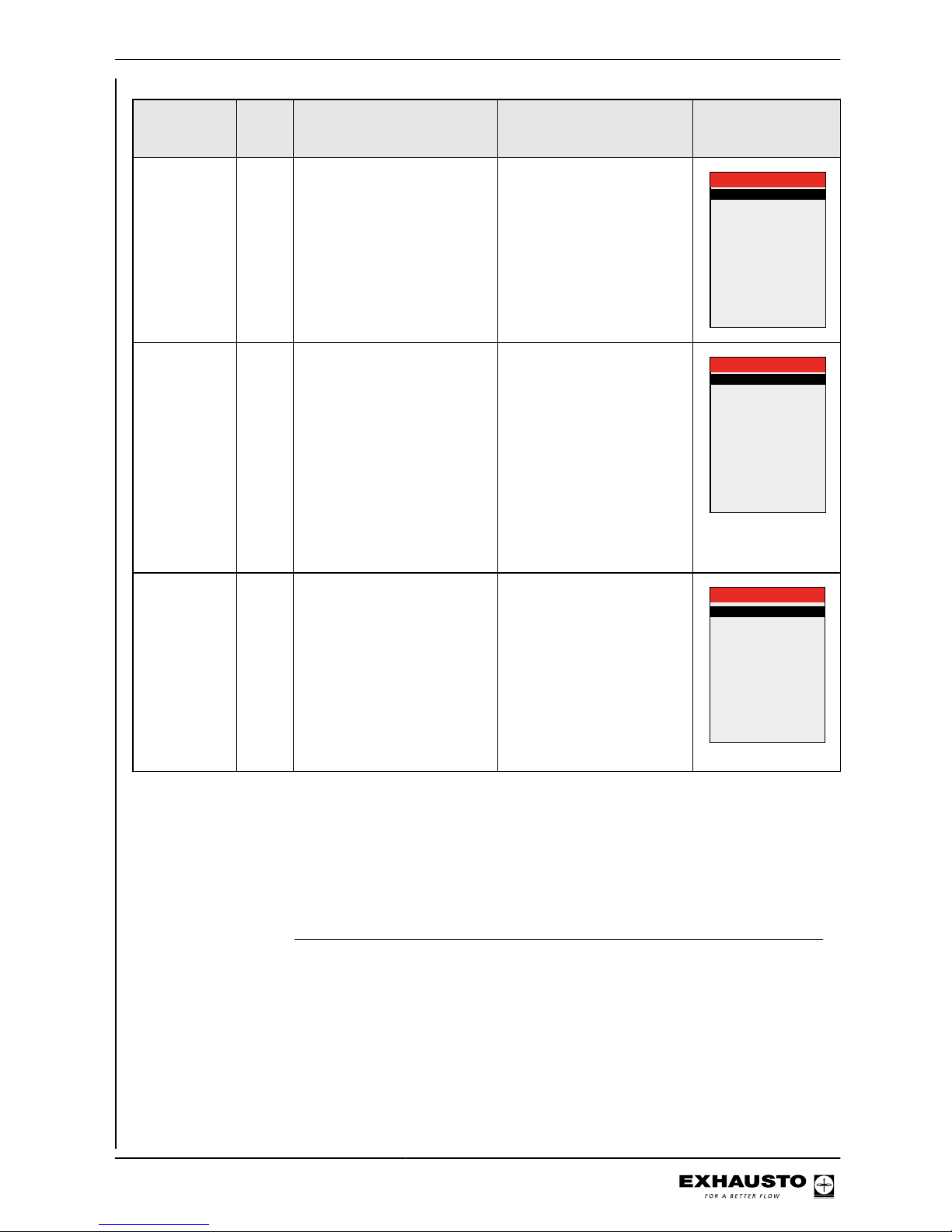

Method Meth-

od no.

(1-8)

Description Following parameters are

set

Menu

6 Constant pressure regulated

supply air with slave-controlled extract air

Requirements:

● MPT-DUCT overpressure sensor in the supply

air duct. Available as an

accessory

● Supply airflow values

for maximum and minimum ventilation

● Extract air balance relative to supply air

3.1.1.4 Constant pressure

Supply air:

Setp. max. >

Setp. min. >

Balance >

Extract air:

1000Pa

0Pa

1.00

Constant

pressure regulation of both

extract air and

supply air

7 Constant pressure regulation

of both extract air and supply

air

Requirements:

● MPT-DUCT negative

pressure sensor in the

extract air duct. Available

as an accessory

● MPT-DUCT overpressure sensor in the supply

air duct. Available as an

accessory

● Extract airflow values

for maximum and minimum ventilation

● Supply airflow values

for maximum and minimum ventilation

3.1.1.4 Constant pressure

Extract air:

