High Speed Sander

Instruction manual

for model ETS1

IMPORTANT

Please make certain that the person who is to use this equipment

carefully reads and understands these instructions before starting

operations.

Part No. D22738 Rev. 0 4/25/01

2- ENG

D22738

SAFETY GUIDELINES - DEFINITIONS

Indicates an

imminently hazardous

situation which, if not avoided, will

result in death or serious injury

.

Indicates a potentially

hazardous situation

which, if not avoided, could

result in

death or serious injury.

Indicates a potentially

hazardous situation

which, if not avoided, may

result in

minor or moderate injury

.

Used without the

safety alert symbol

indicates a potentially hazardous

situation which, if not avoided, may

result in pr

operty damage.

SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we

use the symbols below. Please read the manual and pay attention to these sections.

This manual contains information that is important for you to know and understand. This information

relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you

recognize this information, we use the symbols below. Please read the manual and pay attention to

these sections.

IMPORTANT SAFETY INSTRUCTIONS

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known (to the State of California) to

cause cancer, birth defects or other reproductive harm. Some example of these chemicals are:

l

lead from lead-based paints

l

crystalline silica from bricks and cement and other masonry products

l

arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, always wear MSHA/NIOSH approved, properly fitting face mask or respirator when using

such tools.

When using air tools, basic safety precautions should always be followed to reduce the risk of of

personal injury.

3- ENG

D22738

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS

INJURY AND PROPERTY DAMAGE. READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING THIS EQUIPMENT.WHEN USING AIR TOOLS, BASIC

SAFETY PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE THE RISK OF

PERSONAL INJURY.

SA

VE!

IMPORTANT SAFETY INSTRUCTIONS

SA

VE!

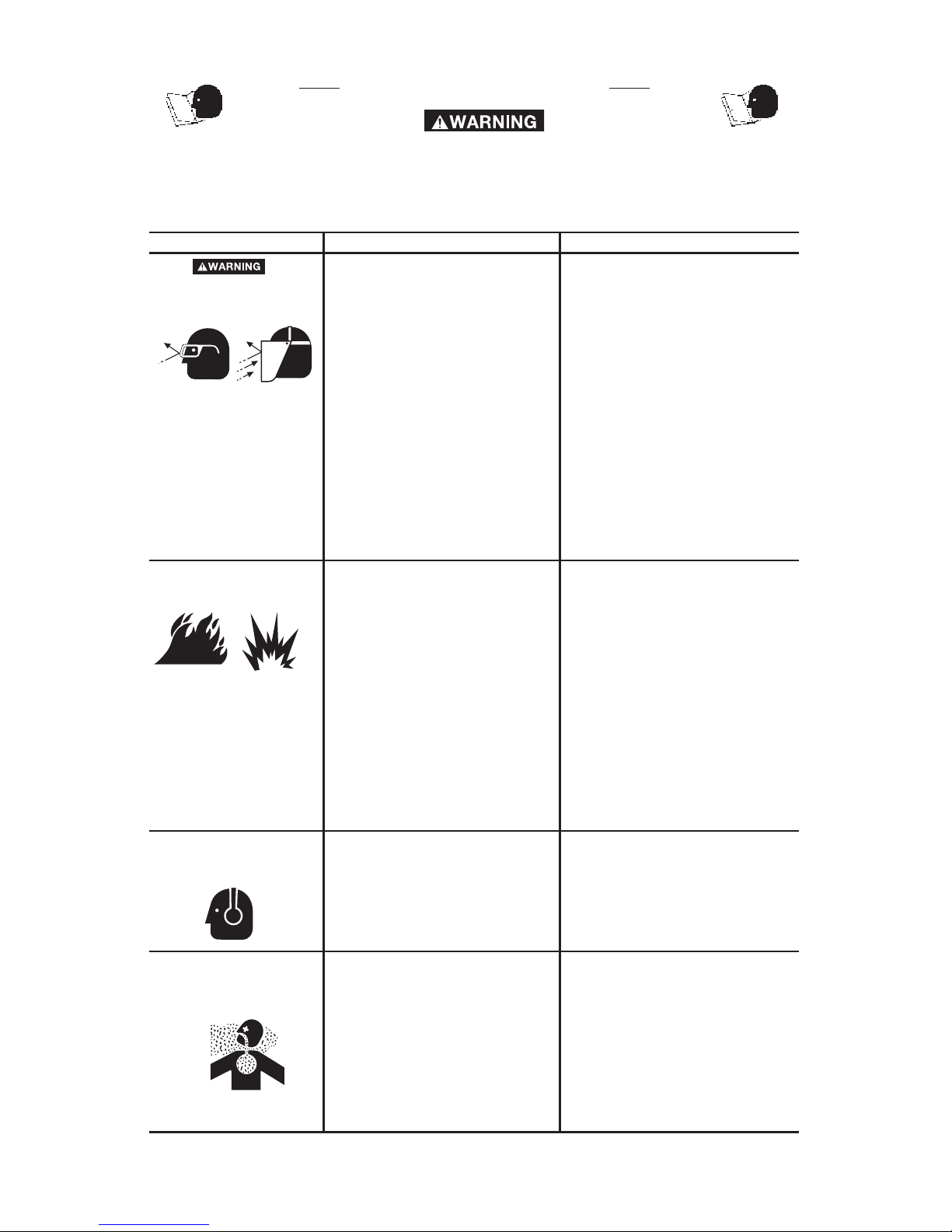

HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF EYE OR HEAD

INJURY

• Air powered equipment and

power tools are capable of

propelling materials such as

metal chips, saw dust, and

other debris at high speed,

which could result in serious

eye injury.

• Compressed air can be hazardous. The air stream can

cause injury to soft tissue areas

such as eyes, ears, etc.

Particles or objects propelled

by the stream can cause injury.

• Tool attachments can be come

loose or break and fly apart

propelling particles at the

operator and others in the work

area.

• Always wear ANSI approved

Z87.1 safety glasses with side

shields.

• Never leave operating tool

unattended. Disconnect air

hose when tool is not in use.

• For additional protection use

an approved face shield in

addition to safety glasses.

RISK OF FIRE OR

EXPLOSION

• Abrasive tools such as sanders

and grinders, rotating tools

such as drills, and impact tools

such as wrenches, hammers,

and reciprocating saws are

capable of generating sparks

which could result in ignition of

flammable materials.

• Exceeding the maximum pressure rating of tools or

accessories could cause an

explosion resulting in serious

injury.

• Make sure that any attachments are securely assembled.

• Never operate tools near

flammable substances such

as gasoline, naptha, cleaning

solvents, etc.

• Work in a clean, well ventilated

area free of combustible

materials.

• Never use oxygen, carbon

dioxide or other bottled gases

as a power source for air tools.

• Use compressed air regulated

to a maximum pressure at or

below the rated pressure of

any attachments.

RISK OF LOSS OF

HEARING

• Long term exposure to noise

produced from the operation

of air tools can lead to

permanent hearing loss.

• Always wear ANSI S3.19

hearing protection.

RISK TO BREATHING

INHALATION HAZARD

• Abrasive tools, such as

grinders, sanders, and cut-off

tools generate dust and

abrasive materials which can

be harmful to human lungs and

respiratory system.

• Some materials such as

adhesives and tar, contain

chemicals whose vapors

could cause serious injury with

prolonged exposure.

• Always wear MSHA/NIOSH

approved, properly fitting face

mask or respirator when using

such tools.

• Always work in a clean, dry,

well ventilated area.

