Exhausto BESF, BESF/7 Series, BESF180-4-1EC, BESF146-4-1, BESF200-4-1EC Series Manual

...

3004349_2017_08_03.fm

BESF

BESF/7

1/64

3004349_2017_08_03.fm

GB - BESF – Product information

1.1 Design.......................................................................................................... 4

1.2 Fitting.......................................................................................................... 6

1.2.1 Fitting indoors ...............................................................................................6

1.2.2 Fitting outdoors (OD)..................................................................................... 7

1.2.3 Fitting the mounting bars............................................................................... 7

1.3 Wiring........................................................................................................... 8

1.3.1 Ventilator without EC control.........................................................................8

1.3.2 Ventilator with EC control..............................................................................9

1.3.3 Fault finding: phase-one EC controls ..........................................................12

1.4 Connecting to duct system........................................................................ 13

1.5 Service and cleaning .................................................................................. 14

1.6 Environmental declaration......................................................................... 14

DK - BESF - Produktvejledning

1.1 Opbygning................................................................................................... 16

1.2 Montage ...................................................................................................... 18

1.2.1 Indendørs placering ....................................................................................18

1.2.2 Udendørs placering (OD) ............................................................................19

1.2.3 Montage af bæreskinner ............................................................................. 19

1.3 El-tilslutning ................................................................................................ 20

1.3.1 Ventilatorer uden EC-styring .......................................................................20

1.3.2 Ventilatorer med EC-styring ........................................................................21

1.3.3 Fejlfinding for 1-fasede EC-styringer...........................................................24

1.4 Kanaltilslutning........................................................................................... 25

1.5 Service og rengøring.................................................................................. 26

1.6 Miljødeklaration........................................................................................... 26

DE - BESF - Betriebsanleitung

1.1 Aufbau.......................................................................................................... 28

1.2 Montage ...................................................................................................... 30

1.2.1 Aufstellung in Innenräumen ........................................................................30

1.2.2 Aufstellung im Freien (OD).......................................................................... 31

1.2.3 Montage von Tragschienen.........................................................................31

1.3 Elektrischer Anschluss .............................................................................. 32

1.3.1 Ventilatoren ohne EC-Automatik .................................................................32

1.3.2 Ventilatoren mit EC-Automatik ....................................................................33

1.3.3 Fehlersuche bei einphasigen EC-Automatik ............................................... 36

1.4 Kanalanschluss........................................................................................... 37

1.5 Wartung und Reinigung ............................................................................. 38

1.6 Umweltdeklaration...................................................................................... 39

NO - BESF - Produktveiledning