Setp. max. >

Setp. min. >

Setp. max. >

Setp. min. >

Supply air:

1000Pa

0Pa

1000Pa

0Pa

External control of fan

speeds

8 External control of both ex-

tract air and supply air

Requirements:

● Two MIO modules to convert 0–10 V to Modbus

● FC max/FC min: Control signal range for external control (e.g. 2-10

V signal)

● Control signal to override external damper* in

the event of, e.g. nighttime cooling or fire

*or other third-party accessory, which is controlled by

external control

3.1.1.4 AUX

Type >

BFO

BMS

101None

Menu 3.1.1 - Operating settings Balance

Definition Balance is the required ratio between the supply and extract airflows. The balance

can only be maintained within certain operating ranges, limited by factors such as:

● Duct characteristics

● Minimum fan rpm

● Minimum airflow required

● Maximum airflow required

3003246-2014-05-21

Starting unit operation

23/100

Example of balance The examples show a unit with manual fan control and balances of 0.80 and 1.20

respectively.

Range The required airflow is

A outside the unit’s normal operating range

B balanced

C unbalanced

NB Less than 1 = less supply air - Greater than 1 = less extract air

Note for methods 3,

4, 7 and 8

Balance is not active for air regulation methods 3, 4, 7 and 8.

Menu 3.1.1.5 Regulators

3.1.1.5 Regulators

Room temperature >

Supply air temp. >

Supply airflow >

Extract airflow >

Supply pressure >

Extract pressure >

Heat retention >

3003246-2014-05-21

Starting unit operation

24/100

Kp and Ti settings should only be changed by persons trained in commissioning ventilation systems.

