Conversion instructions

GB

Retrofit option

ON NETSYNCHRON

Observe additional system documents!

099-008212-EW501 14.03.2011

General instructions

CAUTION

Read the operating instructions!

The operating instructions provide an introduction to the safe use of the products.

• Read the operating instructions for all system components!

• Observe accident prevention regulations!

• Observe all local regulations!

• Confirm with a signature where appropriate.

In the event of queries on installation, commissioning, operation or special conditions at the

installation site, or on usage, please contact your sales partner or our

customer service department on +49 2680 181-0.

Liability relating to the operation of this equipment is restricted solely to the function of the equipm ent. No other

form of liability, regardless of type, shall be accepted. This exclusion of liability shall be deemed accepted by the

user on commissioning the equipment.

The manufacturer is unable to monitor whether or not these instructions or the conditions and methods are

observed during installation, operation, usage and maintenance of the equipment.

An incorrectly performed installation can result in material damage and injure persons as a result. For this reason,

we do not accept any responsibility or liability for losses, damages or costs arising from incorrect installation,

improper operation or incorrect usage and maintenance or any actions connected to this in any way.

© EWM HIGHTEC WELDING GmbH · Dr. Günter-Henle-Str. 8 · D-56271 Mündersbach, Germany

The copyright to this document remains the property of the manufacturer.

Reprinting, including extracts, only permitted with written approval.

Subject to technical amendments.

A list of authorised sales partners can be found at www.ewm-group.com.

NOTE

1 Contents

1

Contents..................................................................................................................................................3

2 Overview .................................................................................................................................................4

2.1 For your safety...............................................................................................................................4

2.2 Proper usage .................................................................................................................................5

2.3 Short description of the working steps required ............................................................................5

3 Conversion .............................................................................................................................................6

3.1 Parts list.........................................................................................................................................7

3.2 Installing the PCB ..........................................................................................................................8

3.2.1 Tetrix 351 AC/DC ...........................................................................................................8

3.2.2 Tetrix 451, 551 AC/DC .................................................................................................11

3.3 Installing the rotary switch at the back of the machine................................................................13

4 Final inspection....................................................................................................................................14

5 Appendix...............................................................................................................................................15

5.1 Circuit diagram.............................................................................................................................15

Contents

For your safety

099-008212-EW501

14.03.2011

3

Overview

For your safety

2 Overview

2.1 For your safety

Do not carry out any unauthorised repairs or modifications!

To avoid injury and equipment damage, the unit must only be repaired or modified by

specialist, skilled persons!

The warranty becomes null and void in the event of unauthorised interference.

• Appoint only skilled persons for repair work (trained service person nel)!

Validity of this document!

This document is only valid in combination with the operating instructions for the

power source being used (welding machine)!

• Read the operating instructions, in particular the safety instructions for the power source

(welding machine)!

Risk of accidents if these safety instructions are not observed!

Non-observance of these safety instructions is potentially fatal!

• Carefully read the safety information in this manual!

• Observe the accident prevention regulations in your country.

• Inform persons in the working area that they must observe the regulations!

CAUTION

Obligations of the operator!

The respective national directives and laws must be observed for operation of the

machine!

• National implementation of the framework directive (89/391/EWG), as well as the

associated individual directives.

• In particular, directive (89/655/EWG), on the minimum regulations for safety and health

protection when staff members use equipment during work.

• The regulations regarding work safety and accident prevention for the re spective country.

• Setting up and operating the machine according to IEC 60974-9.

• Check at regular intervals that users are working in a safety-conscious wa y.

• Regular checks of the machine according to IEC 60974-4.

DANGER

WARNING

4

099-008212-EW501

14.03.2011

2.2 Proper usage

WARNING

Hazards due to improper usage!

Hazards may arise for persons, animals and material objects if the equipment is not

used correctly. No liability is accepted for any damages arising from improper usage!

• The equipment must only be used in line with proper usage and by trained or expert staff!

• Do not modify or convert the equipment improperly!

