Operating instructions

EN

Control

T 4.00 - AC/DC Comfort 2.0

099-00T400-EW501

Observe additional system documents!

21.10.2016

Register now

and benefit!

Jetzt Registrieren

und Profitieren!

www.ewm-group.com

*For details visit

www.ewm-group.com

*

General instructions

WARNING

Read the operating instructions!

The operating instructions provide an introduction to the safe use of the products.

• Read and observe the operating instructions for all system components, especially the

safety instructions and warning notices!

• Observe the accident prevention regulations and any regional regulations!

• The operating instructions must be kept at the location where the machine is operated.

• Safety and warning labels on the machine indicate any possible risks.

Keep these labels clean and legible at all times.

• The machine has been constructed to state-of-the-art standards in line with any applicable

regulations and industrial standards. Only trained personnel may operate, service and

repair the machine.

• Technical changes due to further development in machine technology may lead to a

differing welding behaviour.

In the event of queries on installation, commissioning, operation or special conditions at the

installation site, or on usage, please contact your sales partner or our customer service

department on +49 2680 181-0.

A list of authorised sales partners can be found at www.ewm-group.com.

Liability relating to the operation of this equipment is restricted solely to the function of the

equipment. No other form of liability, regardless of type, shall be accepted. This exclusion of

liability shall be deemed accepted by the user on commissioning the equipment.

The manufacturer is unable to monitor whether or not these instructions or the conditions and

methods are observed during installation, operation, usage and maintenance of the equipment.

An incorrectly performed installation can result in material damage and injure persons as a

result. For this reason, we do not accept any responsibility or liability for losses, damages or

costs arising from incorrect installation, improper operation or incorrect usage and maintenance

or any actions connected to this in any way.

© EWM AG

Dr. Günter-Henle-Straße 8

56271 Mündersbach

Germany

The copyright to this document remains the property of the manufacturer.

Copying, including extracts, only permitted with written approval.

The content of this document has been prepared and reviewed with all reasonable care. The information

provided is subject to change; errors excepted.

Contents

Notes on the use of these operating instructions

099-00T400-EW501

21.10.2016

3

1 Contents

1 Contents .................................................................................................................................................. 3

2 For your safety ....................................................................................................................................... 5

2.1 Notes on the use of these operating instructions .......................................................................... 5

2.1.1 Explanation of icons ....................................................................................................... 6

2.2 Part of the complete documentation .............................................................................................. 7

3 Machine control – Operating elements ................................................................................................ 8

3.1 Overview of control sections .......................................................................................................... 8

3.1.1 Control section A ............................................................................................................ 9

3.1.2 Control section B .......................................................................................................... 11

3.1.3 Control section C .......................................................................................................... 12

3.2 Machine display ........................................................................................................................... 13

3.2.1 Setting the welding current (absolute/percentage) ....................................................... 13

3.3 Operating the machine control ..................................................................................................... 14

3.3.1 Main screen .................................................................................................................. 14

3.3.2 Welding power setting .................................................................................................. 14

3.3.3 Welding parameter setting in the operation sequence ................................................. 14

3.3.4 Setting advanced welding parameters (Expert menu) ................................................. 14

3.3.5 Changing basic settings (machine configuration menu) .............................................. 14

4 Welding procedure ............................................................................................................................... 15

4.1 TIG welding .................................................................................................................................. 15

4.1.1 Setting the shielding gas volume (gas test)/rinse hose package ................................. 15

4.1.2 Welding task selection .................................................................................................. 16

4.1.2.1 Recurring welding tasks (JOB 1–7) .............................................................. 17

4.1.3 Tungsten balling function ............................................................................................. 18

4.1.4 AC balance (optimise cleaning effect and penetration characteristics) ....................... 19

4.1.5 AC amplitude balance .................................................................................................. 20

4.1.6 Arc ignition .................................................................................................................... 21

4.1.6.1 HF ignition ..................................................................................................... 21

4.1.6.2 Liftarc ............................................................................................................ 21

4.1.6.3 Automatic cut-out .......................................................................................... 21

4.1.7 Function sequences/operating modes ......................................................................... 22

4.1.7.1 Explanation of symbols ................................................................................. 22

4.1.7.2 Non-latched mode ......................................................................................... 23

4.1.7.3 Latched mode ............................................................................................... 24

4.1.7.4 spotArc .......................................................................................................... 25

4.1.7.5 spotmatic ....................................................................................................... 27

4.1.7.6 Non-latched operation, version C ................................................................. 29

4.1.8 TIG activArc welding ..................................................................................................... 30

