Page 1

PSO-200

Optical Modulation Analyzer

User Guide

Page 2

Copyright © 2010–2013 EXFO Inc. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted

in any form, be it electronically, mechanically, or by any other means such

as photocopying, recording or otherwise, without the prior written

permission of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Patents

EXFO’s Universal Interface is protected by US patent 6,612,750.

Version number: 2.0.1

ii PSO-200

Page 3

Contents

Contents

Certification Information ....................................................................................................... vi

European Community Declaration of Conformity ................................................................. vii

1 Introducing the PSO-200 Optical Modulation Analyzer ............................. 1

Main Features .........................................................................................................................1

Conventions ............................................................................................................................3

2 Safety Information ....................................................................................... 5

Laser Safety Information .........................................................................................................5

Electrical Safety Information ...................................................................................................6

3 Getting Started with Your Optical Modulation Analyzer ........................... 9

Installing the EXFO Universal Interface (EUI) ...........................................................................9

Cleaning and Connecting Optical Fibers ...............................................................................10

Starting and Exiting the Optical Modulation Analyzer Application .......................................12

4 Setting Up the Optical Modulation Analyzer ........................................... 13

Configuring the Input Signal ................................................................................................13

Setting Other Acquisition Parameters ...................................................................................16

Setting File Autonaming .......................................................................................................18

Identifying Acquisitions ........................................................................................................20

Setting Analysis Parameters ..................................................................................................22

Using Special Modulation Modes .........................................................................................24

Using an External Local Oscillator .........................................................................................27

Locking the Remote Unit ......................................................................................................31

5 Performing Acquisitions ............................................................................ 33

Starting and Stopping an Acquisition ...................................................................................33

Clearing Data During an Acquisition .....................................................................................34

Saving Acquisitions to a File .................................................................................................35

Activating Trigger-Based Acquisitions ...................................................................................36

6 Customizing the Graph and Data Layout ................................................. 39

Selecting and Customizing the Layout ..................................................................................39

Constellation Chart ...............................................................................................................41

Eye Diagrams ........................................................................................................................43

Pattern Diagrams ..................................................................................................................47

Y-Axis Auto Scaling (All Graphs) ............................................................................................47

Optical Modulation Analyzer iii

Page 4

Contents

7 Viewing and Analyzing Results ..................................................................49

Opening an Existing Acquisition File .....................................................................................49

Viewing Acquisition Information ..........................................................................................50

Playing Back Acquisition Files ...............................................................................................51

Zooming and Moving Graphs ...............................................................................................52

Displaying and Setting X-Axis Values ....................................................................................53

Displaying Graphs in Color Grade Mode ...............................................................................54

Displaying Multiple Bursts Simultaneously (Persistence) .......................................................55

Setting Number of Symbol Periods for Eye Diagrams ...........................................................55

Using the Measurement Tables .............................................................................................56

Using Graph Markers ............................................................................................................58

Viewing Signal Distribution Using Histograms ......................................................................60

Distinguishing Data Points from Transitions .........................................................................62

Using Pattern Masks .............................................................................................................64

Using Averaging to Improve Results .....................................................................................70

Applying Advanced Signal Processing Algorithms ................................................................72

Applying Data Filtering .........................................................................................................76

8 Bit Pattern Analysis and the Gearbox ........................................................79

Basic Gearbox Setup Details ..................................................................................................80

Exporting Symbol Patterns ....................................................................................................83

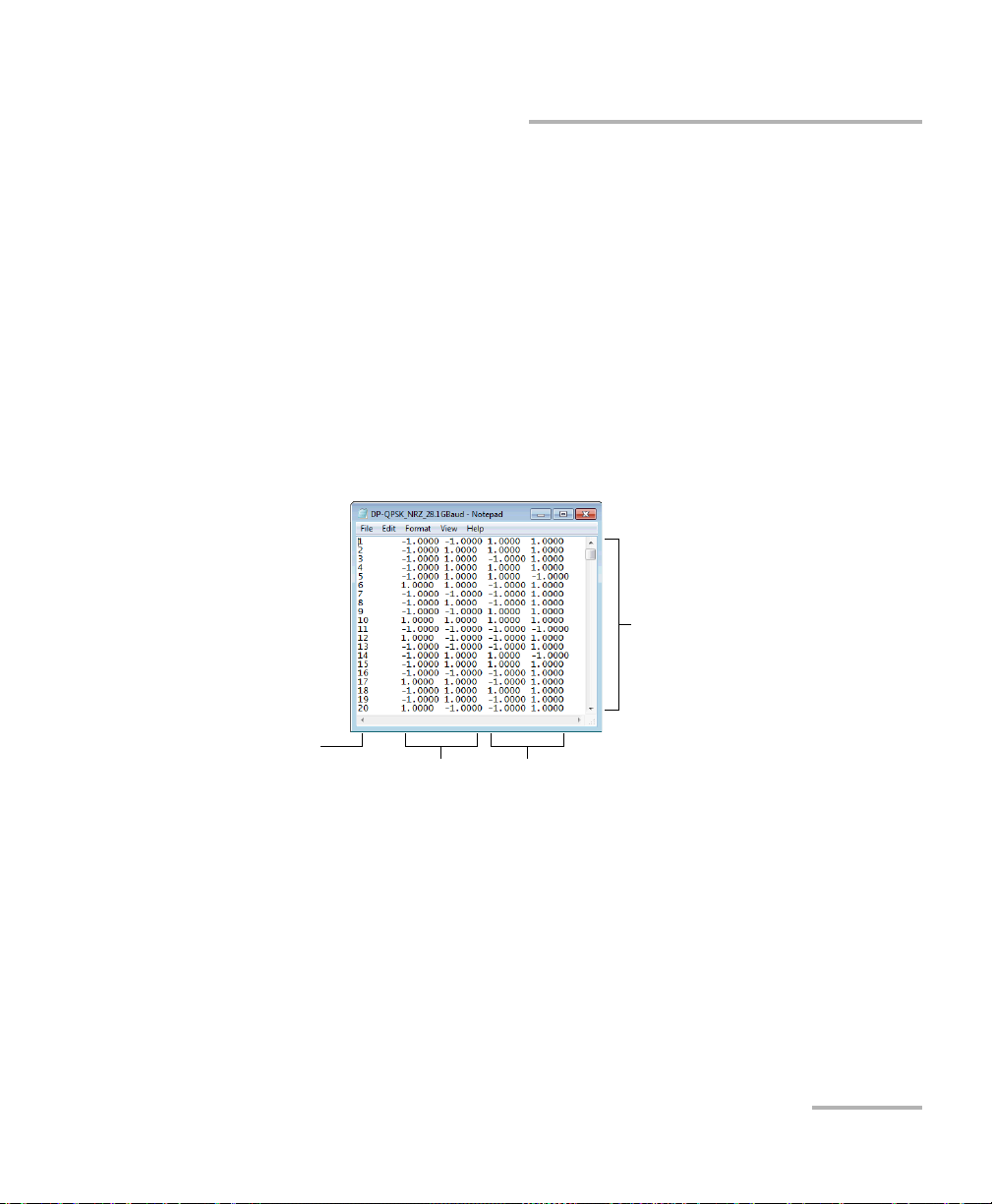

Importing User-Defined Symbol Patterns ..............................................................................84

Performing Detailed Bit Pattern Analysis with the Gearbox ...................................................87

Using PRBS or User-Defined Bit Patterns with the Gearbox .................................................100

Exporting Gearbox Setups ..................................................................................................104

Obtaining and Using Bit/Symbol Error Rates .......................................................................105

9 Post-Processing and Reanalyzing Data ....................................................109

Installing and Using the Application on a Computer ..........................................................109

Installing and Activating Software Options ........................................................................111

Exporting Data ....................................................................................................................113

Copying Graph and Measurements to Clipboard ................................................................114

Reanalyzing Acquisitions with New Settings .......................................................................115

Reverting to Original File ....................................................................................................116

10 Maintenance ..............................................................................................117

Cleaning EUI Connectors ....................................................................................................117

Recycling and Disposal (Applies to European Union Only) ..................................................119

iv PSO-200

Page 5

Contents

11 Troubleshooting ....................................................................................... 121

Solving Common Problems .................................................................................................121

Solving Phase Tracking Issues ..............................................................................................122

Viewing Online Help ...........................................................................................................122

Contacting the Technical Support Group ............................................................................123

Viewing System Information ...............................................................................................124

Transportation ....................................................................................................................125

12 Warranty ................................................................................................... 127

General Information ...........................................................................................................127

Liability ...............................................................................................................................127

Exclusions ...........................................................................................................................128

Certification ........................................................................................................................128

Service and Repairs .............................................................................................................129

EXFO Service Centers Worldwide ........................................................................................130

A Technical Specifications ........................................................................... 131

B SCPI Commands Reference ...................................................................... 133

Quick Reference Command Tree .........................................................................................133

Product-Specific Commands—Description ..........................................................................138

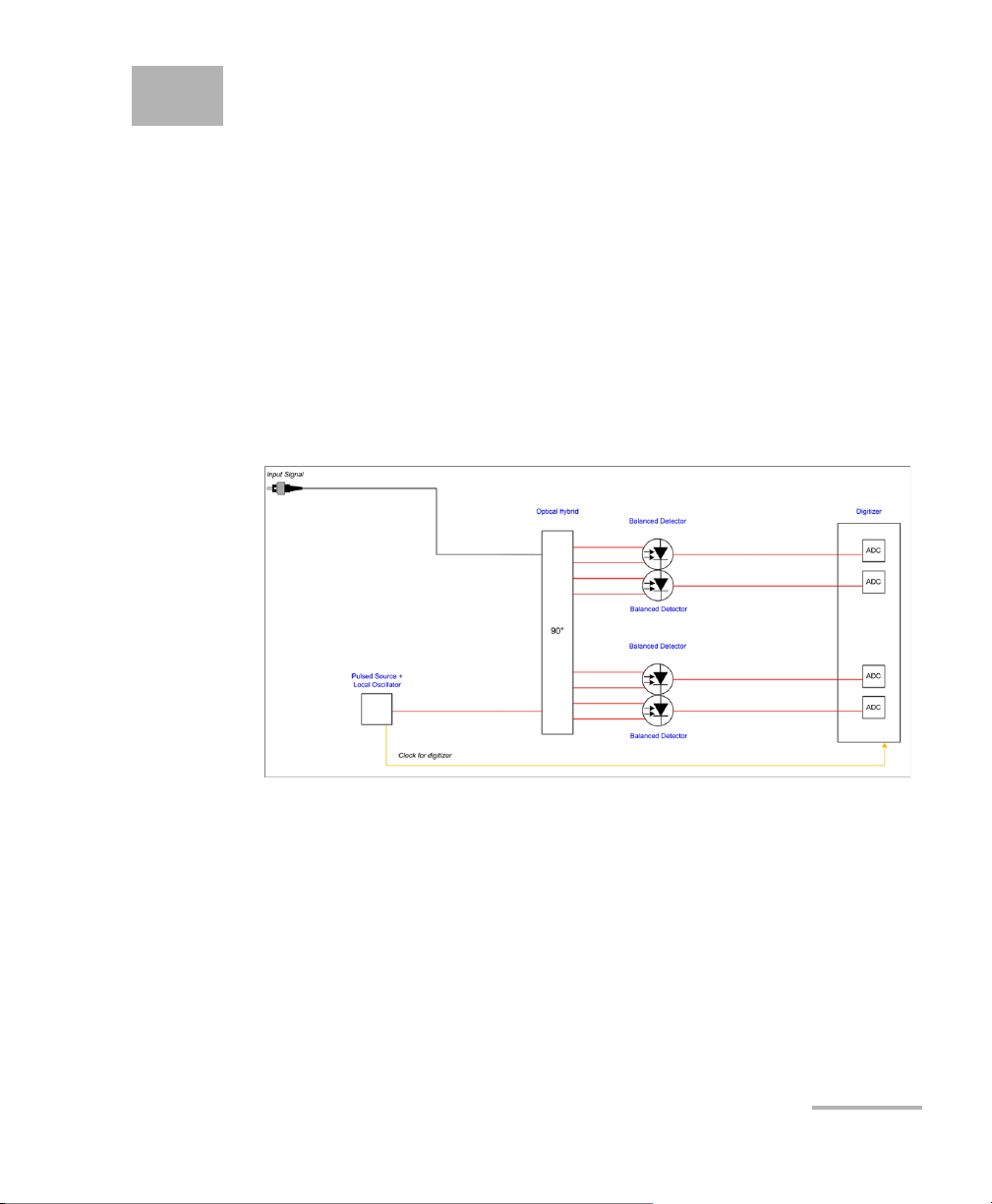

C Coherent Detection and Sampling Methods .......................................... 239

Coherent Detection .............................................................................................................239

Sampling Methods .............................................................................................................240

PSO-200 Principles of Operation .........................................................................................242

Signal Processing Algorithms ..............................................................................................244

D Modulation Schemes ............................................................................... 247

E Measurement Definitions ........................................................................ 251

Data Used for Measurements .............................................................................................251

Measurements for Constellation Charts ..............................................................................252

Measurements for Eye Diagrams ........................................................................................258

Index .............................................................................................................. 267

Optical Modulation Analyzer v

Page 6

Certification Information

Certification Information

North America Regulatory Statement

This unit was certified by an agency approved in both Canada and the

United States of America. It has been evaluated according to applicable

North American approved standards for product safety for use in Canada

and the United States.