4- ENG

D22738

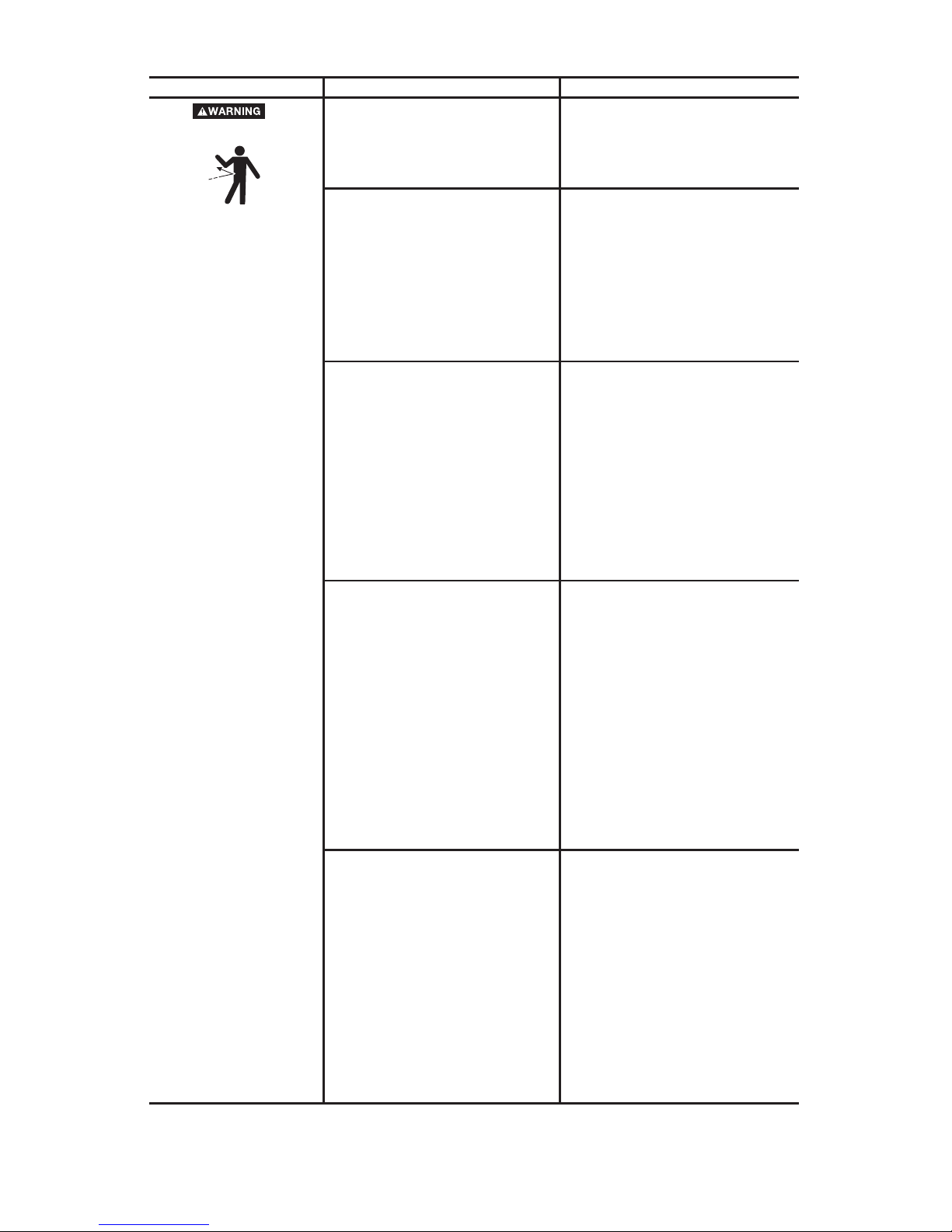

HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF INJURY

• Tools left unattended, or with

the air hose attached can be

activated by unauthorized

persons leading to their injury

or injury to others.

• Power tools can throw

materials throughout the work

area.

• Power tools can become

activated by accident during

maintenance or tool changes.

• Power tools can cause the

workpiece to move upon

contact leading to injury.

• Loss of control of the tool can

lead to injury to self or others.

• Poor quality, improper, or

damaged tools such as grinding

wheels, chisels, sockets, drills,

etc., can fly apart during

operation, propelling particles

throughout the work area

causing serious injury.

• Remove air hose when tool is

not in use and store tool in

secure location away from

reach of children.

• Use only parts, fasteners, and

accessories recommended by

the manufacturer.

• Keep work area clean and free

of clutter. Keep children and

others away from work area

during operation of the tool.

• Keep work area well lit.

• Remove air hose to lubricate

or add grinding attachments,

sanding discs, drills, etc. to the

tool.

• Never carry the tool by the

hose.

• Avoid unintentional starting.

Don't carry hooked-up tool

with finger on trigger.

• Repair servicing should be

done only by an authorized

service representative.

• Use clamps or other devices

to prevent movement.

• Never operate tool while under

the influence of drugs or

alcohol.

• Don't overreach. Keep proper

footing and balance at all

times.

• Keep handles dry, clean, and

free from oil and grease.

• Stay alert. Watch what you are

doing. Use common sense. Do

not operate tool when you are

tired.

• Always use tool attachments

rated for the speed of the

power tool.

• Never use tools which have

been dropped, impacted or

damaged by use.

• Use only impact grade sockets on an impact wrench.

• Do not apply excessive force

to the tool – let the tool

perform the work.

5- ENG

D22738

Free Speed (No Load) 10,000 RPM

Maximum Working Pressure 90 PSI

Pad Diameter 6”

Air Inlet 1/4" NPT

Recommended Hose Size 3/8" I.D.

SPECIFICATIONS

HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF

ENTANGLEMENT

• Tools which contain moving

elements, or drive other

moving tools, such as grinding

wheels, sockets, sanding

discs, etc. can become entangled in hair, clothing, jewelry

and other loose objects,

resulting in severe injury.

• Never wear loose fitting

clothes, or apparel which

contains loose straps or ties,

etc. which could become

entangled in moving parts of

the tool.

• Remove any jewelry, watches,

identifications, bracelets,

necklaces, etc. which might

become caught by the tool.

• Keep hands away from moving

parts. Tie up or cover long hair.

• Always wear proper fitting

clothing and other safety

equipment when using this

tool.

RISK OF

CUT OR BURNS

• Tools which cut, shear, drill,

punch, chisel, etc. are capable

of causing serious injury.

• Keep the working part of the

tool away from hands and

body.

6- ENG

D22738

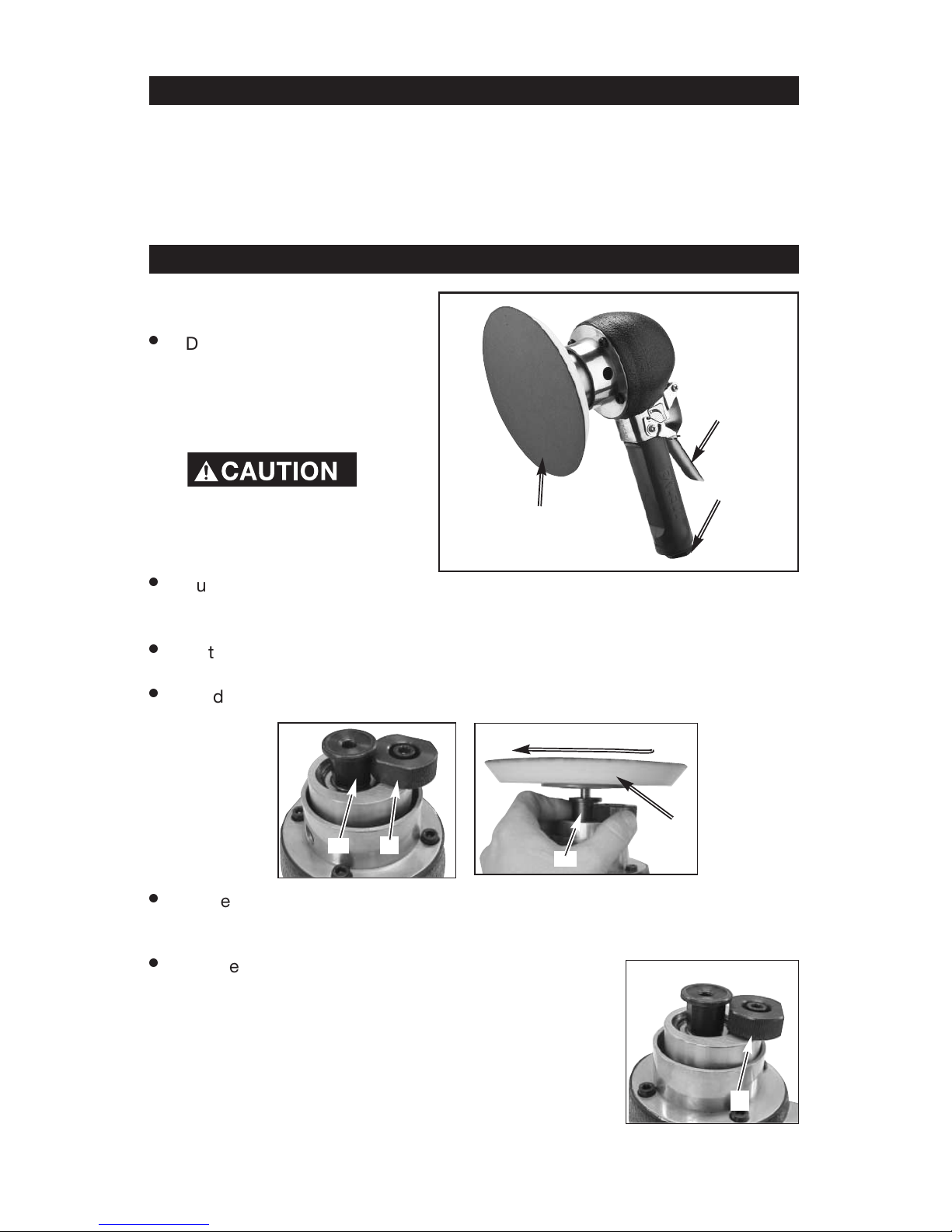

Operation

Before each use:

l

Drain water from air

compressor tank and condensation from air lines. See

air compressor’s operators

manual.

