USER AND SERVICE MANUAL

FOR EXE-RISE CHAIN HOIST

250/500/1000/2000 kg

D8 (DC/LVC)

150/300/600/800/1200 kg

D8+ (DC/LVC)

EXCLUSIVELY DISTRIBUTED BY

LITEC ITALIA S.R.L.

Via Martin Luther King 70, I-31032 Casale sul Sile (TV), Italy

Tel: +390422997300 Fax: +390422997399

www.exetechnology.com

www.litectruss.com

[ORIGINAL INSTRUCTION]

2 / 64

MANUFACTURER IDENTIFICATION

RWM S.R.L.

Sede Legale: Via Bartolomeo Colleoni 80/7, 36034 Malo (VI), Italia

Sede Operativa: Via della Tecnica 15, 36034 Molina di Malo (VI), Italia

Tel: +39 0445 637 002 – Fax: +39 0445 637 019

www.rwmitalia.com

Retain this manual for future reference and use.

Forward this manual to the chain hoist operator and maintainer.

Should you have any questions or have problems with this product, please call RWM S.r.l..

Check the EXE website for the latest version of the manual or the manual related to the year of purchase

of your hoist.

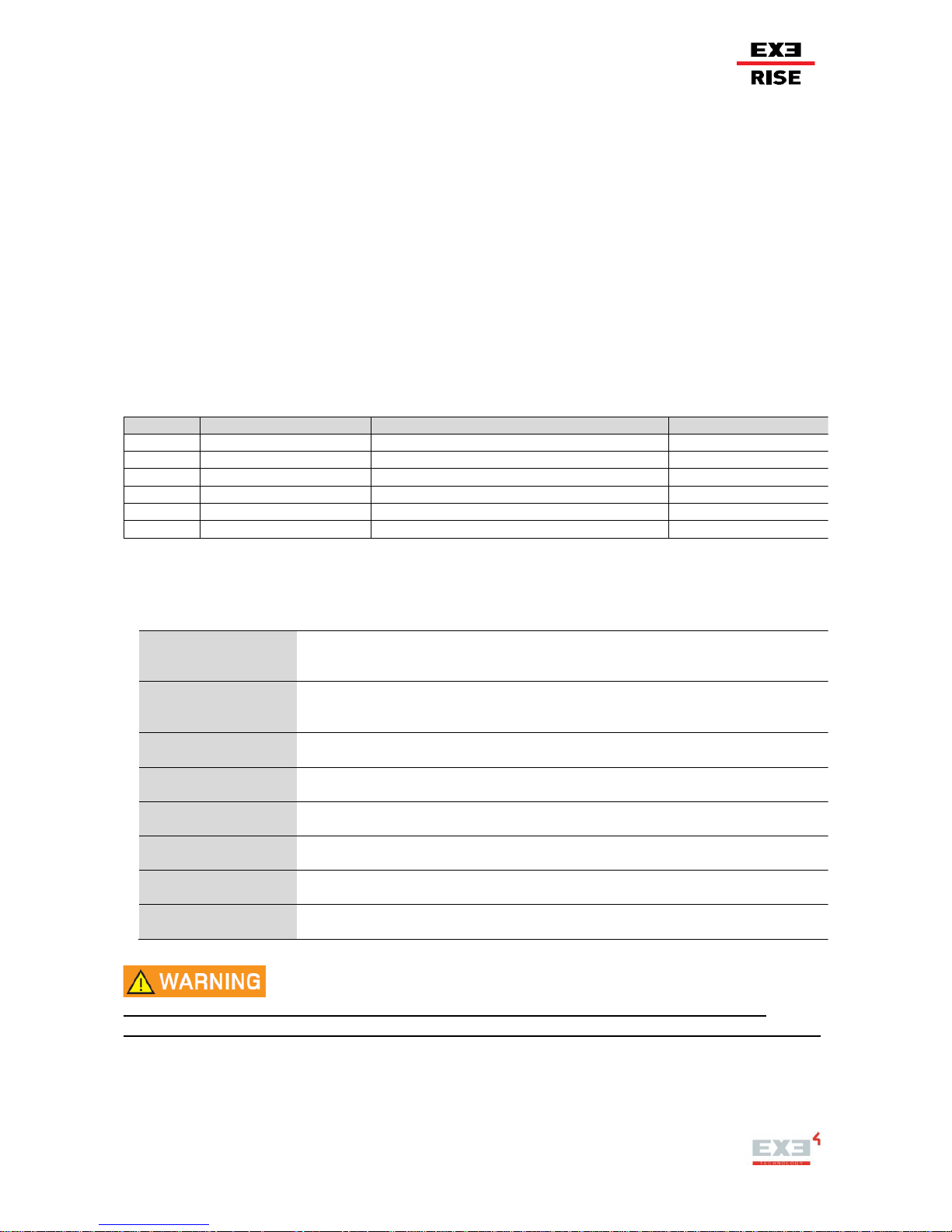

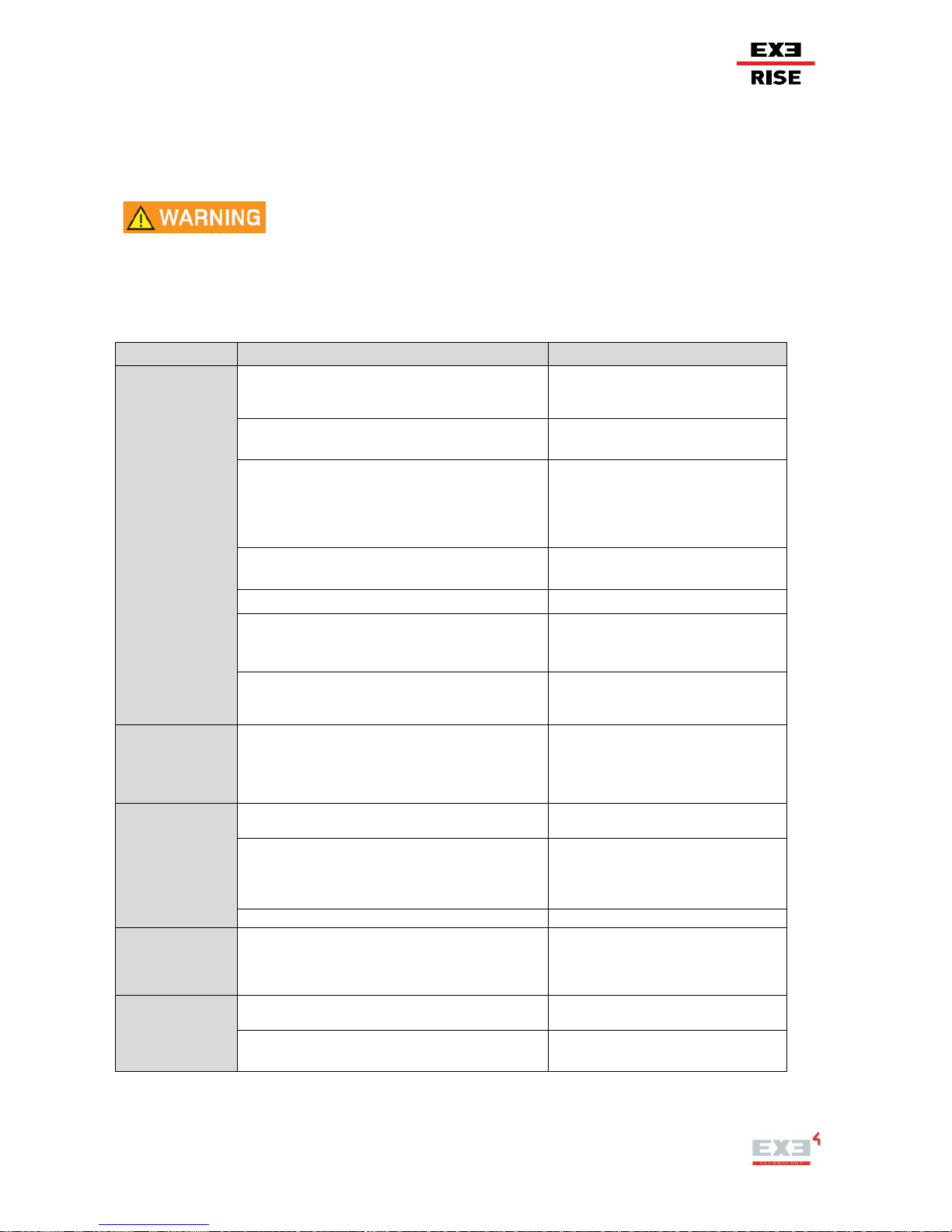

Before using the hoist, please fill in the following information (referred to the hoist identification plate).

Such information must be communicated every time that the RWM S.r.l service department or your local

distributor is contacted. If you are in doubt or need any further information, please contact us.

Customer Name

and address (1)

Customer Name

and address (2)

Model number

Instructions for use

Serial number

Purchase date

Voltage

Nominal capacity

Revision

Modifications

Description

Issue Date

01

All manual

First issue in according to Machine Directive 2006/42/CE

29/11/2017

02

All manual

Update information

28/02/2018

Do not use a chain hoist before all operators have carefully read this manual.

Failure to operate the equipment as here described may cause injury or even death.

3 / 64

CONTENT

CONTENT OF FIGURES................................................................................................................................................ 5

CONTENT OF TABLE ..................................................................................................................................................... 6

1. GENERAL INFORMATION ................................................................................................................................... 7

1.1 MANUAL SCOPE ........................................................................................................................................... 7

1.2 CHAIN HOIST IDENTIFICATION ................................................................................................................ 8

1.3 SAFETY SIGNAL ........................................................................................................................................... 9

1.4 TERMS AND DEFINITIONS ......................................................................................................................... 9

1.5 REPAIRING – REPLACEMENT – WARRANTEE POLICY .................................................................. 10

1.6 DOCUMENTATION...................................................................................................................................... 12

2. SAFETY INFORMATION ..................................................................................................................................... 13

2.1 GENERAL SAFETY WARNING ................................................................................................................. 13

2.2 SAFETY WARNING FOR USE AND MAINTENANCE .......................................................................... 13

2.3 SAFETY WARNING FOR INSTALLATION, ASSEMBLY AND DISASSEMBLY ................................ 15

2.4 SAFETY WARNING FOR INCORRECT USE ......................................................................................... 16

2.5 SAFETY WARNING FOR RESIDUAL RISKS ......................................................................................... 17

2.6 SAFETY WARNING FOR ELETRICAL CONNECTION .......................................................................... 18

3. EXE-Rise CHAIN HOIST INFORMATION ......................................................................................................... 19

3.1 GENERAL DESCRIPTION ......................................................................................................................... 19

3.2 IDENTIFICATION ......................................................................................................................................... 20

3.2.1 Type of Control ..................................................................................................................................... 21

3.3 COMPONENTS DESCRIPTION ................................................................................................................ 23

3.3.1 Chain ..................................................................................................................................................... 24

3.3.2 Hook ....................................................................................................................................................... 25

3.3.3 Chain Bag Bracket ............................................................................................................................... 27

3.3.4 Chain Stop ............................................................................................................................................ 27

3.3.5 Quick Link – Quick link ........................................................................................................................ 27

3.3.6 Chain Guide Plate ................................................................................................................................ 28

3.3.7 Plugs and Socket ................................................................................................................................. 29

3.3.8 Brake ..................................................................................................................................................... 29

3.3.9 Limit switch ................................................................................................................................................. 30

3.3.10 Chain Bag ................................................................................................................................................ 30

3.3.11 Bolts and nuts ............................................................................................................................................ 31

3.3.12 EXE-Rise Chain Hoist Controllers ..................................................................................................... 32

3.4 SAFETY DEVICE ......................................................................................................................................... 33

3.4.1 Primary Safety Component ................................................................................................................ 33

4 / 64

3.4.2 Secondary Safety Component ........................................................................................................... 34

3.4.3 Safety Conditions ................................................................................................................................. 35

3.5 TECHNICAL DATA ...................................................................................................................................... 36

3.6 EXE-Rise DRAWING ................................................................................................................................... 39

4. HANDLING AND INSTALLATION ...................................................................................................................... 41

4.1 HANDING & TRANSPORTATION ............................................................................................................. 41

4.2 TRANSPORT AND STORAGE .................................................................................................................. 42

4.2.1 Packaging storage ............................................................................................................................... 42

4.2.2 Unpacking and ground handling of the hoist ................................................................................... 42

4.3 SUSPENDING THE HOIST ........................................................................................................................ 43

4.3.1 Mounting the hoist “motor-down” (self-climbing mode) .................................................................. 43

4.3.2 Mounting the hoist in “motor-up“ position ......................................................................................... 43

4.4 ELECTRICAL CONNECTIONS................................................................................................................. 44

5. USE ......................................................................................................................................................................... 45

5.1 ATTACHING AND MOVING THE LOAD .................................................................................................. 46

5.2 LOWERING AND DISCONNECTING THE LOAD .................................................................................. 46

5.3 LIMIT SWITCH SETTING AND REPLACEMENT ................................................................................... 47

