Excelitas Technologies X-Cite 120LEDBoost, X-Cite mini+ XTMS, X-Cite mini+ Series, X-Cite mini+ XTML, X-Cite mini+ XT120Lm User Manual

X-Cite® 120LEDBoost User Guide

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

Made in Canada

Excelitas Canada Inc. 2016

All rights reserved

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system or

translated into any language in any form by any means without the prior written consent of Excelitas

Canada Inc. Every effort has been made to ensure information in this manual is accurate; however,

information in this manual is subject to change without notice and does not represent a commitment on

the part of the authors.

Excelitas Canada Inc.

2260 Argentia Road

Mississauga ON L5N 6H7 CANADA

Trademarks

X-Cite® is a registered trademark of Excelitas Canada Inc. All rights reserved.

All other product names are trademarks of their respective owners.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

2

Table of Contents

1 Introduction ...............................................................................................................................5

2 Safety .........................................................................................................................................6

2.1 Glossary of Symbols ...................................................................................................................... 6

2.2 Safety Precautions ........................................................................................................................ 6

3 Getting Started ...........................................................................................................................8

3.1 System Components ..................................................................................................................... 8

3.2 Installation/Set-up ........................................................................................................................ 9

4 Operation – Manual Control ..................................................................................................... 12

4.1 The Basics .................................................................................................................................... 12

4.2 SpeedDIAL Home Screen............................................................................................................. 13

4.3 SpeedDIAL Menu and Settings .................................................................................................... 13

4.3.1 SpeedDIAL Menu Structure ................................................................................................. 14

4.3.2 LCD – Display Screen Brightness and Color Settings ........................................................... 14

4.3.3 Favo – Favorite Intensity Setting......................................................................................... 15

4.3.4 TTL –TTL Mode Control ....................................................................................................... 15

4.3.5 Hand – Display Screen Orientation ..................................................................................... 16

4.3.6 Srvc – Service Data .............................................................................................................. 16

5 Operation - External Control ..................................................................................................... 17

5.1 USB/RS-232 ................................................................................................................................. 17

5.1.1 Driver Installation (via internet) .......................................................................................... 17

5.1.2 Driver Installation (via ZIP file) ............................................................................................ 17

5.1.3 Verify Installation & Get COM Port Number....................................................................... 18

5.1.4 X-Cite® Control Panel / GUI installation .............................................................................. 18

5.1.5 X-Cite® Control Panel – Tips for Use ................................................................................... 19

5.1.6 Commercial Software Support ............................................................................................ 20

5.1.7 Software Developer’s Kit (SDK) ........................................................................................... 20

5.2 TTL ............................................................................................................................................... 20

5.2.1 TTL Mode ............................................................................................................................ 20

5.2.2 TTL Mode Timeout .............................................................................................................. 21

5.2.3 TTL Timing Diagram ............................................................................................................. 22

5.2.4 TTL Signal and LED Status .................................................................................................... 22

5.2.5 TTL Input Specifications ...................................................................................................... 22

5.3 Foot Pedal Control (Optional) ..................................................................................................... 22

6 Troubleshooting ....................................................................................................................... 23

6.1 Error Messages............................................................................................................................ 23

6.2 Failure to Power Up .................................................................................................................... 23

6.3 Low Illumination Intensity .......................................................................................................... 24

6.4 Other Potential Symptoms & Questions ..................................................................................... 25

7 Routine Care and Maintenance ................................................................................................. 25

7.1 General ........................................................................................................................................ 25

7.2 Cleaning - Exterior Surfaces ........................................................................................................ 26

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

3

7.3 Cleaning - Optical Surfaces ......................................................................................................... 26

7.4 Thermal Management System .................................................................................................... 27

8 Technical Specifications ............................................................................................................ 27

8.1 General ........................................................................................................................................ 27

8.2 Electrical ...................................................................................................................................... 27

8.3 Environmental – Operating Conditions ...................................................................................... 28

8.4 Environmental – Transport and Storage Conditions ................................................................... 28

8.5 Input/Output (I/O) Connections ................................................................................................. 28

8.6 Output Stability ........................................................................................................................... 28

9 Regulatory ................................................................................................................................ 29

9.1 Product Safety and Electromagnetic Compatibility .................................................................... 29

9.2 CE Marking .................................................................................................................................. 29

9.3 FCC .............................................................................................................................................. 29

9.4 WEEE Directive ............................................................................................................................ 29

9.5 China RoHS .................................................................................................................................. 30

10 Warranty & Repairs .............................................................................................................. 31

10.1 Warranty Terms .......................................................................................................................... 31

10.2 Returning equipment to Excelitas Technologies......................................................................... 31

11 Contact Information .............................................................................................................. 32

11.1 General ........................................................................................................................................ 32

11.2 Accessories and Replacement Parts ........................................................................................... 32

Table of Figures

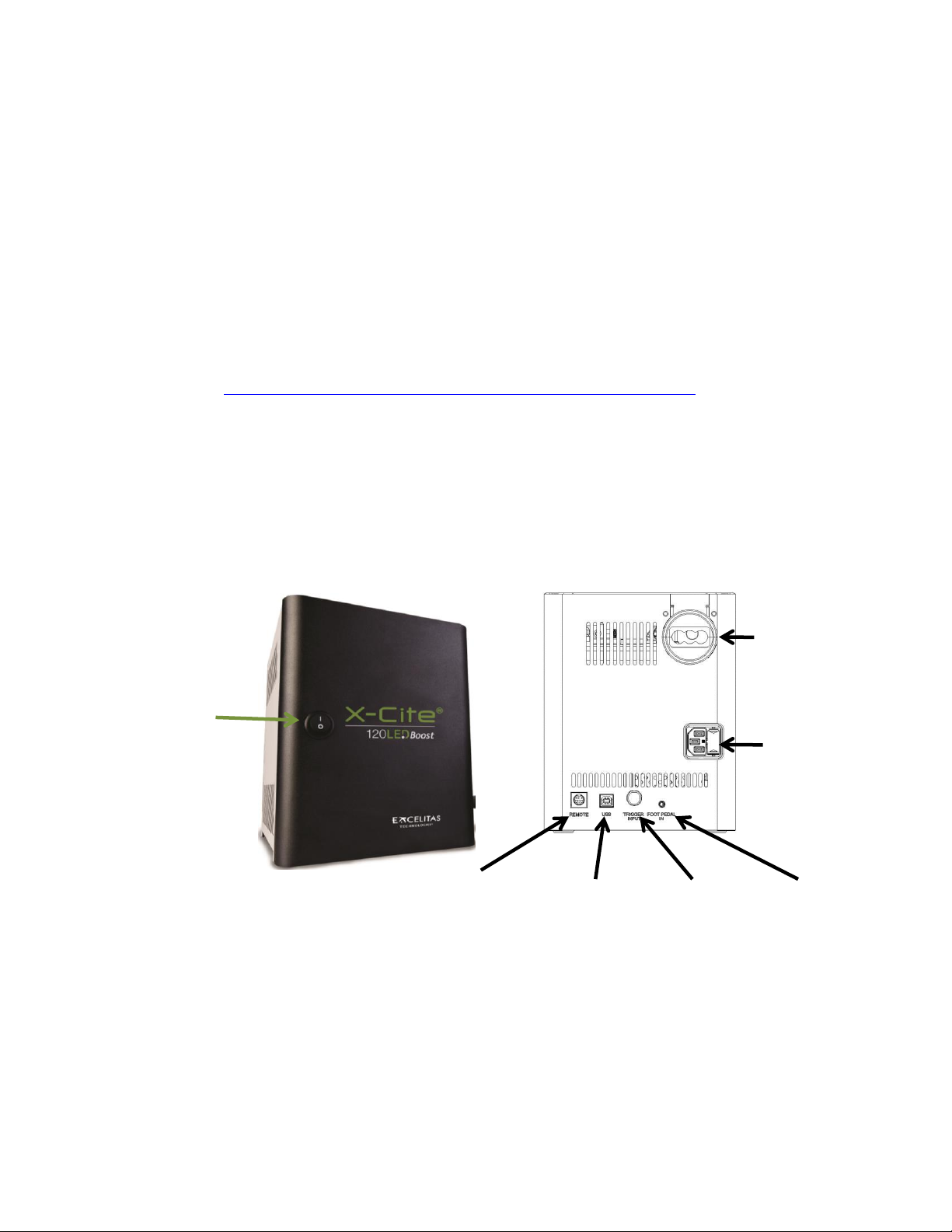

Figure 1 PowerCUBE Front and Rear Panels .............................................................................................. 8

Figure 2 LED Head ...................................................................................................................................... 9

Figure 3 SpeedDIAL .................................................................................................................................... 9