4.1.9 TIG antistick .................................................................................................................. 30

4.1.10 Pulse welding ............................................................................................................... 31

4.1.10.1 Automated pulses ......................................................................................... 31

4.1.10.2 Thermal pulsing ............................................................................................. 32

4.1.10.3 Average value pulsing ................................................................................... 34

4.1.10.4 Metallurgical pulsing (kHz pulsing) ............................................................... 35

4.1.10.5 AC special ..................................................................................................... 37

4.1.11 Welding torch (operating variants) ............................................................................... 38

4.1.11.1 Tap torch trigger (tapping function) ............................................................... 38

4.1.12 Torch mode and up/down speed setting ...................................................................... 38

4.1.12.1 Standard TIG torch (5-pole) .......................................................................... 39

4.1.12.2 TIG up/down torch (8-pole) ........................................................................... 41

4.1.12.3 Potentiometer torch (8-pole) ......................................................................... 43

4.1.12.4 Configuring the TIG potentiometer torch connection .................................... 44

4.1.12.5 RETOX TIG torch (12-pole) .......................................................................... 45

4.1.13 Up/down operation in modes 4 and 14 ......................................................................... 46

4.1.14 Alternating current waveforms ...................................................................................... 47

4.1.15 Ramp function .............................................................................................................. 48

Contents

Notes on the use of these operating instructions

4

099-00T400-EW501

21.10.2016

4.1.15.1 Foot-operated remote control responsiveness.............................................. 48

4.1.15.2 RTF 1 foot-operated remote control .............................................................. 49

4.1.16 Automatic AC frequency ............................................................................................... 50

4.1.17 AC commutation optimisation ....................................................................................... 51

4.1.18 Simultaneous welding on both sides, synchronisation types ....................................... 51

4.1.19 Synchronisation via mains voltage (50Hz / 60Hz) ........................................................ 51

4.1.20 Expert menu (TIG) ........................................................................................................ 52

4.1.21 Aligning the cable resistance ........................................................................................ 54

4.2 MMA welding ................................................................................................................................ 56

4.2.1 Welding task selection .................................................................................................. 56

4.2.2 Hotstart ......................................................................................................................... 57

4.2.2.1 Hotstart current .............................................................................................. 57

4.2.2.2 Hotstart time .................................................................................................. 57

4.2.3 Arcforce ......................................................................................................................... 58

4.2.4 Antistick ......................................................................................................................... 58

4.2.5 Welding current polarity reversal (polarity reversal) ..................................................... 58

4.2.6 Pulse welding ................................................................................................................ 59

4.2.7 Average value pulse welding ........................................................................................ 60

4.3 Filler wire welding ......................................................................................................................... 61

4.3.1 Configuring the welding machine for mechanical arc fusion welding ........................... 61

4.3.1.1 Selecting a welding task by means of the JOB list ....................................... 61

4.3.1.2 Select wire speed operating mode (KORREKTUR / MANUELL).................. 61

4.3.1.3 Setting the welding current and wire speed .................................................. 61

4.3.2 Function sequences/operating modes .......................................................................... 62

4.3.2.1 Explanation of symbols ................................................................................. 62

4.3.2.2 Non-latched mode ......................................................................................... 63

4.3.2.3 3-cycle operation ........................................................................................... 64

4.3.2.4 Latched mode ................................................................................................ 64

4.4 Power-saving mode (Standby) ..................................................................................................... 65

4.5 Access control .............................................................................................................................. 65

4.6 Voltage reducing device ............................................................................................................... 65

4.7 Machine configuration menu ........................................................................................................ 65

4.7.1 Selecting, changing and saving parameters................................................................. 65

5 Rectifying faults .................................................................................................................................... 71

5.1 Warnings (power source) ............................................................................................................. 71

5.2 Error messages (power source) ................................................................................................... 72

5.3 Resetting welding parameters to the factory settings .................................................................. 74

5.4 Display machine control software version .................................................................................... 74

6 Appendix A ............................................................................................................................................ 75