5.4 TURN 1000kg SINGLE REEVE IN 2000kg DOUBLE REEVE ............................................................. 47

6. INSPECTIONS ...................................................................................................................................................... 49

6.1 INITIAL AND EACH ASSEMBLY INSPECTION AND CONTROLS ..................................................... 49

6.2 FREQUENT AND PERIODICAL INSPECTION ....................................................................................... 50

6.2.1 Chain Inspection .................................................................................................................................. 51

6.2.2 Hook Inspection ................................................................................................................................... 53

6.2.3 Chain Bag Inspection .......................................................................................................................... 53

6.3 PERIODICAL CONTROLS ......................................................................................................................... 53

6.4 EXTRAORDINARY INSPECTION ............................................................................................................. 54

7. MAINTENANCE AND REPAIR ........................................................................................................................... 55

7.1 CHAIN MAINTENANCE .............................................................................................................................. 55

7.1.1 Cleaning Chain ..................................................................................................................................... 55

7.1.2 Lubrication of Chain ............................................................................................................................. 55

7.2 BRAKE AND LIMIT SWITCH MAINTENANCE / ADJUSTMENT .......................................................... 56

7.3 CLUTCH AND GREAR BOX MAINTENANCE / ADJUSTMENT .......................................................... 57

7.4 TROUBLESHOOTING ................................................................................................................................. 57

8. SPARE PART ........................................................................................................................................................ 59

9. DEMOLITION AND DISPOSAL .......................................................................................................................... 62

10. DECLARATION MODELS ............................................................................................................................... 63

5 / 64

CONTENT OF FIGURES

Figure 1

Example of EXE-Rise chain hoist plate

8

Figure 2

EXE-Rise chain hoist parts

19

Figure 3

EXE-Rise chain hoist serial number

20

Figure 4

EXE-Rise chain hoist 2000 kg DC principal components

23

Figure 5

Chain dimensions

24

Figure 6

Chain identification

24

Figure 7

Lift chain hook with safety latch” D8 250 kg and D8+ 150 kg - D8 500 kg and D8+ 300kg

25

Figure 8

“Lift chain hook with safety latch” D8 1000 kg and D8+ 600 kg

25

Figure 9

“Lift chain hook with safety latch” D8 2000 kg and D8+ 1200 kg

26

Figure 10

Example of Body Swivel Hook

26

Figure 11

Chain stop

27

Figure 12

Chain bag – bracket Quick Link dimensions

27

Figure 13

End chain – bracket Quick Link dimensions

28

Figure 14

External Chain Guide Plate

28

Figure 15

Plugs and Socket

29

Figure 16

Double brake version

29

Figure 17

Brake Features

29

Figure 18

Limit Switch large medium and body

30

Figure 19

Chain bag

31

Figure 20

Example of securing a load suspended from a tower by means of a locking bar

34

Figure 21

Example of secondary safety component attached directly to the load that is being lifted

(front view)

34

Figure 22

Example of secondary safety component attached directly to the load that is being lifted

34

Figure 23

Example of secondary safety component attached below the hoist, bypassing the hoist

lifting mechanism (front view)

35

Figure 24

Example of secondary safety component attached below the hoist, bypassing the hoist

lifting mechanism (perspective view)

35

Figure 25

EXE-Rise DRAWING: 250kg D8 DC/LVC and 150kg D8+ DC/LVC

39

Figure 26

EXE-Rise DRAWING: 500kg D8 DC/LVC and 300kg D8+ DC/LVC

39

Figure 27

EXE-Rise DRAWING: 1000kg D8 DC/LVC and 600kg D8+ DC/LVC

40

Figure 28

EXE-Rise DRAWING: 2000kg D8 DC/LVC and 1200kg D8+ DC/LVC

40

Figure 29

EXE-Technology package label

41

Figure 30

EXE-Rise motor up e down

43

Figure 31

Reversing of barycentre

47

Figure 32

Required Components

47

Figure 33

Removing the Frame Block

48

Figure 34

Replacement of the Chain hook

48

Figure 35

Re-applying of the frame block

48

Figure 36

External chain guide plate

52

Figure 37

Brake components

57

Figure 38

Spare Part of D8 250kg DC/LVC and, D8+ 150kg DC/LVC

59

Figure 39

Spare Part of D8 500kg DC/LVC and, D8+ 300kg DC/LVC

60

Figure 40

Spare Part of D8 1000kg DC/LVC, D8 2000kg DC/LVC and D8+ 600kg DC/LVC, D8+

1200kg DC/LVC

61

6 / 64

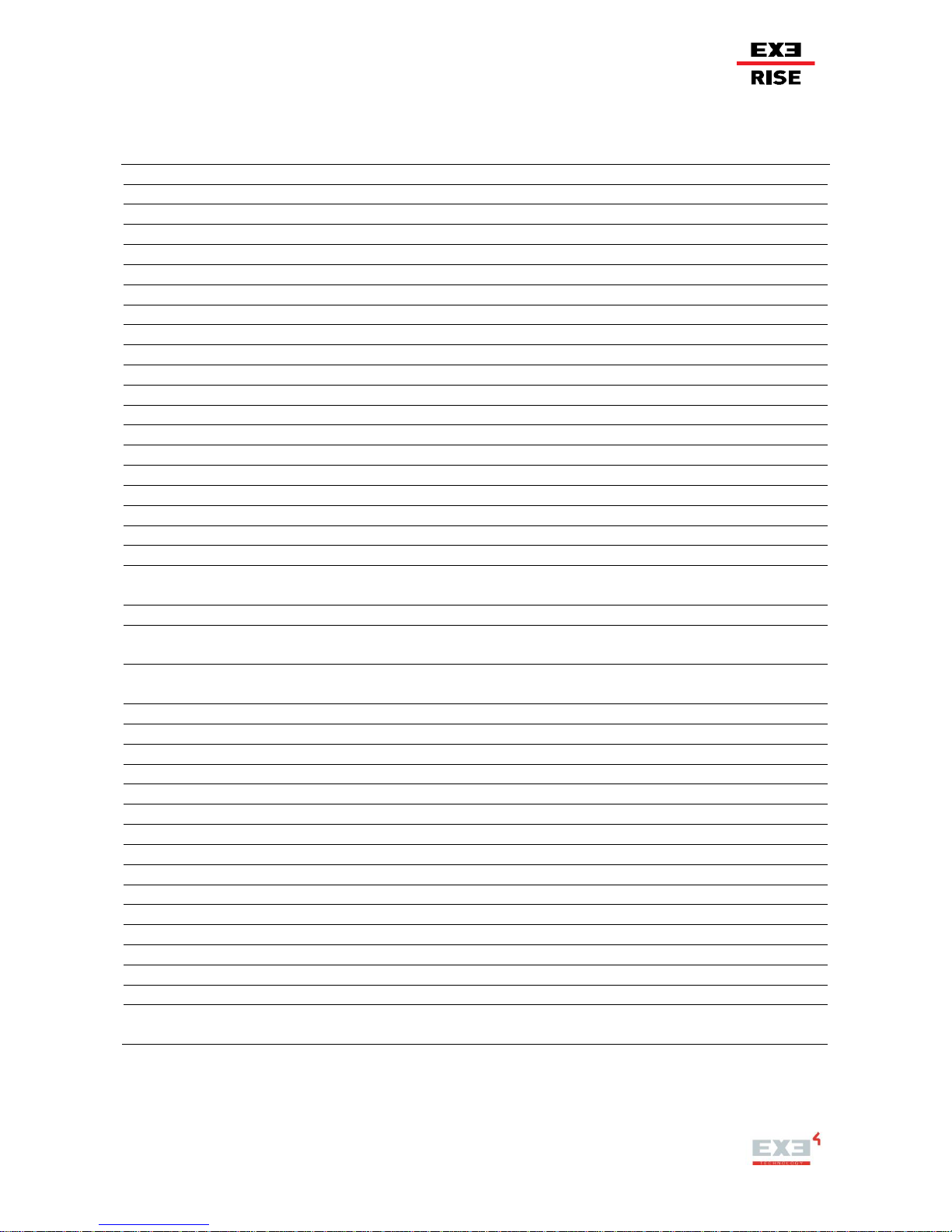

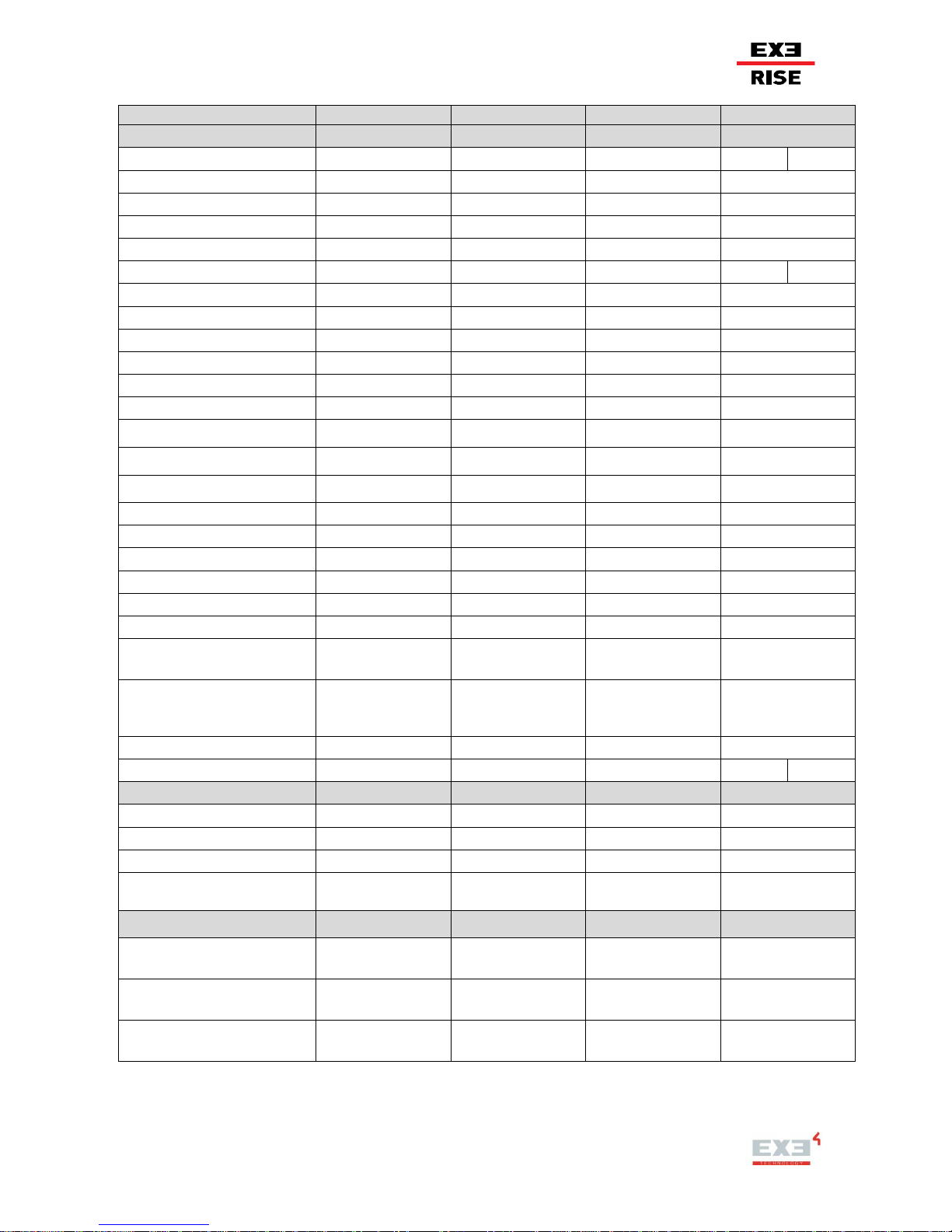

CONTENT OF TABLE

Table 1

Residual risks

18

Table 2

Relation between power and lengths of cable

18

Table 3

EXE-Rise chain hoist parts

19

Table 4

EXE-Rise chain hoist identification

20

Table 5

Selection criteria for electric chain hoists for moving and holding loads above people

21

Table 6

FEM Classification

21

Table 7

Average operating time per day in hours

22

Table 8

Chain measures

24

Table 9

Chain technical data

24

Table 10

Chain stop code

27

Table 11

Chain bag – bracket Quick Link technical data

27

Table 12

End chain – bracket Quick Link technical data

28

Table 13

Brake technical data

30

Table 14

Chain bag characteristic

30

Table 15

Chain bag dimensions

31

Table 16

Chain bag size

31

Table 17

Bolts

31

Table 18

Plug wiring

44

Table 19

Socket wiring

44

Table 20

Minimum frequent inspections

50

Table 21

Minimum periodic inspections

51

Table 22

Troubleshooting based on hoist behavior

58

Table 23

Spare Part of D8 250kg DC/LVC and, D8+ 150kg DC/LVC

59

Table 24

Spare Part of D8 500kg DC/LVC and, D8+ 300kg DC/LVC

60

Table 25

Spare Part of D8 1000kg DC/LVC, D8 2000kg DC/LVC and D8+ 600kg DC/LVC, D8+

1200kg DC/LVC

61

7 / 64

1. GENERAL INFORMATION

Thank you for choosing an EXE-Rise chain hoist.