These instructions apply only for the conversion of the following machine s:

• Tetrix 351, 451, 551 AC/DC

2.3 Short description of the working steps required

• Integration of a 6-stage changeover switch in the rear panel of the casing.

• Integration and wiring of PCB TSYN1 in the machine on the intermediate panel.

Overview

Proper usage

099-008212-EW501

14.03.2011

5

Conversion

Short description of the working steps required

3 Conversion

Risk of injury from electric shock!

Servicing machines that are not disconnected from the mains can lead to serious

injuries!

• Disconnect the machine completely from the mains.

• Unplug the mains plug!

• Wait for 4 minutes until the capacitors have discharged!

Protective earth PE!

To protect persons and animals against dangerous live voltages and electric shocks in

the event of a fault, the casing panels on the unit are connected to a green/yellow

protective earth.

• After conversion, re-connect the protective earth to the casing panels!

CAUTION

Damage to the machine due to missing circuit diagrams when connecting the

accessories!

Wiring the accessories has to follow the machine's circuit diagrams at all times!

• The circuit diagrams can be found in the machine (document pouch on the casing cover)

and may also be included in these conversion instructions!

DANGER

6

099-008212-EW501

14.03.2011

3.1 Parts list

NOTE

Before conversion, check that the retrofit kit is complete (see parts list).

Tetrix 351 AC/DC as an example:

Conversion

Parts list

Figure 3-1

Item 0 Quantity Description Item number

1 1 PCB TSYN1 040-000676-00000

2 1 Flat band cable D-SUB 094-007494-00002

3 4 Thread bolt M4 x 8 mm 044-003002-00000

4 4 Spacer M4 x 35 mm 044-002151-00000

5 4 M4 expanding anchor 094-006502-00000

6 1 PCB holder 094-016978-00000

7 1 Adhesive base 074-000159-00000

8 1 Edge protection 094-007643-00000

9 1 Earthing cable (PE) 094-016979-00000

10 1 Toroidal ferrite core (interference suppression) 034-000157-00000

11 4 Cable binder 044-001275-00000

12 1 Flat band cable 094-000003-00000

13 1 Rotary switch (assembly) 092-008178-00000

14 1 Adhesive film (rotary switch) 094-009599-00000

15 4 Oval-head screw M3x10 044-001414-00001

none 1 Circuit diagram

099-008212-EW501

14.03.2011

7

Conversion

Installing the PCB

3.2 Installing the PCB

• Unscrew right-hand casing cover.

3.2.1 Tetrix 351 AC/DC

• Remove the earth cable from the cover plate.