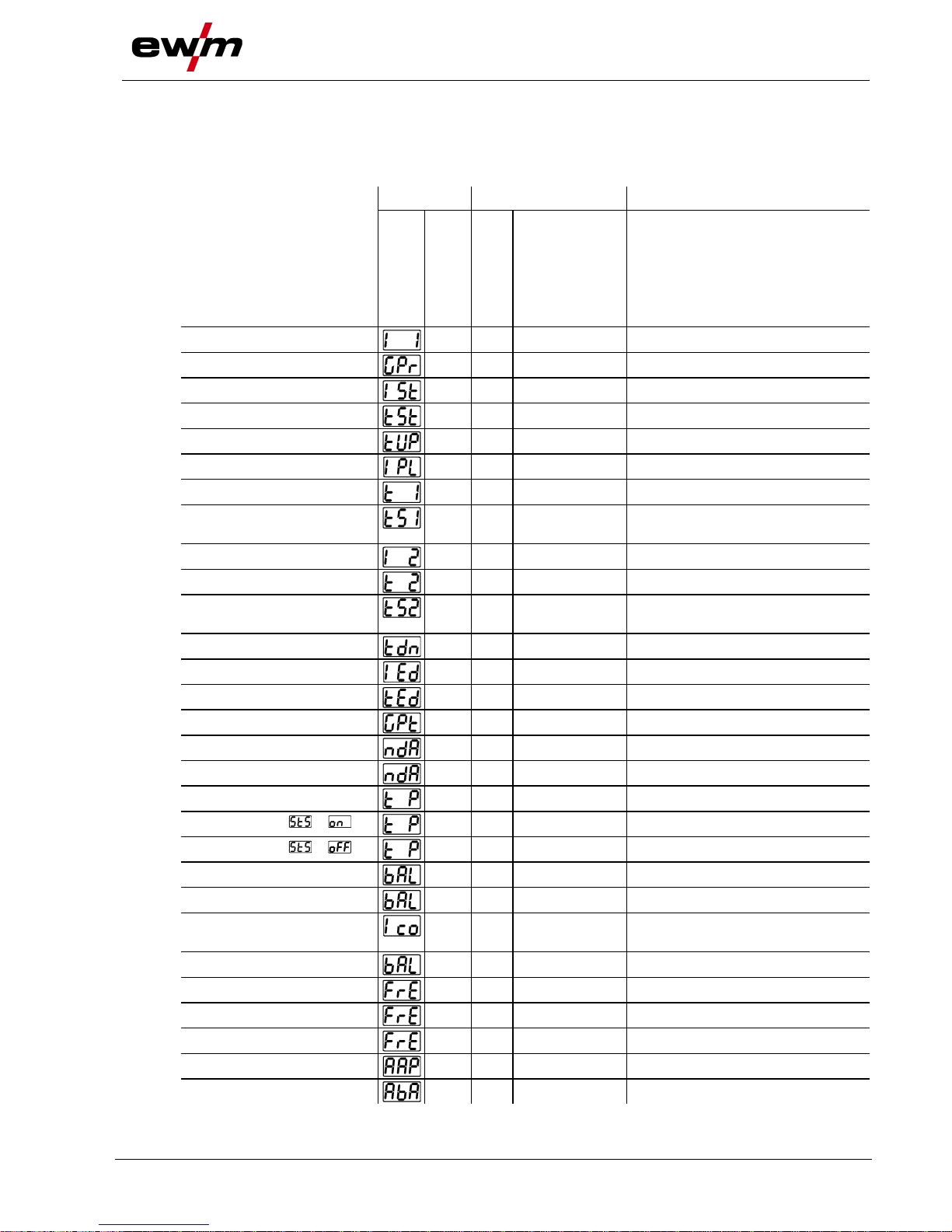

6.1 Parameter overview – setting information .................................................................................... 75

6.1.1 TIG welding ................................................................................................................... 75

6.1.2 MMA welding ................................................................................................................ 76

7 Appendix B ............................................................................................................................................ 77

7.1 Overview of EWM branches......................................................................................................... 77

For your safety

Notes on the use of these operating instructions

099-00T400-EW501

21.10.2016

5

2 For your safety

2.1 Notes on the use of these operating instructions

DANGER

Working or operating procedures which must be closely observed to prevent imminent

serious and even fatal injuries.

• Safety notes include the "DANGER" keyword in the heading with a general warning symbol.

• The hazard is also highlighted using a symbol on the edge of the page.

WARNING

Working or operating procedures which must be closely observed to prevent serious

and even fatal injuries.

• Safety notes include the "WARNING" keyword in the heading with a general warning

symbol.

• The hazard is also highlighted using a symbol in the page margin.

CAUTION

Working or operating procedures which must be closely observed to prevent possible

minor personal injury.

• The safety information includes the "CAUTION" keyword in its heading with a general

warning symbol.

• The risk is explained using a symbol on the edge of the page.

Special technical points which users must observe.

Instructions and lists detailing step-by-step actions for given situations can be recognised via bullet

points, e.g.:

• Insert the welding current lead socket into the relevant socket and lock.

