Excelsys ultimod Designer's Manual

Designer Manual

• Low inrush current

• Conducted EMI meets EN 55022 Level B

• AC Fail status signal

• Output sequencing capability

• Global shutdown capability

• Overcurrent protection standard on all outputs.

• Overvoltage protection on all outputs

• Over temperature limiting on all powerMods and PowerPacs

• Safety Agency Approvals: CE Mark, UL, CSA

• DC OK (Power Good) status signal (consult datasheet)

• Wide output voltage adjustment range

• RoHS compliant

Optional Features

• Reversed fan airflow direction

• Conformal coating

• Low leakage current

Section 4.2

Installation Considerations

The UltiMod series models may be mounted on any of three

surfaces using standard M4 screws. The chassis comes with four

mounting points on the base. Maximum allowable torque is 2Nm.

The maximum penetration depth is 6mm. Additionally, the

fleximountTMsystem on both side walls of the powerPac chassis

facilitates flexible mounting.

When selecting a mounting location and orientation, the unit

should be positioned so air flow is not restricted. Maintain a

50mm minimum clearance at both ends of the UltiMod power

supply and route all cables so airflow is not obstructed. The

standard unit draws air in on the input side and exhausts air out

the load side. If airflow ducting is used, avoid sharp turns that

could create back pressure.

Avoid excessive bending of output power cables after they are

connected to the UltiMod powerMods. For high current outputs,

use cable-ties to support heavy cables and minimise

mechanical stress on output studs. Be careful not to short-out to

neighboring output studs. UltiMod powerMods are supplied

with spring washers on all output screws. These (or equivalents)

should be used and thread locking compounds are not required.

The maximum torque recommended on output connectors is

4Nm. Avoid applications in which the unit is exposed to

excessive shock or vibration levels that exceed the specified

levels. In such applications, a shock absorption mounting

design is required.

Section 4.3

UltiMod Mounting Considerations

•

Always fill all output slots of the UltiMod. If a slot is not filled

with a powerMod, it should be filled with an Empty Slot Cover

(part numbers XB1, XB2 or XB3). Empty Slot covers are

plastic assemblies whose main function is to fill up an empty

slot. Excessive airflow escape from an empty slot may

degrade thermal performance and result in overheating and

damage to the UltiMod unit. Refer to Section 4.11 for optimum

positioning of powerMods.

• Do not unplug powerMods while input power is applied to the

powerPac. The UltiMod is not designed for hot-plug applications.

• Do not restrict airflow to the unit. The cooling fan draws air

into the unit and forces it out at the output terminals.

• Always ensure that output screws are properly torqued before

UltiMod Designer Manual

Designer Manual

www.excelsys.com

2

DESIGNERS’ MANUAL

This UltiMod Designers’ Manual has been prepared by

Excelsys experts to assist qualified engineers and

technicians in understanding the correct system design

practices necessary to achieve maximum versatility and

performance from any of the Ultimod products.

Section 4.1

Overview of UltiMod

The UltiMod series allows users to instantly configure high

efficiency, off-line power supplies. Although very small in size,

(40.4mm high, 260mm long and either 89mm or 127mm wide)

the UltiMod provides up to 1200W of output power. The UX4

delivers up to 600W and can be populated with up to 4

powerMods, the UX6 delivers up to 1200W and can be populated

with up to 6 powerMods.

A complete power supply is configured by selecting and

inserting up to six DC output modules called powerMods to build

a power supply that offers the advantages of a custom supply,

but is assembled from standard and modular building blocks

continuing the Excelsys tradition of industry leading

configurable power supplies.

Manufactured in world class power supply facilities, the UltiMod

is completely user configurable. If output requirements change,

i.e. more power or a different output voltage is needed,

upgrading is easy: simply unlock a single screw and replace

the slide-in powerMod assembly with the preferred alternative.

Allowing additional flexibility, powerMods can be connected in

parallel to increase output power, or in series for higher

voltages (subject to staying within isolation ratings and giving

due consideration to any SELV requirements).

A user-friendly interface on connector J3 of each powerMod

provides control and output sequencing capability, in addition to

useful status indicators. Please consult our Excelsys applications

team if you have other special requirements.

The plug-together architecture facilitates ‘instant’ custom power

solutions with industry leading 17W/in3power density and up to

92% conversion efficiency. The series is designed for highest

efficiencies and consists of two Input AC front ends (powerPacs),

UX4 and UX6 and 11 DC output powerMods (XgA to XgL).