1.1 Oppbygning................................................................................................. 40

1.2 Montering.................................................................................................... 42

1.2.1 Innendørs plassering ..................................................................................42

1.2.2 Utendørs plassering (OD) ........................................................................... 43

1.2.3 Montering av bæreskinner...........................................................................43

1.3 Elektrisk tilkobling...................................................................................... 44

1.3.1 Vifter uten EC-styring .................................................................................. 44

1.3.2 Vifter med EC-styring .................................................................................. 45

1.3.3 Feilsøking for enfasede EC-styringer ..........................................................48

1.4 Kanaltilkobling ............................................................................................ 49

1.5 Service og rengjøring................................................................................. 50

1.6 Miljødeklarasjon.......................................................................................... 50

2/64

3004349_2017_08_03.fm

SE – BESF – Produkthandbok

1.1 Konstruktion................................................................................................ 52

1.2 Montering.................................................................................................... 54

1.2.1 Inomhusmontering ......................................................................................54

1.2.2 Placering utomhus (OD)..............................................................................55

1.2.3 Montering av bärskenor...............................................................................55

1.3 Elanslutning ................................................................................................ 56

1.3.1 Fläktar utan EC-styrning..............................................................................56

1.3.2 Fläktar med EC-styrning..............................................................................57

1.3.3 Felsökning för 1-fas EC-styrningar..............................................................60

1.4 Kanalanslutning.......................................................................................... 61

1.5 Service och rengöring................................................................................ 62

1.6 Miljödeklaration..................................................................................................62

3/64

3004349_2017_08_03.fm GB - BESF – Product information

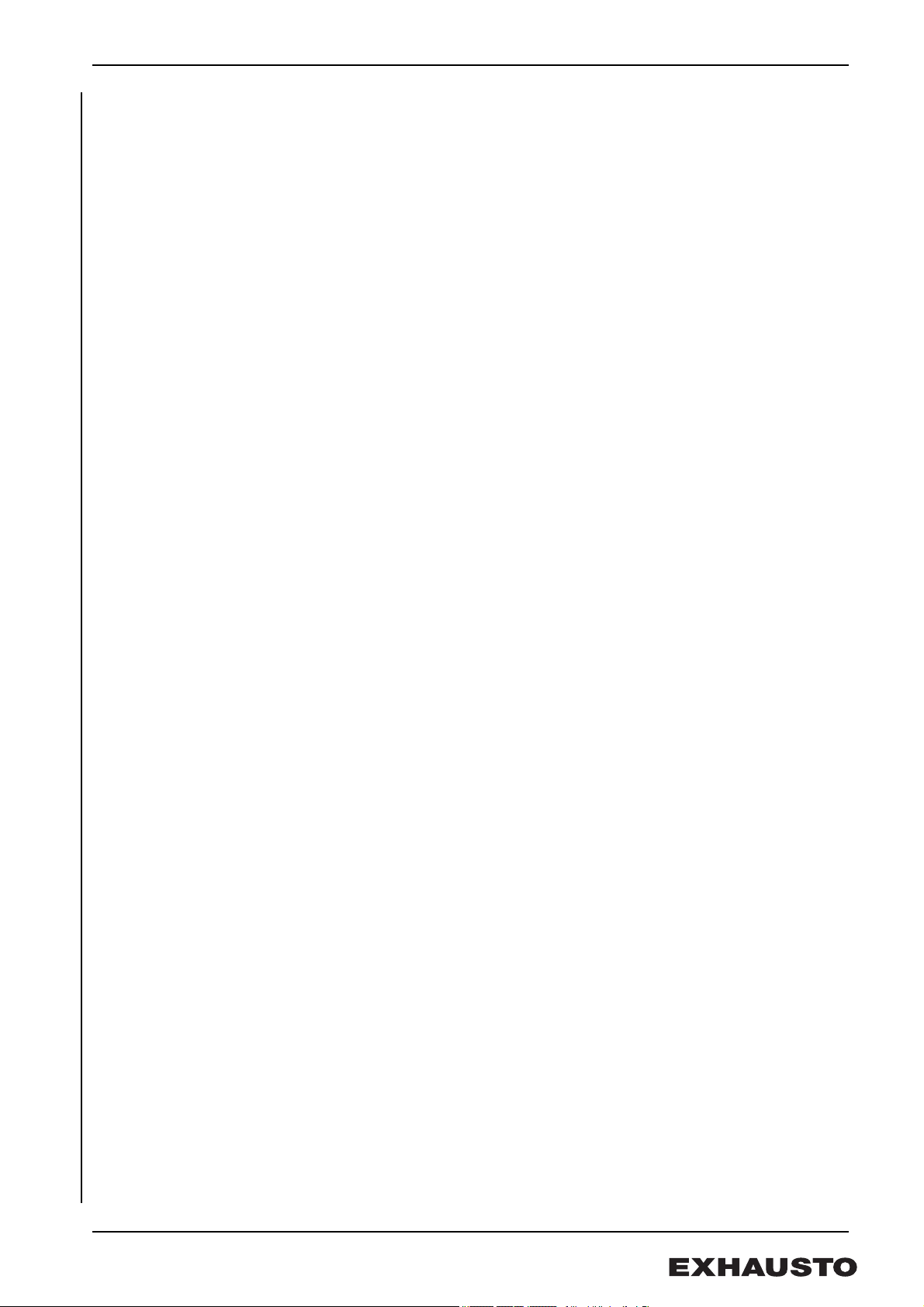

Fig. 1

1. GB - BESF – Product information

EXHAUSTO BESF box ventilators are used in air supply and extraction systems.

The ventilator is not to be used for the transportation of solid particles,

nor in areas where there is a risk of explosive gases.

The ventilator must not be started with the service door open.

1.1 Design

Description BESF is a low-noise centrifugal ventilator with complete insulation and an F-impeller:

• BESF146-4-1

• BESF160-4-1

• BESF160-2-1EC

• BESF180-4-1EC

• BESF200-4-1EC

• BESF225-4-1EC

• BESF250-4-1EC

• BESF280-4-3EC

The ventilator has an internal insulated laminar housing and an external cabinet made

of sheet aluminium.

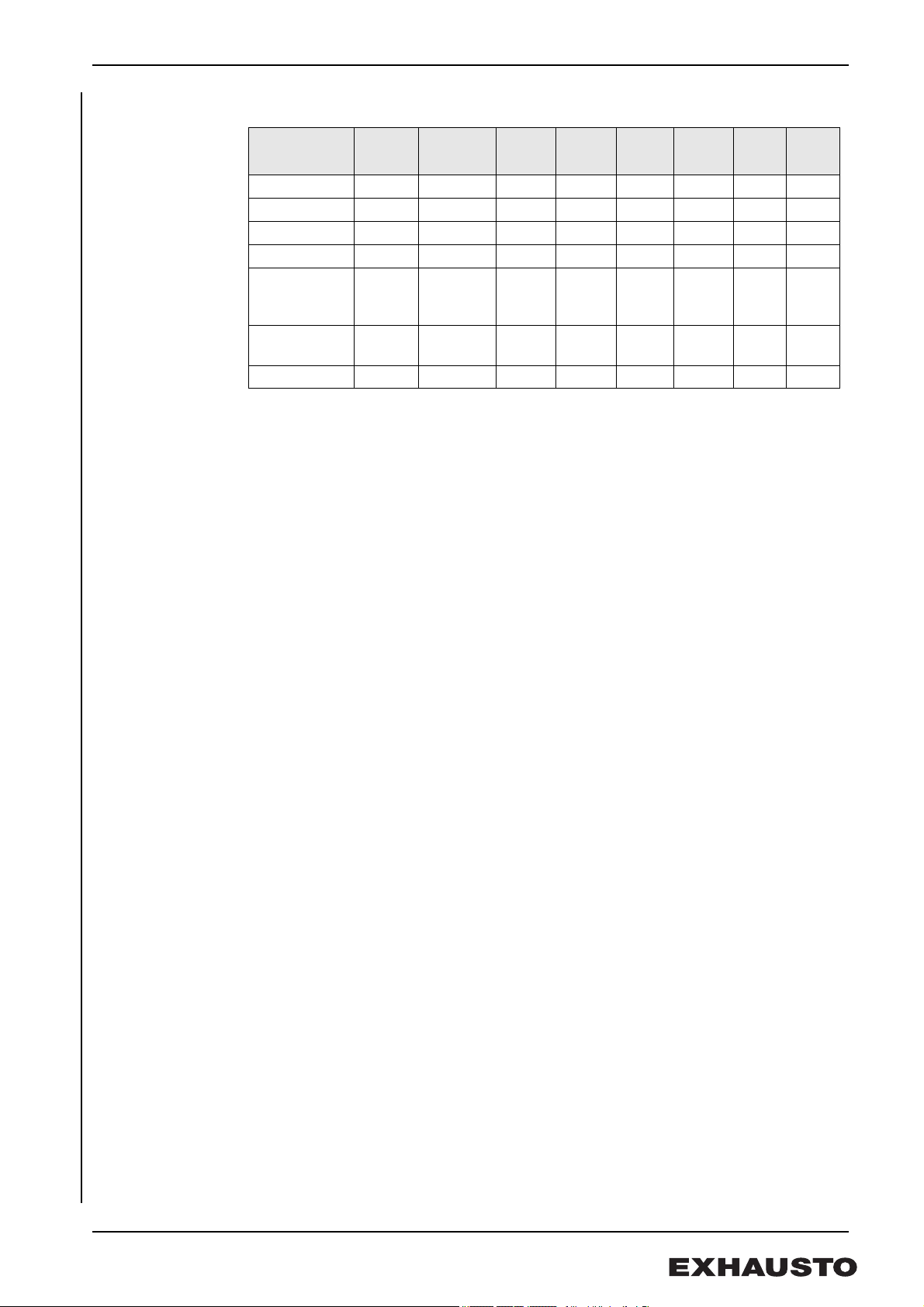

Temperature

limits

Type

BESF –12ºC 60ºC –30ºC 40ºC

Spigot size The ventilator’s connection size conforms to Eurovent.

BESF 146 160/180 200/225 250/280

D (mm)

Transport The ventilator is delivered packaged and can be

transported on a hand trolley. Care must be

taken to avoid any damage to the cabinet and

spigots when the ventilator has been removed

from its packaging.

Temperature - medium

Min. Max. Min. Max.

Ø 160 Ø 200 Ø 250 Ø 315

Temperature – ambient,

running

Size and weight.

BESF 146 160 180 200 225 250 280

Weight kg

13 17 22 (EC) 23 27 32 41 49

4/64

3004349_2017_08_03.fm GB - BESF – Product information

RD13285-01

i

b

a

c

d

e

f

g

h

M

a

x

.

6

0

°

C

M

a

x

.

