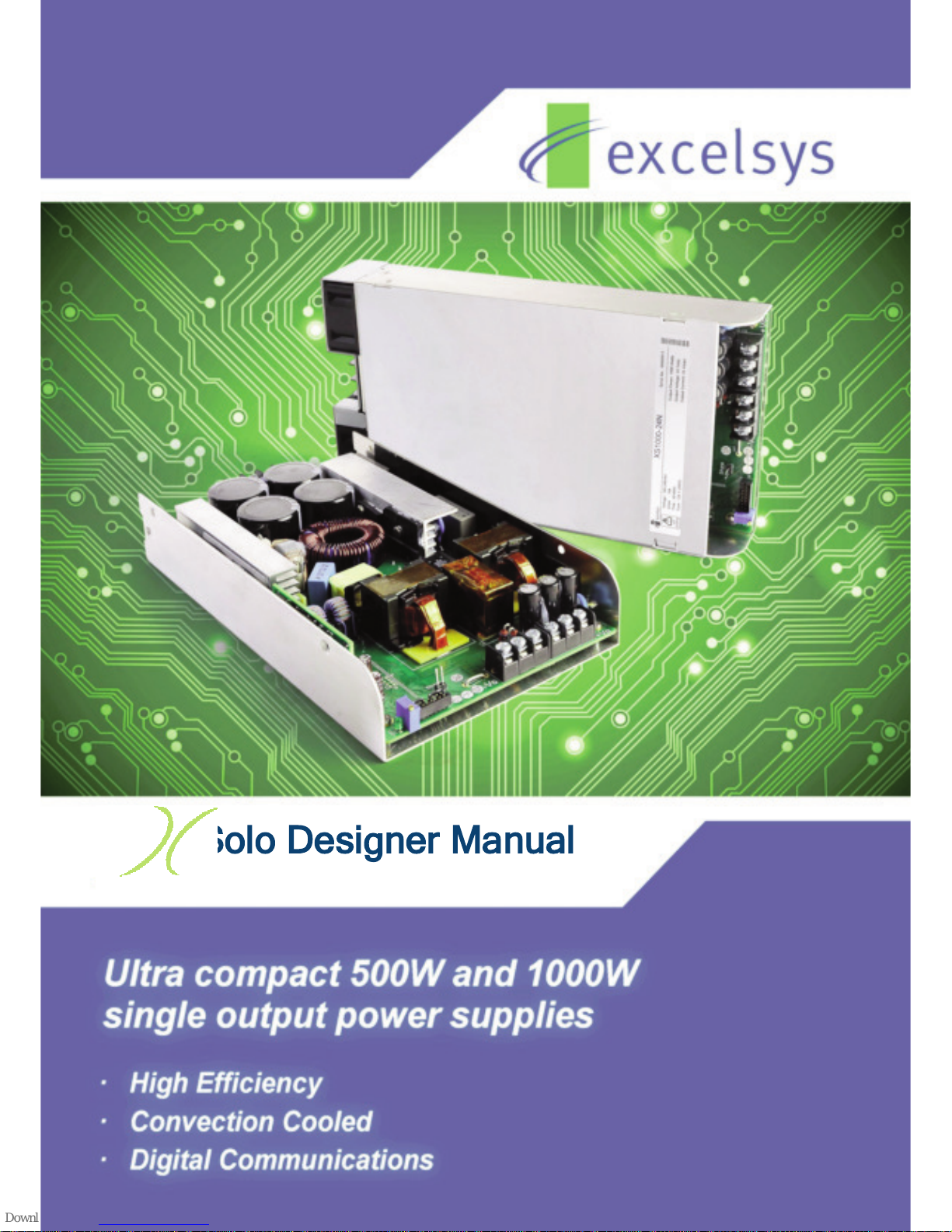

Solo Designer Manual

The Xsolo family of single output power supplies provides up to an incredible 1008W

in an extremely compact package.

Available in two package types, the high efficiency Xsolo delivers an incredible convection

cooled 504W in an open-frame U-channel form factor and up to 1008W in an enclosed, fan

cooled chassis.

The Xsolo platform comes with a host of features including: variable speed fan, 12V/300mA

isolated bias supply, remote ON/OFF, output voltage control and parallel operation for higher

power applications. Nominal output voltages are 24, 36V and 48V with wide adjustment

ranges and user defined set-points. Xsolo carries dual safety certification, EN60950 2

nd

Edition for Industrial Applications and EN60601-1 2ndand 3rdEdition for Medical

Applications, meeting the stringent creepage and clearance requirements, 4KVAC isolation

and <300uA leakage current. Xsolo is designed to meet MIL810G and is also compliant with

SEMI F47 for voltage dips and interruptions as well as being compliant with all relevant EMC

emission and immunity standards.

Optional features include I2C digital communications and OR-ing Function for N+1 redundancy.

The product can also be conformal coated and ruggedised for use in harsh environments. With

convection cooled power capability of over 500W, the Xsolo is ideal for use in a wide range of

applications: industrial, Hi-Rel MIL-COTS applications, as well as acoustically sensitive laboratory

and medical environments.