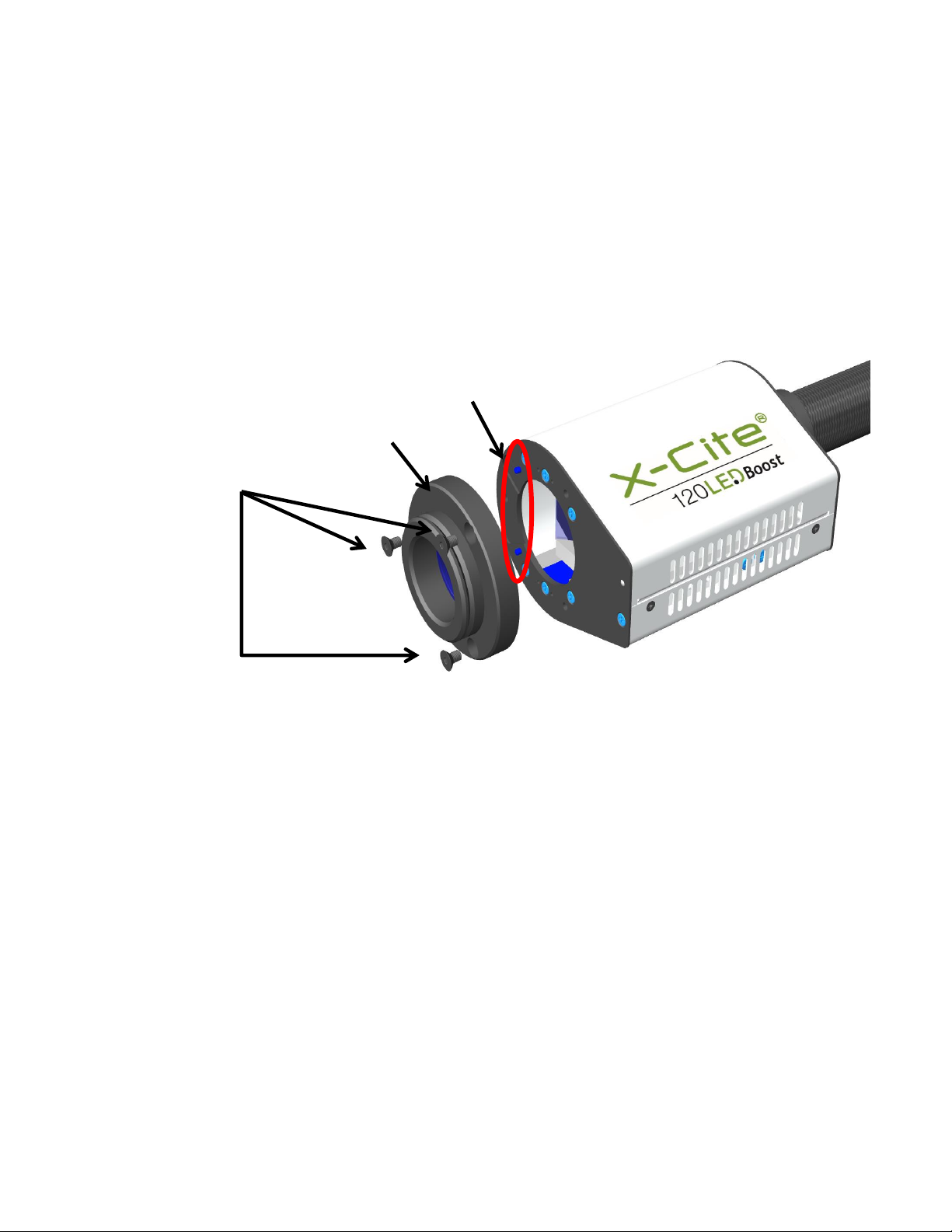

Figure 4 Installing Microscope Flange on LED Head ................................................................................ 10

Figure 5 LED Head and Arrow in Correct Position .................................................................................... 11

Figure 6 SpeedDIAL Home Screen Icons................................................................................................... 13

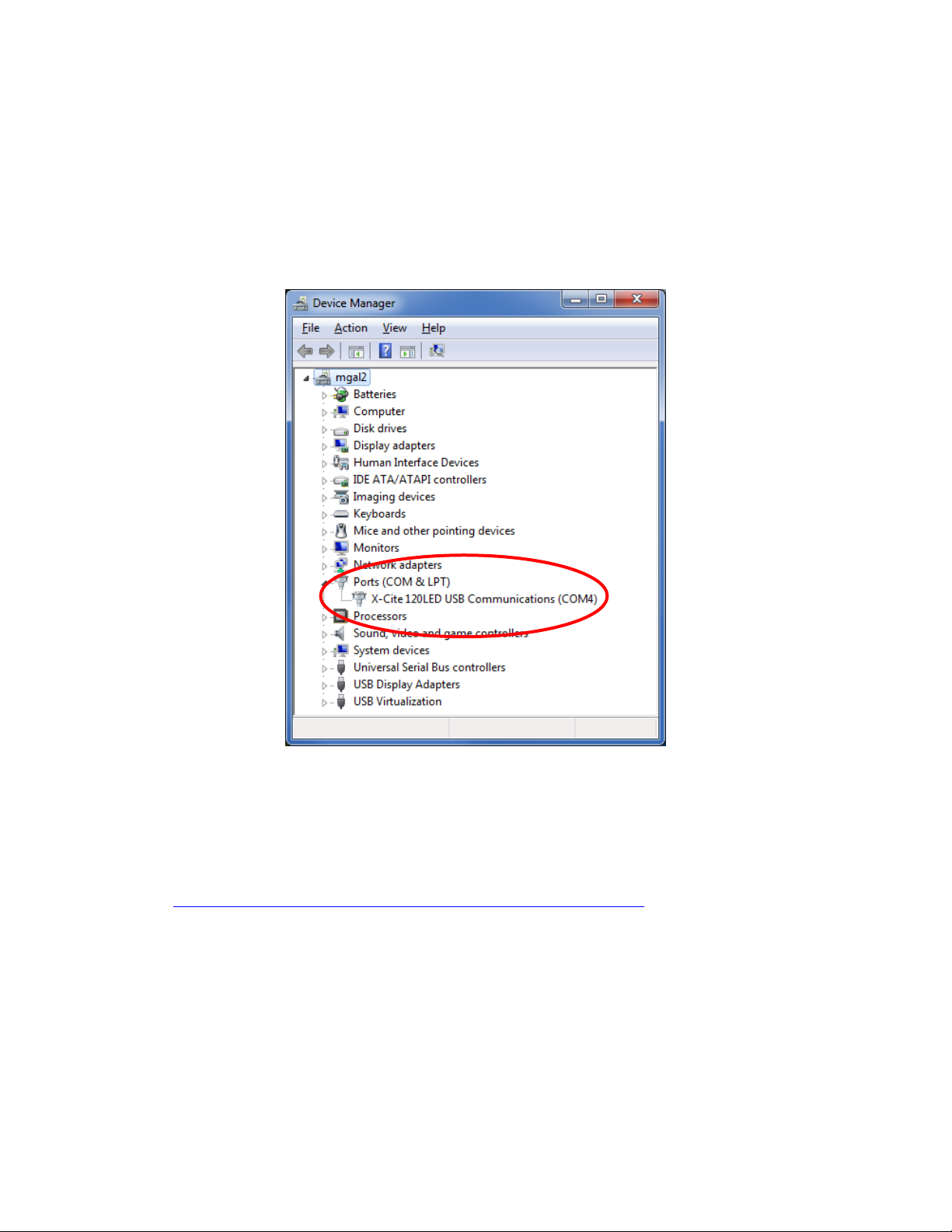

Figure 7 Device Manager, COM Port Listing ............................................................................................ 18

Figure 8 X-Cite® Control Panel ................................................................................................................. 19

Figure 9 Sequence of Events for TTL Mode Timeout (set to 4 hours) ...................................................... 21

Figure 10 Location and Removal of Fuse Tray in AC Receptacle ............................................................... 24

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

4

1 Introduction

Note: The information in this user guide applies to X-Cite 120LED and X-Cite 120LEDBoost

models. For X-Cite 120LEDmini information, refer to user guide #035-00587R.

The new X-Cite® 120LEDBoost is LED illumination, with no compromise required. X-Cite® 120LEDBoost

provides superior optical power and exceptional field uniformity at the specimen level with the broadest

spectrum of fluorescence excitation through manual, PC and TTL control. With LEDs rated to 25,000

hours and no lamps or modules to replace, X-Cite® 120LEDBoost offers sheer simplicity and convenience

to researchers allowing them to focus on their experiments instead of equipment maintenance.

This product is intended for use in fluorescence microscopy illumination. It allows researchers the ability

to excite fluorescence in samples being studied and characterize their location or behavior.

Excelitas Technologies Corp. is a global technology leader focused on delivering innovative, customized

solutions to meet the lighting, detection and other high-performance technology needs of customers.

X-Cite®, formerly of Lumen Dynamics (which was acquired by Excelitas Technologies Corp. in November

2013) offers the Life Science and Analytical Instrumentation market a broad range of innovative lamp

and LED fluorescence illumination and measurement solutions.

Excelitas Technologies recommends reading this manual to discover all the features available in X-Cite®

120LEDBoost.

Thank you for choosing X-Cite®!

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

5

2 Safety

Symbol

Meaning

CAUTION - Risk of danger: consult accompanying documents

WARNING – Eye damage may result from directly viewing ultraviolet light. Protective eye

shielding and clothing must be used at all times.

Input/Output Signals

Input Signal

CAUTION – Hot surface

2.1 Glossary of Symbols

2.2 Safety Precautions

Please observe the following safety precautions at all times during operation and maintenance of this

product. Failure to do so may result in personal injury or property damage.

1. UV emitted from this product. Avoid eye and skin exposure to unshielded product. Do not look

at operating lamp/LED. Eye injury may result.

2. Never look into the light emitting end of the LED head. The light could severely damage the

cornea and retina of the eye if the light is observed directly. Eye shielding must be used at all

times as well as clothing to protect exposed skin.

3. Always make sure the LED head is securely attached to the microscope prior to turning on

power to the unit. This will minimize the risk of exposure to the UV light.

4. To reduce the risk of fire or shock, always replace the fuses with the same type and rating.

5. Disconnecting of main supply source is done by putting the on/off button in the off “O” position

and unplugging the power cord.