Standard Features

• Input Voltage: 85V to 264Vac 47 to 63 Hz

• Outputs: Up to 12 isolated outputs

• Full power output to 40°C; Derating to 70°C

applying power to the powerPac.

• Positive and negative power cables should be arranged as a

twisted pair to minimise inductance.

• Wait 4 minutes after shutting off power before inserting or

removing powerMods.

• UltiMod assemblies do not have user serviceable

components. They must be returned to the factory for repairs.

Contact Customer Service for a RMA number before

returning the unit. Do not attempt to repair or modify the

power supply in any manner other than the exchange of

powerMods as described in this Designers’ Manual.

• Use proper size wires to avoid overheating and excessive

voltage drop.

Section 4.4

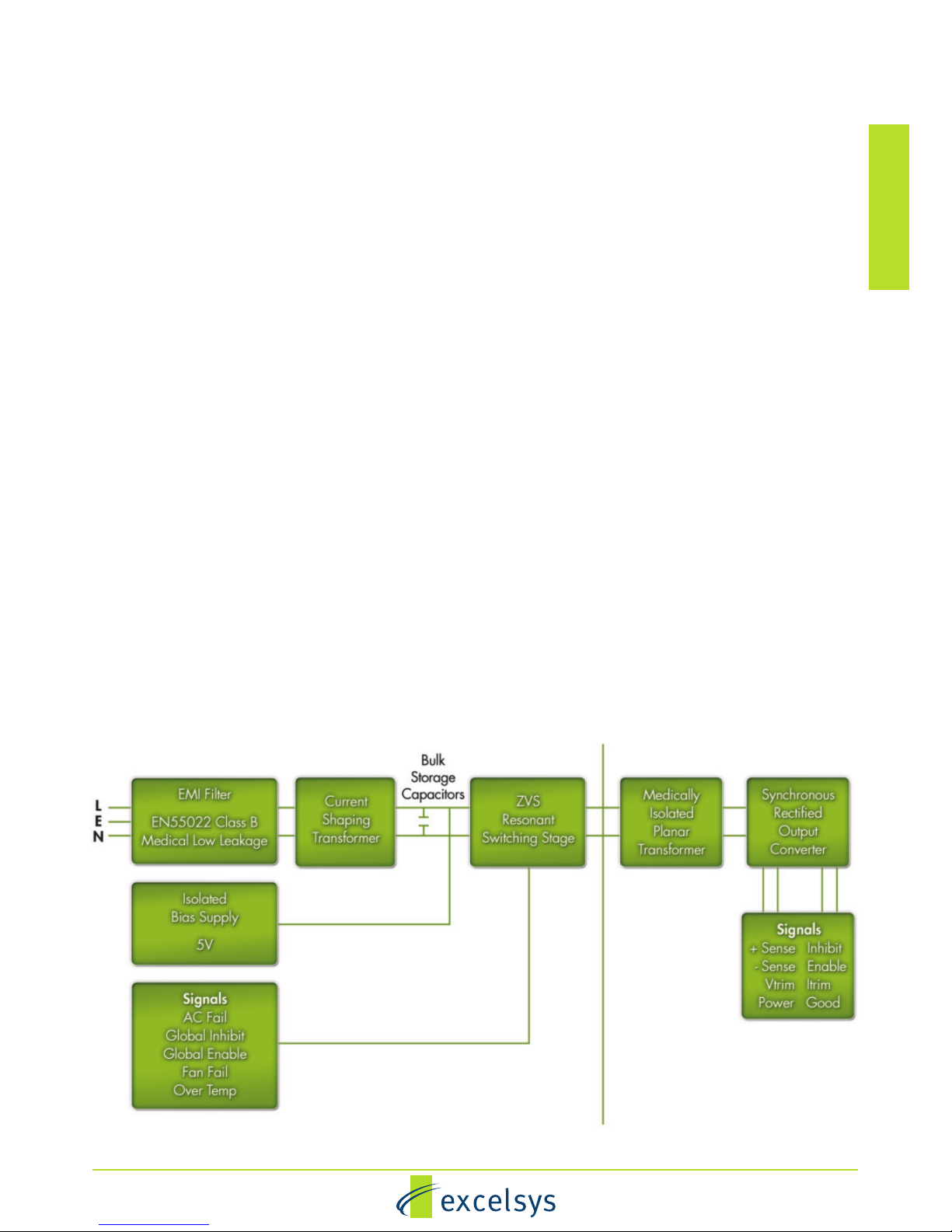

Theory of Operation

The UltiMod is comprised of an appropriate powerPac and a

selection of powerMod DC output modules selected to deliver

the exact volts and amps requirements of the the system

designer. See Operational Block Diagram.

