EWS, Inc. / Environmental Water Systems

Care and Use Manual

Drinking W ater Filtration Systems

Information Provided for the Proper Set-Up, Installation and

Start-Up of the following Filtration Systems

T wo-Stage Undercounter Drinking W ater Filtration Units:

FUGAC200, FUGAC250, UU250

Three-Stage Undercounter Drinking W ater Filtration Units:

FUGAC300, FUGAC350, UU350

In-Line Filtration Unit:

FUGAC150

4.1-1

ALL PRODUCT PROUDLY MANUFACTURED AND ASSEMBLED IN THE USA

Retain this Care & Use Manual for Maintenance and Information

You Must Register this Product - It is a Requirement for Warranty

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

To the Consumer:

4.1-2

EWS, Inc. / Environmental Water Systems

A Special Message to Our Customers,

EWS, Inc. and Environmental Water Systems would like to thank you for your consideration in selecting from our

comprehensive list of residential filtration and conditioning product.

We recommend that you take the time to read the information that pertains to your product as you begin to use it.

The information in this manual is designed to assist your installer to set-up, install and start-up your system properly.

In addition, the information contained in this manual is designed to provide the consumer, the most comprehensive

information on this series of product.

Please contact us if you have any questions, comments or additions to the information provided.

Sincerely,

Customer Service at EWS, Inc.

EWS, Inc. and Environmental Water Systems

9101 W. Sahara A ve., Suite 105-J8

Las Vegas, NV. 891 1 7

Office: 702-256-8182 Available Monday through Friday , 8:30 - 4:30 Pacific S tandard Time

Fax: 702-256-3744 Dedicated and A vailable 24/7

E-Mail: customerservice@ewswater.com

Web Site: www .ewswater .com

Installation of the Filtration System - Please Read the Enclosed Information

Please take the time to familiarize yourself with the unit you are about to install. The Table of Content s will point to

specific instructions for the simple step-by-step instructions for;

Installation of a Dispenser/Faucet

Placement or Locating the Water System

Inlet Supply Water Connection

Connection of Tubing from Supply and to Dispenser/Faucet

System St art-Up and Operation Procedures

You may need the following for proper installation:

• Teflon tape • Work Gloves • Safely Glasses • Knife or scissors

• Adjustable Wrench • Pliers • Screwdriver; straight & phillips • Drill & drill bits

WARNING: V erify that all components are included with the unit and were not lost, misplaced, or damaged in shipping

or handling. Any damage in shipping needs to be reported to the shipping company.

WARNING: Do not attempt to install this system using defective or damaged components. Check and inspect, inlet and

outlet fittings and any other connections on this system that might have been damaged during shipping and handling. Check

all these components again upon installation and start-up for any hidden issues. All plumbing should be done in accordance

with all local plumbing codes. Water Pressure: minimum 25psi, maximum 65p si. Water Temperature Range (cold supply

only): not to exceed 1 10°F or below 40°F. Electrical (if applicable): an uninterrupted a/c supply, (if applicable): make sure

voltage supply is compatible with your unit prior to install

WARRANTY: Warranty Registration of this product is required to have a warranty. A proper inst allation and start-up will

save you time, money and hassles, and is also required for warranty purposes. Any issue as a result of improper application,

set-up, installation and/or start-up will void any warranty .

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS, Inc. / Environmental Water Systems

Table of Contents

INST ALLATION SUMMARY AND INDEX

OF YOUR DRINKING WATER FILTRATION SYSTEM

Placement or Locating the Dispenser/Faucet (2 & 3 Stage Units Only) 4

Installation of the Supplied Dispenser/Faucet (2 & 3 S tage Unit s Only) 5

Dispenser/Faucet Q & A 6

Placement or Locating the Water System 7

Inlet Supply Water Connection

Basic Supplied Connection 8

Preferred Connection 9

Connection of T ubing from Supply and to Dispenser/Faucet 10

4.1-3

System Start-Up and Operation Procedures 11

HOW TO MAINTAIN YOUR SYSTEM

Replacement of Filter Cartridges 12

Replacement of UV Lamp (if applicable) 13

Optional Disinfection Procedure of Empty Unit 13

GENERAL INFORMATION

Water Fitration Systems Included in this Care and Use Manual 14

FILTER REPLACEMENTS AND ORDERING

Filter and UV Lamp Replacements 16

Ordering Filters, UV Lamp Replacements, and Parts 17

Trouble Shooting Guide 18

Schematics 20

Warranty 24

Terms and Conditions of Sale 26

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.1-4

EWS, Inc. / Environmental Water Systems

Placement or Locating the Dispenser/Faucet

Step by step instructions to mount and secure the supplied dispenser/faucet

Professional Installation is Strongly Recommended

Note:

Dispenser/Faucet Not Included with In-Line Units. Sold separately, or use existing or other dispenser.

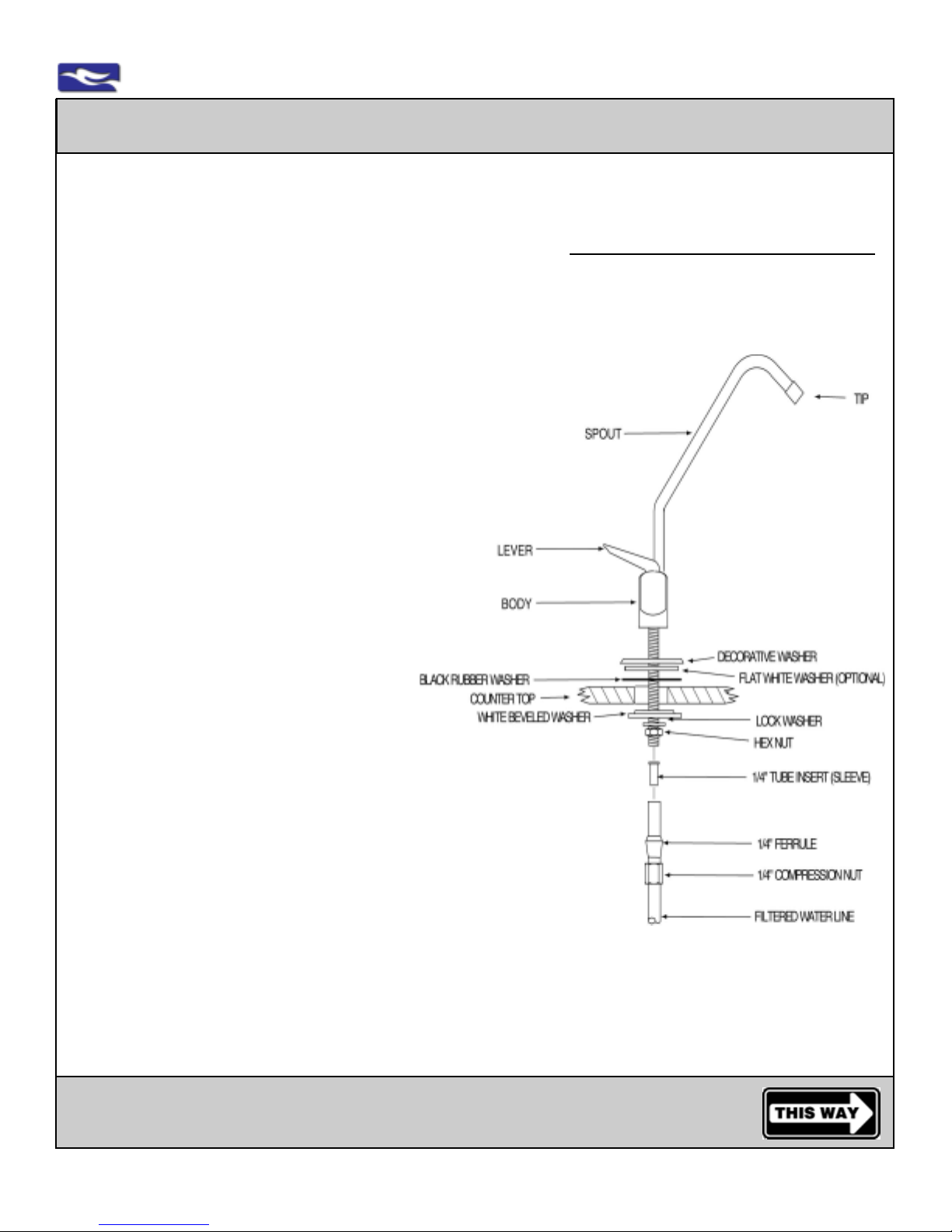

Step 1: Locate Faucet Parts Bag (2 and 3-Stage Units Only)

Parts Included: faucet body with handle, faucet spout with tip, decorative washer, black rubber

washer, white beveled washer, lock washer, hex nut, 1/4” tube insert sleeve,

Included 1/4” plastic compression ferrule, 1/4” compression nut

Optional Part: flat white washer (for use under decorative washer depending on hole/application)

Preferred - Select a standard sink location to mount the faucet.

It is recommended that the faucet be placed in a hole provided on most sinks similar to the ones used for a

sprayer, soap dispenser and/or dishwasher air gap. If the hole or sp ace is unavailable, an alternative location

will be required: MINIMUM HOLE REQUIRED 1/2”, MAXIMUM 1 3/8”

Option A: On the sink. This option is to drill a new hole into the sink rim itself, if space allows.

Option B: On the countertop next to a sink. This option is to position the faucet spout in the

correct location to drain into the sink. This requires a clearance around the faucet

both above and below the countertop. Use the supplied dispenser as a template or

see the enclosed dispenser schematic and dispenser dimensions.