Electronic test and measurement equipment is exempt from FCC part 15,

subpart B compliance in the United States of America and from ICES-003

compliance in Canada. However, EXFO Inc. makes reasonable efforts to

ensure compliance to the applicable standards.

The limits set by these standards are designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the user guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Modifications not expressly approved by the manufacturer could void the

user's authority to operate the equipment.

IMPORTANT

Use of shielded remote I/O cables, with properly grounded shields

and metal connectors, is recommended in order to reduce radio

frequency interference that may emanate from these cables.

vi PSO-200

Page 7

Certification Information

Application of Council Directive(s): 2006/95/EC - The Low Voltage Directive

2004/108/EC - The EMC Directive

2006/66/EC - The Battery Directive

93/68/EEC - CE Marking

And their amendments

Manufacturer’s Name: EXFO Inc.

Manufacturer’s Address: 400 Godin Avenue

Quebec, Quebec

Canada, G1M 2K2

(418) 683-0211

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: PSO-200 / Optical Modulation Analyzer

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Edition 2.0 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use, Part 1: General Requirements.

EN 61326-1:2006 Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements – Part 1: General requirements

EN 60825-1:2007 Edition 2.0 Safety of laser products – Part 1: Equipment classification,

requirements, and user’s guide

EN 55022: 2006 + A1: 2007 Information technology equipment - Radio disturbance

characteristics - Limits and methods of measurement

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

Date: August 17, 2010

DECLARATION OF CONFORMITY

European Community Declaration of Conformity

European Community Declaration of

Conformity

Optical Modulation Analyzer vii

Page 8

Page 9

1 Introducing the PSO-200

Optical Modulation Analyzer

As new advanced modulation schemes enable the transmission of

high-speed optical signals over fiber, research centers, network equipment

manufacturers and eventually carriers need new test instruments to

properly characterize these signals.

Main Features

The PSO-200 Optical Modulation Analyzer uses equivalent-time optical

sampling, allowing the complete characterization of random or repetitive

digital signals at 100 Gb/s, 400 Gb/s, 1 Tb/s and beyond.

The PSO-200 displays constellation charts, eye diagrams and patterns with

very high temporal resolution. It is a useful tool to study and characterize

very high bit-rate systems or very fast events like short pulses, where the

bandwidth of ordinary electrical sampling oscilloscopes is not sufficient.

The PSO-200 can measure a number of modulation formats: OOK, BPSK,

APSK, QPSK and 16-QAM, all in return-to-zero (RZ) or non-return-to-zero

(NRZ) formats.

Optical Modulation Analyzer 1

Page 10

Introducing the PSO-200 Optical Modulation Analyzer

Local oscillator

input port

Input signal port

Trigger port

USB port

Power button

Remote control

indicator/Return

to local mode

Handle

Touchscreen

Support

LAN ports

USB ports

Main Features

The PSO-200 Optical Modulation Analyzer has the following features:

Fully customizable display layout and selection of graphs (intensity,

phase, error-vector magnitude) in eye diagram and pattern modes.

Analysis tools such as averaging, masks, filters and advanced signal

processing algorithms.

Post-processing tools (acquisition import and export, reanalysis with

different settings, offline application).

2 PSO-200

Bit pattern customization with the Gearbox

Remote control available (Ethernet TCP/IP with SCPI commands).

Page 11

Introducing the PSO-200 Optical Modulation Analyzer

Conventions

Before using the product described in this guide, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

Conventions

IMPORTANT

Refers to information about this product you should not overlook.

Optical Modulation Analyzer 3

Page 12

Page 13

2 Safety Information

Laser Safety Information

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

The use of controls, adjustments and procedures other than those

specified herein may result in exposure to hazardous situations or

impair the protection provided by this unit.

IMPORTANT

When you see the following symbol on your unit , make sure

that you refer to the instructions provided in your user

documentation. Ensure that you understand and meet the required

conditions before using your product.

Your instrument is a Class 1 laser product in compliance with standards

IEC 60825-1 2007 and 21 CFR 1040.10. Laser radiation may be encountered

at the output port.

The following label indicates that a product contains a Class 1 source:

Note: The label is located at the back of the unit.

Optical Modulation Analyzer 5

Page 14

Safety Information

Electrical Safety Information

Electrical Safety Information

This unit uses an international safety standard three-wire power cable. This

cable serves as a ground when connected to an appropriate AC power

outlet.

Note: To ensure that the unit is completely turned off, disconnect the power cable.

WARNING

Insert the power cable plug into a power outlet with a

protective ground contact. Do not use an extension cord

without a protective conductor.

Before turning on the unit, connect all grounding terminals,

extension cords and devices to a protective ground via a ground

socket. Any interruption of the protective grounding is a

potential shock hazard and may cause personal injury.

Whenever the ground protection is impaired, do not use the

unit and secure it against any accidental operation.

Do not tamper with the protective ground terminal.

6 PSO-200

Page 15

Safety Information

Electrical Safety Information

The color coding used in the electric cable depends on the cable. New

plugs should meet the local safety requirements and include:

adequate load-carrying capacity

ground connection

cable clamp

WARNING

Use this unit indoors only.

Position the unit so that the air can circulate freely around it.

Do not remove unit covers during operation.

Operation of any electrical instrument around flammable gases

or fumes constitutes a major safety hazard.

To avoid electrical shock, do not operate the unit if any part of

the outer surface (covers, panels, etc.) is damaged.

Only authorized personnel should carry out adjustments,

maintenance or repair of opened units under voltage. A person

qualified in first aid must also be present. Do not replace any

components while power cable is connected.

Capacitors inside the unit may be charged even if the unit has

been disconnected from its electrical supply.

Optical Modulation Analyzer 7

Page 16

Safety Information

Electrical Safety Information

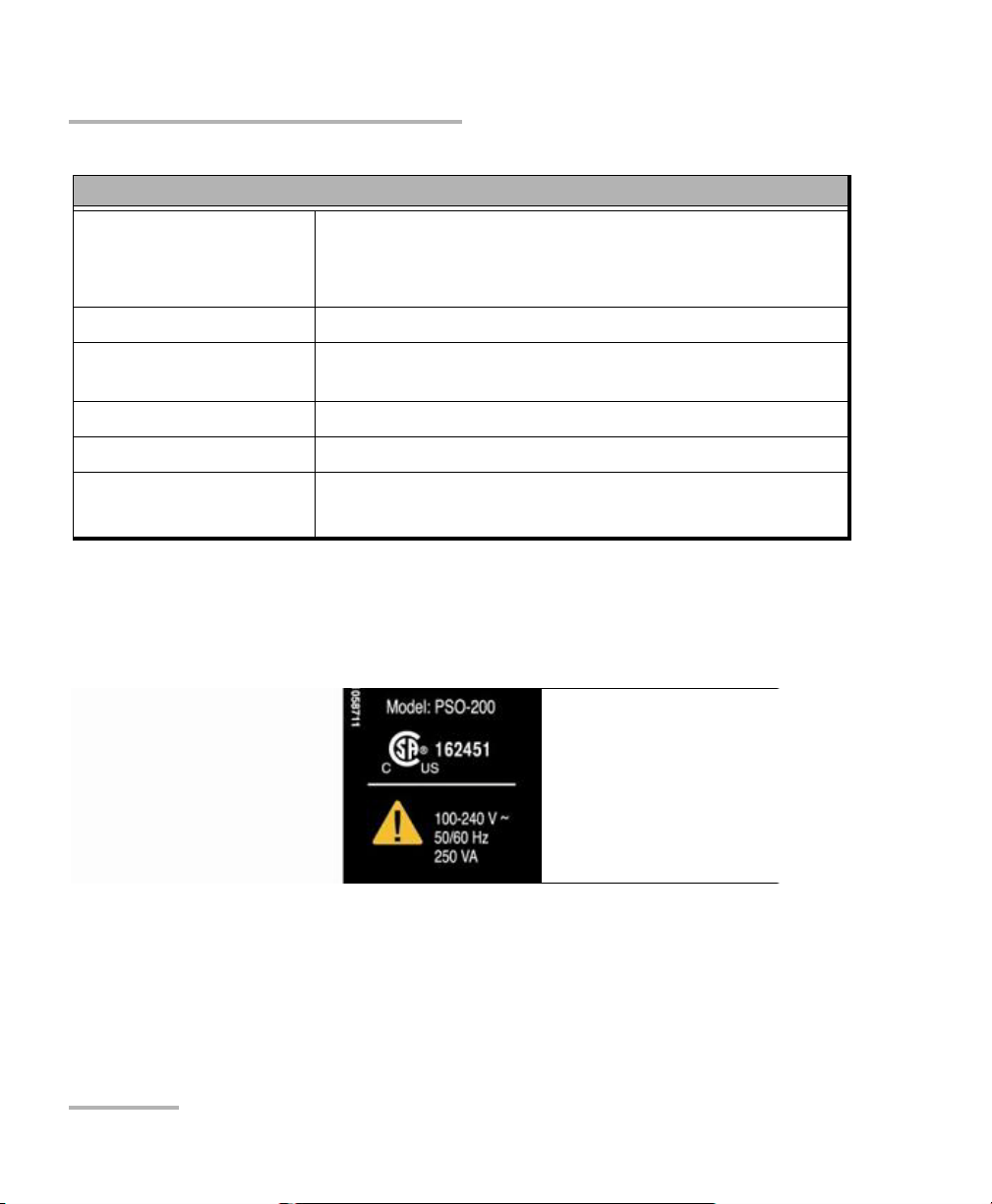

Tem pe ra tu re

Operation

Storage

Relative humidity

a

Equipment Ratings

0 °C to 35 °C (32 °F to 95 °F)

-40 °C to 70 °C (-40 °F to 158 °F)

80 % non-condensing

Maximum operation

2000 m (6562 ft)

altitude

Pollution degree 2

Installation category II

Powe r supp l y rati ng

b

100 V to 240 V (50 Hz/60 Hz)

maximum input power 250 VA

a. Measured in 0 °C to 31 °C (32 °F to 87.8 °F) range, decreasing linearly to 50 % at 40 °C (104 °F).

b. Not exceeding ± 10 % of the nominal voltage.

The following label is located on the back panel of the unit:

8 PSO-200

Page 17

3 Getting Started with Your

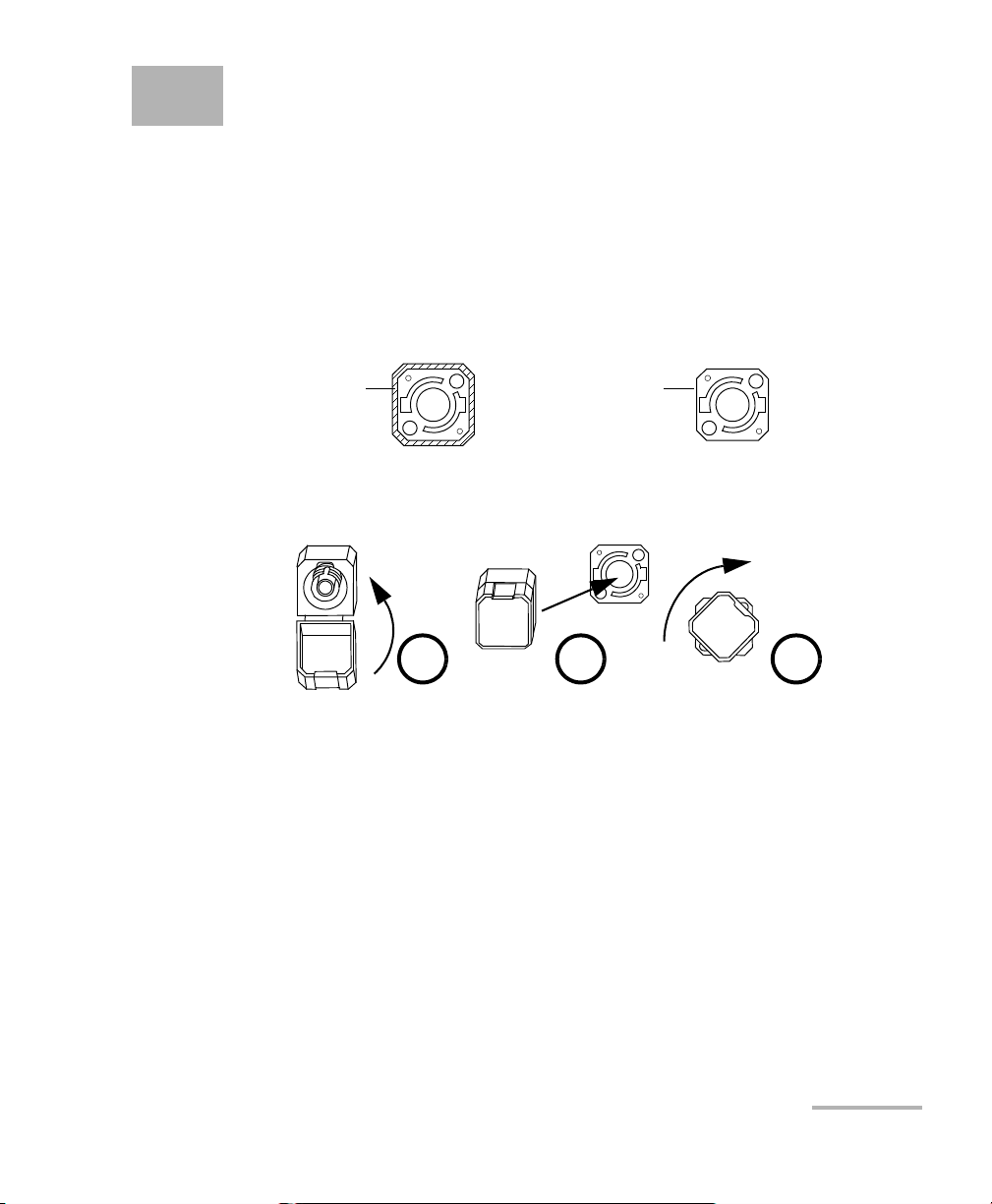

Bare metal

(or blue border)

indicates UPC

option

Green border

indicates APC

option

2 3 4

Optical Modulation Analyzer

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or

non-angled (UPC) polishing. A green border around the baseplate

indicates that it is for APC-type connectors.