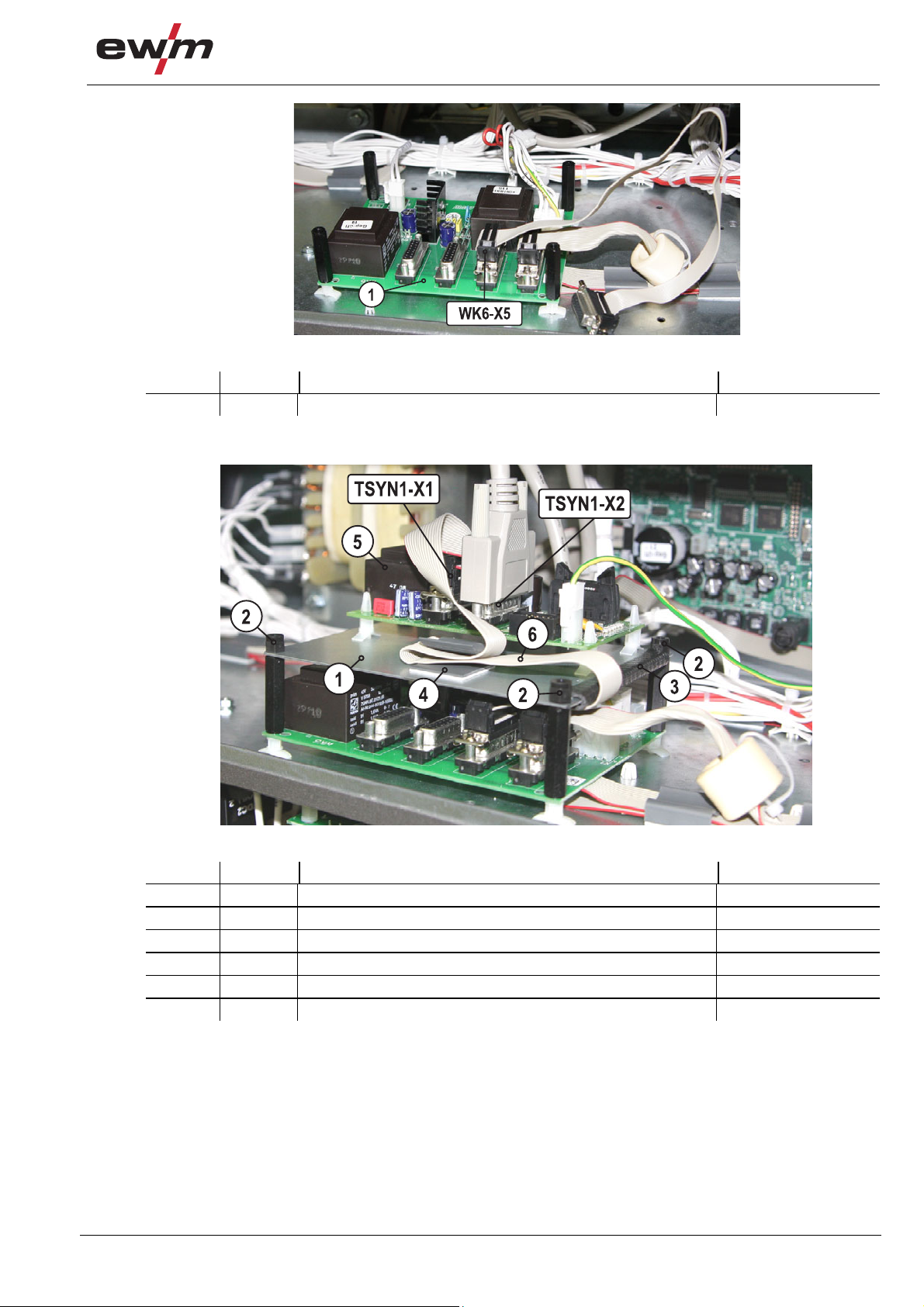

Figure 3-2

Item 0 Quantity Description Item number

1 1 PCB WK 6 2 1 D-SUB cable -

• Remove the D-SUB cable from the WK 6 PCB.

Figure 3-3

Item 0 Quantity Description Item number

1 1 PCB WK 6 2 4 M4 expanding anchor 094-006502-00000

3 4 Spacer M4 x 35 mm 044-002151-00000

• Unfasten the WK 6 PCB from the expanding anchors.

• Replace expanding anchor (without threaded end fitting) with M4 expanding anchor (with threaded end

fitting).

• Attach the WK 6 PCB to the M4 expanding anchors (with threaded end fitting).

• Secure the WK 6 PCB using M4 x 35 mm spacers.

8

099-008212-EW501

14.03.2011

Conversion

Figure 3-4

Item 0 Quantity Description Item number

1 1 PCB WK 6 -

• Attach the D-SUB connection of the flat band cable to the WK6-X5 PCB and screw tight.

Installing the PCB

Item 0 Quantity Description Item number

1 1 PCB holder 094-016978-00000

2 4 Thread bolt M4 x 8 mm 044-003002-00000

3 1 Edge protection 094-007643-00000

4 1 Adhesive base 074-000159-00000

5 1 PCB TSYN1 040-000676-00000

6 1 Flat band cable D-SUB 094-007494-00002

• Attach the PCB holder to the M4 x 35 mm spacers using M4 x 8 mm stud bolts.

• Attach the edge protection to the PCB holder.

• Attach the adhesive base to the PCB holder.

• Attach the D-SUB connection of the flat band cable to the TSYN1-X1 PCB and screw tight (secure the

cable in the adhesive base).