6. It is recommended that ONLY QUALIFIED TECHNICAL PERSONNEL perform any testing or repairs

described in this manual. Disconnect the AC power cord from the unit before opening the cover

of this unit. All cover screws must be replaced prior to applying power to the unit, or safety of

the unit will be impaired.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

6

7. Monitoring the unit during manual operation

The level of UV and visible energy supplied by this product is sufficient to ignite flammable

substances. During manual operation, the unit must be attended at all times by a qualified

operator. The unit must not be left unattended while turned on. If an operator leaves the work

area of the unit, the power switch must be turned off.

8. Monitoring the unit during automated operation

The level of UV and visible energy supplied by this product is sufficient to ignite flammable

substances. Therefore, when the unit is operated unattended in an automated environment, an

alarm function must be provided by the user to indicate a malfunction in the associated

equipment used.

9. Should this X-Cite® unit be used in a manner not specified by Excelitas Technologies, the

protection provided by the equipment may be impaired.

10. This unit is designed for bench top use only! Always ensure that the unit is placed on a hard,

stable surface, ensuring that ventilation openings are not obstructed. Any obstruction of these

openings could result in a possible over-heating condition.

11. Any electronic equipment connected to this product must comply with the requirements of

EN/IEC 60950.

12. To clean the exterior of the unit, use a slightly dampened cloth and a simple water/ detergent

solution only. Avoid the optical surfaces and lenses. Cleaning of optics should only be attempted

by qualified personnel using appropriate fluids and lens paper.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

7

3 Getting Started

Main Power

ON/OFF

Connection to

LED Head

TTL IN

speedDIAL

IN/OUT

AC in /

Fuse Tray

USB IN/OUT

Foot Pedal IN

3.1 System Components

The X-Cite® 120LEDBoost system contains the following components:

1. LED Head and powerCUBE (connected via 1.5m cable)

2. SpeedDIAL Manual Controller

3. Microscope Flange

4. Accessories Box, containing:

a. Quick Start Instruction Sheet (User Guide, Software and Driver downloads:

http://www.excelitas.com/Pages/Product/X-Cite-120LEDBoost.aspx)

b. Hex Tool, 3mm

c. USB Cable

d. Power Cord

e. Safety Precautions Booklet

If any components are missing or appear damaged, please contact Excelitas Technologies immediately.

Figure 1 PowerCUBE Front and Rear Panels

8

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

Protective Cover

Vents on Bottom

Rotating Dial

Display Screen (LCD)

Figure 2 LED Head

Figure 3 SpeedDIAL

3.2 Installation/Set-up

1. Unpack

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

a. Carefully unpack the unit and accessories from the shipping carton.

b. When removing the LED Head and powerCUBE from the carton, ensure that both

components are supported and there is always some slack in the cable. Excessive strain

on the cable may damage or weaken the connection.

c. Do not use the cable as a “handle”. PowerCUBE is packed with a cardboard insert with

handles to assist in removing it from the protective foam. Set aside the insert and

support powerCUBE from the bottom as soon as it is possible to do so. The insert will

not support the full weight of the unit for an extended period of time, and the handles

may tear.

9

2. Install the Microscope Flange

Dowel Pins

Microscope Flange

Hex Fasteners (3)

a. Remove protective wrap from the Microscope Flange, being careful not to touch the

lens surfaces.

b. Remove protective cap from LED Head. Never power up the unit with this cap installed

– it can melt very quickly at high power settings and damage the unit.

c. Align the mounting holes on the Microscope Flange and the LED Head. Attach the

Microscope Flange using the Hex Tool and three (3) fasteners provided. The two (2)

dowel pins on the LED Head will allow you to install the Flange quickly and in the proper

position as required by your microscope.

Figure 4 Installing Microscope Flange on LED Head

3. Position the equipment

a. TIP: The cable connecting the LED Head and powerCUBE has limited flexibility, so take a

moment to position the equipment before connecting it.

b. PowerCUBE should be positioned to avoid sharp bends and strain on the cable,

preferably on the same level as the microscope or slightly above it on a low shelf.

c. The front panel of powerCUBE should be within reach to access the main power switch.

(During operation, all other functions are controlled via speedDIAL or USB interface.)

d. Air vents on both sides of powerCUBE should be clear of obstruction. Recommended

clearance is 20cm (8 inches) on all sides.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

10

4. Connect LED Head to Microscope

Orientation Arrow

(“This Way Up”)

a. Insert Microscope Flange portion of the LED Head into the light port on the microscope,

and secure it using the hardware provided on the microscope. (Refer to relevant

microscope user manual for complete instructions on mounting a standard epifluorescence lamphouse.) General guidelines:

i. Carl Zeiss – Tighten the hex fastener on the side of the light port with the 3mm

Hex Tool.

ii. Leica - Tighten the hex fastener on the side of the light port with the 3mm Hex

Tool.

iii. Nikon – Line up the Microscope Flange “notch” with the pin on the microscope

fitting, hold the LED head firmly against the light port, and twist the collar to

lock the components together.

iv. Olympus - Tighten the hex fastener(s) with the 3mm Hex Tool. Depending on

the model, there may be one (1) fastener on the side, or two (2) fasteners

located at the 10:00 and 2:00 positions. Note for IX3-RFAL use: the epi-light

train aperture MUST be properly aligned before turning on X-Cite®

120LEDBoost, or heat damage may result - see procedure in Olympus manual

for assistance.

b. Verify that LED Head is oriented with air vents facing downwards and the arrow label is

pointing up (see Figure 5). Adjust position if necessary – operating X-Cite® 120LEDBoost

with the LED Head at an angle will affect performance and may cause damage long

term.

c. Verify that the LED Head is securely fastened by attempting to gently rock it from side to

side.

5. Connect speedDIAL to powerCUBE

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

Figure 5 LED Head and Arrow in Correct Position

a. Insert the mini DIN plug into the “Remote” port on the rear of the powerCUBE. Ensure

the arrow mark on the connector is on top and centered. Note: Never force the

11

connector – this can damage the pins. If connector does not insert smoothly, stop and

check for bent pins.

b. Place speedDIAL next to the microscope, or another easily accessible location.

6. Connect USB (if using)

a. Insert “B” (square) end into the “USB” port on rear of the powerCUBE.

b. Insert “A” (flat) end into an available port on the computer.

c. Note: For best performance, use the supplied USB cable or one of equivalent quality

and length. Using a longer USB cable than the one supplied may result in intermittent

communication errors.

7. Connect AC Power

a. Connect female end to AC port on rear of the powerCUBE.

b. Connect male end to a properly grounded electrical outlet.

c. For safe operation, use only the power cord supplied or one with an equivalent rating.

4 Operation – Manual Control

4.1 The Basics

1. Start the unit

a. Flip the rocker switch on the front of powerCUBE to turn X-Cite® 120LEDBoost on.

b. The system will have a brief initialization period (approximately 10 seconds). The

speedDIAL display will show “X-Cite” during this time.

c. When the display shows “x%”, it is ready to use.

d. Note: If speedDIAL will be used for manual control, it must be connected before turning

system on. SpeedDIAL can be damaged if it is plugged into, or unplugged from, the

system while it is powered on.

2. Illuminate a specimen

a. Click the dial (shutter button) on speedDIAL to turn on/off the excitation light.

3. Adjust intensity

a. Turn the dial to adjust intensity - clockwise to increase, counter-clockwise to decrease.

b. The dial is speed sensitive – turning slowly will allow adjustments in smaller increments,

turning quickly will increase the step sizes.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

12

4.2 SpeedDIAL Home Screen

LED ON

TTL Mode

Enabled

speedDIAL Locked

(via Computer)

LED Power Level

Figure 6 SpeedDIAL Home Screen Icons

4.3 SpeedDIAL Menu and Settings

In addition to the intuitive intensity adjustment and illumination ON/OFF control, speedDIAL has several

advanced settings and control options.

To access the main menu, press and hold the dial for one (1) second.

To navigate the menus, turn the dial to scroll through the options. An arrowhead will indicate

the currently selected menu option; click the dial to make a selection.

To adjust settings, turn the dial. To exit the setting adjustment, click the dial.

To exit menu system at any time, press and hold the dial for one (1) second.