4

0

°

C

j

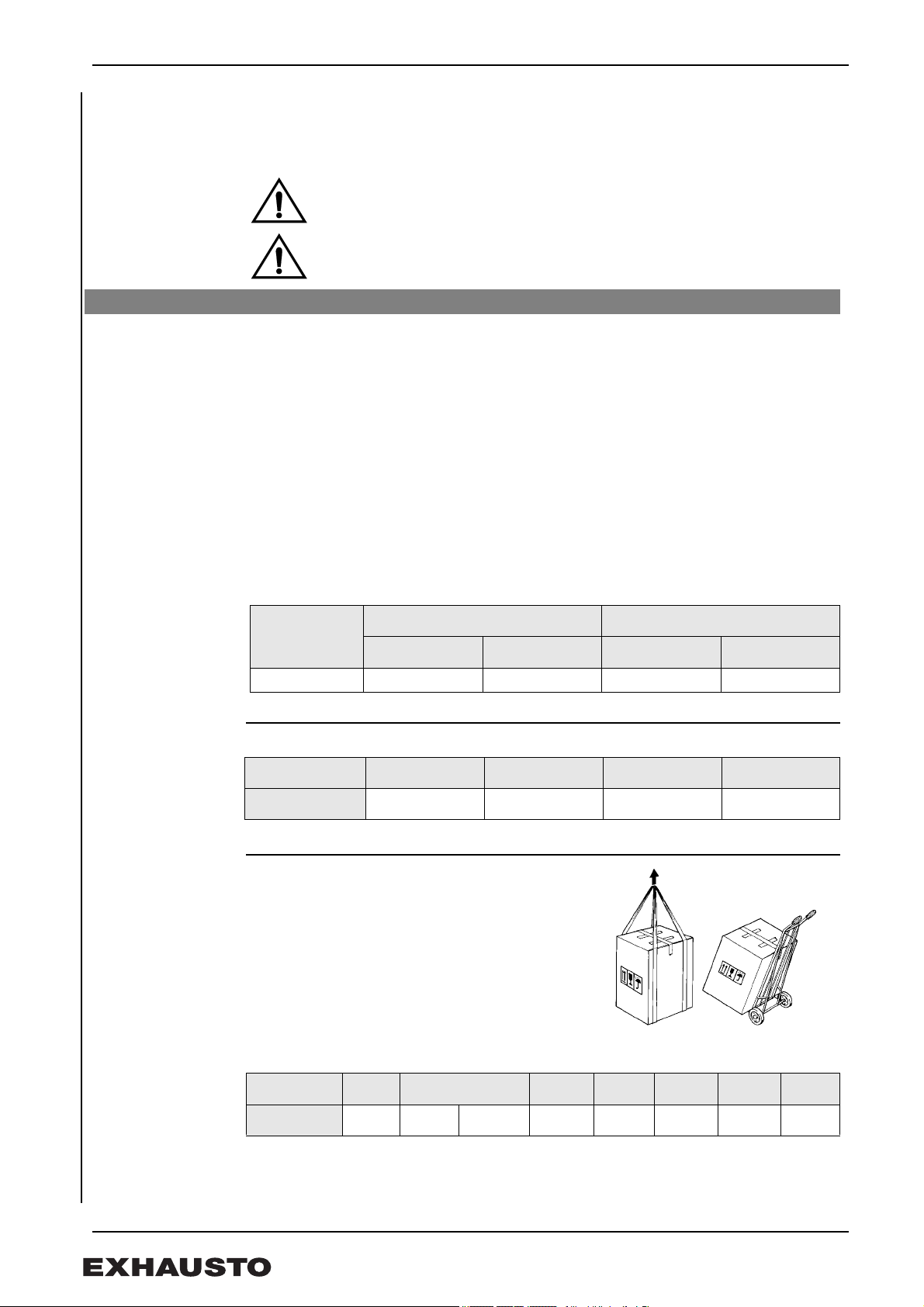

Fig. 2

Main parts

Pos. Part

a Cabinet

b Service door

c Motor

d Centrifugal impeller

e Ventilator housing

f Locking screws (supplied with screwdriver)

g Mounting bars with vibration dampers

h Self-tapping screws

i OSGR coupling (accessory). When fitting the OGSR, the slit must always be

opposite the rivet, so that the guide plates are turned correctly.