Prepare to drill the hole using the dispenser as a template.

• Sinks can be made of, but not limited to, stainless steel, copper, porcelain/steel, enamel/cast iron,

man-made surfaces, stone, concrete, and/or materials known or unknown at this time.

• Countertops can be made of, but not limited to, or be a combination of, natural stone, enamel,

porcelain, concrete, wood, metals and/or man-made materials known or unknown at this time.

CAUTION: Please consult with the sink or countertop manufacture, supplier, fabricator, or

installer for proper drilling techniques and methods.

EXTREME CARE MUST BE T AKEN IN DRILLING THE HOLE FOR ANY SURF ACE. THE SURFACE MA TERIALS OF SINKS AND COUNTERTOPS CAN CHIP OR CRACK. THE MANUFACTURER ASSUMES NO

RESPONSIBILITY FOR ANY DAMAGE RESUL TING FROM THIS INST ALLA TION.

WARNING: USE SAFETY GLASSES OR OTHER EYE PROTECTION WHEN GRINDING OR

DRILLING TO PREVENT POSSIBLE EYE INJUR Y DUE T O FL YING PARTICLES.

Installation of the Supplied Dispenser/Faucet

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

Follow Steps 2 through 12

EWS, Inc. / Environmental Water Systems

4.1-5

Installation of the Supplied Dispenser/Faucet (2 & 3-Stage Units Only)

Step by step instructions to mount and secure the supplied dispenser/faucet

If using another faucet, please review the instructions included with that product**

Above the Surface

Step 2:

Place decorative washer to bottom of faucet body

(optional: place flat white washer under decorative washer)

Step 3:

Place black rubber washer below decorative washer

(or below optional flat white washer)

Step 4:

Place faucet stem through hole and center

Below the Surface

Step 5:

Insert white beveled washer, bevel side up to

fit snugly into a (1 3/8”) pre-drilled hole or flat side

up depending on the application

Step 6:

Place lock washer on this white beveled washer

Step 7:

Spin hex nut onto faucet stem and

tighten hex nut and washers into place

Step 8:

Slide 1/4” compression nut (threads up)

onto 1/4” filtered line

Step 9:

Slide 1/4” plastic compression ferrule, long side

down onto filtered water tube. Ferrule will seat into

compression nut

Step 10:

Insert 1/4” tube insert sleeve into 1/4” filtered water line

Step 11:

Insert 1/4” blue (filtered water) tube into faucet stem. Leave

other end available for system interconnection

Step 12:

Thread 1/4” compression nut onto faucet stem and tighten

Enclosed Dispenser/Faucet Dimensions***

Height: from deck to top of dispenser 8”

from deck to tip of dispenser 6 1/4”

Reach: from center of dispenser to tip 6”

Hole: minimum required 1/2”

maximum 1 3/8”

CAUTION: Do not overtigthen fittings

Note: Spout pulls out from faucet body and has 2 o-rings at base. Insert completely into bottom of faucet body to prevent

leaking. Spount swivels to direct water. Handle and tip can be removed. Handle can be locked up in open position.

** Other faucets check with specifications. ***All dimensions are approximate.

Go to the Placement or Locating the Water System

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.1-6

EWS, Inc. / Environmental Water Systems

Dispenser/Faucet Q & A

Q: I do not want to drill any extra holes or use a separate dispenser/faucet - what can I do?

A: An alternative to installing and using the dispenser/faucet is to consider a direct connection to your

existing kitchen (cold side) faucet. Connect the supply from the cold water angle stop to feed/inlet side of the

filtration system as directed in this manual. Then connect the filtered/outlet side to the cold feed side of the

kitchen faucet. Special fiitings, that are readily available to the plumbing professional, will be required to fit this

application based on line size and materials used.

WARNING: This is not a preferred method due to a more complicated install, lower flow rates to your

kitchen faucet and most importantly, the possibility of water quality issues as a result of the

aerator at the end of the kitchen faucet not intended for filtered water.

Note: There will be a diminishment in your flow rate to the cold side of the faucet (kitchen faucet

has a flow rate of up to 2.3 gallons per minute and the filtered water is delivered up to 1 gallon

per minute). To get filtered water you must be sure you have the faucet to the cold side only.

This application or option may not be applicable for reverse osmosis systems.

Q: I would like to use another dispenser/faucet?

A: Based on many styles and finishes, a consumer may have another dispenser they would like to use.

No problem, all these items have universal or industry standard fittings, or if not, can be easily adapted to fit.

Note: EWS, Inc. includes a standard chrome, long-reach, lead-free faucet with white handle and tip.

Options: EWS provides the following options to match other items at an additional charge;

Change your white tip and handle to black

Change your faucet to the following finshes; white faucet (with white tip and handle), satin

nickel, polished nickel, polished brass, or oil rubbed bronze (all with black handle and tip).

Inquire with your local EWS, Inc. distributor, contact an authorized internet distributor or visit us

on the web (see page 4.1-17 for more details).

Q: Can we connect the filtered water up to other devices?

A: Y es, simply connect by a “T” connection, the filtered water line to any inst ant hot, chiller , ice-maker,

refrigerator, etc. Regarding flow rate, be mindful of too many (3 or more) connections and/or any length

limitations in excess of 15 feet to any item that may create issues with delivery rates. See our Point of Entry ,

Whole Home Appliances to filter all the fixtures within the home.

Note: Spout pulls out from faucet body and has 2 o-rings at base. Insert completely into bottom of faucet

body to prevent leaking. Spount swivels to direct water. Handle and tip can be removed. Handle

can be locked up in open position.

Other faucets check with specifications.

All dimensions are approximate.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS, Inc. / Environmental Water Systems

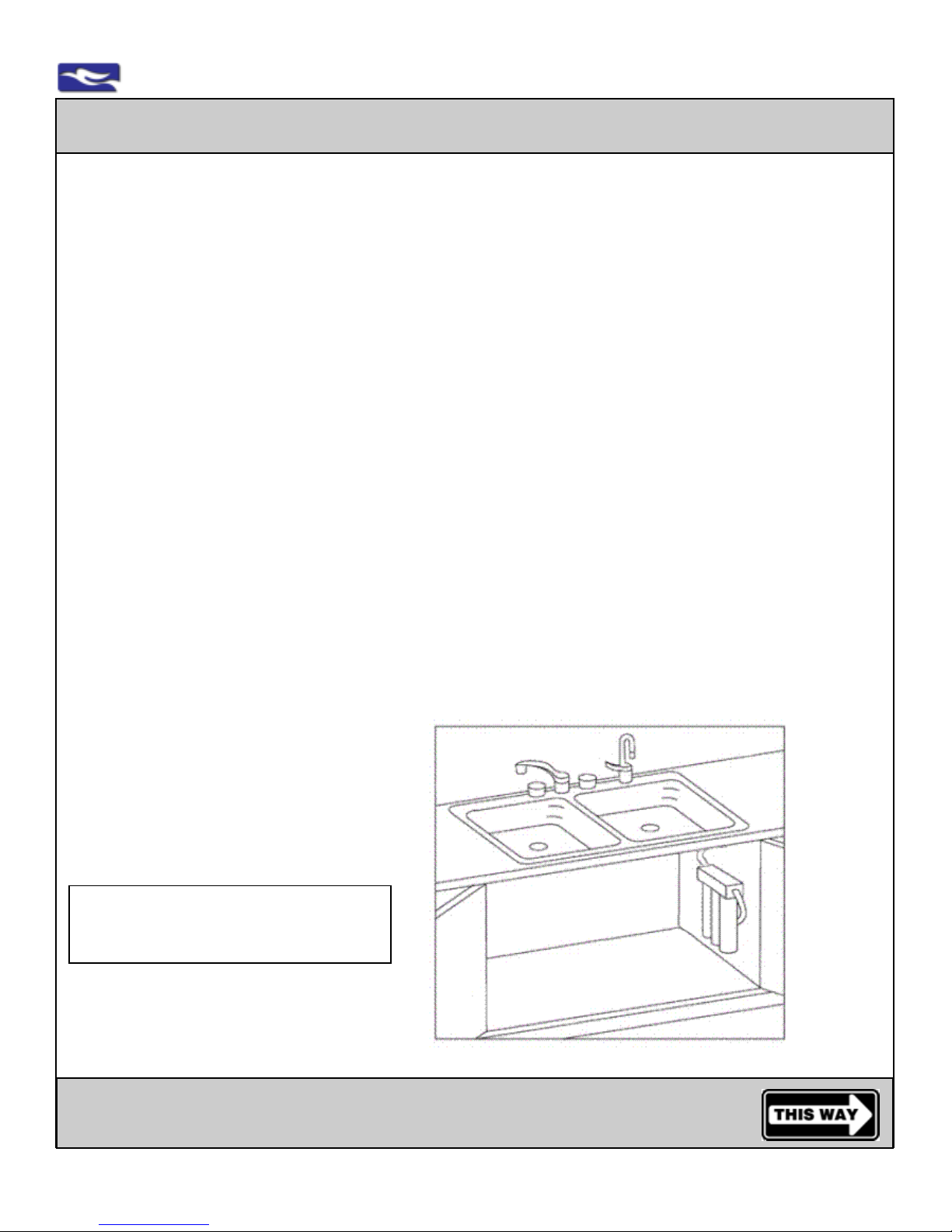

Placement or Locating the Water System

Simply place the water system on a level floor, cabinet bottom or horizontal surface.

