Page 1

QA-805 and

W2CM Interface Module

User Guide

Page 2

Copyright © 2013 EXFO Inc. All rights reserved. No part of this publication

may be reproduced, stored in a retrieval system or transmitted in any form,

be it electronically, mechanically, or by any other means such as

photocopying, recording or otherwise, without the prior written permission

of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

April 12, 2013

Version number 1.0.0

ii QA-805 and W2CM Interface Module

Page 3

Contents

Certification Information ........................................................................................................v

1 Introduction ................................................................................................. 1

QA-805 Features .....................................................................................................................1

Front View of QA-805 .............................................................................................................2

Rear View of QA-805 ..............................................................................................................3

Physical Description of QA-805 Unit .......................................................................................4

Cooling Assembly ...................................................................................................................9

Power Supplies .....................................................................................................................13

QA-805 Technical Specifications ...........................................................................................15

Conventions ..........................................................................................................................16

2 Safety Information ..................................................................................... 17

Laser Safety Warnings ...........................................................................................................17

Operating Cautions ...............................................................................................................18

Installation Instruction Warnings ..........................................................................................19

Equipment Ratings ...............................................................................................................21

3 Getting Started .......................................................................................... 23

Shelf Installation ...................................................................................................................23

Turning the Unit On/Off ........................................................................................................23

4 W2CM-10Gb Ethernet Interface Series ...................................................... 25

Module Installation ...............................................................................................................26

10/100/1000 M Copper and 1 G Optical Interfaces (SFP) ......................................................28

10 G LAN/WAN Optical Interfaces (SFP+) .............................................................................31

5 Maintenance ............................................................................................... 33

Maintaining Air Filters ..........................................................................................................33

Fan Tray Replacing ................................................................................................................34

Power Supply Replacing ........................................................................................................34

Recycling and Disposal (Applies to European Union Only) ....................................................35

6 Troubleshooting ......................................................................................... 37

Contacting the Technical Support Group ..............................................................................37

Transportation ......................................................................................................................38

QualityAssurer 805 iii

Page 4

7 Warranty ......................................................................................................39

General Information .............................................................................................................39

Liability .................................................................................................................................40

Exclusions .............................................................................................................................41

Certification ..........................................................................................................................41

Service and Repairs ...............................................................................................................42

EXFO Service Centers Worldwide ..........................................................................................43

.............................................................................................................................................43

A Technical Specifications ..............................................................................45

QualityAssurer - QA-805 .......................................................................................................45

W2CM 10 Gigabit Ethernet Interface Series ..........................................................................46

Index .................................................................................................................47

iv QA-805 and W2CM Interface Module

Page 5

Certification Information

Certification Information

North America Regulatory Statement

This unit was certified by an agency approved in both Canada and the

United States of America. It has been evaluated according to applicable

North American approved standards for product safety for use in Canada

and the United States.

Electronic test and measurement equipment is exempt from FCC part 15,

subpart B compliance in the United States of America and from ICES-003

compliance in Canada. However, EXFO Inc. makes reasonable efforts to

ensure compliance to the applicable standards.

The limits set by these standards are designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the user guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Modifications not expressly approved by the manufacturer could void the

user's authority to operate the equipment.

UL Information

This unit is certified by the UL and was evaluated according to applicable

UL standards (as confirmed by cULus mark) as well as applicable IEC

standards for use in Canada, the United States, and other countries.

QualityAssurer 805 v

Page 6

Certification Information

Page 1 of 1

DECLARATION OF CONFORMITY

Application of Council Directive(s):

1999/5/EC – The R&TTE Directive

2011/65/UE – Restriction of the use of certain hazardous substances (RoHS)

And their amendments

Manufacturer’s Name and Address:

EXFO Inc. EXFO Europe

400 Godin Avenue Omega Enterprise Park, Electron Way

Quebec City, Quebec Chandlers Ford, Hampshire

G1M 2K2 CANADA SO53 4SE ENGLAND

Tel.: +1 418 683-0211 Tel.: +44 2380 246810

Equipment Type/Environment:

Test & Measurement / Industrial

Trade Name/Model No.:

Next-Generation Network Test Platform—Quality Assurer QA-805

Standard(s) to which Conformity is declared:

EN 60950-1:2006 + A11:2009, 2nd Edition

Information Technology Equipment – Safety – Part 1: General

requirements

EN 61326-1:2006

Electrical equipment for measurement, control and laboratory use –

EMC requirements

– Part 1: General requirements

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer:

Stephen Bull, E. Eng

Vice-President Research and Development

400 Godin Avenue,

Quebec City, Quebec

G1M-2K2, CANADA

August 31, 2011

vi QA-805 and W2CM Interface Module

Page 7

Page 1 of 1

DECLARATION OF CONFORMITY

Application of Council Directive(s):

1999/5/EC – The R&TTE Directive

2011/65/UE – Restriction of the use of certain hazardous substances (RoHS)

And their amendments

Manufacturer’s Name and Address:

EXFO Inc. EXFO Europe

400 Godin Avenue Omega Enterprise Park, Electron Way

Quebec City, Quebec Chandlers Ford, Hampshire

G1M 2K2 CANADA SO53 4SE ENGLAND

Tel.: +1 418 683-0211 Tel.: +44 2380 246810

Equipment Type/Environment:

Test & Measurement / Basic

Trade Name/Model No.:

10 Gigabit Ethernet Interface Series—W2CM

Standard(s) to which Conformity is declared:

EN 60950-1:2006 + A11:2009, 2nd Edition

Information Technology Equipment – Safety – Part 1: General

requirements

EN 61326-1:2006

Electrical equipment for measurement, control and laboratory use –

EMC requirements

– Part 1: General requirements

EN 60825-1:2007 Edition 2.0

Safety of laser products – Part 1: Equipment classification and

requirements

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer:

Stephen Bull, E. Eng

Vice-President Research and Development

400 Godin Avenue,

Quebec City, Quebec

G1M-2K2, CANADA

May 23, 2012

Certification Information

QualityAssurer 805 vii

Page 8

Page 9

1Introduction

EXFO’s QualityAssurer™ QA-805 is targeted at NEMs and NSPs that are

developing and deploying IMS and wireless networks. The QA-805 offers

easy-to-use test solutions covering the complete testing life cycle of LTE,

IMS, VoLT E, an d Vo IP net wo rk s an d s er vic es .

QA-805 Features

Six-unit rack-mounted

Emulation of over 5 million LTE or IMS subscribers

8 million data sessions

1.25 million RTP streams

50 Gbit/s of user-plane data generation and analysis

USB, DP, Ethernet (management)

QualityAssurer 805 1

Page 10

Introduction

Front View of QA-805

Front View of QA-805

This image of the QA-805 chassis provides a realistic view of the front

panel. See the section Chassis Front Panel on page 4, for further details

that identify specific parts of the QA-805.

2 QA-805 and W2CM Interface Module

Page 11

Introduction

Rear View of QA-805

Rear View of QA-805

This image of the rear panel on the QA-805 provides a realistic view of the

back of the chassis. See the section Chassis Back Panel on page 5 for

details of the QA-805 rear panel.