j EC control/terminal box

5/64

3004349_2017_08_03.fm GB - BESF – Product information

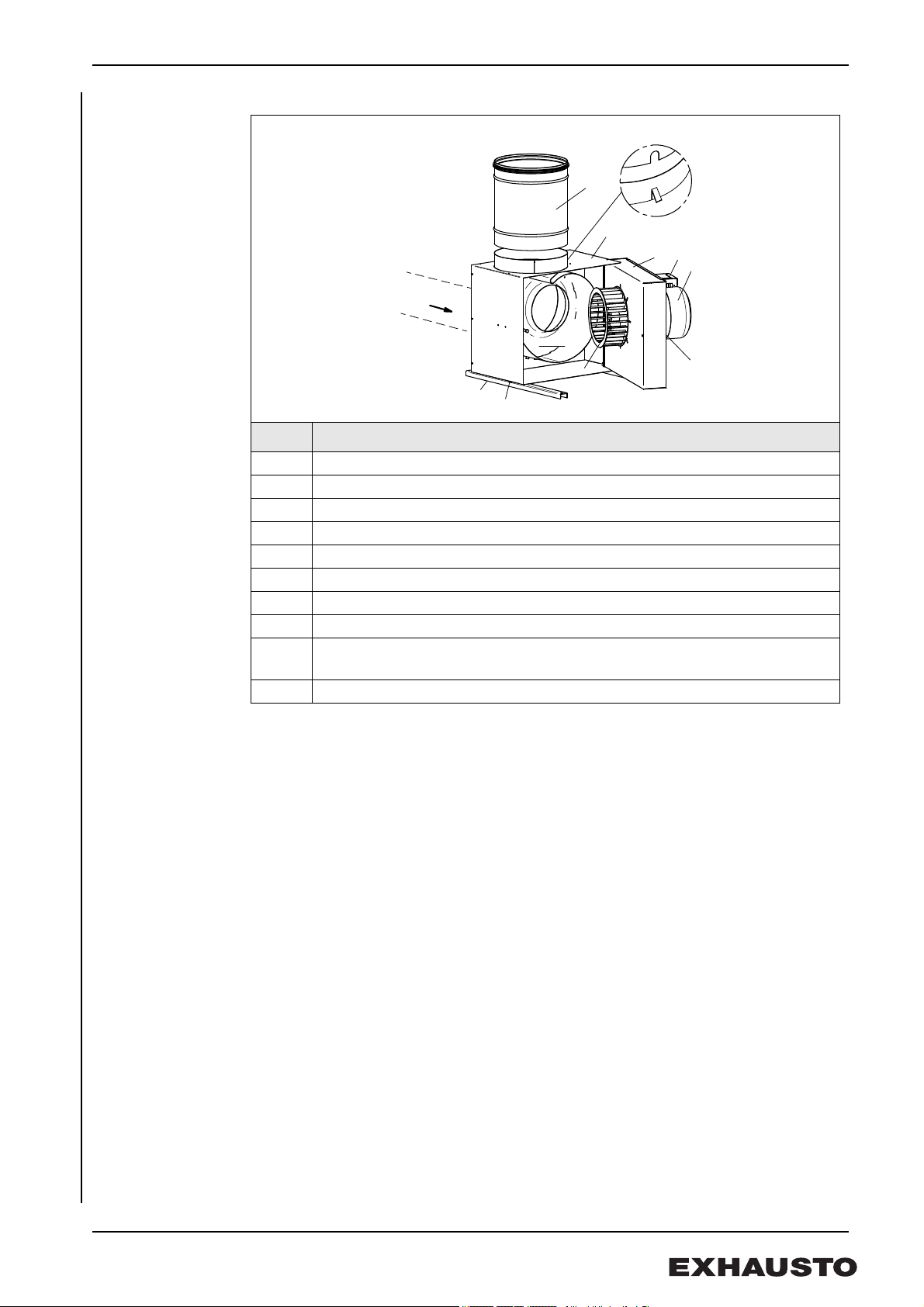

Fig. 3

RD13307-01

D

D

Fig. 4

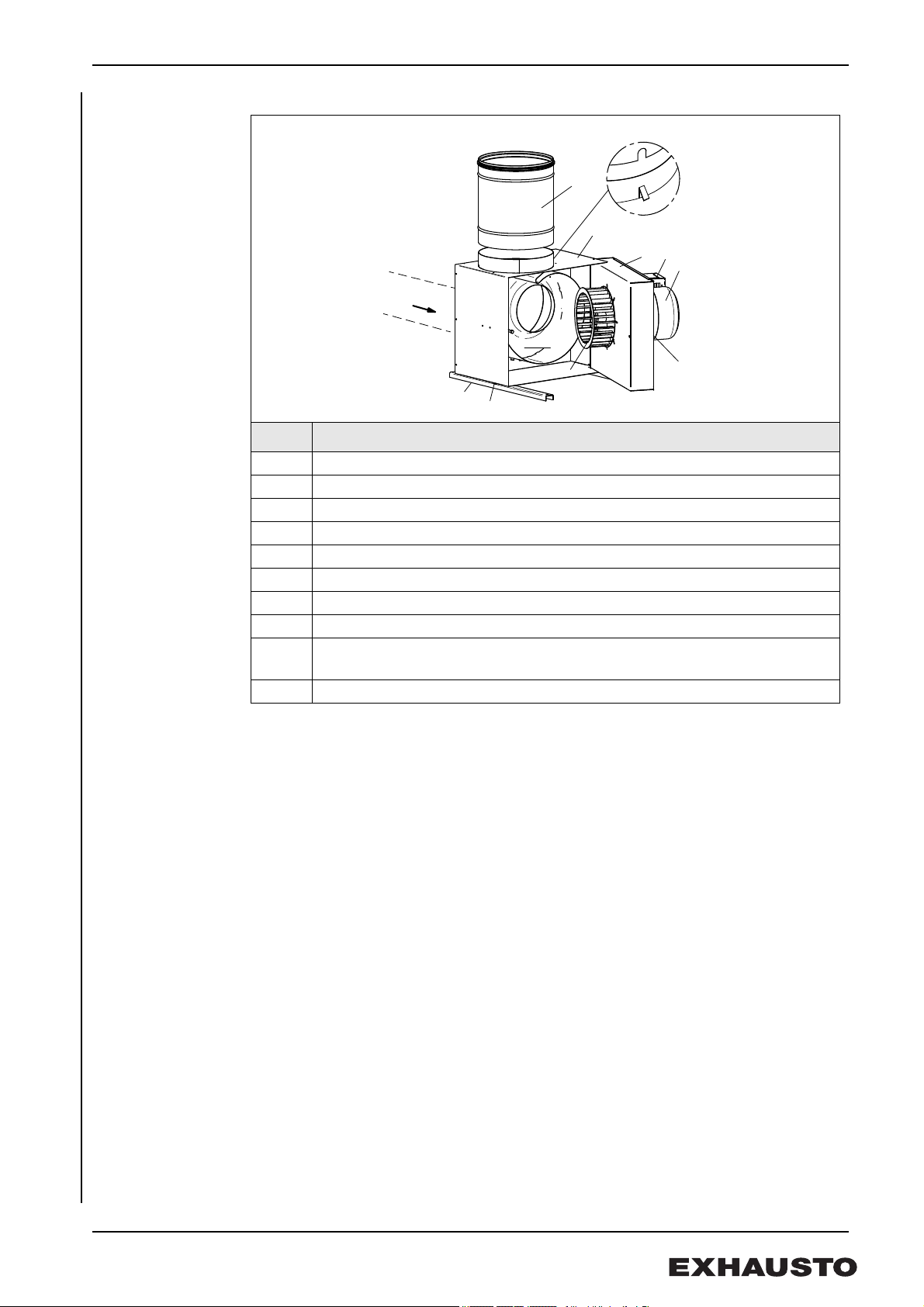

1.2 Fitting

1.2.1 Fitting indoors

There are various ways of fitting the

ventilator indoors (Fig. 3).

If the ventilator is to run intermittently,

there is a risk of condensation in the

motor. Therefore, use mounting

method A or B only.

Service access Wherever the ventilator is fitted, there

should be space enough to be able to

open the service door to an angle of

approx. 90°.

Warning! The motor must never be placed vertically under the cabinet, and the

motor and EC-controls must never be covered or they will overheat.