Always assume for enough space and tubing to remove, move and/or adjust

for filter replacement and maintenance.

If mounting the system to a wall, cabinet side or other vertical surface,

Please see the following;

Step 1: All filter cartridges for the system are preinstalled. If the unit is installed in a permanent

hanging position, a minimum clearance of 2” will be required to allow filter replacement.

Step 2: Mark pilot holes using the bracket as a template.

Step 3: Using a drill bit or punch, drill a hole or punch as a starter hole to catch the mounting

screws.

WARNING: AL TERNA TIVE F ASTENING METHOD MA Y BE REQUIRED FOR PLASTER BOARD,

P ARTICLE BOARD OR SIMILAR MA TERIAL INSTALLA TION. USE SAFETY GLASSES

OR OTHER EYE PROTECTION TOPREVENT POSSIBLE EYE INJURY DUE TO

FL YING P ARTICLES.

4.1-7

Step 4: Set mounting screws (provided) with screw driver. Leave a 1/4” gap between the screw

head and mounting surface to allow the bracket to slide on easily .

Step 5: Slide the bracket over the screws and hang the unit. Make sure unit is level.

Now make the connections of tubing to/from the system.

Helpful Hint:

Find the enclosed Sp anner Wrench that

Kitchen Faucet

Dispenser/Faucet

of filtered water

came with the unit and place it on top of

the bracket.

When finished, roll up this Service Guide

and place on top with wrench.

Take a note of the Model # and WQA

Serial # for the required warranty registration of this unit.

This Service Guide and the wrench will

Filtered Water to

Dispenser/Faucet

Mounted to Wall

(option shown) or

Placed on level floor

Outlet

Inlet from

Cold Inlet/Supply

Connection

(angle stop not

shown)

come in very handy when it’s time for

filter replacement.

Go to the Inlet Supply W ater Connection

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

strictly for illustration purposes only

4.1-8

EWS, Inc. / Environmental Water Systems

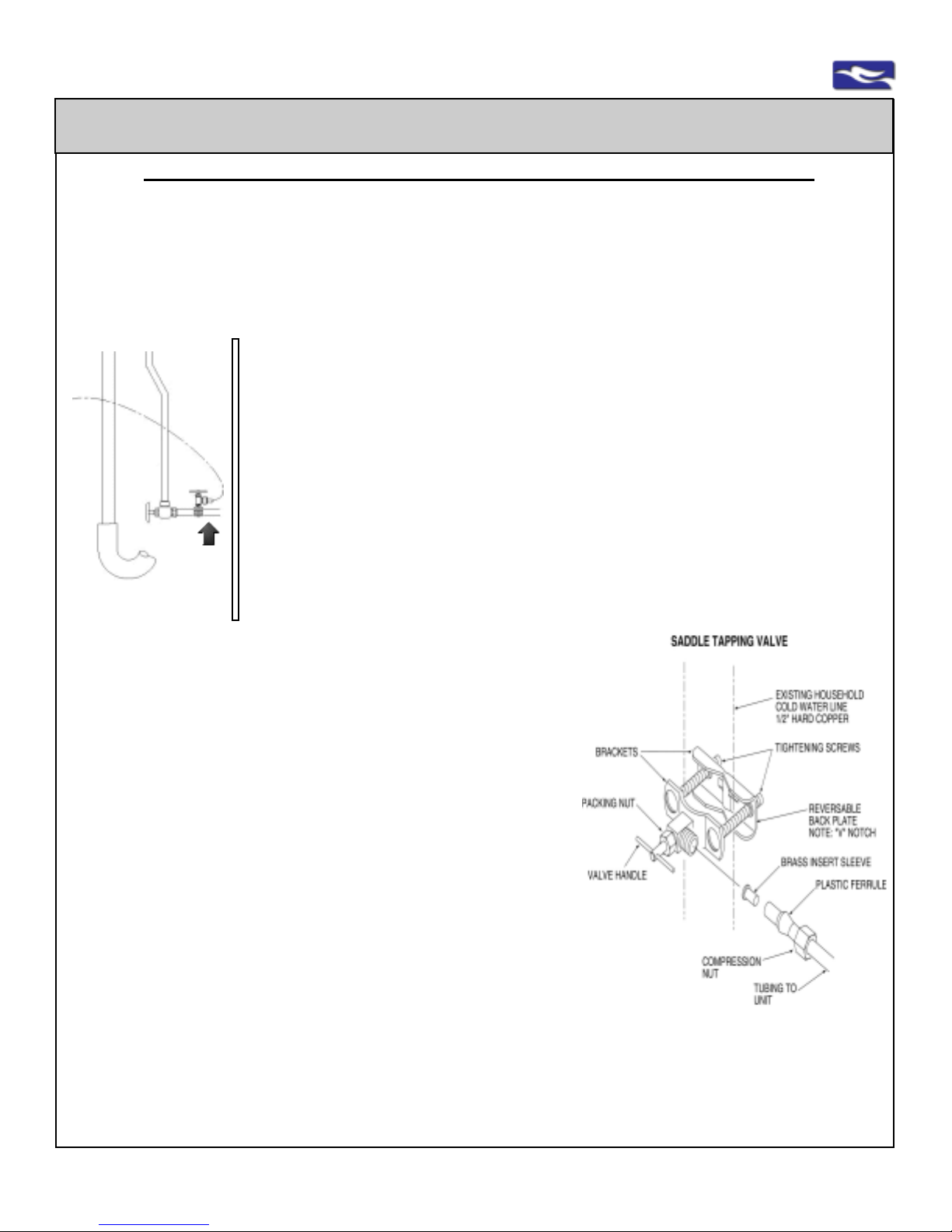

Basic Inlet Supply Water Connection **

Professional Installation Using a Preferred Connection is Strongly Recommended

**This unit is supplied with a saddle tapping valve and should be considered a basic connection for copper , steel or brass

3/8” to 1/2” O.D. pipe prior to the angle stop shut-off of the cold water line to the kitchen faucet. This should be considered

a “do-it-yourself” connection which is not applicable in many situations and may not meet local codes.

A qualified plumber should choose to make the inlet supply water connection by a more preferred method.

Instructions from the bag containing the supplied saddle tapping valve, if applicable

Step 1: From parts bag locate: saddle tapping valve and 4’ of 1/4” tubing, color coded: red or orange (supply line to unit).

wall

angle

stop

cold

supply

to

kitchen

faucet

saddle

tapping

valve

pipe for

install

and

clearance

from wall

supply

tube

to

filtration

unit

drain

and

trap

Step 4: Loosely assemble saddle tapping valve on pipe

A: For all 3/8 O.D. pipe, use side of bracket with side projections

toward or against pipe to prevent distortion of tubing.

B: For all 1/2 O.D. pipe, use “V” side of bracket with that notch

toward or against pipe.

Step 5: T ighten screws evenly . Make sure brackets are parallel,

then tighten firmly until the valve is not moving on the pipe.

CAUTION: Do not over tighten fittings.

Step 6: Connect the 1/4” plastic tubing to the saddle tapping

valve by following these instructions:

A: Slide 1/4” compression nut over plastic tubing with threads toward the

saddle tapping valve.

B: Slide 1/4” plastic ferrule over plastic tubing with long tapered side

toward saddle tapping valve.

C: Place 1/4” brass insert sleeve into the end of the 1/4” or orange/red

plastic tubing.

D: Insert orange/red tubing into saddle tapping valve. Leave other end

available for system interconnection

E: Tighten compression nut onto saddle tapping valve.

Step 2: Locate cold water line that feeds your existing faucet. Determine if there is enough

space to install the saddle tapping valve on the hard line between the wall and the angle

stop.

CAUTION: USE ONL Y COLD WATER LINE. NOT INTENDED FOR SUPPLY BY HOT

WATER.

Step 3: Shut off the main water supply to the house and open the faucet to relieve water

pressure in the hard pipe. NOTE: Shutting the angle stop only , still leaves water in that pipe.

Shut the main supply .

CAUTION: Do not turn valve handle before or while installing the “saddle tapping valve”.

Make sure the piercing lance does not protrude beyond the rubber gasket. Failure to do this

may result in damage to the piercing needle.

NOTE: For Copper Pipe - go directly to #4.

For Steel or Brass Pipe - follow A, B, C below, then go to #4

A: Drill a 3/16” hole in pipe. Use a hand drill to avoid shock hazard.

B: Turn handle to expose lance beyond the rubber gasket no more than 3/16”.

C: Place body of valve over hole so the lance fits into the hole

CAUTION:

Do not over

tighten fittings.

Step 7: Be sure the packing nut is tight, then turn the handle of the saddle tapping valve clockwise

until it is firmly seated. NOTE: For Copper Pipe - the pipe is now pierced.

HINT: Back the end of the piercing lance out, turning the handle counter-clockwise. Then re-insert by turning the handle

of the saddle tapping valve clockwise until it is again firmly seated. This will clear any possible debris that can

block piercing lance and water flow.

Step 8: Turn the handle counter-clockwise to open the valve for water supply . Keep main line shut of f and proceed with

the remainder of the installation and start-up.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS, Inc. / Environmental Water Systems

4.1-9

Preferred Inlet Supply Water Connection - All Applications

Professional Installation Using a Preferred Connection is Strongly Recommended

A qualified plumber should choose to connect the inlet supply water supply by a more preferred connection. ***

The Preferred Inlet Supply Water Connection is Applicable in All Applications and Codes

Replace the Angle Stop with a Proper 3-Way Fitting:

There are a number of options to properly install any one of these drinking water filtration systems.