The UltiMod powerPac modules consist of a fan-cooled semienclosed chassis containing circuitry for an off-line single phase

AC front end, EMI filter, cooling fan, customer interface and

associated housekeeping circuits. Input AC mains voltage

(L1/N, L2 and GND) is applied to an IEC320 type input

connector and then through an EMI filter designed to meet EN

55022 Level B. For medical applications, the EMI filter also

ensures the power supply meets the low earth leakage current

requirements of EN60601-1 3rd Edition.

Inrush current limited by an active soft start cct. Current is

limited by a combination of thermistors (UX4), and thermistors

and SCR's (UX6). This stage is then followed by a high

frequency switching input current shaping boost converter

feeding the ZVS (Zero Voltage Switching) resonant switching

stage. The ZVS stage supplies power to a variety of powerMod

assemblies that provide the desired low voltage, regulated

outputs. Conversion in the output assemblies is achieved by the

most advanced high efficiency converters resulting in reduced

UltiMod Designer Manual

Designer Manual

www.excelsys.com

3

size for magnetics and capacitors; excellent line and load

regulation; wide adjustment range for output and low EMI/RFI

emission.

At initial power-up, the UltiMod outputs are disabled to eliminate

inrush current and a low-power flyback converter operating with

PWM current mode control converts the high voltage DC bus

into regulated low voltage to power the internal housekeeping

circuits and cooling fans. Once the bus potential is within

operating parameters, the AC Fail signal is activated indicating

that the input power is ok, and allows the installed powerMod

outputs to come up. An auxiliary bias supply of 5 Vdc is provided

for peripheral use on interface connector J2. In the case of

medically approved supplies, this bias supply has medical

isolation (4000VAC).

Section 4.5

Configuration (and Reconfiguration)

powerMods may be easily added, replaced, or moved by sliding

the assemblies in or out of a powerPac chassis.

Prior to removing or installing a powerMod module, remove

power from the powerPac and wait 4 minutes. Failure to do so

can result in personal injury and/or damage to the supply. Take

standard ESD precautions when handling powerMods.

Configuring the UltiMod is as easy as 1,2,3!

1. Select the appropriate powerMods for your application.

2. Calculate your power requirements.

3. Select your appropriate powerPac for power and application

from the wide range of powerPacs.

Removing powerMods

powerMods may be removed by removing the screw on the top

surface. Once this screw has been removed the powerMod will

slide out of the chassis. Once a powerMod has been removed,

the empty slot MUST be filled with either another powerMod or

an empty slot cover. If the slot is left empty, it will provide an

airflow escape and may cause inadvertent shutdown of the unit

.

