EWM HIGHTEC WELDING GmbH

Dr. Günter - Henle - Straße 8; D-56271 Mündersbach

Phone: +49 (0)2680.181-0; Fax: +49 (0)2680.181-244

Internet:

www.ewm.de

; E-mail:

info@ewm.de

Operating instructions

GB

Multi-process welding machines for

TIG welding

MMA welding

MIG/MAG welding (option)

• TRITON 260 DC

• TRITON 400 DC

• TRITON 500 DC

These operating instructions must be read before commissioning.

Failure to do so may be dangerous.

Machine may only be operated by personnel familiar with the appropriate safety

regulations.

The machines bear the conformity mark and thus comply with the

•

EC Low Voltage Directive (73/23/EEC)

•

EC EMC Directive (89/336/EEC)

In compliance with IEC 60974, EN 60974, VDE 0544 the machines can be used in

environments with an increased electrical hazard.

© 2004 We reserve the right to make amendments. Art. No.: 099-000072-EWM01 Revised: 19.08.04

Originaldokument

liegt jedem Gerät bei!

Original document

is enclosed with each machine!

Document original

est joint à toute machine!

EG - Konformitätserklärung

EU - conformity declaration

Déclaration de Conformité de U.E.

Name des Herstellers:

Name of manufacturer:

Nom du fabricant:

EWM HIGHTEC WELDING GmbH

(nachfolgend EWM genannt)

(In the following called EWM)

(nommé par la suite EWM)

Anschrift des Herstellers:

Address of manufacturer:

Adresse du fabricant:

Dr.- Günter - Henle - Straße 8

D - 56271 Mündersbach – Germany

info@ewm.de

Hiermit erklären wir, daß das

nachstehend bezeichnete Gerät in

seiner Konzeption und Bauart sowie in

der von uns in Verkehr gebrachten

Ausführung den grundlegenden

Sicherheits-anforderungen der unten

genannten EG- Richtlinien entspricht.

Im Falle von unbefugten

Veränderungen, unsachgemäßen

Reparaturen und / oder unerlaubten

Umbauten, die nicht ausdrücklich von

EWM autorisiert sind, verliert diese

Erklärung ihre Gültigkeit.

We herewith declare that the machine

described below meets the standard safety

regulations of the EU- guidelines

mentionned below in its conception and

construction, as well as in the design put

into circulation by us. In case of

unauthorized changes, improper repairs

and / or unauthorized modificati ons, which

have not been expressly allowed by E WM,

this declaration will lose its validity.

Par la présente, nous déclarons que la

conception et la construc tion ainsi que le

modèle, mis sur le marché par nous, de

l´appareil décrit ci - dessous

correspondent aux directives

fondamentales de sécurité de la U.E.

mentionnées ci- dessous. En cas de

changements non autorisés, de

réparations inadéquates et / ou de

modifications prohibeés, qui n´ont pas été

autorisés expressément par EWM, cette

déclaration devient caduque.

Gerätebezeichnung:

Description of the machine:

Déscription de la machine:

Gerätetyp:

Type of machine:

Type de machine:

Artikelnummer EWM:

Article number:

Numéro d´article

Seriennummer:

Serial number:

Numéro de série:

Optionen:

Options:

Options:

keine

none

aucune

Zutreffende EG - Richtlinien:

Applicable EU - guidelines:

Directives de la U.E. applicables:

EG - Niederspannungsrichtlinie (73/23/EWG)

EU - low voltage guideline

Directive de la U.E. pour basses tensions

EG- EMV- Richtlinie (89/336/EWG)

EU- EMC guideline

U.E.- EMC directive

Angewandte harmonisierte Normen:

Used co-ordinated norms:

Normes harmonisées appliquées:

EN 60974 / IEC 60974 / VDE 0544

EN 50199 / VDE 0544 Teil 206

Hersteller - Unterschrift:

Signature of manufacturer:

Signature du fabricant:

Michael Szczesny , Geschäftsführer

managing director

gérant

05.2000

Table of contents Page

Inhalt/1

Safety instructions.............................................................................................................................S/1

For Your Safety..........................................................................................................................S/1

Transport and set-up..................................................................................................................S/4

Notes on the use of these operating instructions....................................................................... S/4

1 Technical data ...........................................................................................................................1/1

1.1 TRITON 260......................................................................................................................1/1

1.2 TRITON 400/500 ..............................................................................................................1/2

2 Description of the machine......................................................................................................2/1

2.1 TRITON 260......................................................................................................................2/1

2.1.1 Front view.............................................................................................................2/1

2.1.2 Rear view.............................................................................................................2/2

2.2 TRITON 400/500 ..............................................................................................................2/3

2.2.1 Front view.............................................................................................................2/3

2.2.2 Rear view.............................................................................................................2/4

3 Function specification..............................................................................................................3/1

3.1 Operating elements, control T101 ....................................................................................3/1

3.1.1 Additional operating elements TRITON 260 (MIG/MAG option)..........................3/2

3.1.2 Additional operating elements TRITON 400/500 (MIG/MAG option)...................3/3

3.2 TIG welding, general.........................................................................................................3/4

3.2.1 Types of ignition...................................................................................................3/4

3.2.2 Automatic shut-off................................................................................................3/4

3.2.3 Digital display.......................................................................................................3/4

3.2.4 TIG welding torch, operating variants..................................................................3/5

3.2.5 Tapping operating mode......................................................................................3/5

3.3 TIG function sequences ...................................................................................................3/6

3.3.1 Explanation of symbols........................................................................................3/6

3.3.2 TIG non-latched operation...................................................................................3/7

3.3.3 TIG latched operation ..........................................................................................3/8

3.4 TIG pulses, function sequences ......................................................................................3/9

3.4.1 TIG pulses - non-latched operation......................................................................3/9

3.4.2 TIG pulses - latched operation...........................................................................3/10

3.5 MMA welding ..................................................................................................................3/10

3.5.1 TRITON 260 adjustable arcforcing ....................................................................3/10

3.5.2 TRITON 400/500 adjustable arcforcing.............................................................3/11

3.6 MIG/MAG welding (Option).............................................................................................3/11

3.6.1 TRITON 260 (Option).........................................................................................3/11

3.6.2 TRITON 400/500 (Option)..................................................................................3/12

3.7 Remote control................................................................................................................3/13

3.8 TIG interface for mechanised welding (remote control connection socket)....................3/14

3.9 Welding parameter adjustments "internally"...................................................................3/15

3.9.1 P10: Gas pre-flow time ......................................................................................3/15

3.9.2 P1: I-start Ignition current...................................................................................3/16

3.9.3 P2: t-UP Up-slope time ......................................................................................3/16

3.9.4 JP5: Switching between normal or tapping operation........................................3/16

3.9.5 S3 tPulse and S4 tPause TIG pulses, pulse and break time adjustment..........3/16

3.9.5.1 S3 tPulse pulse time ........................................................................3/16

3.9.5.2 S4 tPause Pulse break ....................................................................3/16

3.9.5.3 Example of settings for the pulse and pulse break times ................3/16

3.10 Programming of the torch operation variants .................................................................3/17

3.10.1 Mode 1, standard operation (works setting) with standard TIG torch................3/17

3.10.2 Mode 2, Up/Down operation for standard torches with a rocker .......................3/17

3.10.3 Mode 3, Up/Down operation for standard torches with two triggers..................3/18

3.10.4 Setting the Up/Down speed...............................................................................3/18

3.11 Returning the machine to the works settings..................................................................3/18

3.12 JP13, JP14 and JP15: Configure welding torch connection...........................................3/19

3.13 TRITON 400/500 interface for mechanised MIG/MAG welding (option)........................3/20

Table of contents Page

Inhalt/2

4 Quick start – the shortest way to welding..............................................................................4/1

5 Commissioning .........................................................................................................................5/1

5.1 Area of application............................................................................................................5/1

5.1.1 TRITON 260.........................................................................................................5/1

5.1.2 TRITON 400/500 .................................................................................................5/1

5.2 Setting up the welding machine........................................................................................5/1

5.3 Mains connection..............................................................................................................5/1