Disconnect the tool from

the air supply before

lubricating or changing

sandpaper disc.

l

Lubricate tool, see “Maintenance” section in this manual.

IMPORTANT: The tool MUST be in the lock position to install sandpaper

pad.

l

Rotate drive cylinder lock (A) until the ribbed edges connect with the drive

cylinder (B) and stops.

l

Hold drive cylinder (B) and install sandpaper pad (C), tighten securely.

l

Place desired sandpaper onto sandpaper pad. NOTE: Use approved selfadhesive type sandpaper.

IMPORTANT: The tool MUST be in the unlocked position for orbital action.

l

Rotate drive cylinder lock (A) into unlock position.

ASSEMBLY

OPERATION

Air Inlet

Trigger

Accessories Required

IMPORTANT: Line pressure or hose inside diameter should be increased to

compensate for unusually long air hoses (over 25 feet). Minimum hose diameter

should be 3/8” I.D. and fittings should have 1/4” NPT thread.

Sandpaper

Pad

B

C

B

A

A

7- ENG

D22738

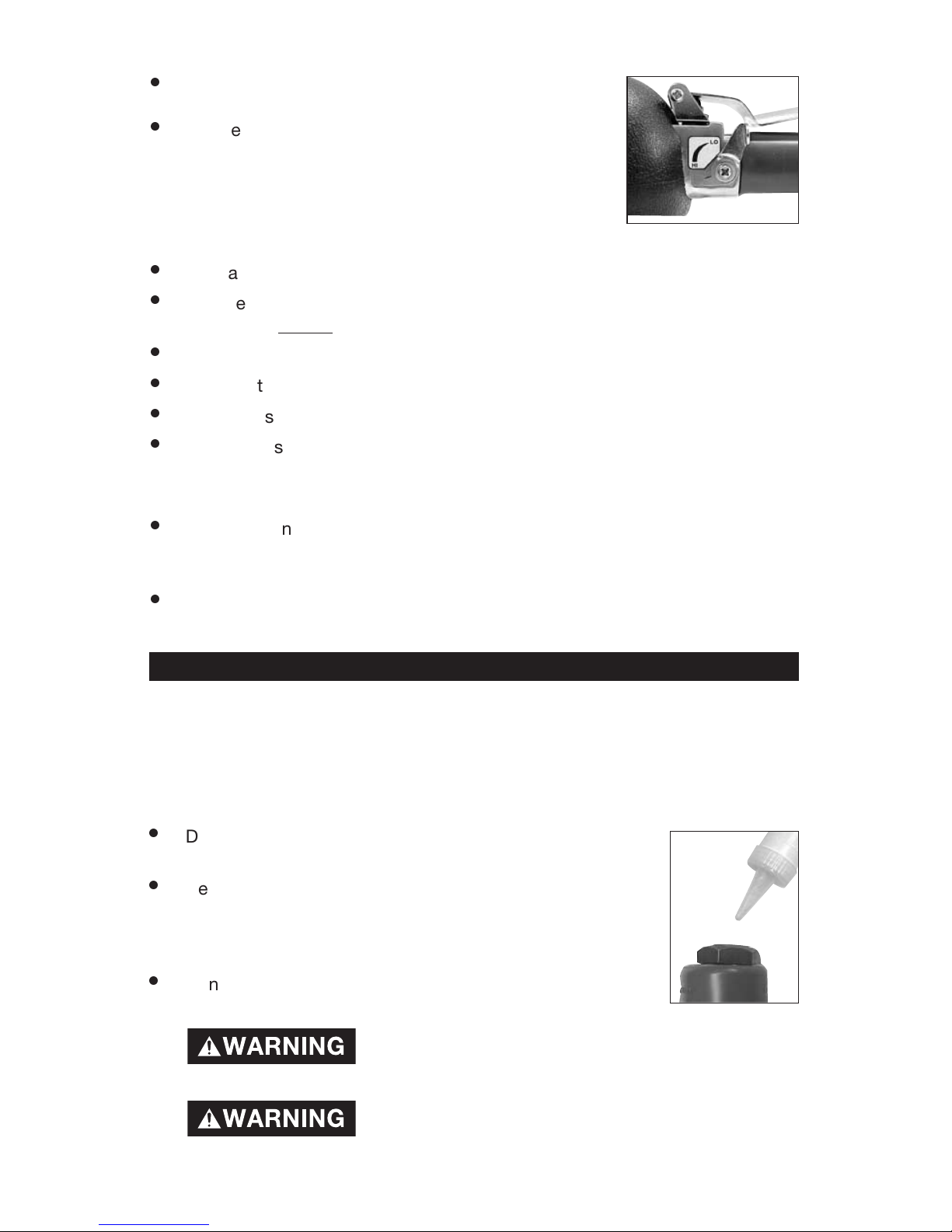

MAINTENANCE

Lubrication

Air tools require lubrication throughout the life of the tool. The air motor and

bearing uses compressed air to power the tool. Because moisture in

compressed air will rust the air motor, you must lubricate the motor daily. An

inline oiler is recommended.

To lubricate the air motor manually:

l

Disconnect the tool from the air supply holding it so the air

inlet faces up.

l

Depress the trigger and place one to two drops of air tool

oil in the air inlet Depressing the trigger helps circulate oil

in the motor. NOTE: Use SAE #10 weight oil if air tool oil is

not available.

l

Connect the tool to an air source, cover the exhaust end

with a towel and run for a few seconds.

Any excess oil in the motor is immediately

expelled from the exhaust port. Always direct

exhaust port away from people or objects.

Failure to lubricate the tool at the air inlet will

void your warranty.

l

Set speed between “HI” and “LO” to the desired

variable speed.

l

Connect tool to air hose of recommended size.

NOTE: The use of a quick connect set makes

connecting easier.

IMPORTANT: The use of air filters and air line

lubricators is recommended.

To use:

l

Turn air compressor on and allow air tank to fill.

l

Set the air compressor’s regulator to 90 PSI. This tool operates at a

maximum 90 PSI pressure.

l

Depress trigger to operate tool.

l

Release trigger to stop tool.

l

Always disconnect air supply when changing sandpaper pads.

l

When job is complete, turn the air compressor off and store as described

in the air compressor operator manual.

Tips

l

Begin sanding with an abrasive grit sandpaper course enough to remove

the high spots. Progress to a finer grit sandpaper until the desired finish is

obtained.

l

Never change from course grit sandpaper to a very fine grit sandpaper,

always progress to the finer grit.

8- ENG

D22738

LIMITED WARRANTY

All merchandise manufactured by DeVilbiss Air Power Company Manufacturing is warranted to be free

of defects in workmanship and material which occur during the first year from the date of purchase by

the original purchaser (initial user). Products covered under this warranty include: air compressors, *air

tools, accessories, service parts, pressure washers, and generators used in consumer applications

(i.e., personal residential household usage only).

Air compressors, *air tools, accessories, service parts, pressure washers, and generators used in

commercial applications (income producing) are covered by a 90 day warranty.

DeVilbiss Air Power Manufacturing will repair or replace, at DeVilbiss’ option, products or components

which have failed within the warranty period. Repair or replacement, and service calls on 60 and 80

gallon air compressors, will be handled by Authorized Warranty Service Centers and will be scheduled

and serviced according to the normal work flow and business hours at the service center location,

and depending on the availability of replacement parts.

All decisions of DeVilbiss Air Power Company Manufacturing with regard to this policy shall be final.

This warranty gives you specific legal rights, and you may also have other rights which vary from state

to state.

RESPONSIBILITY OF ORIGINAL PURCHASER (Initial User):

o

To process a warranty claim on this product, DO NOT return it to the retailer. The product must be

evaluated by an Authorized Warranty Service Center. For the location of the nearest Authorized

Warranty Service Center call 1-800-888-2468, Ext. 2, 24 hours a day, 7 days a week or visit our

web site @ devap.com.

o

Retain original cash register sales receipt as proof of purchase for warranty work.

o

Use reasonable care in the operation and maintenance of the product as described in the Owners

Manual(s).

o

Deliver or ship the product to the nearest DeVilbiss Air Power Manufacturing Authorized

Warranty Service Center. Freight costs, if any, must be paid by the purchaser.

o

Air compressors with 60 and 80 gallon tanks only will be inspected at the site of installation.

