Exhausto BESB, BESB 500, BESB 250, BESB 315, BESB 400 Series Manual

EXHAUSTO A/S

Odensevej 76

DK-5550 Langeskov

Tel. +45 65 66 12 34

Fax +45 65 66 11 10

exhausto@exhausto.dk

www.exhausto.dk

3004355-2012-07-23.fm

11

BESB

3004355-2012-07-23.fm

GB - BESB – Product information

1.1 Main parts.............................................................................................................4

1.2 Transport ..............................................................................................................5

1.3 Fitting....................................................................................................................5

1.3.1 Fitting indoors ...............................................................................................5

1.3.2 Fitting outdoors (OD)..................................................................................... 6

1.3.3 Fitting the mounting bars............................................................................... 6

1.4 Wiring....................................................................................................................7

1.4.1 Ventilator without frequency converter..........................................................7

1.4.2 Ventilator with frequency converter FC .........................................................8

1.4.3 Fault finding one-phase FC motors...............................................................9

1.5 Connecting to duct system:..............................................................................11

1.6 Airflow measurement ........................................................................................12

1.7 Service and cleaning ......................................................................................... 13

DK - BESB - Produktvejledning

1.1 Opbygning..........................................................................................................14

1.2 Transport ............................................................................................................15

1.3 Montage ..............................................................................................................15

1.3.1 Indendørs placering ....................................................................................15

1.3.2 Udendørs placering (OD) ............................................................................16

1.3.3 Montage af bæreskinner .............................................................................16

1.4 El-tilslutning .......................................................................................................17

1.4.1 Ventilatorer uden frekvensomfomer ............................................................17

1.4.2 Ventilatorer med frekvensomformer FC ......................................................18

1.4.3 Fejlfinding for 1-fasede FC-motorer ............................................................ 19

1.5 Kanaltilslutning..................................................................................................21

1.6 Luftmængdemåling............................................................................................ 22

1.7 Service og rengøring.........................................................................................23

D - BESB - Betriebsanleitung

1.1 Aufbau.................................................................................................................24

1.2 Transport ............................................................................................................25

1.3 Montage ..............................................................................................................25

1.3.1 Aufstellung in Innenräumen ........................................................................25

1.3.2 Aufstellung im Freien (OD).......................................................................... 26

1.3.3 Montage von Tragschienen.........................................................................26

1.4 Elektrischer Anschluss ..................................................................................... 27

1.4.1 Ventilatoren ohne Frequenzwandler ........................................................... 27

1.4.2 Ventilatoren mit Frequenzwandler FC......................................................... 28

1.4.3 Fehlersuche bei einphasigen FC-Motoren ..................................................29

1.5 Kanalanschluss..................................................................................................31

1.6 Luftmengenmessung.........................................................................................32

1.7 Wartung und Reinigung ....................................................................................33

N - BESB - Produktveiledning

1.1 Oppbygning........................................................................................................34

1.2 Transport ............................................................................................................35

1.3 Montering............................................................................................................35

1.3.1 Innendørs plassering ..................................................................................35

1.3.2 Utendørs plassering (OD) ........................................................................... 36

1.3.3 Montering av bæreskinner...........................................................................36

1.4 Elektrisk tilkobling.............................................................................................37

1.4.1 Vifter uten frekvensomfomer .......................................................................37

1.4.2 Vifter med frekvensomformer FC ................................................................38

1.4.3 Feilsøking for enfasede FC-motorer............................................................39

1.5 Kanaltilkobling ...................................................................................................41

1.6 Luftmengdemåling.............................................................................................42

1.7 Service og rengjøring........................................................................................43

2/56

3004355-2012-07-23.fm

S – BESB – Produkthandbok

1.1 Konstruktion.......................................................................................................44

1.2 Transport ............................................................................................................45

1.3 Montering............................................................................................................45

1.3.1 Inomhusmontering ......................................................................................45

1.3.2 Placering utomhus (OD)..............................................................................46

1.3.3 Montering av bärskenor...............................................................................46

1.4 Elanslutning ....................................................................................................... 47