6/64

3004349_2017_08_03.fm GB - BESF – Product information

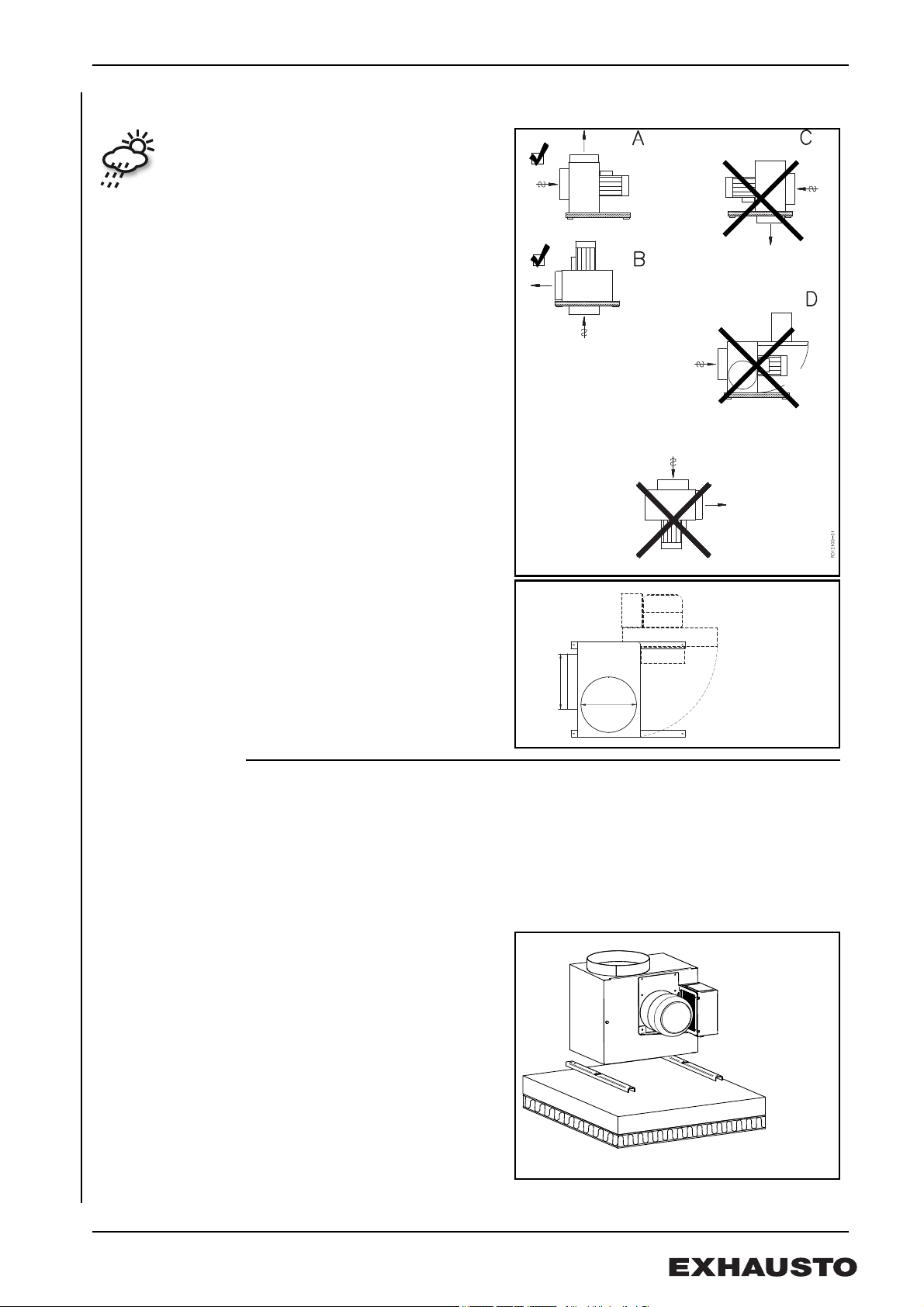

Fig. 5

Fig. 6

RD13307-01

D

D

RD13309-01

Fig. 7

1.2.2 Fitting outdoors (OD)

Outdoor fitting requires special

attention as water must be

prevented from penetrating the

construction. This must be done

through extra jointing and

screening.

Motor and EC motor control, if any,

are prepared for outdoor fitting for

pos. A or B. (Fig. 5)

Service access Wherever the ventilator is fitted, there

should be enough space to be able to

open the service door to an angle of

approx. 90° and to access the locking

screws.(Fig. 6)

1.2.3 Fitting the mounting bars

• Mounting should be done on a stable vibration-resistant base, to minimise any

vibration that might be caused by the ventilator. A cement slab placed on a

wooden base construction is recommended.

• Fit the mounting bars on the cabinet with the supplied fitting screws. The cabinet

has holes already bored for fitting method A.

• Place the ventilator on the supporting base. Do not fasten the ventilator to the

base.(Fig. 7)

7/64

3004349_2017_08_03.fm GB - BESF – Product information

RD12102-01

Fig. 8

1.3 Wiring

General

The wiring must only be done by a qualified electrician.

The fan and motor specifications are listed on the type-plates.

Max. fuse rating = 13 Amp.

If the fuse is a ...it must have the characteristic

melting fuse gG or gM.

control fuse B or C, and comply with IEC 90947-2. -

Max. short circuit current is 10 kA

At start-up and during the initial adjustment of the fan, it is important to control the

direction of rotation of the motor and to check the motor current does not exceed the

manufacturer’s recommended operating current for the motor (to avoid damaging the

motor).

Isolation switch EXHAUSTO A/S would like to draw attention to the fact that, in

accordance with the EU's Machine Directive (appendix 1)

all fan

systems shall include a isolation switch.

The isolation switch must ...

• be lockable or positioned in plain sight in the immediate vicinity of the fan

• be able to disconnect all poles from the supply voltage

— contact distance of at least 3 mm in each pole

• Set up as isolation switch in accordance with standard IEC 60947-1 or

IEC 60947-3.

The isolation switch is not supplied by EXHAUSTO.

Lightning

conductor

Any lightning conductor connected to the fan must be in accordance with applicable

regulations and legislation.

1.3.1 Ventilator without EC control

Wiring Wiring should be done as stipulated in the electrical drawing in the door of the motor’s

terminal box (Fig. 8).

BESF146-4-1

BESF160-4-1

All one-phase ventilators are voltage regulated.

The motor is fitted with a thermal cut-out. The thermal cut-out is factory-fitted, wired in

series to the motor’s power circuit (please see wiring diagram in the terminal box, Fig. 1).

Use the wiring diagram (Fig. 2) if a manual reset is required after a thermal cut-out,

where the thermal cut-out is used as a contact in the control circuit.

The motor has overload protection.