For your safety

Notes on the use of these operating instructions

6

099-00T400-EW501

21.10.2016

2.1.1 Explanation of icons

Symbol

Description

Symbol

Description

Indicates technical aspects which the

user must observe.

Activate and release/tap/tip

Switch off machine

Release

Switch on machine

Press and keep pressed

Switch

Wrong

Turn

Correct

Numerical value – adjustable

Menu entry

Signal light lights up in green

Navigating the menu

Signal light flashes green

Exit menu

Signal light lights up in red

Time representation (e.g.: wait

4 s/activate)

Signal light flashes red

Interruption in the menu display (other

setting options possible)

Tool not required/do not use

Tool required/use

For your safety

Part of the complete documentation

099-00T400-EW501

21.10.2016

7

2.2 Part of the complete documentation

These operating instructions are part of the complete documentation and valid only in

combination with all other parts of these instructions! Read and observe the operating

instructions for all system components, especially the safety instructions!

The illustration shows a general example of a welding system.

Figure 2-1

Item

Documentation

A.1

Options conversion instructions

A.2

Power source

A.3

Cooling unit, voltage converter, tool box etc.

A.4

Transport cart

A.5

Welding torch

A.6

Remote control

A.7

Control

A

Complete documentation

Machine control – Operating elements

Overview of control sections

8

099-00T400-EW501

21.10.2016

3 Machine control – Operating elements

3.1 Overview of control sections

For description purposes, the machine control has been divided into three sections (A, B, C) to

ensure maximum clarity. The setting range for the parameter values are summarised in the

parameter overview section > see 6.1 chapter.

Figure 3-1

Item

Symbol

Description 0

1 Control section A

> see 3.1.1 chapter

2 Control section B

> see 3.1.2 chapter

3 Control section C

> see 3.1.3 chapter

Machine control – Operating elements

Overview of control sections

099-00T400-EW501

21.10.2016

9

3.1.1 Control section A

Figure 3-2

Item

Symbol

Description 0

1 Welding data display (3-digit)

Displays the welding parameters and the corresponding values > see 3.2 chapter

2 Push-button gas test / rinse hose package > see 4.1.1 chapter

3 Operating mode/power-saving mode push-button

--------- Latched > see 4.1.7.2 chapter

------- Non-latched > see 4.1.7.3 chapter

------ spotArc spot welding procedure – signal light turns

green > see 4.1.7.4 chapter

------ spotmatic spot welding procedure –signal light turns red > see 4.1.7.5 chapter

-------- Press button for long interval to put machine into power-saving

mode > see 4.4 chapter.

Activate one of the operating elements to reactivate.

4 Pulsing push-button > see 4.1.10 chapter

------ Automated pulsing (frequency and balance)

------- Signal light turns green: Thermal pulsed TIG welding/MMA pulse welding

------- Signal light turns red: Metallurgical pulsed TIG welding (kHz pulsing)/average

value pulsing

--- Special TIG AC

5

Welding current polarity/tungsten balling push-button

---- Signal light turns green: DC welding with negative polarity on the electrode

holder or welding torch.

---- Signal light turns red: MMA DC welding with positive polarity on the electrode

holder > see 4.2.5 chapter.

---- Alternating current welding/alternating current forms > see 4.1.14 chapter

- Tungsten balling current > see 4.1.3 chapter

Machine control – Operating elements

Overview of control sections

10

099-00T400-EW501

21.10.2016

Item

Symbol

Description 0

6 Welding procedure push-button

--------- TIG welding

---- MMA welding (signal light turns green)

---- Arcforce setting (signal light turns red)

7 Display switching push-button

kW ------- Welding power display

V --------- Welding voltage display

JOB ----- Display and setting of the JOB number with the control button

8 Welding data display (3-digit)

Displays the welding parameters and the corresponding values > see 3.2 chapter

9 Filler wire welding signal light

For machines with filler wire only (AW) > see 4.3 chapter

10 TIG ignition type signal light

Signal light on: Lift arc ignition active/HF start off. You can switch the ignition type in the

Expert menu (TIG) > see 4.1.20 chapter.

11 Character function signal light

Indicates that it is possible to weld in an environment with major electric hazards, such

as in boilers. Service must be informed if this signal light is not on.

12 Coolant fault signal light

Comes on when pressure is lost in the coolant circuit. Check coolant level and ensure

that coolant circuit is leak-tight.

13

VRD

Voltage reduction device (VRD) signal light

The VRD signal light is illuminated when the voltage reduction device is operating

without fault and the output voltage is reduced to a value specified in the relevant

standard (see technical data) > see 4.6 chapter. The voltage reduction device is only

active on VRD machine versions.