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the

baseplate to lock it in place.

Optical Modulation Analyzer 9

Page 18

Getting Started with Your Optical Modulation Analyzer

Cleaning and Connecting Optical Fibers

Cleaning and Connecting Optical Fibers

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

Always inspect fiber ends and make sure that they are clean as

explained below before inserting them into the port. EXFO is

not responsible for damage or errors caused by bad fiber

cleaning or handling.

Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Inspect the fiber using a fiber inspection microscope. If the fiber is

clean, proceed to connecting it to the port. If the fiber is dirty, clean it as

explained below.

2. Clean the fiber ends as follows:

2a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

2b. Use compressed air to dry completely.

2c. Visually inspect the fiber end to ensure its cleanliness.

10 PSO-200

Page 19

Getting Started with Your Optical Modulation Analyzer

Cleaning and Connecting Optical Fibers

3. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the

port’s corresponding notch.

4. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

EXFO uses good quality connectors in compliance with EIA-455-21A

standards.

To keep connectors clean and in good condition, EXFO strongly

recommends inspecting them with a fiber inspection probe before

connecting them. Failure to do so will result in permanent damage to the

connectors and degradation in measurements.

Optical Modulation Analyzer 11

Page 20

Getting Started with Your Optical Modulation Analyzer

Starting and Exiting the Optical Modulation Analyzer Application

Starting and Exiting the Optical Modulation

Analyzer Application

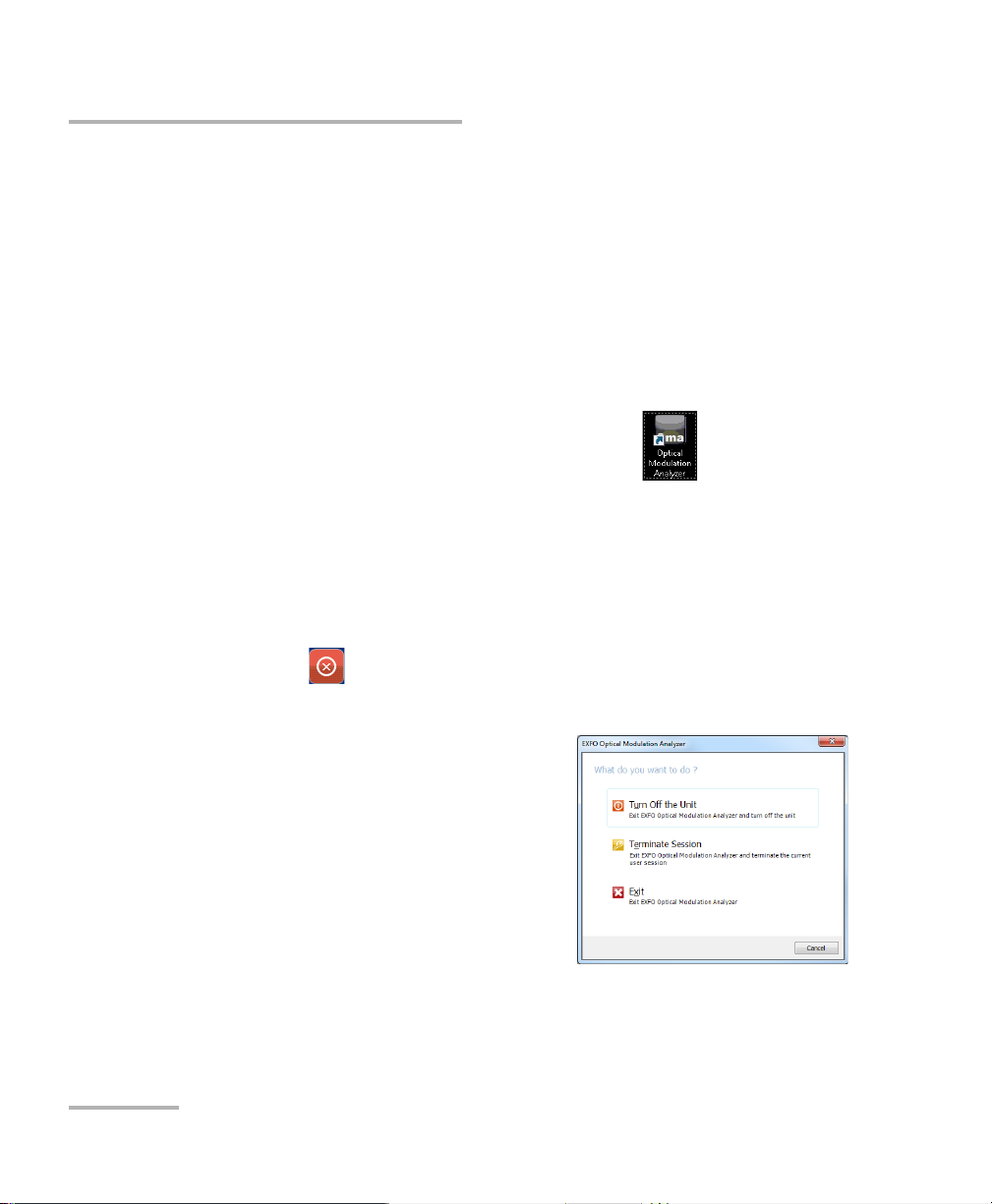

The PSO-200 Optical Modulation Analyzer runs on a Microsoft Windows

environment. When you turn it on, the unit should automatically start the

Optical Modulation Analyzer application.

When starting the application, the PSO-200 requires some time to initialize,

during which certain features, such as the Start button, are not available. A

message is displayed in the status bar while initialization is in progress.

To start the application:

Double-click the shortcut icon on the desktop.

From the Windows Start menu, select All Programs > EXFO >

Optical Modulation Analyzer.

To exit the application:

1. From the File menu, select Exit.

OR

Click the button in the bottom right corner of the main window.

2. Select which shutdown method you want.

Turn off the unit: closes the

application and completely shuts

down the PSO-200.

Terminate session: closes the

application and logs off the

current Windows session, but

does not shut down the PSO-200.

Exit: closes the application only.

Note: If there were unsaved acquisitions, you will be prompted to save them

when you exit the application.

12 PSO-200

Page 21

4 Setting Up the Optical

Modulation Analyzer

You should start by setting parameters on the PSO-200 so that acquisitions

are performed according to the signal you are analyzing and that the results

meet your needs.

You can also change some settings during an acquisition, or even

afterwards to see how it would have affected the results. See Reanalyzing

Acquisitions with New Settings on page 115.

Note: Changing settings during an acquisition will not stop it. However, acquired

bursts will be cleared and new bursts will be taken using the new settings.

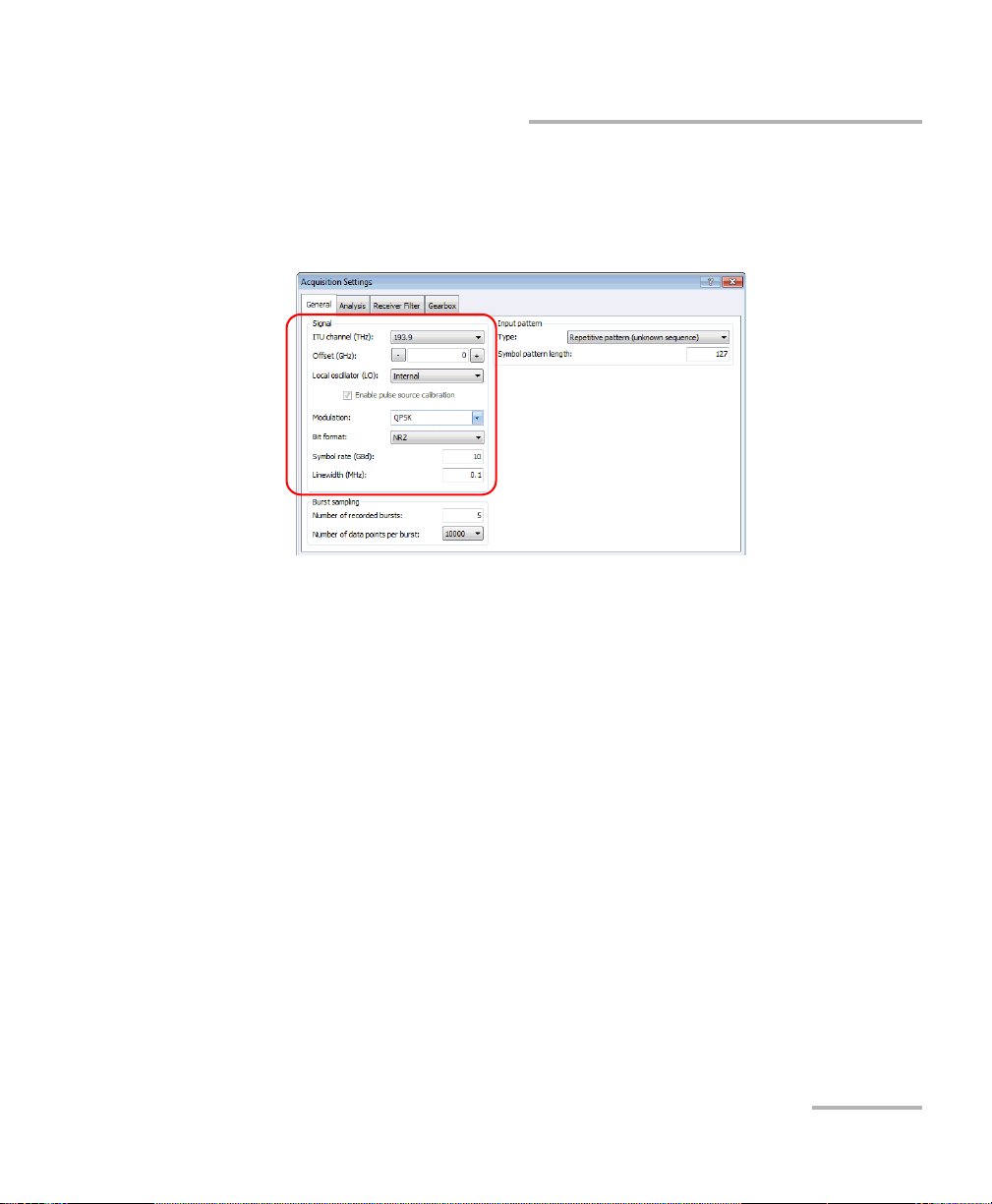

Configuring the Input Signal

You will need to provide the following information about your input signal,

in order to obtain relevant results:

ITU channel and Offset: this is the signal frequency or wavelength. You

can select a channel from the ITU grid (25 GHz spacing), and if

needed, indicate an offset value of up to half the channel.

The signal spectrum needs to be within the receiver spectrum (see

Technical Specifications on page 131), otherwise the constellation

chart might be distorted and noisy, or even not visible at all.

Local oscillator: you can use the PSO-200’s internal pulsed laser source

or your own external laser source. For explanations on when and how

to use an external source, see Using an External Local Oscillator on

page 27).