1.1 MANUAL SCOPE

Scope of manual is to inform operator about properly install, operate of chain hoist to prevent and minimize

risks during the man-machine interaction. In addition, the manual contains also information confidential to the

maintainer to perform maintenance work.

Follow all instructions and signs for inspecting, maintaining and operating this chain hoist. The use of any

chain hoist presents risk of personal injury or property damage. That risk is greatly increased if proper

instructions and warnings are not followed.

Before using this chain hoist, each operator should become thoroughly familiar with all warnings,

instructions, and recommendations in this manual. To carry out these operations, all safety rules specified

therein must be followed. Should some passages not be clear, please contact RWM S.r.l.

The manual should be adhered to and followed to ensure safe, reliable and correct function of the product, in

order to eliminate the possibility of any damage to persons or equipment.

For health and safety reasons people operating, assembling, disassembling, transporting and maintaining

the chain hoist should wear adequate Personal Protection Equipment like, but not limited to, gloves, noise

protection, hard hats and safety shoes.

This manual and the other documents contained in the packing are an integral part of the supply, and must

be carefully kept for the lifecycle of the hoist. You should keep this manual clean, complete and in a legible

condition for future references. They must follow the hoist in case of transfer to any other user or new owner.

The information reported in this document refers solely to care and maintenance of a single chain hoist; that

is to say, the “rigging” process and they way to control the hoist is not covered by this manual.

It is the sole responsibility of the client to check with local authorities if the legislation used by EXE-Rise

chain hoist is acceptable in the country of use.

Please make sure manuals are available at all times for all users and employees. The operator is

responsible for supervising all personnel involved and ensuring they are aware of the hazards and safety

implications of working with the electric chain hoist.

8 / 64

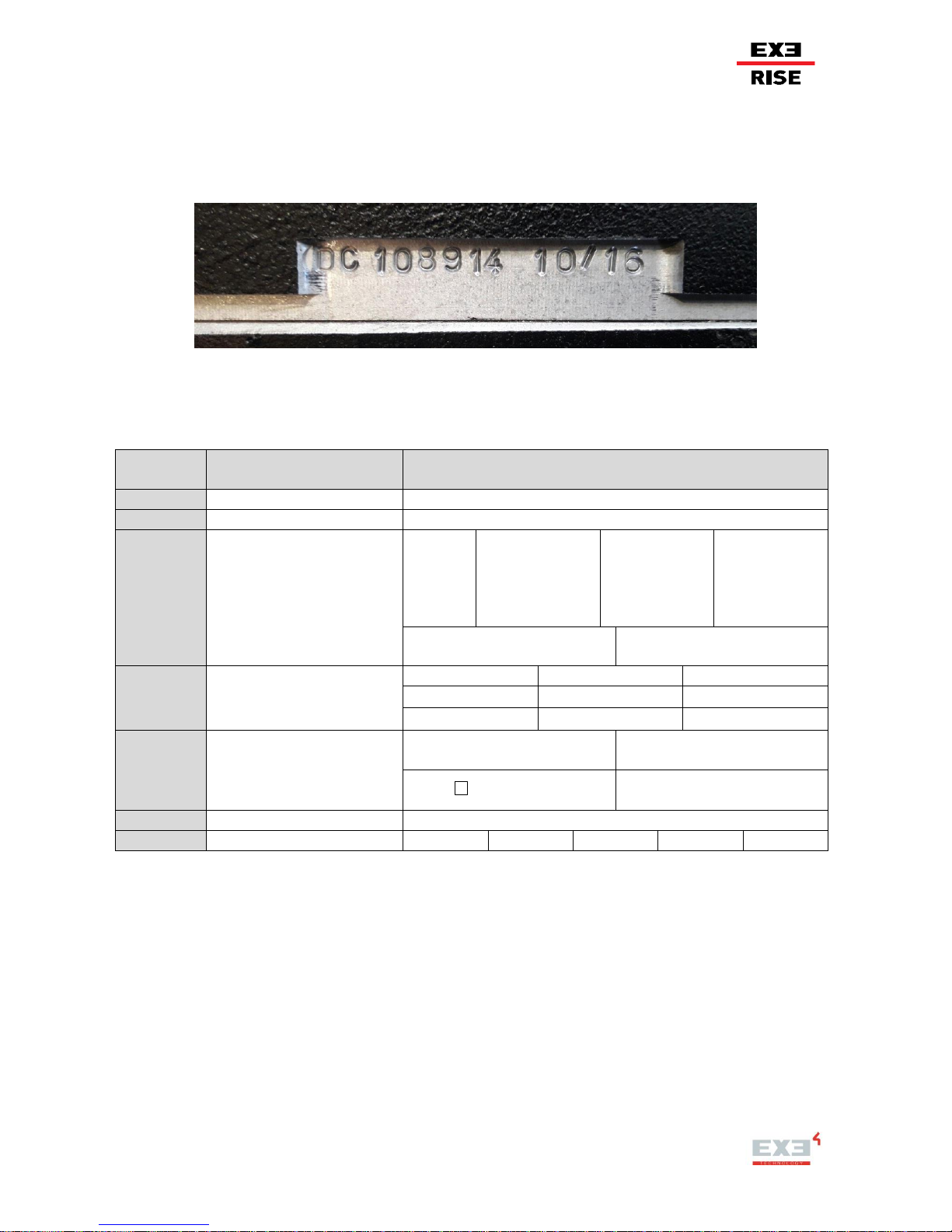

1.2 CHAIN HOIST IDENTIFICATION

EXE-Rise chain hoists are marked on the body by an aluminium plate visibly, legibly and indelibly with

dimensions 90x90 mm and thickness 0.8 mm.

Figure 1 “Example of EXE-Rise chain hoist plate”

The title of plate contains the business name and full address of the manufacturer, designation of the

machinery and website. The body of plate contains:

- Model: commercial name, model and type of machinery;

- Working Load Limit (WLL): the maximum working load designed by the manufacturer;

- Working speed: units of measure “m/min” and “ft/min”;

- Motor power: units of measure “kW”;

- Power supply: operating voltage;

- Brake: number of brakes;

- Years of construction;

- IP Rating code: International Protection Rating (first digit is the solid protection and second digit is the

liquids protection);

- FEM class: European Federation of Materials handling and safety Factor;

- Chain size: units of measure “mm” in according to EN DIN 818-7

- Serial number;

- Safety Factor (SF) and Double Brake: this information is included in a square;

- Warning: Before opening or maintaining a hoist, turn the power supply off. Keep the chain

properly lubricated. Do not lift people. Do not lift over people. Do not lift more than WLL

(Working Load Limit). Failure to comply may lead to serious injury or death.

The plate is in English language. In others languages, the translation is present only in this manual.

9 / 64

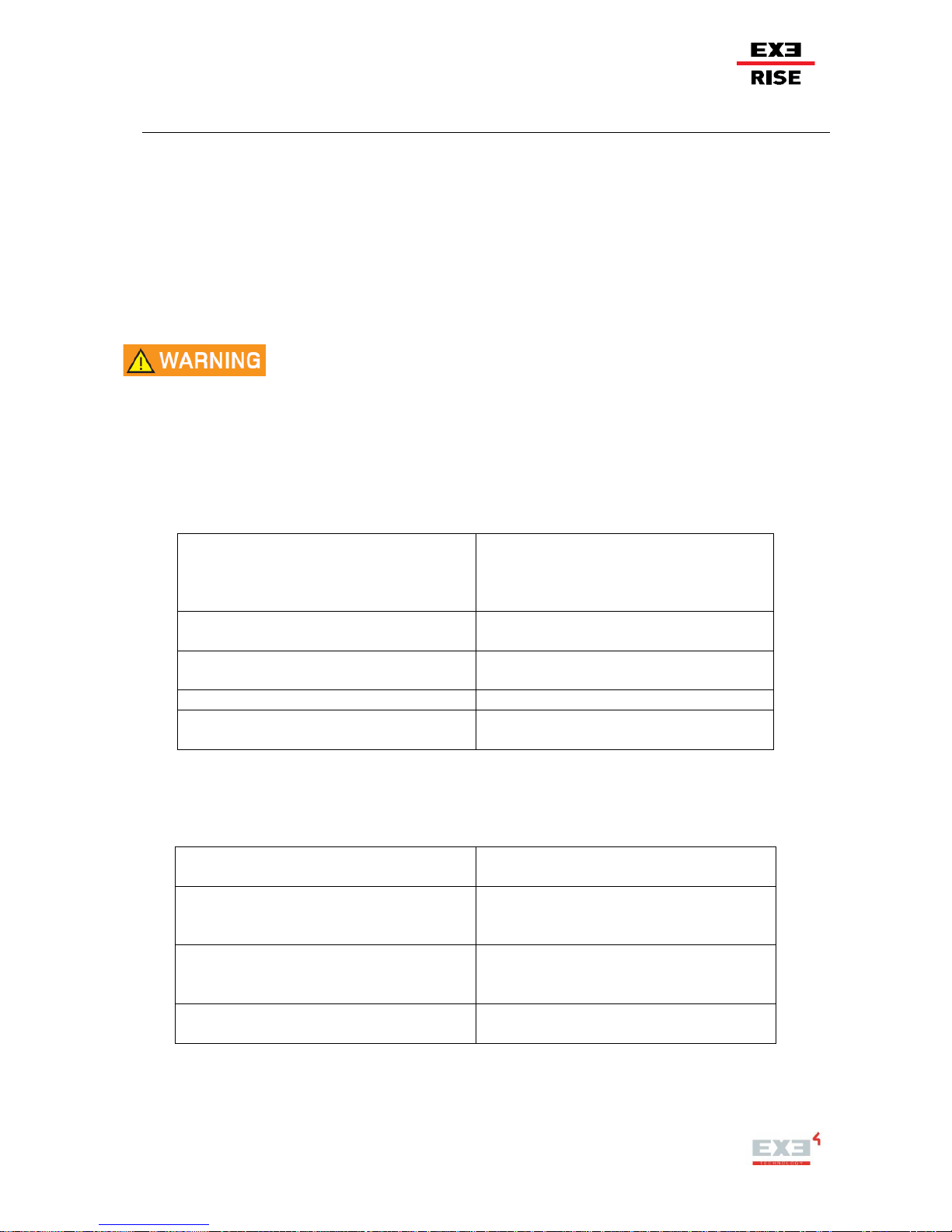

1.3 SAFETY SIGNAL

The present manual contains different safety signal to individuate and to point out precautionary statements.

The safety signals are sentences providing information on potential hazards, and proper procedures, as is

provided below:

DANGER: indicates a hazardous situation which, if not avoided, will result in death or serious injury. This

signal word is to be limited to the most extreme situations.

WARNING: indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE: address practices not related to personal injury.

SAFETY INSTRUCTIONS: is used to list steps, procedures or instructions that might otherwise constitute a

DANGER, WARNING or CAUTION notification. Note that equivalent phrases, such as SAFE OPERATION

PROCEDURES or SAFE SHUT DOWN PROCEDURE, can be used in place of the words “SAFETY

INSTRUCTIONS.“

1.4 TERMS AND DEFINITIONS

Operator: it is intended a person who, by virtue of training and professional experience, has a specific

competence in the field of safety and mechanical equipment and is familiar with the related national rules on

health protection and safety at work and with the rules of good technical practice (technical regulations

issued by the Country in which the hoist is used). The expert must be able to verify the safety and

mechanical equipment and give the related evaluation.

Maintenance: a combination of all technical and administrative actions, including supervision actions,

intended to maintain or restore an entity in a state where they can perform the required function.

Maintainer: personnel authorized to perform maintenance

Lifting Machinery: also known as lifting gear, is a general term for any equipment that can be used to lift

loads. This includes jacks, block and tackle, hoists, rotating screws, gantries, A frames, gin poles, shear legs,

sheerleg, windlasses, lifting harnesses, fork lifts, hydraulic lifting pads, air lift bags, and cranes.

10 / 64

1.5 REPAIRING – REPLACEMENT – WARRANTEE POLICY

REPAIRING AND REPLACEMENTE POLICY

The hoist has been checked and performance verified by RWM S.r.l. or one of its authorised service agents

before shipping.

If the correctly maintained hoist should present a performance problem due to faulty material or

workmanship, after inspection by RWM S.r.l. or authorised agent, repairing or replacement of the unit will be

made free of charge in favour of the original purchaser.

This repairing/replacement policy only applies to installed, under maintenance and operating Hoists, as

highlighted in this manual and does not include the parts subject to normal wear and tear, misuse, improper

installation, inadequate and incorrect maintenance, the effects of hostile environments and unauthorised

repairing/modifications.

The manufacturer and dealers cannot accept responsibility for any damage or lack of functionality due to the

following situations:

- carrying out inappropriate operations for an electric chain hoist;

- product modification without the express authorization of the manufacturer;

- inappropriate operation of the hoist;

- operational errors;

- failure to use the product as stated in the manual.