Single Output Power Supply 500W - 1000W

FEATURES

• Single output: 24V, 36V or 48V

• IEC60950 2

nd

Edition, IEC60601-1 2nd &

3rd Edition & IEC60601-1-2 4th Edition

EMC compliant

• Ultra high efficiency, >92%

• Low profile: 1U height (40mm)

• Convection Cooled 500W

• Fan Cooled 1000W (variable speed fan)

• 12V/300mA bias standby voltage

provided

• Remote ON/OFF Signal

• Power Good Signal

• MIL810G

• 2 MOPP

• SEMI F47 Compliant

• Suitable for Type B and BF rated

applications

• Optional I2C PMBus™Communications

• Optional OR-ing Function

• 5 Year Warranty

• Adjustable output voltage

• 5000m altitude for EN60950 applications

• All models feature active power factor

correction as standard

• Product Options: Conformal Coating,

Low Leakage Current and Ruggedised

APPLICATIONS INCLUDE

• Industrial

• Test & Measurement

• Medical

• Hi-Rel COTS

XS500-24 504 24 21.0 Yes Yes

XS1000-24 1008 24 42.0 Yes Yes

XS500-36 504 36 14.0 Yes Yes

XS1000-36 1008 36 28.0 Yes Yes

XS500-48 504 48 10.5 Yes Yes

XS1000-48 1008 48 21.0 Yes Yes

XS

Model Power Output Output Medical Approval Industrial Approval

(W) Voltage Current UL/EN60601-1 UL/EN60950

(A) 3rd edition 2nd edition

XS Models

Ultra-high efficiency 1U size

Model Vnom Power Description Set Point Dynamic Vtrim Imax Remote Power

(V) (W) Adjust Range (V) Range (V) (A) Sense Good

XS500-24 24 504 Convection Cooled U-Channel 19-28 14-28 21.0 Yes Yes

XS1000-24 24 1008 Enclosed Fan Cooled 19-28 14-28 42.0 Yes Yes

XS500-36 36 504 Convection Cooled U-Channel 26-40 20-40 14.0 Yes Yes

XS1000-36 36 1008 Enclosed Fan Cooled 26-40 20-40 28.0 Yes Yes

XS500-48 48 504 Convection Cooled U-Channel 36-58 29-58 10.5 Yes Yes

XS1000-48 48 1008 Enclosed Fan Cooled 36-58 29-58 21.0 Yes Yes

Xsolo

XS

* Full part numbering information including product options and ordering information on page 65.