• Reattach the D-SUB cable of the WK 6 PCB to the TSYN1-X2 PCB and screw tight.

099-008212-EW501

14.03.2011

Figure 3-5

9

Conversion

Installing the PCB

Figure 3-6

Item 0 Quantity Description Item number

1 1 Rotary switch (assembly) 092-008178-00000

2 1 Flat band cable 094-000003-00000

3 1 Toroidal ferrite core (interference suppression) 034-000157-00000

4 4 Cable binder 044-001275-00000

5 1 Earthing cable (PE) 094-016979-00000

• Insert the flat band cable connector plug through the toroidal ferrite core and secure usin g a cable

binder.

• Lay the flat band cable to the TSYN1-X3 PCB, insert and lock.

• Connect the earthing cable of the TSYN1-PE PCB to the PE earthing contact on the intermediate

plate.

• Secure the harness using the cable binder supplied

10

099-008212-EW501

14.03.2011

3.2.2 Tetrix 451, 551 AC/DC

Conversion

Installing the PCB

7

6

4

3

2

TSYN1-X1

TSYN1-X2

5

1

Figure 3-7

Item 0 Quantity Description Item number

1 4 M4 expanding anchor 094-006502-00000

2 1 PCB holder 094-016978-00000

3 4 Spacer M4 x 35 mm 044-002151-00000

4 1 Edge protection 094-007643-00000

5 4 Spacer 064-000567-00000

6 1 PCB TSYN1 040-000676-00000

7 1 Flat band cable D-SUB 094-007494-00002

• Attach the M4 expanding anchor to the intermediate plate.

• Secure the PCB holder to the M4 expanding anchor using the M4 x 35 mm spacer.

• Insert the spacer into the PCB holder.

• Fit the TSYN1 PCB on the spacer.

• Attach the edge protection to the PCB holder.

• Attach the D-SUB connection of the flat band cable to the TSYN1-X2 PCB and screw tight.

• Attach the D-SUB connection of the flat band cable of the WK 6 PCB to the TSYN1-X1 PCB and

screw tight.

099-008212-EW501

14.03.2011

11

Conversion

Installing the PCB

1

2

4

5

3

TSYN1-X3

PE

TSYN1-PE

Figure 3-8

Item 0 Quantity Description Item number

1 1 Rotary switch (assembly) 092-008178-00000

2 1 Flat band cable 094-000003-00000

3 1 Toroidal ferrite core (interference suppression) 034-000157-00000

4 2 Cable binder 044-001275-00000

5 1 Earthing cable (PE) 094-016979-00000

• Insert the flat band cable connector plug through the toroidal ferrite core and secure usin g a cable

binder.

• Lay the flat band cable to the TSYN1-X3 PCB, insert and lock.

• Connect the earthing cable of the TSYN1-PE PCB to the PE earthing contact on the intermediate

plate.