Note: Setting changes will take effect immediately after selection. However, for the first five (5)

minutes, the new settings are stored in a temporary memory location. If X-Cite® 120LEDBoost is

powered down during this time, settings will revert back to their previous values. To ensure that new

settings will be remembered, wait at least five (5) minutes before powering down the unit.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

13

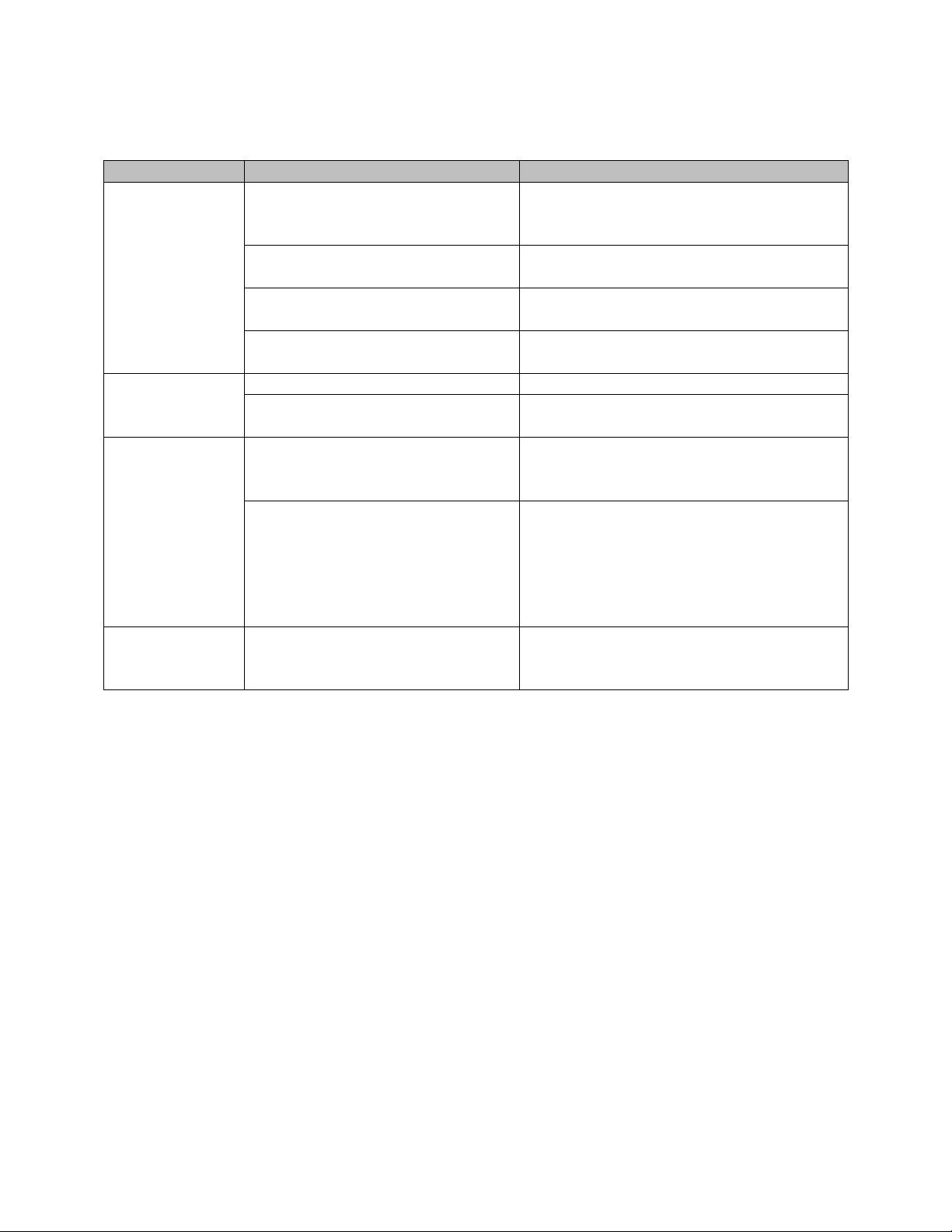

4.3.1 SpeedDIAL Menu Structure

LCD

Dim

Brig

Color

Exit

Favo

Int

Enbl

Spd

Exit

TTL

Enbl

Time

Exit

Hand

Srvc

Hour

SN

Tmp1

Tmp2

S/W1

S/W2

Exit

Exit

4.3.2 LCD – Display Screen Brightness and Color Settings

In the LCD sub menu, the backlight on the display screen can be turned on/off, set to a different

brightness level, or set to a different color.

a. Select the “LCD” option from main menu.

b. To adjust LCD display backlight time out:

i. Select “Dim” and scroll through the time out options, which are: Off and 1 thru

999 seconds in 1 second increments. “Off” will turn off the backlight timer (i.e.

backlight will always be on).

ii. Click dial to save selection and return to “LCD” menu.

c. To adjust LCD brightness:

i. Select “Brig” and scroll through % brightness settings until the desired level is

reached. To turn backlight off, set level to 0%.

ii. Click dial to save selection and return to “LCD” menu.

d. To change LCD color:

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

14

i. Select “Color” and scroll up /down through the options until desired color is on

LCD.

ii. Click dial to save selection and return to “LCD” menu.

e. Select “Exit” to go back to the main menu, or press and hold dial to return to the home

screen.

4.3.3 Favo – Favorite Intensity Setting

In the FAVO sub menu, a favorite, commonly used intensity setting can be saved. When this

mode is enabled, the intensity level will instantly jump to this setting with a double-click of the

dial. A second double-click will toggle back to the previous intensity level.

a. Select “Favo” option from main menu.

b. To set/change the favorite intensity:

i. Select “Int” and scroll through % intensity settings until the desired level is

reached.

ii. Click dial to save selection and return to “Favo” menu.

iii. TIP: Scrolling through % settings in this menu will not actually change the output

in real time, even if LED is on. The favorite intensity should be determined

before entering this menu.

c. To enable/disable favorite intensity mode:

i. Select “Enbl” and scroll up/down to the desired setting.

“On” will enable (i.e. double-click speedDIAL = Favorite setting)

“Off” will disable (i.e. double-click speedDIAL = do nothing)

ii. Click dial to save selection and return to “Favo” menu.

d. To adjust the delay between clicks in the “double-click”:

i. Select “Spd” and scroll up/down to the desired delay setting. “1” will provide

the shortest delay, “10” will be the longest.

ii. Click dial to save selection and return to “Favo” menu.

iii. TIP: If double-clicking results in the light being turned OFF instead of going to

favorite intensity, increase the delay setting.

iv. Note: Setting long delay times will result in a longer response time for regular

ON/OFF control with speedDIAL (the system must wait to see if the single-click

turns into a double-click). Response times for TTL, USB or foot pedal on/off

control will not be affected.

4.3.4 TTL –TTL Mode Control

In the TTL menu, TTL mode can be enabled for experiments that require rapid LED ON/OFF

control. For further information on TTL mode, refer to the External Control, TTL section 5.2.

NOTE: TTL mode MUST be enabled for the system to respond to a TTL signal.

a. Select “TTL” option from main menu.

b. To enable/disable TTL mode:

i. Select the “Enbl” menu item.

ii. Scroll to the desired setting, “On” to enable TTL or “Off” to disable TTL.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

15

iii. Click dial to save selection and return to “TTL” menu.

c. To define the TTL timeout setting:

i. Select the “Time” menu item.

ii. Scroll through the time out options, which are: Never and 4 to 24 hours in half

hour increments. “Never” will turn off the timeout feature (i.e. the cooling

system and driver will always be active when TTL mode is enabled).

iii. Click dial to save selection and return to “TTL” menu.

4.3.5 Hand – Display Screen Orientation

In this menu, the LCD orientation can be rotated 180°. This allows operators to use speedDIAL

on the left or right side of the microscope without blocking the view of the display with their

hand.

a. Select “Hand” option from main menu.

b. Turn dial to toggle between “Right Hand” and “Left Hand” operation. Note that the

screen will flip while adjusting this setting.

c. Click dial to save selection and return to the main menu.

4.3.6 Srvc – Service Data

In the Service menu, information specific to each X-Cite® 120LEDBoost unit can be found. This

includes total hours accumulated on the LED, unit serial number, temperatures measured at

specific locations in the unit, and embedded software versions for powerCUBE and speedDIAL.

Excelitas Tech Support personnel may request some or all of this information during a support

call.

a. Select “Srvc” option from main menu.

b. To obtain the LED “in use” hours:

i. Select the “Hour” menu option.

ii. LED “hours of use” will be shown in one (1) hour increments from 0 to 999

hours. Due to space limitations on the LCD, when 1000 hours are logged, the

format will change to “1.0k hours”, and increments will increase to 100 hours

(e.g. 1142 hours will display as “1.1k hours”). The precise hour-by-hour data will

continue to be available via USB communication.

iii. Click dial to return to “Srvc” menu.

c. To obtain the unit serial number:

i. Select the “SN” menu option.

ii. Serial number of the unit will be shown.

iii. Click dial to return to “Srvc” menu.

d. To obtain current system temperatures:

i. Select “Tmp1” or “Tmp2” as required.

ii. Temperature will be shown in degrees Celsius.

iii. Click dial to return to “Srvc” menu.

e. To obtain the embedded software version numbers:

i. Select the “S/W1” or “S/W2” menu items.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

16

ii. The software version numbers will be shown in the format X.X.X.

iii. Click dial to return to “Srvc” menu.

5 Operation - External Control

5.1 USB/RS-232

A virtual COM port driver must be installed to enable Windows communication via the USB port. For

computers running Windows which are connected to the internet, the driver will install automatically.

For manual installation, the driver is available as a software download from the Excelitas website. Note

that administrator privileges may be required to install drivers on your computer, in which case you may

need to contact your IT department for assistance.

5.1.1 Driver Installation (via internet)

For these instructions: internet is required, Windows 7 prompts are listed

a. Ensure X-Cite® 120LEDBoost is powered off.

b. Ensure X-Cite® 120LEDBoost is connected to the computer with the USB cable.

c. Ensure computer is connected to internet.

d. Power on X-Cite® 120LEDBoost.

e. Driver installation will begin automatically. A dialogue box will confirm installation has

started.

i. If the dialogue box reports that Driver installation was not successful, click on

Get Details.

ii. Click on option to Change Settings to Automatically search Windows for

drivers. Confirm Yes, do this automatically, and save changes.

f. A second dialogue box will confirm successful installation and provide a COM port

number. Note the COM port number for use in other software applications.