5.3.1 Reconnecting the mains voltage 400/415V and 440/460V..................................5/1

5.4 Welding machine cooling system .....................................................................................5/2

5.5 Workpiece lead, general...................................................................................................5/2

5.6 Connection groups............................................................................................................5/2

5.7 MMA welding ....................................................................................................................5/2

5.7.1 Electrode holder...................................................................................................5/2

5.7.2 Workpiece lead ....................................................................................................5/3

5.8 TIG welding.......................................................................................................................5/3

5.8.1 Welding torch, general.........................................................................................5/3

5.8.1.1 Standard TIG torch.............................................................................5/4

5.8.1.2 TIG Up/Down or TIG potentiometer welding torch.............................5/4

5.8.2 Shielding gas supply (shielding gas cylinder to the welding machine)................5/4

5.8.3 Workpiece lead ....................................................................................................5/4

5.9 MIG/MAG welding (option) ...............................................................................................5/5

5.9.1 TRITON 260 ........................................................................................................5/5

5.9.1.1 Supply to the wire feed unit................................................................5/5

5.9.1.2 Workpiece lead ..................................................................................5/5

5.9.2 TRITON 400/500..................................................................................................5/5

5.9.2.1 Supply to the wire feed unit................................................................5/6

5.9.2.2 Workpiece lead ..................................................................................5/6

5.10 Cooling unit function specification ....................................................................................5/6

5.10.1 Coolant error........................................................................................................5/6

6 Maintenance and care...............................................................................................................6/1

7 Operating problems, causes and remedies ...........................................................................7/1

8 Spare parts list ..........................................................................................................................8/1

8.1 TRITON 260 spare parts list.............................................................................................8/1

8.2 TRITON 400/500 spare parts list......................................................................................8/4

9 Accessories, options................................................................................................................9/1

9.1 TRITON 260......................................................................................................................9/1

9.1.1 Standard TIG torch...............................................................................................9/1

9.1.2 TIG Up/Down torch ..............................................................................................9/1

9.1.3 Electrode holder /workpiece lead.........................................................................9/1

9.1.4 Remote control / connection cable.......................................................................9/1

9.1.5 Miscellaneous accessories ..................................................................................9/1

9.2 TRITON 400/500...............................................................................................................9/2

9.2.1 Standard TIG torch...............................................................................................9/2

9.2.2 TIG Up/Down torch ..............................................................................................9/2

9.2.3 Electrode holder /workpiece lead.........................................................................9/2

9.2.3.1 TRITON 400.......................................................................................9/2

9.2.3.2 TRITON 500.......................................................................................9/2

9.2.4 Remote control / connection cable.......................................................................9/2

9.2.5 Miscellaneous accessories ..................................................................................9/2

10 Circuit diagrams......................................................................................................................10/1

10.1 TRITON 260....................................................................................................................10/1

10.2 TRITON 400/500.............................................................................................................10/3

Safety instructions

S/1

For Your Safety

Ignoring the following safety precautions can be fatal.

Observe accident prevention regulations.

Designed use

This machine is manufactured according to the current state of the art and current regulations and

standards. It is to be operated only for the designed use (see Chap. Commissioning/Area of

application).

Use not as designed

This machine may be a hazard to persons, animals and property, however, if it is

• not used as designed

• used by unskilled persons who have not been trained,

• mod ified or co nv er ted im properly

Our operating instructions will provide you with an introduction into the safe use of the

machine.

Therefore please read them closely and only start work when you are familiar with them.

Any person involved in operation, maintenance and repair of this machine must read and follow

these operating instructions, especially the safety precautions. Where appropriate, this must be

confirmed by signature.

Furthermore, the

• relevant accident prevention regulations,

• generally recognized safety regulations,

• regionally specific provisions etc. are to be adhered to.

Electric shocks can be fatal

• The machine may only be connected to correctly earthed sockets.

• Only operate with intact connection lead including protective conductor and safety plug.

• An improperly repaired plug or damaged mains cable insulation can cause electric

shocks.

• The machine may only be opened by qualified and authorised personnel.

• Before opening, pull out the mains plug. Switching off is not sufficient. Wait for 2

minutes until capacitors are discharged.

• Always put down welding torch, stick electrode holder in an insulated condition.

• The machine must not be used to defrost pipes.

Even touching low voltages can cause you to jump and lead to accidents, so:

• Safeguard yourself against falls, e.g. from a platform or scaffolding.

• When welding, operate earth tongs, torch and workpiece properly, not in ways for

which they are not intended. Do not touch live parts with bare skin.

• Only replace electrodes when wearing dry gloves.

• Never use torches or earth cables with damaged insulation.

Safety instructions

S/2

Smoke and gases can lead to breathing difficulties and poisoning.

• Do not breathe in smoke and gases.

• Ensure that there is sufficient fresh air.

• Keep solvent vapours away from the arc radiation area. Chlorinated hydrocarbon fumes

can be converted into poisonous phosgene by ultraviolet radiation.

Workpiece, flying sparks and droplets are hot

• Keep children and animals well away from the working area. Their behaviour is

unpredictable.

• Move containers with inflammable or exposive liquids away from the working area.

There is a danger of fire and explosion.

• Never heat explosive liquids, dusts or gases by welding or cutting. There is also a

danger of explosion if apparently harmless substances in closed containers are able to

build up excess pressure when they are heated.

Take care to avoid fire hazards

• Any kind of fire hazards must be avoided. Flames can form e.g. when sparks are flying,

when parts are glowing or hot slag is present.

• A constant check must be kept on whether fire hazards have been created in the

working area.

• Highly inflammable objects, such as matches and cigarette lighters for example, must

not be carried in trouser pockets.

• You must ensure that fire extinguishing equipment - appropriate to the welding process

- is available close to the welding work area and that easy access is possible.

• Containers in which fuels or lubricants have been present must be thoroughly cleaned

before welding begins. It is not sufficient simply for the receptacle to be empty.

• After a workpiece has been welded, it must only be touched or brought into contact

with inflammable material when it has cooled down sufficiently.

• Loose welding connections can completely destroy protective conductor systems of

interior installations and cause fires. Before beginning welding work, ensure that the

earth tongs are properly fixed to the workpiece or welding bench and that there is a

direct electrical connection from the workpiece to the power source.

Noise exceeding 70 dBA can cause permanent hearing damage

• Wear suitable earmuffs or plugs.

• Ensure that other people who spend time in the working area are not inconvenienced

by the noise.

Secure gas cylinder

• Place shielding gas cylinders in the holders provided for them and secure with safety

chains.

• Take care when handling cylinders; do not throw or heat, guard against them toppling

over.

• When moving by crane, take off the gas cylinder from the welding machine.

Safety instructions

S/3

Interference by electrical and electromagnetic fields is possible e.g. from the welding

machine or from the high-voltage pulses of the ignition unit.

• As laid down in Electromagnetic Compatibility Standard EN 50199, the machines are

intended for use in industrial areas; if they are operated e.g. in residential environments

problems can occur in ensuring electromagnetic compatibility.

• The functioning of heart pacemakers can be adversely affected when you are standing

near the welding machine.

• Malfunctioning of electronic equipment (e.g. EDP, CNC equipment) in the vicinity of the

welding location is possible.

• Other mains supply leads, trip leads, signal and telecommunications leads above,

under and near the welding device may be subject to interference.

Electromagnetic interference must be reduced to such a level that it no longer constitutes

interference. Possible redu ctio n m easu res:

• Welding machines should be regularly maintained (see Sect. “Maintenance and care”)

• Welding leads should be as short as possible and run closely together on or near to the

ground.

• Selective shielding of other leads and equipment in the environment can reduce

radiation.

Repairs and modifications may only be carried out by authorised, trained, specialist

personnel. The warranty becomes null and void in the event of unauthorised interference.

Our operating instructions will provide you with an introduction into the safe use of the

machine.

Therefore please read them closely and only start work when you are familiar with them.

Safety instructions

S/4

Transport and set-up

Machines may only be moved and operated in an upright position.

Before moving, pull out mains plug and place on the machine.

Secure high-pressure shielding gas cylinder with safety chain to prevent it from toppling

over.

When setting up the machine, tilt resistance is only guaranteed up to an angle of 15°

(as specified in EN 60974).