Contact the nearest Authorized Warranty Service Center, that provides on-site service calls, for

service call arrangement.

o

If the purchaser does not receive satisfactory results from the Authorized Warranty Service

Center, the purchaser should contact DeVilbiss Air Power Company Manufacturing.

THIS WARRANTY DOES NOT COVER:

o

Merchandise sold as reconditioned, floor models and/or display models. Any damaged or

incomplete equipment sold "as is".

o

Merchandise used as "rental" equipment.

o

Merchandise that has become inoperative because of ordinary wear, misuse, freeze damage, use

of improper chemicals, negligence, accident, improper and/or unauthorized repair or alterations

including failure to operate the product in accordance with the instructions provided in the

Owners Manual (s) supplied with the product.

*Air Tools: O-Rings and driver blades are considered ordinary wear parts, therefore, they are

warranted for a period of 45 days from the date of purchase.

o

An air compressor that pumps air more than 50% during a one hour period is considered misuse

because the air compressor is undersized for the required air demand. Maximum compressor

pumping time per hour is 30 minutes.

o

Merchandise sold by DeVilbiss Air Power Manufacturing which has been manufactured by and

identified as the product of another company. The product manufacturer's warranty will apply.

o

Repair and transportation costs of merchandise determined not to be defective.

o

Cost associated with assembly, required oil, adjustments or other installation and start-up cost.

o

Any incidental, indirect or consequential loss, damage, or expense that may result from ANY

defect, failure or malfunction of the product. Some states do not allow the exclusion or limitation

of incidental or consequential damages, so the above limitation or exclusion may not apply to

you.

o

Implied warranties, including those of merchantability and fitness for a particular PURPOSE, are

limited to one year from the date of original purchase. Some states do not allow limitations on

how long an implied warranty lasts, so the above limitations may not apply to you.

213 Industrial Drive • Jackson, TN 38301-9615

Telephone: 1-800-888-2468 , Ext. 2

FAX: 1-800-888-9036

Manual de instrucciones

para el modelo ETS1

IMPORTANTE

Asegúrese de que la persona que va a usar esta herramienta lea

cuidadosamente y comprenda estas instrucciones antes de empezar a

operarla.

Pieza Nº D22738 Rev. 0 4/25/01

LIJADORA DE ALTA VELOCIDAD

10- SP

D22738

NORMAS DE SEGURIDAD - DEFINICIONES

Indica una situación

peligrosa inminente la

cual, si no es evitada, podrá ocasionar la

muerte o serias lesiones.

Indica una situación

potencialmente

riesgosa la cual, si no es evitada, podría

ocasionar la muerte o serias lesiones.

Indica una

situación

potencialmente riesgosa la cual, si no es

evitada, puede ocasionar lesiones

menores o moderadas.

Usado sin el símbolo de

seguridad de alerta,

indica una situación potencialmente riesgosa

la cual, si no es evitada, puede ocasionar

daños a la propiedad.

SEGURIDAD Y PREVENCIÓN DE PROBLEMAS. Con el objeto de ayudarlo a reconocer el contenido de

esta información, utilizamos los símbolos indicados debajo. Sírvase leer este manual y prestar atención a

dichas secciones.

Este manual contiene información importante para que usted conozca y comprenda. Esta información

se relaciona con la protección de SU SEGURIDAD y LA PREVENCIÓN DE PROBLEMAS A SU

EQUIPO. Para ayudarlo a reconocer el contenido de esta información, utilizamos los símbolos

indicados debajo. Sírvase leer este manual y prestar atención a dichas secciones.

IMPORTANTES INSTRUCCIONES DE SEGURIDAD

Algunos tipos de aserrín creados por máquinas eléctricas de lijado, aserrado,

amolado, perforado u otras actividades de la construcción, contienen

materiales químicos conocidos (en el Estado de California) como causantes de cáncer, defectos de

nacimiento u otros daños del aparato reproductivo. Algunos ejemplos de dichos productos químicos son:

l

El plomo contenido en algunas pinturas con base de plomo

l

Sílice cristalizado proveniente de los ladrillos, el cemento y otros productos de albañilería

l

Arsénico y cromo provenientes del tratamiento químico dado a la madera

Su riesgo a dichas exposiciones variará dependiendo de la frecuencia con la que usted realice

diferentes tipos de trabajo. Para reducir su exposición a la acción de dichos agentes químicos:

trabaje en zonas bien ventiladas, y hágalo con equipo de seguridad aprobado,

use siempre protección

facial o respirador MSHA / NIOSH aprobados cuando deba utilizar dichas herramientas.

Al utilizar herramientas neumáticas también deben tomarse precauciones básicas de seguridad, a fin

de reducir la posibilidad de riesgo de lesiones personales.

11- SP

D22738

LA OPERACIÓN O EL MANTENIMIENTO INADECUADOS DE ESTE PRODUCTO PUEDEN

OCASIONAR SERIAS LESIONES Y DAÑOS A LA PROPIEDAD. LEA Y COMPRENDA TODAS

LAS ADVERTENCIAS E INSTRUCCIONES OPERATIVAS ANTES DE UTILIZAR ESTE EQUIPO.

AL UTILIZAR HERRAMIENTAS NEUMÁTICAS, SIEMPRE DEBEN SEGUIRSE PRECAUCIONES

BÁSICAS DE SEGURIDAD PARA REDUCIR EL RIESGO DE LESIONES PERSONALES.

CONSER

VAR

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

CONSER

VAR

RIESGO

QUÉ PODRÍA OCURRIR CÓMO PREVENÍRLO

RIESGO DE LESIONES EN

LOS OJOS O LA CABEZA

• Los equipos neumáticos y las

herramientas eléctricas son capaces

de arrojar materiales tales como

virutas de metal, aserrín de la sierra y

otras partículas a alta velocidad, lo

cual podría ocasionarle serias

lesiones oculares.

• El aire comprimido puede ser

peligroso. El chorro de aire puede

ocasionar lesiones sobre los tejidos

blandos en zonas tales como los

ojos u oídos, etc. Partículas u objetos

expulsados por un chorro de aire

pueden ocasionar una lesión.

•

Los accesorios de herramientas

pueden soltarse o romperse y saltar

expulsando partículas contra el operador y otros dentro del área de trabajo.

• Use siempre anteojos de seguridad

ANSI aprobados Z87.1, con

protección lateral.

• Jamás deje desatendida una herramienta mientras esté funcionando.

Desconecte la manguera del aire

cuando dicha herramienta no esté en

uso.

• Para protección adicional use una

máscara facial aprobada, por encima

de los anteojos de seguridad.

RIESGO DE INCENDIO O

EXPLOSIÓN

• Las herramientas abrasivas tales

como lijadoras y amoladoras,

herramientas rotativas tales como

taladros, y las herramientas de

impacto tales como llaves,

martillos y sierras recíprocas, son

capaces de generar chispas que

podrían determinar la ignición de

materiales inflamables.

• Exceder el máximo de la presión

especificada para las herramientas

o sus accesorios, puede causar

una explosión, la que podría

ocasionar serias lesiones.

• Asegúrese de que los accesorios

estén ensamblados con seguridad.

• Jamás opere herramientas en las

cercanías de sustancias inflamables

tales como gasolina, nafta, solvente

limpiadores, etc.

• Trabaje en un área limpia y bien

ventilada, libre de materiales

combustibles.

• Jamás use oxígeno, dióxido de

carbono u otros gases envasados

como fuente de alimentación para

herramientas neumáticas.

• Use el aire comprimido regulado

para cualquier accesorio hasta el

máximo de la presión permitida o

por debajo de los valores

especificados para ellos.

RIESGO DE PÉRDIDA DE

LA AUDICIÓN

• La exposición durante largo

tiempo al ruido producido por la

operación de las herramientas

neumáticas puede conducir a la

pérdida permanente de la

audición.

• Use siempre protección

auditiva ANSI S3.19

RIESGO DE RESPIRACIÓN

PELIGRO DE INHALACIÓN

• Herramientas abrasivas tales

como amoladoras, lijadoras y

cortantes, generan polvo, lo cual

puede ser dañino para los

pulmones y el sistema respiratorio.

• Algunos materiales tales como

adhesivos y alquitrán contienen

productos químicos cuyas

emanaciones pueden ocasionar

serias lesiones ante una prolongada

exposición a las mismas.

• Use siempre protección facial o

respirador MSHA / NIOSH

aprobados cuando deba utilizar

dichas herramientas.

• Trabaje siempre en un área seca y

bien ventilada.