5.1.2 Driver Installation (via ZIP file)

For these instructions, download the driver ZIP file from the Excelitas website

(http://www.excelitas.com/Pages/Product/X-Cite-120LEDBoost.aspx).

a. Ensure X-Cite® 120LEDBoost is powered off.

b. Ensure X-Cite® 120LEDBoost is connected to the computer with the USB cable.

c. Prepare the driver files by extracting and saving the files into a folder on the desktop (or

another easily accessible location).

d. Power on X-Cite® 120LEDBoost.

e. The “new hardware found” wizard will appear. Select No to search Windows update for

the software. Click Next to continue.

f. Select Install from a list or specific location (Advanced) to locate the driver and click

Next. Select Include this location in the search: and browse to the location on your

hard drive where unzipped files were saved in step c. Click Next.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

17

g. Wait for installation to complete. Click Finish.

5.1.3 Verify Installation & Get COM Port Number

a. Open the “Device Manager” utility on the computer.

b. “X-Cite 120LED USB Communications” will be listed under “Ports (COM & LPT)”.

c. Note the COM port number for use in other software applications.

Figure 7 Device Manager, COM Port Listing

5.1.4 X-Cite® Control Panel / GUI installation

For these instructions, download the driver ZIP file from the Excelitas website

(http://www.excelitas.com/Pages/Product/X-Cite-120LEDBoost.aspx).

a. Uninstall any previous versions of X-Cite® Control Panel/GUI. (Previous versions

released under the EXFO name will not be automatically replaced by versions 1.1.0 or

later, and may cause confusion.)

b. Prepare the driver files (if not already done in previous section) by extracting and saving

the files into a folder on desktop (or another easily accessible location).

c. To begin installation, go to unzipped files from step b, double-click on setup.exe or

setup

d. Setup Wizard will open. Follow prompts and click Close when Wizard is finished.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

18

e. To find GUI, go to: Start, All Programs, Lumen Dynamics, X-Cite Control Panel. Click to

ICON

NAME

DESCRIPTION

Alarm

Green = All OK

Red = Alarm on

Click will clear alarm, unless unsafe to ignore

Temperature

Indicates system temperature status

Yellow = warning, LED temp above normal

Red = LED off, temp is too high

Calibration

Not applicable for X-Cite® 120LEDBoost

LED Hours of Use

Power Level

Hide/Unhide Controls

Control Icons

start/open GUI, or click-and-drag to copy a shortcut to desktop or Quick Launch toolbar.

5.1.5 X-Cite® Control Panel – Tips for Use

a. X-Cite® Control Panel is available as a download from the Excelitas website. This tool

provides an interface for controlling the X-Cite® 120LEDBoost via PC and general testing

of the communication port.

b. Note that X-Cite® Control Panel is designed to function with multiple X-Cite® devices,

and not all icons and features can be used with all devices. See the icon table below to

determine which icons are relevant to control of X-Cite® 120LEDBoost.

c. Icon color code:

i. Green icons mean status is OK and/or the function is engaged

ii. Yellow icons mean a warning or “getting ready”

iii. Red icons mean there is an alarm condition

iv. Grey icons mean a feature is not engaged, and/or not available

v. If icons are ALL grey, X-Cite® 120LEDBoost is not connected and/or turned off

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

Figure 8 X-Cite® Control Panel

19

LED Hours

Indicates hours logged on LED

Green = <20K hours, yellow = >20K hours, red = >40K hours

Light Guide

Not applicable for X-Cite® 120LEDBoost

Shutter

Click to turn LED on/off

Intensity

Left mouse click = increase by 1% increment.

Right mouse click = decrease by 1% increment.

Left double click = opens dialog box type in value

Closed-Loop

Feedback

Not applicable for X-Cite® 120LEDBoost

Lock/unlock

Lock/unlock speedDIAL control

Green = speedDIAL is locked

Grey = speedDIAL is unlocked

Lamp

Not applicable for X-Cite® 120LEDBoost

5.1.6 Commercial Software Support

a. X-Cite® 120LEDBoost can be controlled through many commercially available packages.

Where X-Cite® 120LEDBoost specific control may not be available, basic functionality

can be achieved using X-Cite® 120PC or X-Cite® exacte hardware drivers. For an

updated list of software packages that support X-Cite® products, see

http://www.excelitas.com/Downloads/XCite-softwareSupport.pdf

b. For commercial software packages, if requested specify the serial port parameters as:

19,200 baud, no parity, 8 data bits and 1 stop bit.

c. When controlling X-Cite® 120LEDBoost, some commercial software packages may block

manual input from speedDIAL. The lock icon will appear on the speedDIAL display in

these cases.

5.1.7 Software Developer’s Kit (SDK)

The command list for X-Cite® 120LEDBoost is available by request. To obtain the latest update,

please contact Excelitas Technologies.

5.2 TTL

For high speed LED on/off control, TTL triggering can be used. The key thing to note about TTL control in

the X-Cite® 120LEDBoost is: TTL mode MUST be enabled for the system to respond to a TTL signal.

5.2.1 TTL Mode

TTL mode ensures that X-Cite® 120LEDBoost’s cooling system and LED driver are active between

exposures, ensuring the fastest possible response to a TTL signal.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

20

Enabling/disabling TTL mode can be accomplished manually via speedDIAL (refer to

LED off

Timeout clock

LED on

(response at maximum)

Time

elapses

LED on

wake up)

@ time <4h,

TTL = high

@ 4hrs

TTL = high

TTL = low

TTL = low

TTL mode times out

(drivers/cooling turn off,

TTL mode remains)

section 4.3.4) or via computer commands (refer to SDK).

ON/OFF status of the system will be updated on speedDIAL when it is controlled via TTL.

5.2.2 TTL Mode Timeout

There is a potential disadvantage of TTL mode - in this “always active” state, the system

continues to consume energy and mechanical components accumulate wear. To help minimize

unnecessary consumption at the end of an imaging session (or if equipment is accidentally left

on), X-Cite® 120LEDBoost is equipped with a TTL timeout setting. The factory default for the TTL

timeout setting is “Never”, but defining a timeout is recommended for any imaging session that

will end without an operator present to shut down equipment (e.g. middle of the night).

Figure 9 Sequence of Events for TTL Mode Timeout (set to 4 hours)

resets, begins

countdown

(unit stays active)

(after drivers and cooling

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

21

5.2.3 TTL Timing Diagram

Interval

Description

Time (µs)

T1

Delay time, TTL trigger on to LED on

100 @ 100% power

T2

Delay time, TTL trigger off to LED off

30

TTL

LED Status

High

ON

Low

OFF

This plot shows typical TTL timing values. These values should be used as a guide only. Actual

values will be dependent on the specific configuration/control hardware being used.

5.2.4 TTL Signal and LED Status

5.2.5 TTL Input Specifications

a. Connector type: BNC (female port)

b. Maximum low level : +0.8V

c. Minimum high level : +2.2V

d. Maximum high level: + 5.5V

e. Typical input current: 800µA

5.3 Foot Pedal Control (Optional)

For hands-free operation, a foot pedal can be used to manually turn the LED on and off. The foot pedal

is an optional accessory and can be purchased separately from Excelitas Technologies.

1. Installing the foot pedal

a. Locate the “FOOT PEDAL IN” / “FP IN” input port on the rear panel of X-Cite®

120LEDBoost.

b. Insert foot pedal plug.

c. Place foot pedal on floor.

2. Operating the foot pedal

a. Press and release pedal with your foot to toggle LED on and off.

b. On/off status of LED will be shown on speedDIAL display.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

22

c. If desired, the foot pedal can be used in combination with speedDIAL (e.g. turn on with

Error Code

Description

Action

1

LED has exceeded maximum

operating temperature

Turn off the system and wait for the LED to cool

down. Verify that the system has been installed with

adequate clearance for ventilation, especially around

vents on powerCUBE and LED Head. If fan is not

running or the problem persists contact technical

support for assistance.

3 or 5

Internal Error

Power cycle the X-Cite® 120LEDBoost unit. If the

error message reappears contact technical support

for assistance.

6

LED is below minimum

operating temperature

Ensure the room temperature is within the

recommended operating limits. If unit has been

stored / transported in a cold environment, allow it to

warm up to room temperature and restart. If the

problem persists contact technical support for

assistance.

speedDIAL, turn off with foot pedal.) The ON/OFF status of the system will be reflected

on speedDIAL’s home screen whether it is changed via the foot pedal or by any other

means.

6 Troubleshooting

Organized by symptom, this section provides basic troubleshooting information for installation and setup parameters. X-Cite® 120LEDBoost may be serviced by authorized technical personnel only.

6.1 Error Messages

If X-Cite® 120LEDBoost detects a problem, an error message with one of the following codes will appear

on the speedDIAL display.

6.2 Failure to Power Up

If X-Cite® 120LEDBoost fails to POWER up or function properly, use the following checklist to eliminate

the most common causes of problems. Check for the following:

1. Power Connection Check:

a. The power supply cord is securely connected to a grounded (earthed mains socket)

functional outlet.

b. The power supply cord is securely connected into the 3-pin outlet on the rear of the

controller unit.

c. The main AC power switch is in the ON position.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

23

2. Fuse Check:

A B C

a. Check both main power fuses. First disconnect the power cord, then carefully remove

the fuse tray assembly next to the AC receptacle on the rear of the unit. Note:

depending on the orientation of the AC receptacle, the fuse tray may be below or beside

it. The red arrow in figure 10 (A) shows where a flat screwdriver can be inserted to

gently lever out the fuse tray.