If the following is selected Permitted operations

Technician mode (code 1111) Read the settings for the various

regulators

Specialist mode (code 3142) Set Kp and Ti for the various reg-

ulators

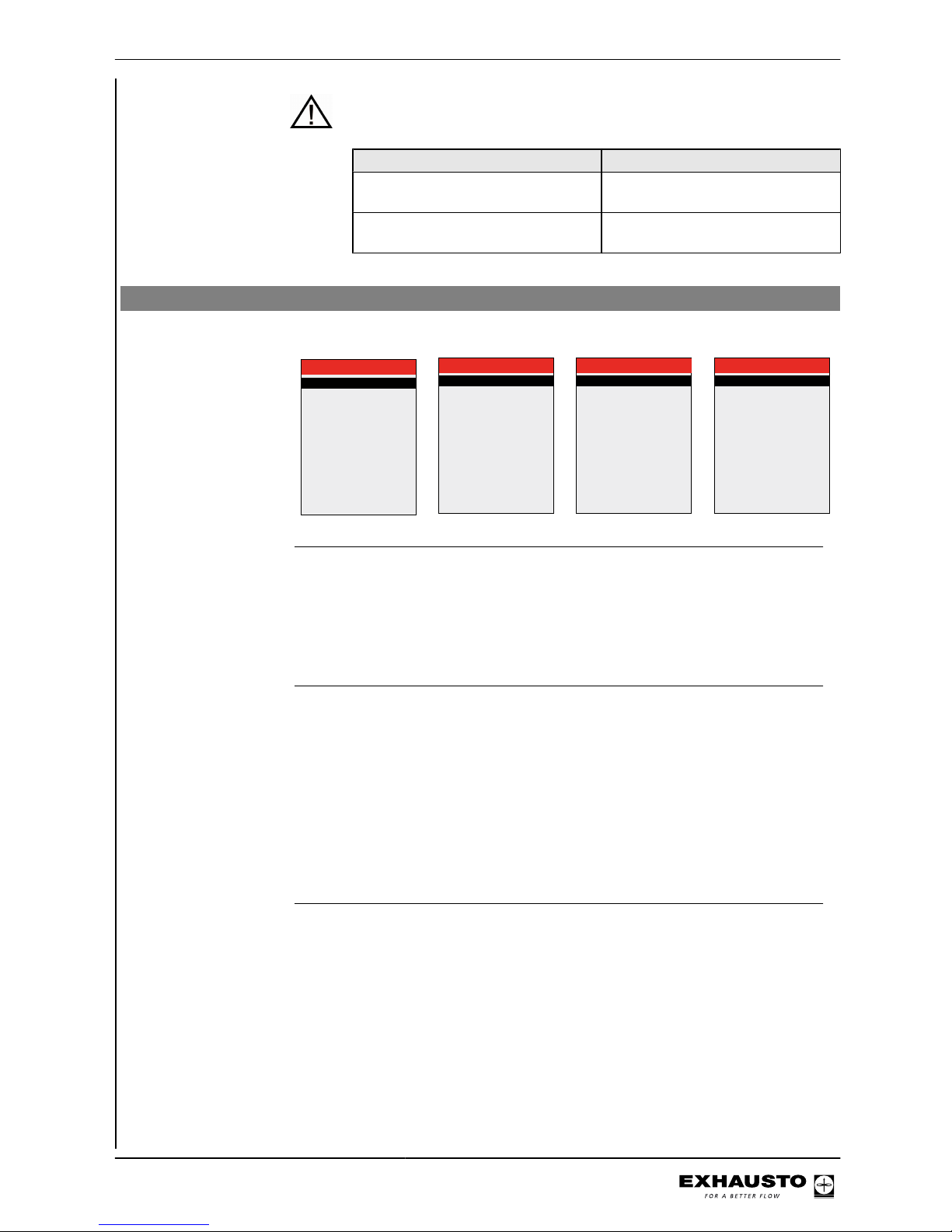

Menus 3.1.1.1.1 to 3.1.1.1.4 Configuring the selected indoor air quality levels

The menus for the four indoor air quality levels contain the same menu items:

3.1.1.1.1 Comfort

Air setpoint >

Air setpoint,cool >

Temp. setpoint >

Abs. /Rel. >

Cool rel. start >

Cool abs. start >

Heat rel. start >

Heat abs. start >

60

80

21,0

Relativ

1,0

---

-1,0

---

%

%

°c

K

K

3.1.1.1.2 Standby

Air setpoint >

Air setpoint,cool >

Temp. setpoint >

Abs. /Rel. >

Cool rel. start >

Cool abs. start >

Heat rel. start >

Heat abs. start >

60

80

21,0

Relativ

1,0

---

-1,0

---

%

%

°c

K

K

3.1.1.1.3 Economy

Air setpoint >

Air setpoint,cool >

Temp. setpoint >

Abs. / Rel. >

Cool rel. start >

Cool abs. start >

Heat rel. start >

Heat abs. start >

60

80

21,0

Relativ

1,0

---

-1,0

---

%

%

°c

K

K

3.1.1.1.4 Manual

Air setpoint >

Air setpoint,cool >

Temp. setpoint >

Abs. / Rel. >

Cool rel. start >

Cool abs. start >

Heat rel. start >

Heat abs. start >

60

80

21,0

Relativ

1,0

---

-1,0

---

%

%

°c

K

K

Menu 3.1.1.1.x - Air set point

Definition Used to set the desired ventilation level for the given indoor air quality level, from 0

to 100%. Press "OK" to end.

Menu 3.1.7 - limits

menu

See the range limits for fan output in Menu 3.1.7 in the HMI panel.

Menu 3.1.1.1.x - Temperature set point

Definition The required supply air or room temperature is set here. If "Absolute" indoor air

quality level is selected (see next section), then the temperature set point can be

selected (with 0.5 degree difference) within the configured "Cooling absolute start"

and "Heating absolute start" ranges (for more details see relevant section).

Menu 3.1.8 - limits

menu

See the range limits for supply air temperature and room temperature in Menu 3.1.8

in the HMI panel.

