EX-2001 Plus v1.3 SME300000060

EXCELL PRECISION CO., LTD.

© Excell Precision Limited 2004. All rights reserved Worldwide.

The information contained herein is the property of Excell Precision Limited

and is supplied without liability for errors or omissions. No part may be

reproduced or used except as authorised by contract or other written

permission. The copyright and the foregoing restriction on reproduction

and use extend to all media in which the information may be embodied.

EX-2001 Plus v1.3 SME300000060

1

EXCELL PRECISION CO., LTD.

TABLE OF CONTENTS

SAFETY............................................................................................................3

CHAPTER 1 SPECIFICATIONS.......................................................................4

CHAPTER 2 OPERATION GUIDE....................................................................5

CHAPTER 3 FRONT AND REAR PANEL........................................................7

3-1 FRONT PANEL.........................................................................................7

3-2 REAR PANEL...........................................................................................8

CHAPTER 4 INSTALLATION...........................................................................9

4-1 LOAD CELL.................................................................................................9

4-2 INDICATOR INSTALLATION AND DIMENSIONS.................................................9

CHAPTER 5 CAPACITY CALIBRATION........................................................11

5-1 PARAMETER SETTING.........................................................................11

5-1-1 Flow Diagram........................................................................................................11

5-1-2 Description...........................................................................................................12

5-2 CALIBRATION SETTING.......................................................................14

5-2-1 Calibration Procedure..........................................................................................14

5-2-2 Zero Calibration...................................................................................................14

5-2-3 Weight Calibration................................................................................................14

5-2-4 Linearity Calibration.............................................................................................15

5-3 PASSWORD SETTING..........................................................................18

5-4 ERROR MESSAGES.............................................................................19

CHAPTER 6 ANIMAL SCALE FUNCTION SETTING.....................................20

CHAPTER 7 INTERFACES............................................................................21

7-1 OP-01 RS-422 & RS-485 INTERFACE...................................................21

7-2 OP-02 PARALLEL BCD OUTPUT...........................................................24

7-3 OP-03 ANALOGUE CURRENT / VOLTAGE OUTPUT INTERFACE........26

7-4 OP-05 PARALLEL PRINTER OUTPUT & RS-232 & CURRENT LOOP...27

7-5 OP-06 RS-232 & CURRENT LOOP........................................................30

7-6 OP-07 RS-232, CURRENT LOOP & DATA CLOCK OUTPUT.................31

7-7 OP-08 CONTROL I /O (2I /4O) INTERFACE...........................................32

CHAPTER 8 MAINTENANCE........................................................................36

8-1 RESET ALL PARAMETERS BACK TO DEFAULT...................................36

8-2 RESET GENERAL FUNCTION PARAMETERS BACK TO DEFAULT.....36

8-3 SELF-DIAGNOSIS MODE......................................................................36

8-3-1 7 Digit Display and LED Status Light Diagnosis................................................37

8-3-2 Keyboard and Calibration ON / OFF Switch Diagnosis.....................................37

8-3-3 RS-232 Serial Output / Input Interface Diagnosis ( OP-06 )..............................37

EX-2001 Plus v1.3 SME300000060

2

EXCELL PRECISION CO., LTD.

8-3-4 BCD Parallel Output Interface Diagnosis ( OP-02 )...........................................37

8-3-5 Analogue Current Output Interface Diagnosis ( OP-03 )...................................38

8-3-6 Parallel Printer Interface Diagnosis ( OP-05 )....................................................38

8-3-7 Main Board EEPROM Memory Diagnosis.........................................................38

8-3-8 OP-08 Control I /O (2I /4O) Diagnosis...............................................................38

CHAPTER 9 FUNCTION TABLE....................................................................39

9-1 GENERAL FUNCTION...........................................................................39

9-2 OP-01, OP-06, OP-07 INTERFACE FUNCTION.....................................40

9-3 OP-02 BCD OUTPUT INTERFACE FUNCTION.....................................41

9-4 OP-03 ANALOGUE OUTPUT INTERFACE FUNCTION.........................41

9-5 OP-05 PARALLEL PRINTER OUTPUT INTERFACE FUNCTION...........42

9-6 OP-08 CONTROL I /O (2I /4O) INTERFACE FUNCTION........................43

EX-2001 Plus v1.3 SME300000060

3

EXCELL PRECISION CO., LTD.

!

rSAFETY

& Disconnect the main power supply before opening the indicator housing or

installing / un-installing the instrument.

& Keep the instrument in a cool dry place. Do not store it at high

temperatures.

& The operating ambient temperature range is -10°C ~ +40°C.

& F.G. is the ground (electrical earth) connection. (Ground impedance < 100Ω)

Avoid connecting the ground connection with other equipment. The

indicator must always be connected to the electrical ground (earth) for safe

operation.

EX-2001 Plus v1.3 SME300000060

4

EXCELL PRECISION CO., LTD.

CHAPTER 1 SPECIFICATIONS

ANALOG DATA

Input sensitivity 0.12 μV/D or more

Max. load cell input voltage -1mV〜16mV

Load cell excitation DC 5V

Load cell current 120mA ( 8- 350Ω load cells )

Zero -14.49 ppm/℃ ( -10℃〜40℃)

Temperature coefficient

Span

-1.65 ppm/℃ ( -10℃〜40℃)

Non-linearity ±0.002%FS

Input noise 8nV⁄√Hz f = 10KHz

Input impedance 250GΩ

Internal resolution 520000

Max. display resolution -999999〜999999

Conversion rate 100 times/sec (max.)

DIGITAL DATA

Display section 7 digits, red LED, 20mm (0.8”), 7-segment

Status display section 6 character display, red LED

Display frequency (times/sec) Selectable, Max 50

Display range -999999 to 999999

Min. division 1, 2, 5, 10, 20, 50

Status display Power, Zero, Motion, Gross, Net, Tare

Decimal point Selectable 0, 0.0, 0.00, 0.000, 0.0000

GENERAL SPECIFICATIONS

Power requirements (AC/W)

AC100V〜240V -15%~+10% 10W

Operating temperature range

-10℃〜+40℃

Operating humidity range

<85% R.H

Physical dimensions 210(W) × 108 (H) × 207(D)

Weight About 1.7 kg

OPTIONS

OP-01 RS422 / RS-485

OP-2-1 Parallel BCD Output ( TTL )

OP-2-2 Parallel BCD Output ( O.C. )

OP-03 Analog Output ( 4 - 20mA )

OP-05 Parallel Printer Output / RS232C & Current Loop

OP-06 RS-232C & Current Loop

OP-07 RS-232C & Current Loop & Data Clock Output

OP-08 Control I / O ( 2I / 4O)

EX-2001 Plus v1.3 SME300000060

5

EXCELL PRECISION CO., LTD.