Figure 10 Location and Removal of Fuse Tray in AC Receptacle

b. If either or both of the fuses are open, replace with the same type (4A, 250V).

c. Note: To determine if a fuse is intact (i.e. OK) or open (i.e. blown), remove the fuse

from the tray and check with a multi-meter set to resistance (Ω). An intact fuse will read

“0Ω” (or another very low value), an open fuse will have an extremely high Ω reading.

d. Note: Fuses that chronically need replacing are usually a signal that something is wrong

and Technical Support should be contacted.

3. SpeedDIAL Check:

a. Verify that the pins on speedDIAL connector are straight.

b. Verify that speedDIAL is plugged securely into powerCUBE.

6.3 Low Illumination Intensity

1. SpeedDIAL Setting Check:

a. Verify that the LED intensity is set to a sufficient level.

b. Verify that the LED Head is turning on.

2. Microscope Check:

a. Verify that the Microscope Flange is appropriate for the microscope configuration.

Note: Some flanges have the same mechanical fitting but different optics.

b. Verify that everything in the microscope beam path is properly aligned and open, e.g.

shutters, apertures, diaphragms, filters, filter cubes, etc.

c. Verify that microscope filter sets are for the appropriate wavelengths.

d. Verify that air objectives are clean / immersion objectives have enough of the

appropriate fluid.

24

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

6.4 Other Potential Symptoms & Questions

Category

Symptom

Action

speedDIAL

Favorite intensity setting: doubleclick turns off LED instead of going to

the stored setting

Increase delay in the speed (Spd) setting.

New settings are forgotten when

unit is shut down and powered up

After changing settings, wait at least five (5)

minutes before shutting unit down.

Turning dial does not scroll through

the menu options

Turn dial in the opposite direction.

“Lock” icon is on display, speedDIAL

not responding to manual control

Send “unlock” command via computer OR

power down unit and restart.

TTL Triggering

TTL signal does not trigger unit

Enable TTL mode.

TTL response time is longer than

usual

Verify that timeout settings are

appropriately set.

Audible Noise

PowerCUBE fan never turns off, even

when LED is not on

Fan continues to run for five (5) minutes

after LED is turned off. If it runs longer,

disable TTL mode (it is likely enabled).

Bubbling noise is coming from LED

Head.

Disconnect LED Head from microscope and

move to a position lower than powerCUBE.

Set LED to 1%, turn on, and run for several

minutes until noise stops. When

remounting LED Head to microscope, ensure

arrow label is pointing straight up.

Output Linearity

Plotting output power vs. intensity

setting is not a straight line

No action. “x%” shown on speedDIAL refers

to LED input current, which is not

necessarily linear with optical output.

7 Routine Care and Maintenance

7.1 General

X-Cite® 120LEDBoost is a very low maintenance system with no consumable components. By

maintaining the following conditions, performance will be maximized and risk of future problems will be

reduced.

1. Maintain a clean work area, keeping the X-Cite® 120LEDBoost air vents unobstructed.

2. Ensure that the cable connecting the powerCUBE and LED Head has some slack in it and is never

cut, stretched, kinked, or forced into a sharp bend.

3. If X-Cite® 120LEDBoost must be moved, ensure that both the powerCUBE and the LED Head are

supported. Never use the cable as a handle.

4. Never leave the internal optics of the LED Head exposed. When not connected to a microscope,

ensure the output port is always covered by a Microscope Flange or the supplied protective

plastic cover.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

25

5. Never touch optical surfaces with fingers, tools or any other abrasive/sticky/sharp materials or

fluids.

6. If cleaning is required, follow the directions in the next section.

7.2 Cleaning - Exterior Surfaces

If necessary, exterior surfaces of X-Cite® 120LEDBoost’s LED Head, powerCUBE and speedDIAL can be

cleaned with a mild soap and water solution and lint-free cloth.

1. Turn unit off and disconnect AC power prior to cleaning.

2. Use a damp cloth only - do not allow cleaning solution to get into I/O ports, air vents or seams.

3. Avoid optical surfaces.

4. Allow the unit to dry before turning it on.

7.3 Cleaning - Optical Surfaces

Cleaning of optical surfaces is not generally required. However, if any visible contamination or

fingerprints appear on the lens surface, cleaning may be necessary.

1. Recommended Cleaning Materials

a. Rubber bulb dust blower

b. Lint-free lens tissue, lint-free cotton swabs

c. Powder-free gloves or finger cots

d. Lens cleaning solution, reagent-grade isopropyl alcohol, or another appropriate solvent

2. Cleaning Procedure

a. Use rubber dust blower to blow off any loose lint, dust or other contaminant.

b. If the contaminant is a fluid (e.g. water, immersion oil), first use a dry lens tissue (or

cotton swab) to wick away as much as possible – do not wipe.

c. Saturate a corner of the lens tissue (or the cotton swab) with cleaning solvent, and

gently wipe the optical surface in one pass. Note: Take care not to “flood” the area

with solvent, particularly near unsealed joints (e.g. lens-retaining ring interface).

d. Repeat the previous step with a fresh portion of lens tissue (or new cotton swab) – this

will help avoid recontamination of the optical surface and minimize the amount of

cleaning required.

e. Let solvent evaporate and verify that the optical surface is clean. Repeat cleaning steps

as necessary.

f. Before reinstalling and/or using the optics, allow them to dry completely.

CAUTION: Before using any solvent, consult the manufacturer’s Material Safety Data Sheet (MSDS)

and your internal Health and Safety Advisor for proper handling, storage, and disposal instructions.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

26

7.4 Thermal Management System

powerCUBE

LED Head

speedDIAL

Height

213mm (8.4″)

116mm (4.6″)

59mm (2.3″)

Width

173mm (6.8″)

90mm (3.5″)

80mm (3.1″)

Depth

260mm (10.2″)a

166mm (6.5″)

a,b

112mm (4.4″)

Weight

3.9kg (8.6lbs)

0.9kg (2lbs)

0.3kg (0.7lbs)

Power Supply

Power Factor Corrected, Universal Input

Input Voltage

100-240VAC, 50/60Hz

Current

3.0A max /100V, 1.5A max/240V

Input Surge

With cold start 40A/115V, 80A/240V

Protection

Over load and over temperature

Fuse Rating

Dual fuse system: each fuse rated at F 4.0A 250V

5x20mm type located in AC receptacle

X-Cite® 120LEDBoost’s unique thermal management system incorporates both air and liquid cooling

technologies. If the general care and maintenance guidelines described above are followed, no further

maintenance is required to ensure continued superior performance.

This robust design is similar to those used in high-powered computers, and through normal use the

liquid will remain contained. If, through accident or negligence, the cable between powerCUBE and the

LED Head is punctured or otherwise damaged, some liquid may escape. Should this occur:

1. Don’t panic.

2. Power off and discontinue using the system.

3. Elevate the damaged portion of the cable.

4. Clean spill with absorbent material. The liquid is a non-toxic mix of propylene glycol and

distilled water. Refer to Material Safety Data Sheet (MSDS), located in the Appendix.

5. Contact Technical Support.

8 Technical Specifications

8.1 General

Notes:

a. Does not include clearance required for cable, minimum 200mm (8″).

b. Does not include microscope flange, varies by type, approximately 10-15mm (0.4-0.6″).

8.2 Electrical

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

27

8.3 Environmental – Operating Conditions

Ambient Temperature

10° to 35° C

Altitude

2000m max

Atmospheric Pressure

700 to 1060 hPa

Relative Humidity

15 to 90% RH (non-condensing)

Installation Category

II

Pollution Degree

2

Enclosure Rating

1

Temperature

-35° to 60° C

Relative Humidity

10 to 95% RH (non-condensing)

Atmospheric Pressure

500 to 1060 hPa

Connection

Connection Style

Purpose

speedDIAL - IN/OUT

Mini DIN plug, 9pos

Communication between speedDIAL and

powerCUBE to control LED and report

status (on/off, intensity adjustment,

system error, etc.)

USB - IN/OUT

B

Communication between computer and

powerCUBE to control LED and report

status.

TTL - IN

BNC

External trigger to turn LED on/off

Foot Pedal - IN

3mm stereo plug

External trigger to turn LED on/off

8.4 Environmental – Transport and Storage Conditions

8.5 Input/Output (I/O) Connections

8.6 Output Stability

For maximum output stability, X-Cite® 120LEDBoost should be set to a power level of 5% or greater. At

lower power levels (<3%), some intensity fluctuation may be observed.

If an application requires lower power levels, strategies to avoid fluctuations include:

Increase power level, and reduce exposure time to compensate for brighter signal.

Increase power level, and use a neutral density filter or iris in the microscope light train to

reduce intensity to an appropriate level for the specimen.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

28

9 Regulatory

Council Directive 2014/35/EU

Low Voltage Directive

Council Directive 2014/30/EU

EMC Directive

Council Directive 2012/19/EU

WEEE Directive

Council Directive 2011/65/EU

RoHS

9.1 Product Safety and Electromagnetic Compatibility

The X-Cite 120LEDBoost has been tested and found to comply with product safety and electromagnetic

compatibility requirements. For a complete list of tests and for certification details, please contact your

X-Cite representative or visit http://www.excelitas.com/Pages/Product/X-Cite-120LEDBoost.aspx.

9.2 CE Marking

9.3 FCC

FCC Class A Digital Device or Peripheral - Information to User

NOTE

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

WARNING

Changes or modifications not expressly approved by Excelitas Technologies could void the user’s

authority to operate the equipment.

9.4 WEEE Directive

The symbol above indicates that this product should not be disposed of along with municipal waste, that

the product should be collected separately, and that a separate collection system exists for all products

that contain this symbol within member states of the European Union.