Operational Block Diagram

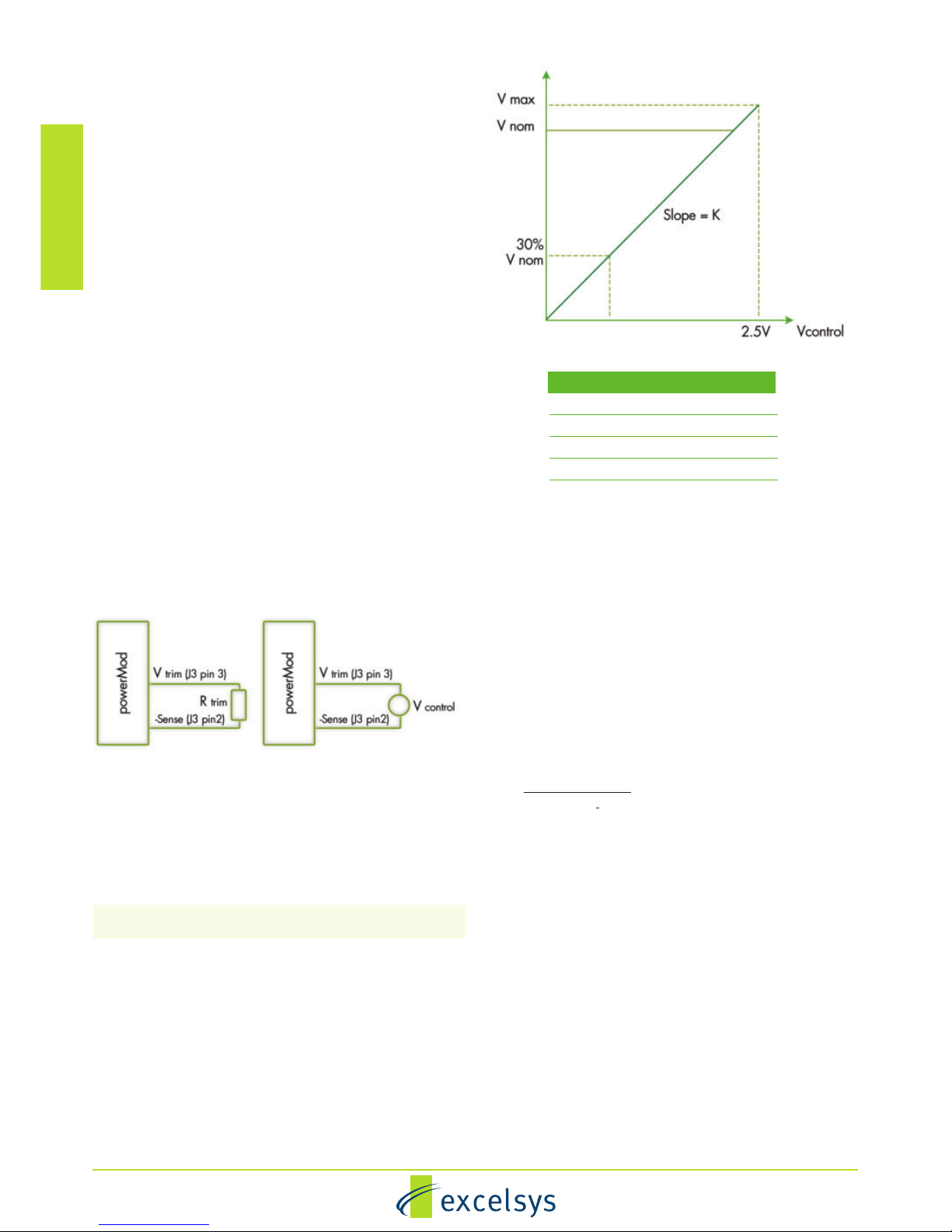

Remote Voltage Programming using a Resistor.

The powerMod output voltage can be adjusted downward using

a remote potentiometer or reduced, using an external

resistance.

Calculation of the the external resistance depends on the actual

initial voltage setting of the powerMod (via the onboard

potentiometer). The preferred method is to set the powerMod

voltage to its maximum rating. e.g. XgK set to 30V. This will

allow the widest possible adjustment range of the output

voltage.

powerMod set to Vmax

Rtrim= [3700V

out - 250K] (2)

[2.5K-Vout ]

Example.

Using a powerMod XgK, determine the resistance value to be

applied to Vtrim pin in order to set powerMod output voltage to

20V.

K for XgK = 12.5

Vout = 20V

Using equation (2)

Rtrim= 6300 ohm

Alternatively if the powerMod voltage is set to new level via the

on-board potentiometer to another level e.g. 21V then the

following formula must be used to calculate the value of Rtrim

www.excelsys.com

4

Installing powerMods

powerMods may be installed in empty slots by simply sliding in

the new powerMod, pushing the module ‘home’ until the

mounting bracket lines up with the hole in the Top Panel, then

securing the module with the M3 x 6 countersunk screw

provided. Power and interface connections can be made after

the powerMod has been installed.

powerMods may be paralleled for more power using bus bars

(Paralleling Links) across the positive and negative output

terminals. See Section 4.6 for details.

Section 4.6

powerMod Operation

The UltiMod has been designed to allow maximum flexibility in

meeting the unique requirements of individual users. The

inherent flexibility resulting from modularity concepts is further

enhanced by this flexibility. Although the products are very

versatile, care should always be taken to ensure that the proper

procedures are followed.

Voltage Adjustment

The UltiMod has been designed with maximum user flexibility as

a key objective. With regards to voltage adjustment this has been

achieved by the wide range of adjustment on each of the

powerMod models. Voltage adjustment may be achieved by:

1. Front-panel potentiometer adjustment (XgA - XgL)

2. Remote resistive programming (XgG - XgL)

3. Remote voltage programming (XgG - XgL)

See diagrams for details on external connections to the V trim

pin (J3 pin3) required for remote voltage programming(XgG XgL).