Fn

Fn

Fn

CAL

CAL

Fn

CAL

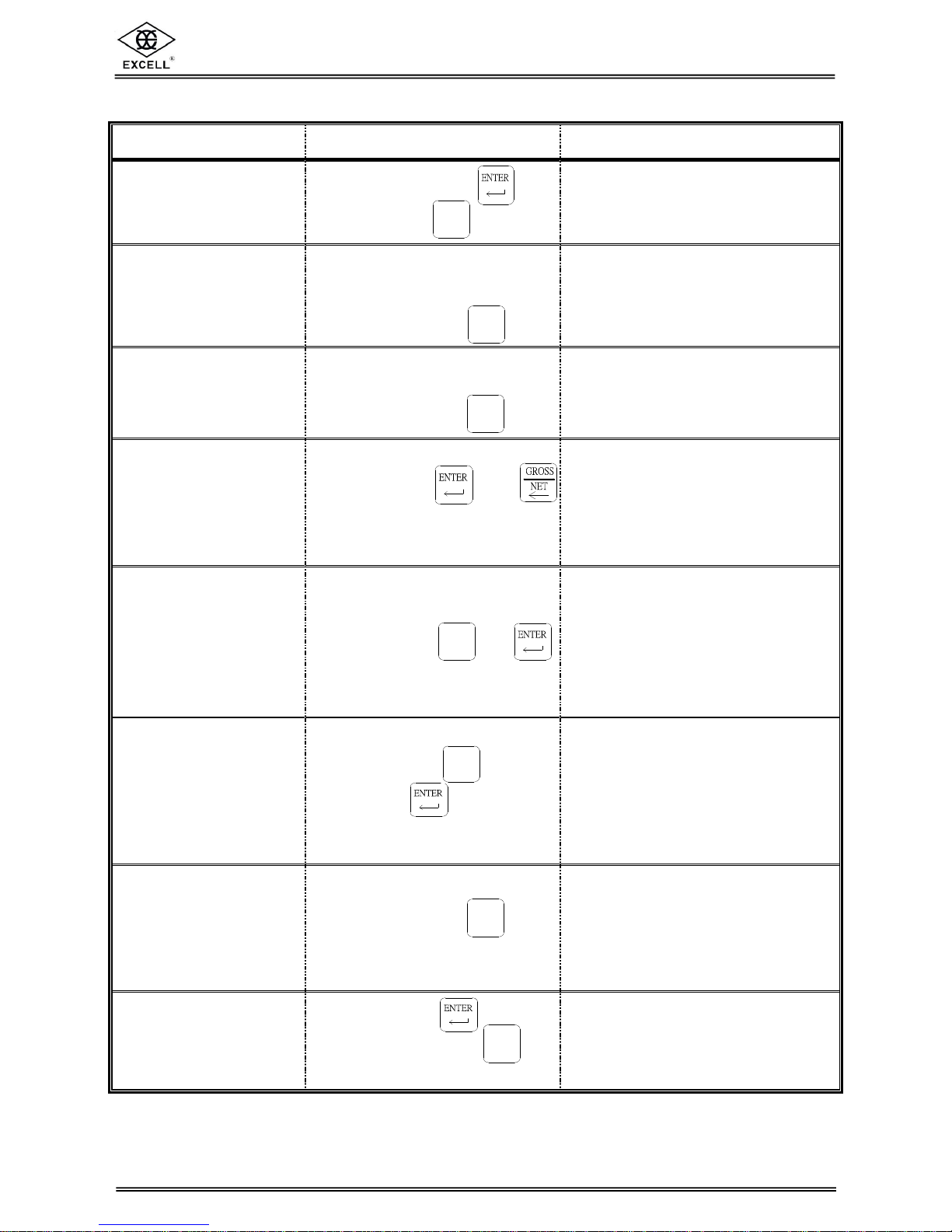

CHAPTER 2 OPERATION GUIDE

FUNCTION OPERATION PROCEDURE DESCRIPTION

General function

setting

Press and hold the key,

then press the

Refer to Chapter 9

Functions Table

to set FUNC. 0 ~ FUNC. 7

Capacity parameter

setting

Switch the capacity calibration

switch to “ON”

and then press the

Set the parameter for decimal

point, max. capacity, min. division,

zero tracking, unstable detection

Refer to < 5-1 > Parameter Setting

Calibration

Switch the capacity calibration

switch to “ON”

and then press the

Calibration procedures.

Refer to < 5-2 > Calibration Setting

Self-diagnosis mode

Turn on the indicator,

press and hold and

the indicator starts the self-test

procedure.

Refer to < 8-3 > Self-diagnosis

Mode for details

Reset all parameters

back to default

Switch the calibration switch to

“ON”, turn on the indicator,

press and hold and

while the indicator is in the

self-testing sequence

Refer to < 8-1 > Reset All

Parameter Back to Default

Reset general function

parameter back to

factory standard setting

Turn on the indicator,

press and hold

, followed

by pressing

while the indicator is in the

self-testing sequence

Refer to < 8-2 > Reset General

Function Parameter Back to

Default

Display software version

Turn on the indicator,

press and hold the

while the indicator is in the

self-test sequence

The main display section displays

the software version,

press any key

to exit

Function parameter

setting

Press and hold ,

followed by pressing

Hi, Lo, Zero Band parameter

setting

EX-2001 Plus v1.3 SME300000060

6

EXCELL PRECISION CO., LTD.

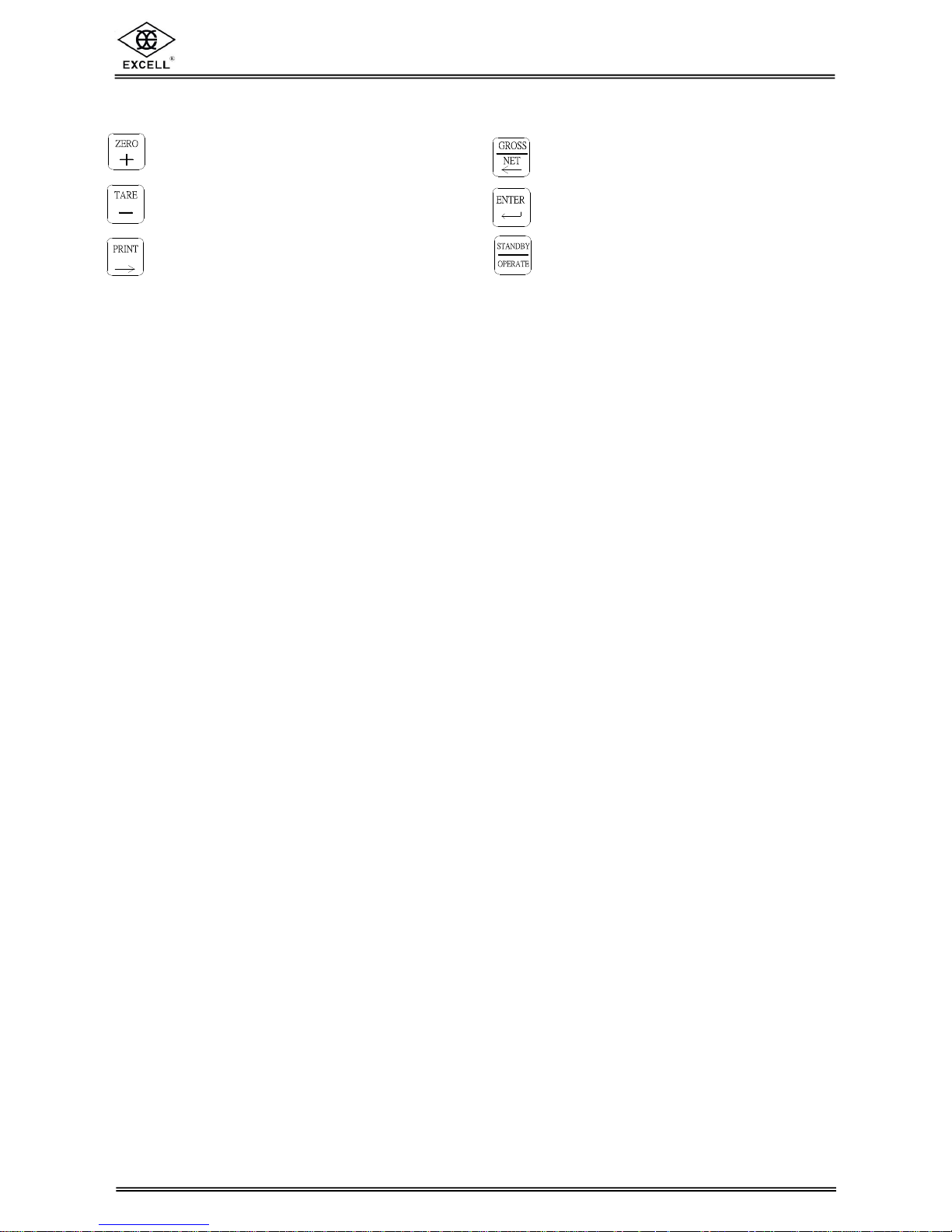

4 Operation of Keys in the Setting Mode

⇒ Cycles the flashing character from 0 to 9 ⇒ Shifts the flashing character to the left

⇒ Cycles the flashing character from 9 to 0 ⇒ Save data

⇒ Shifts the flashing character to the right ⇒ Quit / Exit

EX-2001 Plus v1.3 SME300000060

7

EXCELL PRECISION CO., LTD.