The equipment that you bought has required the extraction and use of natural resources for its

production. It may contain hazardous substances that could impact health and the environment.

29

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

In order to avoid the dissemination of those substances in our environment and to diminish the

pressure on the natural resources, we encourage you to use the appropriate take-back systems.

Those systems will reuse or recycle most of the materials of your end life equipment in a sound

way.

The crossed-out wheeled bin symbol indicated above invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact

your local or regional waste administration.

9.5 China RoHS

The symbol above indicates that this product is in compliance with China RoHS requirements.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

30

10 Warranty & Repairs

SYSTEM COMPONENT

WARRANTY

WARRANTY VOID IF…

X-Cite® 120LEDBoost

powerCUBE

X-Cite® 120LEDBoost Head

1 year

• Unit has been subjected to misuse or

mishandling.

• Unit has been opened or tampered with.

X-Cite® 120LEDBoost

speedDIAL

1 year

• Unit or cabling has been subjected to misuse

or mishandling.

• Unit has been opened or tampered with.

• LCD display damage (physical).

LED assembly

(in X-Cite® 120LEDBoost

Head)

• 25,000 hrs

• 3 years

whichever

Comes first

• Cable damage due to misuse or mishandling.

• LED Head has been opened or tampered with.

• For all other LED Head components, 1 year

warranty applies.

10.1 Warranty Terms

Excelitas Technologies warrants the original purchaser for a period of one (1) full year, calculated from

the date of purchase, that the equipment sold is free from defects in material and workmanship. All

repairs are warranted for 90 days. The LED assembly within the LED Head has a warranty period of

25,000 hours of use or 3 years, whichever comes first.

In the event of a claim under this guarantee, the equipment is to be sent postage and carriage paid,

including a description of the fault, to the Excelitas Technologies Service Center. Returned equipment

will not be received without a Return Material Authorization (RMA) Number, issued by the appropriate

Service Center.

In the case of damage caused by wear and tear, careless handling, neglect, by the use of force or in the

case of interventions and repairs not carried out by an Excelitas Technologies Service Center, the

guarantee ceases to be valid. This guarantee may not form the basis for any claims for damages, in

particular not for compensation of consequential damages.

The warranty is not transferable. No warranty is extended to perishable items, such as fuses and air

filters.

Any claims for units received with defects in material or workmanship must be reported to an

authorized Excelitas Technologies Service Center within 30 days from the original date of receipt.

10.2 Returning equipment to Excelitas Technologies

1. Please make a note of the problem encountered, the steps followed to isolate the problem and

the result of any troubleshooting steps taken.

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

31

2. Contact the nearest Excelitas Technologies Service Center to obtain a Return Material

Authorization (RMA) number. For your convenience, RMA numbers can also be requested online at: http://www.excelitas.com/Pages/Support/Service-Request-Form.aspx

3. Follow shipping instructions provided by the service technician. The unit should be returned in

its original packaging if possible.

11 Contact Information

11.1 General

Excelitas Canada Inc.

Tel: (905) 821-2600 1-800-668-8752 (USA and Canada)

Fax: (905) 821-2055

1-800-668-8752 (USA and Canada)

x-cite@excelitas.com

http://www.excelitas.com/Pages/Product/X-Cite.aspx

For a list of Authorized Service Centers, visit:

http://www.excelitas.com/Pages/Support/Service-Centers.aspx

11.2 Accessories and Replacement Parts

Replacement parts and accessories can be purchased directly from Excelitas Technologies. For ordering

and pricing information contact the inside sales department at:

(905) 821-2600

1-800-668-8752 (USA and Canada)

x-cite@excelitas.com

http://www.excelitas.com/Pages/Contact/Contact-Us.aspx

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

32

Appendix

X-Cite® 120LEDBoost User Guide

035-00536R rev. 4

33

MATERIAL SAFETY DATA SHEET

Prepared to U.S. OSHA, CMA, ANSI and Canadian WHMIS Standards

_____________________________________________________

PART I What is the material and what do I need to know in an emergency?

________________________________________________________________________________

1. PRODUCT IDENTIFICATION

TRADE NAME (AS LABELED)

CHEMICAL NAME/CLASS: Heat Transfer Fluids

SYNONYMS: Inhibited Propylene Glycol

DISTRIBUTOR'S NAME: Dynalene Heat Transfer Fluids

ADDRESS: 5250 West Coplay Road

Whitehall, PA 18052

EMERGENCY PHONE: 1 -800-424-9300 (CHEMTREC)

BUSINESS PHONE: 1-610-262-9686

DATE OF PREPARATION: August 29, 2004

DATE OF REVISION: March 9, 2011

________________________________________________________________________________

CHEMICAL NAME CAS # WT %

Propylene Glycol 57-55-6 >95 NE NE NE NE NE NE

Inhibitor Solution

2. COMPOSITION and INFORMATION ON INGREDIENTS

NE = Not Established C = Ceiling Level See Section 16 for Definitions of Terms Used.

NOTE: All WHMIS required information is included. It is located in appropriate sections based on the ANSI Z400.1-1993 format.

: DYNALENE PG™

EXPOSURE LIMITS IN AIR

ACGIH OSHA

TLV STEL PEL STEL IDLH OTHER

3

mg/m3 mg/m3 mg/m3 mg/m

mg/m

Balance

None of the ingredients in the Inhibitor Solution contribute any significant,

additional hazard to these products. All pertinent hazard information has

been provided in this Material Safety Data Sheet, per the requirements of

the Federal OSHA Hazard Communication Standard (29 CFR 1910.120 0)

and State equivalent standards.

DYNALENE PG™ MSDS

PAGE 1 OF 8

3

mg/m

3

________________________________________________________________________________

(

)

________________________________________________________________________________

3. HAZARD IDENTIFICATION

EMERGENCY OVERVIEW: This product is a clear, odorless, syrupy liquid. Vapors and mists from this product

may be irritating if inhaled. The solution can be irritating to contaminated skin or eyes. This product must be

substantially preheated before ignition can occur. If involved in a fire, this liquid will release toxic gases (i.e. carbon

monoxide and carbon dioxide). This product is not reactive. Emergency responders must wear proper personal

protective equipment and have adequate fire protection for the situation to which they are responding.

SYMPTOMS OF OVER-EXPOSURE BY ROUTE OF EXPOSURE:

The most significant routes of exposure to this product are by

inhalation of the vapors and contact with the skin and eyes.

INHALATION: Inhalation of the mists or vapors of this product may be

irritating to the nose, throat, mucous membranes, and other tissues of

the respiratory system. Propylene Glycol is the main component of

this product. Vapor concentrations of Propylene Glycol are normally

too low at room temperature (due to the low vapor pressure) to cause

significant toxic effects from vapor alone.

CONTACT WITH SKIN or EYES: This product may cause local

redness or irritation of the skin. Repeated or prolonged exposure may

lead to dermatitis. Contact with the eyes will cause redness, irritation,

tearing, and possibly burning.

SKIN ABSORPTION: Based on clinical tests, skin absorption is a

potential route of over-exposure for Propylene Glycol (the main

component of this product). Symptoms of such exposure can include

symptoms described for “Contact with Skin and Eyes”.

INGESTION: Ingestion of this product, while not likely to occur in an

industrial setting, may cause irritation of the mouth and throat, gastric

upset, nausea and vomiting.

INJECTION: Though not an expected route of occupational exposure

for this product, injection (via punctur es or lacerations in the skin) may

cause local reddening, tissue swelling and discomfort.

HEALTH EFFECTS OR RISKS FROM EXPOSURE: An Explanation in Lay Terms. Symptoms associated with overexposure to this product are as follows:

ACUTE: Inhalation of the mists or vapors of this product may be irritating to the nose, throat, mucous membranes, and

other tissues of the respiratory system. This product may also be irritating to contaminated skin or eyes.

CHRONIC: Prolonged or repeated skin exposures may cause irritation, which could lead to dermatitis (dry, chapped

skin).

TARGET ORGANS: Skin, eyes.

________________________________________________________________________________

HAZARDOUS MATERIAL INFORMATION

SYSTEM

HEALTH

FLAMMA BILITY

REACTIVITY

(BLUE)

yellow

RED

0

1

0

PROTECTIVE EQUIPMENT

EYES R ESPIRATORY

For routine industrial applications

HANDS

SEE SECTION 8

BODY

PART II What should I do if a hazardous situation occurs?

________________________________________________________________________________

4. FIRST-AID MEASURES

SKIN EXPOSURE: If this product contaminates the skin, immediately begin decontamination with running water. Remove

exposed or contaminated clothing, taking care not to contaminate eyes. The minimum

minutes. Contaminated individual must seek immediate medical attention, especially if irritation or redness develops.

recommended flushing time is 15

EYE EXPOSURE: If this product enters the eyes, open victim's eyes while under gentle running water. Use sufficient

force to open eyelids. Have victim "roll" eyes. Minimum

flushing is for 15 minutes. Contaminated individual must seek

immediate medical attention, especially if symptoms persist.

INHALATION

respiration to support vital functions. Remove or cover gross contamination to avoid exposure to rescuers.

: If vapors or mists of this product are inhaled, remove victim to fresh air. If necessary, use artificial

DYNALENE PG™ MSDS

PAGE 2 OF 8

INGESTION: Hazards from swallowing this product is not expected to be serious. If symptoms develop, seek medical

attention.

___________________________________________________________________________________________________________

________________________________________________________________________________

5. FIRE-FIGHTING MEASURES

NFPA RATING

The following information is available for Propylene Glycol, the main component of this

product.