1.4.1 Fläktar utan frekvensomvandlare................................................................47

1.4.2 Fläktar med frekvensomvandlare FC ..........................................................48

1.4.3 Felsökning för 1-fas FC-motorer .................................................................49

1.5 Kanalanslutning.................................................................................................51

1.6 Mätning av luftmängd........................................................................................52

1.7 Service och rengöring.......................................................................................53

3/56

3004355-2012-07-23.fm GB - BESB – Product information

- +

m

RD11279-01

Fig. 1

1. GB - BESB – Product information

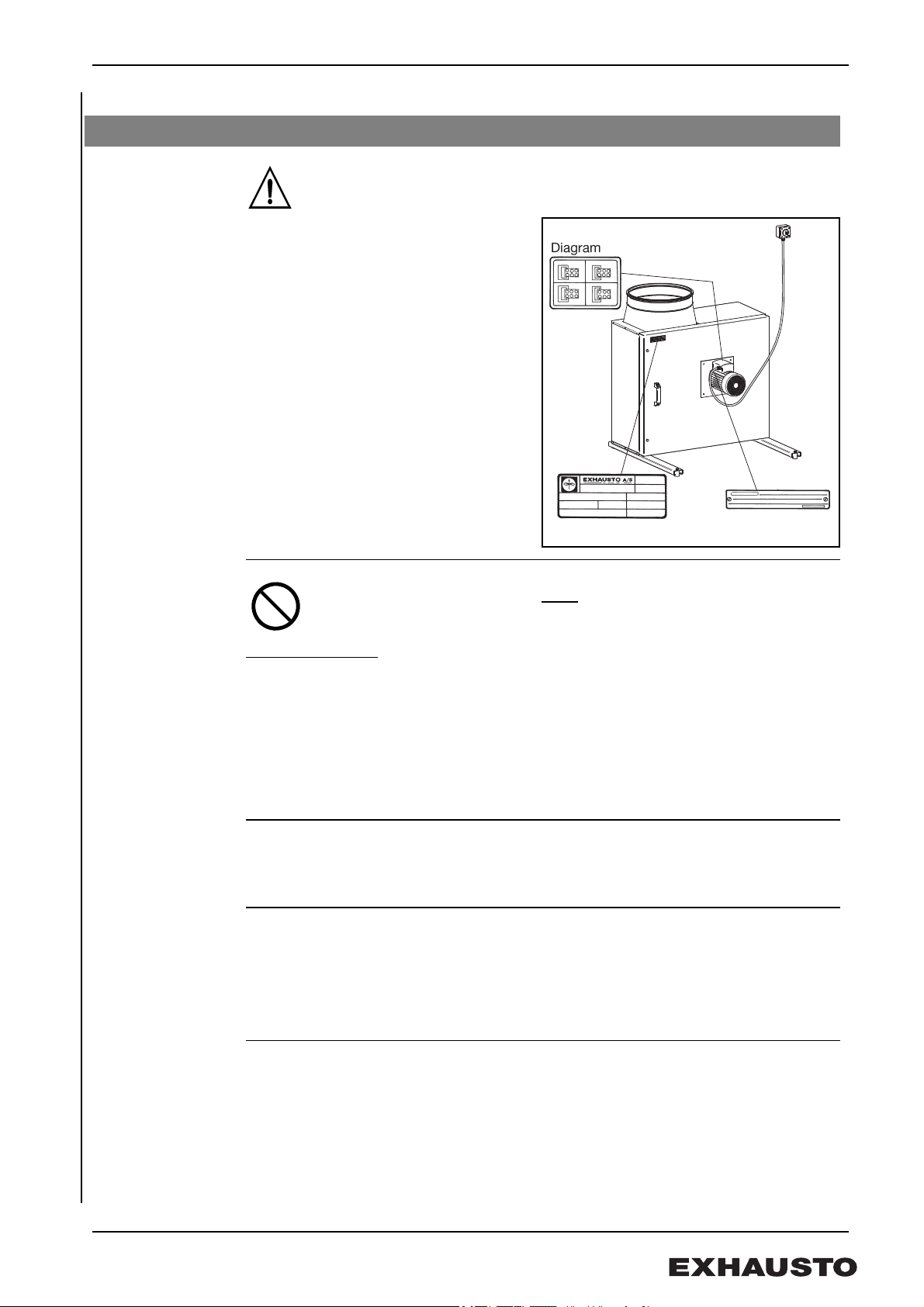

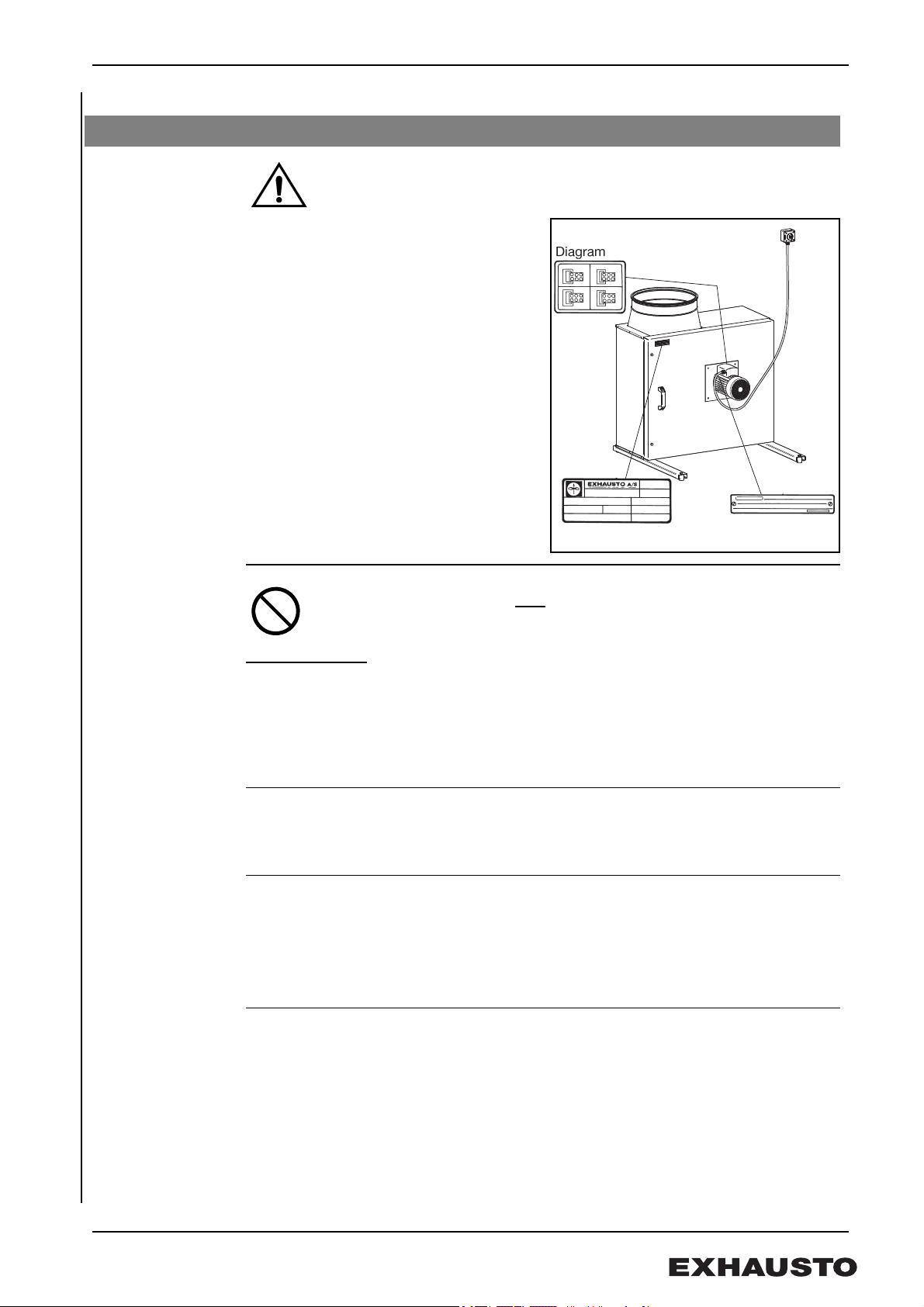

EXHAUSTO BESB box ventilators are used in air supply and extraction systems.

The ventilator is not to be used to transport solid particles, nor in areas

where there is a risk of explosive gases.

The ventilator must not be started with the service door open.

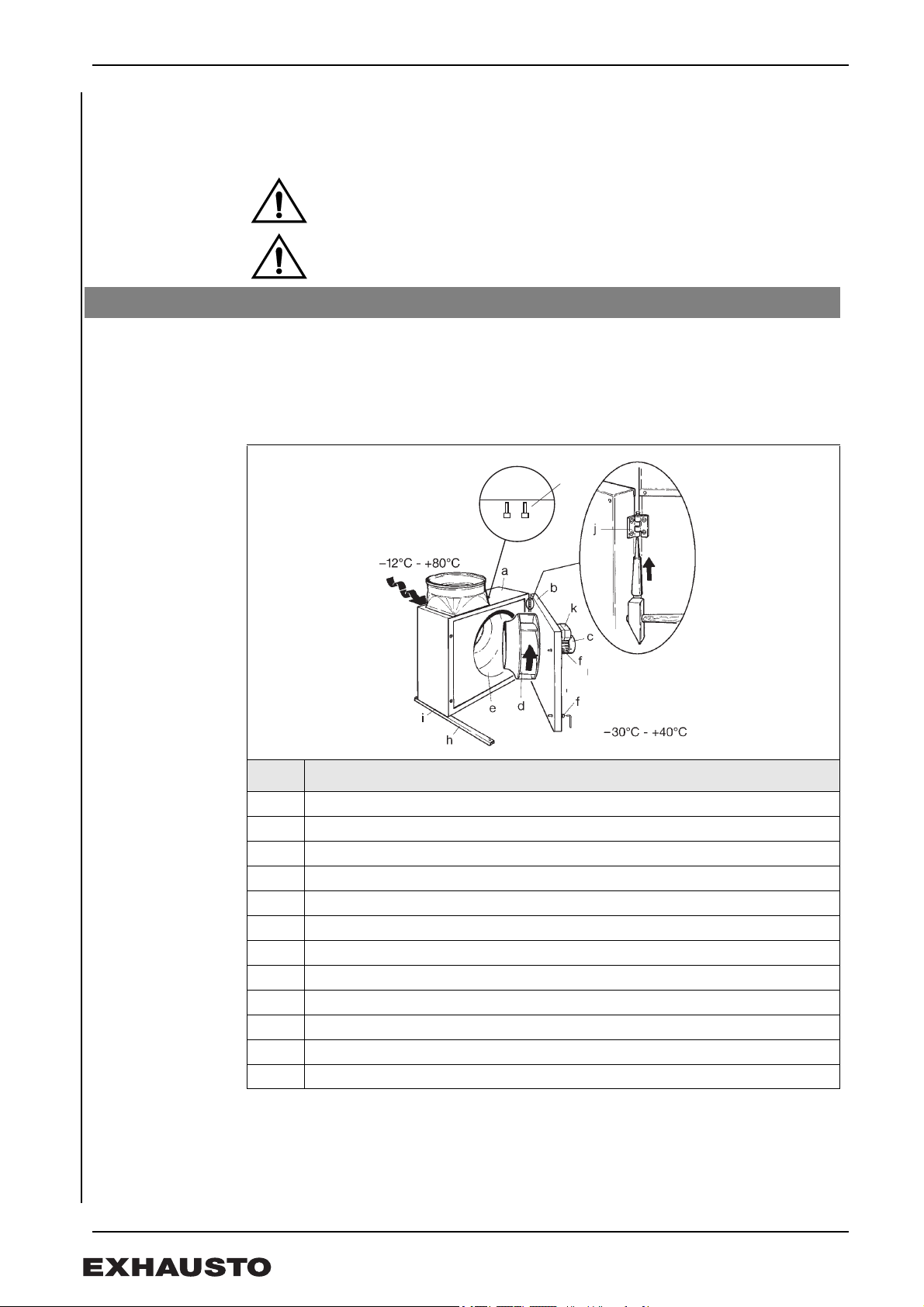

1.1 Main parts

BESB is available in four different sizes, is completely insulated, and has a low-noise

centrifugal fan with cast aluminium backward-bent blades (B-impeller). The ventilator

has an internal insulated housing and an external cabinet, both made of sheet

aluminium.