Fn

CAL

POWERZEROGROSSMOTION

NETTARE ENTERED

Racer

1

2

3

4

ON

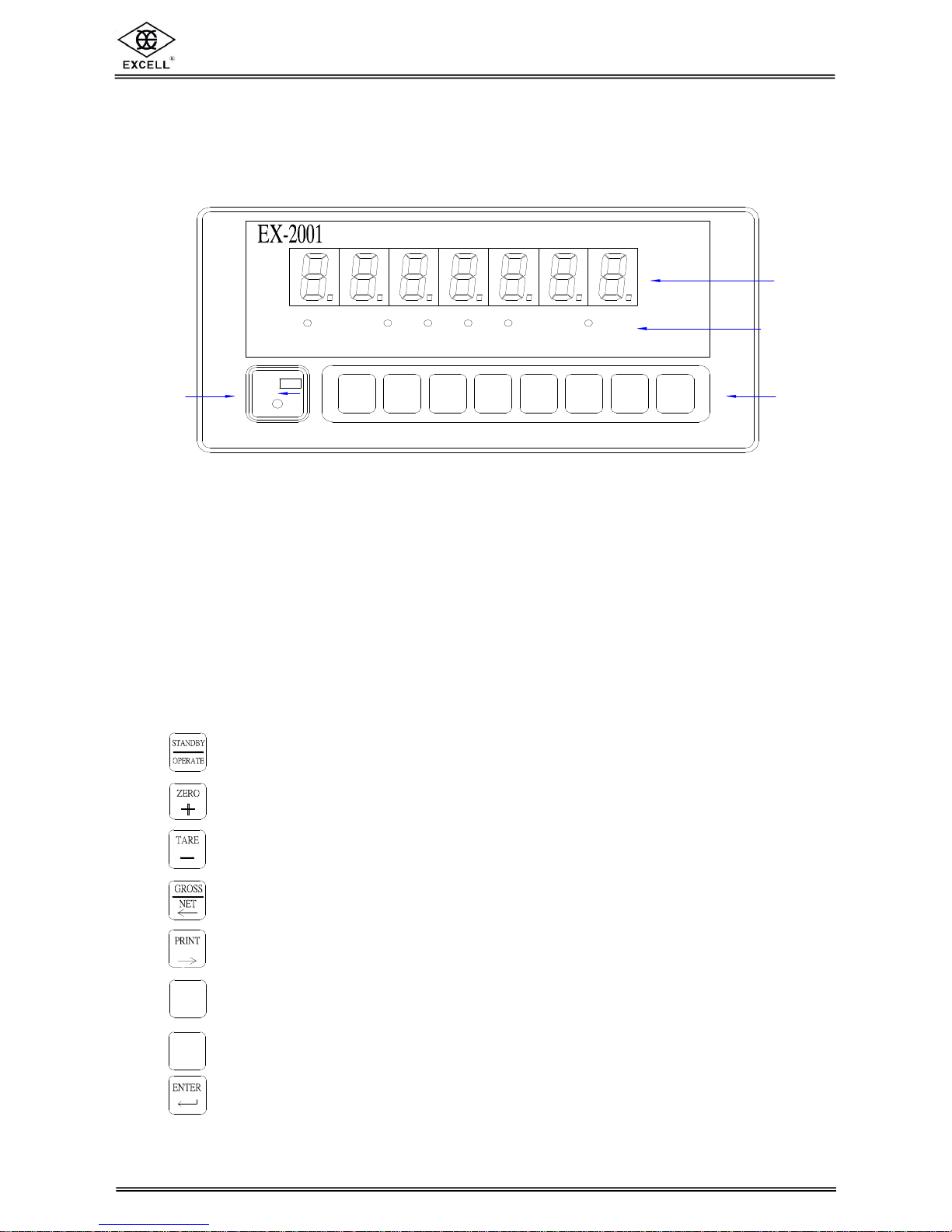

CHAPTER 3 FRONT AND REAR PANEL

3-1 FRONT PANEL

1 MAIN DISPLAY

• Displays gross weight or net weight

2 STATUS INDICATION LIGHTS

☼ POWER : Power Indication

☼ ZERO : Zero status indication

☼ MOTION : Unstable weighing indication

☼ GROSS : Main display section currently displays gross wt.

☼ NET : Main display section currently displays net wt.

☼ TARE ENTERED : Tare indication

3 KEYS

1) Standby mode ON/OFF

2) When setting the parameter or calibration, it works as quit or exit from setting

1) Sets weight back to zero

2) When setting the parameter or calibration, it cycles from 0 to 9

1) Tare function

2) When setting the parameter or calibration, it cycles from 9 to 0

1) Switches between gross wt. / net wt. on the main display

2) When setting the parameter or calibration, it shifts the flashing character to the left

1) Manually output serial / parallel data

2) When setting the parameter or calibration, it shifts the flashing character to the right

1) Weight accumulation, sub-total function (for OP-05)

2) Sets capacity parameter

1) Weight accumulation, grand-total function (for OP-05)

2) Capacity calibration

Confirmation key

Plus

EX-2001 Plus v1.3 SME300000060

8

EXCELL PRECISION CO., LTD.

DATA IN / OUT

LOAD CELL

FUSE/0.5A

AC 100V~240V

CONTROL IN / OUTPUT

2 1 C2 C1

4

3 2 1

OUTPUTINPUT

before opening the covers.

Isolating the ac power

! WARNING

12

3

4

5

4 CAPACITY PARAMETER & CALIBRATION SWITCH

Loosen the black plastic screw and open the square cap on the front panel.

Slide the switch to the left is “ON”

Slide the switch to the right is “OFF”

3-2 REAR PANEL

1. AC power in terminal

2. Fuse 250V / 0.5A

3. Load cell connector

4. Optional interface location (if fitted)

5. Control I/O Interface location

EX-2001 Plus v1.3 SME300000060

9

EXCELL PRECISION CO., LTD.

6

1

2

8

7

5

4

3

Load cell

Load cell cable

Shield

SEN+

SIG-SIG+

EXC+

EXCSEN-

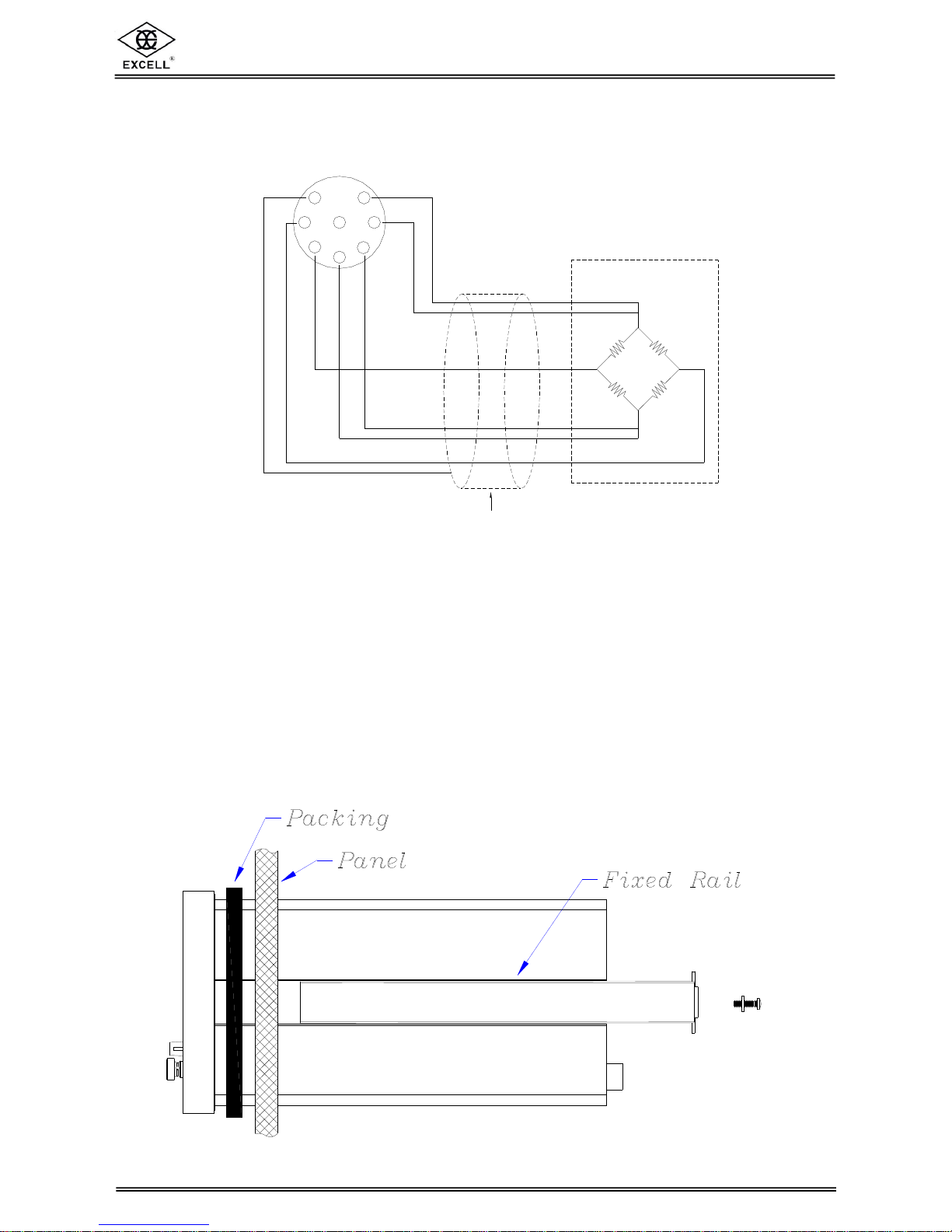

CHAPTER 4 INSTALLATION

4-1 LOAD CELL

Four-wire (five-wire) load cell Six-wire (seven-wire) load cell

Pin 1 & 2 short, connected to EXC+ Pin 1 connected to EXC+

Pin 3 & 4 short, connected to EXC- Pin 2 connected to SEN+

Pin 5 connected to SIG+ Pin 3 connected to EXCPin 6 connected to SIG- Pin 4 connected to SENPin 7 connected to the Shield Pin 5 connected to SIG+