14

Hold

Signal light Status display

After each completed welding task, the last values used in the welding process for the

welding current and welding voltage are shown on the displays, and the signal light will

be on

15 Excess temperature signal light

In case of excess temperature, temperature monitors de-activate the power unit, and

the excess temperature control lamp comes on. Once the machine has cooled down,

welding can continue without any further measures.

16 Access control active signal light

Signal light is on when access control is active on the machine

control > see 4.5 chapter.

17 Simultaneous AC welding on both sides, signal light

This signal light indicates that the function is active > see 4.1.18 chapter.

18 Automatic AC frequency > see 4.1.16 chapter

Machine control – Operating elements

Overview of control sections

099-00T400-EW501

21.10.2016

11

3.1.2 Control section B

Figure 3-3

Item

Symbol

Description 0

1 Parameter selection push-button, left

The welding sequence parameters are selected one after another in an anti-clockwise

direction.

2 Control button

Central control button to be pressed or turned > see 3.2 chapter.

3 Parameter selection push-button, right

The welding sequence parameters are selected one after another in a clockwise

direction.

4 Balance signal light

DC balance (JOBs 0–7)

AC balance (JOBs 1–7), pulse balance, AC amplitude balance (JOBs 0–7)

5 Electrode diameter signal light

Ignition optimisation (TIG)/tungsten balling basic setting

6

Gas post-flow time

7

AMP%

Signal light, two colour

Red: End current

Green: End current time > see 4.1.20 chapter

8

sec

Down-slope time signal light

9

AMP%

sec

Signal light, two colour

Red: Secondary or pulse pause current (% of AMP)

Green: Pulse pause time /slope time (Expert menu)

10

AMP

sec

Signal light, two colour

Red: Main or pulse current

Green: Pulse time /slope time (AMP to AMP%, Expert menu)

11

sec

Signal light

Up-slope time (TIG)/hot start time (MMA)

12

AMP%

Signal light, two colour

Red: Ignition current (TIG)/hot start current (MMA)

Green: Ignition current time (TIG, Expert menu)

Machine control – Operating elements

Overview of control sections

12

099-00T400-EW501

21.10.2016

Item

Symbol

Description 0

13 Gas pre-flow time signal light

14 activArc TIG welding process

• Switch activArc <>

• Correct the activArc characteristic > see 4.1.20 chapter

15 Signal light, two colour

Green: AC frequency (TIG)/pulse frequency (MMA)

Red: Pulse frequency (TIG, kHz pulsing)

3.1.3 Control section C

Figure 3-4

Item

Symbol

Description 0

1 AC frequency rotary knob (JOB 0)

2

Balance

AC balance rotary knob (JOB 0)

3 Tungsten electrode diameter rotary knob (JOB 0)

Machine control – Operating elements

Machine display

099-00T400-EW501

21.10.2016

13

3.2 Machine display

The following welding parameters can be displayed before (nominal values), during (actual values) or

after welding (hold values):

"left display"

Parameter

Before welding

(nominal values)

During welding

(actual values)

After welding

(hold values)

Welding current

Parameter times

Parameter currents

Frequency, balance

JOB number

"right display"

Welding power

Welding voltage

When the hold values are displayed after welding and the settings are then changed (e.g. welding

current), the display will switch to the relevant nominal values.

possible

not possible

The parameters that can be set in the function sequence of the machine control depend on the selected

welding task. This means that if for example you have not selected a pulse variant, then you cannot set

any pulse times in the function sequence.

3.2.1 Setting the welding current (absolute/percentage)

The welding current for the ignition, secondary, end and hot start current can be set as a percentage of

the main current AMP or as an absolute value. To select, use the parameter <dg in the configuration

menu_ref_source_inline>Gerätekonfigurationsmenü</dg_ref_source_inline>.

> see 4.7 chapter

Machine control – Operating elements

Operating the machine control

14

099-00T400-EW501

21.10.2016

3.3 Operating the machine control

3.3.1 Main screen

The machine control switches to the main screen after it has been turned on or a setting has been

completed. This means that the previously selected settings (indicated by signal lights where applicable)

and the nominal value for the current (A) are displayed in the left-hand welding data display. Depending

on the selection, the right-hand display shows the welding voltage (V) nominal value or the welding power

(kW) actual value. The control always switches back to the main screen after 4 sec. of inactivity.

3.3.2 Welding power setting

The welding power is set using the control button. You can also adjust the parameters in the operation

sequence or settings in the different machine menus.

3.3.3 Welding parameter setting in the operation sequence

A welding parameter can be set in two ways in the operation sequence.