Modulation scheme (DPSK, QPSK, etc.): select the scheme according

to the modulation of your signal under test. Dual-polarization signals

are prefixed with “DP” See Modulation Schemes on page 247.

The Free-Run, CW and Intensity Sampling modes allow bypassing

some signal processing algorithms for troubleshooting or other analysis

purposes. See Using Special Modulation Modes on page 24.

Optical Modulation Analyzer 13

Page 22

Setting Up the Optical Modulation Analyzer

Configuring the Input Signal

Bit format (RZ or NRZ): this should be used according to the pulse

carving status of your signal under test (RZ for pulse-carved signals,

NRZ otherwise, as explained in Modulation Schemes on page 247).

This setting affects measurements associated with the waveform.

Symbol rate (in GBd): symbol rate of the input signal. An accurate rate

(±0.05 GBd or better) is needed to recover the correct waveform (via

pattern synchronization) and to get valid time-domain measurements

from the time reconstruction algorithms (see Sampling Methods on

page 240).

Linewidth: controls the speed of the IF tracking algorithm and should

correspond to the signal source’s linewidth (approximately

±0.25 MHz).

If it is set too low, there will be remaining phase noise on the captured

waveform (constellation symbols spread in the phase direction) or

even the phase will not be accurately tracked (cycle slips will occur).

If it is set too high, the algorithm will remove phase noise not

originating from the signal source (constellation symbols will be

compressed in the phase direction).

A proper setting balances these two conditions (equal noise in both

amplitude and phase, or a constellation with symmetric points).

14 PSO-200

Page 23

Setting Up the Optical Modulation Analyzer

Configuring the Input Signal

To configure the input signal type and properties:

1. From the Settings menu, select Acquisition.

2. Under the General tab, enter the settings in the Signal section.

3. Click Apply to confirm your settings, or OK to also close the window.

Optical Modulation Analyzer 15

Page 24

Setting Up the Optical Modulation Analyzer

Setting Other Acquisition Parameters

Setting Other Acquisition Parameters

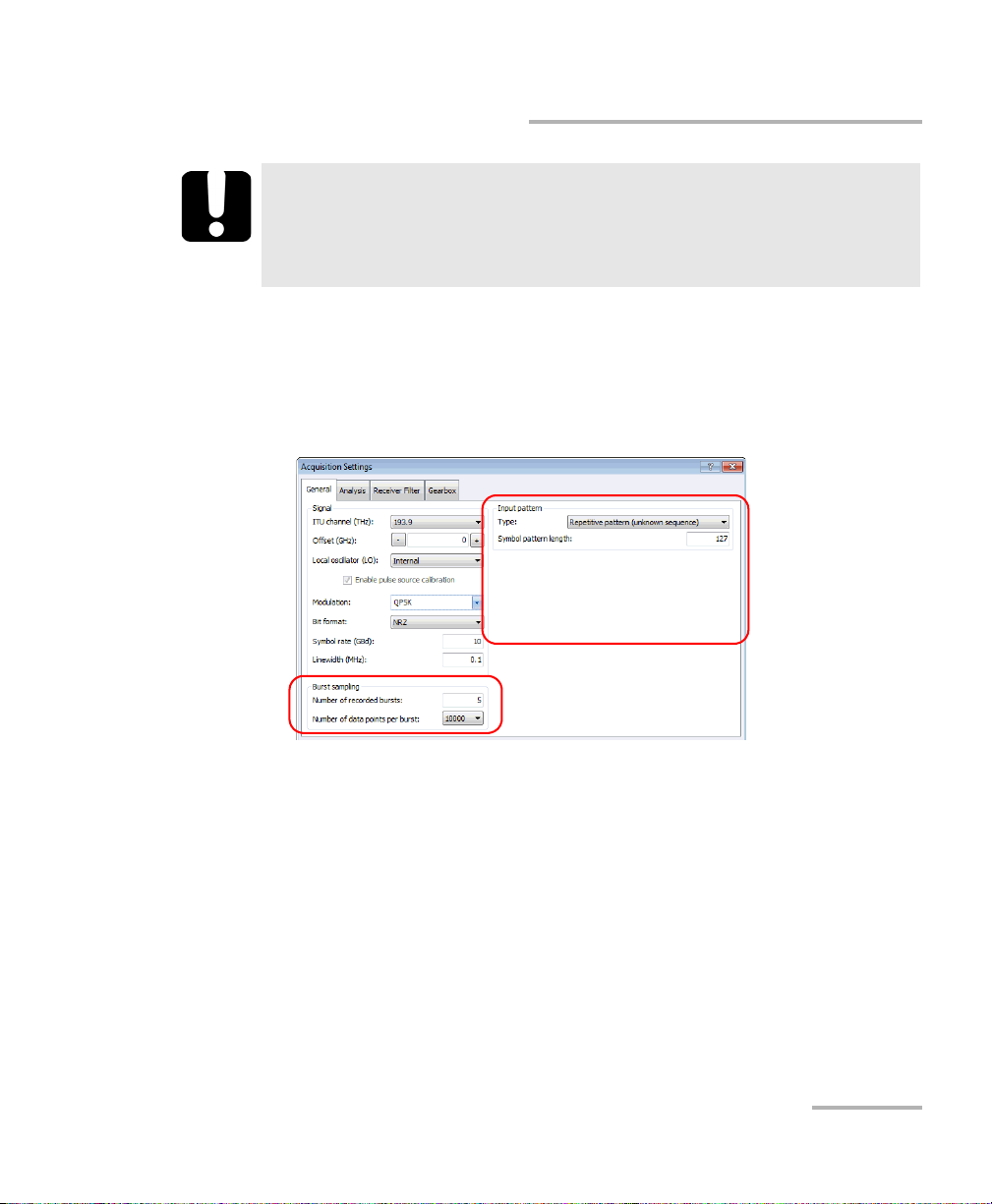

Use the following parameters to improve the recovered waveform:

Burst sampling parameters: you can specify the number of bursts that

will be recorded or buffered by the application, as well as the number

of data points in each burst. A larger number of points will take more

time to process but provide better results.

Input pattern mode and parameters: available modes depend on the

selected modulation scheme.

Random – if random signals (live traffic or framed PRBS) or very

long patterns (2

31

-1 PRBS) are used. The constellation chart and

eye diagrams of amplitude and phase can be measured, but not

the patterns. No filtering, averaging or CD unwrapping possible.

Repetitive (unknown pattern) – if your signal under test comprises

a repetitive pattern with known word length (for example, PRBS

with header data). The pattern can also be recovered.

User-defined symbol pattern – if you know exactly the symbol

pattern or can extract it from an acquisition (such as in Repetitive

mode or if your modulation scheme is not supported by the

PSO-200). This mode improves signal processing algorithms and

allows the calculation of a symbol error rate (SER). For details, see

Importing User-Defined Symbol Patterns on page 84.

PRBS – if your signal is generated from pseudo-random binary

sequences. Since the pattern is known, you can obtain bit error

rate (BER) information and you can use the Gearbox to fine-tune

the bit alignment of your signal stream.

User-defined bit pattern – if you know exactly the sequence of bits

in your signal. As for PRBS, you can obtain the BER and are able to

use the Gearbox.

Note: Free-Run, CW and Intensity Sampling signals do not allow patterns.

16 PSO-200

Page 25

Setting Up the Optical Modulation Analyzer

Setting Other Acquisition Parameters

IMPORTANT

Make sure a pattern can be displayed (magnitude graph) in any of

the pattern mode acquisitions. If pattern synchronization cannot be

achieved, switch the input pattern type to Random.

To set the acquisition parameters:

1. From the Settings menu, select Acquisition.

2. Under the General tab, enter the settings for the burst sampling and

input pattern.

3. If you have selected Repetitive pattern (unknown sequence), simply

enter the Symbol pattern length.

Otherwise, proceed as explained in Bit Pattern Analysis and the

Gearbox on page 79.