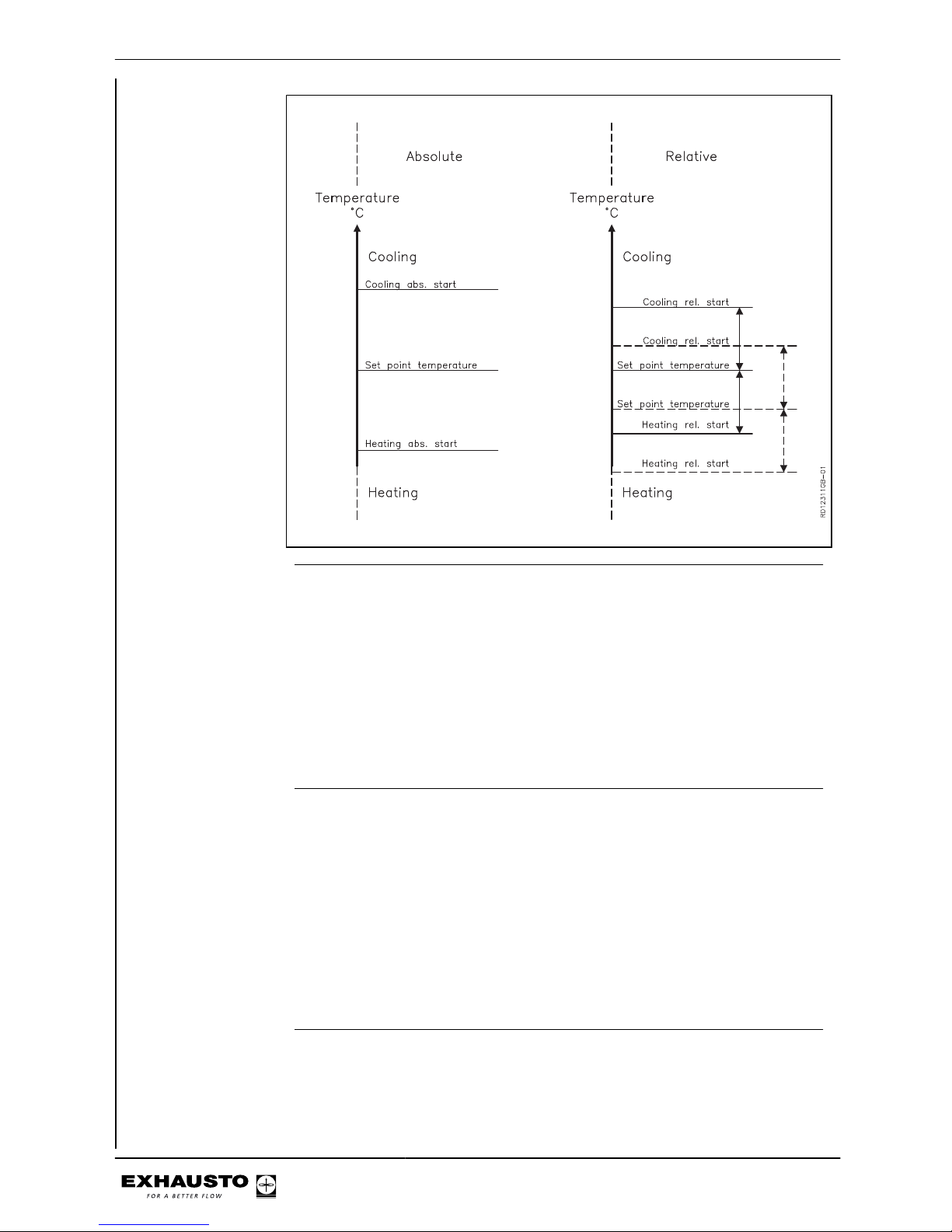

Menu 3.1.1.1.x - Absolute / Relative temperature

Definition Used to select supply air or room temperature in relation to either absolute or relative

temperature.

Absolute - Specify start temperature for heating coil or cooling unit.

Relative - Permitted temperature changes relative to the heating coil or cooling unit

start temperature. See how the temperature variation follows when the set point is

altered (diagram below, dotted lines).

3003246-2014-05-21

Starting unit operation

25/100

Menu 3.1.1.1.x - Cooling relative start

Definition This value determines when cooling must start in relation to the relative tempera-

ture. Low value = narrow temperature regulation range, leading to a comfortable

indoor climate. High value = wider temperature regulation range, which provides

cooling energy savings. Lower and upper limits are shown in the display.

Example If the required room temperature is 21°C, and Cooling Rel. start in the indoor air

quality level menu is set to 3K, the cooling unit will begin to operate on a warm day

when the temperature exceeds 21°C + 3K = 24°C.

Menu 3.1.1.1.x - Heating relative start

Definition This value determines when the heating coil must start in relation to the relative

temperature. Low value = narrow temperature regulation range, leading to a comfortable indoor climate. High value = wider temperature regulation range, which

saves energy because of lower heating requirements. Lower and upper limits are

shown in the display.

Example If the required room temperature is 21°C, and Heating Rel. start in the indoor air

quality level menu is set to -3K, the heating coil will begin to operate on a cold day

when the temperature falls below 18°C (21°C - 3K).

Menu 3.1.1.1.x - Cooling absolute start

Definition This value determines when cooling must start in relation to the absolute tempera-

ture. Lower and upper limits are shown in the display.

3003246-2014-05-21

Starting unit operation

26/100

Example If Cooling abs. start is set to 24°C, the cooling unit will first start to operate when

the temperature exceeds 24°C, even though the daily user has set the required

room temperature to 21°C.

Menu 3.1.1.1.x - Heating absolute start

Definition This value determines when heating must start in relation to the absolute temper-

ature. Lower and upper limits are shown in the display.

Example If Heating abs. start is set to 18°C, the heating coil will not start to operate until the

temperature falls below 18°C, even though the daily user has set the required room

temperature to 21°C.

Generally on temperature regulation

● Start by setting the max. and min. limits

● Set the temperature setpoint

● For other regulators, first set the max./min. and then the setpoint

3.1.1 Operating settings

IAQ. levels >

Air reg. >

Temp. reg. >

Balance >

Regulators >

Supply air

1

1,0

If temperature regulation is changed from Supply Air to Room, the functions on the

next pages will be enabled, and invalid values will be adjusted to valid values. If

temperature regulation is changed from Room to Supply Air, nothing will happen,

as the limits for Room are always within the limits for Supply Air.