Main components

Pos. Part

a Cabinet

b Service door

c Motor

d B-impeller

e Fan housing

f Locking screws (supplied with screwdriver)

g Handle

h Mounting bars with vibration damper

i Self-tapping screws

j Hinges

k Frequency converter / terminal box

m Air flow measuring probes (not included with BESB250)

Min. operating temperature: -12°C max. operating temperature +80°C

Ambient temperature when running: min. -30°C max. +40°C

4/56

3004355-2012-07-23.fm GB - BESB – Product information

Fig. 2

RD11358-01

Fig. 3

1.2 Transport

The ventilator is delivered packaged and can be transported on a pallet. Once unpacked

the ventilator should be handled carefully, especially the spigots etc. Deformation could

result in internal damage to the moving parts.

If there is not a lot of space to move the ventilator, the service door can be dismounted

as shown in section 1.1.

NB The ventilator must not be lifted using the service door handle.

Weight

BESB 250 315 400 500

kg 50 54 (FC) 59 61 (FC) 92 105 97 (-3FC)

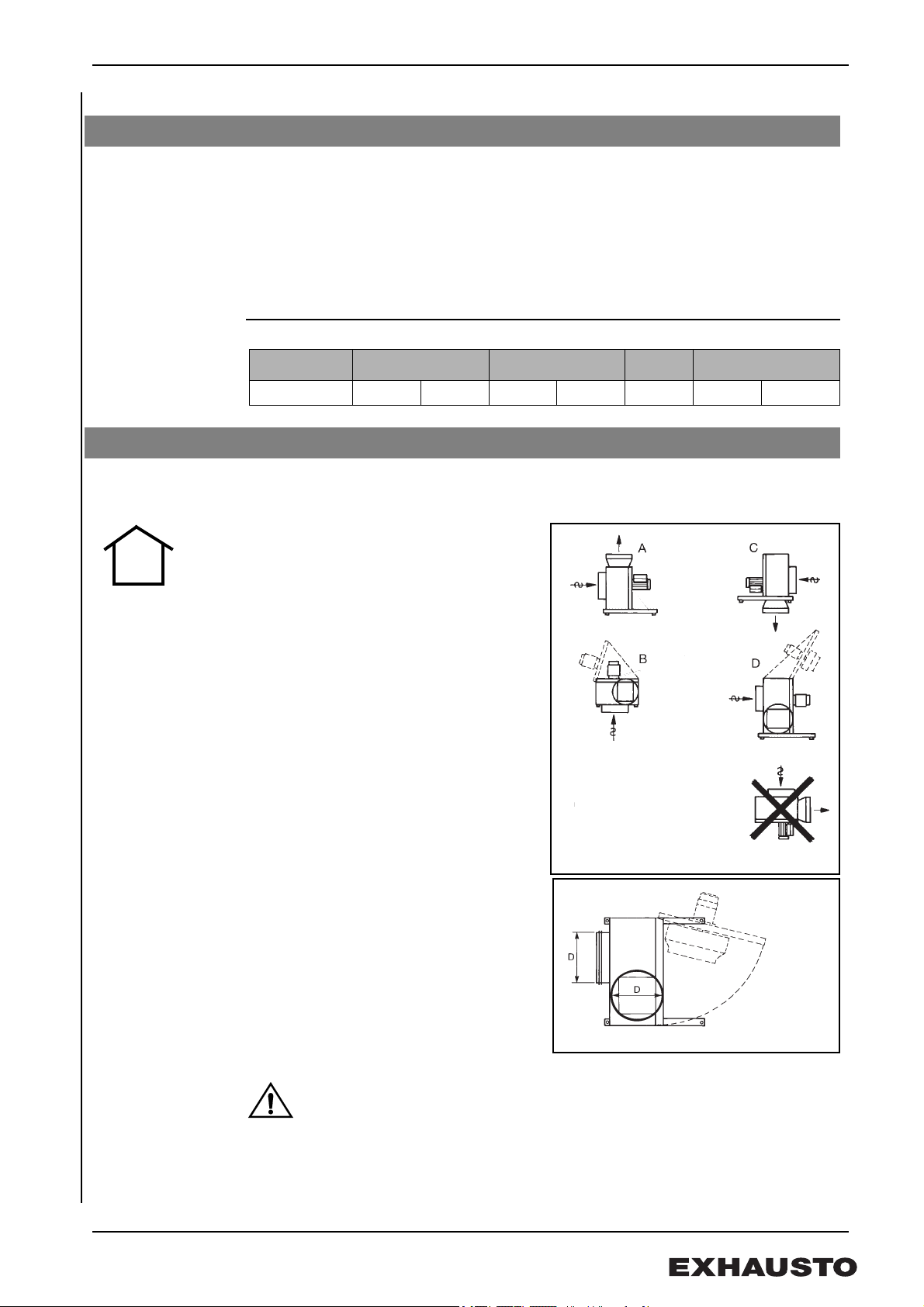

1.3 Fitting

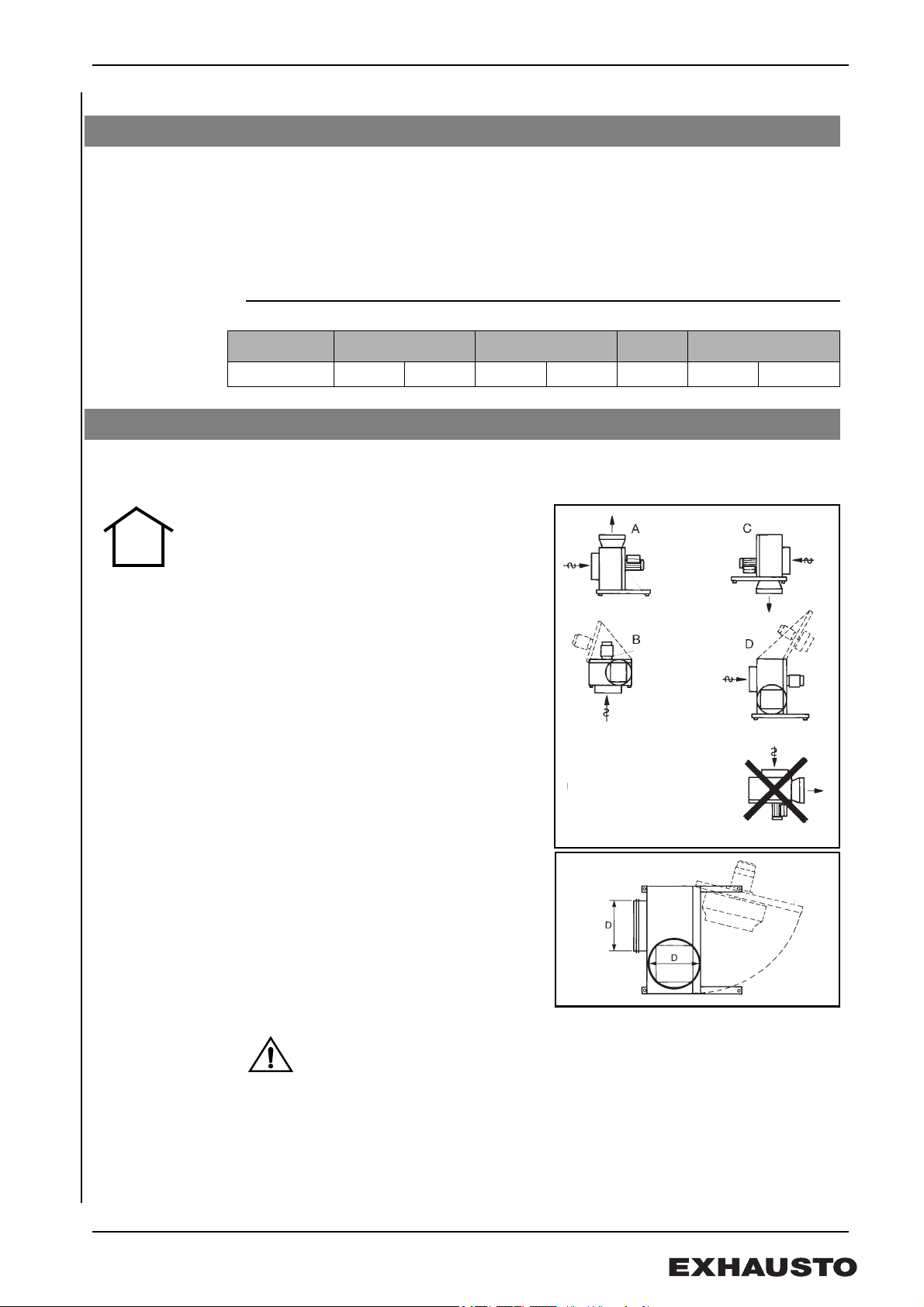

1.3.1 Fitting indoors

There are various ways of fitting the

ventilator indoors (Fig. 2).