Environmental conditions

The welding machine can be operated in a location where there is no risk of explosion at

• an ambient temperature of -10°C (plasma machines 0°C) to +40°C and

• a relative air humidity up to 50% at 40°C.

• where the sur r ou ndi ng air is fr ee of unusual amounts of dust, acids, corrosive gases or

substances etc., insofar as they do not occur during welding.

Examples of unusual operating condition s:

Unusual corrosive smoke, vapour, excessive oil vapour, unusual vibrations or jolts, excessive

quantities of dust such as grinding dust etc., severe weather conditions, unusual conditions near

the coast or on board ship.

• When setting up the machine, ensure that air inle ts and outlets are unobstructed.

The machine is tested to Protection Standard IP23, i.e.:

• Protection against penetratio n of sol id for e ign bod ie s ∅ > 12mm,

• Protection against water spray up to an angle of 60° to the vertical.

Notes on the use of these operating instructions

These operating instructions are arranged in Sections.

To help you find your way around more quickly, in the margins you will occasionally see, in addition

to sub-headings, icons referring to particularly important passages of text which are graded as

follows depending on their importance:

(Note): Applies to special technical characteristics which the user must note.

(Warning): Applies to working and operating procedures which must be followed

precisely to avoid damaging or destroying the machine.

(Caution): Applies to working and operating procedures which must be followed

precisely to avoid endangering people and includes the “Warning” symbol.

Instructions and lists detailing step-by-step actions in given situations can be recognised by bullet

points, e.g.:

• Insert plug of welding current lead into socket (Sect . 5, G2) and lock.

Meaning of the diagram descript io ns:

e.g. (C1) means: Item C / Figure 1 in the respective Section

e.g. (Sect. 3, C1) means: in Section 3 Item C / Figure 1

1 Technical data

1/1

1.1 TRITON 260

TRITON 260

Setting range:

Welding current / voltage

TIG,

MMA

MIG/MAG

5A/ 10.2V – 260A/ 20.4V

5A/ 20.2V – 230A/ 29.2V

5A/ 14.3 – 240A/ 26V

Max. welding current at TIG MMA MIG/MAG

20ºC ambient temperature: 50%DC

60%DC

100%DC

40ºC ambient temperature: 25%DC

35%DC

60%DC

100%DC

260A

240A

190A

260A

230A

170A

130A

230A

210A

160A

230A

200A

150A

110A

240A

220A

170A

240A

210A

160A

120A

Load alternation

10min (60% DC

∧

6 min welding, 4min break)

Open circuit voltage 93V

Mains voltage (tolerances) 3 x 400V (-25% - +15%)

3 x 415V (-25% - +10%)

Frequency 50/60 Hz

Mains fuse (safety fuse - slow-blow) 3 x 16A

Mains connection lead 4 x 1.5mm2

Max. connected power 10.8kVA

Recommended generator rating 14.6kVA

cosϕ / efficiency

0.99 / 89%

Insulation class / Protection

classification

H / IP 23

Ambient temperature

-10°C to +40°C

Machine cooling / Torch cooling Fan / Gas

Workpiece lead 35mm2

Dimensions L/W/H [mm] 560 x 245 x 365

Weight approx. 24.5Kg

constructed to standard

IEC 60974 / EN 60974 / VDE 0544

EN 50199 / VDE 0544 Teil 206

/

1 Technical data

1/2

1.2 TRITON 400/500

TRITON 400 TRITON 500

Setting range:

Welding current / voltage

TIG,

MMA

MIG/MAG

5A/ 10,2V - 400A/ 26,0V

5A/ 20,2V - 400A/ 36,0V

5A/ 14,3V - 400A/ 30,0V

5A/ 10.1V -500 A/ 30.0V

5A/ 20.1V -500A/ 40.0V

5A/ 14.2V -500A/ 39.0V

Duty cycle at 40°C ambient temperature:

40%dc

60%dc

100%dc

Duty cycle at 20°C ambient temperature:

40%dc

45%dc

60%dc

65%dc

100%dc

400A

360A

300A

-

400A

360A

300A

500A

450A

340A

500A

-

475A

-

390A

Load alternation

10min (60% DC

∧

6 min welding, 4min break)

Open circuit voltage 92V 79V at 400V

91V at 460V

Mains voltage (tolerances) 3 x 400V (-25% - +20%)

3 x 460V (-25% - +15%)

3 x 400V (-25% - +20%)

3 x 460V (-25% - +15%)

3 x 415V (-25% - +10%)

Frequency 50/60 Hz

Mains fuse (safety fuse - slow-blow) 3 x 35A

Mains connection lead 4 x 4mm2

Max. connected power 21,5kVA 29 kVA

Recommended generator rating 29,0kVA 39.2kVA

cosϕ / efficiency

0.99 / 89%

Insulation class / Protection

classification

H / IP 23

Ambient temperature

-10°C to +40°C

Machine cooling / Torch cooling Fan / Gas

Workpiece lead 70mm2 95mm2

Dimensions L/W/H [mm] 625 x 335 x 560

Weight approx. 55kg approx. 58Kg

constructed to standard

IEC 60974 / EN 60974 / VDE 0544

EN 50199 / VDE 0544 Teil 206

/

2 Description of the machine

2/1

2.1 TRITON 260

2.1.1 Front view

A1

B1

C1

D1

E1

F1

G1

L1

H1

I1

J1

K1

K1

Fig. 2/1, Front view

Item Symbol Description

A1

Carrying handle

Carrying strap (no illustr.)

B1

Operating elements (see control T101, chap. 3.1)

C1

5-pole connection socket: Standard TIG torch control lead

D1

8-pole connection socket: TIG Up/Down or potentiometer torch control lead

E1

Welding current socket (welding current potential "+"):

MMA welding: Workpiece or electrode holder connection,

TIG welding: Workpiece connection,

MIG/MAG welding: Welding current connection to the WF unit or

workpiece connection

F1

Welding current socket (welding current potential "-"):

MMA welding: Workpiece or electrode holder connection

G1

19-pole connection socket: Remote control connection

H1

Welding current socket (welding current potential "-"):

TIG welding: Welding current connection for welding torch

MIG/MAG welding: Welding current connection to the WF unit or

workpiece connection

I1

Connecting nipple G¼ (welding current potential"-")

Shielding gas connection to the welding torch

J1

Air inlet

K1

Rubber feet

L1

MIG/MAG operating elements (option), see chap. 3.1.1

2 Description of the machine

2/2

2.1.2 Rear view

A2

B2

C2

D2

E2

F2

G2

H2

I2

Fig. 2/2, Rear view

Item Symbol Description

A2

8-pole connection socket cooling unit control lead

B2

0

1

Main switch

Welding machine and where appropriate cooling module "On/Off"

C2

Mains connection cable

D2

7-pole connection socket wire feed unit control lead

E2

Connecting nipple G¼ shielding gas connection to the pressure reducer

F2

Types of ignition changeover switch

HF

: Welding with HF ignition.

HF

: Welding with Liftarc.