Remote Voltage Programming using a Voltage Source

Using an external Voltage source (V

control

), the powerMod

output voltage may be adjusted over a wide range. The

powerMod output voltage may be programmed by referring to

the Voltage Programming Graph and applying the formula

below to set the powerMod output voltage to the required level.

V

output

= K x V

control

(1)

The appropriate K factor for different powerMods are in the

‘Remote Output Voltage Adjustment’ table.

Important: V

control

must not exceed 2.5V.

Example.

Using a powerMod XgK, what external voltage must be applied

to Vtrim pin in order to set powerMod output voltage to 20V.

V

output

= 20V, K=12.5

Using equation (1); V

output

/K=V

control

20V/12.5 = 1.6V.

V

control

= 1.6V

Designer Manual

powerMod K

XgG 1.56

XgH 2.5

XgJ 6.23

XgK 12.5

XgL 24.2

Remote Output Voltage Adjustment of powerMods

Remote Output Voltage Adjustment of powerMods

Remote Output Voltage Adjustment Table

UltiMod Designer Manual

Rtrim = 1000Vout [(4.275 +Vp(1.96-4Vp)] -K(0.1Vp+0.051) (3)

K(Vp +0.51) -0.604Vout

where Vp is the powerMod setpoint voltage expressed as a

proportion of the total trim range and can be calculated using

formula (4).

Vp =(Vset-0.844K) (4)

1.656K

Example.

To set powerMod XgK to 15V when powerMod Vset is 12V.

K=12.5

Using equation (4) Vp = Vset-0.844K

1.656K

= 21-0.844(12.5)

1.656K(12.5)

Vp =0.51

Vout =15V

Using equation (3)

Rtrim = 1000Vout[(4.275+Vp(1.96-4Vp)] -K(0.1Vp+0.051)

[K(Vp +0.051) -604Vout]