Identify the cold water supply line and then you will need to know;

• Size or O.D. diameter of pipe or tubing

• Pipe material (hard or sof t copper, steel, brass, stainless, PVC, plastic, etc...)

• The existing angle stop or fitting will assist in determining the proper 3-way angle stop or fitting needed for

your specific application

A more preferred method to connect the inlet supply line is to shut off

the water main and replace the entire angle stop. This will have a connection from the house main water line, a connection to the cold water

side to the kitchen sink faucet and a much better connection for the

inlet supply to the filtration unit. This will provide one fitting with a shut

off to the kitchen faucet and a shut off to the filtration system. The

replacement of the angle stop is a better plumbing connection and any

number of fittings can be used for the correct application under any

circumstances.

Examples of common connections and fittings available:

• OPTIONS:

1/2” IPS x 3/8” compression x 1/4” compression

3-way angle stop

• OPTIONS:

1/2” compression x 3/8” compression x 1/4” compression

3-way angle stop

Note:

Be sure one outlet is 1/4” compression

for the water filter 1/4” inlet/supply tubing

drain

and

trap

Example:

new 3-way

angle stop or

fitting

kitchen faucet supply

shut

off

cold water

supply pipe

to kitchen

faucet

connection

1/4” filtration

unit supply

connection

wall

water flow

main water

supply pipe

Proper installation is dependent on your specific application and the concept of proper installation is universal.

Locate the supply , shut off your main water supply , install the proper connections

and follow the remaining instructions in this manual.

***EWS, Inc. can not anticipate all the different locations, applications and materials used by your builder and/

or plumbing contractor regarding your household or sink piping, therefore we offer a generic and common fitting

with proper instructions. A qualified plumber , plumbing supply location, or hardware store will have no problem

with alternative parts and advice necessary to install your unit.

Go to the Connections of Tubing to and from System

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.1-10

EWS, Inc. / Environmental Water Systems

Connection of Tubing from Supply and to Dispenser/Faucet

Step 1: Before Making the Connections - Remove Colored Vinyl Plugs Correctly

This system may have come with sample plugs. Please remove before installation.

WARNING: NEVER ATTEMPT TO REMOVE TUBING OR SAMPLE PLUGS BY JUST PULLING .

Follow simple instructions illustrated below to remove properly.

INSPECT: Inspect the fitting for any damage from shipping, handling and/or delivery . STOP, if collet

is damaged in any way; call, fax or e-mail customer service for a replacement fitting.

Step 2: Making the Connections from Inlet/Supply Connection to Unit

and from Unit to Faucet/Dispenser

Firmly insert the tubing completely into the fitting.

You may feel a resistance at the o-rings when you insert the tubing.

Step 2a: Connect the orange/red tubing from the installed Inlet/Supply Connection to the location on

the unit labeled “FEED” (into “Prefilter” housing for all 2-St age Units, “Sediment” housing for

all 3-St age Units, or at “Inlet” for Single-S tage, In-Line Unit s). This is the raw supply water into

the system. Insert and press the tubing firmly and completely into the fitting.

Step 2b: Connect the blue tubing from the installed Dispenser/Faucet to the location on the unit

labeled “F AUCET” (out of “Postfilter” housing for all Units or at “Output” for Single-S t age, InLine Units). This is the filtered water line. Insert and press the tubing firmly and completely

into the fitting.

Never Pull Tube Out T o

Remove

Push Collet In To

Release

T o Insert, Press T ubing In

Firmly and Completely

CAUTION: Always leave the tubing provided to allow lifting the unit for filter replacement and maintenance.

Make sure tubing has gentle curves. Roll and secure as needed. Do not bend or kink tubing.

We do not recommend shortening the tubing, however, If needed, at end, cut tube straight and do

not flatten. A void any tubing contact to hot water lines

WARNING: NEVER A TTEMPT TO REMOVE TUBING BY JUST PULLING .

Follow simple instructions illustrated above to remove properly .

INSPECT: Upon installation, inspect the connection and give the tubing a gentle “tug” to insure

proper connection and integrity of the fitting.

Inspect the fitting for any damage from shipping, handling, delivery , and/or installation.

STOP, if collet is damaged in any way; call, fax or e-mail customer service for a replacement

fitting.

To Test Integrity of Fitting,

Give a Gentle “Tug” To

Insure Proper Connection

See All

Cautions, Warnings and

Inspections

Go to the System St art-Up and Operation Procedures

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS, Inc. / Environmental Water Systems

4.1-11

System St art-Up and Operation Procedures

A proper start-up insures the system is without issues. If anything is discovered, this is the time to

discover it and correct any problems or questions that arise.

Lack of any, or a proper, start-up will void the warranty.

Step 1: For UV Option Only

Connect UV lamp cord and plug in transformer unit to typical 110v electric outlet. (UU250, UU350 only)

NOTE: Electrical outlet must be dedicated and unswitched. Be aware of any GFI outlets and the need

to reset. Surge supression highly recommended.

Step 2: Pull up and lock dispenser/faucet handle (if using another type of dispenser - put into open position).

This will allow water to flow in the open position. Turn off water supply to other devices. Do not make this water

available to any ice-makers, refrigerators or any other devices until the system is completely flushed and

running clear.

Step 3: Slowly - Turn on or open any main water supply which was shut off earlier.

Step 4: Open or make sure there is inlet water supply to the system. Water will begin to flow from dispenser/

faucet. Initially it may sputter until it reaches full flow. Allow system to run steadily for approximately 2 minutes or

more, if needed. This will wash all carbon fines and air from the system. End this flushing of the system once

water runs clear. System is now available to use as normal. Open water supply to other devices, if applicable.

Leave Spanner Wrench that came with unit and this Service Guide on top of unit bracket to assist consumer.

NOTE: If you draw your water into a glass and it appears to be cloudy, it’s only air and nothing bad. Let

the glass sit and watch the air rise and dissipate. The filter cartridges used are full bed depth. The

carbon (GAC) cartridges have a great deal of surface area. With usage, it may take 24-48 hours

for this to correct itself.

Step 5:

Inspect for leaks at all connections, fittings and/or housings. If a problem exists, please shut off water supply to

the system and consider the following solutions;

• Plumbing connections at the inlet/supply connection, saddle tapping valve, or angle stop.

Please review these plumbing procedures and correct.

• Plumbing connections to dispenser/faucet and any other fixtures or cross-connections. Please review

and correct.

• Inspect for leaks at all unit connections such as connections between housings, UV housing and

connections (if applicable), cartridge housings. Report any issues for assistence or needed part(s).

• Inspect for leaks at the labeled “FEED” and “FAUCET” connections between the supplied tubing and

the quick connect fittings. To insure proper connection, give a light “tug” (

check the grip on all fittings.

If any damage was identified in shipping or handling. You’ll need to make a claim with the shipper, as indicated on our

Packing Materials, our Packing Slip and the published General Terms and Standard Conditions of Sale.

If you have identified a problem, please contact our offices. The Best Way; go to www.ewswater.com, click button “Contact

Us” and click link to “Customer Service and Help”, fill out the form and help will be on the way. Let us know if we can offer

advice on a plumbing issue that may not be related to the actual unit, or a question or issue that may be unit related. If in need

of a part under warranty we can readily send it. Parts (original only) needed out of warranty can be obtained through your

contractor, local distribution or at www.waterontheweb.com.

WARNING: Maximum pressure is 65 PSI. Pressure unregulated can surge or exceed the maximum rating on this and

many items in the home. High pressure creates a water hammer or banging pipes. It’s also the reason to use stainless hoses

for washer machine connections and not the rubber. A pressure reducing valve (PRV) at your main water service line (if not

code) is greatly recommended by many manufacturers’ of many different household items, plumbing products and appliances and must be checked annually. A point of use (sink location) pressure limiting valve is also available.

not a hard pull) on tubing to

Finished, Go T o Required Product Registration

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.1-12

EWS, Inc. / Environmental Water Systems

Register this Product - It is a Requirement for Warranty

Familiarize yourself with the system, its’ replacement filters and maintenance.

To Register, take note of the Model # and WQA Serial # found on the unit’s bracket,

Understand your system’s capabilities, put the enclosed Spanner Wrench and this Service

Guide on top of the unit bracket,

See your options in water treatment, for you , your family and your home by EWS, Inc.

Register Your System

our confidential data base will remind you to replace your filters, use our enclosed form

which you can fax or mail to our offices, or register on-line at www.ewswater.com

Replacement of Filter Cartridges

It is recommended that filters be changed at least annually or more frequently based on usage and

local water conditions. The quantity and quality of the water processed effects the life of the filters.

Step 1:

Close inlet water supply to the system.

Step 2:

Open dispenser/faucet. Lock handle in the up position and/or allow water to

flow (water flow should stop in a short time) and keep open to relieve pressure.

CAUTION:

WATER WILL BE PRESENT WHEN FILTERS ARE CHANGED.

A p an, towel, etc. should be placed under the housings to catch any water.

Step 3:

Using your spanner wrench, turn housing (which contains the filter cartridge)

counterclockwise to loosen. Remove housing.

Step 4:

Remove filter and dispose.

NOTE:

See optional disinfection procedure of empty unit before replacing any filters or

UV lamp (if applicable)

Step 5:

Insert new filter(s), replace and tighten housing by turning clockwise.