G2

Changeover switch characteristics

Changing between each of two characteristics in the welding processes

MMA: rutile / basic

MIG/MAG: solid / cored wire

H2

4-pole connection socket cooling unit voltage supply

I2 Air outlet

2 Description of the machine

2/3

2.2 TRITON 400/500

2.2.1 Front view

A3

B3

C3

D3

E3

F3

G3

O3

H3

I3

L3

M3

N3

N3

Fig. 2/3, Front view

Item Symbol Description

A3

carrying handle

B3

0

1

Main switch

Welding machine and where appropriate cooling module "On/Off"

C3

Operating elements (see control T101, chap. 3.1)

D3

5-pole connection socket: TIG standard torch control lead

E3

8-pole connection socket: TIG Up/Down or potentiometer torch control lead

F3

Air inlet

G3

19-pole connection socket: Remote control connection

H3

Connecting nipple G¼ (welding current potential"-")

Shielding gas connection to the welding torch

I3

Welding current socket (welding current potential "-"):

TIG welding: Welding current connection for welding torch

MIG/MAG welding: workpiece connection

L3

Welding current socket (welding current potential "-"):

MMA welding: Workpiece or electrode holder connection

M3

Welding current socket (welding current potential "+"):

MMA welding: Workpiece or electrode holder connection,

TIG welding: workpiece connection

N3

Rubber feet

O3

MIG/MAG operating elements (option), see chap. 3.1.2

2 Description of the machine

2/4

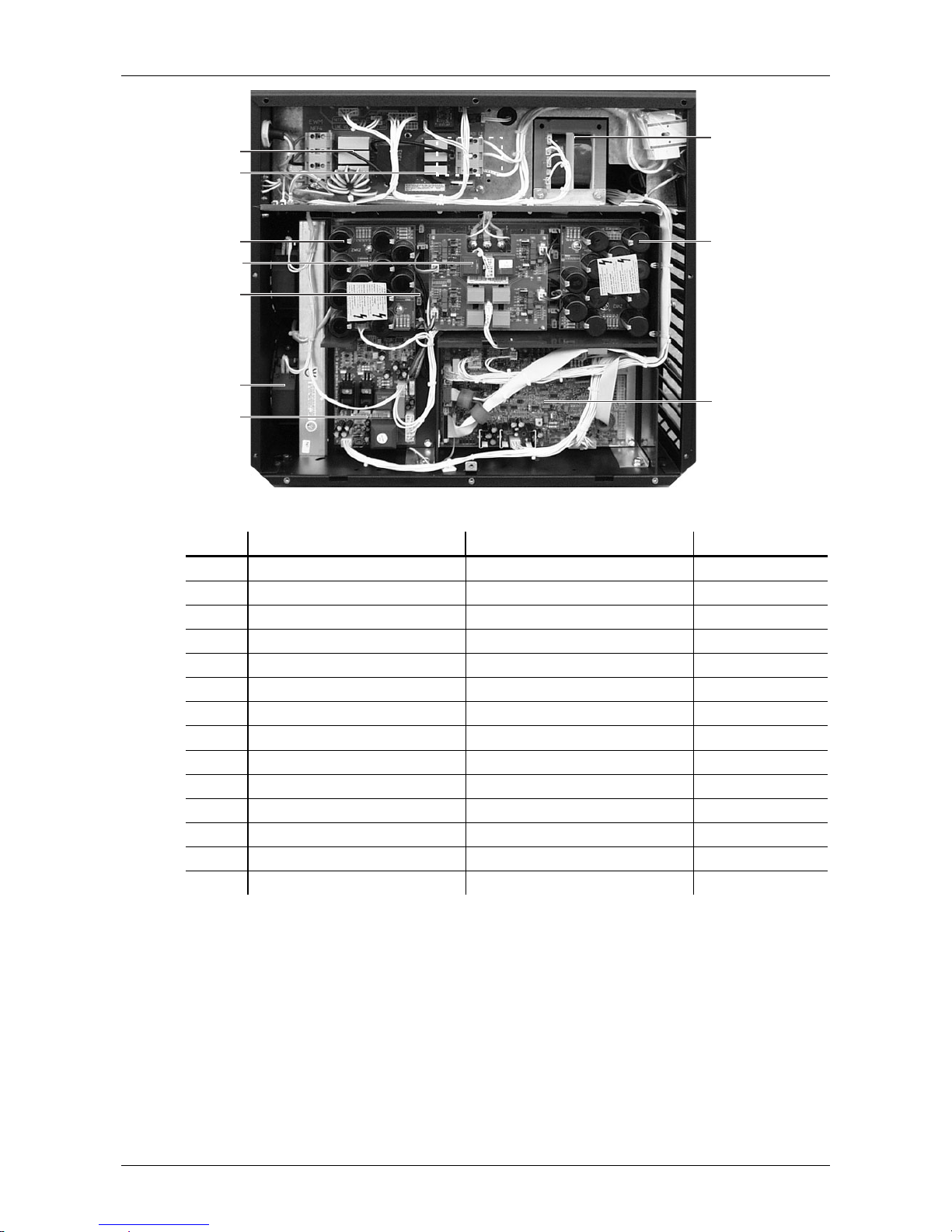

2.2.2 Rear view

A4

B4

D4

F4

J4

K4

L4

I4

E4

Fig. 4/2, Rear view

Item Symbol Description

A4

7-pole connection socket wire feed unit control lead

B4

8-pole connection socket cooling unit control lead

D4

Connecting nipple G¼ shielding gas connection to the pressure reducer

E4

Welding current socket - ; WF connection

F4

Welding current socket +

I4

Mains connection cable

J4

4-pole connection socket cooling unit voltage supply

K4

Types of ignition changeover switch

HF

: Welding with HF ignition.

HF

: Welding with Liftarc.

L4 Air outlet

3 Function specification

3/1

3.1 Operating elements, control T101

AMP

AMP

Puls

VOLT

T101

AMP

AMP %

sec

0

25

50

75

100

0

5

10

15

20

0

5

10

15

20

sec

S

Arcforce

R

u

t

i

l

C

e

l

l

B

a

s

E1

F1

D1

C1

B1

A1

G1

J1

N1

K1

L1

M1

H1

I1

Fig. 3/1: Control T101

Item Symbol Description

A1

Changeover switch MMA / TIG welding process

= MMA welding

= TIG welding

The changeover switch (A2) must be switched to

TIG

MMA

TIG / MMA welding

B1

Puls

TIG pulse /standard welding changeover switch

= TIG pulse

= TIG standard welding

C1

AMPAMP

VOLT

Digital display changeover switch

AMP = welding current display

VOLT = welding voltage display

D1

Digital display (lights up when machine is ready)

Displays the welding voltage or welding current, depending on the switch

position (C1)

E1

Non latched / latched operating mode changeover switch

= non-latched

= latched

F1

AMP

"AMP" signal light

Open-circuit or welding voltage on

G1

AMP

"AMP" rotary dial

Infinite adjustment of the welding current from 5A to maximum current

H1

AMP %

25

50

75

0 100

"AMP%" rotary dial

The secondary current "AMP%" is infinitely adjustable in per cent of the main

current "AMP" (G1). During the welding process, it is possible to switch from the

main current

to the secondary current set at any time using the 2nd torch trigger

(for further operating variants see 3.2.4 TIG welding torch operating variants) .

3 Function specification

3/2

Item Symbol Description

I1

10

sec

0

5 15

20

Gas post-flow time rotary dial

The gas post-flow time is infinitely adjustable from 1 to 20 sec.

J1

Red LED (collective interference)

If the collective interference LED lights up, the power unit is automatically

switched off. Because some interferences are only brief and spurious (e.g.

mains voltage surges), the LED extinguishes again and the welding machine is

ready for welding. If the collective interference LED continues to be lit after an

appropriate waiting time, see the chapter on troubleshooting.

K1

Red LED (low coolant level)

Indicates a low coolant level if the machine is operated with a cooling unit

L1

Yellow LED (excess temperature)

Thermal monitors in the power unit trigger at excess temperature and the

excess temperature indicator lamp lights. Welding can proceed without further

measures after cooling.

M1

10

0

5 15

20

sec

DOWN-SLOPE rotary dial

Lowering time of the main current AMP (G1) to the end-crater current I

end

(minimum current)

infinitely adjustable from 0 to 20 sec.

N1

Arcforce

R

u

t

i

l

C

e

l

l

B

a

s

Applies to MMA welding process only (TRITON 400/500 only)

Selection of arcforcing, rutile, basic or cellulose.

3.1.1 Additional operating elements TRITON 260

GMAW

MIG/MAG

TIG

MMA

- +

1

0

1

22

33

44

A2

B2

Fig. 3/2: Operating elements front view

Item Symbol Description

A2

GMAW

MIG/MAG

TIG

MMA

MIG/MAG or MMA / TIG welding process changeover switch

GMAW

MIG/MAG

= MIG/MAG welding (only possible with WF unit)

TIG

MMA

= TIG or MMA welding, selection on changeover switch (A1)

The welding process is preselected with this changeover switch.