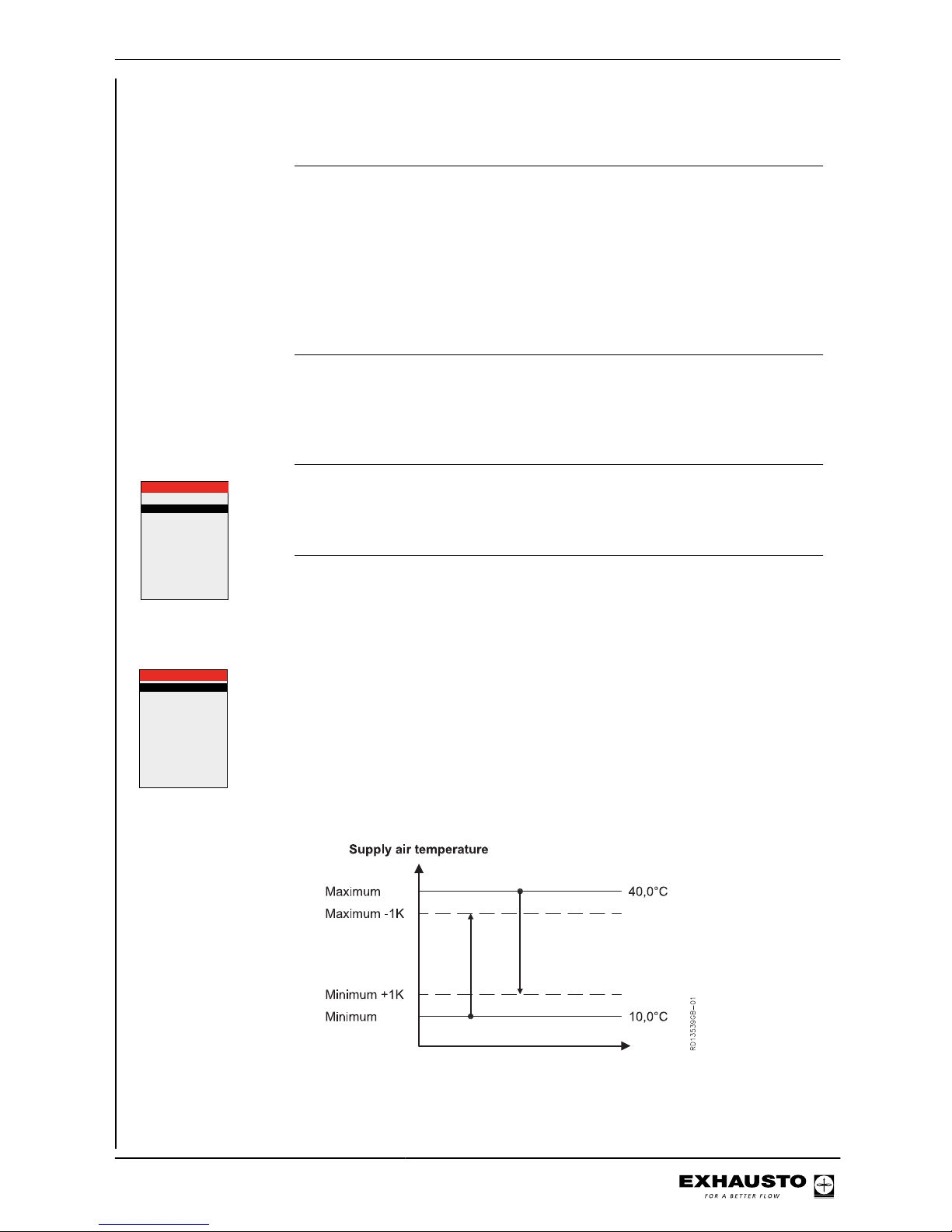

Menu 3.1.8 - Temperature limits

Grænser tillufttemp.

Minimum >

Maksimum >

Grænser rumtemp.

Minimum >

Maksimum >

Maksimum ∆T >

10.0

35.0

10.0

35.0

10.0

°C

°C

°C

°C

K

3.1.8 Temperaturgrænser

Limits, supply air

temperature

3003246-2014-05-21

Starting unit operation

27/100

NB Max. and Min. may never be set closer to each other than 1K.

If the following is selected

temperature will be controlled by...

NB

supply air regulation supply air temperature Supply air temperature

will never be higher than

"Maximum" or lower

than "Minimum".

room temperature regulation

extract air temperature or

TSROOM

However, supply air

temperature will never

be higher than "Maximum" or lower than

"Minimum".