12- SP

D22738

RIESGO

QUÉ PODRÍA OCURRIR CÓMO PREVENÍRLO

RIESGO DE LESIONES

• Las herramientas que se dejan

desatendidas, o con la manguera

de aire comprimido conectada,

pueden ser activadas por personas

no autorizadas, lesionándose o

lastimando a otros.

• Las herramientas eléctricas

pueden arrojar materiales a través

de la zona de trabajo.

• Las herramientas eléctricas pueden

activarse accidentalmente durante

su mantenimiento o durante el

cambio de herramientas.

• Las herramientas eléctricas

pueden causar el desplazamiento

de la pieza de trabajo y producir

lesiones.

• La pérdida del control de la

herramienta puede ocasionarle

lastimaduras o hacerlo a otros.

• Herramientas de calidad pobre,

inapropiadas o dañadas, tales

como ruedas de amolado,

formones, llaves de tubo, taladros,

etc., pueden ser lanzadas durante

la operación, arrojando partículas

a través del área de trabajo,

pudiendo ocasionar serias

lesiones.

• Extraiga la manguera de aire

cuando la herramienta no esté en

uso, y guárdela en un sitio seguro,

fuera del alcance de los niños.

• Utilice solamente partes,

sujetadores y accesorios

recomendados por el fabricante.

• Mantenga el sitio de trabajo limpio

y libre de desorden. Haga que los

niños y otras personas estén

alejados del área de trabajo

durante las operaciones de la

herramienta.

• Mantenga el área de trabajo bien

iluminada.

• Extraiga la manguera de aire de la

herramienta para lubricar o agregar

accesorios de amolado, discos de

lijado, taladros, etc.

• Jamás transporte la herramienta

tomándola de su manguera.

• Evite un arranque accidental. No

transporte la herramienta con su

dedo sobre el gatillo.

• Las reparaciones de servicio deben

ser efectuadas únicamente por

representantes autorizados de

servicio.

• Utilice sujetadores u otros

dispositivos para impedir el

movimiento.

• Jamás opere la herramienta bajo la

influencia de drogas o alcohol.

• No sobreextienda su cuerpo.

Manténgase parado

adecuadamente con sus pies

balanceados en todo momento.

• Mantenga las manijas secas, limpias

y libres de aceite y grasitud.

• Esté alerta. Observe lo que está

haciendo. Use el sentido común. No

opere la herramienta cuando esté

cansado.

• Utilice siempre los accesorios de las

herramientas a la velocidad para la

que han sido especificados.

• Jamás utilice herramientas que se

hayan caído, impactado o dañado

por su uso.

• Use solamente tubos de encastre

estriado de alto impacto para las

herramientas de impacto.

• No aplique excesiva fuerza a la

herramienta; deje que la misma

ejecute su trabajo.

13- SP

D22738

Velocidad libre (sin carga) 10.000 RPM

Máxima presión de trabajo 90 PSI

Diámetro de la plataforma de apoyo 139 mm

Entrada de aire 1/4" NPT

Medida de manguera recomendada 3/8" D.I.

ESPECIFICACIONES

RIESGO

QUÉ PODRÍA OCURRIR

CÓMO PREVENÍRLO

RIESGO DE ENREDO

• Las herramientas que contienen

elementos movibles o que empujan

a otras herramientas movibles,

tales como ruedas de amolar, tubos

de encastre estriados, discos de

lijar, etc., pueden enredarse en el

cabello, las ropas, joyas u otros

objetos sueltos, ocasionando

lesiones severas.

• Jamás use elementos sueltos de su

ropa o indumentaria, conteniendo

tiras sueltas o cintas, etc., que

pudiesen enredarse entre partes

movibles de la herramienta.

• Quítese cualquier joya, reloj,

identificaciones, brazaletes, collares,

etc., que pudiesen ser atrapados

por la herramienta.

• Mantenga alejada de sus manos y

cuerpo aquella parte de la

herramienta que se encuentra en

movimiento. Átese o cubra el

cabello largo.

• Cuando utilice este equipo, use

siempre la indumentaria

apropiada y los demás

elementos de seguridad.

RIESGO DE CORTES O

QUEMADURAS

• Las herramientas de corte, cizallado,

perforado, punzonado, pueden

ocasionar lesiones serias.

• Mantenga sus manos alejadas de

las partes en movimiento.

14- SP

D22738

Operación

Antes de casa uso:

l

Drene el agua condensada del

tanque del compresor de aire y

la acumulada en las cañerías.

Lea el manual del operador

del compresor de aire.

Antes de

lubricar

o cambiar el elemento abrasivo,

desconecte la amoladora de su

suministro de aire.

l

Para la lubricación de la

herramienta lea la sección

"Mantenimiento" de este

manual.

IMPORTANTE: La herramienta DEBE estar en posición de bloqueo para

poder instalar la plataforma de lijado.

l

Gire la traba del cilindro impulsor (A) hasta que los bordes estriados

conecten con el cilindro impulsor (B) y se detenga.

l

Sujete el cilindro impulsor (B) e instale la almohadilla (C) para el papel de

lijado, ajuste firmemente.

l

Coloque el papel de lijar elegido sobre el soporte de lijar. NOTA: Utilice el

papel de lijar autoadhesivo aprobado.

IMPORTANTE: La herramienta DEBE estar en posición

destrabada para la acción orbital.

l

Gire la traba del cilindro impulsor (A) a su posición

desblocante.

OPERACIÓN

ENSAMBLADO

Accesorios requeridos

IMPORTANTE: El diámetro interior de la manguera o cañería debe ser

incrementado para compensar inusuales longitudes de mangueras [más de

7,6 m ( 25 pies)]. El diámetro mínimo de una manguera debe ser de 3/8" D.I. y

las conexiones deben tener 1/4" NPT roscado.

B

C

B

A

A

Gatillo

Entrada

de aire

Plataforma

de lijado

15- SP

D22738

MANTENIMIENTO

Lubricación

Las herramientas neumáticas requieren lubricación a lo largo de su vida útil. El motor

de aire y los rodamientos utilizan aire comprimido para mover la herramienta. La

humedad del aire comprimido oxidará el motor de aire; por lo tanto se deberá lubricar

el motor diariamente. Se recomienda el uso de un aceitador intercalado en la cañería.

Cómo lubricar manualmente el motor del aire:

l

Desconecte la herramienta de su fuente de alimentación sujetándola de forma

que la entrada de aire quede orientada hacia arriba.

l

Presione el dispositivo de seguridad que libera el acelerador y

la palanca de control del mismo, y coloque una o dos gotas de

aceite para herramientas neumáticas en la entrada de aire.

Presionando la palanca que controla el acelerador se ayudará

a circular el aceite dentro del motor. NOTA: Utilice aceite SAE

# 10 en todas las herramientas si el aceite para herramientas

neumáticas no se encuentra disponible.

l

Conecte la herramienta a su fuente de alimentación de aire,

cubra el extremo de escape con una toalla y hágala funcionar

durante unos segundos.

Cualquier exceso de aceite en el motor será

expelido inmediatamente a través del portal

de salida. Oriente dicho portal fuera del alcance de personas u objetos.

La falta de lubricación a la entrada de aire de

la herramienta cancelará su garantía.

l

Fije la velocidad entre "HI" y "LO" al valor deseado.

l

Conecte la herramienta a la manguera de la medida

recomendada. NOTA: El uso de un juego conector

rápido hace las conexiones más fáciles.

IMPORTANTE: Se recomienda el uso de filtros de aire y

lubricadores intercalados en la cañería de aire.

Para usar:

l

Ponga el compresor en marcha y deje llenar el tanque de aire.

l

Calibre el regulador del compresor de aire a 90 PSI. Esta herramienta opera a

un máximo de 90 PSI

de presión.

l

Presione el gatillo para operar la herramienta.

l

Suelte el gatillo para detenerla.

l

Desconecte siempre el suministro de aire cuando cambie el soporte de lijar.

l

Una vez que el trabajo se haya completado, apague el compresor y guárdelo

de acuerdo a lo descripto en el manual del operador del compresor de aire.

Consejos prácticos

l

Comience el lijado con un grano abrasivo grueso, lo suficiente para

remover los sitios más densos. Avance progresivamente hacia hojas de

lijado más fino hasta logar el acabado deseado.

l

Nunca cambie de un grano de lijado grueso a otro muy fino, hágalo

siempre progresivamente hacia el grano más fino.

16- SP

D22738

GARANTÍA LIMITADA

Toda la mercadería fabricada por DeVilbiss Air Power Company Manufacturing está garantizada libre de defectos

en mano de obra y materiales por el término del primer año a partir de la fecha de su compra por parte del

comprador original (usuario inicial). Los productos cubiertos bajo esta garantía incluyen: compresores de aire,

herramientas neumáticas *, accesorios, piezas de servicio, arandelas de presión y generadores, utilizados para el

uso personal (por ejemplo, uso residencial únicamente).