B2

- +

0

1 1

2 2

3 3

4

-

0

1 1

2 2

3 3

4

4+4

Rotary switch Dynamic correction / choke effect setting (for MIG/MAG only)

hard / narrow (+) to soft / wide arc (-)

3 Function specification

3/3

3.1.2 Additional operating elements TRITON 400/500

0,8

1,2...1,6

0,8...1,0

1,2...1,6

0,8...1,0

Arcforce

G3/4Si1

CO 100%

2

G3/4Si1

Ar/Mix

FCAW

CrNi

1,0...1,6

1,0...1,6

Al/Cu

R

u

t

i

l

C

e

l

l

B

a

s

MIG/MAG

GMAW

TIG

MMA

GMAW

MIG/MAG

- +

1

0

1

22

33

44

A3

B3

C3

Fig. 3/3: Operating elements front view

Item Symbol Description

A3

GMAW

MIG/MAG

TIG

MMA

MIG/MAG or MMA / TIG welding process changeover switch

GMAW

MIG/MAG

= MIG/MAG welding (only possible with WF unit)

TIG

MMA

= TIG or MMA welding, selection on changeover switch (A1)

The welding process is preselected with this changeover switch.

B3

- +

0

1 1

2 2

3 3

4

-

0

1 1

2 2

3 3

4

4+4

Rotary switch Dynamic correction / choke effect setting (for MIG/MAG

only)

hard / narrow(+) to soft / wide arc(-)

C3

Does not apply to TIG welding

1. Inner scale, MMA welding:

Selection of arcforcing, rutile, basic or cellulose.

2. Outer scale; MIG/MAG welding

Setting of the welding task according to

the material, wire diameter and type of gas.

3 Function specification

3/4

3.2 TIG welding, general

If welding is performed alternately by different methods, e.g. TIG, MIG/MAG or MMA and if

one or two welding torches and an electrode holder are connected to the machine, the

open-circuit/welding voltage is applied simultaneously to both!

Therefore, always place the torch and the electrode holder on an insulated surface before

starting work and during breaks.

3.2.1 Types of ignition:

HF ignition

The arc is started without contact by high-voltage ignition pulses.

Liftarc

The arc is ignited with contact with the workpiece:

a) The torch gas nozzle must be placed with its rim on the ignition point such that there is a gap of

approx. 2-3 mm between the electrode tip and the workpiece.

b) Carefully touch the workpiece with Tungsten electrode tip. Press torch trigger in accordance

with the operating mode selected.

c) The arc ignites when the torch is lifted off and swivelled into its normal position.

Fig. 3/3: Liftarc

3.2.2 Automatic shut-off

If ignition of the arc does not occur after starting or if the arc is interrupted when the torch is

moved away, an automatic cut-out occurs after 3 sec. HF, gas and the open circuit voltage

(power unit) are switched off.

3.2.3 Digital display

On the digital display (D1), the welding parameters

• welding current and

• welding voltage are shown.

Whether the welding current or welding voltage is to be displayed is selected on the changeover

switch (C1).

3 Function specification

3/5

3.2.4 TIG welding torch, operating variants

The welding process can be controlled with various torch de signs

(TT=torch trigger):

3.2.4.1 Standard TIG torch, 5-pole connection plug

The welding machine is prepared for these torch types as standard.

Symbol Description Functions Operation with

Welding current On/Off TT 1

Standard TIG torch

Design: 1 trigger

secondary current TT 1 in tapping mode

Welding current On/Off TT 1

secondary current

TT 2

Standard TIG torch

Design: 2 trigger

secondary current TT 1 in tapping mode

Welding current On/Off TT 1 (rocker forwards)

secondary current TT 2 (rocker back)

Standard TIG torch

Design: 2 triggers (MG

rocker)

secondary current TT 1 (rocker forwards)

in tapping mode

Special functions with standard TIG torches such as e.g.

Up/Down operation (see Chapter 3.10)

3.2.4.2 TIG Up/Down torch, 8-pole connection plug

The welding machine is prepared for this torch type as standard.

Symbol Description Functions Operation with

Welding current On/Off TT

secondary current TT in tapping mode

TIG Up/Down torch

Design: 1 trigger +

2 triggers (rocker)

Increase / reduce

welding current

Rocker forwards / rocker back

The last welding current set is stored in the memory and is available after switching on

again.

3.2.4.3 TIG potentiometer torch, 8-pole connection plug

Before commissioning, the welding machine must be converted for this type of torch!

(see Chapter 3.12)

Symbol Description Functions Operation with

Welding current On/Off TT

secondary current TT in tapping mode

TIG potentiometer torch

Design: 1 trigger +

1 wheel (potentiometer)

Increase / reduce

welding current

Turn potentiometer backwards /

forwards

3.2.5 Tapping operating mode.

The tapping mode was included particularly for the secondary current (AMP%) by the use of

a trigger on the welding torch.

Torch with one trigger:

• by tapping (brief pressing and releasing) torch trigger 1

(Repeated tapping switches back to the main current).

Torch with two triggers:

There are two ways of switching to the secondary cu rrent:

• by tapping (see torch with one trigger)

• by pressing down and holding torch trigger 2.

Adjustment:

The "tapping operating mode" can be deactivated on the T101/1 circuit board (see Chap. 3.9.4).

3 Function specification

3/6

3.3 TIG function sequences

In the TIG operating modes, the following welding parameters can be adjusted via rotary dials:

• Main current AMP,

• Secondary current AMP%,

• Down-slope time,

• Gas post-flow time.

Other welding parameters are preadjusted to optimum settings for most applications, but can be

changed internally (see Chapter 3.9).

3.3.1 Explanation of symbols

Symbol Meaning

Press torch trigger 1

Release torch trigger 1

AMP

Main current (5A to maximum current)

AMP% Secondary current (0% to 100% of AMP)

I

start

Ignition current (0% to 100% of AMP, adjustable internally, search arc at minimum

setting))

I

end

End-crater current = minimum current

tUp Up-slope time (adjustable internally)

t

Down

Down-slope time

TIG

MMA

TIG/MMA welding process (preselection for welding process)

TIG welding process

MMA welding process

Standard TIG welding (pulses switched off)

TIG pulses On

Non-latched mode

Latched mode

HF

HF ignition switched on

HF

HF ignition switched off

Gas pre-flows (adjustable internally)

Gas post-flows

3 Function specification

3/7

3.3.2 TIG non-latched operation

• Adjust the appropriate changeover switches to the following settings:

TIG

MMA

HF

When the foot-operated remote control RTF is connected, the machine switches

automatically to non-latched operation. The Up- and Down-slopes are switched off.

I

I

start

AMP

t

Up

1. 2.

t

Down

I

end

t

Fig. 3/4: Function sequence of TIG non-latched operation

1st step:

• Press and hold torch trigger 1.

• The gas pre-flow time passes.

• HF ignition pulses jump from the electrode to the workpiece, the arc ignites.

• The welding current flows and immediately assumes the value set for the ignition current I

start

.

• HF is switched off.

• The welding current increases in the adjusted Up-slope time to the main current AMP.

2nd step:

• Release torch trigger 1.

• The main current falls in the adjusted Down-slope time to the end-crater current I

end

(minimum

current).

• The main current reaches the end-crater current I

end

, the arc extinguishes.

• The gas post-flow time set passes.

If the 1st torch trigger is pressed during the Down-slope time, the welding current returns to

the main current AMP set.

3 Function specification

3/8

3.3.3 TIG latched operation

• Adjust the appropriate changeover switches to the following settings:

TIG

MMA

HF

When the foot-operated remote control RTF is connected, the machine switches

automatically to non-latched operation. The Up- and Down-slopes are switched off.

I

I

start

AMP

I

end

t

Up

t

Down

t

AMP%

1. 2. 3. 4.

Fig. 3/5: TIG latched function sequence

Step 1

• Press torch trigger 1, the gas pre-flow time passes.

• HF ignition pulses jump from the electrode to the workpiece, the arc ignites.

• Welding current flows and immediately assumes the ignition current value set (search arc at

minimum setting). HF is switched off.

Step 2

• Release torch trigger 1.

• The welding current increases in the adjusted Up-slope time to the main current AMP.

(Secondary current AMP% see Chap. 3.1)

Changeover from the main current AMP to the secondary current AMP%:

• Press torch trigger 2 or

• Tap torch trigger 1 (tapping mode see also Chap. 3.2.4)

Step 3

• Press torch trigger 1.