QualityAssurer 805 3

Page 12

Introduction

Physical Description of QA-805 Unit

Physical Description of QA-805 Unit

Chassis Front Panel

The following is a picture of the front of the QA-805 rack-mount model.

1. Right Fan Tray [FT1]

2. Left Fan Tray [FT2]

3. Power supplies cover and air filter holder

4. Control Board/Slot 2 [SHMC2] (not populated)

5. Control Board/Slot 1 [SHMC1] (Shelf Manager)

6. Backplane

7. ESD (Electrostatic Discharge) Wrist Strap Terminal (Banana Jack)

8. Rack ears for mounting in 19” rack

9. Power supply unit/slot 1

4 QA-805 and W2CM Interface Module

Page 13

Physical Description of QA-805 Unit

10. Power supply unit/slot 2

11. Power supply unit/slot 3

12. Power supply unit/slot 4

Chassis Back Panel

The following is a picture of the back of the QA-805 chassis.

Introduction

13. Shelf Ground Terminals

14. Individual Power Switch for each power supply

15. Individual AC Inlet for each power supply

16. ESD Wrist Strap Terminal (Banana Jack)

17. Power Bridge slot

18. Shelf FRU (field replacement unit)

QualityAssurer 805 5

Page 14

Introduction

Physical Description of QA-805 Unit

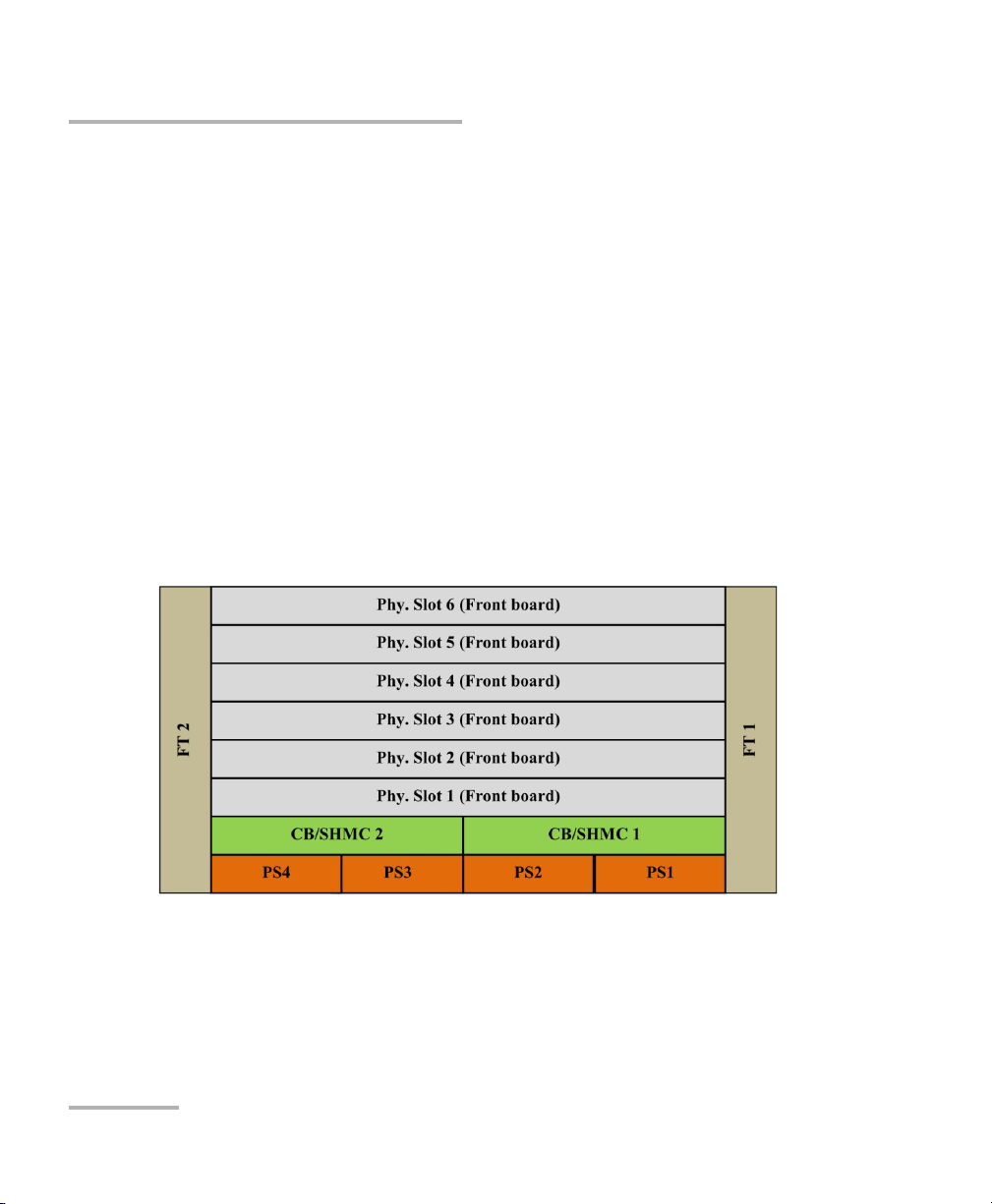

Backplane

The QA-805 provides a monolithic backplane. Power and high speed links

are routed on the same stack up. The backplane supports the following:

6 AdvancedTCA front board slots

6 AdvancedTCA RTM (Rear Transmission Module) slots

2 fan trays

4 power supply slots

Physical Layout

The physical layout of FRUs (field replacement units) populated in the shelf

is shown below.