RWM S.R.L. DECLINES LIABILITY FOR ANY DAMAGES ARISING FROM A NON-COMPLIANT

INSTALLATION AND MAINTENANCE INDICATED IN THIS DOCUMENT.

WARRANTY POLICY

1. For a period of 12 month we undertake to repair, free of charge any damage attributable to faulty

materials or workmanship, provided that the appliance is forwarded, freight paid, to our works or one of

the EXE contract service organisations.

2. The guarantee-period begins with the day of the delivery, proven by a purchase receipt like an invoice

or delivery note or their copies.

3. The guarantee only is applicable for new equipment.

4. The guarantee does not cover damage due to transport damage, negligent handling, overload or parts

subject to normal wear and tear. Nor damages that originate from a case of misuse because of nonobservance the instructions in this manual.

5. Warrantee also does not include the cost to be made to get access to a hoist in case it is built in. It is

the users sole responsibility that hoist can be inspected and service in a normal manner and in places

accessible for persons and their equipment.

6. 6The fitting of replacement parts not supplied by us or modifications of our design by third parties also

invalidates the guarantee.

7. Guarantee repairs do not renew nor extend the guarantee-period.

8. In case of a claim under the guarantee, a malfunction or spare part requirements please contact your

point of sale or EXE

The complete chain hoist comes with a 12 month manufacturer’s limited warranty from the date of purchase.

A 24-month warranty covers the mechanicals parts excluding electrical and wear parts (brake disc, pendant

with cable, safety catch, plastic box, chain bag ).

11 / 64

WARRANTY LIMITATIONS, REMEDIES AND DAMAGES

This warranty does not apply where normal wear, abuse, improper or inadequate maintenance, eccentric or

side loading, overloading, chemical or abrasive actions, excessive heat, outdoor use without appropriate

measures or unauthorised modifications or repairs cause deterioration of the hoists. This warranty does not

apply to products which RWM S.r.l. has determined to have been misused or abused, connected to voltages

other than those recommended, improperly maintained by the user, or where the malfunction or defect can

be attributed to the use of non-genuine RWM S.r.l. parts.

This expressed warranty is in lieu of all other warranties, expressed or implied, of marketing, fitness for a

particular purpose, or in any other manner, no promise or assertion of fact declared by any vendor’s agent or

representative shall constitute a vendor’s warranty or shall determine any liability or obligation.

The vendor guarantees that at the delivery date to the forwarding agent the goods are free from defects in

workmanship and materials. The sole obligation of possible breach of the warranty or contract for negligence

or in any other manner concerning the goods sold, shall be exclusively limited to repair or replacement, f.o.b.

vendor’s shipping point of any part that the vendor determines to be faulty, or, should the vendor determine

that such repair or replacement cannot be undertaken, to a reimbursement of the purchase price upon return

of the goods to the vendor.

Any action against the vendor for breach of contract, negligence or others must be initiated within one year

from the occurrence of such trial action.

No claim for damages to the vendor for any defects of the goods shall be deemed valid or applicable without

the written notification of the purchaser if it is not received by the vendor within one year from the shipping

date.

The vendor is not liable for any damage, injury or loss due to improper use of the goods if, before such

damage, injury or loss, such goods are (1) damaged or used in an improper manner following the delivery of

the vendor to the forwarding agent (2), not serviced, inspected or used in compliance with the applicable

laws and vendor’s written instructions and advices; or (3) installed, repaired, tampered or modified without

compliance with such law, instructions or advices. Under no circumstance the vendor shall be liable for

accidental or consequential damages since these terms are defined in section 2-715 of the uniform

commercial code.

COMPENSATION AND USE UNDER SAFETY

The purchaser must follow and request his labour force to follow the provisions indicated in the instructions

and manuals supplied by the vendor, and must use them and request his labour force to follow such

instructions and manuals and take suitable care in the maintenance of such products. The purchaser must

not remove, or allow anyone to remove, any warning plates or instructions on the product. In the event of

personal injury or damages to property or the Company resulting from the use of the product, the Purchaser

must give a written notification of such injury or damage to the vendor within 48 hours.

The Purchaser must cooperate with the Vendor in the inquiries on such injury or damage and in defence of

any claim for damages.

If the Purchaser fails to follow this section or if the injuries or damages are caused, totally or partially, by the

Purchaser‘s non-observance of the federal or state laws on safety, the Purchaser must indemnify and keep

harmless the Vendor from any claim, loss or expense for injuries or damages connected to the use of the

product.

12 / 64

1.6 DOCUMENTATION

The manual is integral part of EXE-Rise chain hoist and it contains the following documents attached:

- Declaration of conformity of EXE-Rise chain hoist;

- Declaration of conformity of chain;

- Declaration of conformity of hook;

- Wiring Diagrams;

- Data sheet of EXE-Rise chain hoist.

These documents are an integral part of the manual and they are an integral part of the hoist.

13 / 64

2. SAFETY INFORMATION

2.1 GENERAL SAFETY WARNING

Indicated below are the structural and environmental requirements that must be checked by the user for

guaranteeing safe use of the hoist:

The user is responsible for the construction method used for the set-up structure, the related load

capacity and the conditions of the suspension points arranged in the place of use. In addition to the risk

evaluation and operating procedures, project documentation (calculation reports, drawings, etc.) related

to such aspects, must also be prepared.

The set-up structure and the related elements involved (hoist anchoring point, hoist and related

accessories and the load thereof) must be able to bear the imposed loads (during the use of the load)

with a suitable safety factor. In the overall analysis, the dynamic forces must also be considered.

Use of the hoist under conditions other than those described, can result in accidents that may cause injuries

and/or material damages.

Check that the electrical supply system to be used is adequate and conforms to local standards.

Supplementary to the manual, the local statutory regulations governing general accident prevention and

environmental protection are to be enforced.

It is the sole responsibility of the client to check with local authorities if the legislation used by EXE-Rise

chain hoist is acceptable in the country of use.

Do not allow anyone under 18 years of age to operate the chain hoist.

STAY ALERT! Watch what you are doing and use common sense. Do not use the hoist when you are tired,

distracted or under the influence of drugs, alcohol or medication which may diminished control.

The employer has a duty to ensure that the operator has skills and knowledge to understand the contents of

this manual.

2.2 SAFETY WARNING FOR USE AND MAINTENANCE

The hoist can be used only and exclusively by authorised and qualified operator.

The operational parameters of the electric chain hoist also encompass compliance with the predefined

operating, service and maintenance requirements laid down by the manufacturer.

Chain hoists may only be used when in an acceptable technical condition, in accordance with their operating

parameters, by trained personnel in a safe and responsible manner.

14 / 64

The hoist must be used with a control system that meets local electrical safety regulations.

The operational parameters do not allow, but are not limited to:

- exceeding the defined load capacity

- any lateral load to be applied the hoist body

- any side pull to be applied the lift chain

- heaving, pulling or dragging the load

- standing beneath suspended and/or lifted loads

- transporting excessive loads

- pulling on the control cable

- failing to observe the load hook constantly

- failing to observe the load constantly

- running the chain over edges

- slack chain to occur which may cause the load to fall

- use at temperatures below -10° C or above +40° C

- use in an explosive environment.

Bumping operations shall be limited; ground mooring and driving against the limit switches should be

avoided. The manufacturer accepts no responsibility for damage to equipment and third parties ensuing from

such action.

Special attention shall be taken when hoists are used in or near aggressive environments (e.g. Salt water or

chloroform ). The aluminum and steel alloys used might not be particularly suitable for such environments.

Special attention to protect the chain shall be taken. A high level of lubricant as well as a proper condition of

the zinc layer helps to prevent the chain from becoming corroded. Do not allow anyone under 18 years of

age to operate the chain hoist.In addition to the instructions mentioned in this manual, the user must follow

the rules on accident prevention and safety that are in force in the country where the hoist is being used.

Follow these operating instructions:

Only competent persons are permitted to use the equipment. Make sure you are adequately trained.

Know your load before lifting! Make sure all loads exposed are considered. For example but not limited

to; Self-weight of the load to be lifted, Self-weight of the lifting equipment, the dynamic factor caused

by start and stopping of the hoist, point of gravity of the load and environmental influences such as

wind.

When preparing to lift a load, be sure that the attachments to the hook are firmly seated in hook

saddle. Avoid off centre loading of any kind, especially loading on the point of the hook.

Before lifting, check for twists in the load chain. On single reeved chain hoist used in conjunction with

head blocks and ground support systems, check for twists between the hoist and head block. Twisted

load can result in a jammed chain and damage to the hoist.

On double reeved units a twist can occur if the lower hook block has been upturned between the

strands of chain. The hook should be reversed to remove the twist from the chain before operation.

A safe way of storage in order to avoid turns in the chain is to run the lift hook back to the hoist body,

or secure the hook to a fixing point within its transportation case.

Warn personnel of your intention to lift a load. Make sure the only noise in the area is that of running

hoist. This way abnormalities can be detected easier. Use spotters at required position in order to

observe the lift.

In the event of any abnormal sound coming from the hoist, lifting should be ceased immediately and

the noise investigated by a competent person.

15 / 64

Secure the load with a secondary device before entering the area beneath the suspended load . or

use D8+ hoist with EXE-Load cells. Depending on local legislation and the outcome of a risk

assessment the hoist may be left without these precautions.

Take up a slack load chain carefully and start load gently to avoid shock and jerking of the hoist weight

chain. If there is any evidence of overloading, immediately lower the load and remove the excess load.

When lifting, raise the load only enough to clear the floor or support and check all attachments to the

hook and load are firmly seated and secure. Continue to lift only after you are certain all attachments

are in good order and the load is free from any obstructions.

Arrange periodic maintenance to ensure the hoist is functioning correctly and in accordance with this

document.

In general, use of the hoist with materials, adjustments or modifications not envisaged in this

document strictly is prohibited

Maintenance shall be solely executed by RWM S.r.l. authorised persons.

Keep the hoist clean and efficient by carrying out the suggested maintenance program.

Avoid “bumping” of a hoist. With bumping is meant frequently pressing the start and stop button to

adjust the hoist position.

Do not load hoist beyond the rated capacity. Overload can cause failure of some load-carrying part or

create a defect causing subsequent failure at less than rated capacity.

Working inside or near powered equipment can result in electric shock: before carrying out any work on

the hoist, always disconnect power supply and make sure that no one can insert the plug again until the

task is complete.

When possible, maintenance must be carried out without suspended load; failing this, the area must be

enclosed and monitored and the load must be held by means of a secondary safety component.

Do not clean the hoist using a pressure washing device.

Keep maintenance and test reports issued by RWM S.r.l. together with the manual.

All maintenance, repair, adjustment, cleaning operations must be carried out only by qualified personnel

duly trained and competent, who has fully read and understood this document.

Maintenance must be carried out in a safe area whilst using proper tools and safety equipment.

In case of poor ambient lighting, install a lamp for local lighting for maintenance interventions or use

adequate portable devices.

Replace any cable or wire with like for like items.

Use only spare parts identical to those to be replaced or previously authorised by the manufacturer.

Follow industrial hygiene rules during cleaning of the machine.

In the instance of maintenance work being carried out at height, please ensure the correct access

equipment is employed, and local safety regulations are taken into consideration.

No makeshift repairs with the aid of extra pieces or taping are allowed. It is prohibited to warm

equipment with flames, hot air or other instruments in case they are stiffened or blocked.

Always wait for parts to cool if the hoist has been running intensively before maintenance.

2.3 SAFETY WARNING FOR INSTALLATION, ASSEMBLY AND DISASSEMBLY

The hoist must be assembled and disassembled only by authorized and qualified operator. The necessary

qualifications for planning, assembly, disassembly, and activation, depend on the degree of risk and the

location and type of job.

Operator are required to provide current overload protection and grounding on the branch circuit section in

keeping with the code. Check each installation for compliance with the application, operation and

maintenance sections of these articles.

16 / 64

This manual gives the necessary information for safe installation, use, and maintenance in a generic working

environment. Since it is not possible to foresee all the risk conditions of the working environments in which

the hoist will be used, the person responsible for the management and supervision of the installation,

assembly and disassembly must produce their own specific risk assessment each time the hoists are used.

The hoist must be tested only by authorised and qualified operator. The person in charge of management

and supervision is liable to give his approval to the use of electric chain hoists. Such approval can only be

given on condition that the occurred carrying out of the tests is duly proved. Every possible transfer to other

users must be documented in writing.

The hoist is equipped with various guards and devices designed to prevent accidents and to ensure the

product complies with various safety standards.

2.4 SAFETY WARNING FOR INCORRECT USE

Do not lift people. Using the EXE-Rise chain hoist to carry people is strictly forbidden.

Do not use the hoist if it is damaged, malfunctioning, or functioning in an unusual way or exhibits

unusual or incorrect movement or anomalous noises.

Do not use the hoist if the chain is distorted, corroded, damaged, or worn out.

Do not make modifications nor apply accessories other than those provided by RWM S.r.l..

Accessories causing overstressing or leading to accidental unexpected overloads or limiting the free

handling of the load, are not allowed. Therefore only lifting accessories that interpose in a passive way

between the equipment and the load are allowed.