4. Click Apply to confirm your settings, or OK to also close the window.

Optical Modulation Analyzer 17

Page 26

Setting Up the Optical Modulation Analyzer

Setting File Autonaming

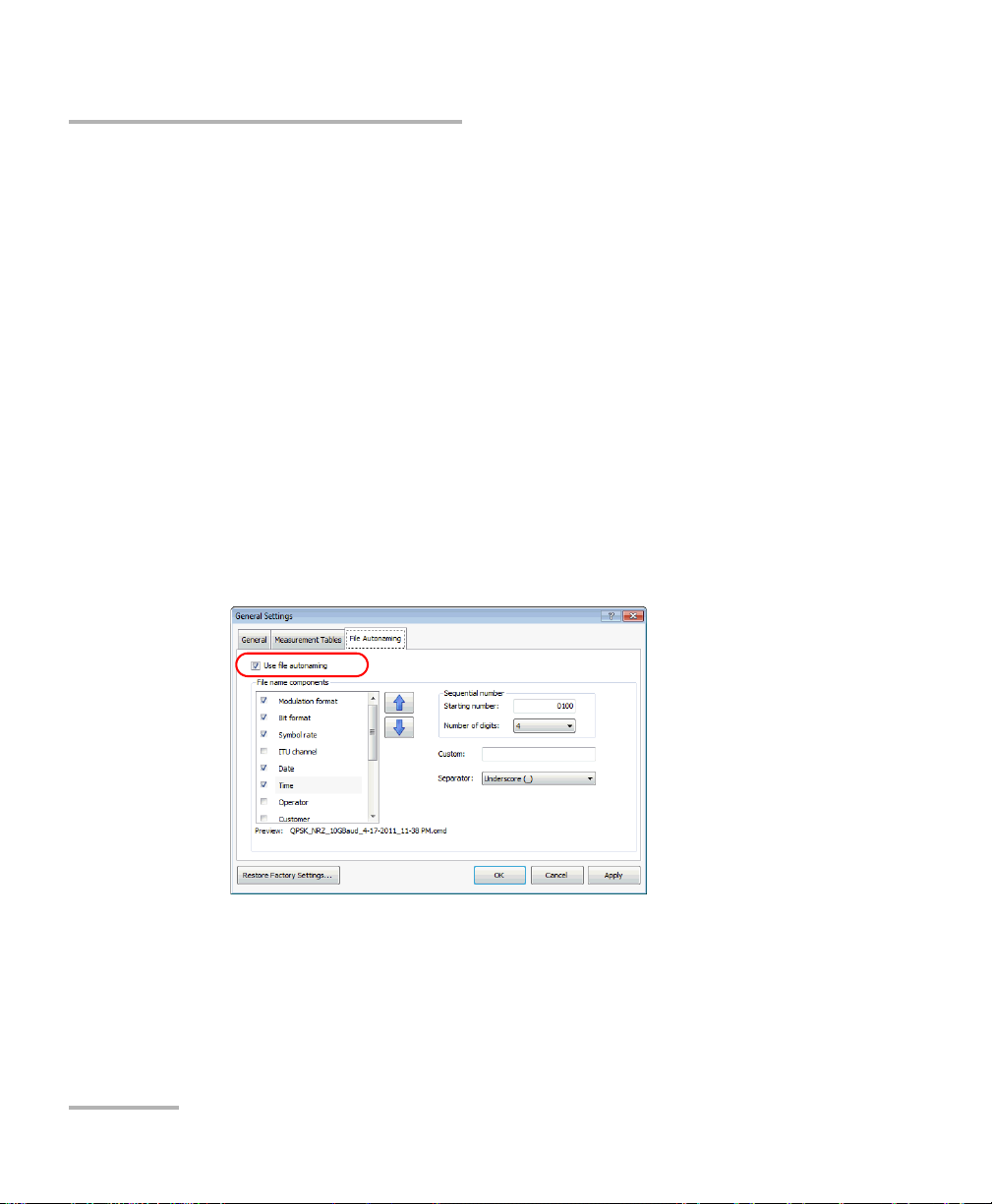

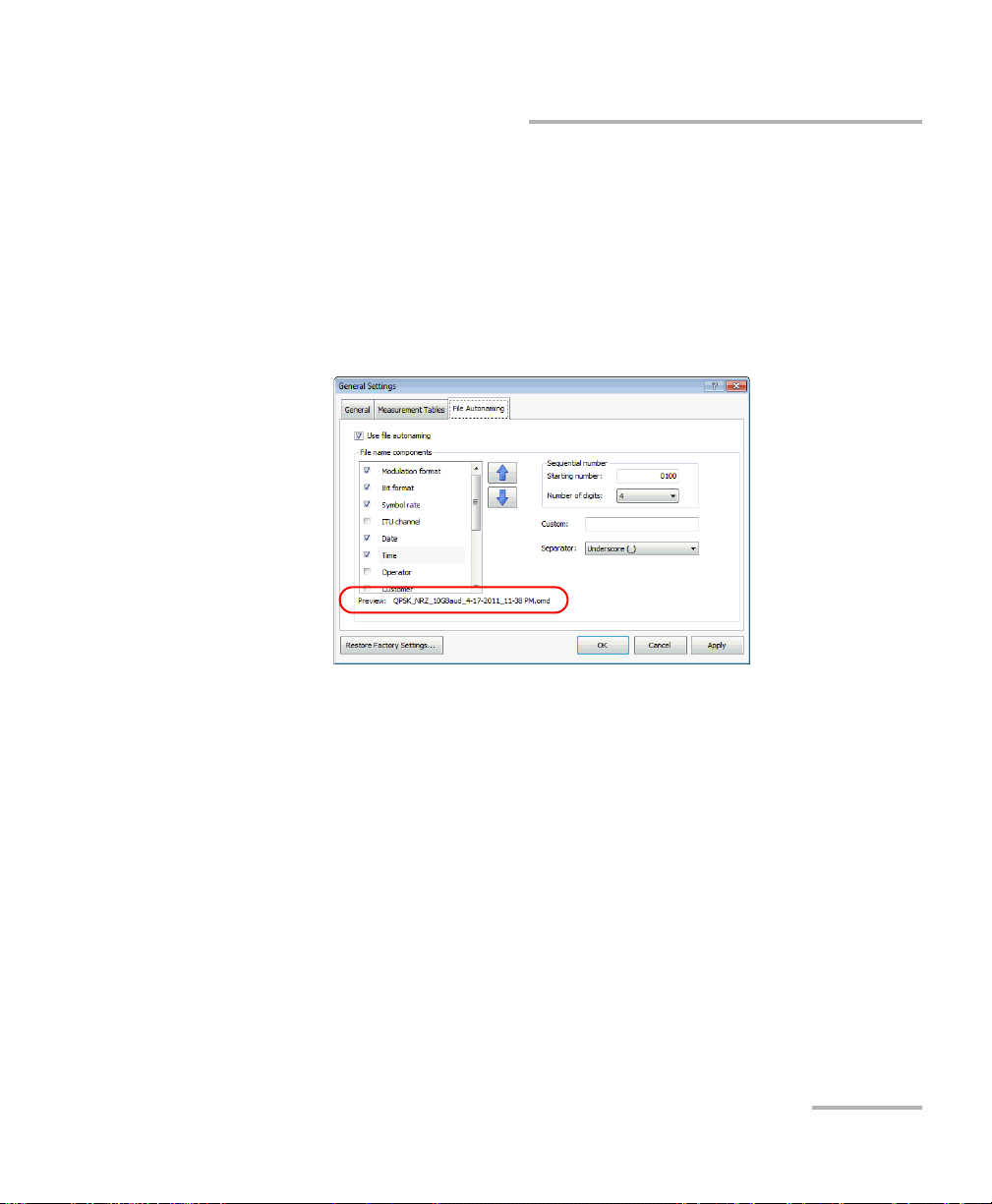

Setting File Autonaming

Autonaming helps you create a predefined file naming scheme for future

saved acquisitions. This can include data components, date/time and

sequential numbering. This way you are sure not to overwrite your

previous files and always follow a standard that is meaningful to you.

Note: Characters that cannot be used in a file name are replaced by a tilde “~”.

Note: Path and file names combined cannot exceed 260 characters. If the items

you have selected lead to a name that is too long, it will be truncated.

To define and activate the autonaming scheme:

1. From the Settings menu, select General.

2. Select the File Autonaming tab.

3. Check the box to enable the option if you want to use autonaming.

18 PSO-200

Page 27

Setting Up the Optical Modulation Analyzer

Setting File Autonaming

4. Define the autonaming scheme. A sample file name shows you the

final output.

Select data components you want to include in the name. You

must select at least one item in the list. You can change the order

using the up and down arrow buttons.

Note: The order of the items is kept until you revert to the factory settings.

Set the sequential number values. You can enter the starting

number and select how many digits are to be used. Once the

sequence reaches the maximum value (for example, 999 for a

3-digit sequence), the sequence is reset to the first value.

If desired, you can include a comment for your file name in the

Custom box. The comment contains up to 100 characters.

Select a separator value to place between the selected data

components.

5. Click Apply to confirm your settings, or OK to also close the window.

Optical Modulation Analyzer 19

Page 28

Setting Up the Optical Modulation Analyzer

Identifying Acquisitions

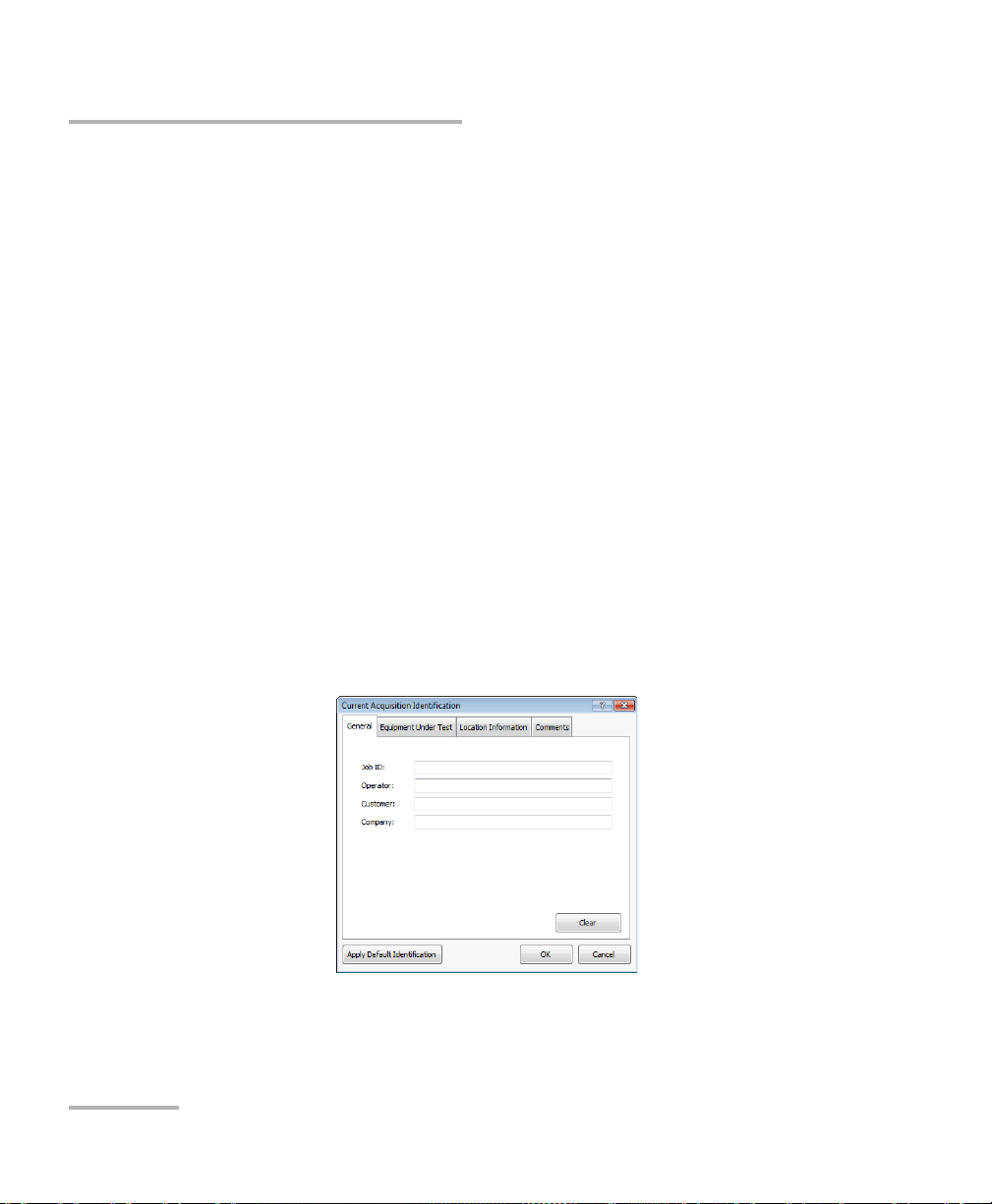

Identifying Acquisitions

Setting up acquisition information can save you time and work, as your

acquisitions will be identified according to your needs each time. You can

either set default information for future acquisitions (especially useful in

conjunction with file autonaming in automated production environments),

or add specific information for the current acquisition.

To enter acquisition identification:

1. If you want to set the default information, from the Settings menu,

select Default Acquisition Identification.

OR

If you want to identify the current acquisition only, from the File menu,

select Properties, then Current Acquisition Identification.

Note: When editing current acquisition details, you can click Apply Default

Identification in any tab to insert the default data.

2. Select the General tab, then fill out the basic information for your

acquisition, such as the operator or customer name.

20 PSO-200

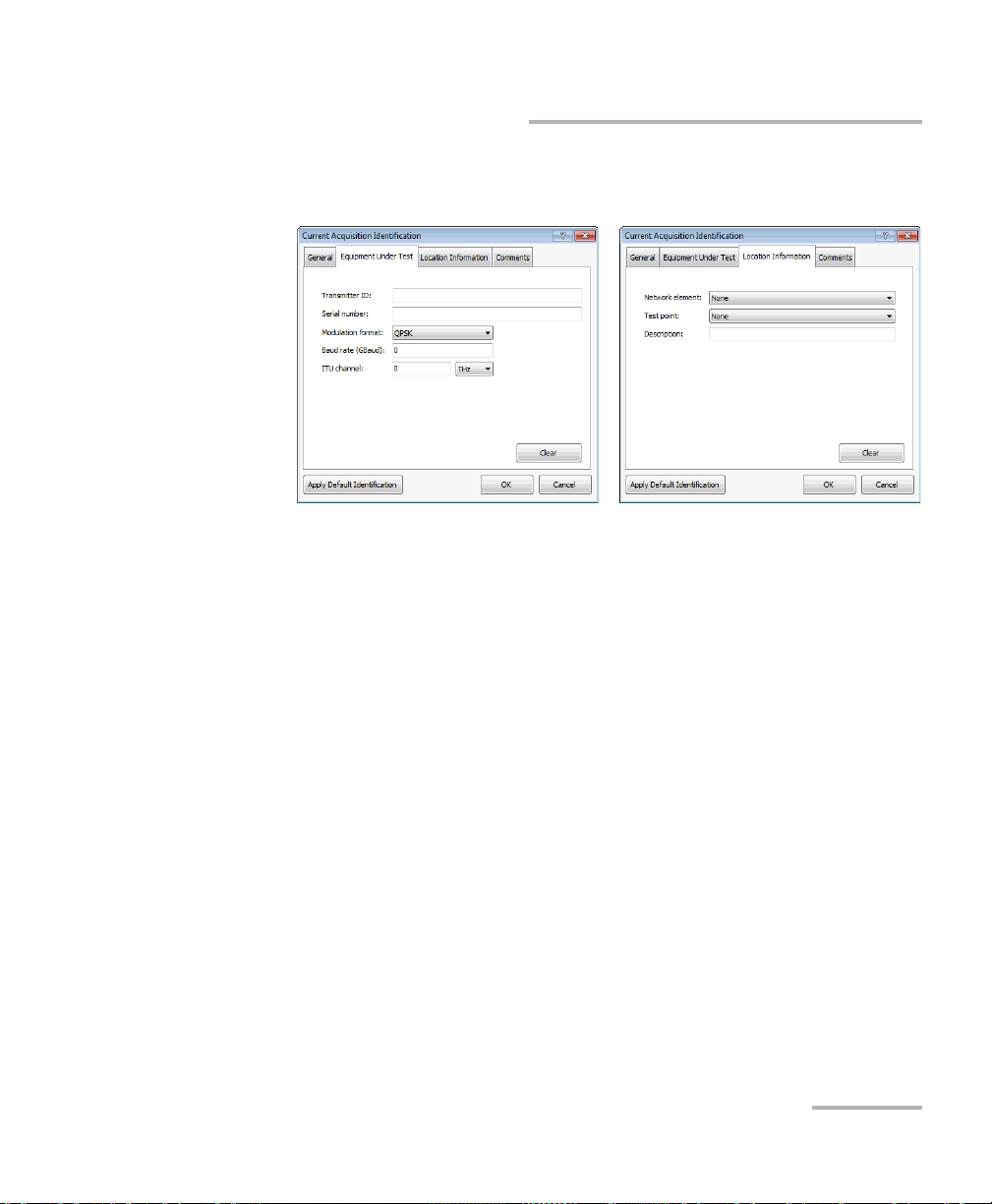

Page 29

Setting Up the Optical Modulation Analyzer

Identifying Acquisitions

3. Select the Equipment Under Test and Location Information tabs and

provide details that pertain to your specific test case.

You can also add a personalized comment in the Comments tab.