• The main current falls in the adjusted Down-slope time to the end-crater current I

end

(minimum

current).

4

th

step

• Release torch trigger 1, the arc extinguishes.

• The gas post-flow time set begins.

Immediate termination of the welding procedure without Down-slope and end-crater

current:

• Briefly press the 1st torch trigger (3rd and 4th step).

The current falls to zero and the gas post-flow time begins.

3 Function specification

3/9

3.4 TIG pulses, function sequences

The machines have an integrated TIG pulse device as standard.

Entering the pulse parameters:

• Pulse current = main current AMP,

• Break current = secondary current AMP%.

The times for the pulse and break current are pre-set at 0.3 sec ex works and can be

changed internally (see Chap. 3.9.5)

TIG pulses can also be realized with the pulse remote controls RTP1 and RTP2.

The function sequences of TIG pulses are principally the same as for standard TIG welding.

As soon as the arc has ignited, the current switches to and from between the pulse current

and pause current with particular times.

When the foot-operated remote control RTF is connected, the machine switches

automatically to non-latched operation. The Up- and Down-slopes are switched off.

See the explanation of symbols under Chap. 3.3.1.

3.4.1 TIG pulses - non-latched operation

• Adjust the appropriate changeover switches to the following settings:

TIG

MMA

HF

AMP%

I

I

start

AMP

I

end

t

Up

t

Down

t

1. 2.

Fig. 3/6: TIG pulses non-latched function sequence

3 Function specification

3/10

3.4.2 TIG pulses - latched operation

• Adjust the appropriate changeover switches to the following settings:

TIG

MMA

HF

I

I

start

AMP

I

end

t

Up

t

Down

t

AMP%

1. 2. 3. 4.

Fig. 3/7: TIG latched function sequence

3.5 MMA welding

If welding is performed alternately by different methods, e.g. TIG, MIG/MAG or MMA and if

one or two welding torches and an electrode holder are connected to the machine, the

open-circuit/welding voltage is applied simultaneously to both!

Therefore, always place the torch and the electrode holder on an insulated surface before

starting work and during breaks.

• Adjust the appropriate changeover switches to the following settings:

TIG

MMA

This machine has the following features in electrode operation:

Arcforcing

Shortly before the electrode threatens to stick, the arcforcing device sets an increased current

designed to impede sticking of the electrode. The value of the current increase depends on the

arcforce setting. Excellent welding properties are achieved with all difficult electrodes by adjustable

arcforcing.

Hotstart

The hotstart device has the effect of better ignition of the stick electrodes by an increased ignition

current.

Antistick

If the stick electrode sticks in spite of the arcforcing device, the machine automatically switches

over to the minimum current within about 1 sec, so that overheating of the electrode is prevented. If

the antistick device has responded, check the main current setting and if necessary correct it.

3.5.1 TRITON 260 adjustable arcforcing

Two arcforcing settings can be selected on the characteristics changeover switch (Chap. 2,

G2) on the rear of the machine:

• Characteristics 1: BASIC (welding with stick electrodes enveloped with basic

material),

• Characteristics 2: RUTILE (welding with stick electrodes enveloped with rutile),

3 Function specification

3/11

3.5.2 TRITON 400/500 adjustable arcforcing

Adjustment at 8 levels is possible before and during the welding operation.

Settings are made on the inner scale:

"Rutile" setting::

Low arcforcing ⇒ gentle arc,

little increased current before short-circuit.

Used with stick electrodes enveloped with rutile.

"Bas" setting:

Moderate arcforcing ⇒ normal arc,

moderate increased current before short-circuit.

Used with stick electrodes enveloped with basic material.

"Cell" setting:

High arcforcing ⇒ hard arc,

high increased current before short-circuit.

Used with cellulose stick electrodes.

3.6 MIG/MAG welding (Option)

If welding is performed alternately by different methods, e.g. TIG, MIG/MAG or MMA and if

one or two welding torches and an electrode holder are connected to the machine, the

open-circuit/welding voltage is applied simultaneously to both!

Therefore, always place the torch and the electrode holder on an insulated surface before

starting work and during breaks.

• To be able to use the MIG/MAG welding process, a wire feed unit must be connected.

The MIG/MAG function sequences are described in the operating instructions of the wire

feed unit.

• Adjust the appropriate changeover switches to the following settings:

GMAW

MIG/MAG

• Adjust further settings on the WF unit.

3.6.1 TRITON 260

In MIG/MAG welding, only the following operating and display elements on the welding

machine are active:

• The digital display,

• the welding voltage or current changeover switch display (C1),

• the characteristics changeover switch (Chap. 2, G2) on the rear of the welding machine:

Characteristics 1: 0.8-1.0 MIG/MAG GMAW (welding with steel wire),

Characteristics 2: 0.9-1.2 FCAW (welding with cored wire),

• Rotary switch Dynamic correction / choke effect setting.

3 Function specification

3/12

3.6.2 TRITON 400/500

In MIG/MAG welding, only the following operating and display elements on the welding

machine are active:

• The digital display (D1),

• the welding voltage or current changeover switch display (C1),

• the roatry dial characteristic line (B3),

• Rotary switch Dynamic correction / choke effect setting.

8 permanently programmed characteristic lines are stored for MIG/MAG welding. These can

be called up in 8 levels.

The type of material, wire diameter and type of gas are stored in one characteristic line.

Setting is with the aid of the outer scale and can be done before the welding operation.

Characteri-

stic line

number

Material Wire

diameter

(mm)

Type of

gas

1

FCAW (cored wire)

0.9 – 1.2

2

G3/4Si1 (low-alloy steel)

0.8 – 1.0

Ar/Mix

3

G3/4Si1 (low-alloy steel)

1.2 – 1.6

Ar/Mix

4

G3/4Si1 (low-alloy steel)

0.8 – 1.0

CO

2

100%

5

G3/4Si1 (low-alloy steel)

1.2 – 1.6

CO

2

100%

6

CrNi (high-alloy steel)

0.8

various

7

CrNi (high-alloy steel)

1.0 – 1.6

various

8

Al/Cu (aluminium or

copper alloys)

1.0 – 1.6

Ar 100%

3 Function specification

3/13

3.7 Remote control

Only the remote controls described in these operating instructions should be connected.

Plug in and lock the remote control to the remote control connection socket only, and only

when the welding machine is switched off (chap. 2.1.1, G1 for TRITON 260 and chap. 2.2.1,

G3 for TRITON 400/500). The remote control must never be connected to a wire feed unit.

See the operating instructions for the remote control for more detailed information.

Foot-operated remote control RTF 1 Manual remote control RT1

Functions:

• Welding current "ON/OFF"

(switches on after the pedal

has been pressed).

• Infinitely adjustable welding

current (in %) depending on

the preselected main

current or I

1

of the welding

machine.

Functions:

• Infinitely adjustable welding

current (in %) depending on

the welding current I

1

preselected on the welding

machine.

When the foot-operated remote control

RTF 1 is connected, the machine

switches automatically to non latched

operation. Up- and Down-Slope will be

switched off.

RTP 1 manual remote control RTP 2 manual remote control

RT P 1

t1t

1

I1I

1

I1I

1

I2I

2

t1t

1

t2t

2

0

50

75

100250

25

50

75

100

t (sek)2t (sek)

2

0,05

0,5

1

1,5

2

t (sek)1t (sek)

1

x10

0,05

0,5

1

1,5

2

I1I

1

I2I

2

I1I

1

(%AMP)

(% I )

1

(% I )

1

I2I

2

Functions:

• TIG / MMA

• Pulse / spot / normal

• The percentage settings

of the main and

secondary current

depending on the

preselected welding

current I

1

of the welding

machine.

• Pulse, spot and break

times are infinitely

adjustable.