solo

1

www.excelsys.com

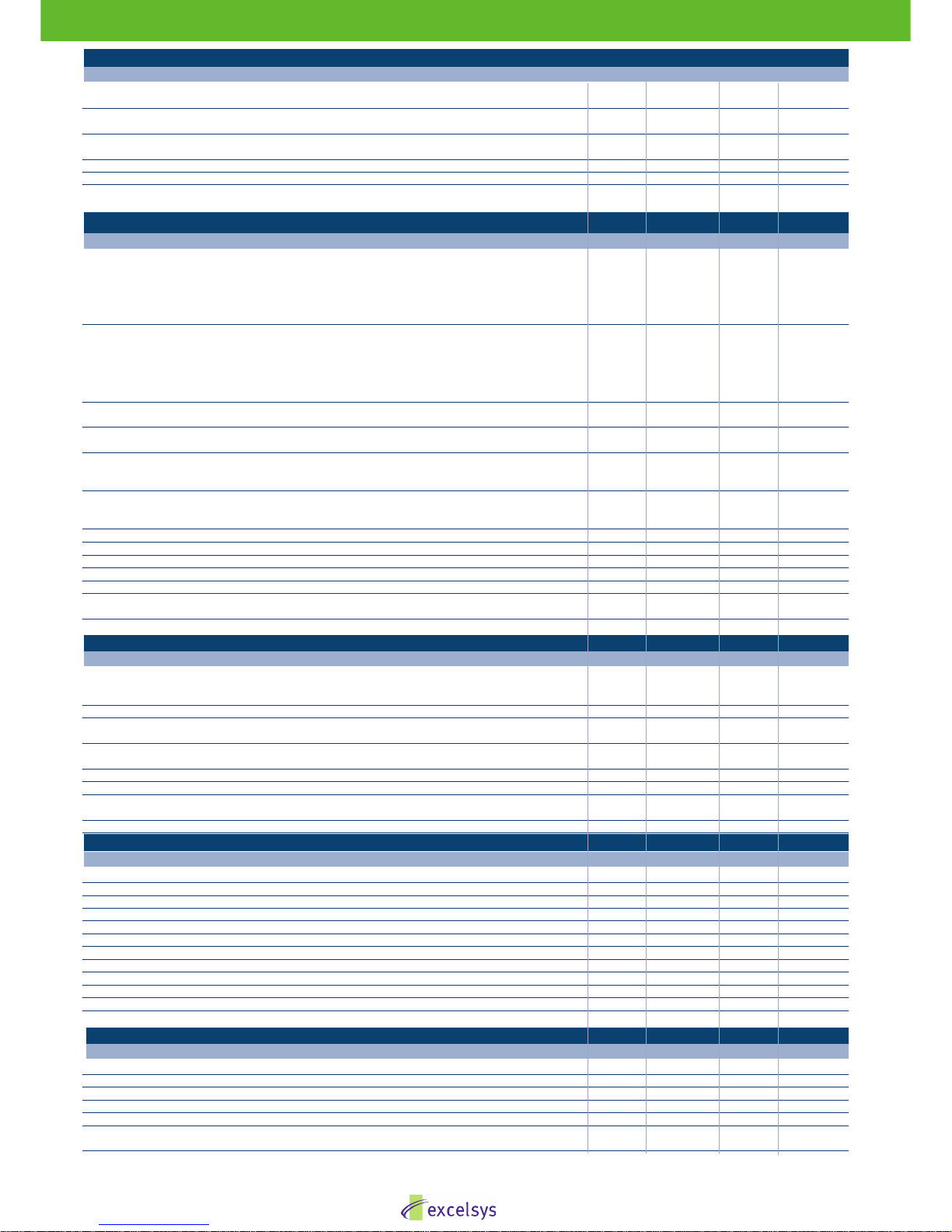

INPUT

Parameter Conditions/Decription Min Nom Max Units

Input Voltage Range Universal Input 47-440Hz 85 264 VAC

120 380 VDC

Power Rating XS500 504 W

XS1000 1008 W

Input Current XS500 5 A

XS1000 10 A

Inrush Current 230VAC @ 25°C 25 A

Undervoltage Lockout Shutdown 65 74 VAC

Fusing XS500 250VAC F8A HRC

XS1000 250VAC F12A HRC

OUTPUT

Parameter Conditions/Description Min Nom Max Units

Output Voltage Range XS500/1000-24: Multi-turn potentiometer 19 28 VDC

XS500/1000-24: Dynamic Vtrim range 14 28 VDC

XS500/1000-36: Multi-turn potentiometer 26 40 VDC

XS500/1000-36: Dynamic Vtrim range 20 40 VDC

XS500/1000-48: Multi-turn potentiometer 36 58 VDC

XS500/1000-48: Dynamic Vtrim range 29 58 VDC

Output Current Range XS500-24 21 A

XS1000-24 42 A

XS500-36 14 A

XS1000-36 28 A

XS500-48 10.5 A

XS1000-48 21 A

Load & Cross Regulation For 25% to 75% load change ±0.2 %

ORing Option ±0.4 %

Transient Response For 25% to 75% load change Voltage Deviation 2.5 %

Settling Time 500 µs

Ripple and Noise XS500/1000-24: 20MHz 240 mV pk-pk

XS500/1000-36: 20MHz 360 mV pk-pk

XS500/1000-48: 20MHz 480 mV pk-pk

Overvoltage Protection XS500/1000-24: Latching 33 34 37 VDC

XS500/1000-36: Latching 44 47 52 VDC

XS500/1000-48: Latching 61 63 69 VDC

Overcurrent Protection Straight line with hiccup activation at <30% of Vnom. 105 115 130 %

Line Regulation For ±10% change from nominal line ±0.5 %

Remote Sense 0.5 VDC

Overshoot 2 %

Rise Time Monotonic 3 5 ms

Turn-on Delay From AC in 500 800 ms

From Remote On/Off 10 ms

Hold-up Time For nominal output voltages at full load. 17 ms

GENERAL

Parameter Conditions/Description Min Nom Max Units

Isolation Voltage Input to Output 4000 VAC

Input to Chassis 1500 VAC

Output to Chassis 1500 VAC

Efficiency 230VAC, 1008W @ 24V/36V/48V >92 %

Safety Agency Approvals EN60601-1 2nd and 3rd Edition, cTUVus 60601-1

EN60950 2nd Edition, cTUVus 60950

Leakage Current 264VAC, 60Hz, 25°C 300 µA

264VAC, 60Hz, 25°C (Option 4) 150 µA

Signals See Page 3

Bias Supply Always on, current 300mA, 50mA XS500 12.0 VDC

Weight XS500 1.1 Kg

XS1000 1.3 Kg

MTBF Telecordia SR-332, 40°C ground benign, parts count. 550,000 Hours

EMC

Parameter Standard Level Units

Emissions

Conducted EN55011, EN55022, FCC Class B

Radiated EN55011, EN55022, FCC Class B

Harmonic Distortion EN61000-3-2 Class A Compliant

Flicker & Fluctuation EN61000-3-3 Compliant

Immunity

Electrostatic Discharge EN61000-4-2 Level 2

Radiated Immunity EN61000-4-3 Level 3

Fast Transients-Burst EN61000-4-4 Level 3

Input Line Surges EN61000-4-5 Level 3

Conducted Immunity EN61000-4-6 Level 3

Voltage Dips EN61000-4-11, SEMI F47 Compliant.

(1)

Compliant

ENVIRONMENTAL

Parameter Conditions/Description Min Nom Max Units

Operating Temperature -40 +70 °C

Storage Temperature -40 +85 °C

Derating See Page 62 for full temperature deratings

Relative Humidity Non-condensing 5 95 %RH

Shock and Vibration Designed to meet MIL810G

(2)

55 G

Altitude EN60601-1 Operational: 3000m, Storage 8000m 3000 m

EN60950 Operational: 5000m, Storage 8000m 5000 m

Single Output Power Supply 500W - 1000W

Xsolo

2

www.excelsys.com

Single Output Power Supply 500W - 1000W

Ultra-high efficiency 1U size

Xsolo

solo

XS1000-24N

Section 6.1

Overview of Xsolo

The Xsolo family of single output power supplies provides up to an incredible 1008W in an extremely compact package.