1. Push the "left" or "right" arrow keys (flashing signal light will indicate your selection). Turn the control

button to set the parameter value.

2. Press briefly on the control button (operation sequence selection) and then turn the button (navigate to

the required parameter). Press again to apply the selected parameter as the setting (corresponding

signal light flashes). Turn the button to set the parameter value.

The welding parameter setting is shown on the left-hand display while it is being set. A parameter

abbreviation or a deviation in the specified parameter value upwards or downwards is shown on the righthand display:

Display

Meaning

Increase the parameter value

To return to the factory settings.

Factory setting (example value = 20)

Parameter is set to optimum value

Decrease the parameter value

To return to the factory settings.

3.3.4 Setting advanced welding parameters (Expert menu)

The Expert menu contains functions and parameters which cannot be set directly in the machine control

or which do not need to be et on a regular basis. The number and display of these parameters depends

on the previously selected welding procedure or the functions.

To select them hold the control button for more than 2 sec. Select the required parameter/menu item by

turning (navigate) and pressing (confirm) the control button.

You can also or alternatively use the push-buttons to the left and right of the control button to navigate.

3.3.5 Changing basic settings (machine configuration menu)

The basic welding system functions can be adjusted in the machine configuration menu. Only

experienced users should change the settings > see 4.7 chapter.

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

15

4 Welding procedure

4.1 TIG welding

4.1.1 Setting the shielding gas volume (gas test)/rinse hose package

• Slowly open the gas cylinder valve.

• Open the pressure regulator.

• Switch on the power source at the main switch.

• Set the relevant gas quantity for the application on the pressure regulator.

• The gas test can be activated at the machine control by pressing the "Gas test/purge " push-

button > see 3.1.1 chapter.

Setting the shielding gas quantity (gas test)

• Shielding gas flows for approx. 20 seconds or until the push-button is pressed again.

Purging long hose packages (purging)

• Press push-button for about 5 sec. Shielding gas flows continuously until the push-button is pressed

again.

If the shielding gas setting is too low or too high, this can introduce air to the weld pool and may cause

pores to form. Adjust the shielding gas quantity to suit the welding task!

Setting instructions

Welding process

Recommended shielding gas quantity

MAG welding

Wire diameter x 11.5 = l/min

MIG brazing

Wire diameter x 11.5 = l/min

MIG welding (aluminium)

Wire diameter x 13.5 = l/min (100 % argon)

TIG

Gas nozzle diameter in mm corresponds to l/min gas throughput

Helium-rich gas mixtures require a higher gas volume!

The table below can be used to correct the gas volume calculated where necessary:

Shielding gas

Factor

75% Ar/25% He

1.14

50% Ar/50% He

1.35

25% Ar/75% He

1.75

100% He

3.16

For connecting the shielding gas supply and handling the shielding gas cylinder refer to the

power source operating instructions.

Welding procedure

TIG welding

16

099-00T400-EW501

21.10.2016

4.1.2 Welding task selection

The setting of the tungsten electrode diameter has a direct influence on the machine functionality, TIG

ignition behaviour and minimum current limits. The ignition energy is controlled by the set electrode

diameter. Smaller electrode diameters requires less ignition current and less ignition current time than

greater electrode diameters. The set value should correspond to the tungsten electrode diameter. The

value can also be set to meet individual requirements, e.g. for thin panels a smaller diameter is

recommended to reduce the ignition energy.

The electrode diameter setting determines the minimum current limit, which in turn affects the ignition,

main and secondary current. The minimum current limits have a positive effect on the ignition behaviour

and ensure a very high arc stability for each electrode diameter selected. The minimum current limit

function is enabled ex works, but can be disabled with parameter in the machine configuration

menu > see 4.7 chapter.

For foot-operated remote control mode, minimum current limits are disabled by default.

The following welding task is an example of use:

EXIT

4s

mm

inch

?

Figure 4-1

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

17

4.1.2.1 Recurring welding tasks (JOB 1–7)

The user has 7 more memory locations at their disposal to save recurring or different welding tasks on a

permanent basis. To do so, simply select the required memory location (JOB 1–7) and the welding task is

set as described previously.

The three rotary knobs for AC frequency, AC balance and the tungsten electrode diameter are

exceptions. These settings are made in the operation sequence (signal lights with same name).

Switching a JOB is only possible if no welding current flows. Up-slope and down-slope times can be set

individually for latched and non-latched operation.

Selection

Figure 4-2

When one or more of the recurring welding tasks (JOB 1–7) has been selected the JOB signal light

comes on.