Los compresores de aire , herramientas neumáticas *, accesorios, piezas de servicio, arandelas de presión, y

generadores utilizados para aplicaciones comerciales (que producen ingresos) quedan cubiertos por una garantía

de 90 días.

DeVilbiss Air Power Company Manufacturing reparará o reemplazará, a criterio de DeVilbiss, productos o

componentes que hubiesen fallado dentro del periodo de garantía. La reparación o el reemplazo y las solicitudes

de servicio en compresores de aire de 60 y 80 galones, serán atendidos por los servicentros autorizados para

garantías; en ellos serán programados y atendidos de acuerdo al flujo normal de trabajo durante el horario

comercial, en el sitio de servicio, dependiendo de la disponibilidad de piezas de reemplazo.

Todas las decisiones de DeVilbiss Air Power Company Manufacturing relacionadas con esta póliza serán finales.

Esta garantía le otorga derechos legales específicos, aunque también podrá usted tener otros derechos que

varían entre estados.

RESPONSABILIDAD DEL COMPRADOR ORIGINAL (Usuario Inicial):

o

Para procesar un reclamo relacionado con la garantía de este producto, NO lo devuelva al comerciante. El

producto debe ser evaluado por un servicentro autorizado para atención de garantías. Para conocer el

domicilio del servicentro autorizado para atención de garantías más cercano, llame al 1-800-888-2468, Ext. 2,

disponible 24 horas al día, los 7 días de la semana, o visite nuestro sitio web en www.devap.com

o

Retenga el recibo del pago original como comprobante de su compra para reclamar trabajos cubiertos por la

garantía.

o

Mantenga un cuidado razonable en la operación y mantenimiento del producto tal como se describe en

el(los) Manual(es) del propietario.

o

Entregue o envíe el producto al servicentro autorizado para atención de garantías más cercano a DeVilbiss

Air Power Company Manufacturing. Los gastos de flete - en caso de haber alguno - deberán ser pagados

por el comprador.

o

Los compresores de aire con tanques de 60 y 80 galones solamente serán inspeccionados en el sitio de

instalación. Para convenir la atención del servicio en su sitio de instalación, deberá contactar al servicentro

autorizado para atención de garantías que atiende servicios domiciliarios.

o

Los compradores deberán contactar directamente a DeVilbiss Air Power Company Manufacturing, si no

recibiesen resultados satisfactorios de su servicentro para atención de garantías.

ESTA GARANTÍA NO CUBRE:

o

Mercadería vendida como reacondicionada, modelos de piso y/o exhibición. Cualquier equipamiento dañado

o incompleto vendido "en el estado en que se encuentra".

o

Mercadería usada como equipo "de alquiler".

o

Mercadería que se ha tornado inoperante debido a su uso ordinario, inadecuado, por daños de

congelamiento, utilizado con productos químicos inadecuados, negligencia, accidente, alteraciones y/o

reparaciones no autorizadas incluyendo aquellas fallas operativas debidas a la operatividad del producto de

acuerdo a las instrucciones suministradas en el(los) Manual(es) del propietario.

*Herramientas neumáticas: O-rings y hojas impulsoras son partes consideradas de desgaste ordinario por lo

tanto, ellas quedan garantizadas solamente durante un periodo de 45 días a partir de la fecha de su compra.

o

Un compresor de aire que bombea aire por

más

del 50% durante una hora está considerado como uso

inadecuado, dado que el compresor de aire est

á

subdimensionado para la demanda de aire requerida. El

máximo tiempo de bombeo por hora para un compresor es de 30 minutos.

o

La mercadería vendida por DeVilbiss Air Power Company Manufacturing que haya sido fabricada e

identificada como producto de otra empresa quedará cubierta por la garantía de su fabricante.

o

Costos de reparación y transporte de mercadería determinada como no defectuosa.

o

Los costos asociados con el ensamblado, requerimiento de aceite, ajustes u otras instalaciones y costos de

puesta en marcha.

o

Cualquier pérdida, daño o expensa incidental o consecuencial resultante de CUALQUIER defecto, falla o

funcionamiento inadecuado del producto. Algunos estados no admiten la exclusión o limitación de daños

incidentales o consecuenciales, en tal caso la limitación o exclusión arriba mencionada no será aplicable.

o

Las garantías implícitas. Incluidas aquellas de comercialización y aptitud PARA UN PROPÓSITO EN

PARTICULAR, quedan limitadas a un año a partir de la fecha original de su compra. Algunos estados no

permiten la duración de las limitaciones relativas, en dichos casos, las limitaciones arriba mencionadas no

serán de aplicación.

213 Industrial Drive • Jackson, TN 38301-9615

Teléfono: 1-800-888-2468 , Ext. 2

FAX: 1-800-888-9036

Manuel d'instructions

pour modèle ETS1

IMPORTANT

Veuillez vous assurer que la personne qui utilise cet outil lit attentivement et

comprend ces instructions avant de commencer à utiliser l'outil.

Nº de pièce D22738 Rév. 0 4/25/01

PONCEUSE HAUTE VITESSE

18- FR

D22738

MESURES DE SÉCURITÉ - DÉFINITIONS

Indique un danger

imminent qui, s'il

n'est pas évité, causera de graves

blessures ou la mort.

Indique la

possibilité

d'un danger qui, s'il n'est pas évité,

pourrait

causer de graves blessures

ou la mort.

Indique la

possibilité

d'un danger,

qui, s'il n'est pas évité peut

causer des

blessur

es mineures ou moyennes.

(sans le symbole

d'attention) :

Indique la

possibilité d'un danger qui, s'il n'est pas

évité, peut

causer des dommages à la

propriété.

SÉCURITÉ ET PRÉVENTION DE PROBLÈMES D'ÉQUIPEMENT. Afin de vous aider à identifier

cette information, nous avons utilisé les signes de danger ci-dessous. Veuillez lire ce guide en

portant une attention particulière à ces sections.

Il est important de prendre connaissance et de comprendre tous les renseignements que contient ce

guide. Cette information porte sur VOTRE SÉCURITÉ et sur LA PRÉVENTION DE PROBLÈMES

D'ÉQUIPEMENT. Afin de vous aider à identifier cette information, nous avons utilisé les signes de

danger ci-dessous. Veuillez lire ce guide en portant une attention particulière à ces sections.

CONSIGNES DE SÉCURITÉ IMPORTANTES

La poussière produite par le ponçage électrique le sciage, le

meulage, le perçage et autres activités de construction peut

contenir des produits chimiques qui sont reconnus, par l'état de la Californie, de causer le cancer, les

anomalies congénitales ou autres maux de reproduction. Ces produits chimiques comprennent, entre

autres :

●●

le plomb provenant des peintures à base de plomb;

●●

la silice cristalline provenant de briques, de béton ou d'autres produits de maçonnerie

●●

l'arsenic et le chrome provenant du bois de charpente traité chimiquement

Le risque d'exposition à ces produits dépend de la fréquence d'exécution de ce genre de travaux.

Afin de réduire l'exposition à ces produits chimiques, travaillez dans un endroit bien aéré et utilisez de

l'équipement de sécurité approuvé,

portez toujours un masque facial ou respirateur homologué

MSHA/NIOSH bien ajusté lorsque vous utilisez de tels outils.

Lorsque vous utilisez un outil pneumatique, il faut toujours suivre les mesures de sécurité de base afin

de réduire le risque de blessures corporelles.

19- FR

D22738

UN EMPLOI OU UN ENTRETIEN NON APPROPRIÉ DE CE PRODUIT PEUT CAUSER DES

BLESSURES GRAVES ET DES DOMMAGES À LA PROPRIÉTÉ. LISEZ ATTENTIVEMENT TOUS

LES AVERTISSEMENTS ET LES DIRECTIVES D'UTILISATION AVANT D'UTILISER CET OUTIL.

EN UTILISANT UN OUTIL PNEUMATIQUE, IL FAUT TOUJOURS SUIVRE LES MESURES DE

SÉCURITÉ DE BASE AFIN DE RÉDUIRE LE RISQUE DE BLESSURES CORPORELLES.

À CONSER

VER!

MESURES DE SÉCURITÉ IMPORTANTES

À CONSER

VER!

DANGER

RISQUE PRÉVENTION

RISQUE DE BLESSURES

AUX YEUX OU À

LA TÊTE

• Tout équipement pneumatique et

outils électriques sont capables de

projeter, à vitesse élevée, des

matériaux tels que des copeaux, de

la sciure et d'autres débris, ce qui

pourrait causer des blessures graves

aux yeux.