Front FRU Physical Layout

6 QA-805 and W2CM Interface Module

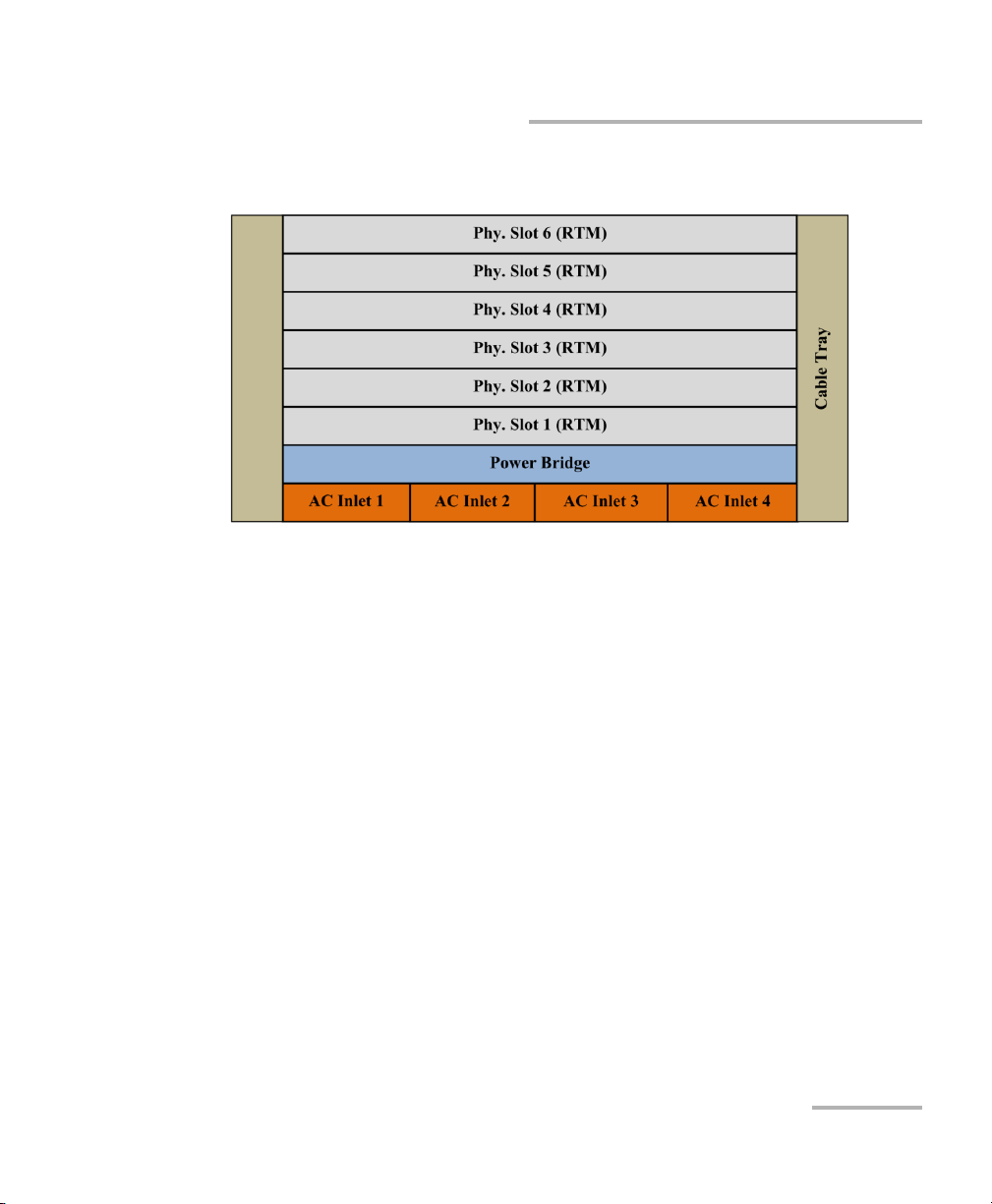

Page 15

Introduction

Physical Description of QA-805 Unit

Rear FRU Physical Layout

Logic Ground

Logic ground is used as reference for low voltage electronics and is

isolated from the chassis/shelf ground and 48 V power lines. For EMI/EMC

purposes, it might be needed to connect the logic ground and shelf ground

together.

To connect both grounds, a screw with a conductive metal washer is

installed in this location (GND) as shown in the following picture. To

disconnect, remove this screw.

QualityAssurer 805 7

Page 16

Introduction

Physical Description of QA-805 Unit

Note: The screw is installed by default.

8 QA-805 and W2CM Interface Module

Page 17

Introduction

Cooling Assembly

Cooling Assembly

Fan Tray

There are 2 fan tray cassettes in the system. The cooling is performed side

to side. While the fan tray is a single mechanical block, it has 2 functions:

front board cooling and RTM cooling. The front and rear blanks are

necessary for proper airflow.

The fan tray contains electronics such that it is detected as a fully PICMG

compliant IPMC by the shelf manager. It contains hot-swap circuitry,

common fusing, fan supervising, and control circuitry.

The system utilizes push pull cooling with 2 separately managed fan trays

and 4 independent cooling zones. Integrated power supplies enable using

48 V fans without any degradation in performance under 90 – 264 V.

Under normal operating conditions the shelf manager cooling algorithm

sets the fan speed to an acceptable level.

The cooling algorithm works based on temperature events coming from

FRUs. Fan speed in a particular cooling zone will be increased if any FRU in

that zone reports a temperature crossing non-critical threshold. For safety

reasons, if any FRU reports a temperature crossing critical threshold, the

fan speed in all cooling zones will be increased.

QualityAssurer 805 9

Page 18

Introduction

Cooling Assembly

The following depicts the fan tray with air filter frame:

To remove the fan tray:

1. Loosen the locking mechanism and move the head to the left or right

2. Hold the head while pulling out the fan tray using the handle.

To insert the fan tray:

1. Loosen the locking mechanism and move the head to the left or right

(away from the fan tray).

(away from the fan tray).

2. Hold the head while inserting the fan tray using the handle.

3. Tighten the locking mechanism.

The following depicts the fan tray locking mechanism:

10 QA-805 and W2CM Interface Module

Page 19

Introduction

Cooling Assembly

CAUTION

Rotating fan blades can cause injury or cut. Keep hands clear when

servicing. Allow time for fan blades to slow to a stop before fully

removing.

CAUTION

Electrostatic Discharge (ESD) Sensitive Equipment:

To avoid damage due to electrostatic discharge, all removable cards

must be stored and handled using approved ESD protective

packaging. When removing and installing cards use a grounding

wrist strap and work in an approved ESD safe work area.

A GND connection point is located on the front of the chassis.

QualityAssurer 805 11

Page 20

Introduction

Cooling Assembly

Air Filter

The air filter provides:

Filtration of intake air from dust particles

Additional static pressure to achieve uniform airflow

Air filter frame is mounted on the right fan tray cassette.

To change the air filter:

1. Extract the fan tray (FT1, right side looking from front).

2. Replace only the filter material.

3. Re-use the filter frame.

12 QA-805 and W2CM Interface Module

Page 21

Introduction

Power Supplies

Power Supplies

Up to 4 AC power supplies can be plugged in the shelf. The Blutek

BPA-R850-480A power supply is shown below and features the following:

Total output power 850 W-48 VDC output under 90-264 V input

AC frequency range 47-63 Hz

EMI filter EN55022 Class B, FCC Part 15

Active PFC = 0.99

Hot-swappable

Power supply present and power OK sensors

Bi-colour LED indicates Power OK

CAUTION

Internal fusing: Input voltage to this unit is classified as hazardous

connection.

CAUTION

This unit contains electronic components that are sensitive to static

electricity. All electronic boards in this shelf are protected by Shelf

Ground. It is recommended that anti static wrist straps be worn and

connected to a known good shelf ground connection when

servicing.

QualityAssurer 805 13

Page 22

Introduction

Power Supplies

Powering the Shelf

For each power supply, a separate AC inlet as well as switch is provided.

Use power cords rated for currents which exceed the maximum power

supply current.

CAUTION

When working near the power supply power inlets, the shelf

operating voltage falls into 90 - 264 V range. This voltage is

considered hazardous.