Pin 6 connected to SIG Pin 7 connected to the Shield

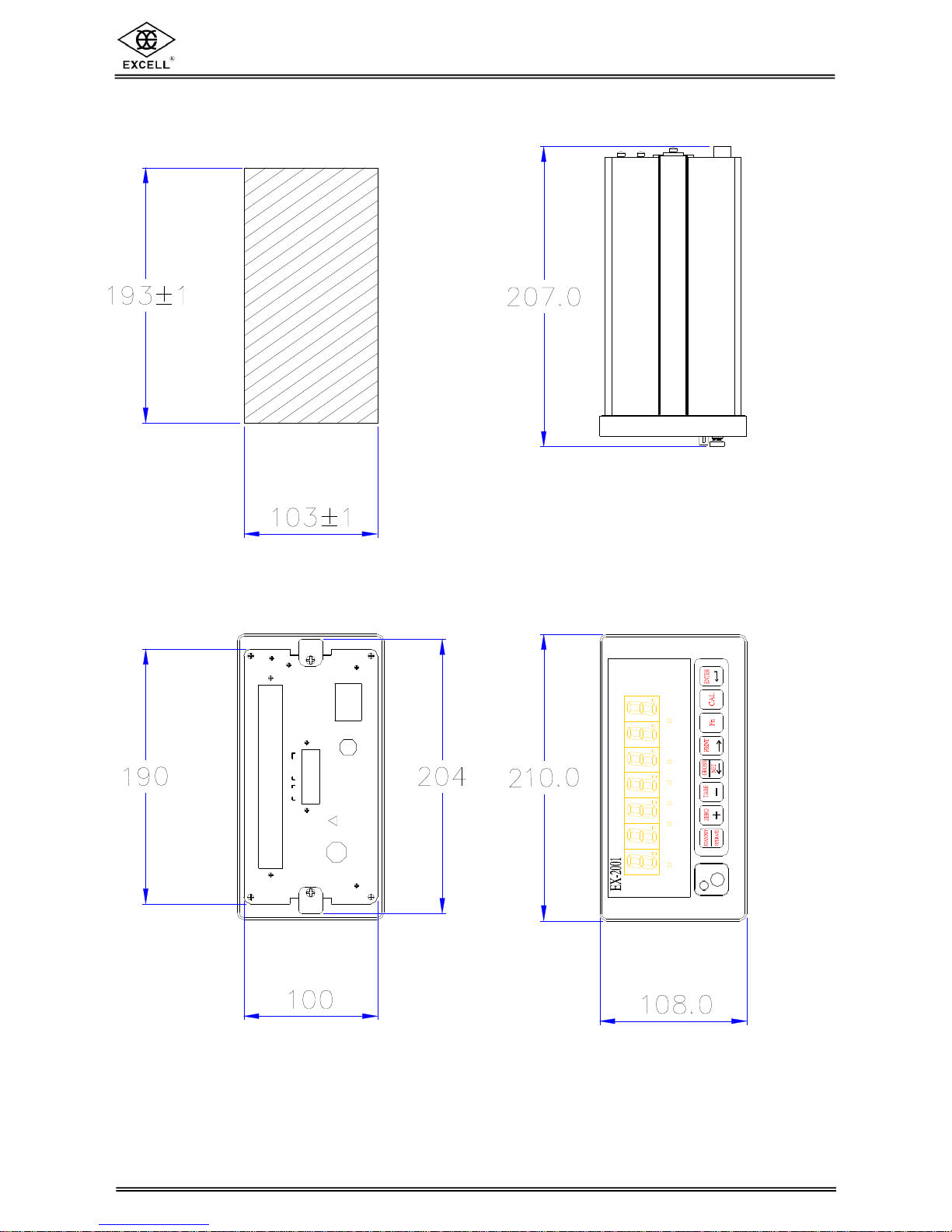

4-2 INDICATOR INSTALLATION AND DIMENSIONS

2 The indicator can be installed in a control panel as detailed below

EX-2001 Plus v1.3 SME300000060

10

EXCELL PRECISION CO., LTD.

! WARNING

before opening the covers.

Isolating the ac power

LOAD CELL

AC 100V~240V

IN / OUTPUT

2

FUSE/0.5A

CONTROL

INPUT

1 2

OUTPU T

4

C2 C1

3 1

DATA IN / OUT

Racer Plus

MOT IONPOW ER ZERO G RO SS NET ENTE REDTAR E

2 INDICATOR DIMENSIONS (measurement unit: mm)

EX-2001 Plus v1.3 SME300000060

11

EXCELL PRECISION CO., LTD.

Fn

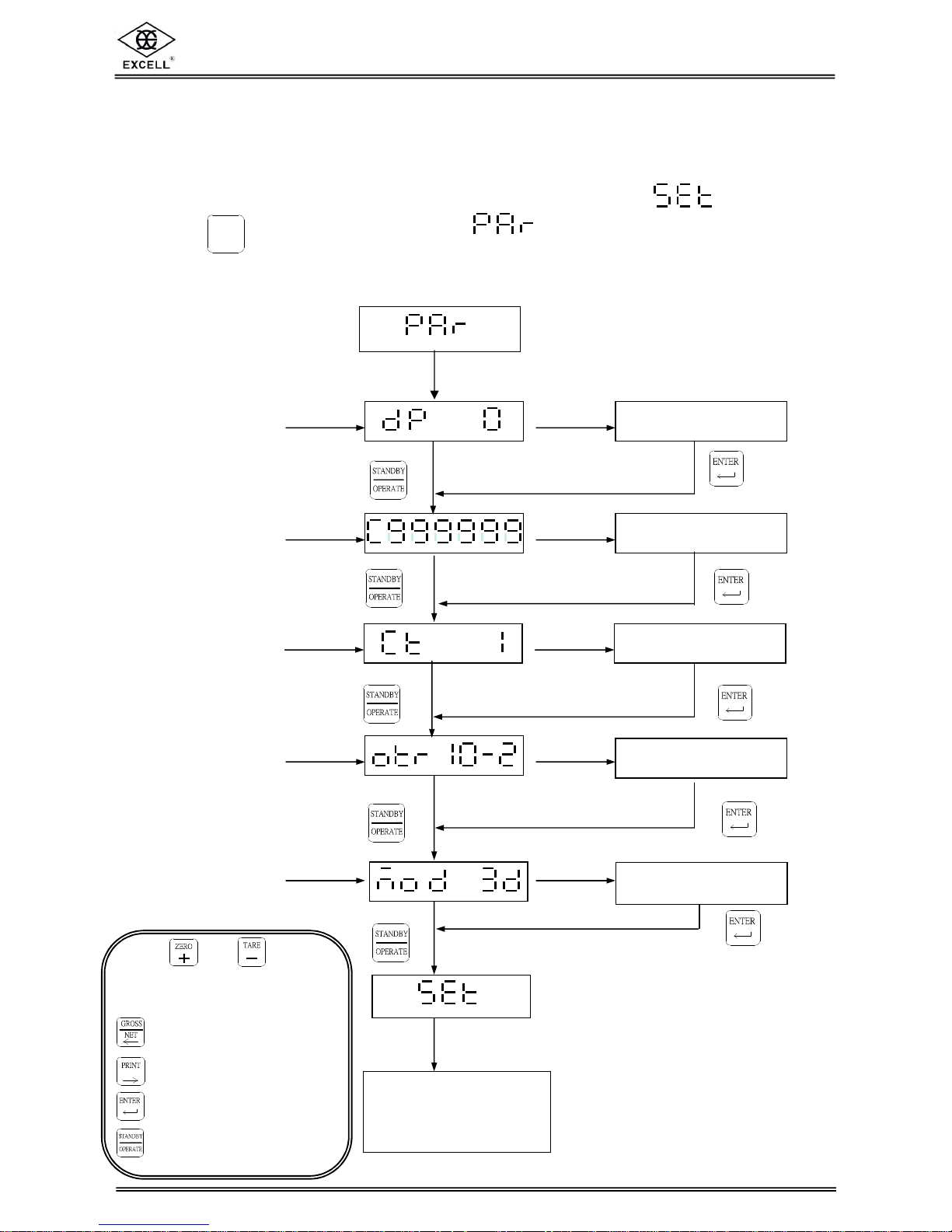

CHAPTER 5 CAPACITY CALIBRATION

5-1 PARAMETER SETTING

Switch the capacity calibration switch to “ON” and the display shows .

Press the key and the display shows . then enter the setting mode.

Refer to 3-1 Front Panel for the key functions to set the relative parameters.

5-1-1 Flow Diagram

1.

2.

3.

4.

4.

5.

5.

.

Decimal Point

.