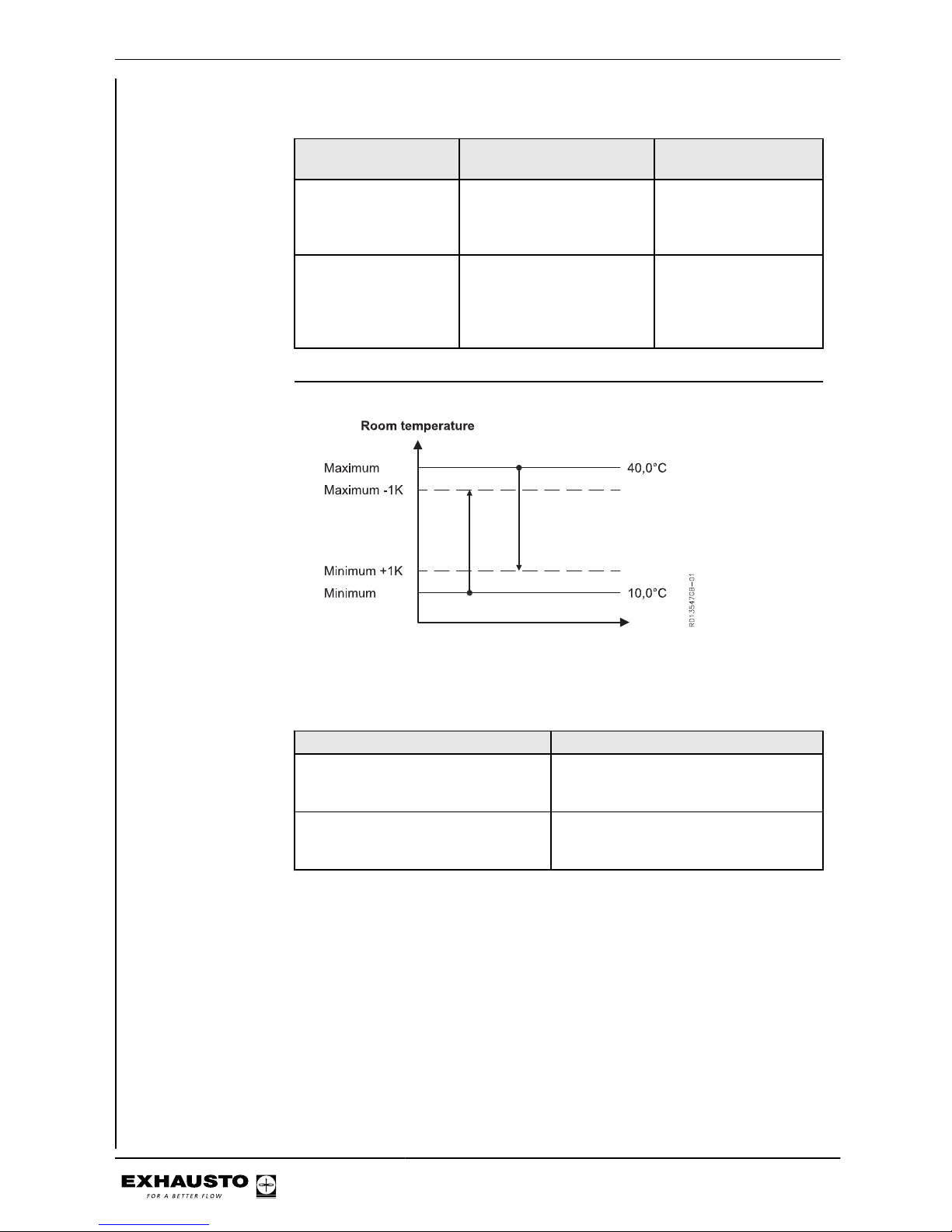

Limits, room temperature

NB Max. and Min. may never be set closer to each other than 1K.

If the following will be adjusted....

Supply air temp. maximum is set lower

than the room temp. maximum.

The room temp. maximum is automatically reduced to the same value as the

supply air temp. maximum.

The supply air temp. minimum is set

higher than the room temp. minimum.

The room temp. minimum is automatically increased to the same value as the

supply air temp. minimum.