14 QA-805 and W2CM Interface Module

Page 23

Introduction

QA-805 Technical Specifications

QA-805 Technical Specifications

Physical Dimensions

Width: 482.60 mm (19 in)

Height: 265.90 mm (10.47 in)

Depth: 388.45 mm (15.29 in)

Weight: 25.50 kg (56 lbs)

D (cable trays): 466.15 mm (18.35 in)

Power Specification

4 slots for redundant hot-swappable power supplies

850 W/power supply at low line (90 V) and high line (264 V)

2N and N+1 (with additional bridge board) redundancy for full mesh

backplane

N+1 redundancy for dual star backplane

Cooling Capability

Push Pull Cooling Scheme

300 W+/ Front Board

35 W+/ RTM

Shelf Management

Pigeon Point SHMM500 shelf manager

Intelligent Fan Trays (IPMC based)

QualityAssurer 805 15

Page 24

Introduction

Conventions

Conventions

Before using the product described in this guide, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

16 QA-805 and W2CM Interface Module

Page 25

2 Safety Information

Laser Safety Warnings

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

The use of controls, adjustments and procedures other than those

specified herein may result in exposure to hazardous situations or

impair the protection provided by this unit.

IMPORTANT

When you see the following symbol on your unit , make sure

that you refer to the instructions provided in your user

documentation. Ensure that you understand and meet the required

conditions before using your product.

Your instrument is a Class 1 laser product in compliance with standards

IEC 60825-1 2007 and 21 CFR 1040.10. Laser radiation may be encountered

at the output port.

The following label indicates that a product contains a Class 1 source:

QualityAssurer 805 17

Page 26

Safety Information

Operating Cautions

Use only EXFO-supplied or approved Class 1 SFP, SFP+, or XFP

optical transceivers.

Operating Cautions

Rotating fan blades can cause injury or cut. Keep hands clear when

servicing. Allow time for fan blades to slow to a stop before fully

removing.

CAUTION

CAUTION

CAUTION

Electrostatic Discharge (ESD) Sensitive Equipment:

To avoid damage due to electrostatic discharge, all removable cards

must be stored and handled using approved ESD protective

packaging. When removing and installing cards use a grounding

wrist strap and work in an approved ESD safe work area.

A GND connection point is located on the front of the chassis.

18 QA-805 and W2CM Interface Module

Page 27

Safety Information

Installation Instruction Warnings

Installation Instruction Warnings

Rack Mounting

If rack mounted units are installed in a closed or multi-unit rack assembly,

they may require further evaluation by Certification Agencies. The

following items must be considered:

1. The ambient temperature within the rack may be greater than room

temperature. Installation should be such that the amount of air flow

required for safe operation is not compromised. The maximum

temperature for the equipment in this environment is 40 ºC.

Consideration should be given to the maximum rated ambient.

2. Installation should be such that a hazardous stability condition is not

achieved due to uneven loading.

3. Reliable earthing of rack-mounted equipment should be maintained.

4. Thumbscrews should be tightened with a tool after both initial

installation and subsequent access.

CAUTION

Do not lift the chassis by the fan tray handle.

Input Supply

Check nameplate ratings to assure there is no overloading of supply

circuits that could have an effect on overcurrent protection and supply

wiring.

Unit is provided with multiple power inputs. To disconnect all from the

unit remove all incoming power sources.

QualityAssurer 805 19

Page 28

Safety Information

Installation Instruction Warnings

Card Installation

Cards installed in the QA-805 unit are hot-swap tolerant but should only be

hot-swapped when not in use by an application.

Cooling

To ensure optimum cooling within the chassis, all empty slots in the

chassis (front and back) must be filled with the appropriate sized Filler

Panel/Air Baffle.

Ensure that cards are plugged in parallel to the slot. Applying

downward force may result in damage to cards.

CAUTION

20 QA-805 and W2CM Interface Module

Page 29

Equipment Ratings

Tem pe ra tu re

Operation

Storage

Relative humidity

Safety Information

Equipment Ratings

Equipment Ratings

0 °C to 40 °C (32 °F to 104 °F)

–40 °C to 70 °C (–40 °F to 158 °F)

a

95 % non-condensing

Maximum operation

2000 m (6562 ft)

altitude

Pollution degree 2

Overvoltage category II

Input power

unit

each power cord

a. Measured in 0 °C to 31 °C (32 °F to 87.8 °F) range, decreasing linearly to 50 % at 40 °C (104 °F).

b. Not exceeding –10 % to 6 % of the nominal voltage.

b

850 W

100 - 240 V; 50/60 Hz; 11/5 A

QualityAssurer 805 21

Page 30

Page 31

3 Getting Started

AM4020M's HotSwap Switch

Hard Drive's HotSwap Switch

Shelf Installation

CAUTION

Improper installation might cause system damage or personal injury.

Consider the following guidelines:

1. Install the system only in an area with restricted access.

2. Follow the installation rules governed in your country.

3. Power distribution to the shelf must include over current protection

devices.

4. Use appropriate protective bonding conductor according to over

current limits for power lines.

5. Make sure that personnel will not interfere with cables and cords

connected to the rack/shelf.

6. Make sure that the ventilation openings are not disturbed by cables and

rack construction, to allow proper shelf airflow. Otherwise, it may lead

to system damage.

Turning the Unit On/Off

QualityAssurer 805 23

Page 32

Getting Started

Turning the Unit On/Off

Turning Off the Unit

To safely turn off the QA-805, please ensure the following steps

are taken:

1. Stop all test applications and save results to prevent measurement loss.

2. Power down the Processor v1(AM4020M System Controller) by pulling

out the HotSwap switch to its first click position. Wait until the Blue

HotSwap LED stops flashing and turns Solid Blue to indicate that the

System Controller has shut down safely.

3. Power down the Hard Drive(AM4500) by pulling out the HotSwap

switch. Wait until the Blue HotSwap LED stops flashing and turns Solid

Blue to indicate that the Hard Drive has shut down safely.

4. Power down all active power supplies.

Turning On the Unit

To safely turn on the QA-805, please ensure the following steps

are taken:

1. Ensure that all empty slots are filled with the appropriate sized Filler

Card/Air Baffle.

2. Ensure that the HotSwap switches on both the Processor v1(AM4020M

System Controller) and Hard Drive(AM4500) are fully pushed in.

3. Power up all required power supplies.

24 QA-805 and W2CM Interface Module

Page 33

4W2CM-10Gb Ethernet Interface

Series

The W2CM-10GbE module tests fixed-mobile converged networks and

services like wireless (2G/3G/LTE), IMS, VoLTE, and VoIP. It is specially

designed for signaling and user-plane testing of network elements such as

the P-GW, S-GW, eNodeB, SBC, CSCFs, BGF, HSS, and IMS application

servers.

With EXFO’s QA-805, the W

2

W

CM-4GbE modules can emulate tens of millions of subscribers,

generating real-world traffic toward LTE, IMS, and VoIP networks.

Note: The W

hardware, but extra capacity can be enabled through the purchase of an

upgrade licence. Please see Contacting the Technical Support Group on

page 37 to contact EXFO.

W2CM-10GbE 2-slot module

2

CM-10GbE Lite and W2CM-4GbE options use the same physical

2

CM-10GbE, W2CM-10GbE Lite, and

QualityAssurer 805 25

Page 34

W2CM-10Gb Ethernet Interface Series

Module Installation

W2CM-10GbE Lite/W2CM-4GbE 1-slot module

Module Installation

The W2CM modules are hot-swappable, but care must be taken when and

how the modules are removed.