8/64

3004349_2017_08_03.fm GB - BESF – Product information

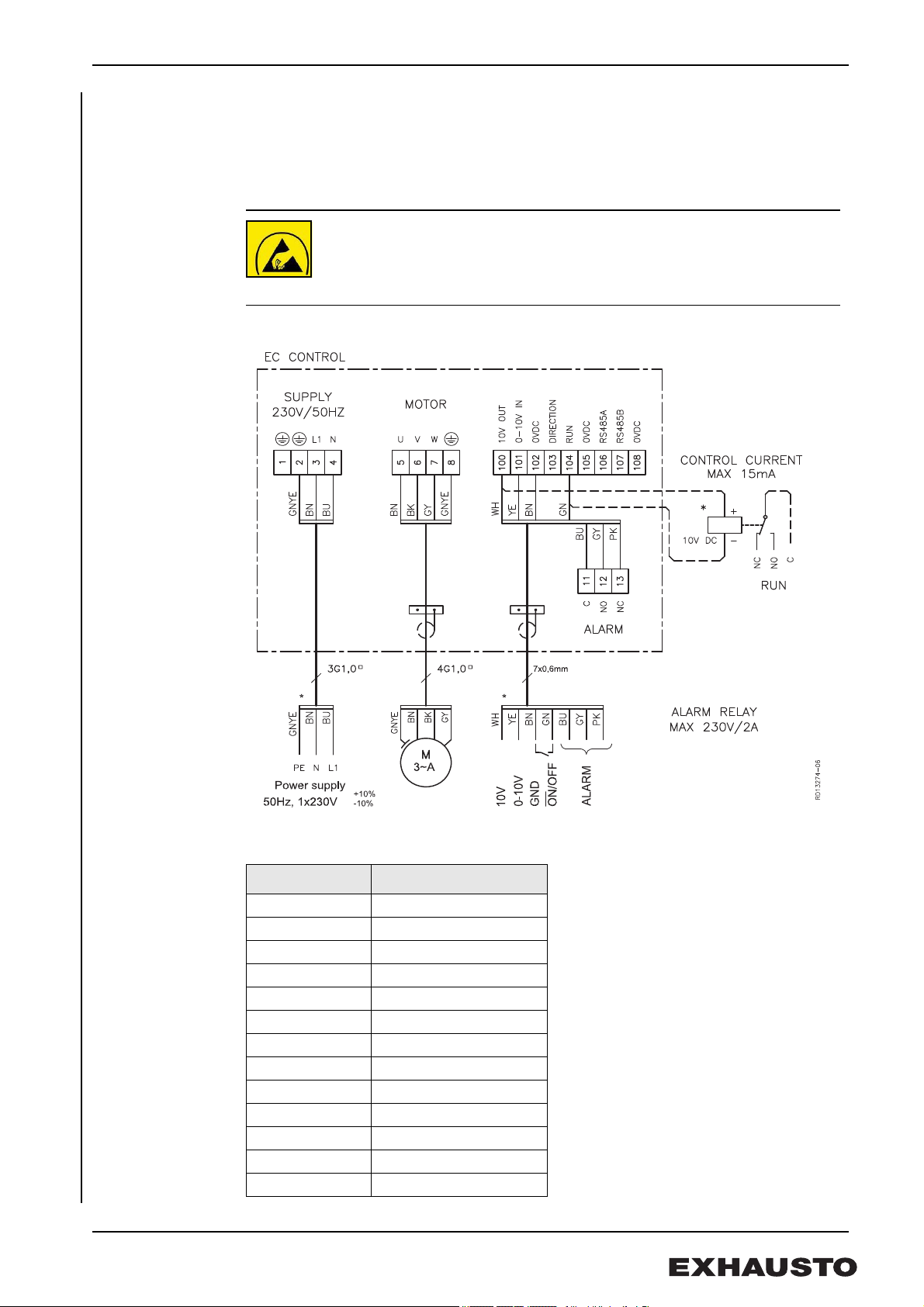

Fig. 9

1.3.2 Ventilator with EC control

General Ventilators marked “EC” have built-in EC control system.

Cables Cables for control signals must be screened. The wiring for control signal inputs must

be completely insulated from the supply wirings.

ESD

The electrician must be ESD protected when

• detaching the cover on the EC control

• working with the EC control

BESF160-2-1EC, BESF180-4-1EC, BESF200-4-1EC, BESF225-4-1EC, BESF250-4-1EC

Diagram

Key to diagram

* Not supplied by EXHAUSTO.

Terminal Signal description

100 10 V DC

101 0-10 VDC

102 0 V DC (chassis)

103 Direction of rotation

104 Start/stop

105 0 V DC (chassis)

106 RS485 + (A)

107 RS485 - (B)

108 0 V DC (chassis)

11 Alarm C

12 Alarm NO

13 Alarm NC

9/64

3004349_2017_08_03.fm GB - BESF – Product information

Fig. 10

Leakage current During operation EC control have a leakage current of less than 3.5 mA. The leakage

current must be earthed, as there is a risk of the motor becoming live.

Earth leak circuit

breakers

If current earth leak circuit breakers are fitted in the installation, they must be of

a type that meets the following requirements:

• PFI type A breaker that breaks the circuit when a vagrant current with DC

content (pulsating DC) in accordance with EN 61008.

• The circuit breakers must be marked with the following symbol:

Requirements • Disconnection time of max 0.3 seconds

Dimensioning of

the neutral

conductor

Multiple one-phase BESF with EC installations in a shared network with a common

neutral require special dimensioning of the neutral, as the current is not a pure sine

wave.

Example Three EC motors are installed sharing 3 phases; thus, the neutral current is the sum of

the three motors’ current.

Existing

installations

If you are fitting motors to an existing installation, ensure the neutral conductor can

handle the resultant load.

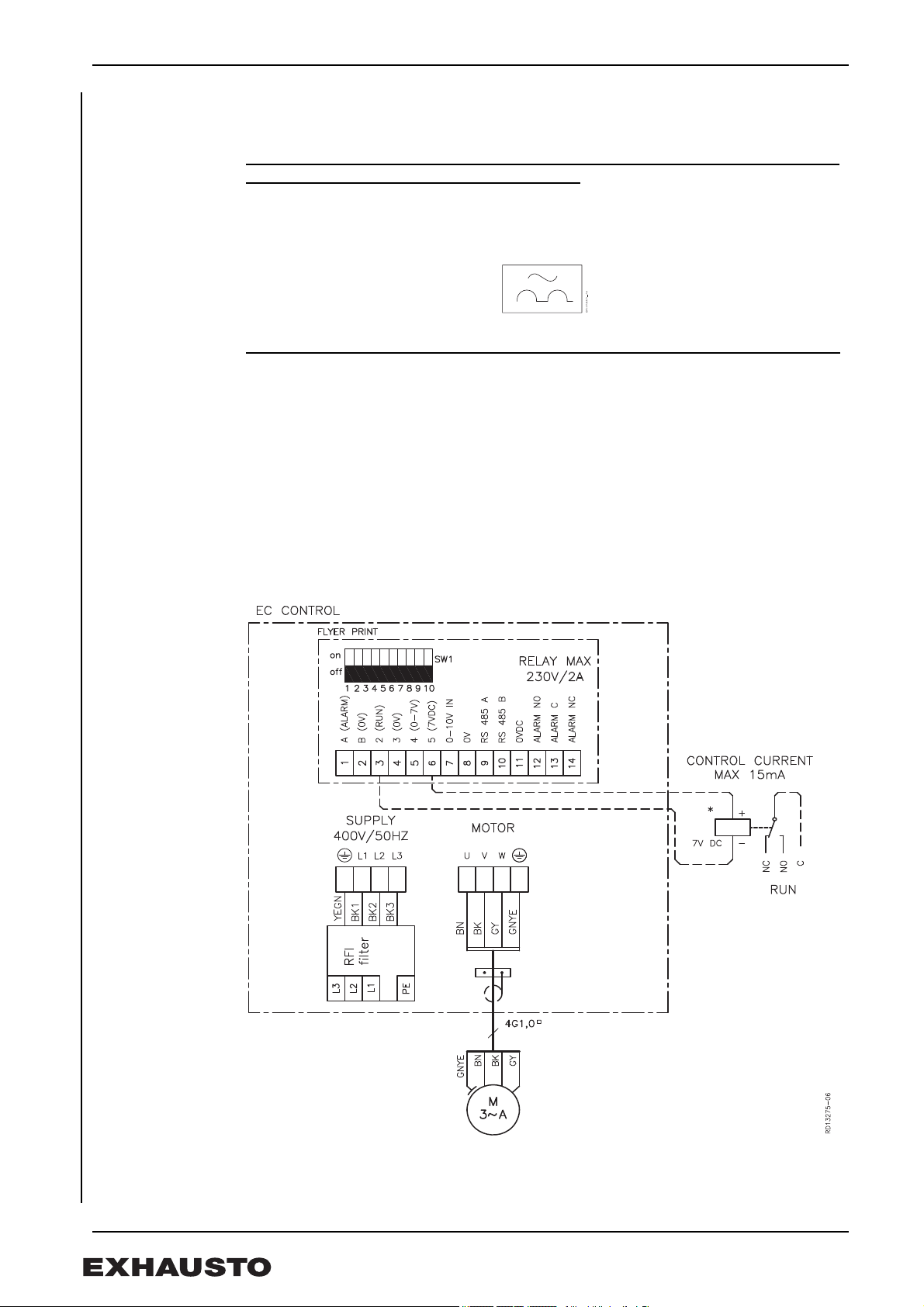

BESF280-4-3EC

Diagram

* Not supplied by EXHAUSTO.