.

Setup completed

Max. Capacity

Setup completed

Min. Division

.

Setup completed

Zero Tracking

. .

.

Setup completed

Unstable

Detection

.

Switch the

calibration switch

to OFF

Setup completed

.

Using and keys to

choose the desired

settings

⇒ Shift the flashing digit

one space to left

⇒ Shift the flashing digit

one space to right

⇒ Save the settings

⇒ Exit the settings

EX-2001 Plus v1.3 SME300000060

12

EXCELL PRECISION CO., LTD.

5-1-2 Description

1) Decimal Point

Setting the weight decimal point position, with the following options: 0, 0.0, 0.00,

0.000, 0.0000.

2) Max. Capacity

Depending on the decimal point position, the max capacity can be set from 99.999

to 999999.

3) Min. Division

Depending on the decimal point position and the max capacity, the min. division

could be set as 1, 2, 5, 10, 20, 50.

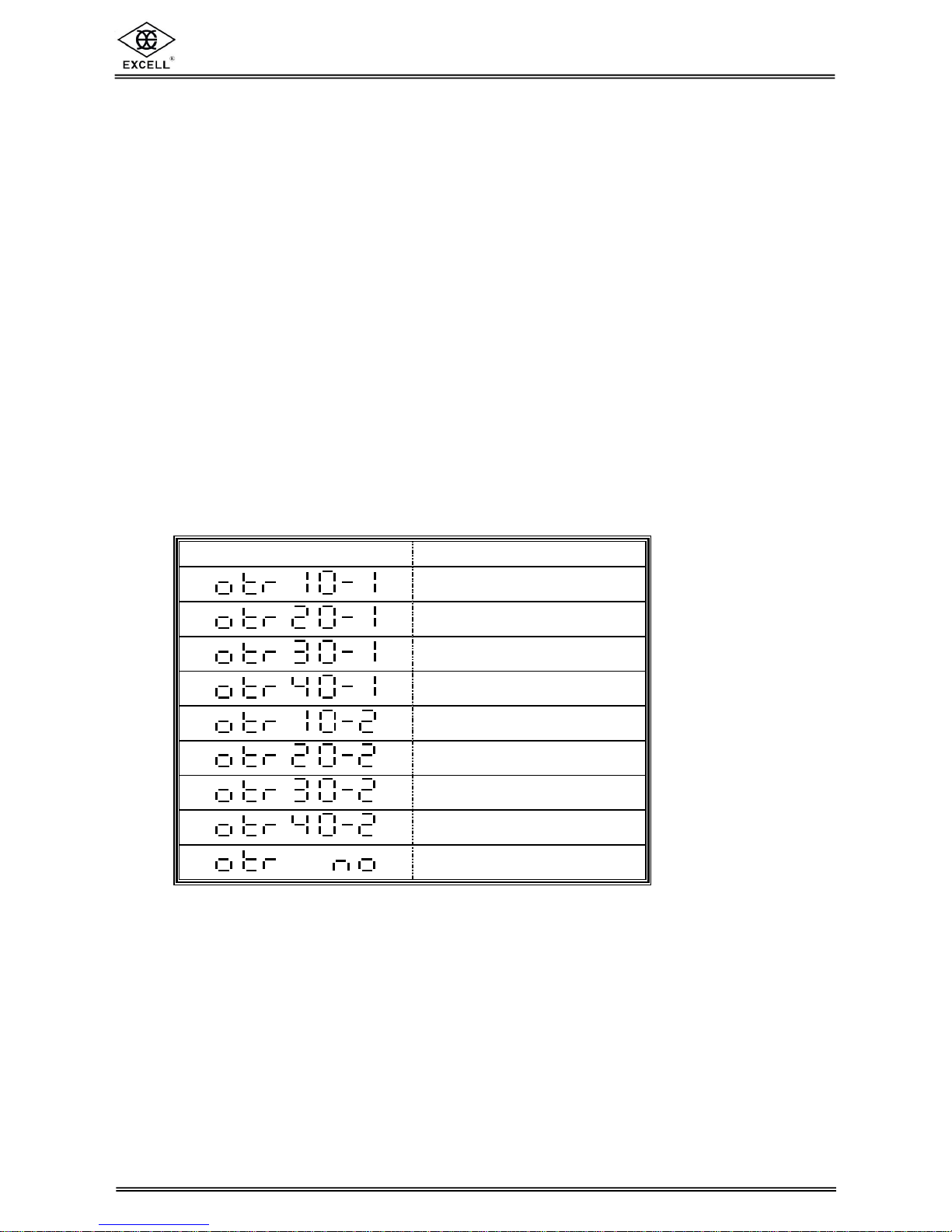

4) Zero Tracking

Display Division / Time

. . .

1 D / 1 sec

. . .

2 D / 1 sec

. . .

3 D / 1 sec

. . .

4 D / 1 sec

. . .

1 D / 2 sec

. . .

2 D / 2 sec

. . .

3 D / 2 sec

. . .

4 D / 2 sec

. .

No zero tracking

EX-2001 Plus v1.3 SME300000060

13

EXCELL PRECISION CO., LTD.

5) Unstable Detection

Display Division / Time

.

1 d / sec

.

2 d / sec

.

3 d / sec

.

4 d / sec

.

5 d / sec

.

No detection

EX-2001 Plus v1.3 SME300000060

14

EXCELL PRECISION CO., LTD.

CAL

5-2 CALIBRATION SETTING

Please allow the indicator to warm up at least 15 to 30 minutes before calibration.

Switch the capacity calibration switch to “ON” and the display shows .

Press the key and the display shows . then enter the setting mode.

5-2-1 Calibration Procedure

Zero Calibration

Weight Calibration

5-2-2 Zero Calibration

a) Make sure that there are no objects on the weighing platform and press

the key, after the indicator has stabilized the display will show

“ ……. ”. The calibration is completed after about 5 seconds.

b) To skip the “Zero calibration” procedure, press the key.

5-2-3 Weight Calibration

a) Place an accurate weight onto the platform; use the front panel keys to key in

the weight value. Press the key, after the indicator is stabilized the display will

show “ ……. ”. The calibration is completed after about 5 seconds.

b) To skip the weight calibration, press the .

Zero Calibration

Complete

d

Confirmation

completed

Switch the calibration

switch to OFF

Place

calibrated

weight

⇒ Increase the number of

the flashing digit

⇒ Decrease the number

of the flashing digit

⇒ Shift the flashing digit

one space to left

⇒ Shift the flashing digit

one space to right

⇒ Save the settings

⇒ Exit the settings

EX-2001 Plus v1.3 SME300000060

15

EXCELL PRECISION CO., LTD.

. . . . . .

Before linearity calibration, make sure “Zero calibration” and “Weight Calibration” are properly

performed. Set the calibration switch to ON position.

Press

CAL

key

Choose

Press

key

Press

to next step Press

key to previous step

Press

to next step Press

key to previous step

Enter the correct weight value

Press

to next step

The calibrated weight value

is displayed when the

signal is stable

Press

to next step

After finishing the first linearity calibration,

choose to continue or exit the linearity mode

by pressing

.

◆ Refer to 5-4 Error Messages when any error message appears during the procedure.

5-2-4 Linearity Calibration

Five point linearity calibration.

Choosing from 1P ~ 5P by

pressing

key.

⇒ No linearity

calibration value at this point

⇒ linearity calibration

value present at this point

The weight value is displayed.

⇒ Increase the number of

the flashing digit

⇒ Decrease the number

of the flashing digit

⇒ Shift the flashing digit

one space to left

⇒ Shift the flashing digit

one space to right

⇒ Save the settings

⇒ Exit the settings

EX-2001 Plus v1.3 SME300000060

16

EXCELL PRECISION CO., LTD.

Recall Linearity correction point

Set the calibration switch to ON position.

Press

CAL

key

Choose

Press

key

Press

key

Press

key

After finishing the first linearity calibration,

choose to continue or exit the linearity mode

by pressing

.

Five point linearity calibration.

Choosing from 1P ~ 5P by

pressing

key.

⇒ No linearity

calibration value at this point

⇒ Linearity

calibration value at this point

The weight value is displayed.

⇒ Increase the number of

the flashing digit

⇒ Decrease the number

of the flashing digit

⇒ Shift the flashing digit

one space to left

⇒ Shift the flashing digit

one space to right

⇒ Save the settings

⇒ Exit the settings

EX-2001 Plus v1.3 SME300000060

17

EXCELL PRECISION CO., LTD.

CAL

Clear a linearity correction point

Set the calibration switch to ON position.

Press key

Choose

Press

key

Press

key

Press

key

After finishing the first linearity calibration,

users can choose to continue or exit the

linearity mode by pressing

.

Five point linearity calibration.

Choosing from 1P ~ 5P by

pressing

key.