Inserting a Module

Follow these steps to insert a module into the QA-805 Chassis:

1. Remove any Filler Cards/Air Baffles required, to provide space for the

module being inserted.

2. Before inserting the card, ensure that the levers on either side of the

card are in the fully open position, perpendicular to the faceplate.

3. Align the card with the card rails and gently glide the card straight into

the chassis. Ensure that the guide-pins insert into their associated holes

in the chassis.

4. Ensure that no cables are between the card's faceplate and the chassis.

5. To fully seat the card into the chassis, use constant pressure while

closing both levers, allowing the levers to pull the card into position.

26 QA-805 and W2CM Interface Module

Page 35

W2CM-10Gb Ethernet Interface Series

Module Installation

6. Ensure levers fully lock into the closed position. If the chassis is

powered up, the Blue HotSwap LED flashes briefly and then turns off.

7. Secure the module to the chassis with the screws on either side of the

module.

8. If required, connect the External Time Sync cables to the card to

provide the synchronized hardware based timestamps for test

measurements.

9. Re-insert any cables into the test-port as required.

Extracting a Module

Follow these steps to remove a module from the QA-805 Chassis:

1. If the chassis is powered up, ensure that the module is not in use in any

Test Application, otherwise measurement data could be lost.

2. Fully loosen the screws on either side of the module.

3. Remove any cables connected to the module, noting their positions if

needed.

4. If the External Time Sync cables are plugged into this card, move them

to another card in the system to ensure the chassis will still have a

synchronized hardware based timestamp.

5. If the chassis is powered up, release the HotSwap latches to start the

HotSwap process. The Blue HotSwap LED will blink for several

seconds. When the LED is solid blue, the card can be safely extracted.

6. Slowly open both levers, applying constant pressure to unseat the card

from the chassis's backplane.

7. Slide the module carefully out of the chassis along the guide rails.

8. Fill any open slots in the chassis with an appropriate

Filler Card/Air Baffle.

QualityAssurer 805 27

Page 36

W2CM-10Gb Ethernet Interface Series

10/100/1000 M Copper and 1 G Optical Interfaces (SFP)

10/100/1000 M Copper and 1 G Optical

Interfaces (SFP)

Eight SFP interfaces are available on the faceplate for either optical or

copper plugable SFPs. Neither copper nor optical SFPs have built-in LEDs

consequently two LEDs per SFP are positioned right beside each SFP cage.

LED definition for 10/100/1000 M copper SFP:

LED# Label Color Definition

1 Activity Off Idle

Green Unidirectional Activity RX

Yellow Bidirectional Activity

Red Unidirectional Activity TX

LED# Label Color Definition

2 Link/Speed Off No link

Green 10 Mbps

Yellow 100 Mbps

Red 1 Gbps

28 QA-805 and W2CM Interface Module

Page 37

W2CM-10Gb Ethernet Interface Series

10/100/1000 M Copper and 1 G Optical Interfaces (SFP)

LED definition for 1 G optical SFP:

LED# Label Color Definition

1 Activity Off Idle

Green Unidirectional Activity RX

Yellow Bidirectional Activity

Red Unidirectional Activity TX

LED# Label Color Definition

2 Laser On/Signal Off Laser off

Green Laser on - signal, with link

Yellow Laser on - signal, no link

Red Laser on - no signal

10/100/1000 M Copper SFP

The component for the copper SFP is the

Finisar FCLF8520P2BTL which supports a

10/100/1000BASE-T operation, and

integrates a Marvell's PHY 88E1111. The

FCLF8520P2BTL uses the SFP's RX_LOS

pin for link indication while 1000BASE-X

auto-negotiation should be disabled on

the host system.

QualityAssurer 805 29

Page 38

W2CM-10Gb Ethernet Interface Series

10/100/1000 M Copper and 1 G Optical Interfaces (SFP)

1 G Optical SFP

The following optical Class 1 Laser SFPs from Finisar are

supported:

EXFO

Product #

Transceivers

(Finisar)

FTB-8590 FTLF8519P2BNL

1000BASE-SX

Multi-rate:

GigE, 1xFC, 2xFC

FTB-8591 FTRJ1319P1BTL

1000BASE-LX

Multi-rate:

GigE, 1xFC, 2xFC

FTB-8592 FTRJ1519P1BCL

1000BASE-ZX

Multi-rate:

GigE, 1xFC, 2xFC

Optical SFP with LC connector

Output

Power

(dBm)

MIN = -9

MAX= -3

MIN = -9.5

MAX = -3

MIN = 0

MAX = +5

Rx Sensitivity

(dBm)

(@ GigE)

MIN = n/a

MAX = -20

(@ GigE)

MIN = n/a

MAX = -22

(@ GigE)

MIN = n/a

MAX = -22

SFP Specs

850 nm

SR /500 m

1310 nm

IR1 /10 km

1550 nm

LR2 /90 km

30 QA-805 and W2CM Interface Module

Page 39

W2CM-10Gb Ethernet Interface Series

10 G LAN/WAN Optical Interfaces (SFP+)

10 G LAN/WAN Optical Interfaces (SFP+)

Two Class 1 Laser SFP+ interfaces are available on the faceplate. On the

host side, these SFP+ interfaces are connected directly to the LIM FPGA.

The following optical SFP+ from Finisar, are supported:

EXFO

Product #

FTB-8690 FTLX8571D3BCL

Transceivers

(Finisar)

Multi-rate

MIN = -5

MAX = -1

9.95-10.3 Gbit/s

10GBASE-SR/SW

FTB-8691 FTLX1471D3BCL

Multi-rate

MIN = -8.2

MAX=+0.5

9.95-10.5 Gbit/s

10GBASE-LR/LW

10GFC

FTB-8692 FTLX1671D3BCL

Multi-rate

MIN = -4.7

MAX =+4.0

9.95-10.3 Gbit/s

10GBASE-ER/EW

Optical SFP+ with LC Connector

Output

Power

(dBm)

Rx Sensitivity

(dBm)

@ 10.3 Gbit/s

MIN = -11.1

MAX = 0.5

@ 10.3 Gbit/s

MIN = -12.6

MAX= 0.5

@ 10 Gbit/s

MIN = -14.1

MAX = -1.0

SFP+ Specs

850 nm

300 m OM3

1310 nm

10 km SMF

1550 nm

40 km SMF

QualityAssurer 805 31

Page 40

W2CM-10Gb Ethernet Interface Series

10 G LAN/WAN Optical Interfaces (SFP+)

LED definition for 10 G optical SFP+:

LED# Label Color Definition

1 Activity Off Idle

LED# Label Color Definition

2 Laser On/Signal Off Laser off

Green Unidirectional Activity RX

Yellow Bidirectional Activity

Red Unidirectional Activity TX

Green Laser on - signal, with link

Yellow Laser on - signal, no link

Red Laser on - no signal

32 QA-805 and W2CM Interface Module

Page 41

5 Maintenance

To help ensure long, trouble-free operation:

Always inspect fiber-optic connectors before using them and clean

them if necessary.