Available in two package types, the high efficiency Xsolo delivers an incredible convection cooled 504W in an open-frame

U-channel form factor and up to 1008W in an enclosed, fan cooled chassis.

The Xsolo platform comes with a host of features including: variable speed fan, 12V/300mA isolated bias supply, remote ON/OFF,

output voltage control and parallel operation for higher power applications. Nominal output voltages are 24V, 36V and 48V with wide

adjustment ranges and user defined set-points. Xsolo carries dual safety certification, EN60950 2nd Edition for Industrial

Applications and EN60601-1 2nd and 3rd Edition for Medical Applications, meeting the stringent creepage and clearance requirements, 4KVAC isolation and <300uA leakage current. Xsolo is designed to meet MIL810G and is also compliant with SEMI F47 for

voltage dips and interruptions as well as being compliant with all relevant EMC emission and immunity standards.

Optional features include I2C digital communications and OR-ing Function for N+1 redundancy. The product can also be conformal

coated and ruggedised for use in harsh environments. With convection cooled power capability of over 500W, the Xsolo is ideal for

use in a wide range of applications: industrial, Hi-Rel MIL-COTS applications, as well as acoustically sensitive laboratory and medical environments.

Section 6.2

Xsolo Features

EN60950 2nd Edition & EN60601-1 2nd and 3rd Edition•

MIL810G•

2 MOPP•

SEMI F47 Compliant•

Ultra high efficiency, >92%•

Low profile: 1U height (40mm)•

Convection Cooled 500W/Fan Cooled 1000W (variable speed fan)•

12V/300mA bias standby voltage provided•

Remote ON/OFF Signal, Power Good Signal•

5 Year Warranty•

Suitable for type B and BF rated applications•

Adjustable output voltage•

5000m altitude for EN60950 applications•

Product Options: Conformal Coating, Low Leakage Current,•

Ruggedised , PMBus, & OR-ing function

APPLICATIONS INCLUDE

Industrial•

Test & Measurement•

Medical•

Hi-Rel/MIL-COTS•

Communication•

www.excelsys.com

3

www.excelsys.com

Single Output Power Supply 500W - 1000W

Xsolo

Section 6.3

Installation Considerations

The Xsolo models may be mounted on any of three surfaces

using standard M3 screws. The chassis comes with four mounting points on the base. Maximum allowable torque is 2Nm. The

maximum penetration depth is 6mm. Maintain a 50mm minimum

clearance at both ends of the Xsolo power supply and route all

cables so airflow is not obstructed. The XS1000 unit draws air in

on the input side and exhausts air out the load side. If airflow ducting is used, avoid sharp turns that could create back pressure.

XS500 units are convection cooled. See Excelsys Application

Note: AN1504 on

website.

Avoid excessive bending of output power cables after they are

connected to the Xsolo powerMods. For high current outputs, use

cable-ties to support heavy cables and minimise mechanical

stress on output studs. Be careful not to short-out to neighbouring

output studs.

The maximum torque recommended on output connectors is

3Nm. Avoid applications in which the unit is exposed to excessive

shock or vibration that exceed the specified levels. In such applications, a shock absorption mounting design is required.

Section 6.4

Xsolo Control and Signals (Analog)

Voltage Adjustment

The Xsolo has been designed with maximum user flexibility as a

key objective. The output voltage can be adjusted over a wide

range by a number of methods.

Voltage adjustment and setting may be achieved by:

1. Voltage Setting via the on board potentiometer.

2. Remote voltage programming by applying a control voltage

(Vcontrol) between J5 Pin 9 (Vtrim) and J5 Pin 10 (-Sense)

3. Remote voltage programming by applying a resistor between

J5 Pin 9 (Vtrim) and J5 Pin 10 (-Sense).

An Excel spreadsheet has been developed to help users calculate output voltage and control values. These are available to

download from the support section of our website;

http://www.excelsys.com/technical-support/

XS500-24 and XS1000-24

By applying a control voltage (Vcontrol) between J5 Pin 9 (Vtrim)

and J5 Pin 10 (-Sense) the output voltage of XS1000-24 and

XS500-24 may be adjusted over a wide range. Vcontrol can be

read from the graph below or calculated with the formula:

Voutput = 12.59 x Vcontrol

Important: Vcontrol must not exceed 2.5V

Example.

Setting the output voltage to 20VDC via the Vtrim Pin

Voutput/12.59 = Vcontrol

20V/12.59 = 1.59V.

Vcontrol = 1.59V

See Graph for full range.

XS500-48 and XS1000-48

Using an external Voltage source (Vcontrol), the output voltage of

the XS1000-48 and XS500-48 may be adjusted over a wide

range.

By applying a control voltage (Vcontrol) between J5 Pin 9 (Vtrim)

and J5 Pin 10 (-Sense) the output voltage of XS1000-48 and

XS500-48 may be adjusted over a wide range. Vcontrol can be

read from the graph below or calculated with the formula

Voutput = 24.75 x Vcontrol

Important: Vcontrol must not exceed 2.5V

Example.

Setting the output voltage to 40VDC via the Vtrim Pin

Voutput/24.75 = Vcontrol

40V/24.75 = 1.62V.

Vcontrol = 1.62V

See Graph below for full range.