10/64

3004349_2017_08_03.fm GB - BESF – Product information

Key to diagram

Terminal Signal description Comments

1 Alarm in EFC1P panel A

2 0 V DC (chassis) EFC1P panel B

3 Start/stop EFC1P panel 2

4 0 V DC (chassis) EFC1P panel 3

5 0-7 V DC EFC1P panel 4

6 7 V DC EFC1P panel 5

7 0-10 V DC

8 0 V DC (chassis)

9 RS485 + (A)

10 RS485 - (B)

11 0 V DC (chassis)

12 Alarm NO

13 Alarm C

14 Alarm NC

Dipswitch 1 • Dip 1-6: Modbus address

• Dip 7-8 Always OFF

• Dip 9: Analog source(0-10V) or EFC1P

• Dip 10: Always OFF

Dip 9

0-10 Volt OFF

EFC1P panel ON

Leakage current The EC-control system produces a leakage current when running. The leakage current

must be earthed, as there is a risk of the motor becominglive.

A leak current of up to 150 mA can be generated.

The ventilator must be properly earthed to comply with EN50178.

Earth leak circuit

breakers

If current earth leak circuit breakers are fitted in the installation, they must be of

a type that meets the following requirements:

• PFI type B breaker according to EN 61008, that breaks the circuit when a

vagrant current with DC content (pulsating DC) or smooth vagrant current

is registered.

• The circuit breakers must be marked with the following symbols:

11/64

3004349_2017_08_03.fm GB - BESF – Product information

1.3.3 Fault finding: phase-one EC controls

Diodes • Diode 1: Red

• Diode 2: Yellow

• Diode 3: Green

Troubleshooting

chart

Error code Green Red Yellow Error Relay

None + - 1Reserved

2 - + Blinks twice/pauses 4 seconds Below voltage 170 v +

3 - + Blinks three times/pauses 4

4 + - Blinks four times/pauses 4 seconds Overcurrent: Reduced

5Reserved

6 + - Blinks six times/pauses 4 seconds Overheating: Reduced

7 - + Blinks seven times/pauses 4

8 - + Blinks eight times/pauses 4

9 - + Blinks nine times/pauses 4 seconds MCE Fault (IRF Chip

10 - + Blinks 10 times/pauses 4 seconds Motor blocked +

11 - + Blinks 11 times/pauses 4 seconds Motor phase missing +

12 Reserved

13 - + Reserved

14 Reserved

15 Reserved

16 - + Blinks 16 times/pauses 4 seconds Communication error +

• Green diode lights up: no errors

• Red diode lights up: there is an error. Alarm relay has been tripped.

• Yellow diode: blinks for error type

Above voltage 255 v +

seconds

-

rpm

-

rpm

Overheating: Stop +

seconds

Hardware error +

seconds

+

general fault)

NB When the error has been remedied, the LED indicator (LED blink) on the EC control can be reset

by temporarily cutting the power until the LED goes out.

EXHAUSTO provides a two-year manufacturer's warranty on the fan.

12/64

3004349_2017_08_03.fm GB - BESF – Product information

Fig. 11

Fig. 12

Fig. 13

Fig. 14

1.4 Connecting to duct system

Ducts To achieve maximum performance with minimal energy consumption the ventilator

should be connected to the duct system with the specified lengths of duct before and

after the ventilator. The ventilator must always be connected to the duct system using

FLF to avoid any chance of vibrations being transmitted. The spigots on the ventilator

and the OGSR are fitted with rubber seals.

BESF with fitted OGSR BESF without OGSR

Sound The ventilator is fitted with mufflers in accordance with the requirements of the operating

area. The sound pressure for all types of BESF is less than 70 dB (A).

The duct system must be insulated against sound propagation, heat loss and

condensation.

Protective net A protective net (accessory) with a mesh size of 12 mm must be fitted if the ventilator is

not fitted to a duct.

13/64

3004349_2017_08_03.fm GB - BESF – Product information

Fig. 15

1.5 Service and cleaning

Cleaning The ventilator must be cleaned at least twice a year. To clean the ventilator:

Step Action

1 Switch off the power supply to the

unit using the isolation switch

2 Open the service door.

3 Wash the ventilator housing and

the centrifugal impeller thoroughly

with soap and water. The parts

must be dry and the service door

closed before the ventilator is

restarted.

4 The centrifugal impeller can be

removed and cleaned.

Measure the exact position of the

impeller on the axle before

removing it. Make sure that any

weights on the centrifugal impeller

are not removed.

Make sure that cooling air can

move freely through the motor

cover.

Warning! If, once reassembled, the ventilator vibrates violently this might be due to an

imbalance caused by dirt on the centrifugal impeller.

Warranty EXHAUSTO provides a two-year factory warranty on the ventilator, valid from invoice

date.

1.6 Environmental declaration

Product

description

Materials used Cabinet, screw, fan housing and support rails are made of recycleable hot-dip

EXHAUSTO BESF is a an easily serviced radial fan with forward curved blades. The fan

is insulated against fire, noise and heat with 30 mm of mineral wool. The fan impeller is

directly mounted on the motor shaft, thus reducing losses and wear and resulting in

lower repair costs.

Service and cleaning is done by opening the hinged cover. This provides access to all

parts in contact with the air. The motor is mounted outside the airstream.

The fan is supplied with mounting rails with vibration dampers. The fan is CE approved

and EMC tested in accordance with the applicable directives.

galvanised steel sheet. The insulation consists of mineral wool which can be recycled

after dismantling the fan. The gaskets consist of CFC and HCFC free cellular rubber.

The motor consists of aluminium, steel and copper, and in some cases a plastic cooling

jacket. The packaging consists of corrugated cardboard.