4. Click Apply to confirm your settings, or OK to also close the window.

Optical Modulation Analyzer 21

Page 30

Setting Up the Optical Modulation Analyzer

Setting Analysis Parameters

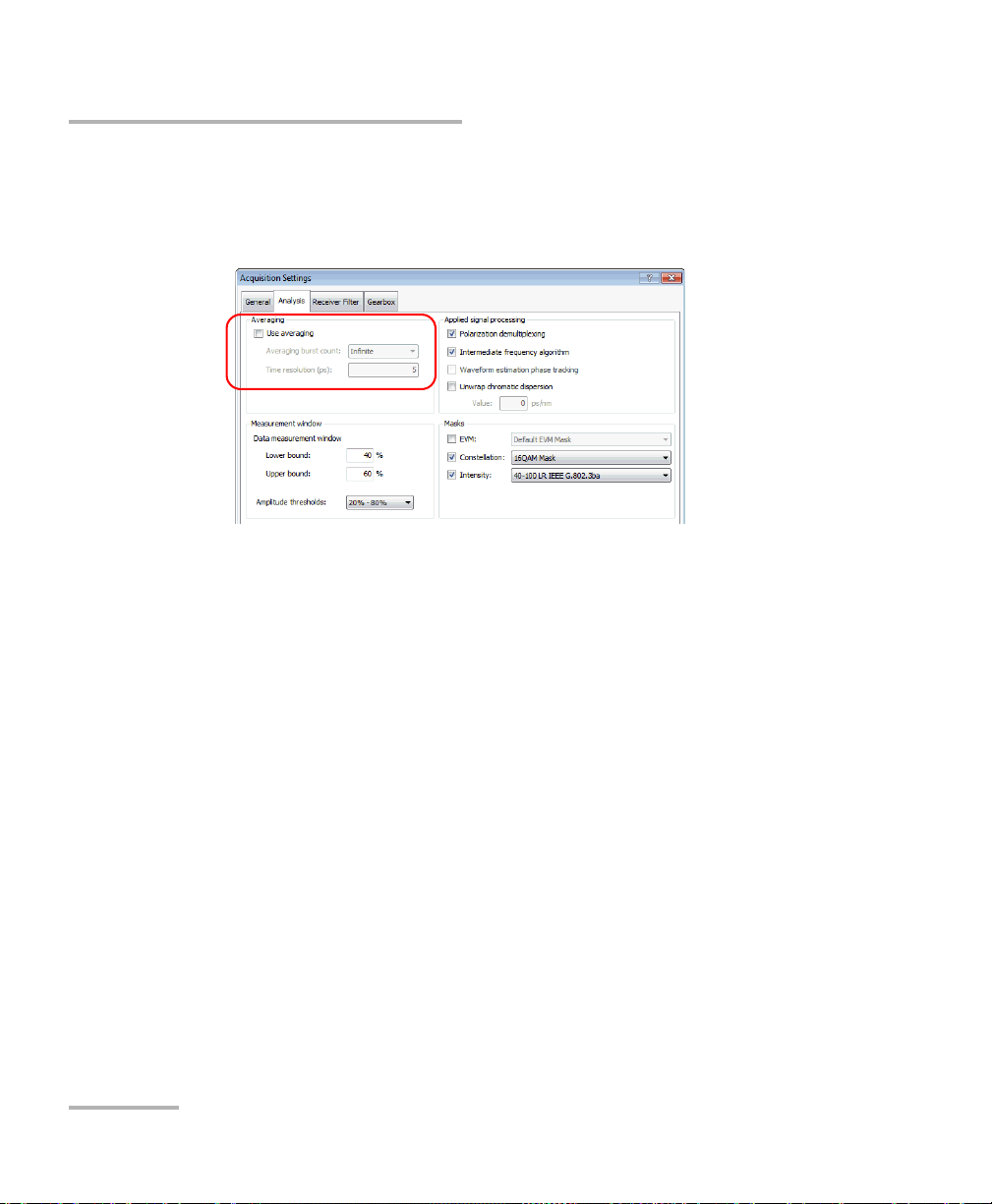

Setting Analysis Parameters

The signal can be analyzed while being acquired or afterwards in

reanalysis mode. The following tools are available.

Burst averaging (see Using Averaging to Improve Results on page 70).

Measurement windows:

Data – time range defined as percentages of the symbol period, as

explained in Distinguishing Data Points from Transitions on

page 62.

Amplitude – intensity range defined as percentages of the eye

amplitude, as explained in Measurements for Eye Diagrams on

page 258. It is used to compute values like “rise” and “fall” times

and provides the eye height.

Specific optional signal processing algorithms (see Applying Advanced

Signal Processing Algorithms on page 72). Available algorithms depend

on the selected modulation format.

Pattern masks to test the quality of the signal and perform quick

pass/fail analysis (see Using Pattern Masks on page 64).

22 PSO-200

Page 31

Setting Up the Optical Modulation Analyzer

Setting Analysis Parameters

To set the analysis parameters:

1. From the Settings menu, select Acquisition.

2. Under the Analysis tab, select the desired analysis options.

3. Click Apply to confirm your settings, or OK to also close the window.

Optical Modulation Analyzer 23

Page 32

Setting Up the Optical Modulation Analyzer

Using Special Modulation Modes

Using Special Modulation Modes

In some situations, when the input signal does not represent

phase-encoded data, it can be valuable to bypass some of the signal

processing algorithms to visualize the signal with a better refresh rate or

under different conditions. For example, it may be useful to study just the

intensity before a phase-encoding transmitter is set up correctly, for

debugging purposes.

You can also export the signal data obtained when bypassing some

algorithms to analyze with your own tools (such as MATLAB algorithms).

The Optical Modulation Analyzer application offers the following modes:

Mode Usage

Free-run General debugging, oscilloscope-like behavior;

useful in initial connections to ensure signal input

Continuous wave CW laser analysis, analyze phase noise

Intensity sampling Fast, useful for a first tuning of the system under test,

shows waveform envelope

Here are the signal processing algorithms (applied or optional) for each

mode (for details, see Signal Processing Algorithms on page 244):

Signal Processing Algorithms

(in order)

Free-Run CW

Intensity

Sampling

Polarization demultiplexing Optional Optional Optional

Time reconstruction vector – – Applied

Intermediate frequency recovery – Optional –

Alignment –––

Other algorithms – Applied –

24 PSO-200

Page 33

Setting Up the Optical Modulation Analyzer

Using Special Modulation Modes

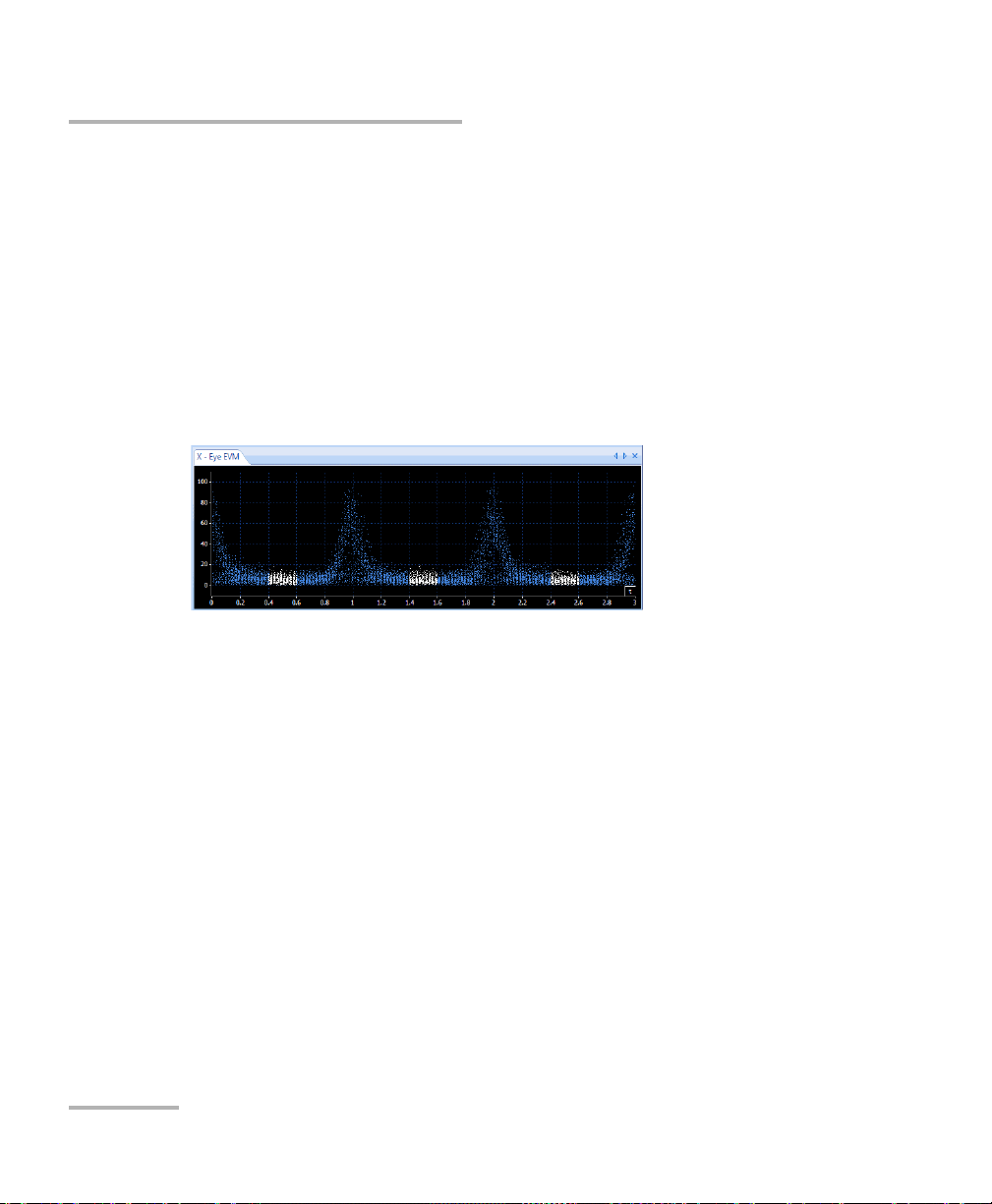

The figure below shows an example of intensity sampling of 42 GBd QPSK

data (top: intensity eye diagram; bottom: corresponding 127 bit pattern).

The intermediate frequency recovery algorithm is bypassed so that only

intensity is sampled. The phase information is not retrieved.

Optical Modulation Analyzer 25

Page 34

Setting Up the Optical Modulation Analyzer

Using Special Modulation Modes

To select a special modulation mode and activate optional

algorithms:

1. From the Settings menu, select Acquisition.

2. Under the General tab, select the special mode in the Modulation list.

3. Under the Analysis tab, select the desired signal processing algorithms

to apply.

4. Click Apply to confirm your settings, or OK to also close the window.

26 PSO-200

Page 35

Setting Up the Optical Modulation Analyzer

Using an External Local Oscillator

Using an External Local Oscillator

The External local oscillator (LO) option allows you to use your own laser

as a source for the local oscillator instead of the PSO-200 internal laser. This

is useful in the following cases:

When your signal source has an extremely low phase noise, such that

the overall phase noise becomes dominated by the internal LO source.

If you use as LO a laser source with equivalent (or better) phase noise

characteristics, you can reduce the total phase noise in acquisitions.

To accomplish self-homodyne measurements by using the same laser

source split between the signal and LO, offering identical phase noise

characteristics on both.

In order to cancel the influence of the source phase noise on the

measurements, and thus not requiring phase tracking, you must

ensure that the delays of the signal and LO paths will match precisely

(even more when your laser source has wider linewidth).

The external laser source must meet the specified power range (see

Technical Specifications on page 131) and must use

polarization-maintaining fiber (PMF).

When the external LO source is distinct from the signal source:

The ITU Channel parameter also applies to the external LO source, so

both sources must have the same frequency/wavelength.

The Linewidth parameter should be set to the wider laser source.

Optical Modulation Analyzer 27

Page 36

Setting Up the Optical Modulation Analyzer

Using an External Local Oscillator

By default, the application automatically calibrates the external LO source

during acquisitions. You can disable this option, but you should only do so

if the application requires it (see message below), in which case the

application will try to use the last calibration values obtained with the

internal LO.

Note: Changing the frequency/wavelength or symbol rate will clear the

calibration values, thus requiring the above procedure.

28 PSO-200

Page 37

Setting Up the Optical Modulation Analyzer

Using an External Local Oscillator

To enable the external local oscillator:

1. From the Settings menu, select Acquisition.

2. Under the General tab, select External in the Local oscillator list.

Optical Modulation Analyzer 29

Page 38

Setting Up the Optical Modulation Analyzer

Using an External Local Oscillator

3. If necessary only, disable the automatic calibration by clearing the

Enable pulse source calibration box.

4. Click Apply to confirm your settings, or OK to also close the window.

5. Connect your external laser source to the Local Oscillator Input port

on the PSO-200 front panel.

6. Start an acquisition.

IMPORTANT

If you revert to Internal LO, ensure your external source is

disconnected before clicking Start for the next acquisition.