Welding procedure

TIG welding

18

099-00T400-EW501

21.10.2016

4.1.3 Tungsten balling function

The tungsten balling function provides optimum tungsten balling, ensuring that the best ignition and

welding results are achieved during AC welding.

Optimum tungsten balling requires a sharpened electrode (about 15–25°) and the set electrode diameter

on the machine control. The set electrode diameter affects the current for tungsten balling and,

consequently, also the ball size.

Press the tungsten balling push-button to activate the function. If required, this current can be adjusted on

an individual basis using the parameter (+/- 30 A). The user presses the torch trigger and the function

is started by non-contact ignition (HF start). The balled end is formed and the function then ends.

Tungsten balling should be performed on a test component as surplus tungsten may be melted and this

may lead to impurities on the weld seam.

Balling

mm

inch

Figure 4-3

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

19

4.1.4 AC balance (optimise cleaning effect and penetration characteristics)

To weld aluminium and aluminium alloys, AC welding is used in combination with a continuous change in

polarity of the tungsten electrode. The process encompasses two phases (half-waves): a positive and a

negative one. The positive phase cracks the aluminium oxide layer on the material surface (so called

cleaning effect).

At the same time, tungsten balling occurs at the tip of the tungsten electrode. The size of this balled end

depends on the length of the positive phase. Please note that an excessively big balled end will cause the

arc to become unstable and diffuse, with low penetration. In the negative phase, the tungsten electrode is

cooled and the required penetration is realised. Make sure to select the correct durations (balance) for

positive phase (cleaning effect, balled end size) and negative phase (penetration depth) by setting the AC

balance. The default (zero setting) balance setting is 65%, referring to the duration of the negative halfwave.

Figure 4-4

Welding procedure

TIG welding

20

099-00T400-EW501

21.10.2016

4.1.5 AC amplitude balance

As with AC balance, durations (balance) for positive phase and negative phase are set for AC amplitude

balance. The balance changes in terms of the current amplitude.

Figure 4-5

Increasing the current amplitude in the positive half-wave facilitates the cleaning effect and the

cracking of the oxide layer.

Raising the negative current amplitude increases the penetration.

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

21

4.1.6 Arc ignition

4.1.6.1 HF ignition

Figure 4-6

The arc is started without contact from high-voltage ignition pulses.

a) Position the welding torch in welding position over the workpiece (distance between the electrode tip

and workpiece should be approx. 2-3mm).

b) Press the torch trigger (high voltage ignition pulses ignite the arc).

c) Ignition current flows, and the welding process is continued depending on the operating mode

selected.

End the welding process: Release or press the torch trigger depending on the operating mode

selected.

4.1.6.2 Liftarc

Figure 4-7

The arc is ignited on contact with the workpiece:

a) Carefully place the torch gas nozzle and tungsten electrode tip onto the workpiece and press the torch

trigger (liftarc current flowing, regardless of the main current set).

b) Incline the torch over the torch gas nozzle to produce a gap of approx. 2-3 mm between the electrode

tip and the workpiece. The arc ignites and the welding current is increased, depending on the

operating mode set, to the ignition or main current set.

c) Lift off the torch and swivel to the normal position.

Ending the welding process: Release or press the torch trigger depending on the operating mode

selected.

4.1.6.3 Automatic cut-out

The automatic cut-out function will be triggered by two conditions during the welding process:

• During the ignition phase (ignition fault) If there is no welding current within 3s after starting

the welding.

• During the welding phase (arc interruption) If the arc is interrupted for longer than 3s.

In both cases, the welding machine ends the ignition or welding process immediately.

Welding procedure

TIG welding

22

099-00T400-EW501

21.10.2016

4.1.7 Function sequences/operating modes

4.1.7.1 Explanation of symbols

Symbol

Meaning

Press torch trigger 1

Release torch trigger 1

I

Current

t

Time

Gas pre-flow

Ignition current

Up-slope time

Spot time

AMP

Main current (minimum to maximum current)

AMP%

Secondary current

Pulse time

Pulse pause time

Pulse current

Pulsed TIG welding: Slope time from main current (AMP) to secondary current (AMP%)

Pulsed TIG welding: Slope time from secondary current (AMP%) to main current (AMP%)

Down-slope time

End-crater current

Gas post-flow

Balance

Frequency

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

23

4.1.7.2 Non-latched mode

Figure 4-8

1st cycle:

• Press torch trigger 1 and hold down.

• Gas pre-flow time elapses.

• HF ignition pulses jump from the electrode to the workpiece. The arc ignites.

• The welding current flows and immediately assumes the value of the ignition current .

• HF switches off.