Remote voltage programming by an external resistor/potentiometer can also be implemented on the Xsolo. Simply apply

the appropriate resistor value between J5 Pin 9 (Vtrim) and J5

Pin 10 (-Sense). An Excel spreadsheet has been developed to

help users calculate output voltage and resistor values. These

are

available to download from the support section of our website;

http://www.excelsys.com/technical-support/

Current Limit Adjustment ( Voltage)

The Xsolo has been designed to allow users to adjust the onset

of Current Limit for reduced power or constant current applications. By applying a voltage (Vcontrol) between the Itrim pin, (J5

Pin 13), and -Vout, current limit of the Xsolo can be adjusted

from 0 A to the max rated current of the supply.

An Excel spreadsheet has been developed to help users calculate output current and control voltage values. These are available

to download from the support section of our website;

http://www.excelsys.com/technical-support/

4

Current Limit Adjustment on XS1000-48

By applying a control voltage (Vcontrol) between Itrim (J5, Pin 13)

and -Vout, current limit can be adjusted from 0-21A. Vcontrol can

be read from the graph below or calculated with the formula

Ioutput = 8.06 x Vcontrol

Important: Vcontrol should not exceed 3.0V for XS1000-48

Example.

Setting the output current limit of the XS1000-48 to 15A via the

Itrim Pin

Ioutput/8.06 = Vcontrol

15A/8.06 = 1.86VDC.

Vcontrol = 1.86VDC

See Graph for full range.

Current Limit Adjustment via Resistor/Potentiometer

The Xsolo has been designed to allow users to adjust the onset

of Current Limit by applying a resistor between the Itrim pin, (J5

Pin 13), and -Vout. An Excel spreadsheet has been developed

to help users calculate the appropriate resistor values to set output current. These are available to

download from the support section of our website;

http://www.excelsys.com/technical-support/

Current Limit Programming (Foldback)

The Current Limit characteristics of the Xsolo can be programmed to be either Straight Line or Foldback. The previous

sections refer to setting the Straight Line Current Limit of the

Xsolo. To implement Foldback Current Limit, an Excel spreadsheet has been developed to help users calculate the appropriate resistor values to define the onset and final current limit

points of the foldback current curve These are available to download from the support section of our website;

http://www.excelsys.com/technical-support/

Remote ON/OFF

The Xsolo may be inhibited by means of an appropriate signal

applied to an opto-isolated input (diode of an opto-isolater) on

pins J5 connector Pin 2 (positive) and Pin 1 (negative). The delay

from Inhibit to output turning OFF is typically <1ms.

Maximum current source allowed is 6.5mA.

Maximum applied voltage allowed is 13V.

Fan Fail

Fan Fail is an Open collector signal indicating that at least one of

the Xsolo fans has failed. This does not cause power supply

shutdown. The power supply will continue to operate for 10ms

after the temperature alarm signal is generated.

Current Limit Adjustment on XS500-24

By applying a control voltage (Vcontrol) between Itrim (J5, Pin 13)

and -Vout, current limit can be adjusted from 0-21A. Vcontrol can

be read from the graph below or calculated with the formula

Ioutput = 15.27 x Vcontrol

Important: Vcontrol should not exceed 1.5V for XS500-24

Example.

Setting the output current limit of the XS500-24 to 15A via the

Itrim Pin

Ioutput/15.267=Vcontrol

15A/15.267 = 0.98V.

Vcontrol = 0.98VDC

Current Limit Adjustment on XS1000-24

By applying a control voltage (Vcontrol) between Itrim (J5, Pin 13)

and -Vout, current limit can be adjusted from 0-42A. Vcontrol can

be read from the graph below or calculated with the formula

Ioutput = 15.267 x Vcontrol

Important: Vcontrol should not exceed 3.0V for XS1000-24

Example.

Setting the output current limit of the XS1000-24 to 30A via the

Itrim Pin

Ioutput/15.267=Vcontrol

30A/15.267 = 1.96VDC.

Vcontrol = 1.96VDC

See Graph for full range.

Current Limit Adjustment on XS500-48

By applying a control voltage (Vcontrol) between Itrim (J5, Pin 13)

and -Vout, current limit can be adjusted from 0-10.5A. Vcontrol

can be read from the graph below or calculated with the formula

Ioutput = 8.06 x Vcontrol

Important: Vcontrol should not exceed 1.5V for XS500-48

Example.

Setting the output current limit of the XS500-48 to 7.5A via the

Itrim Pin

Ioutput/8.06 = Vcontrol

7.5A/8.06 = 0.93V.

Vcontrol = 0.93VDC

www.excelsys.com

Single Output Power Supply 500W - 1000W

Xsolo

5

The Fan Fail signal is accessed via J5 connector Pin 12. There is

an on-board series current limit resistor of 2k connecting Pin 12 to

the collector of an NPN transistor opto-coupler output. The

emitter is connected to J5 Pin 8 – or Pin 14 (Common). When a

fan-fail condition is detected this transistor turns off.

Maximum current source allowed is 6.5mA.

Maximum applied voltage allowed is 13V.

AC Mains Fail

AC Mains fail signal is accessed through J5 connector Pin 6.

There is an on-board series current limit resistor of 2kohm

connecting Pin 6 to the collector of an NPN transistor optocoupler output. The emitter is connected to J5 Pin 8 or Pin 14

(Common).During normal operation the transistor is ON. When

input voltage is lost or goes below 80VAC the opto-transistor is

turned OFF at least 2 ms before loss of output regulation. (The

output voltage waveform above assumes a pull-up resistor to a

maximum voltage of +13V)

Maximum current source allowed is 6.5mA.