Do not try to lengthen the lifting chain or repair it if damaged.

Do not hit, deform, or crush the hoist chain; danger of cracks or broken links may occur.

Do keep the hoist and chain away from open fire or flame.

Do not use the lifting chain as sling and do not wrap the chain around the load.

Do not put tools or foreign bodies in the links of the chain.

Do not place the load on the point or on the spring latch of the hook.

Do not perform welding to any component.

Do not use the hoist if it is not perfectly efficient, even if it can still function.

Do not use the hoist with worn out, open hook or with missing spring latch.

Do not lift loads exceeding the maximum working load limit of the hoist (In Motor-down mode the self-

weight of the hoist should be taken into consideration. The self-weight of the hoist should be added to

your payload calculations).

Do not allow the load to swing or twist while lifting.

Do not lift the load above people or do not leave hanging loads without the operator’s control and

appropriate measures.

Do not use the hoist outdoors or anywhere with water jets or environmental conditions without adequate

protection.

The use in explosive, aggressive atmosphere or with high concentration of powders or oily substances

suspended in the air is prohibited. Electrical devices produce arcs or sparks that can cause a fire or

explosion.

Do not operate hoist at unusual extremes of ambient temperatures. The product is designed for use in

temperatures ranging between -10°C and +40°C.

It is prohibited to tamper with the hoist in order to modify its performances.

17 / 64

Do not remove or tamper with the protective and safety devices

Use of the hoist is prohibited to unauthorised operators who are not adequately trained in use of the

hoist and the associated dangers.

Do not use of the hoist outside the limits indicated in this document.

Make sure the chain is running straight into the hoist body. Any side pull will cause significant wear

and tear on the hoist.

Do not apply a lateral load to the body of the hoist.

Make sure the pick-up points are always in-line with the hoist. Any side pull will cause an increase in

loading on both the hoist and the structure.

2.5 SAFETY WARNING FOR RESIDUAL RISKS

Residual risks related to a machine are accident risks that remain after the carrying out of all the safety

measures taken by the manufacturer (and which therefore must be managed by the user).

The most serious residual risks are indicated on the hoists safety labels. These are as listed below (Table 1).

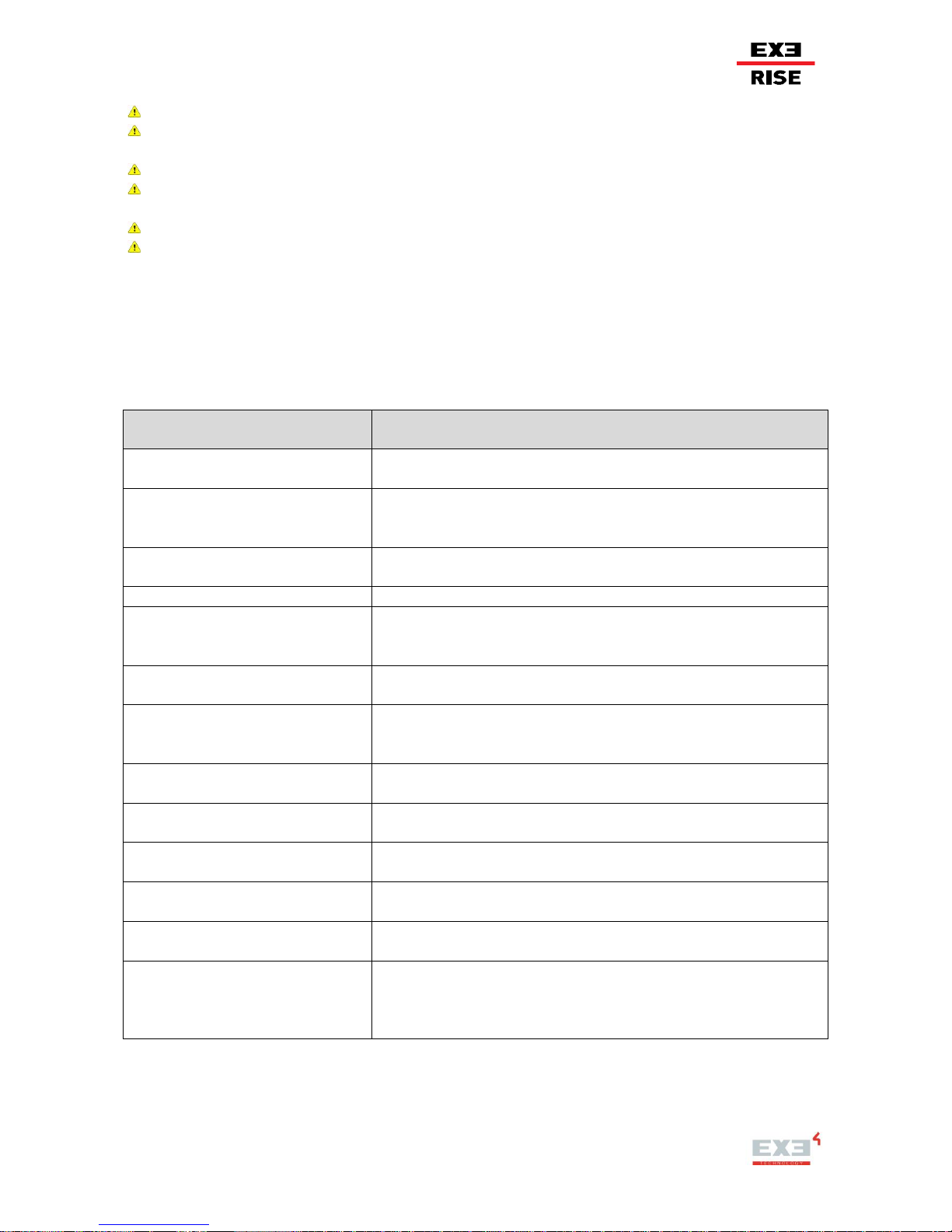

Residual risk, dangerous zone

and person exposed

Course of action to eliminate or reduce risk

Malfunction or falling load due to

overload

Do not exceed the hoist load limit

Various types of risks owing to the

wrong installation and use of the

hoist.

Read the instructions before installing or using the hoist

Fall risk to people being lifted by

the hoist

It is prohibited to lift people by means of the hoist

Damage to hoist due to dry chain

Chain should be kept lubricated

Risks of structural collapse

Check structure is able to support the proposed load. Check all

components in the lifting system are suitably rated and able to bear

the proposed load

Risk of injury from malfunction hoist

or manoeuvre error

Working area should be managed and access controlled

Fall risks (of the installer or

serviceman) from the load or

structure

Appropriate PPE should always be used. Climbing the load or

structures should be avoided if possible. When possible carry out all

maintenance at ground level

Various types of risks owing to the

illegibility of the labels

Do not remove or cover labels

Various types of risks owing to the

lack in periodical maintenance

Check that the annual periodical maintenance has been carried out.

Various types of risks when used in

severe weather conditions

Check the environment conditions before using the hoist.

Malfunctioning risks owing to wrong

power supply

Make sure that the power supply is the same as indicated on the

chain hoist plate.

Chain fall due to damaged chain

bag

Check bag for damage before use. Do not fill bag over 75%

capacity

Various types of risks owing to

(electrocution, malfunctioning, etc.)

non-sectioning before any

maintenance intervention.

Before any maintenance intervention, disconnect the power supply

from the hoist. Maintenance operations can be carried out only by

competent and authorised persons.

18 / 64

Residual risk, dangerous zone

and person exposed

Course of action to eliminate or reduce risk

Sudden start owing to the insertion

of the plug into a normal socket.

Do not insert the hoist power plug directly into a CEE socket. The

hoist may only be powered using suitable control devices, such as

EXE-DRIVE controllers. For low voltage controlled hoists, a

dedicated controller must be used with an UP/DOWN push-button

panel that complies with the wiring diagram provided.

Various types of risks owing to

tampering or removal of the safety

devices.

It is prohibited to tamper or remove the safety devices

Table 1: “Residual risks”

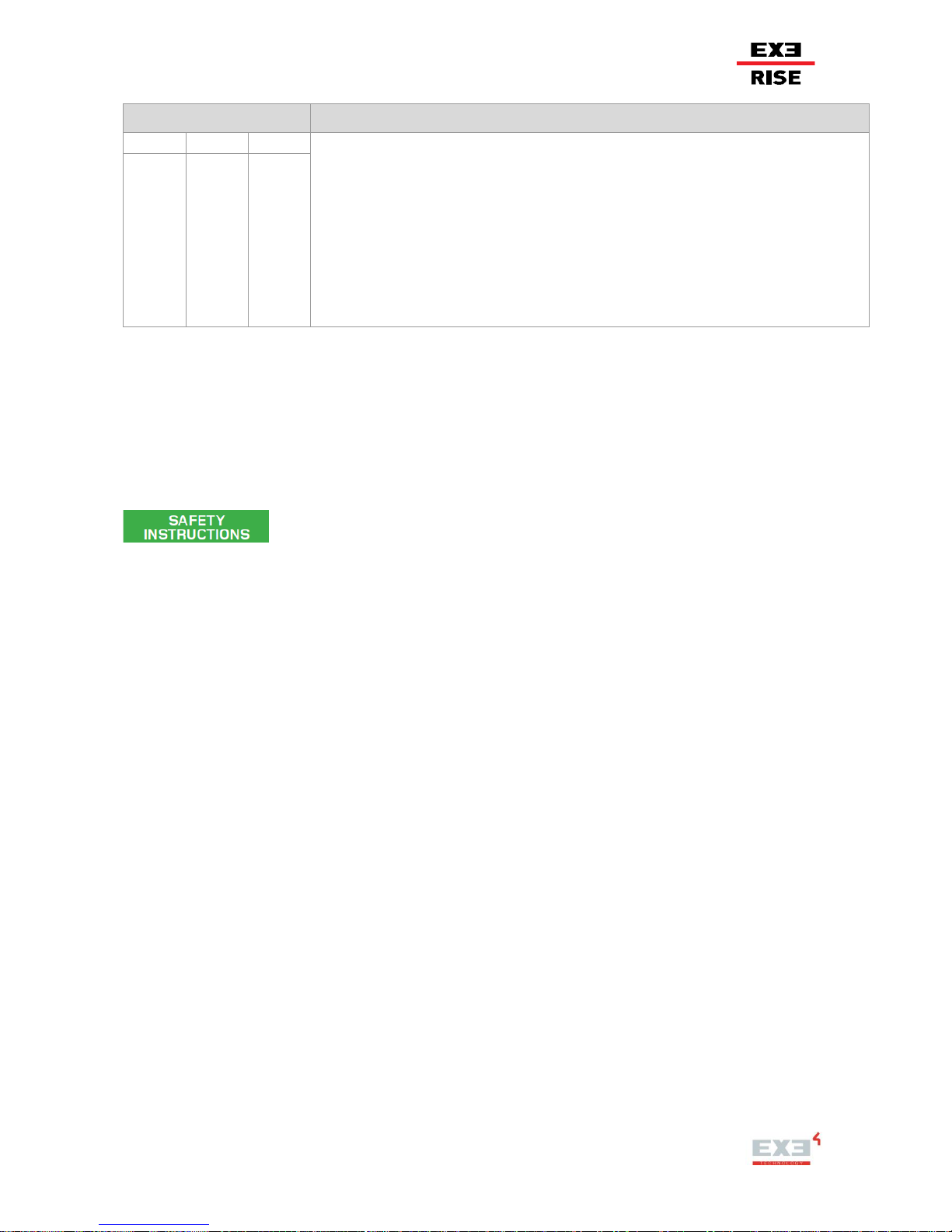

2.6 SAFETY WARNING FOR ELETRICAL CONNECTION

Before a hoist is connected to its control device the power supply shall be checked for correct voltage.

A fluctuation of +/- 10% is allowed. In order to prevent a voltage drop, the user should ensure there is the

minimum number of connections as possible in any power cable run.