CAUTION:

The GAC Postfilter (GAC-00 for units FUGAC200, FUGAC300) has a gasket

that must be at the top of the filter to be replaced correctly . All other filters do

not have a top or bottom and can be inserted either way .

CAUTION:

Inspect O-Ring for housing base. Make sure it is clean, free of any debris and

not damaged or kinked. Make sure it is correctly seated into the channel

inside the housing before replacement.

Upper

Housing

to Bracket

GAC-00

PostFilter

(ONLY)

Gasket

Faces Up

all other

cartridges

can go in

either

direction

Housing

O-Ring

Housing to

be removed

Step 6: FOLLOW SYSTEM START-UP AND OPERATION PROCEDURES

AND FOLLOW PROPER TUBING CONNECTION INFORMATION

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS, Inc. / Environmental Water Systems

Annual Replacement of UV Lamp (if applicable)

Step 1:

Unplug the transformer. Then disconnect the UV lamp cord.

NOTE:

•T wo-Stage Units - UV module is set between the filter housings.

•Three-Stage Units - UV module is set on top of bracket (easier access)

Step 2:

Pull firmly on the UV lamp tail only to remove the lamp. Do Not remove

cap at top of UV Module

Two-Stage Unit s only: Snap the UV module from the bracket clip s to

gain access for lamp removal. Do not disconnect any fittings.

Step 3:

Insert and firmly press new UV lamp into the top of the cap.

Reconnect UV lamp cord.

Two-Stage Unit s only: Thread UV lamp cord through bracket hole and

then snap the UV module back into the bracket clips.

Step 4:

Reconnect UV lamp cord. Plug in unit transformer.

WARNING:

DO NOT DISCONNECT UV MODULE FROM THE FACTORY CONNECTIONS AND DO NOT OPEN UV CAP FROM UV MODULE FOR

TYPICAL UV LAMP REPLACEMENT.

4.1-13

4

3

2

SCHEMATIC FOR ILLUSTRA TION

1

1 - Fully Assembled UV Module

2 - UV Module Housing

3 - UV Cap with Quartz Glass Sleeve

4 - UV Lamp with Lamp Cord

PURPOSES

Optional Disinfection Procedure of Empty Unit

NOTE:

All containers, surfaces and items exposed to water can accumulate a clear or discolored film which may also be

slippery or slimey to the touch. This is a bio-film that is non-pathenogenic and usually of no harm.

This film is most commonly a nuisance and is readily wiped off. It is this reason we suggest a simple

cleaning procedure prior to returning new filters to the filtration system.

This procedure may be performed at any time when changing filters

or after extended periods of inactivity of the system.

Step 1: Follow Step s 1 through 4: Replacement of Filter Cartridges. Empty all housings of their filters.

Step 2: Using chlorine bleach, measure 1/2 cup and pour into first housing base (side of the unit labeled “FEED”

into “Prefilter” housing for all 2-Stage Unit s, “Sediment” housing for all 3-Stage Unit s).

Step 3: Replace all empty housings and tighten. T ake note of the housing O-Ring.

Close dispenser/faucet to prevent water flow.

Step 4: Slowly Open water inlet valve and allow system to completely fill. Let water sit in system for at least 5 minutes

(leaving it for a longer time will not hurt).

Step 5: Open dispenser/faucet and let the water run for at least 5 minutes.

WARNING: DO NOT USE THIS WA TER.

Step 6: Now the system, tubing, faucet, and all connections should be disinfected. Follow steps for Replacement

of Filter Cartridges and Replacing UV Lamp (if applicable) and prior to Step #5, wipe away any residual found in

housings or around unit to totally clean this system prior to new filter and UV replacement.

Follow System Start-Up and Operation. Always follow proper tubing connection information.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.1-14

EWS, Inc. / Environmental Water Systems

Water Fitration Systems Included in this Care and Use Manual

For Proper Installation, Information and Maintenance - Identify your Filtration System

check the unit check replacements for easy future reference

In-Line, Single-Stage, Limited Usage, Point of Use Filtration Units

Model No: FUGAC150

Improves taste, clarity and odor by removing chlorine and other volatile organic compounds. The

upgraded filter also safeguards against lead and cysts (giardia and cryptosporidium). Meets or

complies with NSF St andard 53.

Easy to Reference Filter Replacement Code: 7

Note: Dispenser/Faucet Not Included with In-Line Unit s. Sold separately , or use existing or other dispenser .

Undercounter Drinking Water Filtration and UV Unit s

Standard Two Stage Undercounter Drinking Water Systems

Model No: FUGAC200 - Good

Improves taste, clarity and odor by removing chlorine and other volatile organic compounds. The 5micron pre-sediment filter serves to remove suspended matter, dirt, rust and sediment and improves

performance of other filters. Meets or complies with NSF St andard 42.

Easy to Reference Filter Replacement Codes - the Set Includes: 1, 6

Model No: FUGAC250 - Better

Improves taste, clarity and odor by removing chlorine and other volatile organic compounds. The

upgraded filter also safeguards against lead and cysts (giardia and cryptosporidium). The 5-micron

pre-sediment filter serves to remove suspended matter, dirt, rust and sediment and improves

performance of other filters. Meets or complies with NSF St andard 53.

Easy to Reference Filter Replacement Codes - the Set Includes: 1, 7

Model No: UU250 - Best

Our best selling unit for sink filtration since1987

This unit improves, removes and safeguards like above model FUGAC250. The additional UV module

protects against bacterial, viral, E-coli and other microorganisms and is tested 99.9% effective.

The 5-micron pre-sediment filter serves to remove suspended matter, dirt, rust and sediment and

improves performance of other filters. Meets or complies with NSF S tandards 53 and 55.

Easy to Reference Filter Replacement Codes - the Set Includes: 1, 7, 16

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS, Inc. / Environmental Water Systems

Undercounter Drinking Water Filtration and UV Unit s

Three Stage Units for Heavier Sediment and/or Particulate Applications

Model No: FUGAC300

Improves taste, clarity and odor by removing chlorine and other volatile organic compounds. The

5-micron pre-sediment filter serves to remove suspended matter, dirt, rust and sediment and

improves performance of other filters. The 20-micron pre-filter is added for heavier sediment and/or

particulate water applications. Meets or complies with NSF S tandard 42.

Easy to Reference Filter Replacement Codes - the Set Includes: 1, 2, 6

Model No: FUGAC350

Improves taste, clarity and odor by removing chlorine and other volatile organic compounds. The

upgraded filter also safeguards against lead and cysts (giardia and cryptosporidium). The 5-micron

pre-sediment filter serves to remove suspended matter, dirt, rust and sediment and improves

performance of other filters. The 20-micron pre-filter is added for heavier sediment and/or particulate

water applications. Meets or complies with NSF St andard 53.

Easy to Reference Filter Replacement Codes - the Set Includes: 1, 2, 7

Model No: UU350

This unit improves, removes and safeguards like above model FUGAC350. The additional UV

module protects against bacterial, viral, E-coli and other microorganisms and is tested 99.9%

effective. The 5-micron pre-sediment filter serves to remove suspended matter , dirt, rust and sediment

and improves performance of other filters. The 20-micron pre-filter is added for heavier sediment

and/or particulate water applications. Meets or complies with NSF S tandards 53 and 55.

Easy to Reference Filter Replacement Codes - the Set Includes: 1, 2, 7, 16

4.1-15

NOTE: All completely assembled units include the following standard features:

Two and Three Stage Drinking Water Systems include: White 10" housing with filtration cartridges, spanner wrench to open

housings for easy filter replacement, chrome, lead-free faucet with white trim for dispensing water, self-piercing saddle tapping

valve for water line connection with shut-off valve (see service guide for your correct application), all necessary tubing (color coded)

to make proper connections, simple to use mounting bracket, UV lamp and setup (UV unit only) and complete service guide with

installation and use instructions.

In-Line Units are completely assembled units that include the following standard features: White 10" housing with filtration

cartridges,mounting bracket, spanner wrench to open housings for easy filter replacement, saddle tapping valve, tubing and

complete service guide with use instructions.

Register this Product - It is a Requirement for Warranty

Visit www.ewswater.com, Click on Customer Care and then

Click for the “Product Registration” link

EWS, Inc. will keep this information confidential and will offer you reminders to replace your filters and offer

you updates on water issues and concerns

Filter Replacements and How to Order

For more information on the entire product line

from sink to whole home, visit us on the web

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.1-16

EWS, Inc. / Environmental Water Systems

Filter and UV Lamp Replacements

Easy Reference: Filter Code No: 1 Replace: UP TO A YEAR*

Model No: PRESED-05 Pre-Sediment Filter (5-micron)

5-Micron Prefilter is a pure polypropylene full-bed depth filter with exceptional dirt holding capability .

The removal of any dirt, silt, rust or suspended matter protects the remaining cartridges and extends

the performance of other filters. Meets FDA requirements for food and beverage contact.

In Use: All 2- and 3-Stage and In-Line Sediment Units :

FUGAC200, FUGAC250, FUGAC300, FUGAC350, UU250, UU350

Easy Reference: Filter Code No: 2

20-Micron Prefilter is a pleated filter with exceptional dirt holding capability . The removal of any dirt,

silt, rust or suspended matter protects the remaining cartridges and extends the performance of

other filters and is used in very particulate water conditions. Meets or complies with all FDA

requirements for food and beverage contact.