Maximum applied voltage allowed is 13V.

Over-Temperature Protection (OTP)

This is an opto-isolated open collector transistor signal

indicating that excessive temperature has been reached due to

fan failure or operation beyond ratings. This signal is activated

at least 10ms prior to system shutdown. The OTP signal is

accessed via J5 connector Pin 7. There is an on-board series

connect limit resistor of 2Kohm connecting Pin 7 to the collector

of an NPN transistor opto-coupler output.The emmitter is

connected to J5 Pin 8 or Pin 14 (Common).

The Fan Fail and Temp Alarm signal waveforms in the diagram

assume connection via a pull-up resistor to the 12 V bias source

or an external voltage.

Remote Sense

Remote sensing can be used to compensate for voltage drops in

the output loads.

Remote sensing may be implemented by connecting the

Positive Sense pin (J5 pin 11) to the positive side of the remote

load and the Negative Sense pin (J5 pin 10) to the negative side

of the remote load. The maximum line drop, which can be compensated for by remote sensing, is 0.5V, subject to not exceeding the maximum module voltage at the output terminals.

Power Good Signal

The Xsolo contains an internal comparator which monitors the

output voltage and determines whether this voltage is within

normal operation limits. When the output voltage is within normal limits, the PowerGood signal is activated. The signal is

implemented by an open collector of an opto-isolater which is

available on J5 Pin 3 (collector) and J5 Pin 4 (emitter) (transistor ON = Power Good).

Section 6.5

Parallel Connection and N+1 Redundant

operation

How to Connect in Parallel

To achieve increased current capacity, 2 or more Xsolo power

supplies may be connected in parallel. To connect in parallel the

current share header J20 must be added to each Xsolo product,

all -Vo pins must be connected together and then the outputs

must be trimmed to within 5mV of each other using the on-board

potentiometer. Only then can the positive parallel connectors be

attached, and the parallel supplies connected to the load.

For optimal current sharing with OR-ing option a 10% min load

is recommended. If paralleling 3 or more Xsolos consult

Excelsys for applications support.

Recommended Jumper for J20: HARWIN M7567-05

(Jumper Socket, Black, 2.54mm, 2-way)

How to implement N+1 Redundancy

Xsolo can be utilised in systems that require N+1 redundant

operation. The OR-ing option must be selected. Then simply

connect the required number of Xsolo power supplies in parallel using the procedure for Parallel Connection of Xsolo.

J20 (Attach jumper here)

Output Signal Connector J5

Single Output Power Supply 500W - 1000W

Xsolo

6

www.excelsys.com

80ms < t1 < 600ms

10ms < t2 < 20ms

t3 = 10ms

t4 > 10ms

t5 > 2ms

10mS

Section 6.8

Xsolo Acoustic Noise

The XS500 provides up to 504W with no fan cooling and is

therefore a silent power supply. The XS1000 has an integral

temperature controlled fan that only operates if and when the

output load and internal component temperatures require.

Please refer to the Acoustic Noise vs Output Power XS1000

graph below.

At loads below 500W the fan is not required and the XS1000 is

Section 6.7

Xsolo Efficiency

The Xsolo series offer unrivalled efficiency with a maximum efficiency of over 92%. It is often the case that power supplies are

operating at lower levels than their maximum ratings. Most

power supplies have optimised efficiency at a higher load ratings

(close to full rating) but perform significantly worse at light or

lower loads.

The Xsolo design and component selection ensures that conversion losses are kept to a minimum over a wide range of output

loads. For example, in the graph below, The XS1000 is still over

90% efficient at 30% of rated output (300W).

www.excelsys.com

7

Single Output Power Supply 500W - 1000W

Xsolo

Output Power (W)

Acoustic Noise V’s Output Power XS1000

Noise Level dBA

Efficiency V’s Load XS1000

Output Power (W)

Efficiency

Efficiency V’s Load XS500

Efficiency

Output Power (W)

Section 6.6

Options

Environmental Conformal Coating (Option C)

Xsolo is available with conformal coating for harsh environments and MIL-COTs applications. It is IP50 rated against dust

and protected against vertical falling drops of water and non

condensing moisture. Conformal coating material is

polyurethane based and military qualified.

Ruggedised Option (Option R)

Xsolo is available with extra ruggedisation for applications that

are subject to extremes in shock and vibration. These parts

have been tested on 3 axes, for a total of 300hours at 1.67g’s

rms.

Conformally Coated and Ruggedised (Option S)

Features Options

00 = no options

01 = I2C/PMBus

02 = OR-ing Function

03 = 2C/PMBus + OR-ing Function

04 = Low Leakage

05 = I2C/PMBus + Low Leakage

06 = OR-ing Function + Low Leakage

07 = I2C/PMBus + OR-ing Function + Low Leakage

The XS500 is over 90% efficient at loads of 250W or higher.

The XS500 provides up to 504W with no fan cooling and is

therefore a silent power supply. The XS1000 has a temperature controlled fan that only operates if and when the output

load and internal component temperatures require.

Please refer to the Acoustic Noise vs Output Power XS1000

graph below. At loads below 500W the fan is not required and

the XS1000 is silent.