With methods B and D the service door

must be kept in the open position during

service. A safety fitting for this purpose can

be supplied (including an assembly kit).

If the ventilator is to run intermittently, there

is a risk of condensation in the motor.

Therefore, use mounting method A or B

only.

Service access Wherever the ventilator is fitted, there

should be space enough to be able to open

the service door to an angle of approx. 80°

and to access the locking screws.

Warning The motor must never be placed vertically under the cabinet and the

motor and frequency converter must never be covered or they will

overheat.

5/56

3004355-2012-07-23.fm GB - BESB – Product information

A

B

C

D

Fig. 4

Fig. 5

RD11358-01

RD12105-01

Fig. 6

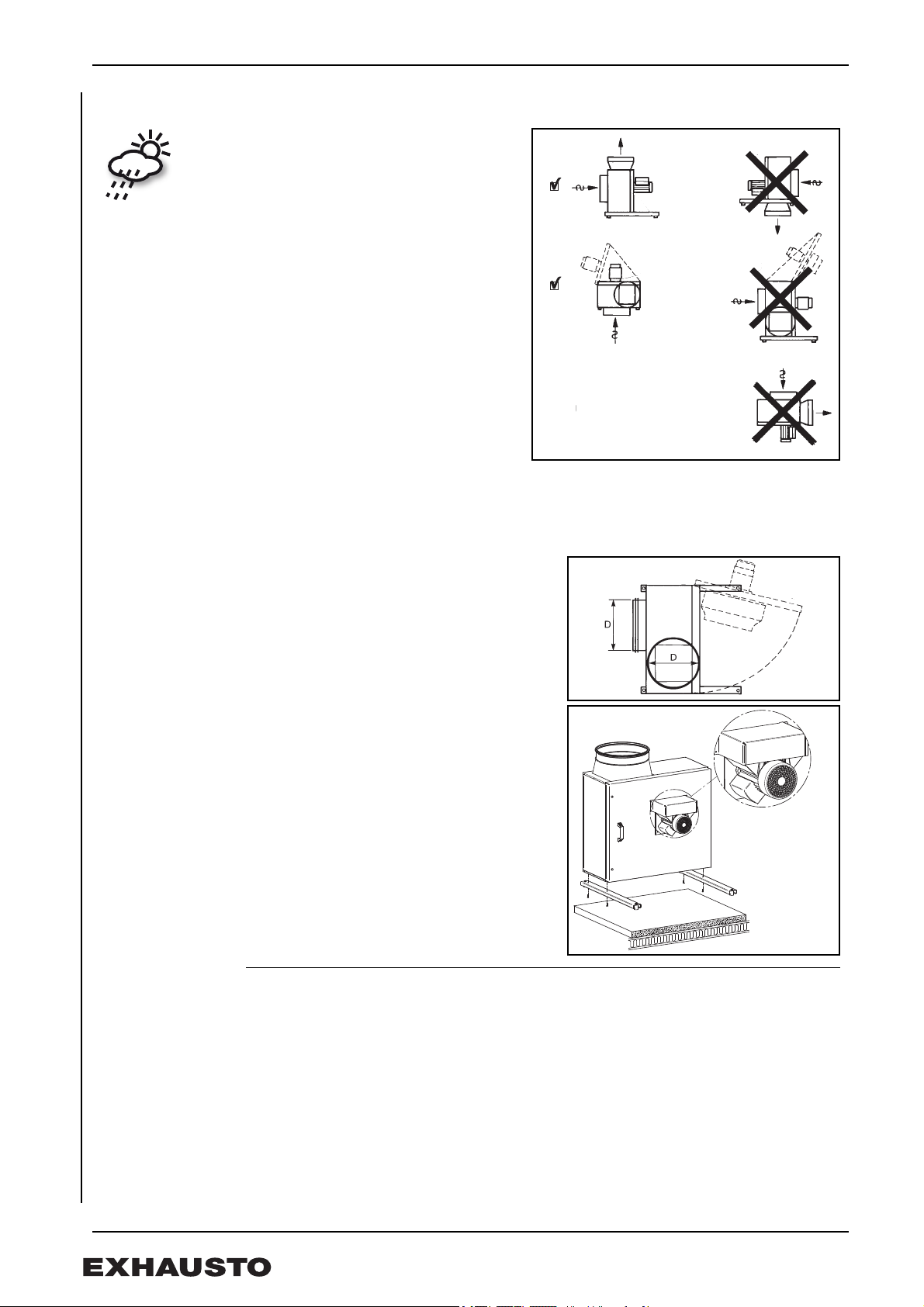

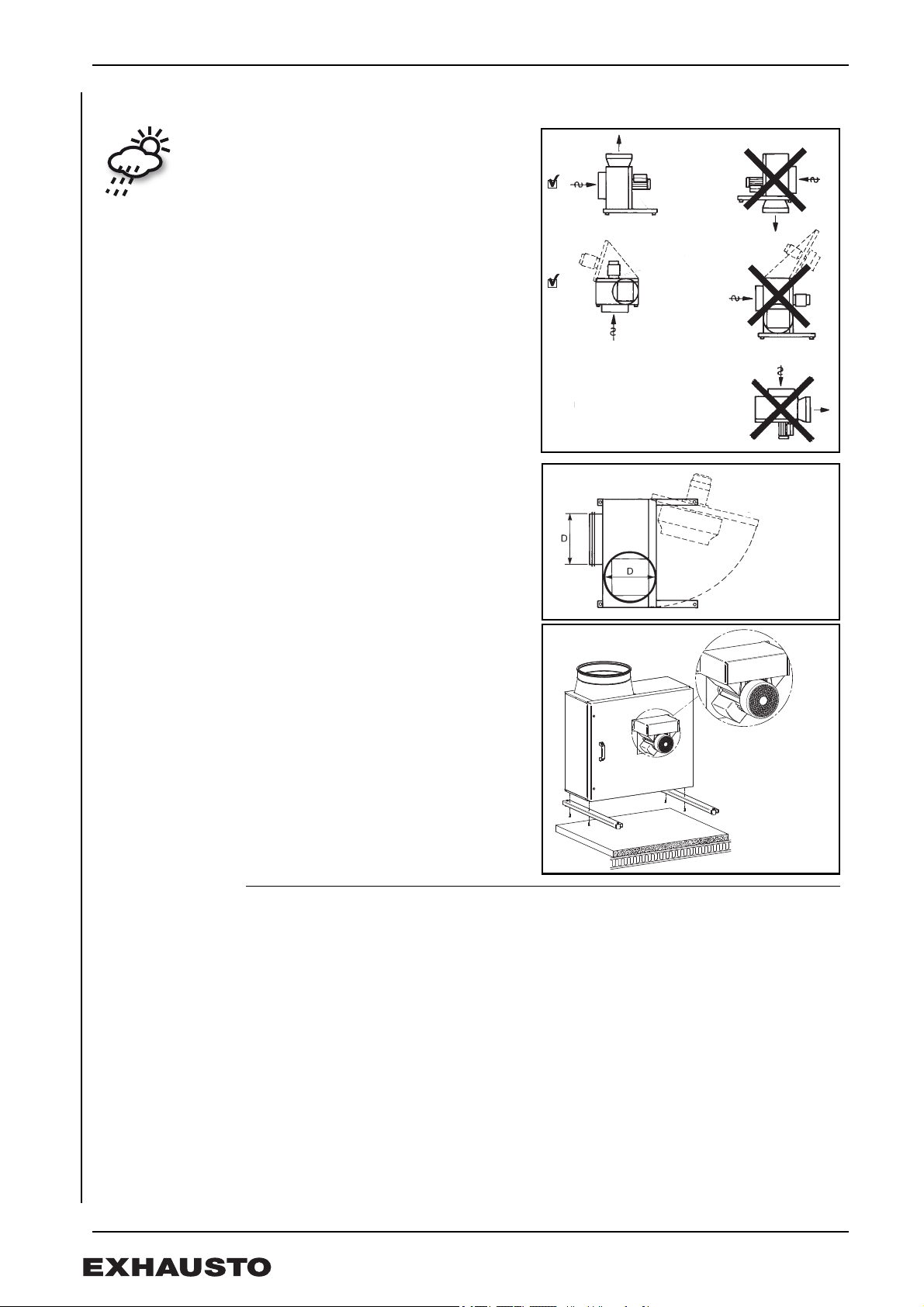

1.3.2 Fitting outdoors (OD)

OD type ventilators are designed for

outdoor use.