• Secure the harness using the cable binder supplied

12

099-008212-EW501

14.03.2011

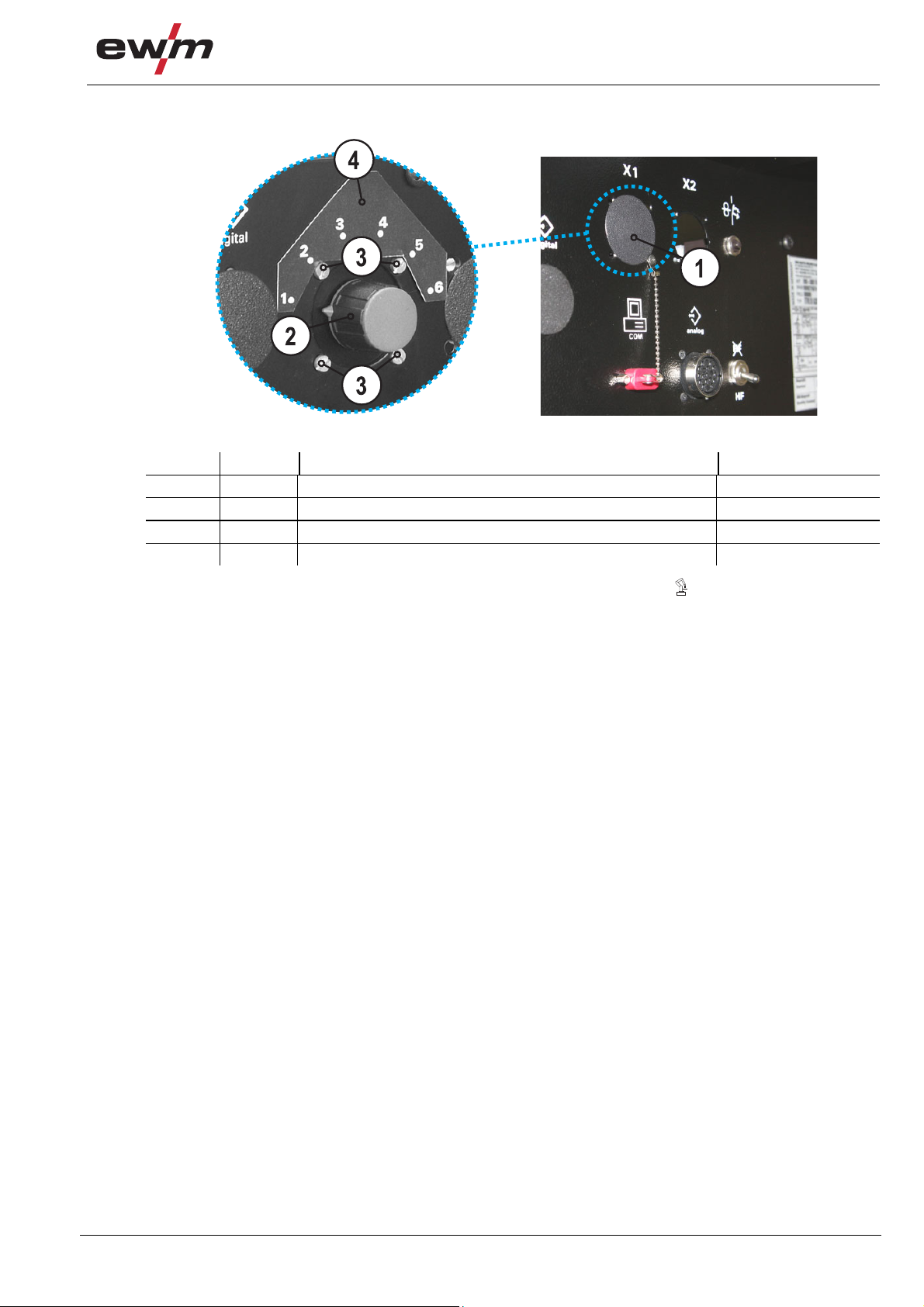

Installing the rotary switch at the back of the machine

3.3 Installing the rotary switch at the back of the machine

Figure 3-9

Item 0 Quantity Description Item number

1 1 Blind plug

2 1 Rotary switch (assembly) 092-008178-00000

3 4 Oval-head screw M3x10 044-001414-00001

4 1 Adhesive film (rotary switch) 094-009599-00000

• Remove the blind plug from the X1 connection (with older machines, the symbol may be shown

instead of X1).

• Remove the rotary dial cover and arrow indicator from the rotary switch.

• Insert the rotary switch from inside the casing rear panel and secure from the outside using the ovalhead screws.

The step switch is equipped with a switching stage limiter nipple, which has to point to the right

during installation.

• Attach the sticker above the rotary switch at the casing rear panel (see figure).

• Reattach the rotary dial and arrow indicator to the rotary switch.

To align the rotary dial with the sticker scale proceed as follows:

• Using a socket wrench, screw the rotary dial tight up to the point that the steps can be switched.

• Turn the rotary dial to the different switch positions to the left until it overwinds.

• Continue turning until the arrow indicator points to position 1 again.

• Screw the rotary dial tight.

• Fit on the rotary dial cover.

• Attach the flat band cable connector plug to the VP13-X1 PCB (rotary switch) and lock.