RT P 2

t1t

1

I1I

1

0

50

75

100250

25

50

75

100

2,5

5

7,5

10

12,5 15

Hz

sec

x10

x100

x10

x100

x0,1x1x0,1

x1

17,5

20

22,5

25

Balance%Balance

%

10

30

50

70

90

250-2500

0,25-2,5

0,25-2,5

25-250

2,5-25

2,5-25

Hz / secHz /

I

1I1

I2I

2

Hz

I1I

1

I2I

2

I1I

1

(% AMP)

(% I )

1

(% I )

1

I2I

2

Functions:

• TIG / MMA

• Pulse / spot / normal

• The percentage settings of

the main and secondary

current depending on the

preselected welding current I

1

of the welding machine.

• Frequency and spot times

infinitely adjustable.

• Coarse adjustment of the

cycle frequency.

• Pulse/break ratio (balance)

adjustable from 10% to 90%.

• For remote controls RTP 1 and RTP 2, adjust the following settings on the appropriate

changeover switch:

TIG

MMA

3 Function specification

3/14

3.8 TIG interface for mechanised welding (remote control connection

socket)

The welding current sources feature a very high standard of safety.

This safety standard is also retained when peripheral equipment is connected for automatic

welding if this peripheral equipment fulfils the same criteria, particularly with regard to their isolation

from the mains supply.

This is ensured by the use of transformers according to VDE 0551.

The welding machines are equipped for automated operation as standard.

For automated applications, control inputs and a galvanically isolated relay contact are avail ab le at

the remote control connection socket (TRITON 260; Chap. 2, G1); TRITON 400/500; Cha p. 2,

G3).

Interface for mechanised welding

19 pole connection socket (TRITON 260; Chap.2, G1); TRITON 400/500; Chap. 2, G3):

• Pin A Output: Connection for cable screen.

• Pin B/L Output: Current relay contact (I>0) to the user (galvanically isolated)

maximum load +/- 15 V / 100 mA.

• Pin F Output: Potentiometer reference voltage 10 V, max. 10 mA.

• Pin K Output: Power supply +15 V, max. 75 mA.

• Pin V Output: Power supply -15V V, max. 25mA mA.

• Pin C Input: Nominal value for main current, 0-10V (0V = I

min

, 10V = I

max

)

• Pin D Input: Nominal value for secondary current, 0-10V (0V = I

min

, 10V = I

max

).

• Pin J/U Output: 0V

• Pin R Input: Start / stop.

• Pin H Input: Switching between main and secondary current.

• Pin S Input: Switching between MMA and TIG operation.

• Pin M/N/P Input: Nominal value identification.

• Pin G Output: I

nominal

0-10V

Cable screenCable screen

10V/max.10mA

A

B

L

F

C

D

E

T

S

V

K

U

J

R

H

M

N

P

G

I>0I > 0

Nc

Nc

0V

+15V/75mA

-15V/25mA

Start/Stop

Tig / MMATig

/ MMA

Pulser I / I

HL

Pulser I/I

HL

FR-Typ1

FR-Typ2

FR-Typ3

I

NOMINAL

Start Stop MMA / TIG

Secondary

Current I

L

Secondary

Current

I

L

I

L H

I

Main

Current I

H

Main

Current

I

H

PE

10k10k

Nominal Value

Identification.

Nominal

Value

Identification.

Nominal value identification.Nominal

value identification.

External Nominal

Values

For

Main Current Active

External Nominal

Values

For

Main

Current Active

External Nominal Values For

Main Current

0-10V

External Nominal Values For

Main

Current 0-10V

External Nominal Values For

Secondary Current

0-10V

External Nominal Values For

Secondary

Current 0-10V

External Nominal Value

For Main

And

Secondery Current Active

External Nominal Value

For

Main And

Secondery

Current Active

Fig. 3/8: Interface for mechanised welding, 19-pole

3 Function specification

3/15

3.9 Welding parameter adjustments "internally"

The welding parameters are preadjusted to optimum settings for most applications, changes are

only necessary for special applications.

The welding parameters can be changed on the T101 circuit board in the welding machine.

Explanation of symbols

Symbol Meaning

Jumper open

:

Jumper closed

Turn trimmer to the right

Turn trimmer to the left

Bestückungsdruck (044-442395-00002)

IWIGmax

IELmax

tPause

tPuls

Istart

tUP

Frontplatte

Dynamikerw.Dynamik-Schalter

V/A-Meter

Brenner

Dynamik

MIG ein/aus

Peripherie

Erw.

Fernreg.

Prog.

Inv.Steuersatz

02

EWM

T101

V53

C98

C97

C96

C95

C94

C93

C92

C91

C90

C89

C88

C87

C86

C85

C84

P10

P2

P1

V70

V43

D17

D14

C83

C82

R214

R213

R212

JP7

R211

S4 S3

S2

S1

K1

R210

R209R208

V69

V68

V67

V66V65

V64

V63V62

V61

JP10

JP18

V60

V59

R207

JP17

V58

V57

R206

R205

C81

R204

V56

D21

V55

R203 C80

R201

R199

R198

P11

P12

R195

R194

R193

C79

R191

R190

V52

C78

C77

R189 R188

R187

C76

C75

R186

X7

1

X12

2431

10

9

X10

2

1

10

9

X11

2

1

R185

D20

R184

V51

V50

R183

R182

C74

R181

R180

C73

R179

D19

C72

JP16

1

V49

V48

V47

R178

V46

V45

R177

R176

10

9

X2

2

1

R175

C71

C70 C69

Q4

D18

C68

C67

JP14

JP15

R174

C66

R173

R172

N6

D16

C65

R171

R170

R169

V44

C64

R168

R167

R166

C63

R165

R164

R163

V42

C62

R162

R161

R160

V41

D15

C61

R159

R158

R157

V40

V39

R156

R155

R154

C60

R153

V38

JP13 1

R152

R151

R150

C59

L10

L9

L8L7

C58

C57

L6

L5

L4

C56

C55

RX6

RX5

RX4

RX3

+

C54

+

C53

RX2

M4

M3

M2

M1

M0

RX1

+

C52

10

9

X9

2

1

L3

L2

V37

L1

C51

R148R146

R145

V36

R139

R138

C50

R137

R136

V35

R135

V34

C49

R134

V33

V32

V31

R133

R132

R131

R130

V30

C48

R129

R128

R127

V29

C47

R126

R125

R124

V28

C46

R123

R122

R121

V27

C45

R120

R119

R118

D13

V26

C44

R117

R116

R115

V25

C43

R114

R113

R112

V24

C42

R111

R110

R109

D12

V23

R108

C41

R107

R106

V22

R105

R104

V21

C40

R103

JP5

V20

V19

R102

R101

V18

R100

R99

R98

R97

V15

V17

V16

R96

R95

C39C38

Q3

C37

D11

D3

D7

R94

D10

R93

R92R91

C36

R90

R89R88

C35

R87

R86

R85

C34

R84

R83

R82

C33

R81

C32

R80

R79

R78

R77

R76

V14

C31

LED2

R74

R73

P9

V13

R71

16

15

X8

2

1

X6

12

7

6

1

R70

R69

V12

JP12

C30

R68

D9

D8

R67

R66

N5

R65

R64

R63

R62

R61

R60

R59

R58

C29

Q2 C28

V11

C27

R57

R56

C26

R55

R54

R53

R52

C25

C24

C23

D6

R51

V10

C22

R50

JP11

R49

R48

C21

C20

C19

C18

D5

R47

R46

R45

R44

R43

R42

C17

V9

R41

26

25

X1

21

N4

V8

R40

P4

R38

R37

R36

R35

D1

D4

D2

R34

R33

R32

R31

R30

P6

P5

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C14

C15

16

15

X3

2

1

X4

18

10

9

1

X5

12

7

6

1

V7

C13

C16

LED1

R18

N2

N3

N1

Q1

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12

R13

R14

R15

R16

R17

R21

R22

R24

R25R26

R27

V6

P3

V1

V2

V3

V4

V5

P10

S3

tPuls

S4

tPause

JP16

JP5

P2

tUP

JP15

JP14

JP13

P1

Istart

Fig. 3/9: T101 screen printed PCB

3.9.1 P10: Gas pre-flow time

The gas pre-flow time is infinitely adjustable from 0 to 5 sec (works setting 0.2 sec).