A and B fitting methods should be

used for outdoor fitting. Fitting

methods C and D require a specially

designed ventilator (Fig. 4) — contact

EXHAUSTO.

All exterior seams, including spigots

have been jointed to prevent water from

getting inside.

The cabinet is class C4 DS/EN ISO12

944.2 certified and designed for

outdoors.

Service access Wherever the ventilator is fitted, there should

be space enough to be able to open the

service door to an angle of approx. 80° and to

access the locking screws.

Ventilator and

frequency

converter

1.3.3 Fitting the mounting bars

The motor of the FCOD-type BESB ventilator

is covered to prevent outdoor condensation

damaging the electronics (Fig. 6).

• Mounting should be done on a stable vibration-resistant base, to minimise any

vibration that might be caused by the ventilator. A cement slab placed on a

wooden base construction is recommended.

• Fit the mounting bars on the cabinet with the supplied fitting screws. The cabinet

has holes already bored for fitting method A.

• BESB 400 and 500: When using fitting method B (Fig. 2/4) for BESB 400 and

500, holes (Ø16 - Ø20) are bored in the cabinet for the fitting of the mounting

bars.

• Fit the mounting bars while the ventilator is on the pallet.

• Sit the ventilator on the supporting base. Do not fasten the ventilator to the base.

6/56

3004355-2012-07-23.fm GB - BESB – Product information

Fig. 7

1.4 Wiring

General

Wiring of the ventilator should only be performed by a qualified electrician.

The ventilator and motor specifications

are listed on the ventilator’s type plate.

Max. fuse rating = 13 Amp.

At start-up and during the initial

adjustment of the ventilator, it is important

to control the direction of rotation of the

motor and to check the motor current does

not exceed the manufacturer’s

recommended rated current for the motor

(to avoid damaging the motor).

Repair

switch

The switch must …

EXHAUSTO A/S stresses that according to the Machine Directive

(Appendix 1), a repair switch must

the ventilator.

• be lockable or positioned in plain sight in the immediate vicinity of the

ventilator.

• be able to disconnect all poles from the electrical supply.

– contact distance of at least 3 mm in each pole.

• set up as a power supply isolator in accordance with standard EN 60

204-1.

The repair switch is not supplied by EXHAUSTO.

be fitted in the fixed installation of

1.4.1 Ventilator without frequency converter

Wiring Wiring should be done as stipulated in the electrical drawing in the door of the motor's

terminal box (Fig. 7).

BESB250-4-1,

BESB315-4-1

All one-phase ventilators are voltage regulated.

The motor is fitted with a thermal cut-out. The thermal-cut out is factory installed and

wired in series to the motor's power circuit (electrical diagram in the terminal box fig. 1).

Use the circuit diagram (Fig. 2) if a manual reset is required after a thermal cut-out,

where the thermal cut-out is used as a contact in the control circuit.

The motor has overload protection.

BESB500-4-3 The ventilator has a three-phase motor, which cannot be voltage regulated.

NB The motor does not have a thermal cut-out and should have a correctly rated

circuit breaker installed.

The motor can be regulated using an installed external frequency converter max. 50 Hz.

7/56

3004355-2012-07-23.fm GB - BESB – Product information

Fig. 8

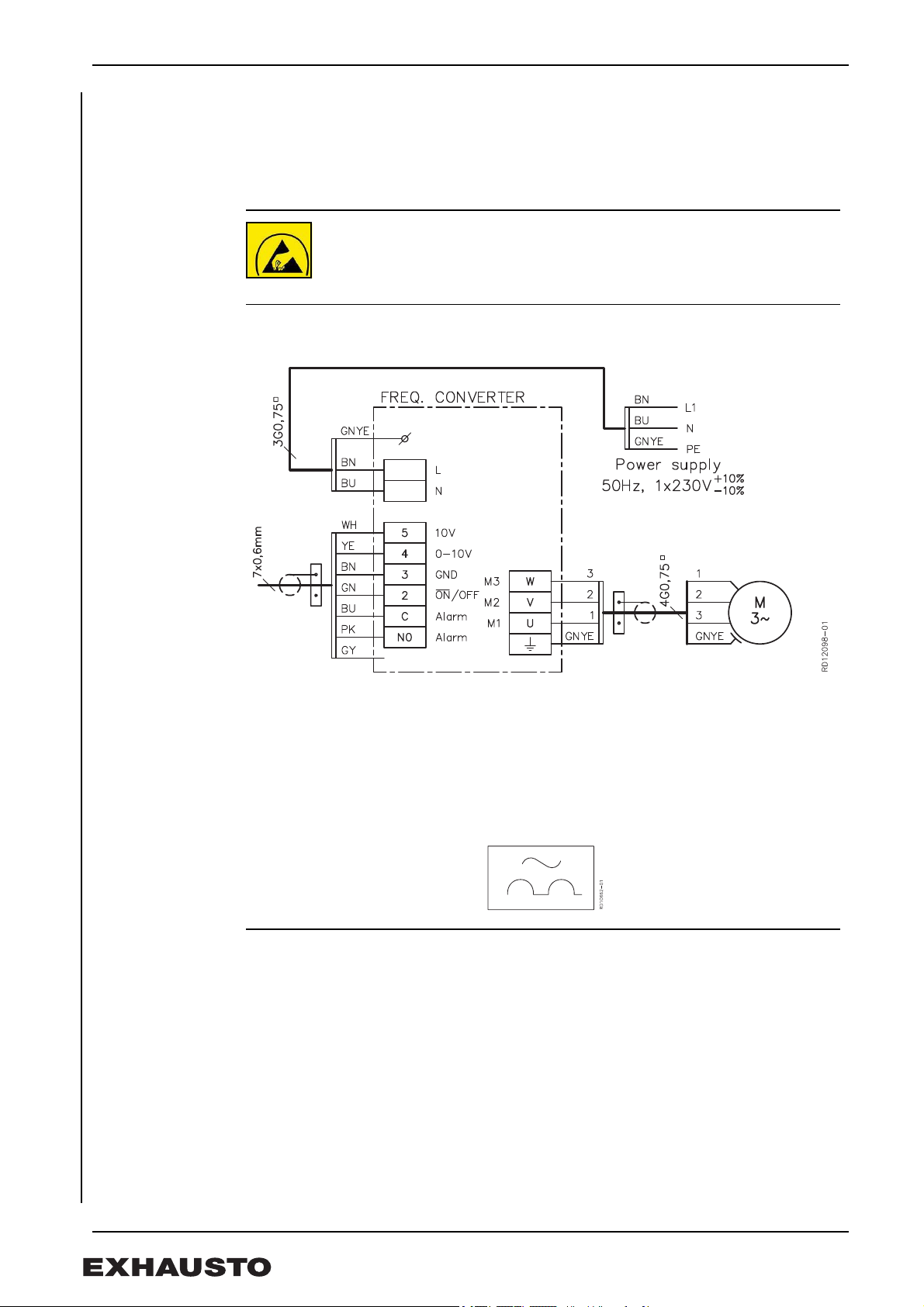

1.4.2 Ventilator with frequency converter FC

General Ventilators marked FC have a built-in frequency converter.

Cables Cables for control signals must be screened. The wiring for control signal inputs must

be completely insulated from the supply wirings.

ESD

The electrician must be ESD protected when

• detaching the cover on the frequency converter

• working with the frequency converter

BESB250-4-1FC, BESB315-4-1FC, BESB400-4-1FC, BESB500-4-1FC

Diagram

Leakage current When operating the FC-motor frequency converters have a leakage current of less than

3.5 mA. The leakage current must be earthed, as there is a risk of the motor becoming

live.

Earth leak circuit

breakers

Dimensioning of

the neutral

conductor.