FLASH POINT, °C (method): 99°C (210°F), Closed Cup

AUTOIGNITION TEMPERATURE, °C: 371°C (700°F)

FLAMMABLE LIMITS (in air by volume, %): Lower (LEL): 2.6%

Upper (UEL)

The following information is available for this product.

: 12.5%

FIRE EXTINGUISHING MATERIALS:

HEALTH

FLAMMABILITY

1

0

OTHER

0

REAC

Water Spray: YES (cooling only) Carbon Dioxide: YES Foam: YES

Dry Chemical: YES Other: Any "ABC"Class Halon: YES

UNUSUAL FIRE AND EXPLOSION HAZARDS: This product must be substantially

pre-heated before ignition can occur. When involved in a fire, this material may decompose and produce irritating vapors

and toxic gases (e.g., carbon oxides).

Explosion Sensitivity to Mechanical Impact: Not sensitive.

Explosion Sensitivity to Static Discharge: Not sensitive.

SPECIAL FIRE-FIGHTING PROCEDURES: Incipient fire responders should wear eye protection. Structural fire fighters

must wear Self-Contained Breathing Apparatus and full protective equipment. Move fire-exposed containers if it can be

done without risk to firefighters. If possible, prevent run-off water from entering storm drains, bodies of water, or other

environmentally areas. Decontaminate fire-response equipment with soap and water solution if necessary.

________________________________________________________________________________

6. ACCIDENTAL RELEASE MEASURES

SPILL AND LEAK RESPONSE: Uncontrolled releases should be responded to by trained personnel using pre-planned

procedures. Proper protective equipment should be used. In case of an uncontrolled release, clear the affected area,

protect people, and respond with trained personnel.

SMALL SPILL: Cover with absorbent material (floor absorbent, vermiculite, etc.) Soak up spill and place material into a

drum.

LARGE SPILL: Personnel involved with large releases should wear protective equipment. Stop spill at source, dike the

area surrounding the spill to prevent further exposure. Prevent material from entering sewer system. If pump is available,

pump spilled material into 55-gallon drums for proper disposal. If necessary, absorbents such as vermiculite, clay floor

absorbent may be used on spill and shoveled into drums.

Personal Protective Equipment should be Level D: chemical resistant gloves (rubber gloves and Nitrile gloves), and

coveralls, safety glasses, safety shield. If heated, this product may displace oxygen in an enclosed area.

Monitoring of oxygen level is recommended. Decontaminate the area thoroughly. If necessary, decontaminate spill

response equipment with soap and water solution. Dispose of in accordance with Federal, State and local hazardous

waste disposal regulations (see Section 13, Disposal Considerations).

___________________________________________________________

PART III How can I prevent hazardous situations from occurring?

_________________________________________________________________________________________________________________________________________________________________

7. HANDLING and STORAGE

WORK PRACTICES AND HYGIENE PRACTICES: As with all chemicals, avoid getting this product ON YOU or IN YOU.

Wash thoroughly after handling this product. Do not eat or drink while handling these materials. Use in a well-ventilated

location. Use ventilation and other engineering controls to minimize potential exposure to the aerosol, sprays and vapors

of this product. Remove contaminated clothing immediately.

DYNALENE PG™ MSDS

PAGE 3 OF 8

_____________________________________________________

_____________________________________________________

7. HANDLING and STORAGE

STORAGE AND HANDLING PRACTICES: All employees who handle this material should be trained to handle it safely.

Use in a well-ventilated location. Open drums and other containers of this product slowly, on a stable surface. Drums

and other containers of this product should be properly labeled. Empty drums and containers may contain residual

amounts of this product, therefore, empty containers should be handled with care. Move drums of this product carefully,

with the appropriate drum-handling equipment.

Store drums and other containers in a cool, dry location, away from direct sunlight, or sources of intense heat. Storage

areas should be made of fire-resistant materials. Keep containers away from incompatible chemicals (See Section 10,

Stability and Reactivity).

________________________________________________________________________________

8. EXPOSURE CONTROLS - PERSONAL PROTECTION

VENTILATION AND ENGINEERING CONTROLS: Use with adequate ventilation. General methods include mechanical

(local exhaust) ventilation, process or personnel enclosure and control of process conditions. Local exhaust ventilation

may be necessary when this material is heated or a mist created. Supply sufficient replacement air to make up for air

removed by exhaust system. Prudent practice is to ensure eyewash/safety shower stations are available near areas

where This product is used.

RESPIRATORY PROTECTION: None needed for normal circumstances of use. If respiratory protection is needed, use

only protection authorized in 29 CFR 1910.134, or applicable State regulations. Use supplied air respiration protection if

oxygen levels are below 19.5% or are unknown.

EYE PROTECTION: Splash goggles or safety glasses.

HAND PROTECTION: Wear butyl rubber, natural rubber, neoprene, Nitrile rubber, or other suitable gloves for routine

industrial use.

BODY PROTECTION: Use body protection appropriate for task.

PERSONAL PROTECTIVE EQUIPMENT LEVEL: D

________________________________________________________________________________

Unless otherwise specified, the following information is available for Propylene Glycol, the main component of this

product.

RELATIVE VAPOR DENSITY (air = 1): 2.62

FREEZING/MELTING POINT or RANGE: At 95% Concentration: -51°C (-60°F) (Product)

EVAPORATION RATE (n-BuAc=1): Not available.

SPECIFIC GRAVITY (water = 1): 1.038

SOLUBILITY IN WATER: Soluble.

VAPOR PRESSURE, mm Hg @ 20 °C: 0.07

ODOR THRESHOLD: Not applicable.

COEFFICIENT WATER/OIL DISTRIBUTION: Log P (oct) = -1.41, -0.30

BOILING POINT: 188°C (371°F)

pH: Approximately 8.9

APPEARANCE AND COLOR: This product is a colorless, odorless, syrupy liquid with a faint, chemical odor. Alternate

colors are available, pending customer preferences.

HOW TO DETECT THIS SUBSTANCE (warning properties): The appearance is a distinguishing characteristic of this

product.

9. PHYSICAL and CHEMICAL PROPERTIES

DYNALENE PG™ MSDS

PAGE 4 OF 8

_____________________________________________________

________________________________________________________________________________

STABILITY: Stable.

DECOMPOSITION PRODUCTS: Mainly carbon dioxide and carbon monoxide.

10. STABILITY and REACTIVITY

MATERIALS WITH WHICH SUBSTANCE IS INCOMPATIBLE: Strong oxidizers, strong acids, acid chlorides, acid

anhydrides, chloroformates, or strong reducing agents.

HAZARDOUS POLYMERIZATION: Will not occur.

CONDITIONS TO AVOID: Contact with incompatible chemicals.

________________________________________________

PART IV Is there any other useful information about this material?

_________________________________________________________________________________________________

TOXICITY DATA: Additional toxicology information for components greater listed in Section 2 (Composition and

Information on Ingredients) in concentration is provided below.

PROPYLENE GLYCOL:

Skin-Human: 500 mg/7 Days; Mild irritation effects

Skin-Human: 104 mg/3 days - Intermittent, Moderate irritation effects

Skin-Man 10%/2 days

Eye effects-Rabbit, adult : 100 mg, Mild irritation effects

Eye effects-Rabbit, adult: 500 mg/24 hours, Mild irritation effects

DNA Inhibition-Mouse-Subcutaneous: 8000 mg/kg

Cytogenetic Analysis-Mouse-Subcutaneous: 8000 mg/kg

Cytogenetic Analysis-Hamster: fibroblast: 32 g/L

Intraperitoneal-Mouse TDLo: 100 mg/kg (15 days preg): Teratogenic

effects

Intraperitoneal-Mouse TDLo: 100 mg/kg (11 days preg): Reproductive

effects

Oral-Child TDLo: 79 g/kg/56 weeks, Intermittent: Central nervous

system and brain effects

SUSPECTED CANCER AGENT: The ingredients of this product are not listed on the following lists: FEDERAL OSHA Z

LIST, NTP, IARC or CAL/OSHA, and therefore are not considered to be, nor suspected to be, cancer-causing agents by

these agencies.

IRRITANCY OF PRODUCT: This product may cause irritation to contaminated tissues.

SENSITIZATION TO THE PRODUCT: The components of this product are not known to cause sensitization after

prolonged or repeated exposures.

REPRODUCTIVE TOXICITY INFORMATION: Listed below is information concerning the effects of this product and their

components on the human reproductive system.

Mutagenicity: The components of this product are not reported to cause mutagenic effects in humans.

Embryotoxicity

: This product is not reported to produce embryotoxic effects in humans.

Teratogenicity: This product is not reported to cause teratogenic effects in humans.

Reproductive Toxicity

A mutagen is a chemical, which causes permanent changes to genetic material (DNA) such that the changes will

propagate through generational lines. An embryotoxin is a chemical, which causes damage to a developing embryo (i.e.

within the first eight weeks of pregnancy in humans), but the damage does not propagate across generational lines. A

teratogen

generational lines. A reproductive toxin

is a chemical, which causes damage to a developing fetus, but the damage does not propagate across

MEDICAL CONDITIONS AGGRAVATED BY EXPOSURE: It is anticipated that mainly skin and eye disorders may be

aggravated after over-exposure.

RECOMMENDATIONS TO PHYSICIANS: Treat symptoms and eliminate over-exposure.

11. TOXICOLOGICAL INFORMATION

PROPYLENE GLYCOL (Continued):