• L'air comprimé peut être dangereux.

Le jet d'air risque de causer des

blessures aux tissus mous du corps,

tels que les yeux, les oreilles, etc.

Les particules propulsées par le jet

peuvent causer des blessures.

• Les accessoires des outils peuvent

se desserrer ou briser et voler ou

projeter des particules dans la

direction de l'utilisateur ou d'autres

personnes dans l'aire de travail.

• Portez toujours des lunettes de

protection homologuées ANSI

Z87.1 avec des écrans latéraux.

• Ne laissez jamais l'outil sous

tension sans supervision.

Débranchez le boyau d'air lorsque

l'outil n'est pas en usage.

• Pour obtenir une protection

supplémentaire, portez un

masque facial homologué en

plus des lunettes de protection.

RISQUE D'INCENDIE OU

D'EXPLOSION

• Les outils abrasifs tels que les

ponceuses et les meules, les outils

rotatifs tels que les perceuses,

ainsi que les outils à impact (les

clés, les marteaux et les scies à

va-et-vient) sont capables de

produire des étincelles qui

pourraient allumer des matériaux

inflammables.

• L'utilisation d'une pression

supérieure à la pression maximale

de l'outil ou de l'accessoire

pourrait provoquer une explosion

et risque de causer des blessures

graves.

• Assurez-vous que les accessoires

sont bien attachés.

• N'utilisez jamais les outils près de

matières inflammables, telles que

l'essence, le kérosène, des solvants

de nettoyage, etc.

• Travaillez à un endroit propre, bien

aéré et loin de toute matière

combustible.

• N'utilisez jamais de l'oxygène, du

dioxyde de carbone ou autre gaz en

cylindres comme source

d'alimentation des outils

pneumatiques.

• Utilisez de l'air comprimé réglé à

une pression maximale égale à ou

inférieure à la pression nominale de

l'accessoire utilisé.

RISQUE DE PERTE DES

CAPACITÉS AUDITIVES

• Une exposition prolongée au bruit

produit par les outils pneumatiques

peut entraîner la perte permanente

des capacités auditives.

• Portez toujours des dispositifs

de protection des oreilles

homologués ANSI S3.19.

RISQUE PAR INHALATION

• Les outils abrasifs tels que les

meules, les ponceuses et les outils

à découper produisent de la

poussière et des matériaux abrasifs

qui risquent d'endommager les

poumons et le système respiratoire

des êtres humains.

• Certains matériaux, tels que des

produits adhésifs et le goudron,

contiennent des produits chimiques

dont les vapeurs risquent de causer

des blessures graves après une

exposition prolongée.

• Portez toujours un masque facial

ou respirateur homologué

MSHA/NIOSH bien ajusté lorsque

vous utilisez de tels outils.

• Travaillez toujours dans une région

propre, sèche et bien aérée.

20- FR

D22738

DANGER

RISQUE

PRÉVENTION

RISQUE DE BLESSURES

• Les outils laissés sans supervision,

ou dont le boyau d'air est branché,

peuvent être mis en marche par

des personnes non autorisées et

causer des blessures à l'utilisateur

ou à d'autres personnes.

• Les outils électriques peuvent

propulser des matériaux à travers

l'aire de travail.

• Les outils électriques peuvent être

mis en marche accidentellement

lors de l'entretien ou lors des

changements d'outils.

• Les outils électriques peuvent

entraîner le déplacement de la

pièce sur laquelle vous travaillez

lorsqu'ils entrent en contact avec

la pièce, ce qui pourrait entraîner

des blessures.

• La perte de contrôle de l'outil peut

causer des blessures à l'utilisateur

ou à d'autres personnes.

• Les outils de mauvaise qualité,

inappropriés ou endommagés, tels

que les meules de rectification, les

ciseaux, les douilles, les

perceuses, etc., peuvent se

détacher lors de l'utilisation et

projeter des particules à travers

l'aire de travail, ce qui risque de

causer des blessures graves.

• Débranchez le boyau d'air lorsque

l'outil n'est pas en usage et rangez

l'outil à un endroit sûr, hors de la

portée des enfants.

• Utilisez seulement les pièces,

attaches et accessoires

recommandés par le fabricant.

• Gardez l'aire de travail propre et

libre d'encombrements. Gardez les

enfants et autres personnes éloignés

de l'aire de travail lorsque l'outil est

en fonction.

• Assurez-vous que l'aire de travail est

bien éclairée.

• Retirez le boyau d'air lors de la

lubrification et lors du changement

des accessoires de rectification, de

ponçage, de perçage, etc.

• Ne transportez jamais l'outil en le

saisissant par le boyau.

• Évitez les mises en marche

accidentelles. Ne portez pas l'outil

branché avec le doigt sur la détente.

• Toute réparation d'entretien devrait

être effectuée par un représentant

de service autorisé.

• Utilisez des serre-joints ou

d'autres dispositifs pour empêcher

tout mouvement.

• N'utilisez jamais l'outil lorsque

vous êtes sous l'influence de

drogues ou d'alcool.

• Ne pas trop se pencher. Maintenez

en tout temps les pieds fermement

au sol et gardez l'équilibre.

• Assurez-vous que les poignées

sont sèches, propres et libre

d'huile et de graisse.

• Restez alerte. Soyez attentif.

Utilisez le bon sens. N'utilisez pas

l'outil lorsque vous êtes fatigué.

• Utilisez toujours des accessoires

d'une vitesse nominale appropriée

pour l'outil électrique.

• N'utilisez jamais les outils qui sont

tombés, qui ont subi un impact ou

qui ont été endommagés par

l'utilisation.

• Utilisez seulement des douilles de

catégorie capable de subir

l'impact d'une clé à percussion.

• N'appliquez pas trop de force sur

l'outil - laissez l'outil travailler.

21- FR

D22738

Vitesse sans charge 10 000 tr/min

Pression maximale de fonctionnement 90 lb/po

2

Diamètre des tampons de ponçage 6 po

Prise d'air 1/4 po NPT

Dimension de boyau recommandée 3/8 po (dia. int.)

SPÉCIFICATIONS

DANGER

RISQUE PRÉVENTION

RISQUE

D'ENCHEVÊTREMENTS

• Les outils comprenant des

éléments mobiles ou qui

entraînent d'autres outils

mobiles, tels que des meules

de rectification, douilles ou

disques de ponçage, etc.,

peuvent devenir emmêlés dans

les cheveux, les vêtements, les

bijoux ou autres objets

desserrés, ce qui risque de

provoquer des blessures

graves.

• Ne portez jamais des vêtements

amples ou munis d'attaches ou

de bandes qui peuvent se

détacher et devenir emmêlées

dans les pièces mobiles de

l'outil.

• Enlevez tous les bijoux, montres,

pièces d'identification, bracelets,

chaînes, etc. qui risquent de

devenir coincés dans l'outil.

• Gardez les mains éloignées des

pièces mobiles. Attachez ou

couvrez les cheveux longs.

• Portez toujours des vêtements

bien ajustés et d'autres articles

de sécurité en utilisant cet outil.

RISQUE DE COUPURES

OU DE BRÛLURES

• Les outils à découper, diviser,

percer, poinçonner ou cisailler,

etc., peuvent causer des

blessures graves.

• Gardez les pièces travaillantes

de l'outil bien éloignées des

mains et du corps.

22- FR

D22738

Utilisation

Avant chaque utilisation :

l

Vidangez l'eau accumulée dans

le réservoir du compresseur d'air

ainsi que toute condensation des

conduites d'air. Consultez le

guide de l'utilisateur du

compresseur d'air.

Débranchez l'outil de la

source d'alimentation d'air

avant la lubrification et

avant de changer le disque

de ponçage.

l

Lubrifiez l'outil. Consultez la section intitulée " Entretien " de ce guide.

IMPORTANT : L'outil DOIT être dans la position verrouillée pour poser le tampon

de ponçage.

l

Tournez le verrou du cylindre d'entraînement (A) jusqu'à ce que le rebord

nervuré entre en contact avec le cylindre d'entraînement (B) et s'arrête.

l

Maintenez le cylindre d'entraînement (B), posez le tampon de ponçage (C)

et serrez fermement.

l

Placez le papier de ponçage désiré sur le tampon de ponçage.

REMARQUE : Utilisez du papier de ponçage auto-adhésif

approuvé.

IMPORTANT : L'outil DOIT être en position déverrouillée pour

permettre le mouvement orbital.

l

Tournez le verrou du cylindre d'entraînement (A)

jusqu'à ce qu'il soit en position déverrouillée.