Example For example if three FC motors are installed, sharing 3-phases, the neutral current is the

Existing

installations

Only Type-A earth leak circuit breakers can be used with one-phase FC motors, as

required by IEC755 (Amendment 2). The circuit breaker activates when faulty current is

registered with DC component. These circuit breakers are marked with:

Multiple one-phase BESB with FC installations in a shared network with a common

neutral, require special dimensioning of the neutral, as the current is not a pure sine

wave.

sum of the three motors’ current.

If you are fitting motors to an existing installation, check that the neutral conductor can

cope with the resultant load.

8/56

3004355-2012-07-23.fm GB - BESB – Product information

RD12119-01

Fig. 9

LED

Fitting fuses for the

BESB250 and BESB315

Fitting fuses

for the

BESB400 and

BESB500

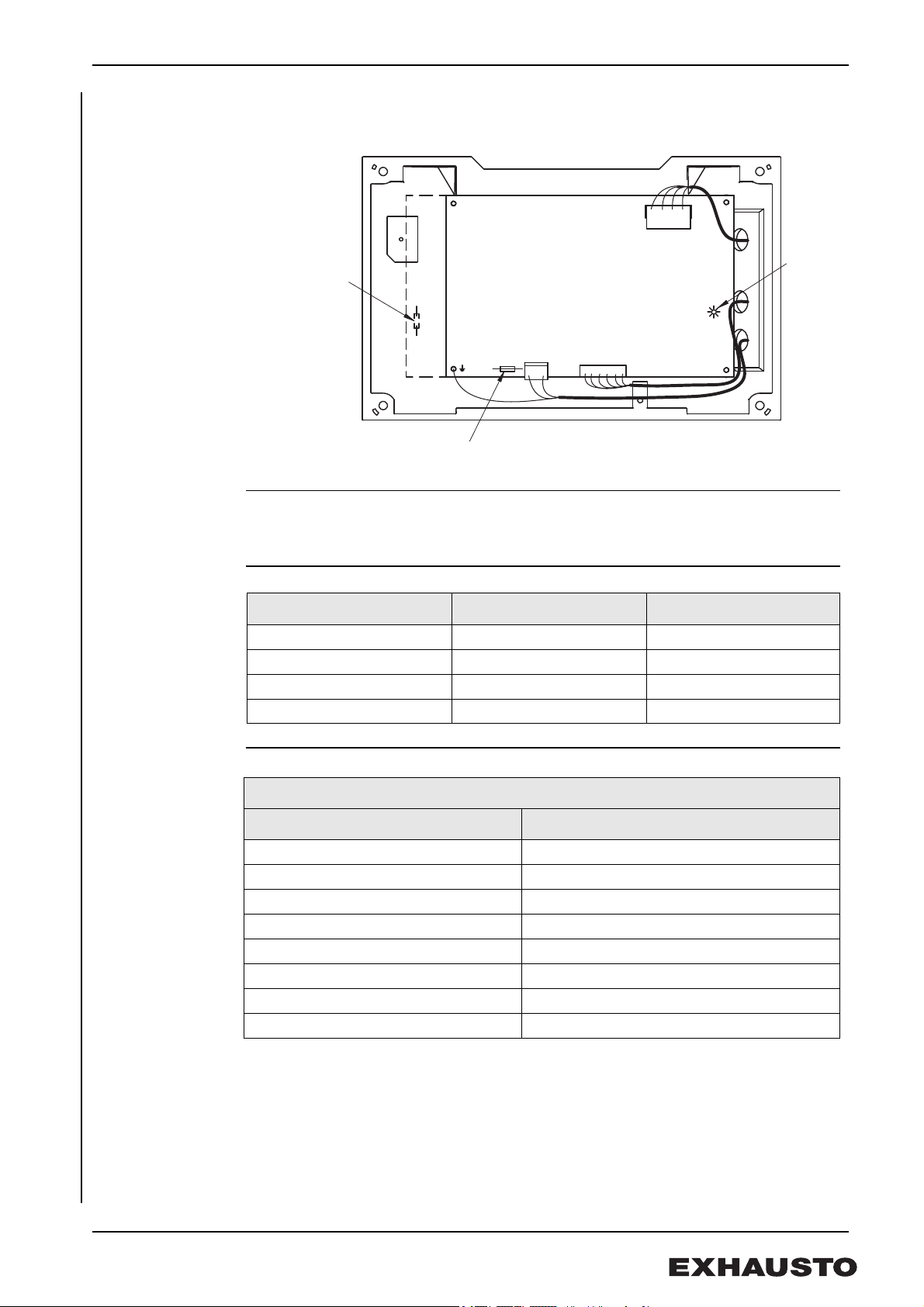

1.4.3 Fault finding one-phase FC motors.

Frequency

converter fuses

LED does not light Check:

• The mains is 1 X 230 V

• fuses

Fuse table

BESB400-4-1FC 2 10A T10AH

BESB500-4-1FC 2 10A T10AH

Fault finding chart

Once every second Normal operation.

Once every four seconds Fault: High temperature

Blinks twice every four seconds Fault: Low voltage

Blinks three times every four seconds Fault: Overvoltage (generator)

Blinks four times every four seconds Fault: Overload (motor current )

Blinks five times every four seconds Fault: Output module fault

Blinks six times every four seconds Fault: Communication time-out

Blinks seven times every four seconds Fault: Phase error

Ventilator type Fuse rating Typ e

BESB250-4-1FC 4A T4AH

BESB315-4-1FC 4A T4AH

The green LED indicates:

LED blinking: Description

When the error has been remedied, the LED indicator of the frequency converter can be

reset by temporarily cutting the power until the LED goes out.