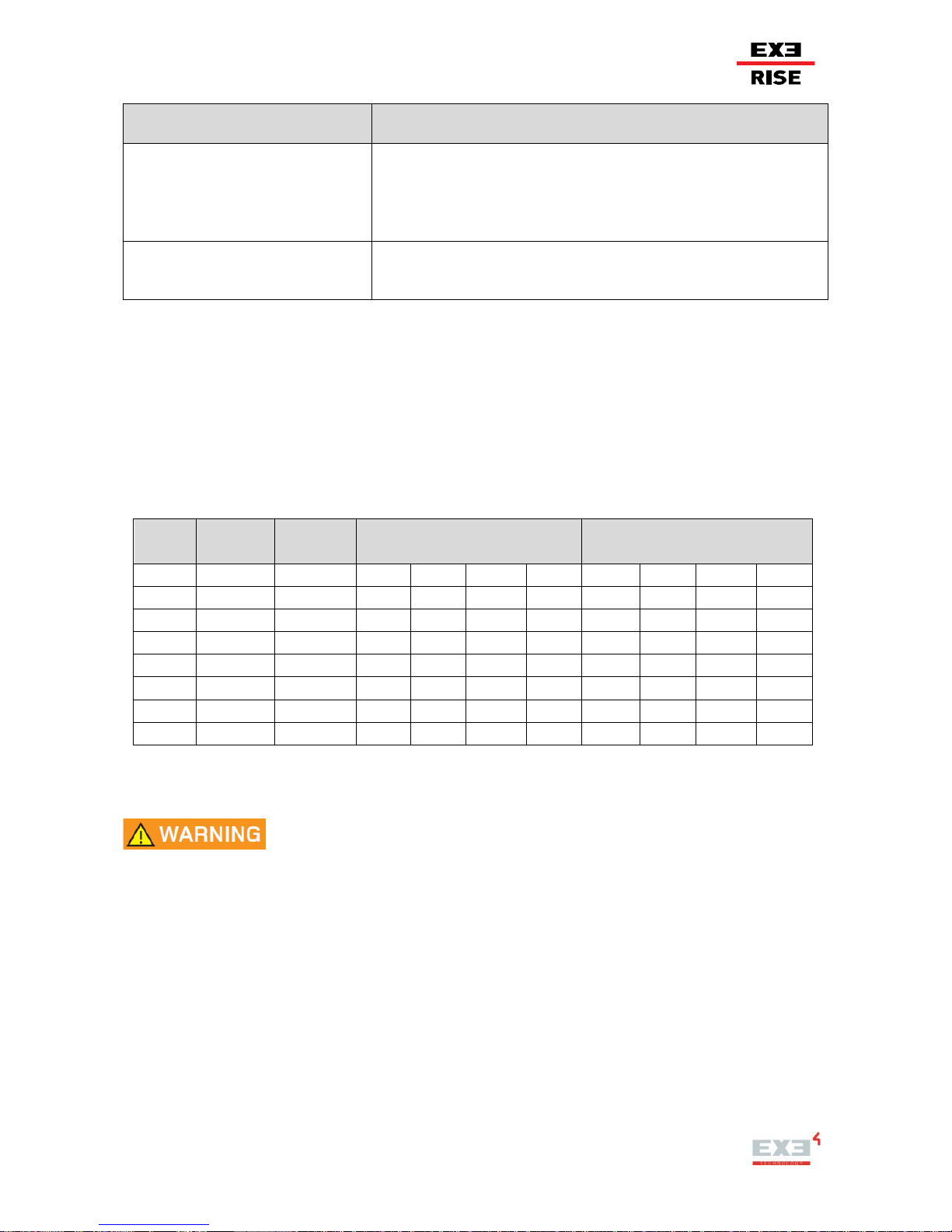

Keep length of power cables as short as possible (see table below) and remove corrosion on the contacting

pins of the electrical connectors as it might lead to a voltage drop.

In order to minimize the voltage drop between the power source and the hoist the following cable lengths

shall be used as maximum (see Table 2).

Model

(*)

Capacity

Capacity

1,5 mm 2 wiring

2,5 mm 2 wiring

kilogram

Pounds

400V/50Hz

230V/50Hz

400V/50hz

230V/50Hz

SF-8

250

kg

551

lbs

250 m 820

ft

75 m 246

ft

255 m 837

ft

80 m 262

ft

SF-8

500

kg

1102

lbs

100 m 328

ft

40 m 131

ft

110 m 361

ft

45 m 148

ft

SF-8

1000

kg

2205

lbs

65 m 213

ft

25 m 82

ft

75 m 246

ft

25 m 82

ft

SF-8

2000

kg

4409

lbs

65 m 213

ft

25 m 82

ft

75 m 246

ft

25 m 82

ft

D8+

150

kg

331

lbs

250 m 820

ft

75 m 246

ft

255 m 837

ft

80 m 262

ft

D8+

300

kg

661

lbs

100 m 328

ft

40 m 131

ft

110 m 361

ft

45 m 148

ft

D8+

600

kg

1323

lbs

65 m 213

ft

25 m 82

ft

75 m 246

ft

25 m 82

ft

D8+

1200

kg

2646

lbs

65 m 213

ft

25 m 82

ft

75 m 246

ft

25 m 82

ft

(*)

EXE-Rise Models are explained in paragraph 3.2

Table 2 “Relation between power and lengths of cable”

The electrical power plug must be disconnected from the power supply of the hoist in case of maintenance or

emergency.

Dangerous voltage drop can be caused by using excessively long extension cables as well as by

overheating the wire.

19 / 64

3. EXE-Rise CHAIN HOIST INFORMATION

The intended use of EXE-Rise chain hoist is to vertically lift loads or hold loads once lifted within the rated

capacity of the model selected. They can be installed either as a fixed device or can be mobile.

3.1 GENERAL DESCRIPTION

The EXE-Rise chain hoist are designed for installation of structures aimed at realizing events.

Events include elements such as concerts, shows, conferences, meetings, exhibitions,

presentations, demonstrations, television or film shoots and the like. The position of these events

include, among other places, theaters, multipurpose halls, studios, film sets, television and radio

broadcasts, concert halls, convention centers, schools, exhibitions, fairs, museums, clubs,

recreational parks, sports facilities, outdoor theaters and meetings.

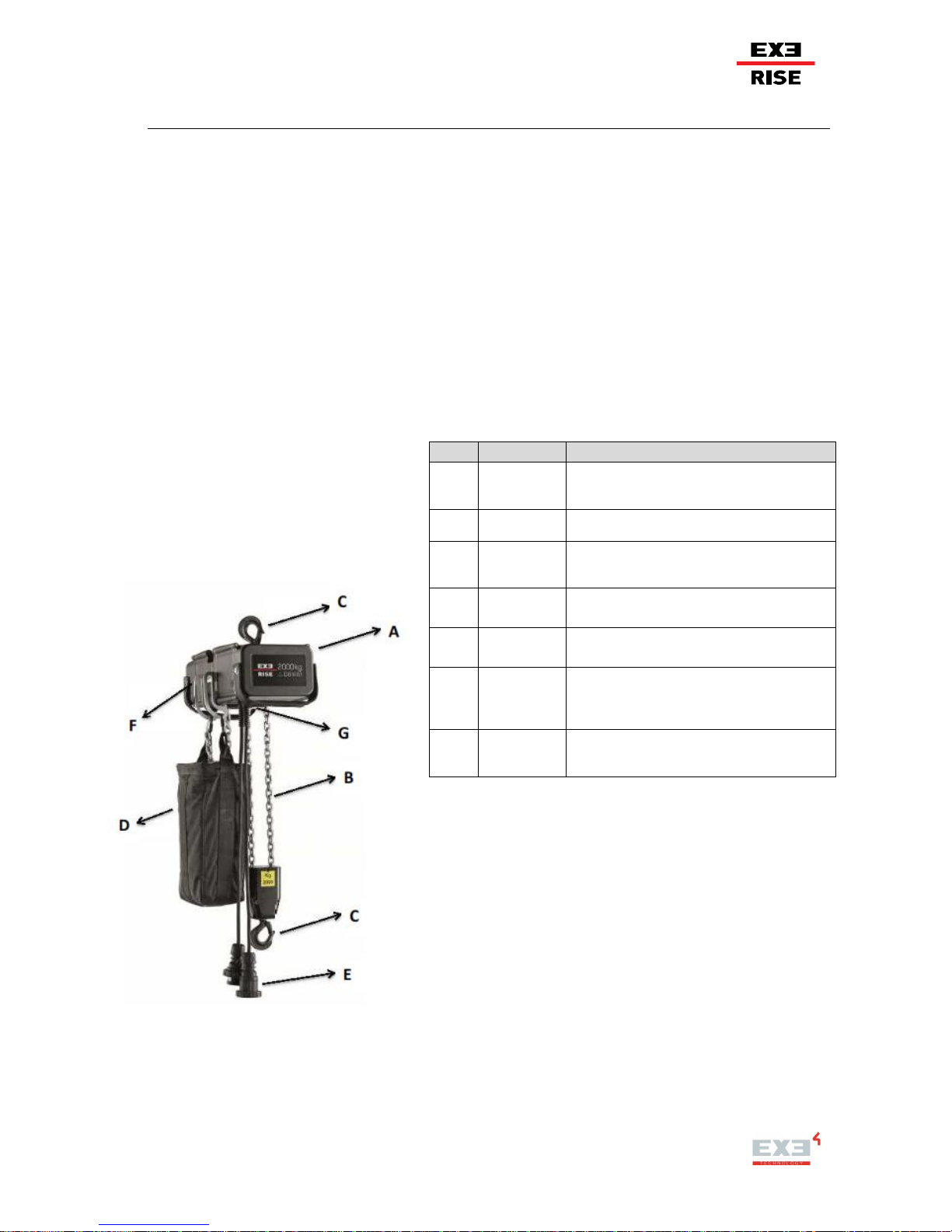

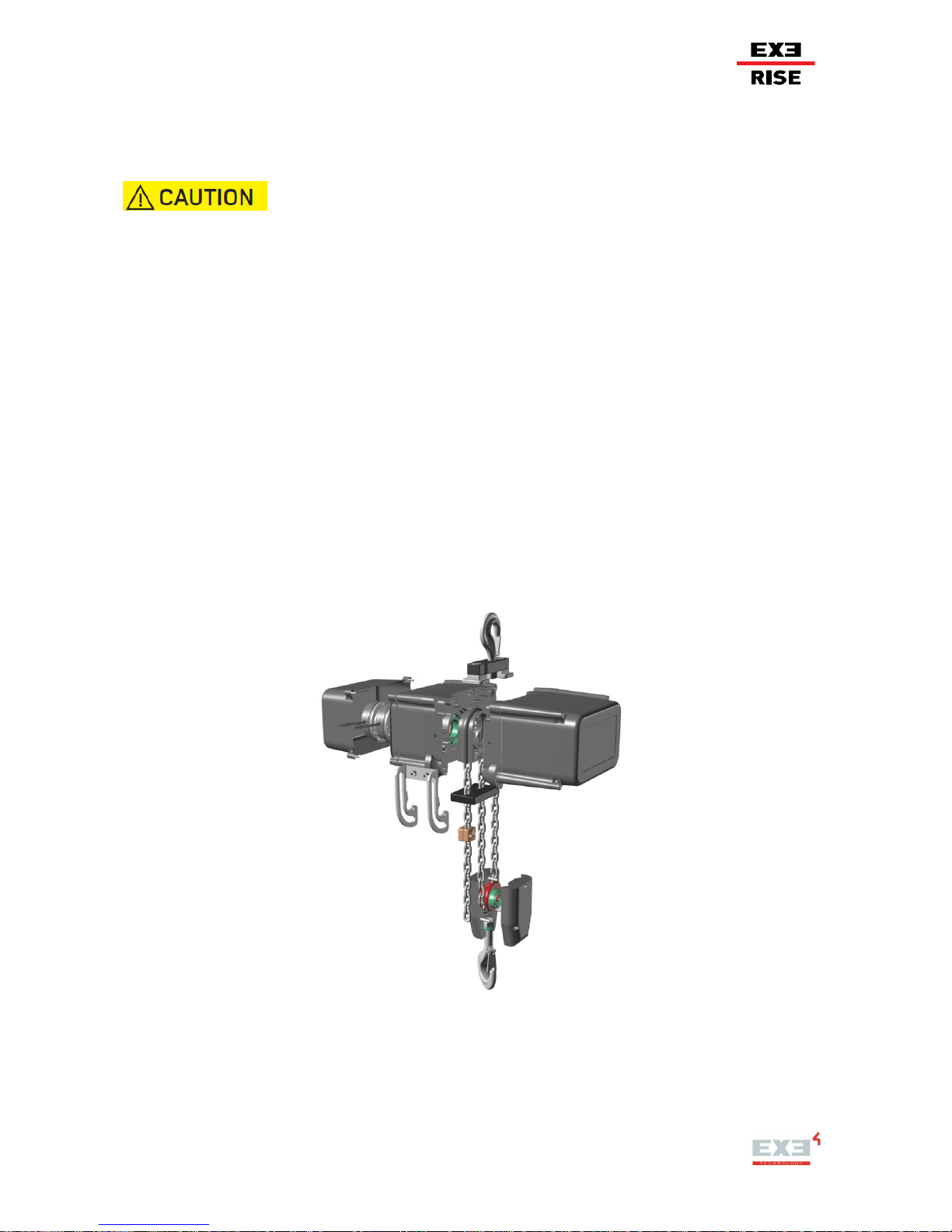

The EXE-Rise chain hoist consists in several parts. In Figure 2 and in Table 3 are reported main of these.

Table 3 “EXE-Rise chain hoist parts”

Figure 2 “EXE-Rise chain hoist parts”

COD

TITLE

DESCRIPTION

A

BODY

The body s made in cast aluminium to be as

light, yet as strong as possible. The matt black

finish is corrosion resistant and non-reflective.

B

CHAIN

The chain is in Zinc Galvanized, with grade of

steel equal to 80.

C

HOOK

The hook is in Carbon Steel and they are

equipped with a sprung safety latch that prevents

accidental release of loads

D

CHAIN

BAG

The chain bag is in Polyvinyl chloride coated

65% PVC (Nylon 840), 35% Polyamide.