30 PSO-200

Page 39

Setting Up the Optical Modulation Analyzer

Locking the Remote Unit

Locking the Remote Unit

If you control the unit remotely, you can set it so that the keyboard, mouse

and touchscreen are inactive. This can be useful when you do not want

someone to accidently change your settings.

To lock the unit when using remote control:

1. From the main window, select the Settings menu, then General.

2. Select the General tab.

3. Under SCPI, select the option to lock the unit.

The lock takes effect when you start the remote communication. You can

unlock the unit via remote control or using the return to local button on the

front of the unit.

Optical Modulation Analyzer 31

Page 40

Page 41

5 Performing Acquisitions

Starting and Stopping an Acquisition

Once you start an acquisition, it will continue until you stop it. If you had a

previous acquisition that you have not saved, you will be prompted to save

it before starting a new one.

While an acquisition is in progress, the on-screen data and graphs are

updated upon each burst, and you can still change the display layout.

However, you cannot use the playback controls, or open or save files.

To start an acquisition:

Press the Start button.

OR

From the Measurement menu, select Start.

To stop an acquisition:

While the acquisition is in progress, press the Stop button.

OR

From the Measurement menu, select Stop.

Note: Closing the application will also stop the acquisition.

Optical Modulation Analyzer 33

Page 42

Performing Acquisitions

Clearing Data During an Acquisition

Clearing Data During an Acquisition

While an acquisition is in progress, you can clear the data already acquired

at any time in order to capture a clean signal without the glitches that might

have been introduced during manipulations.

All graphs and measurement tables are reset, and burst count restarts at 1.

The Y axis is re-scaled to a normalized unit.

To clear acquired data:

While an acquisition is in progress, press the (Clear) button.

OR

From the Measurement menu, select Clear Data.

34 PSO-200

Page 43

Performing Acquisitions

Saving Acquisitions to a File

Saving Acquisitions to a File

Once an acquisition is completed, you can save it for later analysis and

playback.

You can set a default folder to use for future acquisitions. The application

offers you to save the file in this folder, but you can always select a different

location.

Note: If autonaming was enabled (see Setting File Autonaming on page 18), the

application will suggest an appropriate name, but you can change it.

To set a default folder for your saved files:

1. From the Settings menu, select General.

2. Select the General tab.

3. Under Storage, locate the folder you want using the Browse button.

4. Click Apply to confirm your settings, or OK to also close the window.

To save an acquisition file:

1. From the File menu, select Save As.

2. Navigate to the folder where you want to save the file.

3. Click Save.

If you had previously saved the file, you can use Save instead of Save As to

automatically save it with its current name and location. You can also use

the button on the main window.

Optical Modulation Analyzer 35

Page 44

Performing Acquisitions

Ready Ready Ready Ready Ready Ready

Tri g

Burst

Analysis

Triggered acquisition (1 burst/trig)

Ready

Tri g

Burst

Analysis

Triggered acquisition (6 bursts/trig)

Ready

Tri g

Burst

Analysis

Triggered acquisition (6 bursts/trig, trigs too fast)

12 3456 123

Activating Trigger-Based Acquisitions

Activating Trigger-Based Acquisitions

You could use an external equipment, such as a BER tester, to initiate burst

acquisitions on the PSO-200 based on trigger signals. This can be useful in

automated long-term tests.

When you start this acquisition process, the application will be on hold,

waiting for a trigger signal (which can occur hours later) to acquire new

bursts as specified. This process will stop if you press the Stop button or

when it reaches the specified number of trigs.

If the external trig signal occurs while the previous burst is still being

acquired, the PSO-200 will ignore this trig signal and wait for the next one.

Note: You must stop the trigger-based acquisition in order to change its settings.

36 PSO-200

Page 45

Performing Acquisitions

Activating Trigger-Based Acquisitions

To activate triggered acquisitions:

1. From the Settings menu, select Acquisition.

2. Under the Gate Acquisition tab, select Acquire a burst when

receiving a signal....

3. Select the trigger parameters as follows:

Number of recorded bursts: bursts buffered in memory, overriding

the equivalent setting in the General tab.

Number of bursts to acquire per trig event

Stop acquisition after N trig events: will stop after this number of

“useful” trigs (trigs leading to a burst acquisition, not counting

skipped trigs).

Save to file after stopping the acquisition: the acquisition will be

saved in the location (path) specified in General Settings, using

autonaming if enabled (or generic names “OMDFileX.omd”

otherwise). A file can contain at most 140 bursts.

Trig signal: select whether to use the rising signal (reaching 2.5 V

upwards) or the falling signal (reaching 2.5 V downwards).

4. Click Apply to confirm your settings, or OK to also close the window.

5. Connect your external equipment to the Trigger port on the PSO-200

front panel.

6. Press the Start button. The application will wait for the trigger signal.

Optical Modulation Analyzer 37

Page 46

Page 47

6 Customizing the Graph and

Split bars

Data Layout

Selecting and Customizing the Layout

The application’s main window is fully customizable. You can start with

one of the preset single- or dual-polarization layouts that may already suit

your needs. Each layout contains a set of graphs and tables.

Note: Predefined layouts are not editable. Once you close a tab, you can only

make it appear again by re-selecting a layout that contains it.

Note: Dual-polarization layouts are available even if your unit does not support it,

allowing you to open files previously acquired on other units. Polarizations

are identified by X and Y.

Optical Modulation Analyzer 39

Page 48

Customizing the Graph and Data Layout

Selecting and Customizing the Layout

At any time during of after acquisitions, you can change the displayed

graphs (except the constellation), resize the tabs or close those you do not

want to see. The application will remember your layout for your next work

session.

Available graphs in the Optical Modulation Analyzer application are

described later in this chapter.

To select a predefined layout:

1. From the Display menu, select Layout.

2. Select which layout better suits your situation. You can also use the

keyboard shortcuts.

To change the graph on a tab (eye or pattern):

1. Right-click on the graph tab for which you want to change the content.

OR

Select the graph tab, then in the Display menu, select Graph Type.

2. Select a new type of graph to display.

To r es i ze a t ab :

Use the split bars enclosing the tab you want to resize.

To close a tab:

Click the button in the upper right corner of the tab.

To change the displayed polarization:

1. From the Display menu, select Polarization.

2. Select the polarization (X or Y) to display on all graphs and tables.

Note: The Polarization option is only available if you are viewing a

dual-polarization signal on a single-polarization layout.

40 PSO-200

Page 49

Customizing the Graph and Data Layout

}

}

“Q”

“I”

Symbol

I-Value

Q-Value

Polar-to-Rectangular Conversion

Project signal to

“I” and “Q” axes

Constellation Chart

Constellation Chart

Useful when characterizing advanced modulation schemes such as

DP-QPSK, the constellation chart is a representation of a signal modulated

in phase and/or in amplitude.

It shows valid symbols (amplitude and phase relative to the carrier) of a

modulation format on a polar graph. Since each symbol is encoded with n

bits (depending on the modulation scheme), there will be 2

symbols.

n

permitted

The “I” axis (in-phase) represents the “real” part of the complex field,

while the “Q” axis (quadrature) represents the “imaginary” part.

The length of the vector to the symbol in the chart is the amplitude of the

signal (normalized in the Optical Modulation Analyzer application), and its

angle from the “I” axis is the phase of the signal.

Note: There is one constellation chart per polarization state (X and Y).

Optical Modulation Analyzer 41

Page 50

Customizing the Graph and Data Layout

Constellation

point

Tra nsit ions

Constellation Chart

The figure below shows an example of a QPSK constellation with four

points (2-bit symbols) comprising the data-carrying signal. No time

information is given since it would be on the z axis.

Transitions between constellation points contribute significantly to the

spectral content of the input signal, and hence the optimization of these

transitions is often the most critical aspect of transmitter operation.

Consequently, the PSO-200 is designed to not only display the constellation

points, but also visualize these transitions with high accuracy.

If the signal is without error, the ideal symbol would appear as a single

point on the constellation. However, signal impairments and modulation

errors cause deviations and the symbols will show as a group of points

dispersed around the ideal location.

For details about the measurements derived from the constellation chart,

see Measurements for Constellation Charts on page 252.

42 PSO-200

Page 51

Customizing the Graph and Data Layout

Symbol period

Eye Diagrams

Eye Diagrams

An eye diagram is a trace of the intensity, magnitude, or phase, as a

function of time, where the corresponding time vector has been “folded”

to an integer number of symbol periods (see Equivalent-Time Sampling on

page 241).

Traditionally, intensity (power) has been shown in eye diagrams, since the

power itself contains the information in on-off keying (OOK) data

modulation. With more complex phase-encoded signals with coherent

detection, I/Q amplitude and phase are also shown in eye diagrams.

To acquire the eye diagram, the PSO-200 relies on a time reconstruction

algorithm that works like a software-based clock recovery.

Note: All eye diagrams are normalized on the Y-axis.

Several system performance measures can be derived by analyzing the eye

diagram. It allows you to determine whether the signal exhibits excessive

jitter or noise, or if it is too slow to change, or displays unacceptable

overshoot. Distortion of the signal waveform due to inter-symbol

interference (ISI) and noise appears as closure of the eye diagram.

For details about the measurements derived from the eye diagrams, see

Measurements for Eye Diagrams on page 258.

Optical Modulation Analyzer 43

Page 52

Customizing the Graph and Data Layout

ItB() ReE tB()()=

Qt

B

() ImE tB()()=

NRZ-QPSK data

QPSK data

Eye Diagrams

I/Q Eye Diagrams

The I (in-phase) and Q (quadrature) eye diagrams represent the “real” and

“imaginary” parts of the complex field as a function of time, respectively.

where t

is the remainder after division with the symbol period .

B

The I eye diagram can be seen as the data visible by looking from the right

of the constellation chart. Similarly with the Q eye diagram by looking from

the top.

Phase Eye Diagram

Eye diagram of arg(E(tB)). No amplitude information is provided.

This graph shows the different phases of the signal and the transitions. Its

use is to see the phase shifts in PSK and QAM modulations.

The example below shows four phase levels: /4, 3 /4, -/4, -3/4.

44 PSO-200

Page 53

Customizing the Graph and Data Layout

NRZ-QPSK data

NRZ-QPSK data

Magnitude Eye Diagram

Eye diagram of P(tB)

1/2

=|E(tB)|. No phase information is given.

Intensity Eye Diagram

Eye diagram of P(tB)=|E(tB)|2. No phase information is given.

Eye Diagrams

Note: Intensity = Magnitude²

Optical Modulation Analyzer 45

Page 54

Customizing the Graph and Data Layout

NRZ-QPSK data

Eye Diagrams

Error Vector Magnitude (EVM) Diagram

The quality of the transmitted signal can be established by looking at the

error vector, which compares the received signal with an ideal signal,

taking into account both phase and magnitude errors.

The error vector magnitude (EVM) value is computed in the data

measurement window (excluding measurements from transitions).

When a pattern exists, EVM values are relative to the “expected” reference

constellation point. In random mode (no pattern), EVM values are relative

to the nearest constellation point.

EVM values on the Y axis range from 0 % to 100 %. In some cases, the value

can even be above 100 %.

For details about EVM measurements and calculations, see Measurements

for Constellation Charts on page 252.

46 PSO-200

Page 55

Customizing the Graph and Data Layout

27-1 NRZ-QPSK

Pattern Diagrams

Pattern Diagrams

You can view all graphs (I/Q, intensity, magnitude, phase and EVM) as a

pattern instead of an eye diagram. The pattern diagram is a continuous

curve between different amplitude and/or phase states, as a function of

time. It helps viewing the capacity of the system to transmit all signal

combinations.

In standard sampling oscilloscopes, a pattern clock (which sends out a

pulse synchronized with the periodic pattern) may be used to trigger the

scope. In contrast, the PSO-200 uses a software algorithm to reconstruct

the pattern.

On pattern diagrams, the X axis is either symbol- or time-based. At a 100 %

zoom value, you can see the entire signal for the symbol pattern.

Y-Axis Auto Scaling (All Graphs)

The unit does not display intensity data (Y axis) in mW, but rather scales it

to a normalized unit. Each time you press Start (or Clear Data), the unit

computes a scaling factor based on the first burst, and uses it for

subsequent bursts.

Note: To see the difference in intensity between the X and Y polarizations,

compare the Power Level values from both result tables. You can also see

the values in the constellation charts.

Optical Modulation Analyzer 47

Page 56

Page 57

7 Viewing and Analyzing

Results

Opening an Existing Acquisition File

You can recall previously saved acquisition files on your unit or on another

computer for further analysis.

Note: You cannot open a file while an acquisition is in progress.

To open an acquisition file:

1. From the File menu, select Open.

2. Locate the file you want to open.

3. Click Open.

You can also open a file directly from the main window by clicking .

Optical Modulation Analyzer 49

Page 58

Viewing and Analyzing Results

Expands into

more details

Viewing Acquisition Information

Viewing Acquisition Information

When opening a previously acquired file for analysis, you can view

information about the parameters that were used for acquisition.