9/56

3004355-2012-07-23.fm GB - BESB – Product information

Fig. 10

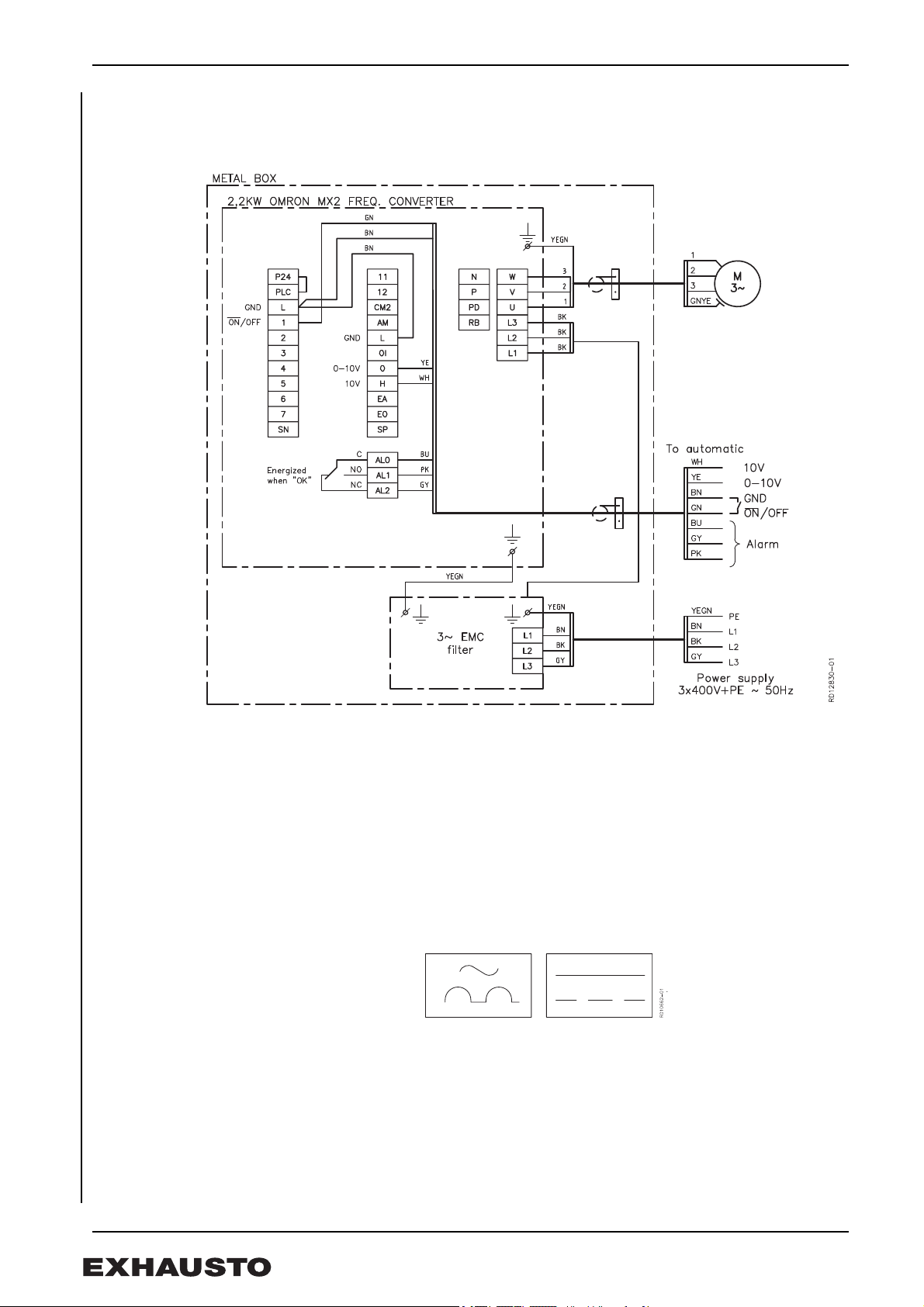

BESB500-4-3FC

Diagram

Leakage current The FC- motor’s frequency converter produces a leakage current when running. The

leakage current must be earthed, as there is a risk of the motor becoming live.

A leakage current of up to 150 mA can be generated.

To comply with EN50178 the unit must be suitably earthed.

Earth leak circuit

breakers

Only type-B circuit breakers must be used with model BESB500-4-3FC in compliance

with IEC755 Amend. 2, for faulty current with DC component (pulsating DC) and for

smooth vagrant current.

These circuit breakers are marked with:

Fault finding See the instruction manual for the frequency converter (in the electronic housing).

When the error has been remedied, the LED indicator of the frequency converter can be

reset by temporarily cutting the power until the LED goes out.

10/56

3004355-2012-07-23.fm GB - BESB – Product information

RD11360-01

Fig. 11

RD11361-01

Fig. 12

Fig. 13

1.5 Connecting to duct system:

Flexible

connections

Sound pressure

level

The ventilator must always be connected to the duct system with FLF, to avoid any

chance of vibrations being transmitted. The spigots on the ventilator are standard-sized

and fitted with rubber seals.

To achieve maximum performance with minimal energy consumption the ventilator

should be connected to the duct system with the specified lengths of duct before and

after the ventilator. The FLF connections must always be fitted as shown.

The ventilator is fitted with sound dampers suited to the requirements of the operating

area. The sound pressure for all types of BESB is less than 70 dB (A). The duct system

is insulated against sound propagation, heat loss, fire and condensation.

No Duct A protective net (accessory) with mesh size of 12 mm must be fitted if the ventilator is

not fitted to a duct. It should be noted that:

• such fittings result in a pressure drop in the system

• Air volume measurements cannot be measured correctly when there is no duct

fitted on the suction side

11/56

3004355-2012-07-23.fm GB - BESB – Product information

qv62 Δp

m

× ls⁄[]=

qv85 Δp

m

× ls⁄[]=

qv91 Δp

m

× ls⁄[]=

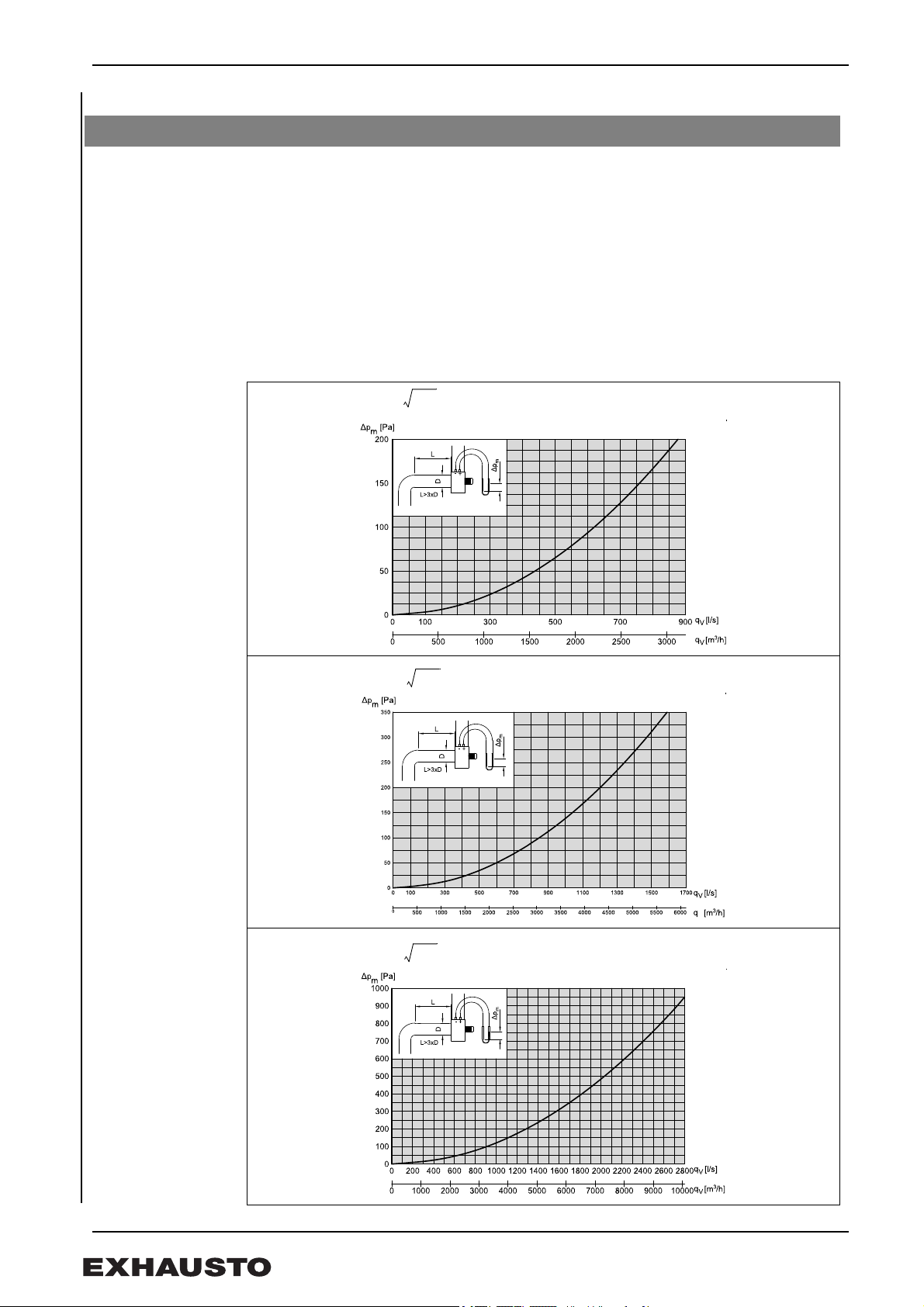

1.6 Airflow measurement

The box ventilators, apart from model BESB250, have measuring points for determining

air flow. A manometer is connected to the test points and the air flow (qv) can be

calculated by using the formula and diagrams.

Margin of error < ± 8% of actual air flow with the duct system on the suction side is as

shown on the diagrams.

Calculations are based on the following conditions:

Temperature: 20°C

Density: 1.2 kg/m3

Pressure measurement, Δpm [Pa], at 20°C

1 m3/s = 1000 l/s = 3600 m3/h

BESB315:

BESB400:

BESB500:

12/56

3004355-2012-07-23.fm GB - BESB – Product information

Fig. 14

02

01

03

13

04

07

06

11

12

08

09

10

05

RD12107-01

Fig. 15

1.7 Service and cleaning

EXHAUSTO provides a two-year factory warranty on the box ventilator, valid from

invoice date. The motor in an EXHAUSTO box ventilator is fitted with special ball

bearings that are lubricated and sealed, and maintenance-free. Any replacement of

these bearings should be carried out by technicians from EXHAUSTO SERVICE or

similarly qualified professionals.

The ventilator must be cleaned at least once a year. To clean the ventilator:

• Switch off the power supply to the

ventilator using the repair circuit

breaker. Open the service door when

the fan has stopped running.