E

PLUG and

SOCKET

The plug and socket are produced from

Polyamide 6 as well as PC7ABSm (IP66/67)

F

BRACKET

The chain-bag bracket in aluminum and the

design ensures the bag is positioned correctly to

accept chain without the need for any

adjustment.

G

GUIDE

PLATE

The chain guide plate is made in PVC to

prevent breaking the chain guide if the chain

jams(Small body hoists use steel guide plate.

20 / 64

3.2 IDENTIFICATION

The chain hoist EXE-Rise are uniquely identified by a serial number carved on the hoist body. The

manufacturer RWM marked years of construction too.

Figure 3 “EXE-Rise chain hoist serial number”

Accordance with the procedure that RWM Srl has established, EXE-RISE hoists are encoded as follows:

XRH + A + B + CCC+ DDD+ EE + F

CODE

FORMAT

DESCRIPTION

TYPE

XRH

EXE-Rise chain Hoist

----

A

version hoist number

1 – 2 – 3 – 4 – 5 – 6 – 7 – 8 ….

B

type of control and limit

switch size

D=Direct

Control

L= Low Voltage

Control - limit

switch 50 m

M= Low

Voltage

Control - limit

switch 30 m

N= Low

Voltage

Control - limit

switch 30 m RWM

N= Low Voltage Control -

limit switch 75 m

V=EXE-Vario 20 m/min

CCC

load capacity/10

015 =150 kg

025=250 kg

030 =300 kg

050 =500 kg

060 =600 kg

080=800kg

100 =1000 kg

120 =1200 kg

200 =2000 kg

DDD

model hoist

S8- = D8 SF 8:1

D8- = D8 SF 5:1- 1 brake

D8+ = D8+ SF 10:1

DB- = D8 SF 5:1- 2 brake

EE

chain length in meter

max length = 100 m / 220 lbs

F

chain bag size

XS S M L X (XL)

Table 4 “EXE-Rise chain hoist identification”

For example LT XRH1D100DB-20M is EXE-Rise chain hoist D8 bouble brake direct control with WLL

1000kg, chain bag size M and with 20m of chain.

21 / 64

3.2.1 Model

EXE-Rise Chain hoist models are based on a German standard that differentiates between three types of

electric chain hoists:

D8 Hoist

Electric chain hoist according to DGUV 115 (formerly known as BGV D8) "Winches, lifting and pulling

devices") for use as a chain hoist for lifting loads in construction.

D8 Plus Hoist

Electric chain hoist based on DGUV 115 "Winches, lifting and pulling devices" for use as a chain hoist for

lifting loads in construction with the special characteristic of being able to hold loads statically above people

without the use of secondary safety devices. The types of electric chain hoists specified above can be

operated both individually and in groups. The choice of the type of electric chain hoist depends on the

operating conditions:

D8

D8 with

secondary safety device

D8 Plus**

With people under the load

Holding loads

not permitted

permitted

permitted

Erection /dismantling,

rigging operations

not permitted

not permitted

not permitted

Scenic movement

not permitted

not permitted

not permitted

Complex scenic

movement

not permitted

not permitted

not permitted

Table 5 “Selection criteria for electric chain hoists for moving and holding loads above people”

Local legislation shall be checked for specific regulations. For guidance we refer to the German regulation

DGUV 17 (formerly known as BGV) The user could refer to German SQ-P2 code-of-practice for information,

which can be obtained at www.igww.org

* Source: IGVW SQ P2 – Electric chain hoists

** For statically indeterminate loads, Load cells shall be used in combination with hoist control. The lifting operation shall be stopped in

the event of exceeding the pre-set over- or underload – limits. Values shall be derived from structural analysis of the applied loads

3.2.2 Type of Control

Selection of the hoist also depends on the duty class needed. The duty class refers to the time the hoist can

operate under full load. EXE-Rise chain hoists have a minimum rating of 1Bm and maximum rating of 2m as

per FEM classification; See table 6.

Class

1Bm

1Am

2m

3m

Duty factor of motor

25%

30%

40%

50%

Starts per hour

150

180

240

300

Table 6 “FEM Classification”

Depending on its operating hours and the load applied the same hoist can also be used in another duty

class. Please contact RWM for support if this is required. Table 7 gives guidance for correct selection

22 / 64

Load spectrum

Average operating time per day in hours

≤0.25

≤0.5

≤1

≤2

≤4

≤8

≤16

Light

1Bm

1Am

2m

3m

Moderate

1Bm

1Am

2m

3m Heavy

1Bm

1Am

2m

3m

Very Heavy

1Bm

1Am

2m

3m

Table 7 “Average operating time per day in hours”

Direct control hoists

The terms direct control (DC) and low-voltage controlled (LVC) refer to the system used to manage hoist

movement, not to the power supply voltage.

With DC hoists, the travel direction is determined directly by the phase sequence of the three phase power

supplied to the red CEE plug fitted (CEE 16A 6h 400 VAC – 3PH). Phase reversing contactors are inside the

controller and not inside the hoist. The hoist lifts when the three power phases are in normal sequence and

lowers when they are inverted.

DC hoists have an integrated mechanical emergency overload device known as the slip clutch. This slip

clutch is adjustable but changes to this device must only be performed by an officially trained and competent

person. A chain stop (a two part metal block) is attached to the end of the load chain, 11 links form the end,

which prevents the chain from running through the hoist should it overrun the length of the chain.

The chain stop shall be placed 11 links from the end. This gives the user or person carrying out any

inspection, access an unloaded length of chain as measuring reference compared to rest of the chain which

will have been under load.

Low Voltage Controlled hoist

LVC hoists are fitted with a CEE plug (CEE 16A 6h 400 VAC – 3PH) for three phase power and a yellow

CEE plug (CEE 16A 4h 24 VAC – 3PH) for control purposes. The direction signal is given by a low voltage

hoist controller and is transmitted along the control cable which activates reversing contactors inside the

hoist body. LVC hoists have an integrated mechanical emergency overload device known as the slip clutch.

This slip clutch is adjustable but changes to this device must only be performed by an officially trained and

competent person.

LVC hoists also have an integrated adjustable electrical limit switch that halts the lifting and lowering

operation at pre-set positions. The control signal is a 24 VAC low voltage circuit.

These electrical limit switches can be set to limit the chain travel during both lifting and lowering operations.

The factory default settings can be adjusted by altering the position of the “up” and “down” cams. The limit

switches are factory calibrated in such a way as to stop the motor automatically a few links before the chain

comes to an end in both directions.

After setting the up/down selector, press the start button on the control unit to which the EXE-Rise LVC hoist

has been connected. When the external up / down button is selected the control signal activates the

contactor inside the hoists and powers the motor, setting the chain in motion in the required direction. The

23 / 64

chain will continue to travel through the hoist in the chosen direction until it reaches a mechanical stop on the

chain, or until the electrical limit switch reaches its pre-set end point. Once the limit switch is activated the

hoist can only be run by reversing the direction of travel.

Any control unit used to power EXE-Rise LVC hoists must provide an "un-inverted" three phase power

supply. An incorrect sequence of phases make the hoist run in a different direction as the limit switch. This

will result in damage of the limit switches and potential over run of the chain.

Electric chain hoists are offered in a variety of designs and feature options; as well as with different safety

devices. This means that the choice of chain hoist is extremely important. Consideration must be given to

risks arising from the nature of the intended operational use and the specific operating conditions.

The selection must be based on the hazards arising from the type of use, taking into account the specific

conditions of use whilst abiding to the local laws in the country of use. We strongly advise that the

user/operator carries out a risk assessment on which the choice of your hoist shall be based.

3.3 COMPONENTS DESCRIPTION

Every single component of the EXE-Rise hoist body is manufactured in Italy. The high grade Lifting chain is

coming from Germany and complies with the strictest EN and DIN standards relating to lifting in the

entertainment industry. The EXE-Rise clutch system is located outside the load path. The DC brakes give a

real instant response to electrical impulses thanks to a unique component specifically created for us. The 5pocket load wheel, helical gears with dynamic lubrication and the precise aluminum chain guide make

the EXE-Rise series one of the quietest on the market.

Figure 4 “EXE-Rise chain hoist 2000 kg DC principal components”

24 / 64

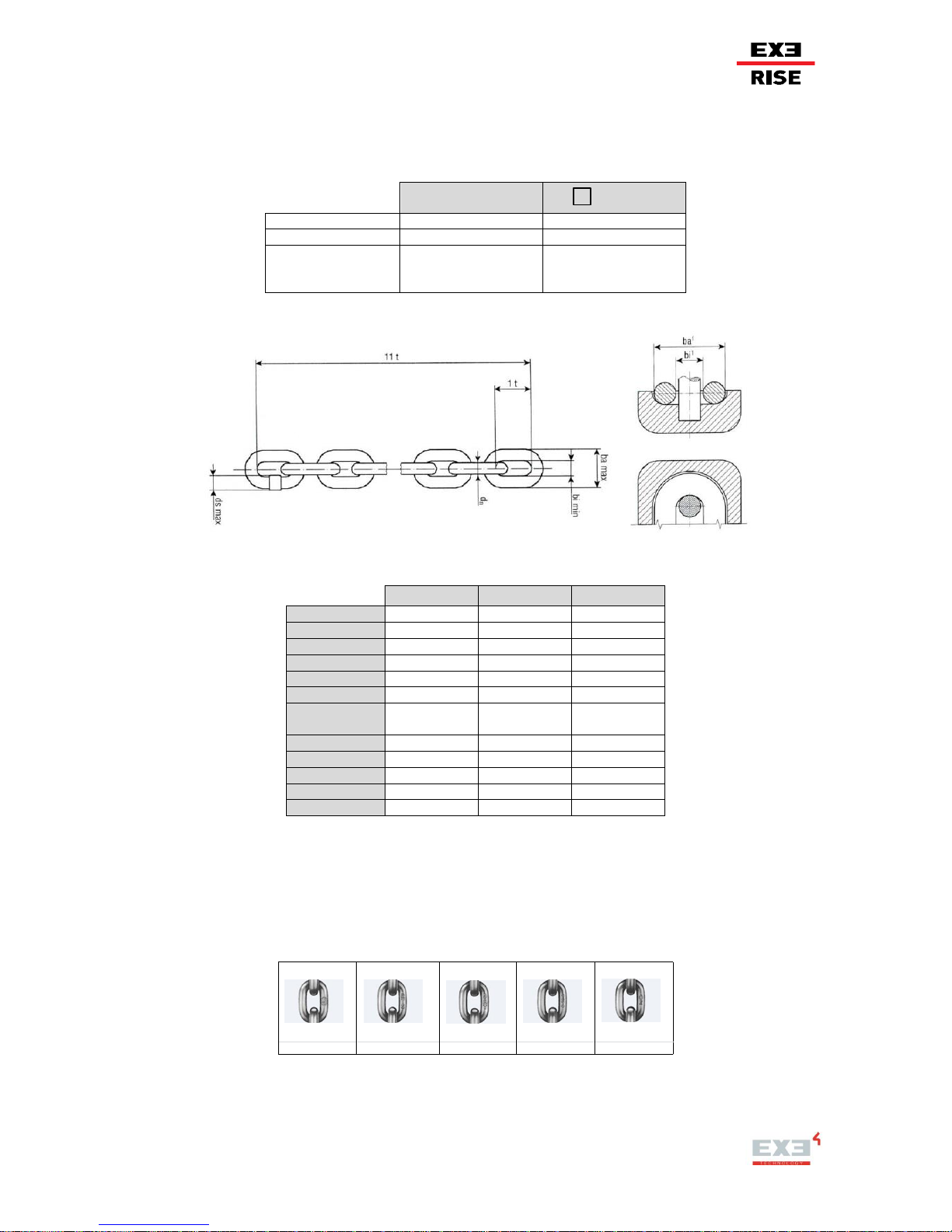

3.3.1 Chain

The chain used for EXE-Rise chain hoist is in Zinc Galvanized Steel EN DIN 818-7 (grade of steel: 80).

There are five measures in order to hoist chain of destination:

CHAIN

SF-8

D8+

4x12 mm

D8 250 kg

D8+ 150 kg

6x18 mm

D8 500 kg

D8+ 300 kg

8x24 mm

D8 1000 kg

D8 2000 kg

D8+ 600 kg

D8+ 800 kg

D8+ 1200 kg

Table 8 “Chain measures”

Figure 5 “Chain dimensions”

Each chain has specific characteristics, among them the most important are reported:

Table 9 “Chain technical data”

LEGEND:

dn: nominal diameter – 1t: nominal pitch – bi

min

: minimum inner width – ba

max

: maximum outside width – Gauge length: 11t (11 links) –

ds

max

:maximum welding diameter – σ

min

: minimum stress at breaking force – F

min

: Minimum Breaking Force (MBF) – A

min

:minimum total

ultimate elongation – WLL: max Working Load Limit.

Chain can be identified from the manufacturers stamped identification marks on the chain. The stamps

shown are repeated at regular intervals along the length of the chain.