In Use: FUGAC300, FUGAC350, UU350 (all 3-stage units only)

Easy Reference: Filter Code No: 6

Model No: GAC-00 Granular Activated Carbon (GAC) Postfilter

Filter is designed for effective reduction of taste, clarity and odor problems such as Chlorine and

VOC's. Cartridges are designed to allow water to pass through entire carbon bed to allow

maximum adsorption. Meets or complies with NSF St andard 42.

In Use: FUGAC200, FUGAC300

Easy Reference: Filter Code No: 7

Model No: GACB-50 Carbon Block 1-Micron Postfilter

Filter is an upgraded postfilter designed for effective reduction of taste, clarity and odor problems

such as Chlorine and VOC's. In addition, the filter reduces Lead and Cysts such as Giardia and

Cryptosporidium. Cartridges are designed to allow water to pass through entire carbon bed to

allow maximum adsorption. Meets or complies with NSF S tandard 53.

In Use: FUGAC150(in-line), FUGAC250, FUGAC350, UU250, UU350

Model No: PRESED-20 Pre-Sediment Filter (20-micron)

Replace: UP TO A YEAR*

Replace: UP TO A YEAR*

Replace: UP TO A YEAR*

Easy Reference: Filter Code No: 16 Replace: ANNUALLY*

Model No: UV -LAMP (lamp only) UV Lamp - UV Bacteria-Kill Units

UV Unit contains a 6 Watt UV lamp that effectively kills bacteria (>99%). A 316 Bonded St ainless

Steel Interior enhances kill power by reflecting UV light and eliminates degradation of polypropylene

housing. Due to advanced design, water is spun through the module to eliminate shadowing and

shading which additionally maximizes kill power. UV Module meets or complies with NSF S tandard

55.

In Use: UU250, UU350

*Replacement of all filters are based on local water conditions and usage.

UV lamp replacement annually (or, as needed within the year)

For all removal capacities, test results and compliances.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

Visit www.ewswater.com

EWS, Inc. / Environmental Water Systems

4.1-17

Ordering Filters, UV Lamp Replacements, and Parts

There are several ways to obtain and order filter replacements for your unit.

Contact;

... your builder, plumbing contractor and/or your inst aller that provided the product...,

... the kitchen & bath showroom, distributor, and/or ret ailer where you purchased the product...,

... or use the internet in the following manner...,

Go to our Corporate Site @

www .ewswater.com and note the “Showroom Locator” button towards the

top right side of every page. Click on your S tate and scroll towards a distributor. You can call someone

close to you (hopefully someone will be responsive), let them know what you have, and they can place

your order. As a manufacturer , EWS, Inc. does not sell direct to consumers, only into distribution.

The most convenient way to purchase the correct filters for your unit may be

to visit an authorized web distributor such as www.waterontheweb.com

Follow these easy instructions to obtain the correct filters for your system;

1......... Go to Filters & Parts,

2......... Find Sink Units,

3......... Find Filter Cartridge Replacement

4......... Identify the unit you own and use the scroll down menu to enter your model #, (for

example UU250) and Click Go

5......... At the blue highlighted T ab for Filter Replacement you will see your complete

set of filters for your particular unit. Now just follow the secure store instructions

to complete the purchase and you’re done.

Waterontheweb is very similar to the EWS Corporate Site in order to provide the consumer with the most complete

information and an e-commerce solution to the consumer’s needs. This site is designed to be simple and prevents any

confusion as to what items are needed for any particular unit. This distributor will place their order with EWS, Inc.

(similar to any other distributor) and will ship your order directly to the address you designated in the store.

To order needed parts from the same authorized internet distributor;

1......... Go to Filters & Parts,

2......... Find Sink Units,

3......... Find Parts Replacement

4......... Either enter your part # and press go or scroll down through the parts listing

5......... Click on the “Order” button to order a part (return to this page if you need more

items) for your particular unit. Once complete, just follow the secure store instructions

to complete the purchase and you’re done. Call or e-mail us if you need any help.

Thank you and we hope we have been of assistance in this matter .

EWS, Inc. and Environmental Water Systems – Customer Service

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.1-18

EWS, Inc. / Environmental Water Systems

T rouble Shooting Guide - Drinking Water Filtration Systems

Problem

Any or All Leaks

Leaks at Tubing Connections

Leak at inlet fitting

(labeled “Feed” &/or “PreFilter” for all 2-Stage Units or

“Sediment” for all 3-Stage

Units)

or

Leak at outlet fitting

( labeled “Faucet” &/or

“Postfilter” or “Output”)

Leak at 90 degree elbow

connection(s) for all 3-Stage

Units (FUGAC300,

FUGAC350, UU350)

Possible Causes

Excessive pressure or pressure

surges

Various causes to inspect

•Is the tubing cut with a straight

end to grab squarely?

•Is the tubing inserted completely

into fitting?

•Broken collect or fitting

•Is there a problem with the collet

and the quick-connect fitting?

•Tubing incorrectly removed

•Damaged in shipping,handling,

and/or delivery

Damaged in shipping,handling,

and/or delivery

Solution

Pressure reducing valve (PRV) at main water supply

to maintain pressure at or below 65 PSI or the addition of a Pressure Limiting Valve (item# FMP-60) on

the inlet tube prior to the point of use unit

•Follow instructions for Connection of Tubing.

Access the filter unit, remove tubing by depressing

the collet and pulling tubing out. Using a utility razor

squarely cut 1/2" off tubing from the end. Make

knife,

sure end of tubing is not flattened Reinsert the tubing

into the fitting as far as possible. Check for leaks.

•Tug on tubing (do not pull hard) to check fitting and

the integrity of the connection

•Upon inspection, prior to install or a result of proper

start-up and inspection and fitting is damaged,

then

Replace simple part (item# fc-std-all)

Replace simple part (item# fc-jg-90)

Leak at plastic compression

fitting at UV Module (UU250,

UU350)

Leak at connection between

housings on 2-Stage Units

(FUGAC200, FUGAC250)

No water

Not enough water

Water flow is restricted

Low flow from unit

Damaged in shipping,handling,

and/or delivery

Damaged in shipping,handling,

and/or delivery

Water supply is off

Saddle tapping valve piercing not

complete, if applicable

Low water pressure

Kinked or bent tubing

Saddle tapping valve, if applicable

may be restricting flow or misapplied on type of pipe being used

(only applicable on hard pipe of

copper, brass or steel)

Clogged prefilter cartridge

Replace simple part (item# fc-uv-jaco)

Replace simple part (item# fc-fu-conn) with proper

procedure (no plumbing needed)

•Turn main water supply on

•Saddle tapping valve not open, if applicable

•Turn water on at inlet connection, other if applicable

•Follow instructions to re-do piercing or use a

preferred method to make this connection

•Open dispenser/faucet

Unit may not operate properly at less than 25 PSI

feed line pressure (max: 65 PSI)

Make longer loop with tubing to remove kink or bend

Back the end of the piercing lance out, turning the

handle counter-clockwise. Then re-insert by turning

the handle of the saddle tapping valve clockwise until

it is again firmly seated. This will clear any possible

debris that can block piercing lance and water flow.

If there is flow rate through unit without filters then

there is a need to replace sediment and/or other

filters based on water conditions and usage

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS, Inc. / Environmental Water Systems

T rouble Shooting Guide - Drinking W ater Filtration Systems

4.1-19

Problem

Leak at the supplied

dispenser/faucet spout

Leak at the supplied

dispenser/faucet base by

handle (brass “T”)

Leak at the connection to

supplied dispenser/faucet

Leak at another Mfg’s faucet

and/or connection to another

device

Leak at Inlet Water Supply

Connection

Leak at cartridge housing

Possible Causes

Spout needs to be re-inserted

O-ring issue at inserted brass

piece or “T” that holds and operates handle

Dispenser connections need to be

properly made

All connections need to be

properly made

Various causes to inspect.

Saddle tapping valve may not be

applicable or installed correctly

Misaligned, damaged or

missing o-ring

Cracked housing due to pressure

issues, misaligned filter replacement and/or overtightening

Solution

•Spout pulls out from faucet body that’s why it swivels.

Spout has 2 o-rings at base and is inserted

completely into bottom of body to prevent leaking.

•Replace the supplied faucet dispenser

(item# depends on any finish option)

•Check connections at various locations and

re-connect, re-insert, tighten and/or correct.

•Consult with Mfg of other product and/or installer to

check connections at various locations and reconnect, re-insert, tighten and/or correct.

•Check connections and/or correct.

•Follow the inlet supply water instructions in this

manual and/or install the preferred inlet connection

•Locate and align O-ring into groove inside housing

•Replace simple part (item # h-f-o-ring)

•Replace part (item # h-filter) and correct issue that

caused the problem (no plumbing needed)

Leak at UV housing

UV not working

Unpleasant taste and/or odor

Metallic flavor

Discoloration

Rotten egg smell from water

Cloudy water

At Cap: Misaligned, damaged or

missing o-ring

Cracked housing due to pressure

issues, misuse, and/or

overtightening

Lamp damaged, lamp cord has not

been connected, transformer is not

plugged in, connected to wrong

type of outlet or lamp has burned

out

•Need to replace filters

•System needs disinfecting

•System was idle, stored or

misused for a long period of time.

•System under unfavorable conditions or changing water conditions

•Hydrogen sulfide, iron, manganese is in the household water

supply

•System misapplied

•New installation, changing filters,

disinfecting the system

•Open/close and open of water

supply to home or in home

•Locate and align O-ring into groove inside cap

•Replace part (item # h-uv) and correct issue that

caused the problem (no plumbing needed)

•Connect lamp cord and/or Plug in transformer.