3003246-2014-05-21

Starting unit operation

28/100

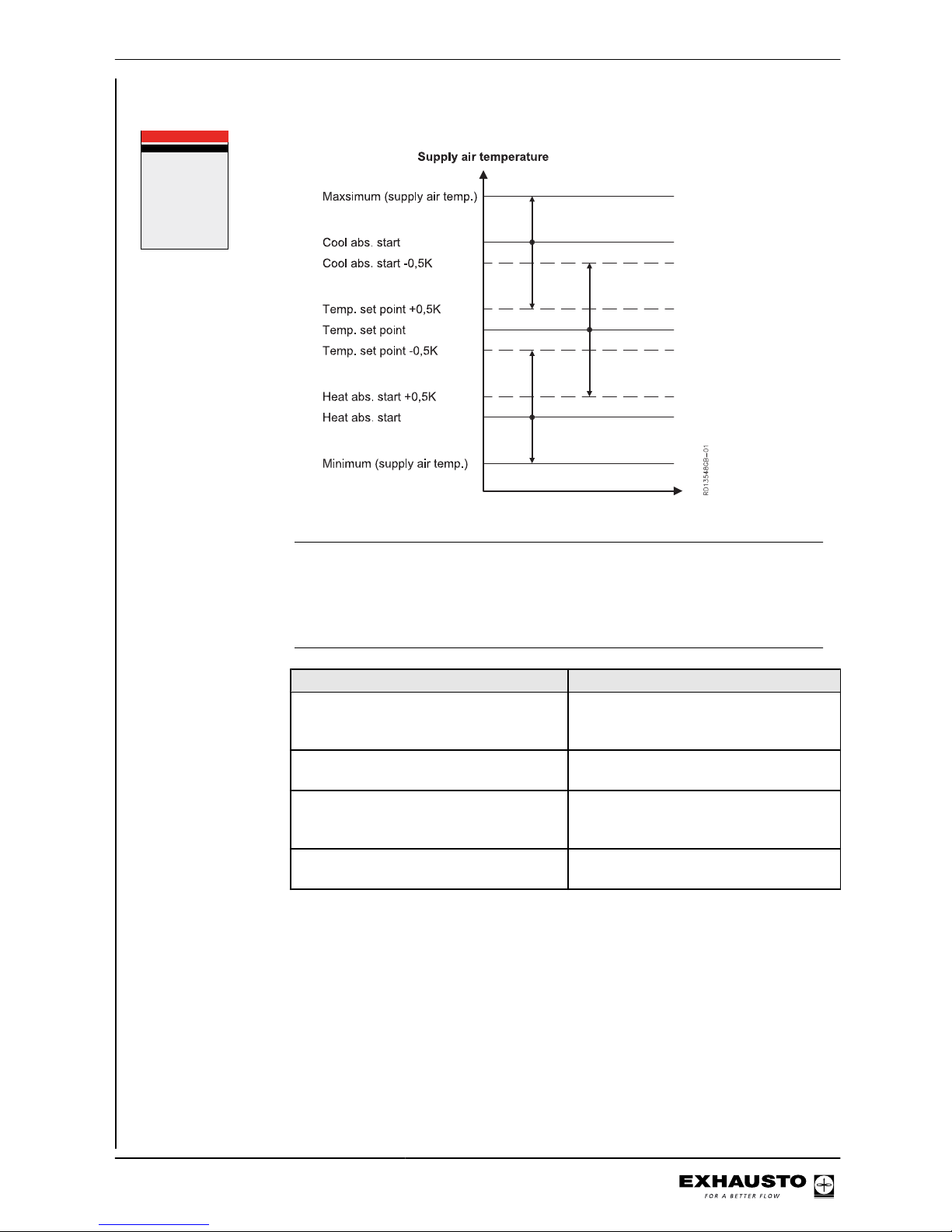

Menu 3.1.1.1.x - Supply air regulation, absolute

Air setpoint >

Air setpoint,cool

Temp. setpoint >

Abs. / Rel. >

Cool rel. start >

Cool abs. start >

Heat rel. start >

Heat abs. start >

3.1.1.1.x xxxxxxx

60

80

21,0

Absolute

---

26,0

---

21,0

%

°c

°c

°c

NB Temp. setpoint can never be set closer to Heating abs. start or Cooling abs. start

than 0.5K.

Heating abs. start and Cooling abs. start can never be set closer to each other than

1K.

If the following will be adjusted....

Maximum supply air temp. is set to a value lower than Cooling abs. start

Cooling abs. start will automatically reduce to the same value as Maximum

supply air temp.

Cooling abs. start is set to a value lower

than (Temp. setpoint + 0.5K)

Temp. setpoint will automatically reduce

to (Cooling abs. start - 0.5K).

Minimum supply air temp. is set to a value

higher than Heating abs. start

Heating abs. start will automatically rise

to the same value as Minimum supply air

temp.

Heating abs. start is set to a value higher

than (Temp. setpoint - 0.5K)

Temp. setpoint will automatically rise to

(Heating abs. start + 0.5K).