14/64

3004349_2017_08_03.fm GB - BESF – Product information

Materials in %

BESF

146

Aluminium 10% 10% 13% 10% 8% 11% 10% 9%

Fe 75% 76% 70% 74% 75% 75% 78% 77%

Copper 4% 4% 2% 2% 2% 3% 4% 4%

Mineral wool 6% 6% 4% 5% 6% 5% 5% 5%

PCB;

electronic

components

Plastic, cellular

rubber

Other 2% 2% 3% 2% 2% 2% 1% 1%

1% 1% 7% 7% 6% 4% 2% 3%

1% 1% 1% < 1% 1% < 1% 1% < 1%

BESF160

Ej EC

BESF

160

BESF

180

BESF

200

BESF

225

BESF

250

BESF

280

15/64

3004349_2017_08_03.fm DK - BESF - Produktvejledning

Fig. 1

1. DK - BESF - Produktvejledning

EXHAUSTO boxventilator BESF anvendes til transport af luft i indblæsnings- og

udsugningsanlæg.

Ventilatoren må ikke anvendes til transport af faste partikler, eller hvor

der er risiko for eksplosive gasarter.

Ventilatoren må ikke startes med åben servicelåge.

1.1 Opbygning

Beskrivelse BESF er en totalisoleret og lydsvag centrifugalventilator med F-hjul:

• BESF146-4-1

• BESF160-4-1

• BESF160-2-1EC

• BESF180-4-1EC

• BESF200-4-1EC

• BESF225-4-1EC

• BESF250-4-1EC

• BESF280-4-3EC

Ventilatoren består indvendigt af et pladeformet ventilatorhus, som er isoleret, og

udvendigt af et kabinet af galvaniseret plade

Temperaturgrænser

Variant

BESF -12ºC 60ºC -30ºC 40ºC

Studsmål Ventilatorens studsmål er i overensstemmelse med Eurovent.

BESF 146 160/180 200/225 250/280

D (mm)

Transport Ventilatoren leveres emballeret og kan

transporteres på sækkevogn. Efter udpakning skal

ventilatoren transporteres og behandles, således at

kabinet og studse ikke deformeres.

Temperatur - medie Temperatur - omivelser, drift

Min. Max. Min. Max.

Ø 160 Ø 200 Ø 250 Ø 315

Størrelse og vægt

BESF 146 160 180 200 225 250 280

Vægt - kg

13 17 22(EC) 23 27 32 41 49

16/64

3004349_2017_08_03.fm DK - BESF - Produktvejledning

RD13285-01

i

b

a

c

d

e

f

g

h

M

a

x

.

6

0

°

C

M

a

x

.

4

0

°

C

j

Fig. 2

Hovedkomponenter

Pos. Part

aKabinet

bServicelåge

c Motor

d Centrifugalhjul

e Ventilatorhus

f Låseskrue (værktøj medleveres)

g Bæreskinner med svingningsdæmpere

h Selvskærende skruer

i Overgangsstykke OSGR (tilbehør). (Ved montage af OGSR skal slidsen altid

være ud for tappen, således at ledepladerne vender korrekt).

j EC-styring/klemkasse

17/64

3004349_2017_08_03.fm DK - BESF - Produktvejledning

Fig. 3

Fig. 3

RD13307-01

D

D

Fig. 4

1.2 Montage

1.2.1 Indendørs placering

Ventilatoren kan indendørs monteres

på forskellige måder (fig. 3).

Ved intermitterende drift, hvor der er

risiko for kondensvand i motoren, må

kun monteringsmetode A og B

benyttes.

Serviceadgang Ved udvælgelse af den nøjagtige

placering skal der være plads til, at

servicelågen kan åbnes 90º.

Advarsel Motoren må aldrig placeres lodret under kabinettet og desuden skal

det sikres, at motor og EC-styring ikke tildækkes, da det vil kunne

forårsage overophedning.

18/64

3004349_2017_08_03.fm DK - BESF - Produktvejledning

Fig. 5

Fig. 6

RD13307-01

D

D

RD13309-01

Fig. 7

1.2.2 Udendørs placering (OD)

Udendørs montering kræver særlig

opmærksomhed, idet det gennem

ekstra fugning og afskærmning

skal sikres, at der ikke trænger

vand ind i konstruktionen.

Motor og eventuel EC-motorstyring er

forberedt for udendørs montering for

pos. A eller B, jf. fig. 5.

Serviceadgang Ved udvælgelse af den nøjagtige

placering skal der være plads til, at

servicelågen kan åbnes ca. 90° og der

skal være adgang til låseskruerne.

1.2.3 Montage af bæreskinner

• Underlaget skal være plant, stabilt og svingningsdødt for at minimere overførslen

af eventuelle svingninger fra ventilatoren. Anvend f.eks. en cementflise oven på

en solid trækonstruktion.

• Monter bæreskinnerne på kabinettet med de medleverede skruer. I

monteringsmetode A er kabinettet forboret.

• Stil ventilatoren løst oven på underlaget. Den skal ikke fastspændes.

19/64

3004349_2017_08_03.fm DK - BESF - Produktvejledning

RD12102-01

Fig. 8

1.3 El-tilslutning

Generelt

El-installationen skal foretages af autoriseret el-installatør.

Ventilator- og motorspecifikationer fremgår af de monterede typeskilte.

Max. forsikring = 13 Amp.

Hvis forsikringen er en ...skal den være med karakteristik

smeltesikring gG eller gM.

automatsikring B ellerC, og opfylde IEC 90947-2.

Max. kortslutningsstrøm er 10 kA

Ved opstart og indregulering af ventilationsanlægget er det vigtigt at kontrollere

motorens omløbsretning, og at strømforbruget ikke overstiger mærkestrømmen på

typeskiltet, da det vil medføre overbelastning af motoren.

Forsyningsadskiller EXHAUSTO A/S gør opmærksom på, at der i henhold til

Maskindirektivet (bilag 1) skal

opsættes en forsyningsadskiller i den

faste installation af ventilatoren.

Forsyningsadskilleren skal...

• være aflåselig, eller placeres synligt i nærheden af ventilatoren.

• kunne afbryde alle poler fra forsyningsspændingen

- kontaktafstand min. 3 mm i hver pol.

• udføres som forsyningsadskiller i hht. IEC 60947-1 eller IEC 60947-3

Forsyningsadskilleren er ikke en del af EXHAUSTO’s leverance.

Lynafledning... ...skal ske i henhold til gældende love og bestemmelser.

1.3.1 Ventilatorer uden EC-styring

El-tilslutning El-tilslutningen foretages iht. el-diagrammet, der findes i låget på motorens klemkasse

(fig. 8).

BESF146-4-1

BESF160-4-1

Alle 1-fasede ventilatorer er spændingsregulerbare.

Motoren er forsynet med termosikring. Termosikringen er fra fabrikken koblet i serie

med motorens strømkreds (eldiagram i klemkassen fig. 1). Hvis der ønskes manuelt

reset ved termisk udfald, anvendes el-diagram fig. 2, hvor termosikringen anvendes i

styrekredsen for en kontaktor.

Motoren er overbelastningsbeskyttet.

20/64

Loading...

Loading...