•Make sure unit plugged into an unswtiched electrical

outlet. Check GFI reset. Surge suppression is highly

recommended

•Replace UV Lamp

•Replace filters and follow start up procedures

•Follow disinfection procedure

•Flush system by running water, replace filters and/or

disinfect

•Determine what changed in your water supply and

Flush, Replace and/or Disinfect, or change type of

water treatment system based on local water conditions. Call your municipality or have your well tested.

•Hydrogen sulfide, iron and manganese must be

removed from household water supply before filter

system. Visit our web site for other systems.

•Specify the correct system for the application

It is simply - air. Check by filling glass and watch air

dissipate. Run and flush system for several minutes.

Sometimes it takes 24 - 48 hours to totally clear due

to the full bed depth of our filters

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.1-20

Two-S tage Model #s: FUGAC200, FUGAC250

Ref # Part Description

1 h-filter Housing base

1a Upper housing

2 PRESED-05 5 Micron Pre-Sediment Filter Cartridge

3 fc-std-all JG 1/4”x1/4”m-white quick connect

4 bracket-2 aluminum bracket, powder coat

5 fd-ch-wh Std chrome w/wh, long reach

6 stv-2 saddle tapping valve

7 t-blue 1/4” pe tubing 60” bl-p

8 t-orange 1/4” pe tubing 60” or-p

9 GAC-00 GAC Filter Cartridge (FUGAC200)

9a GACB-50 Upgraded GAC Cartridge (FUGAC250)

10 h-f-o-ring Housing base o-ring

11 fc-fu-conn Dual male connect between housings

Not pictured: spanner wrench (all units)

EWS, Inc. / Environmental Water Systems

Two-St age Filtration Unit

Schematic, Parts, Installation:

for illustration purposes only

See faucet

information

5

7

See inlet

connection

informatin

7

Three-Stage

Filtration Unit

Schematic and Installation:

for illustration purposes only

3

10

9**

or

9a

1

Three-St age Model #s: FUGAC300, FUGAC350

Ref# Part Description

1-8,10 items from above remain the same

9 or 9a GAC filters Depending on unit

Add (not pictured)

1,10 see above add’l housing for 3rd stage

2 a PRESED-20 20 micron pleated filter

4 to 4a bracket-3 alum bracket 3-stage

Not pictured: spanner wrench (all units)

1a

4

11

3

1a

2

9**

GAC-00 PostFilter

(FUGAC200, FUGAC300 ONL Y)

Gasket Faces Up

2, 9a

all other cartridges can go

in either direction

10

1

illustrated quick connect fitting

and proper tubing connection

8

6

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS, Inc. / Environmental Water Systems

Two-S tage with UV Model #: UU250

Ref# Part Description

1,1a h-filter Housing base and Upper Housing

2 **PRESED-05 5 Micron Pre-Sediment Filter Cartridge

3 fc-std-all JG 1/4”x1/4”m-white quick connect

4c bracket-uv2 aluminum uv-2 bracket, powder coat

5 fd-ch-wh Std chrome w/wh, long reach

6 stv-2 saddle tapping valve (Not Shown)

7 t-blue 1/4” pe tubing 60” bl-p

8 t-orange 1/4” pe tubing 60” or-p

9a **GACB-50 Upgraded GAC Block Filter Cartridge

10 **h-f-o-ring Housing base o-ring

12 fc-jg-90 JG 1/4 x 1/4 elbow

13 fc-uv-jaco Jaco compression @ uv module

14 h-u-clip Bracket clip uv housing

15 UV -LAMP UV Replacement Lamp with Cord

16a h-uv UV assembly cap with quartz glass sleeve

16 b UV housing with housing o-ring

17 **pou-uv-e68 UV Transformer

**Not pictured: Part not pictured in this schematic

Not pictured: spanner wrench (all units)

Three-Stage

Filtration Unit

with UV Disinfection

Schematic and Installation:

for illustration purposes only

3

4c

1a

12

4.1-21

Two-St age Filtration Unit

with UV Disinfection

Schematic, Parts, Installation:

for illustration purposes only

See faucet

information

5

7

8

See inlet

connection

informatin

3

13

2

9a

1

14

15

16a

16b

Three-St age with UV Model #: UU350

Ref# Part Description

1-17 all items above remain the same

Add (not pictured)

1,10 see above add’l housing for 3rd stage

2 a PRESED-20 20 micron pleated filter

4c to 4d bracket-uv3 alum uv-3-stage bracket

Not pictured: spanner wrench (all units)

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

illustrated quick connect fitting

and proper tubing connection

4.1-22

EWS, Inc. / Environmental Water Systems

In-Line, Limited Usage, Single-Stage Unit s

Model #: FUGAC150

Ref # Part Description

1 h-filter Housing base

1a Upper housing

3 fc-std-all JG 1/4”x1/4”m-white quick connect

4b bracket-inline In-line single bracket

6 stv-2 saddle tapping valve

7 t-blue 1/4” pe tubing 60” bl-p

8 t-orange 1/4” pe tubing 60” or-p

9 GACB050 Upgraded GAC Cartridge

10 h-f-o-ring Housing base o-ring

Not pictured: spanner wrench (all units)

In-Line, Single-Stage Unit

Schematic, Parts, Installation:

for illustration purposes only

Note: Faucet/Dsipenser Not

Included with In-Line Units,

sold separately or use existing

or other dispenser.

4b

3

1a

3

10

Note:

In-Line Units do not come with Dispenser/Faucets.

shown for illustration purposes only

Dispenser/Faucet can be purchased separately

See inlet

connection

informatin

7

6

8

9

cartridge

can go in either

direction

1

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

illustrated quick connect fitting

and proper tubing connection

EWS, Inc. / Environmental Water Systems

NOTES

What unit(s) do I have? What filters do I need to order?

Reminder to Register your Purchase

register on-line at ww.ewswater.com, click the “PRODUCT REGISTRATION” Button,

then the link for “Online Interactive Registration”

4.1-23

Find the enclosed Sp anner Wrench that came with the

unit and place it on top of the bracket.

When finished, roll up this Service Guide and place on

top with wrench.

This Service Guide and the wrench will come in very

handy when it’s time for filter replacement.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

Helpful Hint:

4.1-24

EWS, Inc. / Environmental Water Systems

Limited Warranty

Notification:

This warranty is referenced by EWS, Inc. in all literature, addressed in General T erms and S tandard Conditions of Sale,

and is published in its entirety in all EWS, Inc. product manuals, websites, and in all service guides supplied with all

product.

Limited Warranty:

EWS, Inc., a Nevada corporation, hereby warrants all products to the original consumer purchaser to be free from

defects in material and workmanship as stated in the following paragraphs:

• All residential point of use: countertop filtration, in-line filtration, undercounter drinking water filtration, shower filtration,

residential reverse osmosis, and point of entry pre-sediment units or systems for one year from date of purchase.

• All residential point of entry: pH decreasing and softener (resin and ion-exchange) systems, Environmental (EWS)

Water Systems, pyrolox units, CWL whole-home (filtration media) systems, pH increasing reagent (sacrificial media)

units for 10 years on the tank and riser , 10 years on the ICN conditioner(s) (if applicable) and 3 years on the valve head

from date of purchase.

• All commercial systems: Dependent on specification and application, please consult with EWS, Inc. upon specifica-

tion.

• All filtration medias, resins, cartridges, uv lamps, and/or membranes are not covered by any warranty. Filter media,

resin, cartridge, uv lamp, and/or membrane replacement or maintenance schedule will vary and must be replaced, as

necessary , as determined by usage and local water conditions.

Product performance may vary based on local water conditions, proper product specification and application, proper

plumbing application, setup, installation, startup, maintenance and/or usage. To ensure proper operation, follow all

setup, installation, start-up and maintenance procedures as detailed in all service guides.

Not intended for use where water is microbiologically unsafe or with water of unknown quality without adequate disinfection before or after unit(s). The contaminants or other substances removed or reduced by these and any other water

filtration or treatment devices are not necessarily in your water. T o confirm the presence of any primary and secondary

contaminants, have your water supply completely analyzed by an independent and approved facility or if applicable,

contact your local water utility for information. Aesthetic, non-health related, or constituent s without set federal st andards may be part of water testing but are insufficient to determine proper application of any water filtration or treatment

device.

EWS, Inc. will replace, free of charge, during the warranty period, any part which proves defective in material and/or

workmanship under proper product and plumbing specification and application, normal and proper installation, use,

service and proper care as published in detail in all service guides included with product. Labor charges are excluded

from any warranty service or repair and are not the responsibility of EWS, Inc. Shipping charges may apply to delivered

replacement parts or materials. Charges may also apply for the cost of any replacement media, resin, cartridges, uv

lamp and/or membrane from any warranty service or repair. Information can be obt ained at any time through a local

dealer, distributor , representative or direct from EWS, Inc. and/or on-line at; www .ewswater.com or www .ewswater .com/

techandspec.html. Replacement parts can be obtained from your local dealer , distributor or contractor .

This warranty is the exclusive warranty granted by EWS, Inc. and is in lieu of all other warranties of merchantability and

fitness for a particular purpose and is further limited to defective parts replacement only . Labor charges and/or damage

incurred in setup, installation, and startup, or repair , or replacement, as well as, incidental and consequential damages

connected there with, are excluded, and are not the responsibility of, and will not be paid by EWS, Inc.