Prise d'air

Déclencheur

Tampon de

ponçage

ASSEMBLAGE

UTILISATION

Accessoires requis

IMPORTANT : La pression de ligne ou le diamètre interne du boyau devraient être

augmentés pour compenser les boyaux d'air extrêmement longs [plus de 25 pieds

(7,5 m)]. Le diamètre interne minimum des boyaux devrait être de 3/8 po et les raccords

devraient avoir un filetage de 1/4 po NPT.

B

C

B

A

A

23- FR

D22738

ENTRETIEN

Lubrification

Il faut lubrifier les outils pneumatiques pendant toute leur vie utile. Le moteur à air et le

roulement utilisent de l'air comprimé pour alimenter l'outil. Parce que l'humidité dans l'air

comprimé peut corroder le moteur à air, il faut lubrifier le moteur chaque jour. Nous

recommandons l'utilisation d'un graisseur en ligne.

Lubrification manuelle du moteur à air :

l

Débranchez l'outil de la source d'alimentation d'air en le saisissant

de façon à ce que le trou de prise d'air soit dirigé vers le haut.

l

Appuyez sur le déclencheur et versez une ou deux gouttes d'huile

pour outils pneumatiques dans le trou de prise d'air. Le fait

d'appuyer sur le déclencheur aide à faire circuler l'huile dans le

moteur. REMARQUE : Utilisez de l'huile SAE n° 10 si de l'huile

pour outils pneumatiques n'est pas disponible.

l

Branchez l'outil à une source d'alimentation d'air, couvrez

l'extrémité d'échappement avec un chiffon et faire fonctionner l'outil pendant quelques

secondes.

Tout excès d'huile dans le moteur sort

immédiatement de l'orifice d'échappement.

Assurez-vous que l'orifice d'échappement n'est jamais dirigé vers d'autres

personnes ou vers des objets.

Si l'outil n'est pas lubrifié au trou

de prise d'air, la garantie sera annulée.

l

Réglez la vitesse à la vitesse désirée entre les

positions "HI" et "LO".

l

Branchez l'outil au boyau d'air de la dimension

recommandée.

REMARQUE : L'utilisation d'un ensemble à connexion rapide

facilite le raccordement.

IMPORTANT : Nous recommandons l'utilisation de filtres à

air et de dispositifs de lubrification des conduites d'air.

Utilisation :

l

Mettez le compresseur d'air en marche et attendez que le réservoir soit rempli.

l

Réglez la pression du compresseur à 90 lb/po2. Cet outil fonctionne à une pression

maximale de 90 lb/po2.

l

Appuyez sur le déclencheur pour faire fonctionner l’outil.

l

Relâchez le déclencheur pour arrêter l'outil.

l

Débranchez toujours la source d'alimentation d'air avant de changer les tampons de ponçage.

l

Lorsque le travail est terminé, arrêtez le compresseur d'air et rangez-le, tel

qu'indiqué dans le guide de l'utilisateur du compresseur d'air.

Conseils

l

Commencez le ponçage avec un papier à poncer abrasif assez grossier pour

enlever les points en saillie. Poursuivez avec un papier à poncer progressivement

plus fin jusqu'à ce que le fini désiré soit obtenu.

l

N'utilisez jamais un papier à poncer très fin tout de suite après avoir utilisé un papier

à poncer grossier. Utilisez progressivement un grain plus fin.

D22738

GARANTIE LIMITÉE

Toute marchandise fabriquée par DeVilbiss Air Power Company Manufacturing est garantie contre tout défaut de fabrication ou

de matériau au cours de la première année suivant la date de l'achat par l'acheteur d'origine (utilisateur initial). Les produits

couverts par cette garantie comprennent : les compresseurs d'air, *outils pneumatiques, accessoires, pièces de rechange,

laveuses à pression et génératrices utilisés comme biens de consommation (c.-à-d., utilisés à la maison à des fins personnelles

seulement).

Les compresseurs d'air, *outils pneumatiques, accessoires, pièces de rechange, laveuses à pression et génératrices utilisés à des

fins commerciales (produisant un revenu) sont garantis pour une période de 90 jours.

DeVilbiss Air Power Manufacturing réparera ou remplacera, à sa discrétion, les produits ou composants s'étant avérés

défectueux dans les limites de la période de garantie. Les réparations ou les remplacements ainsi que les dépannages requis sur

les compresseurs d'air de 60 et 80 gallons seront effectués dans un centre de service après-vente agréé et seront effectués

pendant les heures libres d'une journée ouvrable et selon la disponibilité des pièces nécessaires.

Toute décision prise par DeVilbiss Air Power Company Manufacturing en ce qui concerne cette politique est finale.

Cette garantie vous donne certains droits particuliers. Il se peut que vous ayez d'autres droits, variant d'une province à l'autre et

d'un état à l'autre.

RESPONSABILITÉ DE L'ACHETEUR D'ORIGINE (utilisateur initial) :

o

Pour faire une réclamation de garantie pour ce produit, NE retournez pas le produit au vendeur au détail. Le produit doit être

évalué par le personnel d'un centre de service après-vente agréé. Pour connaître l'emplacement du centre de service aprèsvente agréé le plus près de chez vous, composez le 1-800-888-2468, poste 2, 24 heures par jour, 7 jours par semaine ou

visitez notre site Web à www.devap.com.

o

Conservez le reçu de caisse comme preuve d'achat en cas de travaux requis sous la garantie.

o

Appliquez tous soins raisonnables lors de l'utilisation et de l'entretien du produit, conformément aux recommandations dans

le ou les guide(s) du propriétaire.

o

Livrez ou expédiez le produit au centre de service après-vente agréé de DeVilbiss Air Power Manufacturing le plus proche. Le

fret doit, le cas échéant, être acquitté par l'acheteur.

o

Seuls, les compresseurs d'air à réservoir de 60 et 80 gallons seront inspectés sur les lieux de leur installation. Veuillez

communiquer avec le centre de service après-vente agréé le plus proche offrant le service sur place, pour faire les

arrangements nécessaires dans un tel cas.

o

Tout acheteur qui n'est pas satisfait de l'intervention du centre de service après-vente agréé est prié de communiquer

directement avec DeVilbiss Air Power Company Manufacturing.

NON COUVERT PAR CETTE GARANTIE :

o

Marchandise remise à neuf, modèles de salon ou d'exposition et tout équipement endommagé ou incomplet vendu " tel quel ".

o

Marchandise employée comme équipement de location.

o

Marchandise ayant cessé de fonctionner en raison d'usure normale, d'usage abusif, d'exposition au gel, d'usage de produits

chimiques non appropriés, de négligence, d'accident, de réparations ou de modifications non appropriées ou non

approuvées, y compris tout manquement à observer les directives d'utilisation du produit figurant dans le ou les guide(s) du

propriétaire fournis avec le produit.

*Outils pneumatiques : les joints toriques et pales d'entraînement sont considérés comme des pièces d'usure normale ; par

conséquent, ils ne sont garantis que pour une période de 45 jours de la date d'achat.

o

Un compresseur d'air pompant durant plus de 50% d'une heure sera considéré comme ayant subi un usage abusif puisque

sa capacité est inférieure à la demande exigée. La durée maximale de pompage ne doit pas excéder 30 minutes dans une

heure.

o

Marchandise vendue par DeVilbiss Air Power Manufacturing mais fabriquée par et identifiée sous le nom d'une autre

compagnie. Dans ce cas, la garantie du fabricant du produit s'applique.

o

Frais de réparation et de transport de marchandise non reconnue comme étant défectueuse.

o

Coûts associés à l'assemblage, l'ajout nécessaire d'huile, les réglages ou autres frais d'installation et de mise en marche.

o

Toute perte, tout dommage direct ou indirect ou tout frais pouvant résulter d'un défaut quelconque, d'une défaillance ou d'un

mauvais fonctionnement du produit. Certaines provinces et certains états ne permettent pas l'exclusion ni la limitation des

dommages directs ou indirects. Par conséquent, il se peut que les exclusions ou limitations mentionnées ci-dessus ne

s'appliquent pas dans votre cas.

o

Toutes garanties implicites, y compris celles portant sur la valeur marchande et l'application du produit pour une utilisation

particulière, sont limitées à un an à compter de la date d'achat d'origine. Certaines provinces et certains états ne permettent

pas la limitation de la période d'une garantie implicite. Par conséquent, il se peut que les limitations mentionnées ci-dessus

ne s'appliquent pas dans votre cas.

213 Industrial Drive • Jackson, TN 38301-9615

Téléphone : 1-800-888-2468, poste 2

Télécopieur : 1-800-888-9036

Loading...

Loading...