Keep the unit free of dust.

Clean the unit casing and front panel with a cloth slightly dampened

with water.

Store unit at room temperature in a clean and dry area. Keep the unit

out of direct sunlight.

Avoid high humidity or significant temperature fluctuations.

Avoid unnecessary shocks and vibrations.

If any liquids are spilled on or into the unit, turn off the power

immediately, disconnect from any external power source and let the

unit dry completely.

The use of controls, adjustments and procedures other than those

specified herein may result in exposure to hazardous situations or

impair the protection provided by this unit.

WARNING

Maintaining Air Filters

Due to the environment the system operates in, the filters will accumulate

dust, causing a degradation in filtration and airflow to the system.

Therefore the filters must be replaced periodically with the frequency

depending on the environment, for instance, in clean laboratory

environment - one time per half year.

The first air filter is mounted on the right fan tray and intended for filtering

the air used for cooling the ATCA blades. The second air filter is located at

lower front of the shelf and intended for filtering the air used for cooling the

AC power supplies.

QualityAssurer 805 33

Page 42

Maintenance

Fan Tray Replacing

To replace the ATCA card cage air filter, perform the following:

1. Slowly remove the right fan tray.

2. Remove the screws from the filter on the fan tray.

3. Remove the filter from the card cage.

4. Remove the dust from the fan tray with a soft brush.

5. Insert a new filter in the frame and screw it on the fan tray.

6. Insert the fan tray in the system.

To replace the AC power supplies filter, perform the following:

1. Remove the front panel covering the power supply slots.

2. Carefully and slowly remove the old filter.

3. Install a new filter.

4. Replace the front panel.

The old air filter can be cleaned with a vacuum cleaner but this is not

recommended since the filter will never regain its original properties after

cleaning.

Fan Tray Replacing

Fan trays should be replaced due to wear and tear. The malfunction of a

fan tray will be reported via the shelf manager (fan tachometer sensors). In

case of failure, immediately replace the faulty fan tray, otherwise the

degradation in cooling performance may cause overheating of the ATCA

blades. For further details, see Fan Tray on page 9.

Power Supply Replacing

A power supply should be replaced in case of failure. The malfunction of

the power supply will be reported via the shelf manager (Power OK

sensor), the red LED at the front of power supply and additionally via the

front panel LED.

34 QA-805 and W2CM Interface Module

Page 43

Maintenance

Recycling and Disposal (Applies to European Union Only)

Recycling and Disposal

(Applies to European Union Only)

For complete recycling/disposal information as per European Directive

WEEE 2012/19/UE, visit the EXFO Web site at www.exfo.com/recycle.

QualityAssurer 805 35

Page 44

Page 45

6 Troubleshooting

Contacting the Technical Support Group

To obtain after-sales service or technical support for this product, contact

local EXFO Navtel Product Group representative at one of the following

numbers.

For detailed information about technical support, visit the EXFO Web site at

www.exfo.com.

Technical Support Group

160 Drumlin Circle

Concord, ON L4K 3E5

CANADA

For detailed information about technical support, and for a list of other

worldwide locations, visit the EXFO Web site at www.exfo.com.

To accelerate the process, please have information such as the name and

the serial number (see the product identification label), as well as a

description of your problem, close at hand.

1 800 267-7235 (USA and Canada)

Tel.: 1 905 738-3741

Email: info@exfo.com

QualityAssurer 805 37

Page 46

Troubleshooting

Transportation

Transportation

Maintain a temperature range within specifications when transporting the

unit. Transportation damage can occur from improper handling. The

following steps are recommended to minimize the possibility of damage:

Pack the unit in its original packing material when shipping.

Ensure all cards are secured with the screws provided.

Avoid high humidity or large temperature fluctuations.

Keep the unit out of direct sunlight.

Avoid unnecessary shocks and vibrations.

38 QA-805 and W2CM Interface Module

Page 47

7 Warranty

General Information

EXFO Inc. (EXFO) warrants this equipment against defects in material and

workmanship for a period of XX Number of Years XX from the date of

original shipment. EXFO also warrants that this equipment will meet

applicable specifications under normal use.

During the warranty period, EXFO will, at its discretion, repair, replace,

or issue credit for any defective product, as well as verify and adjust the

product free of charge should the equipment need to be repaired or if the

original calibration is erroneous. If the equipment is sent back for

verification of calibration during the warranty period and found to meet all

published specifications, EXFO will charge standard calibration fees.

The warranty can become null and void if:

unit has been tampered with, repaired, or worked upon by

unauthorized individuals or non-EXFO personnel.

IMPORTANT

warranty sticker has been removed.

case screws, other than those specified in this guide, have been

removed.

case has been opened, other than as explained in this guide.

unit serial number has been altered, erased, or removed.

unit has been misused, neglected, or damaged by accident.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED,

IMPLIED, OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL EXFO BE LIABLE FOR

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

QualityAssurer 805 39

Page 48

Warranty

Liability

Liability

EXFO shall not be liable for damages resulting from the use of the product,

nor shall be responsible for any failure in the performance of other items to

which the product is connected or the operation of any system of which

the product may be a part.

EXFO shall not be liable for damages resulting from improper usage or

unauthorized modification of the product, its accompanying accessories

and software.

40 QA-805 and W2CM Interface Module

Page 49

Warranty

Exclusions

EXFO reserves the right to make changes in the design or construction of

any of its products at any time without incurring obligation to make any

changes whatsoever on units purchased. Accessories, including but not

limited to fuses, pilot lamps, batteries and universal interfaces (EUI) used

with EXFO products are not covered by this warranty.

This warranty excludes failure resulting from: improper use or installation,

normal wear and tear, accident, abuse, neglect, fire, water, lightning or

other acts of nature, causes external to the product or other factors beyond

the control of EXFO.

IMPORTANT

In the case of products equipped with optical connectors, EXFO will

charge a fee for replacing connectors that were damaged due to

misuse or bad cleaning.

Certification

Exclusions

EXFO certifies that this equipment met its published specifications at the

time of shipment from the factory.

QualityAssurer 805 41

Page 50

Warranty

Service and Repairs

Service and Repairs

EXFO commits to providing product service and repair for five years

following the date of purchase.

To send any equipment for service or repair:

1. Call one of EXFO’s authorized service centers (see EXFO Service

2. If equipment must be returned to EXFO or an authorized service

3. If possible, back up your data before sending the unit for repair.

4. Pack the equipment in its original shipping material. Be sure to include

5. Return the equipment, prepaid, to the address given to you by support

Centers Worldwide on page 43). Support personnel will determine if

the equipment requires service, repair, or calibration.

center, support personnel will issue a Return Merchandise

Authorization (RMA) number and provide an address for return.

a statement or report fully detailing the defect and the conditions under

which it was observed.

personnel. Be sure to write the RMA number on the shipping slip. EXFO

will refuse and return any package that does not bear an RMA number.

Note: A test setup fee will apply to any returned unit that, after test, is found to

meet the applicable specifications.