• Assemble the machine in the reverse order.

Conversion

099-008212-EW501

14.03.2011

13

Final inspection

Installing the rotary switch at the back of the machine

4 Final inspection

Protective earth PE!

To protect persons and animals against dangerous live voltages and electric shocks in

the event of a fault, the casing panels on the unit are connected to a green/yellow

protective earth.

• After conversion, re-connect the protective earth to the casing panels!

Danger due to failure to carry out the final inspection!

After installation or conversion, all mechanical and electrical connections must be

checked for correct installation to avoid any potential injuries.

• No leads or tubes should be squashed or laid on sharp ed ges.

• Check all mechanical connections to ensure that they are fitted correctly!

• Carry out the final inspection!

• Carry out the functional test!

CAUTION

Test!

Before re-commissioning, it is essential that an "inspection and test during operation"

is carried out conforming to IEC / DIN EN 60974-4 "Arc welding devices - inspection and

testing during operation"!

• For detailed instructions, please see the standard operating instruct ions for the welding

machine.

NOTE

• Keep the conversion instructions with the machine documentation!

• When ordering spare parts, ensure that the item number and serial number of the

machine are quoted!

DANGER

WARNING

14

099-008212-EW501

14.03.2011

5 Appendix

5.1 Circuit diagram

X8

X8/2

Appendix

Circuit diagram

7734-00

Zeichnungsnummer:

W K - 6

X4

D-Sub.

15polig

X5

D-Sub.

15polig

od.

X1

X4/10

X4/9

X4/8

X4/7

X4/6

X4/5

X4

X4/4

X4/3

X4/2

X4/1

X6

D-Sub.

15polig

od.

15polig

D-Sub.

Bus Eingang

A1-

Programmierstecker

T S Y N - 1

X7

X2

Bus Ausgang

X5

PE

D-Sub.

15polig

od.

15polig

D-Sub.

or communicated or forwarded to third parties

without our express permission!

NACHRUESTUNG NETSYNCHRON

It may not be reproduced or utilised in any way

This drawing is protected by copyright.

X11/26

-15V

X11/25

-15V

X11/24

+15V

X11/23

+15V

X11/22

+5V1

X11/21

+5V1

X11/20

0V1

X11/19

0V1

X11/18

+10V Uref.

X11/17

+10V Uref.

X11/16

0V-Ana.

X11/15

0V-Ana.

X11/14

OE

X11/13

Ana. C

Ana. B

Ana. A

A2

B2

A1

B1

CLK1

CLK1

A1-X5/

X5/2

X5/1

PE

CS2

CS1

RD1

WR1

X11/9

X11/8

X11/7

X11/6

X11/5

X11/4

X11/3

X11/2

X11/1

D-Sub.

15polig

X11

X11/12

X11/11

Frontplatte

X11/10

X8

Systembus

Datum: Name:

25.01.2011 NIEDENTHAL

11

Blatt: /

gezeichnet:

DETAILZEICHNUNG TETRIX 35X/45X/55X AC/DC

REIBEL

25.01.2011

Änderung-

Änderung-

Änderung-

Änderung-

geprüft von:

Wählschalter

X3

X3/1

X3/2

X3/3

X3/4

X3/5

0°

60°

120°

180°

240°

Ringkern

0°

60°

120°

180°

240°

X1/1

X1/2

X1/3

X1/4

X1/5

X1

1234567

A

X3/6

300°

300°

X1/6

X3/7

NC

NC

X1/7

X3/8

NC

NC

X1/8

8

X3/9

X3/10

+5V

+5V

+5V

+5V

X1/9

X1/10

S1

8pol. Umschalter

A2-

V P 1 3

X2/4

X2/3

X2/2

X2/1

X14/12

X14/11

X14/10

X14/9

X14/8

X14/7

X14/6

X14/5

X14/4

X14/3

X14/2

X14/1

T 3 2 0 / 1

X2

Lüfter

X14

Peripherie

Computer

X7

9polig

D-Sub.

099-008212-EW501

14.03.2011

15

Loading...

Loading...