3003246-2014-05-21

Starting unit operation

29/100

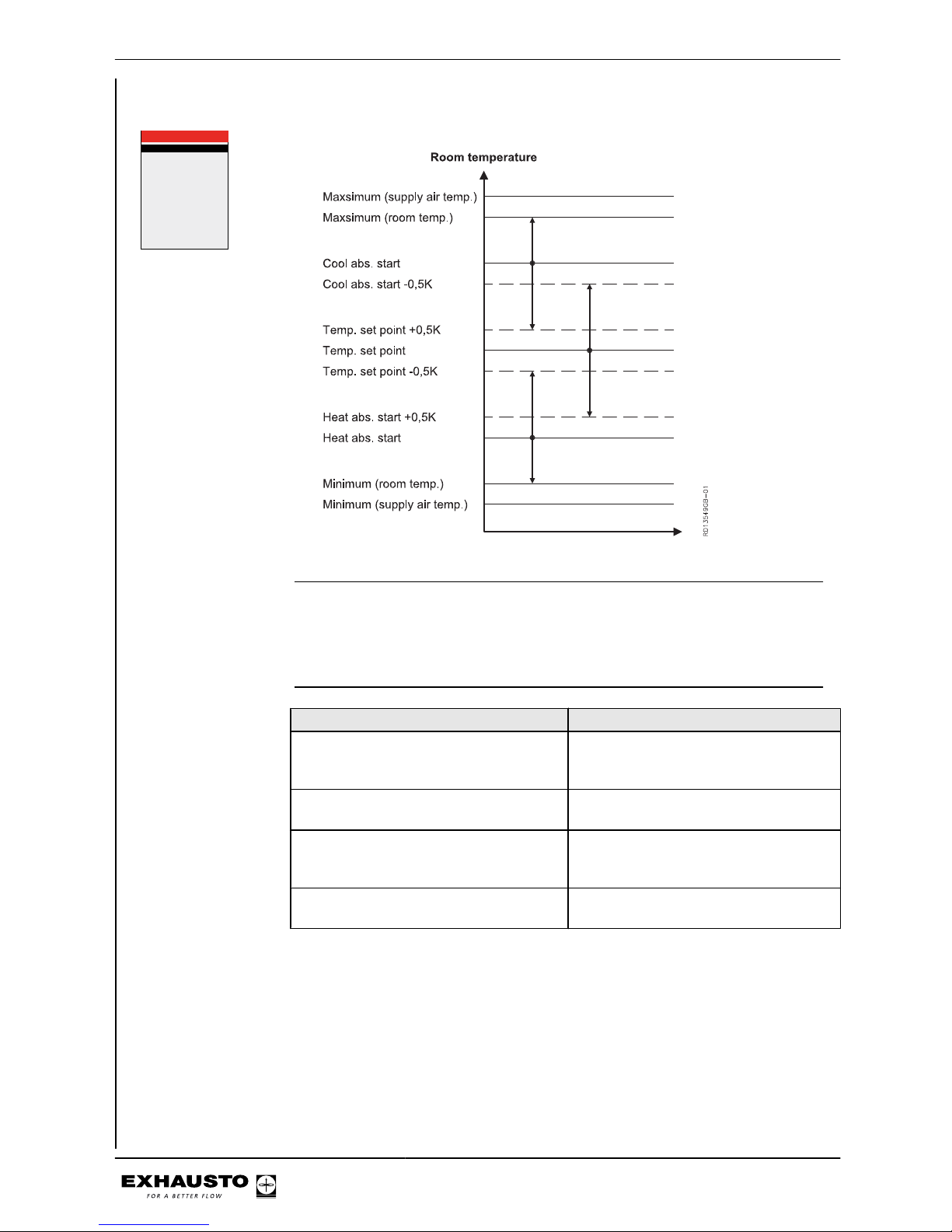

Menu 3.1.1.1.x - Room temperature regulation, absolute

Air setpoint >

Air setpoint,cool

Temp. setpoint >

Abs. / Rel. >

Cool rel. start >

Cool abs. start >

Heat rel. start >

Heat abs. start >

3.1.1.1.x xxxxxxx

60

80

21,0

Absolute

---

26,0

---

21,0

%

°c

°c

°c

NB Temp. setpoint can never be set closer to Heating abs. start or Cooling abs. start

than 0.5K.

Heating abs. start and Cooling abs. start can never be set closer to each other than

1K.

If the following will be adjusted....

Maximum room temp. is set to a value

lower than Cooling abs. start

Cooling abs. start will automatically reduce to the same value as Maximum

room temp.

Cooling abs. start is set to a value lower

than (Temp. setpoint + 0.5K)

Temp. setpoint will automatically reduce

to (Cooling abs. start - 0.5K).

Minimum room temp. is set to a value

higher than Heating abs. start

Heating abs. start will automatically rise

to the same value as Minimum room

temp.

Heating abs. start is set to a value higher

than (Temp. setpoint - 0.5K)

Temp. setpoint will automatically rise to

(Heating abs. start + 0.5K).

3003246-2014-05-21

Starting unit operation

30/100

Loading...

Loading...