This warranty is void for any damages due to improper product and/or plumbing specification and/or application, misuse,

abuse, neglect, accident, acts of nature, action of any military or civil authorities, improper handling and transportation,

or improper setup, installation, and/or startup, or any violation of instructions furnished by EWS, Inc., or any replacement parts other than genuine parts or replacements supplied by EWS, Inc.

This warranty is not a warranty of merchantability , fitness, taste, aesthetics, and/or performance that may be subject to

improper product and/or plumbing specification and/or application, misuse, abuse, neglect, accident, acts of nature,

action of any military or civil authorities, improper handling and transportation, or improper setup, installation, and/or

startup, or any violation of instructions furnished by EWS, Inc.

This warranty is not a warranty of merchantability , fitness, taste, aesthetics, and/or performance that may be personal

and of subjective opinion and that does not relate to the performance of any system.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

EWS, Inc. / Environmental Water Systems

4.1-25

Limited Warranty - Original Purchaser ’s Responsibility

Keep a record of the purchase receipt and/or installation receipt. Purchaser is required fill out warranty registration form(s)

on applicable product(s) and register all product by either on-line @ www.ewswater .com, telephone, postal delivery , fax, email (either register@ewswater.com or information provided to customerservice@ewswater .com). Failure to do so voids

the warranty . EWS, Inc. does not sell, show or make available any information on any consumer in our database. This

database is to ensure, if needed, proper warranty service, and good customer service for years to come. Please see our

privacy policy published in our website at www.ewswater .com.

Know Y our W ater:

• If on a municipal system, large or small, it is your right as a consumer to have access to the most recent test results and

to expect adherence to federal guidelines, as well as any state or local requirements. Any problems should be reported to

the appropriate agencies. Please acquire those municipal test results to become an informed consumer .

• If on an individual well, have your water completely and independently tested. Local code may require a simple test for

coliform bacteria to approve a well, however you may be unaware of potential problems for you and/or your home. A local

water salesman is looking to close a sale and is going to test for hardness minerals and a few simple and obvious issues,

which may or may not be contamination problems. Their solution is almost always the same and yet may provide no

resolution to any true problems. Obtain our “Guide for the Private Well Owner” on our website; www .ewswater .com (under

Service Guides). Review our section on well water testing and applications in our complete catalog with your local

distributor , dealer, or our representative or visit our website.

• WARNING:

Some restrictions apply to the use of softeners. Contact your local municipal water district or Gov't Agency. Brine

discharge is already restricted on, or may be a problem for, septic applications and waste water treatment facilities. Since

some states have already restricted softeners to metered valves to prevent excessive brine discharge, EWS, Inc. only

provides metered valving in its line of softeners.

Restrictions may also apply to hot-side only , salt-exchange tanks or services, or an outright ban. Local water dealers and

other organizations do not inform consumers of these issues and believe these rules are unenforcable. The consumer is

ultimately responsible.

Softeners may also provide warranty issues with pools and spas, certain other products and finishes. Softened water

should not be used for drinking, cooking, pets or plants and is usually bypassed or “looped away” from the cold side of the

kitchen sink. Reverse osmosis, which also has its drawbacks and issues with other products and materials, may be used

to remove the salt from the water that the softener put in at the kitchen sink, yet may be misapplied for the actual local

water conditions.

Any problems of water quality , or the fitness of any EWS, Inc. product that is associated with any mechanical, construction, application, installation, and/or environmental issue(s) (ie: flow rates, line pressure, piping materials, broken supply

lines, changing water conditions; well or municipal water quality , et. al.), known or unknown, of the home or facility will not

be considered by EWS, Inc. until such issue(s) have been resolved.

Responsibility for the proper product and/or plumbing specification, application and/or installation of any device manufactured by EWS, Inc. lies with the consumer, their builder contractor, plumbing sub-contractor and any other installer of

choice. Items do not specify and/or install themselves. EWS, Inc. has provided many sources to acquire information on

the proper application of systems and their installation prior to any purchase. EWS, Inc. manufactures a complete product

line of point of use water filtration systems and point of entry filtration, softening and/or conditioning systems and/or

appliances. EWS, Inc. and the distributors of EWS, Inc. will stand behind the warranties of materials and workmanship.

However, EWS, Inc. and the distributors of EWS, Inc. and the Environment al Water Systems Product Line do not bear any

responsibility for improper applications of product and/or improper installation. It is for this reason that EWS, Inc. provides

complete information on all product for your understanding, specification, application and selection, and proper plumbing

application and installation.

T o obtain warranty service support, cont act your local dealer or contractor from whom you obtained the product or contact

EWS, Inc., Customer Service, via phone, fax, or email.

www.EWSWATER.com office: 702-256-8182 (m-f; 8:30-4:30, pst) fax: 702-256-3744 customerservice@ewswater.com

4.1-26

EWS, Inc. / Environmental Water Systems

PRICING POLICY

EWS, Inc. has a current, published, and widely distributed, Pricing Guide that contains suggested list prices for certain water filtration

and conditioning products ("Products") sold by EWS, Inc. ("Seller"). Seller assumes no obligation to sell to anyone any of the

Products listed herein, known or unknown, at any price.

This current Pricing Guide has been prepared for the convenience of Seller's distributors and their customers. The list prices

shown are guides only and do not purport to represent actual prices in any particular market and are not intended to interfere with the

right and responsibility of Seller's distributors to establish their own resale prices.

All current prices herein set forth supersede all prior lists and are subject to change without notice. Seller may also, from time

to time, change, modify, alter, improve and/or discontinue without notice the sale of any of the Products listed herein.

All seller's orders are accepted and delivered based upon the Terms and Conditions found on this Pricing Policy page, found in

this Pricing Guide, available in all Seller’s Product Manuals and reprinted on the reverse side of all invoices submitted and monthly

statements sent. Please read them carefully. They provide information that is important to Seller's distributors and their customers.

GENERAL TERMS AND STANDARD CONDITIONS OF SALE

Invoices are expressly limited to and made conditional upon the terms and conditions contained herein. Objection by Buyer to any

of the terms contained herein shall be deemed to have been waived (if not previously waived) if written notice of the objection is not

received by EWS, Inc. ("EI") within ten calendar days of the date of the first invoice or before part of the described goods are accepted

by Buyer, whichever occurs first. Any additional or different terms proposed by Buyer are rejected unless assented to in writing by EI.

1. PRICES: All prices are in U.S. dollars. Prices are subject to change without notice. Orders will be invoiced at prices

prevailing at time of shipment. All prices are F.O.B. our warehouse, Southern California and exclusive of any shipping, delivery,

packaging or handling charges that may apply.

2. TERMS OF PAYMENT: The terms of payment on approved accounts only shall be net thirty days in U.S. dollars from the date

of invoice to date of receipt of payment in our offices for all invoiced products whether partial or complete delivery of the product under

order. All past due accounts are subject to a charge of 11/2% per month (18% per annum) for each month or fraction of a month on

the unpaid balance.

3. TAXES: Prices do not include sales, use, excise or similar taxes. The amount of any present or future sales, use, excise

or other tax applicable to the sale or use of EI's products or equipment shall be paid by the Buyer unless the Buyer shall have provided

EI with a tax exemption certificate acceptable to taxing authorities.

4. ACCEPTANCE: All purchase orders are subject to acceptance by EI at its corporate offices in Las Vegas, Nevada and are

subject to these Standard Conditions of Sale, unless otherwise expressly provided.

5. SHIPMENTS: Delivery to carrier shall constitute delivery to customer. EI's responsibility terminates upon delivery in good

order to carrier. All goods are shipped at the customer's risk. Any claim for loss or damage in transit should be made promptly by

customer against carrier. These and other shipment terms are written clearly on the reverse side of all packing slips that accompany

all accepted shipments. All costs of freight, transportation, handling, in-route storage, certification and other documentation are to be

paid by Buyer. Any other terms will be issued to Buyer, in writing, with approved credit and an established EI/Buyer relationship.

6. DELAYS; FORCE MAJEURE: EI shall not be liable for delays in delivery of the goods or failure to deliver the goods caused,

in whole or in part, by inability to obtain transportation, equipment, or material, insurrection, fires, floods, storms, embargoes, action

of any military or civil authorities, whether legal or de facto, strikes, labor difficulties, lockouts, acts of God, or other similar or different

circumstances beyond the control of EI.

7. CANCELLATION: The Buyer may not cancel all or part of an order without verifiable notification to, and acceptance by EI.

8. RETURN OF MATERIALS: No Product may be returned to EI without written approval by a Company Officer. A restocking

charge of 25% will be assessed (45% if unit had been used) NO EXCEPTIONS. Product must be returned freight pre-paid, boxed

and in resale condition. EI will never take responsibility, under warranty or return, for improperly installed and/or misrepresented

units.

9. SELLER'S SECURITY INTEREST: EI shall retain a security interest in the goods sold hereunder until Buyer has paid in full

for such goods provided by EI in connection therewith and has performed all of Buyer's obligations under this contract.

10. COLLECTION: Buyer shall reimburse EI for all costs of collection, including reasonable attorney's fees, incurred by EI to

collect any monies owing under this contract. A $45.00 service charge will be invoiced on all returned checks.

11. WAIVER AND MODIFICATION: No waiver or modification of any of these Standard Conditions of Sale shall be effective

unless such waiver or modification is in writing and signed by an officer of the Company in Las Vegas, Nevada. In event any part of