• Wash the ventilator housing and the

centrifugal impeller thoroughly with

soap and water. The parts must be

dry and the service door closed

before the ventilator is restarted.

• The centrifugal impeller can be

dismounted and cleaned. Measure

the exact position of the impeller on

the axle before removing it. The

factory position of the impeller is

shown on the cabinet behind the

service door. If there are weights on

the centrifugal impeller do not remove

them.

• Check that cooling air can move

freely through the motor cover.

Spare parts Ventilator components that can be ordered as spare parts are marked with position

numbers. When ordering spare parts supply the ventilator type and the production order

number (PO); both can be read on the information plate.

Spare parts

1. B-impeller

2. Motor plate

3. Axle extender

4. Frequency converters

(for BESB250-4-1FC, BESB315-4-1FC, BESB400-4-1FC,

BESB500-4-1FC, BESB500-4-3FC)

5. Covering

6. Condensator (for BESB250-4-1, BESB315-4-1)

7. Motor

8. Ball bearings N-side

9. Ball bearings D-side

10. Service door

11. Handle

12. Locking screws

13. 2 x Mounting rail with vibration damper

EXHAUSTO reserves the right to introduce changes to these guidelines without prior

notice.

13/56

3004355-2012-07-23.fm DK - BESB - Produktvejledning

Fig. 1

- +

m

RD11279-01

1. DK - BESB - Produktvejledning

EXHAUSTO boxventilator BESB anvendes til transport af luft i indblæsnings- og

udsugningsanlæg.

Ventilatoren må ikke anvendes til transport af faste partikler, eller hvor

der er risiko for eksplosive gasarter.

Ventilatoren må ikke startes med åben servicelåge.

1.1 Opbygning

BESB findes i 4 størrelser og er en totalisoleret og lyd-svag centrifugalventilator med

bagudbøjede skovle (B-hjul) i støbt aluminium. Ventilatoren består indvendigt af et

ventilatorhus, som er isoleret, og udvendigt af et kabinet, begge dele af aluzink.

Hovedkomponenter

Pos. Part

a Kabinet

b Servicelåge

c Motor

d Centrifugalhjul (B-hjul)

e Ventilatorhus

f Låseskrue (værktøj medleveres)

gHåndtag

h Bæreskinne med svingningsdæmpere

i Selvskærende skrue

j Hængsel

k Frekvensomformer/klemkasse

m Målestudse til luftmængde måling (ikke BESB250)

Temperatur medie min.: -12°C max.: +80°C

Temperatur omgivelser, drift min.: -30°C max.: +40°C

14/56

3004355-2012-07-23.fm DK - BESB - Produktvejledning

Fig. 2

RD11358-01

Fig. 3

1.2 Transport

Ventilatoren leveres emballeret og kan transporteres på træpalle. Efter udpakning skal

ventilatoren transporteres og behandles således, at kabinet og studse m.v. ikke

deformeres, da dette kan forårsage berøring imellem roterende dele og heraf følgende

behov for efterjustering/reparation.

Ved transport gennem trange passager ind til opstillingsstedet, er der mulighed for

demontering af servicelågen som vist i afsnit 2.1” Opbygning”.

Bemærk Ventilatoren må ikke løftes i håndtaget på servicelågen.

Vægt

BESB 250 315 400 500

(kg) 50 54(FC) 59 61(FC) 92 105 97(-3FC)

1.3 Montage

1.3.1 Indendørs placering

Ventilatoren kan indendørs monteres på

forskellige måder (fig. 2).

Ved monteringsmetode B og D skal

servicelågen kunne fastholdes i åben

position ved servicering. Til dette formål

kan leveres et sikkerhedsbeslag incl.

monteringssæt som tilbehør.

Ved intermitterende drift, hvor der er risiko

for kondensvand i motoren, må kun

monteringsmetode A eller B benyttes.

Serviceadgang Ved udvælgelse af den nøjagtige placering

skal der være plads til, at servicelågen kan

åbnes ca. 80° og der skal være adgang til

låseskruerne.

Advarsel Motoren må aldrig placeres lodret under kabinettet og desuden skal det

sikres, at motor og eventuelt frekvensomformer ikke tildækkes, d a det vil

kunne forårsage overophedning.

15/56

3004355-2012-07-23.fm DK - BESB - Produktvejledning

A

B

C

D

Fig. 4

RD11358-01

Fig. 5

RD12105-01

Fig. 6

1.3.2 Udendørs placering (OD)

Hvis ventilatoren har typebetegnelsen OD

er det en udendørs variant.

Ved udendørs montage skal

monteringsmetode A eller B benyttes.

Monteringsmetode C og D kræver en

specialbygget ventilator - kontakt

EXHAUSTO (fig. 4).

Alle udvendige samlinger samt studse er

fuget for at forhindre vandindtrængning.

Kabinettets materialer opfylder kravene til

klasse C4 iht. DS/EN ISO12 944.2 og er

egnet til udendørs placering.

Serviceadgang Ved udvælgelse af den nøjagtige

placering skal der være plads til, at

servicelågen kan åbnes ca. 80° og der

skal være adgang til låseskruerne.

Ventilatorer med

frekvensomformer

Ved udendørsopstilling af BESB med

typebetegnelsen FCOD er motoren

overdækket for at undgå

kondensdannelse i elektronikdelen (fig.

6).

1.3.3 Montage af bæreskinner

• Underlaget være plant, stabilt og svingningsdødt for at minimere overførslen af

eventuelle svingninger fra ventilatoren. Anvend f.eks. en cementflise oven på en

solid trækonstruktion.

• Monter bæreskinnerne på kabinettet med de medleverede skruer. I

monteringsmetode A er kabinettet forboret.

• BESB 400 og 500: Når monteringsmetode B (fig. 2/4) vælges til BESB 400 og

500, bores frihuller (Ø16 - Ø20) i kabinettet for møtrikkerne på bæreskinnerne.

• Monter bæreskinnerne mens ventilatoren ligger på træpallen af hensyn til

transporten.

• Stil ventilatoren løst oven på underlaget. Den skal ikke fastspændes.

16/56

3004355-2012-07-23.fm DK - BESB - Produktvejledning

Fig. 7

1.4 El-tilslutning

Generelt

El-installationen skal foretages af autoriseret el-installatør.

Ventilator- og motorspecifikationer fremgår

af de monterede typeskilte.

Max. forsikring = 13 Amp.

Ved opstart og indregulering af

ventilationsanlægget er det vigtigt at

kontrollere motorens omløbsretning, og at

strømforbruget ikke overstiger

mærkestrømmen på typeskiltet, da det vil

medføre overbelastning af motoren.

Reparationsafbryder

Afbryderen skal...

EXHAUSTO A/S gør opmærksom på, at der i henhold til

Maskindirektivet (bilag 1) skal

faste installation af ventilatoren.

• være aflåselig, eller placeres synligt i nærheden af ventilatoren.

• kunne afbryde alle poler fra forsyningsspændingen

- kontaktafstand min. 3 mm i hver pol.

• udføres som forsyningsadskiller i hht. EN 60 204-1

Reparationsafbryderen er ikke en del af EXHAUSTO’s leverance.

opsættes en reparationsafbryder i den

1.4.1 Ventilatorer uden frekvensomfomer

El-tilslutning El-tilslutningen foretages iht. el-diagrammet, der findes i låget på motorens klemkasse

(fig. 7).

BESB250-4-1,

BESB315-4-1

Alle 1-fasede ventilatorer er spændingsregulerbare.

Motoren er forsynet med termosikring. Termosikringen er fra fabrikken koblet i serie

med motorens strømkreds (eldiagram i klemkassen fig. 1). Hvis der ønskes manuelt

reset ved termisk udfald, anvendes el-diagram fig. 2, hvor termosikringen anvendes i

styrekredsen for en kontaktor.

Motoren er overbelastningsbeskyttet.

BESB500-4-3 Ventilatoren er forsynet med en 3-faset normmotor, som ikke kan spændingsreguleres.

Bemærk Motoren indeholder ikke termosikring og skal overbelastningsbeskyttes ved

hjælp af et motorværn som indstilles på motorens mærkestrøm.

Motoren kan frekvensreguleres fra en ekstern frekvensomformer indstillet på

max. 50 Hz.

17/56

Loading...

Loading...