Function Setting

Increase gas pre-flow time

Reduce gas pre-flow time

3 Function specification

3/16

3.9.2 P1 I-start: Ignition current

The ignition current is infinitely adjustable from 0% to 100% of the main current AMP (G1) (works

setting 30%)

Function Setting

Increase ignition current

Reduce ignition current

(search arc in 0% position)

3.9.3 P2 t-UP: Up-slope time

Current increase from the ignition current I

start

to the value of the main current AMP (G1) infinitely

adjustable from 0 to 5 sec (works setting 0.1 sec).

Function Setting

Increase Up-slope time

Reduce Up-slope time

3.9.4 JP5: Switching between normal or tapping operation

(works setting tapping operation)

Operating mode configuration Setting

Tapping released : JP5

Tapping blocked JP5

3.9.5 S3 tPulse and S4 tPause: TIG pulses, pulse and break time adjustment

Switch position

0/1 2/3 4/5 6/7 8/9

A/B C/D E/F

Time [sec]

0.1 0.3 0.5 0.7 0.9 1.1 1.3 1.5

Table 1: Coding switch

3.9.5.1 S3 tPulse: Pulse time (works setting 0.3 sec)

The pulse time can be adjusted from 0.1 sec to 1.5 sec in 0.2 sec steps on coding switch S3 (see

table 1)

3.9.5.2 S4 tPause: Pulse break (works setting 0.3 sec)

The pulse break can be adjusted from 0.1 sec to 1.5 sec in 0.2 sec steps on coding switch S4 (see

table 1)

3.9.5.3 Example of settings for the pulse time and pulse break

Requirement: The pulse time should be 1.1 sec and the break time 0.5 sec:

• Coding switch S3 must be switched to position A or B,

• Coding switch S4 must be switched to position 4 or 5,

3 Function specification

3/17

3.10 Programming of the torch operation variants

The user can select the following functions (TT=torch trigger):

• Operating modes standard TIG welding torch with 5-pole connector plug

Mode1: Operation with standard TIG torch, welding current on/off,

no Up/Down function (MG rocker or separate TT)

Mode2: Up-Down operation with standard TIG torch (MG rocker)

Mode3: Up-Down operation with standard TIG torch (2 separate TT)

• Changing Up-Down speed.

The function is selected with the torch triggers on the welding torch

(does not apply to standard TIG torches with one TT, see also Chap. 3.10.4).

3.10.1 Mode1, standard operation (works setting) with standard TIG torch

Design: 2 trigger

Symbol Functions Operation with

Welding current On/Off TT 1

secondary current TT 2

secondary current TT 1 in tapping mode

Design: (MG rocker)

Welding current On/Off TT 1 (rocker forwards)

secondary current TT 2 (rocker back)

secondary current TT 1 (rocker forwards)

in tapping mode

Programming Mode1:

• Switch off the machine and wait approx. 3 sec.

• Set the main current rotary dial (G1) to maximum.

• Press and hold torch triggers 1 and 2 at the same time.

• Switch on the machine Î Display (D1) indicates maximum current.

• Release both torch triggersÎ Display (D1) indicates minimum current.

• Torch trigger 2: press 1x.

• Press torch trigger 1 Î the mode is stored in the memory Î the half-maximum current is

displayed.

• Switch off the machine, wait approx. 3 sec and switch on again Î machine ready in mode 1.

3.10.2 Mode 2, Up/Down operation for standard torches with a rocker

Design: 2 triggers (MG rocker)

Symbol Functions Operation with

Welding current On/Off TT 1+2 simultaneously

UP function: TT 1 (rocker forwards)

Down function: TT 2 (rocker back)

secondary current TT 1+2

in tapping mode

Programming Mode2:

• Switch off the machine and wait approx. 3 sec.

• Set the main current rotary dial (G1) to maximum.

• Press and hold torch triggers 1 and 2 at the same time.

• Switch on the machine Î Display (D1) indicates maximum current.

• Release both torch triggersÎ Display (D1) indicates minimum current.

• Press torch trigger 2 2x.

• Press torch trigger 1 Î the mode is stored in the memory Î the half-maximum current is

displayed.

• Switch off the machine, wait approx. 3 sec and switch on again Î machine ready in mode 2.

3 Function specification

3/18

3.10.3 Mode 3, Up/Down operation for standard torches with two triggers

Design: 2 trigger

Symbol Functions Operation with

Welding current On/Off TT 1

secondary current TT 1 in tapping mode

Up/Down function

Down = press and hold

Up = tap and hold

TT 2

Programming Mode3:

• Switch off the machine and wait approx. 3 sec.

• Set the main current rotary dial (G1) to maximum.

• Press and hold torch triggers 1 and 2 at the same time.

• Switch on the machine Î Display (D1) indicates maximum current.

• Release both torch triggersÎ Display (D1) indicates minimum current.

• Press torch trigger 2 3x

• Press torch trigger 1 Î the mode is stored in the memory Î the half-maximum current is

displayed.

• Switch off the machine, wait approx. 3 sec and switch on again Î machine ready in mode 3.

3.10.4 Setting the Up/Down speed

This adjustment applies both to the standard TIG torches (5-pole),

and to the Up/Down torches (8-pole).

It is possible to select 3 changing speeds of the Up-Down function:

• Up-Down speed=1 (rapid current changing speed)

• Up-Down speed=2 (moderate current changing speed)

• Up-Down speed=3 (slow current changing speed)

Programming Up/Down speed:

• Switch off the machine and wait approx. 5 sec.

• Set the main current rotary dial (G1) to maximum.

• Press and hold torch triggers 1 and 2 at the same time.

• Switch on the machine Î Display (D1) indicates maximum current.

• Release both torch triggersÎ Display (D1) indicates minimum current.

• Press torch trigger 1 1 to 3x, depending on the Up/Down speed required.

• Press torch trigger 2 Î the mode is stored in the memory Î the maximum current is displayed.

• Switch machine off and on again Î programmed Up/Down speed is programmed.

3.11 Returning the machine to the works settings

Necessary if the machine has been changed to Up/Down function but no standard TIG torch

with a trigger is available at the moment.

Switch off machine > plug in jumper JP16 > switch on machine > switch off machine > remove

jumper JP16.

After resetting the machine, it has the works settings with the following values:

• Up-Down value at maximum (100% of AMP)

• Up-Down mode = 1 (i.e. Up-Down function for standard TIG torches is switched off)

• Up-Down speed = 2 (i.e. moderate current changing speed)

3 Function specification

3/19

3.12 JP13, JP14 and JP15: Configure welding torch connection

When connecting a potentiometer torch, the following jumpers must be change d inside the welding

machine (see fig. 3.9):

Welding torch configuration Setting

Prepared for TIG standard or Up-Down torch (works setting) : JP13 JP14 : JP15

Prepared for potentiometer torches JP13 : JP14 JP1 5

3 Function specification

3/20

3.13 TRITON 400/500 interface for mechanised MIG/MAG welding

(option)

The welding current sources feature a very high standard of safety.

This safety standard is also retained when peripheral equipment is connected for automatic

welding if this peripheral equipment fulfils the same criteria, particularly with regard to their isolation

from the mains supply.

This is ensured by the use of transformers according to VDE 0551.

The welding machines are equipped for automated operation as standard.

For automated applications, control inputs and galvanically isolated relay contacts are available on

the machine connection sockets.

Use only shielded control leads!

Interface for mechanised welding

Pin Input / Output Designation

A

Output Connection for cable screen

B Output +Iactual (10V = 1000A welding current)

C Input Interface for mechanised welding ON (relay with 0V)

D/E/F Input Selection of welding process*

G/S Output 0V

H Output Power supply +15 V, max. 75 mA

J/U Input Fixed-wire

L Output +Uactual (10V = 100V welding voltage)

M Input UnominalAU

(2V to 10V = 10V to 50V welding voltage)

N Input Nominal value input for WF, 0-10V

(0V = 0.5m/min, 10V = 24m/min wire feed speed)

P Input Start signal of machine (relay with 0V)

R Output Reference voltage 10 V, max. 10 mA.

T Output Power supply -15V , max. 25mA

V Output Current relay contact (I>0) to the user (galvanically isolated)

maximum load +-15V / 100 mA

Interface for mechanised

welding, Pin

*Selection of

welding

characteristic line

(see Chap. 3.6.2)