After repair, the equipment will be returned with a repair report. If the

equipment is not under warranty, you will be invoiced for the cost

appearing on this report. EXFO will pay return-to-customer shipping costs

for equipment under warranty. Shipping insurance is at your expense.

Routine recalibration is not included in any of the warranty plans. Since

calibrations/verifications are not covered by the basic or extended

warranties, you may elect to purchase FlexCare Calibration/Verification

Packages for a definite period of time. Contact an authorized service center

(see EXFO Service Centers Worldwide on page 43).

42 QA-805 and W2CM Interface Module

Page 51

Warranty

EXFO Service Centers Worldwide

EXFO Service Centers Worldwide

If your product requires servicing, contact your nearest authorized service

center.

EXFO Headquarters Service Center

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

EXFO Europe Service Center

Winchester House, School Lane

Chandlers Ford, Hampshire S053 4DG

ENGLAND

EXFO Telecom Equipment

(Shenzhen) Ltd.

3rd Floor, Building 10,

Yu Sheng Industrial Park (Gu Shu

Crossing), No. 467,

National Highway 107,

Xixiang, Bao An District,

Shenzhen, China, 518126

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

Tel.: +44 2380 246800

Fax: +44 2380 246801

support.europe@exfo.com

Tel: +86 (755) 2955 3100

Fax: +86 (755) 2955 3101

support.asia@exfo.com

QualityAssurer 805 43

Page 52

Page 53

A Technical Specifications

SPECIFICATIONS

QA-813 QA-805 QA-604

Platform 13 slots, rack-mounted 5 slots, rack-mounted 4 slots, rack-mounted or desktop

Hot-swappable modules Up to 6 W

2

CM-10GbE or

13 W

2

CM-10GbE-Lite

Up to 2 W

2

CM-10GbE or

5 W

2

CM-10GbE-Lite

Up to 4 SCM-GbE or 2 MCM-GbE

(or MCM-GbE-Lite)

Reset Per platform, per interface or per port

(hardware or software)

Per platform, per interface or per port

(hardware or software)

Per platform, per interface or per port

(hardware or software)

Interfaces USB, DP, Ethernet (management) USB, DP, Ethernet (management) USB (2), VGA, Ethernet (management)

Operating system Linux Linux Solaris

Processor and memories AMC Core i7 2.53 GHz, 8 GB RAM,

500 GB hard disk

AMC Core i7 2.53 GHz, 8 GB RAM,

500 GB hard disk

Intel Core 2 Duo, 2 GHz, 2 GB RAM (min),

120 GB hard disk (min)

Remote control Standard Windows applications

such as VNC and Exceed

Standard Windows applications

such as VNC and Exceed

Standard Windows applications

such as VNC and Exceed

Size (H x W x D)

577 mm x 443 mm x 434 mm

(22.72 in x 17.44 in x 17.09 in)

265.90 mm x 482.60 mm x 388.45 mm

(10.47 in x 19 in x 15.29 in)

101 mm x 483 mm x 362 mm

(4 in x 19 in x 14 ¼ in)

Weight 29 kg (64 lb) 25.50 kg (56 lb) 5.5 kg (12.1 lb)

Power supply Recommended rectifier:

Input: 90-277 V, 47-63 Hz, 25 A x 4

Output: 60 V — Max. 17200 W

850 W, 90 to 264 V input,

single plus 5 VSB output

100 to 240 V, 50/60 H

IMPORTANT

The following technical specifications can change without notice.

The information presented in this section is provided as a reference

only. To obtain this product’s most recent technical specifications,

visit the EXFO Web site at www.exfo.com.

QualityAssurer - QA-805

QualityAssurer 805 45

Page 54

Technical Specifications

Test s

n

d

H

S

S

C

AMR,

S

2

(W

C

)

e

2

W

C

)

T

t

2

(W

C

)

p

5

(W

C

)

C

A

s

s

8

H

s

Hard

ce

)

d

Q

)

Q

)

A

t

e

1

8

1

8

1

W2CM 10 Gigabit Ethernet Interface Series

W2CM 10 Gigabit Ethernet Interface Series

olutio

Protocol supporte

ODEC support

IP/LTE endpoints per module

Number of sessions per modul

hroughpu

Number of RTP streams

er module

onnection speed

Number of port

ot-swappable modules Ye

ware varian

Platforms supporte

vailable SFP

ransceiver modul

LTE eNodeB, P-GW, S-GW, MME

SBC, security gateways, BGF, IMS I/P/C-CSCF, HSS, SIP proxy/registrar

TTP, SMTP,POP,RTSP, GTP-c, GTP-u, S1-AP, S1-MME, NAS, SIP, Diameter, Megaco/H.248, RTP/RTCP,

RTP/SRTCP, TLS, IPSec, IKEv1, IKEv2, IPv4, IPv6, TCP, UDP, SCTP, DHCP, DN

ILBC, G.711, G.729, G.721, G.722, G.726, G.723, G.728, EVRC, EVRC-B, GSM-EFR, GSM-FR, GSM-HR, H.263, H.264, DTMF

million (WCM-10GbE), 1 million

million (WCM-10GbE), 1 million (

2

0 Gbit/s

12 000

uto-negotiate 10/100/1000/10000 Mbit/

x 1GbE and 2 x 10GbE

A-805 (2xW2CM-10GbE or 5xW2CM-10GbE-Lite

A-813 (6xW2CM-10GbE or 13xW2CM-10GbE-Lite

000Base-T SFP

50 nm, 500 m SFP

310 nm, 10 km SFP

50 nm, 300 m SFP+

310 nm, 10 km SFP+

M-10GbE), 10 Gbit/s (W2CM-10GbE-Lite

2

M-10GbE), 256 000 (W

CM-10GbE (2 slots module), W

M-10GbE-Lite

M-10GbE-Lite

CM-10GbE-Lite

CM-10GbE-Lite (1 slot module

46 QA-805 and W2CM Interface Module

Page 55

Index

Index

A

AC requirements ......................................... 21

after-sales service ........................................ 37

C

caution

of personal hazard................................. 16

of product hazard.................................. 16

certification information ................................v

cleaning

front panel............................................. 33

conventions, safety ..................................... 16

current, electrical ........................................ 21

customer service.......................................... 42

E

equipment returns ...................................... 42

F

front panel, cleaning ................................... 33

I

identification label ...................................... 37

input current ............................................... 21

P

power source, AC ........................................ 21

product

identification label ................................. 37

specifications ......................................... 45

R

return merchandise authorization (RMA) .... 42

S

safety

caution................................................... 16

conventions ...........................................16

warning .................................................16

service and repairs....................................... 42

service centers ............................................. 43

shipping to EXFO......................................... 42

specifications, product ................................45

storage requirements ..................................33

symbols, safety ............................................ 16

T

technical specifications................................ 45

technical support......................................... 37

temperature for storage .............................. 33

transportation requirements.................. 33, 38

L

label, identification ..................................... 37

M

maintenance

front panel............................................. 33

general information............................... 33

maximum input current .............................. 21

QualityAssurer 805 47

UL.................................................................. v

Underwriters Laboratories (UL)...................... v

U

Page 56

Index

W

warranty

certification ........................................... 41

exclusions .............................................. 41

general .................................................. 39

liability................................................... 40

null and void.......................................... 39

48 QA-805 and W2CM Interface Module

Page 57

NOTICE

抩⛙

CHINESE REGULATION ON RESTRICTION OF HAZARDOUS SUBSTANCES

₼⦌␂ℝ☀⹂䓸德棟Ⓟ䤓屓⸩

NAMES AND CONTENTS OF THE TOXIC OR HAZARDOUS SUBSTANCES OR ELEMENTS

CONTAINED IN THIS EXFO PRODUCT

▔⚺⦷㦻 EXFO ℶ❐₼䤓㦘㹡㦘⹂䓸德㒥⏒侯䤓⚜䱿✛⚺摞

O

Indicates that this toxic or hazardous substance contained in all of the homogeneous