Figure 6 “Chain identification”

Permittance stamp Grade Type Manufacturing no. Batch no.

CHAIN 4x12

CHAIN 6x18

CHAIN 8x24

Code

XRC032-01M

XRC0618-01M

XRC0618-01M

Weight

0.35

0.78

1.39

dn [mm]

4.0

6.0

8.0

1t [mm]

12.0

18.0

24.0

bi

min

[mm]

5.0

7.2

9.6

ba

max

[mm]

13.7

20.2

27.0

Gauge length

[mm]

132.0

198.0

264.0

ds

max

[mm]

4.3

6.5

8.6

σ

min

[N/mm2]

800

800

800

F

min

[kN]

20.1

45.2

80.4

A

min

10 %

10 %

10 %

WLL [kg]

320

720

1280

25 / 64

3.3.2 Hook

The hooks are forget Carbon Steel or Alloy Steel with heat treatment in according to Machinery Directive.

Small body hoists use Stainless Steel.

CHAIN SWIVEL HOOK

D8 250 kg and D8+ 150 kg - D8 500 kg and D8+ 300 kg

Figure 7. “Lift chain hook with safety latch” D8 250 kg and D8+ 150 kg - D8 500 kg and D8+ 300 kg

D8 1000 kg and D8+ 600 kg

Figure 8. “Lift chain hook with safety latch” D8 1000 kg and D8+ 600 kg

DIMENSIONS [ mm ]

A B D G H L O

73

51

15

16

20

64

18

DIMENSIONS [ mm ]

A B D G H L O

92

64

20

21

27

72

30

26 / 64

D8 2000 kg and D8+ 1200 kg

Figure 9. “Lift chain hook with safety latch” D8 2000 kg and D8+ 1200 kg

The standard ingress protection Level of IP55 means that when the hoist is used in wet environments,

adequate protection of the hoist body is required.

BODY SWIVEL HOOK

Body swivel hook is an assemblage of a plate with two holes, two fixing screws and hook (see Chain Swivel

Hook for models).

Figure 10. “Example of Body Swivel Hook”

EXE-Rise chain hoists with a lifting speed up to 8m/min generate a dynamic factor of 1.2 during start and

stop. Tolerances in lifting speed up to 5% can occur within same models of the same manufacture. Lifting

speeds vary depending on the load, and if the load is lifted or lowered.

DIMENSIONS [ mm ]

A B D G H L O

122

82

30

28

36

97

33

27 / 64

3.3.3 Chain Bag Bracket

The chain-bag bracket allows the hoist to be used motor up or down. The design ensures the bag is

positioned correctly to accept chain without the need for any adjustment, reducing the chance of chain spills.

3.3.4 Chain Stop

Fits below dead end link on lifting chain for added measure of safety.

Table 10 “Chain stop code”

Figure 11 “Chain stop”

3.3.5 Quick Link

CONNECTION INSTEAD OF BRACKET

Chain bags shall be suspended by Quicklinks or Carabiners made according to DIN 56927 or equivalent

standard. Some bags are supplied with a suitable rated captive spring hook. Only rated hooks supplied by

RWM should be used.

CONNECTION INSTEAD OF BRACKET

Litec Code

Chain size

[mm]

XRSFC412

4x12

XRSFC515

6x18

XRSFC722

8x24

Litec Code

CHB004

Commercial name

Quick link

Description

Material: Zinc Galvanized

Carbon Steel

Color: black

Diameter: 6 mm

DIN

DIN 56927

SWL (Safe Working Load)

250 kg

Safety Factor

10:1

Weight

47 g

Table 11 “Chain bag – bracket Quick Link

technical data”

Figure 12 “Chain bag – bracket

Quick Link dimension”

28 / 64

Manufactured according to BGV C-1. It has a compact shape, is galvanized and stamped with the DIN

standard, manufacturer´s name and the carrying capacity.

Figure 13 “End chain – bracket Quick Link dimension”

Table 12 “End chain – bracket Quick Link technical data”

3.3.6 External Chain Guide Plate

The External Chain Guide Plate is made from a special PVC is used to minimize the chance of chain

jamming should the chain become twisted. This sacrificial plate helps protect both the chain and internal

chain guides. (Small body hoists use steel guide plate).

Figure 14 “External Chain Guide Plate”

Litec Code

Chain size [mm]

WLL

d c e l h b weight

[kg]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[g]

CHB037

6x18

7x22

8x24

140

5.0

3.0

22.0

52.0

13.0

13.0

25

CHB041

4x12

50

3.5 - -

29.0

10 5 9

CHB041

5x15

90

4.0 - -

32.0

11 5 13

29 / 64

3.3.7 Plugs and Socket

Plugs and sockets are produced from POLYAMIDE 6 as well as PC/ABS.

The main characteristics of these

materials are:

- excellent impact resistance combined with high rigidity and solidity,

- high thermal stability (self-extinguishing),

- very good insulating qualities,

- high disruptive strength,

- high abrasion resistance,

- high weathering resistance,

- very good chemical resistance to various chemicals,

- free from cadmium and halogen (fluorine, chlorine, bromine, jodine,

astatine),

- black color.

Figure 15 “Plug and socket”

3.3.8 Brake

The spring-applied brake is a single-disk brake with two friction surfaces. Several compression springs

create the braking torque by friction locking. The brake is released electromagnetically.

Figure 16 “Double brake version”

The spring-applied brake is designed for the conversion of mechanical work and kinetic energy into heat. For

operating speed. Due to the static brake torque, the brake can hold loads without speed difference.

Emergency braking is possible at high speed. The more friction work, the higher the wear.

Figure 17 “Brake Features”

30 / 64

EXE-Rise chain

hoist

D8 250 kg

D8+ 150 kg

D8 500 kg

D8+ 300 kg

D8 1000 kg

D8+ 600kg

D8 2000 kg

D8+ 800 kg - 1200 kg

DC Brake Size

06

08

10

DC Brake Power

20W

25W

30W

DC Brake

Operating Voltage

105VDC

105VDC

105VDC

DC Brake Rated

Torque

4Nm

8Nm

16Nm

DC Brake Rated

Torque Reduction

at the speed

specified x%

(1500r/min)

87% (1500 r/min)

85% (1500 r/min)

83% (1500 r/min)

Table 13 “Brake technical data”

3.3.9 Limit switch

Limit switch consists of 4 cams and a gear motor that transfers movement through a primary input reduction

stage (worm gear and helical toothed gear) and one or more secondary output stages (pairs of straight

toothed gears).

Figure 18 “Limit Switch large medium and body”

3.3.10 Chain Bag

Chain Bag used for EXE-RISE chain hoist is in Polyvinyl chloride coated polyamide 65% PVC (Nylon 840),

35% Polyamide. There are five size (XS, S, M, L, XL) in order to hoist chain of destination.

Table 14 “Chain bag characteristic”

Description

Nylontex 840 P.V.C. flame ritardent + PP BELT

Material

Polyvinyl chloride coated polyamide 65% PVC (Nylon

840), 35% Polyamide +

PP Yanr Multifilament 100% (Melting Points ≈ 165°)

Color

Black

Classification

Reaction to fire classification: E

combustible not inflammable - partially fire retardant.

Conformity to EN 119925-2

Safely Factor

5:1

31 / 64

Figure 19 “Chain bag”

Table 15 “Chain bag dimensions”

Table 16 “Chain bag size”

3.3.11 Bolts and nuts

All bolts and nuts used in the line of forces, shall be fastened by means

of a torque wrench. Grade 8.8 bolts are used and the following torque

shall be applied.

Table 17 “Bolts”

SPECIFICATIONS

CHAIN BAG XS

CHAIN BAG S

CHAIN BAG M

CHAIN BAG L

CHAIN BAG XL

Litec Code

CHB029

CHB024

CHB025

CHB026

CHB027

External

Dimensions [cm]

14x9

20x17

20x17

20x17

27x21

Height [cm]

40

34

42

58

65

Selfweight [kg]

≈ 0.75

≈ 1.00

≈ 1.00

≈ 1.00

≈ 1.00

CHAIN

Up to 26m

@75%

(26-40)m

@75%

From to 40m

@75%

4X12

XS

XS

-

6X18 S M

L

8X24 M L

XL

8.8 bolts

Lbsft

Nm

M4 2 3

M5

4,5 6 M6

7,5

10

M8

18

25

M16

159

215

32 / 64

3.3.12 EXE-Rise Chain Hoist Controllers

More EXE-Rise Chain hoists shall be operated by controllers designed and specified for this purpose. We

advise to use the EXE-DRIVE range controllers for proper use of your EXE-Rise chain hoist.

The use of other brands, in alternative to EXE-DRIVE controllers is not recommended unless they comply

with the applicable directives and standards. The controller shall provide the required control and monitoring

functions for save operation. The control system must meet the requirements of:

1. EN 60204-32: 2008 Safety of machinery - Electrical equipment of machines - Part 32: Requirements for

hoisting machines (IEC 60204-32: 2008);

2. 2006/42 / EC - Machinery Directive;

3. 2014/30 / EC - Electromagnetic Compatibility (EMC) Directive.

Controllers shall be chosen depending on the power consumption of an individual hoist, which can vary, as

well as its model (direct control or Low voltage control) or the amount of hoist one would like to control at the

same time.

We strongly advise to keep good view on the load being lifted. Using more than two hoist on one load

requires much more attention. Based on a risk analysis the user shall identify if the hoist and controllers need

additional control options such as Load cells, encoders etc...

In case the controller is equipped with Molded Case Circuit Breakers (MCCB), make sure the correct setting

of amperage is applied and the correct MCCB.

33 / 64

3.4 SAFETY DEVICE

The hoist is equipped with various guards and devices designed to prevent accidents and to ensure the

product complies with various safety standards.

3.4.1 Primary Safety Component

The guards and devices listed below must not be removed by the user. Before operation the user should

ensure all guards and devices are present, correctly fitted and have correct setting.

Removal of these guards and safety devices should only be allowed during maintenance by competent and

authorised persons and in controlled conditions.

Chain guide plate

EXE Rise chain hoists are fitted with a special plastic chain guide plate that provides various safety

functions.

- Prevents accidental contact with the internal moving parts.

- Prevents accidental contact with the internal parts that could reach high temperatures.

- Prevents wear between the chain and internal chain guide.

- Prevents jamming of the chain.

- Helps to reduce the chance of twisted chain entering the hoist.

These chain guides are a consumable item and should be replaced if they become worn.

Badly worn plates can be a sign of misuse. Eg. Side loading of the chain.

Hooks

The hooks are equipped with a sprung safety latch that prevents accidental release of loads when applied

correctly to the hook.

If this spring latch does not engage against the point of the hook correctly, or can fall through the opening of

the hook, the hook has overloaded and shall be replaced.

An unloaded hook attached to a lifting point can disengage itself when put under tension.

Therefore the hook shall be held under tension manually until loaded

Slip Clutch

The Slip clutch is designed and set up to act in the case of excessive load and therefore only shall be

considered as an emergency overload device. If overloaded, it starts to slip and the hoist will not lift.

The slip clutch shall never be used as a lifting height limiter.

If the clutch is subject to prolonged slipping it can overheat and become damaged. The clutch should not be

allowed to slip continuously for several seconds.

Considering the above statements, these hoists should not be used in an application where a suspended

load can be increased by adding additional weight. For example food lifts etc.

34 / 64

Figure 20: Example of securing a load

suspended from a tower by means of a

locking bar

Figure 21: Example of a secondary safety

component attached directly to the load that is

being lifted (front view)

Figure 22: Example of a secondary

safety component attached directly to

the load that is being lifted

3.4.2 Secondary Safety Component

A secondary safety component is a second independent suspension element of equivalent capacity to the

primary suspension point, which is intended to prevent the fall of the load should the primary point fail. Some

application examples are illustrated here below.

When operating a system according to the German DGUV V54 standard, or if maintenance is required on a

hoist that is still suspended, a secondary safety device should be used.

35 / 64

Figure 23: Example of a secondary safety

component attached below the hoist, bypassing

the hoist lifting mechanism (front view)

Figure 24: Example of a secondary

safety component attached below

the hoist, bypassing the hoist lifting

mechanism (perspective view)

Never use a chain clutch to connect the hoists lifting chain to a safety device. A lateral load to the lifting chain

can easily lead to failure.

3.4.3 Safety Conditions

Environmental conditions

To ensure the hoists function correctly, the following environmental conditions shall be observed:

Temperature

Temperature ranging between -10°C and +40°C

Humidity

The relative humidity must not be higher than 50% with maximum temperature of

+40°C. A higher relative humidity is allowed al lower temperatures (ex. RH. 90% AT

20°C).

Altitude

Maximum altitude at 3000m

Electromagnetic

environment

The hoist is designed to work correctly in an industrial type electromagnetic

environment, falling within the emission and immunity limits provided by the

harmonized rules currently in force

Wind

Wind can have a significant influence on the load suspended. The exposed influence

shall be considered at all time

Lighting of work place

During the set-up, dismantling and maintenance, it is favourable that the diffusion intensity does not have a