⇒ No linearity

calibration value at this point

⇒ Linearity calibration

value at this point

The weight value is displayed.

⇒ Increase the number of

the flashing digit

⇒ Decrease the number

of the flashing digit

⇒ Shift the flashing digit

one space to left

⇒ Shift the flashing digit

one space to right

⇒ Save the settings

⇒ Exit the settings

EX-2001 Plus v1.3 SME300000060

18

EXCELL PRECISION CO., LTD.

5-3 PASSWORD SETTING

Set the calibration switch to ON position.

Set the new password

* Enter “0000” to skip password

setting.

Confirm the password (re-

enter

the password again)

Press key

Press

key

Press

key

4 Once the password is set, whenever users access to the calibration mode or

the other function settings, the display shows

After I sec.

,

and users need to enter the password.

4 If the password is incorrect, . is displayed.

⇒ Increase the number of

the flashing digit

⇒ Decrease the number

of the flashing digit

⇒ Shift the flashing digit

one space to left

⇒ Shift the flashing digit

one space to right

⇒ Save the settings

⇒ Exit the settings

EX-2001 Plus v1.3 SME300000060

19

EXCELL PRECISION CO., LTD.

5-4 ERROR MESSAGES

(1) The output voltage of load cell is < - 0.1mV/V or > 4mV/V

(2) The weight setting value is not over the setting value of prior

section.

(3) The actual weight value is not over the value of prior section.

(4) The setting value is 0.

(5) Calibration resolution is less 0.12μV / d.

(6) . Incorrect password

EX-2001 Plus v1.3 SME300000060

20

EXCELL PRECISION CO., LTD.

CHAPTER 6 ANIMAL SCALE FUNCTION SETTING

2 FUNC. 8 = 1 (Animal scale function is active)

“

” is displayed, when there is no object on the weight panel:

The weight of live stocks is measured and showed in the display, (20 kg in this

example):

The weight value will be held until removing all the objects on the weight panel. When

the weight value is below zero band and display shows “ ” , the scale is

ready for another weighing operation.

.

EX-2001 Plus v1.3 SME300000060

21

EXCELL PRECISION CO., LTD.

DATA OUT

REAR PANEL

1

23

4

5

98

76

4

32

1

89

76

5

CHAPTER 7 INTERFACES

7-1 OP-01 RS-422 & RS-485 INTERFACE

2 OP-01 RS-422 / RS-485

With this interface up to 10 indicators can be connected together and data transferred

to a host controller.

FUNC. 70 should be set to “ 1 ”

2 Connector pin assignment

Pin number

Function

1 SDA

2 SDB

3 RDA

4 RDB

5 TRM

6

7

8

SG

9 RDB’

EX-2001 Plus v1.3 SME300000060

22

EXCELL PRECISION CO., LTD.

SDA

SDB

RDA

RDB

TRM(5)

SG

RDB'(9)

SDB(2)

SDA(1)

RDA(3)

SG(6.7.8)

RDB(4)

EX-2001#1

FUNC67=01

EX-2001#2

FUNC67=02

EX-2001#10

FUNC67=10

RDB'(9)

TRM(5)

SG(6.7.8)

RDB(4)

SDA(1)

SDB(2)

RDA(3)

RDB'(9)

TRM(5)

RDB(4)

SG(6.7.8)

RDA(3)

SDB(2)

SDA(1)

DA

DB

TRM(5)

SG

RDB'(9)

SDB(2)

SDA(1)

RDA(3)

SG(6.7.8)

RDB(4)

EX-2001#1

FUNC67=01

EX-2001#2

FUNC67=02

EX-2001#10

FUNC67=10

RDB'(9)

TRM(5)

SG(6.7.8)

RDB(4)

RDA(3)

SDB(2)

SDA(1)

RDB'(9)

TRM(5)

SG(6.7.8)

RDB(4)

RDA(3)

SDB(2)

SDA(1)

HOST COMPUTER

HOST COMPUTER

RS-422

RS-485

2 Connection method

4 Remark:

When connecting the last EX-2001 indicator, the fifth pin (TRM) and the ninth pin

(RDB’) should be connected together, excluding the following two conditions:-

♦ The host computer has a built-in terminator.

♦ The host computer does not have signal ground (SG).

EX-2001 Plus v1.3 SME300000060

23

EXCELL PRECISION CO., LTD.

2 Refer to Chapter 9 Function Table to set FUNC. 60 ~ FUNC. 67

2 Transmit format

S T

,

G S

,

+ 1 2 3 4

.

5 6 g CR LF

Header 1 Header 2 Weight Data ( 8 digits ) Units Terminators

Header 1

ST : Stable / US : Unstable / OL : Over Load

Header 2

GS : Gross weight / NT : Net weight / TR : Tare

Weight Data ( 8 digits )

The first digit is the + / - symbol for weight value. The next seven digits include

decimal point and weight value.

When the weight is over loaded ( Header 1 : OL ), all digits will be transmitted “blank”

(sp) except the + / - signal and the decimal point.

Units

Kg, g, t, lb or “blank”

Terminators

CR, LF is the data finish code.

2 Command mode

COMMAND FUNCTION

READ, RW Reads weight

ZERO, MZ Back to zero

TARE, MT Tare

NTGS Switches gross / net weight

MG Displays gross weight

MN Displays net weight

CT Clears tare

ΠThe command string must be terminated with CR ( 0DH ) , LF ( 0AH ).

• If a wrong command is received, the indicator will reply “E” + “ error command ”.

Ž If the command mode has been selected “with address”, (FUNC. 61 = 4)

then every command must be preceded with an indicator address in the format:-

“ @ address ”

Example: To read the weight value form indicator addressed as 01 (“01” selected in

FUNC. 67)

The complete command is @01RW<CR><LF>

EX-2001 Plus v1.3 SME300000060

24

EXCELL PRECISION CO., LTD.

REAR PENAL

DATA OUT

1

25

5026

7-2 OP-02 PARALLEL BCD OUTPUT

2 Pin assignment

BCD parallel output interface

uses Centronic 50 PIN connector

Pin number Function Pin number Function

1 SG 26 SG

2

1×10

27 Gross/-NET

3

2×10

28

4

4×10

29

5

8×10

30

6

1×10¹

31

7

2×10¹

32

8

4×10¹

33 Stable

9

8×10¹

34

10

1×10²

35

11

2×10²

36

12

4×10²

37

13

8×10²

38

14

1×10³

39

15

2×10³

40

16

4×10³

41

17

8×10³

42 POSITIVE

18

1×10

43 DP10¹

19

2×10

44 DP10²

20

4×10

45 DP10³

21

8×10

46 DP10

22

1×10

47 OVER

23

2×10

48

24

4×10

49 Data ready

25

8×10

50 Hold input

EX-2001 Plus v1.3 SME300000060

25

EXCELL PRECISION CO., LTD.

Signal out

SG

TTL Output

Signal out

SG

30mA(max.)

+30V(max.)

Open Collector

Output

SG

Hold Input

Signal in

+5V

Data output

Data ready

Hold

2ms

5ms

2 Refer to Chapter 9 Function Table to set FUNC. 80 ~ FUNC. 83

2 Output equivalent circuit

2 Hold Input

2 Output / Input signal description

ΠA total of 33 bit outputs are provided. To set the output logic level, refer to Chapter

9 FUNC 82 and FUNC 83.

• If Open Collector output is selected, an external resistor is required to limit the

current in the interface.

The voltage should not exceed 30Vdc and current should be less than 30mA.

Ž “Hold input” is the only one input signal. To activate the “Hold input”, just connect

the Hold input to SG signal. When Hold is working, all BCD outputs will be held

and cannot be altered.

EX-2001 Plus v1.3 SME300000060

26

EXCELL PRECISION CO., LTD.

DATA OUT

A- A+

DATA OUT

J1

7-3 OP-03 ANALOGUE CURRENT / VOLTAGE OUTPUT

INTERFACE

2 Connections

Interface specification

Analogue current output : 0 ~ 20 mA

Load resister : 0 ~ 550 Ω

Resolution : 12 bit

2 Refer to Chapter 9 Functions Table to set FUNC 85 ~ FUNC 89

2 Voltage output

J1 short if the voltage output is 0 ~ 10V.

J1 open if the current output is 4 ~ 20mA.

EX-2001 Plus v1.3 SME300000060

27

EXCELL PRECISION CO., LTD.