materials for this part is below the limit requirement in SJ/T11363-2006

嫷䯉年㦘㹡㦘⹂䓸德⦷年捷ↅ㓏㦘⧖德㧟㠨₼䤓⚺摞⧖⦷ SJ/T11363-2006 㪖屓⸩䤓

棟摞尐㻑ⅴₚᇭ

X

Indicates that this toxic or hazardous substance contained in at least one of the homogeneous

materials used for this part is above the limit requirement in SJ/T11363-2006

嫷䯉年㦘㹡㦘⹂䓸德咂⺠⦷年捷ↅ䤓㩟⧖德㧟㠨₼䤓⚺摞怔⒉ SJ/T11363-2006 㪖

屓⸩䤓棟摞尐㻑ᇭ

Part Name

捷ↅ⚜䱿

Toxic or hazardous Substances and Elements

㦘㹡㦘⹂䓸德✛⏒侯

Lead

杔

(Pb)

Mercury

㻭

(Hg)

Cadmium

椣

(Cd)

Hexavalent

Chromium

⏼ↆ杻

(Cr VI)

Pol yb ro mi na ted

biphenyls

⮩䅃勣啾

(PBB)

Polybrominated

diphenyl ethers

⮩䅃ℛ啾搩

(PBDE)

Enclosure

⮥⮂

OO O O O O

Electronic and

electrical

sub-assembly

䟄✛䟄兓ↅ

XO X O X X

Optical

sub-assembly

a

⏘ⷵ兓ↅ

a

a. If applicable.

Ⱁ㨫抑䞷ᇭ

XO O O O O

Mechanical

sub-assembly

a

㧉㬿兓ↅ

a

OO O O O O

MARKING REQUIREMENTS

㪖㽷尐㻑

Product

ℶ❐

Environmental protection use period (years)

䘾⬒≬㔳∎䞷㦮棟 ( )

Logo

㪖㉦

his Exfo product

㦻 EXFO ℶ❐

10

Battery

a

䟄㻯

a

f applicable.

5

NOTICE

抩⛙

CHINESE REGULATION ON RESTRICTION OF HAZARDOUS SUBSTANCES

₼⦌␂ℝ☀⹂䓸德棟Ⓟ䤓屓⸩

NAMES AND CONTENTS OF THE TOXIC OR HAZARDOUS SUBSTANCES OR ELEMENTS

CONTAINED IN THIS EXFO PRODUCT

▔⚺⦷㦻 EXFO ℶ❐₼䤓㦘㹡㦘⹂䓸德㒥⏒侯䤓⚜䱿✛⚺摞

O

Indicates that this toxic or hazardous substance contained in all of the homogeneous

materials for this part is below the limit requirement in SJ/T11363-2006

嫷䯉年㦘㹡㦘⹂䓸德⦷年捷ↅ㓏㦘⧖德㧟㠨₼䤓⚺摞⧖⦷ SJ/T11363-2006 㪖屓⸩䤓

棟摞尐㻑ⅴₚᇭ

X

Indicates that this toxic or hazardous substance contained in at least one of the homogeneous

materials used for this part is above the limit requirement in SJ/T11363-2006

嫷䯉年㦘㹡㦘⹂䓸德咂⺠⦷年捷ↅ䤓㩟⧖德㧟㠨₼䤓⚺摞怔⒉ SJ/T11363-2006 㪖

屓⸩䤓棟摞尐㻑ᇭ

Part Name

捷ↅ⚜䱿

Toxic or hazardous Substances and Elements

㦘㹡㦘⹂䓸德✛⏒侯

Lead

杔

(Pb)

Mercury

㻭

(Hg)

Cadmium

椣

(Cd)

Hexavalent

Chromium

⏼ↆ杻

(Cr VI)

Pol yb ro mi na ted

biphenyls

⮩䅃勣啾

(PBB)

Polybrominated

diphenyl ethers

⮩䅃ℛ啾搩

(PBDE)

Enclosure

⮥⮂

OO O O O O

Electronic and

electrical

sub-assembly

䟄✛䟄兓ↅ

XO X O X X

Optical

sub-assembly

a

⏘ⷵ兓ↅ

a

a. If applicable.

Ⱁ㨫抑䞷ᇭ

XO O O O O

Mechanical

sub-assembly

a

㧉㬿兓ↅ

a

OO O O O O

Page 58

MARKING REQUIREMENTS

㪖㽷尐㻑

Product

ℶ❐

Environmental protection use period (years)

䘾⬒≬㔳∎䞷㦮棟 ( )

Logo

㪖㉦

This Exfo product

㦻 EXFO ℶ❐

10

Battery

a

䟄㻯

a

a. If applicable.

Ⱁ㨫抑䞷ᇭ

5

Page 59

P/N: 1063196

www.EXFO.com · info@exfo.com

CORPORATE HEADQUARTERS 400 Godin Avenue Quebec (Quebec) G1M 2K2 CANADA

Tel.: 1 418 683-0211 · Fax: 1 418 683-2170

EXFO AMERICA 3400 Waterview Parkway Suite 100 Richardson, TX 75080 USA

EXFO EUROPE Winchester House,

EXFO ASIA-PACIFIC 100 Beach Road,

EXFO CHINA Beijing Global Trade Center, Tower C,

EXFO SERVICE ASSURANCE 270 Billerica Road Chelmsford MA, 01824 USA

EXFO FINLAND Elektroniikkatie 2 FI-90590 Oulu, FINLAND

TOLL-FREE (USA and Canada) 1 800 663-3936

© 2013 EXFO Inc. All rights reserved.

Printed in Canada (2013-04)

School Lane

#25-01/03 Shaw Tower

Room 1207, 36 North Third Ring Road

East, Dongcheng District

Tel.: 1 972-761-927 · Fax: 1 972-761-9067

Chandlers Ford, Hampshire S053 4DG ENGLAND

Tel.: +44 2380 246 800 · Fax: +44 2380 246 801

SINGAPORE 189702

Tel.: +6563338241 · Fax: +6563338242

Beijing 100013 P. R. CHINA

Tel.: +86 (10) 5825 7755 · Fax: +86 (10) 5825 7722

Tel.: 1 978 367-5600 · Fax: 1 978 367-5700

Tel.: +358 (0) 403 010 300 · Fax: +358 (0) 8 564 5203

Loading...

Loading...