For details on the parameters displayed, see Setting Up the Optical

Modulation Analyzer on page 13.

To view data and parameters from the current acquisition:

1. From the File menu, select Properties, then Current Acquisition

Information.

2. Click Close when done.

50 PSO-200

Page 59

Viewing and Analyzing Results

Move forward to the next frame

Move back to the

previous frame

Start playback

Pause playback

Stop playback and

return to first frame

Move to the end of

the sequence

Playing Back Acquisition Files

Playing Back Acquisition Files

Once you have acquired bursts, or after opening a previously saved file,

you can use the playback buttons to see the behavior of the acquired

signal. All bursts will be played at the same speed as when acquired.

You can also find the playback controls in the Playback menu.

Note: While playing back, the burst number (with its date and time) and total

burst count are displayed in the status bar.

You can set the playback to either stop at the end of the sequence, or loop

back to the first frame and continue until you press the Stop button.

To set the playback to loop:

1. From the Settings menu, select General.

2. Select the General tab.

3. Under Playback, select the Play in loop option.

4. Click Apply to confirm your settings, or OK to also close the window.

Optical Modulation Analyzer 51

Page 60

Viewing and Analyzing Results

Zoom to a selected area

Selection mode

Move view area (Pan)

Full view

Zoom out

Set zoom according to

both axes

Set zoom according to

vertical axis

Set zoom according to

horizontal axis

Zoom in

Zooming and Moving Graphs

Zooming and Moving Graphs

Once you have acquired data, you can use zoom and pan functions on the

graphs to better see the results. The Zoom and Pan buttons are located on

the right side of the main window.

When modifying the zoom level of a pattern diagram, or if you move its

view area, all pattern diagrams for the same polarization will adjust to

this new zoom level. This allows inter-graph validation and analysis.

Constellation graphs are always zoomed isotropically (same zoom

level on both axes) to keep their square appearance.

52 PSO-200

Page 61

Viewing and Analyzing Results

Displaying and Setting X-Axis Values

Displaying and Setting X-Axis Values

For eye and pattern graph types, you can customize the display of the

X axis, by selecting the units and by selecting whether values will be shown

on the axis or not (if values are not shown, the first and last values are

indicated on the sides).

Eye diagrams: units can be time- or period-based

Pattern diagrams: units can be time- or symbol-based

Note: Time unit prefixes will automatically adjust to fit the values (ns, ps, etc.).

Note: These features will have an effect on all applicable graphs.

To customize the display of the X axis:

1. From the Settings menu, select General.

2. Select the General tab.

3. In the Graphs section, check the boxes to display units on the graphs,

and select the appropriate units to use.

4. Click Apply to confirm your settings, or OK to also close the window.

Optical Modulation Analyzer 53

Page 62

Viewing and Analyzing Results

Brighter points (almost white)

Displaying Graphs in Color Grade Mode

Displaying Graphs in Color Grade Mode

The Color Grade mode is much like using phosphor persistence on an

oscilloscope. The more a specific point is hit, the brighter it is displayed.

This quickly gives you a view of the distribution of points on the plots.

Color Grade is available during both acquisition and playback, and for the

following types of graphs:

Constellation charts

Eye diagrams (I-Q, Phase, Intensity, Magnitude, EVM)

Note: When going backwards in Playback mode, colors will be reset.

Note: Color Grade is applied to all relevant graphs at once. It is not available

when Averaging is active.

To activate Color Grade:

From the Display menu, select Color Grade. Clear the option to remove

the effect.

54 PSO-200

Page 63

Viewing and Analyzing Results

2 periods 3 periods

Displaying Multiple Bursts Simultaneously (Persistence)

Displaying Multiple Bursts Simultaneously

(Persistence)

With the Persistence mode, charts can display simultaneously the data of

up to 5 bursts (layers) to help identifying areas with a high number of

points. The “infinite” option accumulates the points from all bursts, which

is similar to the Color Grade mode but with a single color.

Note: Persistence is applied to all relevant graphs at once. It is not available when

Color Grade is enabled.

To set the persistence level:

1. From the Display menu, select Persistence.

2. Select the number of layers (1 to 5 or infinite). The default is 1, which

means no persistence.

Setting Number of Symbol Periods for Eye Diagrams

You can display eye diagrams with 1 to 5 symbol periods.

To set the number of symbol periods:

1. From the Display menu, select Periods.

2. Select the number of periods (1 to 5).

Optical Modulation Analyzer 55

Page 64

Viewing and Analyzing Results

Global results table

Constellation and eye results tables

(X and Y polarizations)

Using the Measurement Tables

Using the Measurement Tables

The measurement table is used to view the calculated results for each axis

(I, Q, phase, magnitude). You can decide to display the table or not, and

you can customize it to optimize result viewing.

In preset layouts, measurement tables are associated with the

corresponding chart. There is also one table per polarization state.

However, you can change the layout, or even decide to only display a

general table that shows information common to both polarizations.

For details on each of the available measurements, see Measurement

Definitions on page 251.

Note: You can copy the contents of the table to the Windows clipboard for use in

another application, as explained in Copying Graph and Measurements to

Clipboard on page 114.

56 PSO-200

Page 65

Viewing and Analyzing Results

Using the Measurement Tables

To customize the measurement table display:

1. From the Settings menu, select General.

2. Select the Measurement Tables tab.

3. Select which items you want to view in the measurement tables.

4. Click Apply to confirm your settings, or OK to also close the window.

Optical Modulation Analyzer 57

Page 66

Viewing and Analyzing Results

Move selected marker

Toggle marker

Data about selected

marker

Markers

Polar coordinates (R and )

Using Graph Markers

Using Graph Markers

To help you evaluate values and differences (deltas) in precise locations of

any graph type, you can display and position sets of markers on the graph

and view corresponding data on a tiny dashboard.

There are two markers for each axis: X1, X2, Y1, Y2. You can move markers

from end to end, independently from each other.

Constellation charts also include a diagonal line from the center to crossing

pairs of markers (X1|Y1 and X2|Y2), and the dashboard provides

corresponding polar coordinates.

58 PSO-200

Page 67

Viewing and Analyzing Results

Using Graph Markers

To display (or hide) markers and dashboard for a graph:

Right-click on a graph, then select Show Markers (or Hide Markers).

OR:

1. Select a graph.

2. From the Display menu, select Show Markers (or Hide Markers).

To select and move a marker:

In Selection mode, drag the marker on the screen with the mouse or

touchscreen.

OR:

1. Click the toggle marker button until you reach the desired marker

(indicated on the button).

2. Press or hold the arrow buttons on each side of the marker button in

the dashboard unti the marker is correctly positioned.

Note: If you zoom in on the graph, markers retain their position (thus possibly

becoming invisible). If you then move a marker with an arrow button, the

marker comes back to the visible area, then moves in regular increments.

Optical Modulation Analyzer 59

Page 68

Viewing and Analyzing Results

Viewing Signal Distribution Using Histograms

Viewing Signal Distribution Using Histograms

In cases where you want to see a more detailed distribution of points in a

region, you can display a horizontal or vertical histogram on top of a graph.

Horizontal histogram: each bar, displayed vertically from the bottom,

represents the number of points for the corresponding value on the

horizontal axis. For example, in an Intensity-vs.-Time graph, each bar

would represent a specific time value.

Vertical histogram: each bar, displayed horizontally from the left,

represents the number of points for the corresponding value on the

vertical axis. For example, in an Intensity-vs.-Time graph, each bar

would represent a specific intensity value.

The histogram is defined by the enclosed area of markers, so markers must

be displayed first. Moving markers or zooming the graph automatically

recalculates the histogram values. The histogram is scaled on the graph

area so that the highest value is in the middle.

When a histogram is displayed, the following values appear in the graph

corner:

Mean and standard deviation

Total hit count in histogram

Peak-to-peak value (max – min)

Signal-to-noise ratio (SNR) (for vertical histograms only on eye and

pattern graphs, and does not apply to EVM and Phase graphs)

Note: You cannot display horizontal and vertical histograms simultaneously on a

graph.

Note: Histograms are not available when averaging is set, since there are no

points to count in this mode (see Using Averaging to Improve Results on

page 70).

60 PSO-200

Page 69

Viewing and Analyzing Results

Horizontal histogram

Histogram values

Vertical histogram

Viewing Signal Distribution Using Histograms

To display a histogram on a graph:

1. Select a graph.

2. From the Display menu, select Show Markers (if they are not already

displayed), then position them as needed.

3. From the Display menu, select Show Horizontal/Vertical Histogram.

A check mark will appear next to the menu item.

OR:

Right-click on a graph and select Show Markers, then right-click on the

graph again and select Horizontal/Vertical Histogram.

To remove the histogram from a graph:

1. Select a graph.

2. From the Display menu, select Show Horizontal/Vertical Histogram

again to clear the menu item, or select Hide Markers.

OR:

Right-click on a graph and select Horizontal/Vertical Histogram to clear

the menu item, or select Hide Markers.

Optical Modulation Analyzer 61

Page 70

Viewing and Analyzing Results

Data measurement window

(lower and upper bounds)

Symbol period

Tra nsit ions

40 % 60 %

Sample QPSK (NRZ)

Distinguishing Data Points from Transitions

Distinguishing Data Points from Transitions

You can display “real data points” in white on all graphs simultaneously to

distinguish them from other points, called “transitions”. It allows you to

rapidly see if data points are where they should be (a point in the transition

path would be considered as an error).

Data points are determined using a measurement window, which is a time

range that you define as a percentage of the symbol period, as shown

above. The following default values are set according to standards:

Available Range NRZ Default RZ Default

Lower bound 0 – 100 % 40 % 47.5 %

Upper bound 0 – 100 % 60 % 52.5 %

With data points highlighted in white, the application allows you to hide (or

show) transition points, on the constellation chart only.

Note: You cannot modify the display of data points and transitions when graphs

are shown in Color Grade mode or when averaging is set (see Using

Averaging to Improve Results on page 70).

62 PSO-200

Page 71

Viewing and Analyzing Results

Distinguishing Data Points from Transitions

To highlight data points in white:

From the Display menu, select Highlight Data Points. Clear the option to

remove the color.

Note: This feature will have an effect on all applicable graphs at once.

To hide or show transitions (constellation chart only):

Right-click on the graph, then select Hide Transitions (or Show

Transitions).

OR:

1. Select the constellation chart.

2. From the Display menu, select Hide Transitions (or Show

Transitions).

To modify the data measurement window:

1. From the Settings menu, select Acquisition.

2. Under the Analysis tab, set the lower and upper bounds of your

measurement window, as a percentage of the bit period.

3. Click Apply to confirm your settings, or OK to also close the window.

Optical Modulation Analyzer 63

Page 72

Viewing and Analyzing Results

Eye EVM maskEye intensity maskConstellation mask

Using Pattern Masks

Using Pattern Masks

You can display masks on graphs to test signal quality and perform a quick

pass/fail verification of signal compliance to applicable standards. Masks

are used to determine whether a sampling point fits in the normal pattern

or not; points considered “in error” can optionally be highlighted in red.

There are three available mask types, as illustrated below:

Intensity mask: consists of upper and lower zones and a center

polygon. Data points and transition points inside these areas are

considered as errors.

Constellation mask: consists of a circular area around each symbol.

Data points outside the circle are considered as errors.

EVM mask: consists of a single polygon area. Data points and transition

points inside the polygon are considered as errors.

64 PSO-200

Page 73

Viewing and Analyzing Results

Using Pattern Masks

The following standard masks are provided with the application:

IEEE G.802.3ba ITU G.959.1 Other

40-100 LR (large ratio) NRZ 10G 1310 nm RZ 40G custom

40-100 SR (small ratio) NRZ 10G 1550 nm

NRZ 40G

Note: When an acquisition file contains masks, you can view their settings in the

Current Acquisition Information window.

Activating and Displaying Masks

When masks are activated, measurement tables can include hit test results

(hit counts and hit ratios). Values are computed the same way as BER/SER

(one per polarization, total and per burst). See how to display these results

or not in Using the Measurement Tables on page 56.

Note: Masks are not available when Averaging is active and cannot be applied on

averaged data.

Optical Modulation Analyzer 65

Page 74

Viewing and Analyzing Results

Using Pattern Masks

To activate and select masks:

1. From the Settings menu, select Acquisition.

2. Under the Analysis tab, select the desired mask types and masks.

The drop-down lists correspond to available mask definition files,

either provided with the application or custom-made.

3. Click Apply to confirm your settings, or OK to also close the window.

Note: The eye period is automatically set to 1 (and cannot be changed) when an

intensity or EVM mask is active, no matter if masks are actually shown.

To show or hide masks on the graphs:

1. From the Display menu, select Masks > Show/Hide Masks.

2. Optionally select Highlight points in masks in the same menu. Points

in error will be displayed in bright red.

Note: You can show or hide masks at any time, even while an acquisition is in