113

2514

1

2

3

4

7-4 OP-05 PARALLEL PRINTER OUTPUT & RS-232 & CURRENT

LOOP

2 Pin assignment

Pin number Function Pin number Function

1 STROBE 14 NC

2 D0 15 ERROR

3 D1 16 INIT

4 D2 17 NC

5 D3 18 SG

6 D4 19 SG

7 D5 20 SG

8 D6 21 SG

9 D7 22 SG

10 ACK 23 SG

11 BUSY 24 SG

12 NC 25 SG

13 NC

2 Refer to Chapter 9 Functions Table to set FUNC 90 ~ FUNC 99

2 RS-232 pin position

2Refer to Chapter 9 Functions Table to set FUNC. 60, 62, 63, 64

Pin number Function Pin number Function

1 TXD 3 C. LOOP1

2 SG 4 C. LOOP2

EX-2001 Plus v1.3 SME300000060

28

EXCELL PRECISION CO., LTD.

2 Print format

Format 1 ( FUNC. 90=0 )

FUNC. 95 ≠ 0 ⇒ Print “SN” value FUNC. 95 = 0 ⇒ No “SN” value

DATE : 2004/08/30

DATE : 2004/08/30

TIME : 12:13:36

TIME : 12:13:36

SN. : 1 GROSS : 11.5 kg

GROSS : 11.5 kg

TARE : 1.5 kg

TARE : 1.5 kg

NET : 10.0 kg

NET : 10.0 kg

Format 2 ( FUNC. 90=1 )

Material : 0

DATE : 2004/08/30

SN. TIME

NET(kg)

1 12:14:39 11.5

2 12:14:45 6.5

SUB TOTAL

DATE : 2004/08/30

COUNT : 2

NET : 18.0 kg

3 12:14:57 8.0

SUB TOTAL

DATE : 2004/08/30

COUNT : 1

NET : 8.0 kg

GRAND TOTAL

DATE : 2004/08/30

COUNT : 3

NET : 26.0 kg

Format 3 ( FUNC. 90=2 )

SN. DATE TIME GROSS (kg) TARE (kg)

NET (kg)

1 2004/08/30 12:16:19 7.0

2.0

5.0

2 2004/08/30 12:16:31 7.0

2.0

5.0

SUB TOTAL 10.0

3 2004/08/30 12:17:00 12.0

7.0

5.0

4 2004/08/30 12:17:19 12.0

7.0

5.0

GRAND TOTAL 20.0

EX-2001 Plus v1.3 SME300000060

29

EXCELL PRECISION CO., LTD.

25 mm

Label Width

2 mm

Label Space

Format 4 ( FUNC. 90=3 )

EZ-2 print format

FUNC. 95 ≠ 0 ⇒ Print “SN” value

FUNC. 95 = 0 ⇒ No “SN” value

2004/11/26 08:53:05

2004/11/26 08:53:05

SN. : 1

GROSS : 5.00

GROSS : 5.00

TARE : 0.00

TARE : 0.00

NET : 5.00

NET : 5.00

2004/11/26 08:52:05

2004/11/26 08:52:05

SN. : 1

GROSS : 5.00

GROSS : 5.00

TARE : 0.00

TARE : 0.00

NET : 5.00

NET : 5.00

25 mm

Label Width

EX-2001 Plus v1.3 SME300000060

30

EXCELL PRECISION CO., LTD.

FG

RxD

TxD

SG

+ AC

- AC

C.LOOP

C.LOOP

1

2

3

4

5

7

12

13

CONNECTION

7-5 OP-06 RS-232 & CURRENT LOOP

2 RS-232 / Current Loop

RS-232C is a bi-directional output/input; Current Loop is one-way output only,

and the output data format is the same as RS-232.

EX-2001 Plus v1.3 SME300000060

31

EXCELL PRECISION CO., LTD.

1

2

3

4

DATA/

CLK

GND

FG

RxD

TxD

SG

+ AC

- AC

C.LOOP

C.LOOP

1

2

3

4

5

7

12

13

CONNECTION

7-6 OP-07 RS-232, CURRENT LOOP & DATA CLOCK OUTPUT

2 RS-232 / Current Loop

RS-232C is a bi-directional output/input; Current Loop is one-way output only,

and the output data format is the same as RS-232.

2 Data Clock serial output

FUNC. 70 should be “ 0 ”

Pin Position

Function

1 + 5V

2 DATA

3 CLK

4 GND

Inner Connection

EX-2001 Plus v1.3 SME300000060

32

EXCELL PRECISION CO., LTD.

C2

CONTROL

1 2

INPUT

3

OUTPUT

4

C1

1 2

IN / OUTPUT

OUTPUT 1~4

12V

C1

30VDC/250VAC

1A

+12V

INPUT 1~2

C2

7-7 OP-08 CONTROL I /O (2I /4O) INTERFACE

2 External input and relay output

Output Pin Function

1 : Zero Band

2 : Hi

3 : Ok

4 : Lo

Input / output connectors on the rear panel

The output circuit of Relay

The input circuit

EX-2001 Plus v1.3 SME300000060

33

EXCELL PRECISION CO., LTD.

Start

Check Weighing

Mode Selected

( FUNC.53 setting)

Comparison

occurs at any

time

Comparison occurs

after inputting

external judgment

signal

Auto

comparison

FUNC.53 = 0FUNC.53 = 1FUNC.53 = 2

Judgment

Signal Input

N

NET < LO

LO ≦ NET

< HIGH

NET ≧ HIGH

LO / UNDER

Output

OK / FINAL

Output

HI / OVER

Output

Y

Y

Y

N

N

Input judgment

signal

Lead time count

down of inputting

judgment signal

(FUNC.55 setting)

N

Y

Y

NET > Auto

transmit range

(FUN10 setting)

N

The weight value

is stable

N

Y

Y

NET < LO

LO ≦ NET

< HIGH

NET ≧ HIGH

LO / UNDER

Output

OK / FINAL

Output

HI / OVER

Output

Y

Y

Y

N

N

Y

NET < LO

LO ≦ NET < HIGH

NET ≧ HIGH

LO / UNDER

Output

OK / FINAL

Output

HI / OVER

Output

Y

Y

Y

N

N

Y

( One time weighing

comparison occurs after

receiving the external

judgment signal, including the

lead time )

( One time weighing comparison

occurs when the weight of the

object is over Zero and stable )

2 HI , OK , LO Output Procedure

EX-2001 Plus v1.3 SME300000060

34

EXCELL PRECISION CO., LTD.

2 The Flow Chart of HI , OK , LO Setting

Press and hold , followed by pressing , to enter the check weighing mode.

CAL

Press

key

Key in the “High Limit Value”

by using the keys described

at the right hand side.

Press

key to complete

the setting and go to the next

step

⇒ Increase the number of

the flashing digit

⇒ Decrease the number

of the flashing digit

⇒ Shift the flashing digit

one space to left

⇒ Shift the flashing digit

one space to right

⇒ Save the settings

⇒ Exit the settings

Press or key to select the high

value ( ), low value ( )

, and zero ( )

.

EX-2001 Plus v1.3 SME300000060

35

EXCELL PRECISION CO., LTD.

0

Zero band

Hi

Lo

Zero band

Lo

Hi

Lo

Zero _ band

OK

Hi

Absolute value

comparison

Func54=1

Zero band

Lo

OK

Hi

Func54=0

General comparison

0

Zero band

Hi Lo

Zero band

Lo

Hi Lo

Zero _ band

ok

high

Absolute Value Comparison

Func54=1

Zero band

Lo ok

high

Func54=0

General Comparison

EX-2001 Plus v1.3 SME300000060

36

EXCELL PRECISION CO., LTD.

Fn

Fn

CHAPTER 8 MAINTENANCE

8-1 RESET ALL PARAMETERS BACK TO DEFAULT

(1) Switch the capacity calibration switch to “ON”, press and hold keys

together when the indicator is in the self-testing sequence.

(2) The display shows . .

(3) Press and hold the key until the display shows . Switch the calibration

switch to “OFF”.

8-2 RESET GENERAL FUNCTION PARAMETERS BACK TO

DEFAULT

(1) When the indicator reset back to zero, press and hold keys.

The indicator is in the self-testing sequence.

(2) The display shows . .

(3) Press and hold the key until the indicator resets.

8-3 SELF-DIAGNOSIS MODE

(1) When the indicator reset back to zero, press and hold keys.

The indicator is in the self-testing sequence.

(2) When the display shows , it means the indicator is already in the

Self-diagnosis mode.

(3) Press and keys to select a diagnosis item. Press the key to enter

the selected item for diagnosis and press to exit.

EX-2001 Plus v1.3 SME300000060

37

EXCELL PRECISION CO., LTD.

No. Display Diagnosis Item

1

7 digits display and LED status lights

2

Keyboard and calibration ON / OFF switch

3

OP-06 RS-232 serial output / input interface

4

OP-02 BCD parallel output interface

5

OP-03 Analogue current output interface

6

OP-05 Parallel printer interface

7

EEPROM memory on main board

8

OP-08 Control I/O interface

8-3-1 7 Digit Display and LED Status Light Diagnosis

7 digit display shows ~ , “.” And at the same time, the LED status

lights turn on and off in order.