The XS500 can also be cooled using system air flow. Please

refer to XS500 derating curves get detailed line and temperature

derating of the XS500.

Single Output Power Supply 500W - 1000W

Xsolo

powerMod 0.958 failures per million hours

4slot powerPac 0.92 failures per million hours

6slot powerPac 0.946 failures per million hours

The figures for the powerPac excludes fans.

Example:

What is the MTBF of UX4DD00

UX4 FPMH = 0.92

XgD FPMH = 0.286

Total FPMH = 1.49

MTBF = 670,000 hours at 40°C

Xsolo MTBF

Xsolo has an MTBF of 550,000 hours at 40°C and full load

based on the Telecordia SR-332 (fans excluded).

MTBF and Temperature

Reliability and MTBF are highly dependent on operating temperature. The figures above are given at 40°C. For each 10°C

decrease, the MTBF increases by a factor of approximately 2.

Conversely, however, for each 10°C increase, the MTBF

reduces by a similar factor. Therefore, when comparing manufacturer's quoted MTBF figures, look at the temperature information provided. Contact Excelsys for detailed analysis of MTBF

for your specific application conditions.

Section 7.2

Safety Approvals

UltiMod and Xsolo carry dual safety certification,

UL/EN60950 2nd Edition for Industrial Applications and

UL/EN60601-1 2nd and 3rd Edition for Medical Applications,

meeting the stringent creepage and clearance requirements,

4KVAC isolation and <300uA leakage current. The Xgen series

also carries full safety approvals. Refer to individual Xgen

Datasheets for the relevant safety approvals carried by each

model.

UltiMod, Xsolo and Xgen are designed to meet MIL810G and

are also compliant with SEMI F47 for voltage dips and interruptions as well as being compliant with all relevant EMC emission

and immunity standards (Eee individual datasheets for details).

Safety Approvals

Low Voltage Directive (LVD) 2006/95/EC

The LVD applies to equipment with an AC input voltage of

between 50V and 1000V or a DC input voltage between 75V and

1500V. The XSolo series is CE marked to show compliance with

the LVD.The relevant European standard for UltiMod, Xsolo and

Xgen models is EN60950 (Information technology). The 2nd

Edition of this standard in now published and all relevant

Excelsys power supplies are certified to the latest edition as well

as the 1st Edition.

The relevant European standard for UltiMod, Xsolo and Xgen

models is EN60601-1 (Medical Devices Directive). The 3rd

Edition of this standard is published and all Excelsys medically

approved power supplies are certified to this latest edition as

well as the 2nd Edition. With appropriate packaging, the UltiMod,

Xsolo and Xgen models can also meet the requirements of

EN61010-1 for industrial scientific measuring equipment and

process control.

UltiMod, Xsolo and Xgen models are certified to comply with the

requirements of IEC950, EN60950, UL60950 (1st and 2nd

Editions), and CSA 22.2 no. 234 and IEC1010, when correctly

installed in a limited access environment.

The UltiMod, Xsolo and Xgen series are certified to comply with

the requirements of IEC601-1, EN60601-1, UL60601-1 (2nd and

Section 7.1

Reliabilty

The 'bath-tub' curve shows how the failure rate of a power supply

develops over time. It is made up of three separate stages.

Immediately after production, some units fail due to defective

components or production errors. To ensure that these early failures do not happen while in the possession of the user, Excelsys

carries out a burn-in on each unit, designed to ensure that all

these early failures are detected at Excelsys. After this period,

the power supplies fail very rarely, and the failure rate during this

period is fairly constant. The reciprocal of this failure rate is the

MTBF (Mean Time Between Failures).

At some time, as the unit approaches its end of life, the first signs

of wear appear and failures become more frequent. Generally

'lifetime' is defined as that time where the failure rate increases to

five times the statistical rate from the flat portion of the curve.

In summary, the MTBF is a measurement of how many devices

fail in a period of time (i.e. a measure of reliability), before signs

of wear set in. On the other hand, the lifetime is the time after

which the units fail due to wear appearing.

The MTBF may be calculated mathematically as follows:

MTBF = Total x t / Failure , where

Total is the total number of power supplies operated simultaneously.

Failure is the number of failures.

t is the observation period.

MTBF may be established in two ways, by actual statistics on

the hours of operation of a large population of units, or by calculation from a known standard such as Telecordia SR-332 and

MIL-HDBK-217 and its revisions.

Determining MTBF by Calculation

MTBF, when calculated in accordance with Telecordia, MILHDBK-217 and other reliability tables involves the summation of

the failure rates of each individual component at its operating

temperature. The failure rate of each component is determined

by multiplying a base failure rate for that component by its operating stress level.

The result is FPMH, the failure rate per million operating

hours for that component.

Then FPMH for an assembly is simply the sum of the individual

component FPMH.

Total FPMH = FPMH1 + FPMH2 + ………….. +FPMHn

MTBF (hours) = 1,000,000

FPMH

In this manner, MTBF can be calculated at any temperature.

Section 7 Reliabilty, Safety, EMI and Technical Resources

8

www.excelsys.com

PowerMods are capable of providing hazardous energy levels

(>240 VA). Equipment manufacturers must provide adequate

protection to service personnel.