Rtrim = 17,214 ohm

The power rating of the trim resistor can be as low as 100mW

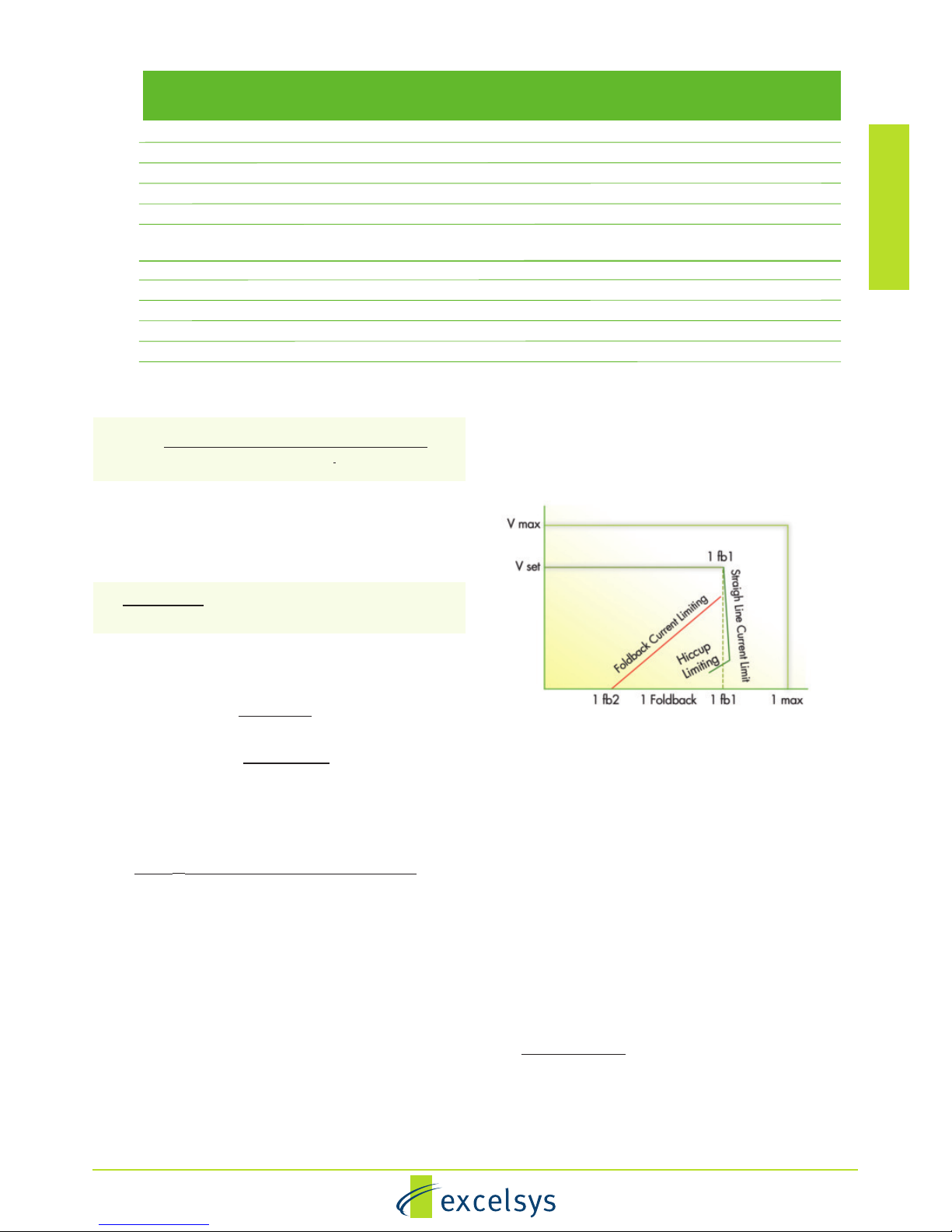

Over Current Protection (OCP)

A variety of over current protection methods are possible with the

Ultimod series. See the ‘Output powerMod Summary’ table

which indicates the available current limit modes on each

powerMod.

powerMods XgG to XgL can have Straight-line current limit or

Foldback current limit. See ‘Output powerMod Summary

Specifications’ table for nominal current limit values.

Simple external application circuits may be used to achieve

programmable foldback current and user programmable current

limit levels (reduced). See Current Limit Programming

www.excelsys.com

5

Designer Manual

UltiMod Designer Manual

diagrams and Foldback Programmable Current Limit diagram.

The default current limit characteristic is Straight Line Current

Limit.

Programming Current Limit

The current limit can be programmed to your requirements (in

both Straight line and Foldback modes).

Straight line Current Limit can be programmed using an external

voltage source or resistor/potentiometer. Connection between

the Itrim pin (J3 pin4 and the -Vout terminal) will set the current

limit to the desired level.

Straight Line Current Limit Using a Voltage Source

The formula below will calculate the required external control

voltage required to set the current limit of a powerMod:

If Current Limit is Less than 85% of Maximum Current

Itrim = FIlim + CF - 0.53 (5)

If Current Limit is Greater than 85% of Maximum Current:

Itrim = FIlim + CF - 1.325 (6)

0.558

Where F is a conversion factor for each powerMod and CF is a

correction factor.

Note that application of any voltage >2.5V to Itrim will not increase

Visit the UltiMod Online Configurator to get the best recommendation for your application at

www.excelsys.com/xgen_configurator/configure.html

Model Vnom Set Point Current Limit

Dynamic Vtrim Imax Power OVP 1 Remote Power

(V) Adjust Range (V)

Foldback Range (V) (A) (W) Tracking Sense Good

% of Vset (V)

XgA 12.0 10.8-15.6 - - 12.5 150 - - -

XgB 24.0 19.2-26.4 - - 8.3 200 - - -

XgC 36.0 28.8-39.6 - - 5.6 200 - - -

XgD 48.0 38.5-50.4 - - 4.2 200 - - -

XgE 24.0 5.0-28.0 - - 5.0 120 - - Yes

XgF 24.0 5.0-28.0 - - 3.0 72 - - Yes

24.0 5.0-28.0 - - 3.0 72 - - Yes

XgG 2.5 1.5-3.6 Yes 1.0-3.6 40.0 100 110-115% 0.5 Yes

XgH 5.0 3.2-6.0 Yes 1.5-6.0 36.0 180 110-115% 0.5 Yes

XgJ 12.0 6.0-15.0 Yes 4.0-15.0 18.3 220 110-115% 0.5 Yes

XgK 24.0 12.0-30.0 Yes 8.0-30.0 9.2 220 110-115% 0.5 Yes

XgL 48.0 24.0-58.0 Yes 8.0-58.0 5.0 240 110-115% 0.5 Yes

Current Limit Characteristics

Output powerMod Summary Specifications

Loading...

Loading...