8-3-2 Keyboard and Calibration ON / OFF Switch Diagnosis

Switch the calibration switch to “ON”, or press any keys and the corresponding digit

goes from → on the display.

8-3-3 RS-232 Serial Output / Input Interface Diagnosis ( OP-06 )

(1) Short circuit the 2nd pin and 3rd pin of the SER. OUT. D-SUB 25 pin connector.

= Working properly = Malfunction

(2) If connecting to a computer (The communication protocol has to be compatible),

if ~ can be read, it indicates that the RS-232 is in working order.

8-3-4 BCD Parallel Output Interface Diagnosis ( OP-02 )

(1) The decimal point flashes during the diagnosis.

(2) The program sends out OFF→ON→OFF signals from each of BCD output bit.

(3) If is displayed, this indicates that no BCD interface is installed.

EX-2001 Plus v1.3 SME300000060

38

EXCELL PRECISION CO., LTD.

8-3-5 Analogue Current Output Interface Diagnosis ( OP-03 )

(1) Use and keys to select output current.

(a) : 4mA

(b) : 12mA

(c) : 20mA

(2) If is displayed, this indicates that an interface has not been

installed.

8-3-6 Parallel Printer Interface Diagnosis ( OP-05 )

(1) Connect the interface to the printer.

(2) Press the key and the printer will print date, time and ASCII code as 30H ~ 7AH

characters or figures.

(3) If is displayed, this indicates that the printer or the interface is not working

properly.

(4) If is displayed, the interface is not connected to the indicator.

8-3-7 Main Board EEPROM Memory Diagnosis

= Working properly = Malfunction

8-3-8 OP-08 Control I /O (2I /4O) Diagnosis

_

A

ctivate the input signal by choosing

(ON) or (OFF)

Press key to alternately select

one of

parameters ( ~ )

EX-2001 Plus v1.3 SME300000060

39

EXCELL PRECISION CO., LTD.

CHAPTER 9 FUNCTION TABLE

9-1 GENERAL FUNCTION

FUNC. NO. FUNCTION SET VALUE DEFAULT

0 ON

FUNC. 0

Tare and Zero function

when the weight is

unstable

1 OFF

0

0 ON

FUNC. 1

Tare function with

negative gross weight

1 OFF

0

0 ON

FUNC. 2 Key function

0000

↓

1111

1

OFF

0000 corresponding

keys from left to right

are

0000

0 OFF

FUNC. 3

Auto Zero function

after power on

1 ON

0

FUNC. 4 Zero range

0D

↓

9D

When the weight is in this

range

±(Set value × Min. division)

it displays “0”

0

FUNC. 5 Weighing Filter

0

↓

5

The larger the value the

greater the amount of

filtering.

When set to 0, the filter will

adjust automatically.

2

0 Unlimited

1 20 times/sec

2 10 times/sec

FUNC. 6 A/D sampling frequency

3 5 times/sec

2

0 Unlimited

1 20 times/sec

2 10 times/sec

3 5 times/sec

FUNC. 7 Display update rate

4 1 times/2sec

1

0 OFF

FUNC. 8 Animal scale

1 ON

0

EX-2001 Plus v1.3 SME300000060

40

EXCELL PRECISION CO., LTD.

9-2 OP-01, OP-06, OP-07 INTERFACE FUNCTION

SET VALUE

FUNC. NO. FUNCTION

PARAMETER

DESCRIPTION

DEFAULT

0 As displayed

1 Gross

2 Net

FUNC. 60 Data type

3 Tare

0

0 Stream transmit

1 Auto-transmit

2

Press t key to transmit

3

Command mode

(without address)

FUNC. 61 Transmit mode

4

Command mode

(with address)

0

0 1200

1 2400

2 4800

3 9600

FUNC. 62 BAUD rate

4 19200

1

0 N, 8, 1

No parity bit,

8 data bit, 1 stop bit

1 O, 7, 1

Odd parity bit,

7 data bit, 1 stop bit

FUNC. 63

Parity bit

Data bit

Stop bit

2 E, 7, 1

Even parity bit,

7 data bit, 1 stop bit

2

0 None

1 kg

2 g

3 t

FUNC. 64 Units

4 lb

1

0 Continuous output

FUNC. 65

Unstable or

over the max.

capacity

1 Stop output

0

0

Positive

(more than + 5D)

FUNC. 66

Auto-transmit

conditions

1

Positive / negative

(more than + 5D,

less than - 5D)

0

FUNC. 67

Command

address

00

↓

99

When the FUNC. 61 is set in

4, it will use this address

0

0 Standard Format

FUNC. 68 Output format

1 UMC 600

0

0 W/o limit

1 1 Time/ Sec.

2 2 Times/ Sec.

3 5 Times/ Sec.

4 10 Times/ Sec.

FUNC. 69

Transmit

frequency

5 20 Times/ Sec.

4

0 Close RS422/485

FUNC. 70 Output type

1 Start RS422/485

0

EX-2001 Plus v1.3 SME300000060

41

EXCELL PRECISION CO., LTD.

9-3 OP-02 BCD OUTPUT INTERFACE FUNCTION

SET VALUE

FUNC. NO. FUNCTION

PARAMETER

DESCRIPTION

DEFAULT

0 As displayed

1 Gross

FUNC. 80 Data type

2 Net

0

0 Stream transmit

1 Auto-transmit

FUNC. 81 Transmit mode

2

Press the key to transmit

0

0 Positive logic

FUNC. 82

Output data

logic

1 Negative logic

0

0 Positive logic

FUNC. 83 Signal logic

1 Negative logic

0

9-4 OP-03 ANALOGUE OUTPUT INTERFACE FUNCTION

SET VALUE

FUNC. NO. FUNCTION

PARAMETER

DESCRIPTION

DEFAULT

0 As displayed

1 Gross

FUNC. 85 Data type

2 Net

0

FUNC. 86

Low point of

weight value

000000

↓

999999

0

FUNC. 87

Low point of

output current

value

0.0 mA

↓

20.0 mA

When the weight value

reaches the val

ue set in Func.

86, the current output

is the value set in Func. 87

4.0 mA

FUNC. 88

High point

Weight value

000000

↓

999999

16000

FUNC. 89

High point

Output current

value

0.0 mA

↓

20.0 mA

When the weight value

reaches the valu

e set in Func.

88, the current output

is the value set in Func. 89

20.0 mA

EX-2001 Plus v1.3 SME300000060

42

EXCELL PRECISION CO., LTD.

9-5 OP-05 PARALLEL PRINTER OUTPUT INTERFACE FUNCTION

SET VALUE

FUNC. NO. FUNCTION

PARAMETER

DESCRIPTION

DEFAULT

FUNC. 90 Data format

0

â

Select print format 0

0

Press the to transmit

FUNC. 91 Transmit mode

1

Auto / press to transmit

0

FUNC. 92

The size of left

hand side

margin

0 ~ 80

(characters)

0

FUNC. 93

The space

between

blocks of data

0 ~ 80

( LF )

TIME: 14:20:30

GROSS: 23.5kg

TIME: 15:30:20

GROSS: 21.0kg

5

FUNC. 94

Material

number

000000

â

999999

When printing the material

number, it keeps the same

value as previously set.

0

FUNC. 95 Serial number

00000

â

65535

When printing the serial

number, it automatically

increments. It resets to 00000

after restarting the indicator or

after printing out the total

weight.

1

0 None

1 kg

2 g

3 t

FUNC. 96 Units

4 lb

1

FUNC. 98 Date setting

2000 yr.

â

2099 yr.

FUNC. 99 Time setting

00:00:00

â

23:59:59

FUNC. 93

FUNC. 92

EX-2001 Plus v1.3 SME300000060

43

EXCELL PRECISION CO., LTD.

9-6 OP-08 CONTROL I /O (2I /4O) INTERFACE FUNCTION

SET VALUE FUNC.

NO.

FUNCTION

PARAMETER

DESCRIPTION

DEFAULT

FUNC. 50

Input 1 1

FUNC. 51

Input 2

0 ⇒ No capacity

1 ⇒ Zero

2 ⇒ Tare

3 ⇒ Clear Tare

4 ⇒ judgment_comm_flag

2

0000

Positive logic

FUNC. 52

Output logic

1111

Negative logic

0000

0 Comparison occurs at any time

1

Comparison occurs after inputting

external judgment signal

FUNC. 53

Hi,OK,Lo

Check weighing

mode

2 Auto comparison

0

0 General comparison +

FUNC. 54 Comparison mode

1 Absolute value only comparison +/-

0

FUNC. 55

Lead time setting

for activating

comparison

0.0

↓

25.5

Lead time setting for inputting

external judgment

signal

0.5

Loading...

Loading...