Environmental Parameters

The UltiMod, Xsolo and Xgen series are designed for the following parameters

Material Group IIIb, Pollution Degree 2

Installation Category 2

Class I

Indoor use (installed, accessible to Service Engineers only).

Altitude: -155 metres to +3000 metres from sea level.

Humidity: 5 to 95% non-condensing.

Operating temperature -20°C to 70°C

Derate to 70°C. See powerPac Derating for details.

Approval Limitations

Use in North America

When these products are used on 180 to 253 Volts AC mains

with no neutral, connect the two live wires to L (live) and N (neutral) terminals on the input connector.

Standard

Creepage Distances XL, XC, XK, XQ, XT, XB, XH models

Primary mains circuits to earth: 2.5mm spacing

Primary mains circuits to secondary: 5mm spacing

Dielectric strength XL, XC, XK, XQ, XT, XB, XH models

Primary mains circuits to chassis: 1500VAC

Primary mains circuits to secondary: 3000VAC

Medical

Creepage Distances UltiMod, Xsolo, XM, XV, XR, XZ, XN,

XW models

Primary mains circuits to earth: 4mm spacing

Primary mains circuits to secondary: 8mm spacing

Dielectric strength UltiMod, Xsolo, XM, XV, XR, XZ, XN,

XW models

Primary mains circuits to chassis: 1500VAC

Primary mains circuits to secondary: 4000VAC

The primary to secondary test is not possible with modules fitted

to the unit, as damage to the EMI capacitors will occur.

Output Isolation

Xsolo : Output to Chassis isolation is 1500VAC.

UltiMod, Xgen: Output to Output Isolation is 500VDC

Output to Chassis Isolation is 500VDC

Section 7.3

EMC Characteristics

EMC Directive 2004/108/EC

Component Power Supplies such as the UltiMod, Xsolo and

Xgen series are not covered by the EMC directive. It is not possible for any power supply manufacturer to guarantee conformity of the final product to the EMC directive, since performance is

critically dependent on the final system configuration. System

compliance with the EMC directive is facilitated by Excelsys

products compliance with several of the requirements as outlined in the following paragraphs. Although the UltiMod, Xsolo

and Xgen series meet these requirements, the CE mark does

not cover this area.

EMISSIONS

Power Factor (Harmonic) Correction

The UltiMod, Xsolo and Xgen series incorporates active power

factor correction and therefore meets the requirements of

EN61000-3-2. Power factor: 0.98.

EN61000-3-3 Flicker & Voltage Fluctuation Limits

UltiMod, Xsolo and Xgen power supplies meet the requirements

of the limits on voltage fluctuations and flicker in low voltage supply systems.

EN55022 Class B Conducted Emissions

For system compliance to EN55022, Level B, additional filtering

may be required, for technical support, contact our Applications

Engineering team.

IMMUNITY

The UltiMod, Xsolo and Xgen series has been designed to meet,

and tested to, the immunity specifications outlined below:

EN61000-4-2 Electrostatic Discharge Immunity

8kV Air discharge applied to Enclosure

6kV Contact with Enclosure

EN61000-4-3 Radiated Electromagnetic Field

10Volts/metre 80MHz to 2.5GHz applied to Enclosure

EN61000-4-4 Fast Transients-Burst Immunity

+/-2kV

EN61000-4-5 Input Surge Immunity

Xsolo:

+/-4kV Common Mode 1.2/50 S (Voltage); 8/20uS (Current)

+/-2kV Differential Mode 1.2/50 S (Voltage) 8/20 S (Current)

UltiMod and Xgen:

+/-2kV Common Mode 1.2/50 S (Voltage); 8/20uS (Current)

+/-1kV Differential Mode 1.2/50 S (Voltage) 8/20 S (Current)

EN61000-4-6 Conducted Immunity

10 V/m 150KHz to 80MHz

EN61000-4-11 Voltage Dips

0% 1s Criteria B

40% 100ms Criteria B

70% 10ms Criteria A

Further details on all tests are available from Excelsys.

Guidelines for Optimum EMC Performance

All Excelsys products are designed to comply with European

Normative limits (EN) for conducted and radiated emissions and

Immunity, when correctly installed in a system. However, power

supply compliance with these limits is not a guarantee of system

compliance and system EMC performance can be impacted by

a number of items.

Cabling arrangements and PCB tracking layouts are the greatest contributing factors to system EMC performance. All cables

and PCB tracks should be treated as radiation sources and

antenna. Every effort should be made to minimise current carrying loops that can radiate, and to minimise loops that could have

noise currents induced into them.

a. Keep all cable lengths as short as possible.

b. Minimise the area of power carrying loops to minimise radia-

tion, by using twisted pairs of power cables with the maximum

twist possible.

c. Run PCB power tracks back to back.

d. Minimise noise current induced in signal carrying lines, by twisted

pairs for sense cables with the maximum twist possible.

e. Do not combine power and sense cables in the same harness

f. Ensure good system grounding. System Earth should be a

“starpoint”. Input earth of the equipment should be directed to

the “starpoint” as soon as possible. The power supply earth

should be connected directly t

EMI for XF

The Xsolo series of power supplies have been designed for used

in harsh environments including military applications. For additional information relating to MIL STD 461F, CE101 and CE102

EMI characterization, please contact Excelsys Technologies.

www.excelsys.com

9

REV 1.1.0

Loading...

Loading...