• The welding current ramps up to the main current (AMP) in the selected up-slope time .

If torch trigger 2 is pressed together with torch trigger 1 during the main current phase, the welding

current decreases to the secondary current (AMP%) in the set slope time .

If torch trigger 2 is released, the welding current increases again to the main current AMP in the set slope

time . The parameters and can be set in the Expert menu (TIG) > see 4.1.20 chapter.

2nd cycle:

• Release torch trigger 1.

• The main current falls to the end-crater current (minimum current) in the set down-slope time .

If the 1st torch trigger is pressed during the down-slope time,

the welding current returns to the set main current AMP

• Main current reaches the end-crater current ; the arc is extinguished.

• Set gas post-flow time elapses.

When the foot-operated remote control RTF is connected, the machine switches automatically to

non-latched operation.

The up- and down-slopes are switched off.

Welding procedure

TIG welding

24

099-00T400-EW501

21.10.2016

4.1.7.3 Latched mode

Figure 4-9

1st cycle

• Press torch trigger 1; gas pre-flow time elapses.

• HF ignition pulses jump from the electrode to the workpiece. The arc ignites.

• Welding current flows and immediately assumes the set ignition current (search arc at minimum

setting). HF switches off.

2nd cycle

• Release torch trigger 1.

• The welding current ramps up to the main current (AMP) in the selected up-slope time .

Switching from the main current AMP to secondary current (AMP%):

• Press torch trigger 2 or

• Tap torch trigger 1 (torch modes 1–6).

The slope times and can be set > see 4.1.20 chapter.

3rd cycle

• Press torch trigger 1.

• The main current decreases to the end-crater current within the set down-slope time .

4th cycle

• Release torch trigger 1; arc is extinguished.

• Set gas post-flow time runs.

Ending the welding process immediately without a down-slope or end-crater current:

• Press the 1st torch trigger briefly > 3rd and 4th cycles (torch modes 11–16).

Current drops to zero and the gas post-flow time begins.

When the foot-operated remote control RTF is connected, the machine switches automatically to

non-latched operation.

The up- and down-slopes are switched off.

A double-digit torch mode (11-x) needs to be set at the welding machine control to use the

alternative welding start (tapping start). The number of torch modes available depends on the

machine type.

From mode 11 upwards, the tapping start function can also be deactivated when required

(welding stop by tapping remains active). To do so, the parameter must be switched to in

the machine configuration menu > see 4.7 chapter.

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

25

4.1.7.4 spotArc

This process is suitable for tack welding or joint welding of metal sheets made from steel and CrNi alloys

up to a thickness of approximately 2.5 mm. Metal sheets of different thicknesses can also be welded on

top of one another. As this is a one-sided process, it is also possible to weld metal sheets onto tubular

sections such as round or square pipes. In arc spot welding, the arc melts through the upper metal sheet

and the lower metal sheet is melted onto it. This produces flat, fine-textured welding tacks which require

little or no post weld work, even in visible areas.

?

EXIT

4s

?

Figure 4-10

The up-slope and down-slope times should be set to “0” to achieve an effective result.

Welding procedure

TIG welding

26

099-00T400-EW501

21.10.2016

Figure 4-11

As an example the process is shown with HF ignition. Arc ignition with lift arc is also possible,

however > see 4.1.6.2 chapter.

Sequence:

• Press torch trigger and hold down.

• The gas pre-flow time elapses.

• HF ignition pulses jump from the electrode to the workpiece. The arc ignites.

The welding current flows and immediately assumes the value of the ignition current

• HF switches off.

• The welding current ramps up to the main current (AMP) in the selected up-slope time.

The process ends when the set spotArc.time elapses or by releasing the torch trigger.

When switching on the spotArc function, Automatic pulsing is switched on as well. Any other

pulsing variant can be selected as well, or no pulsing at all.

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

27

4.1.7.5 spotmatic

In contrast to spotArc operating mode, the arc is not ignited by pressing the torch trigger as is usual, but

by briefly touching the tungsten electrode against the workpiece. The torch trigger is used for welding

process activation. The process can be activated separately for each spot or also on a permanent basis.

The setting is controlled using the process activation parameter in the configuration

menu > see 4.7 chapter:

• Separate process activation ( > ):

The welding process has to be reactivated for every arc ignition by pressing the torch trigger.

• Permanent process activation ( > ):

The welding process is activated by pressing the torch trigger once. The following arc ignitions are

initiated by briefly touching the tungsten electrode against the workpiece.

For spotmatic the separate process activation and the short spot time setting range are enabled by

default.

Ignition by touching the tungsten electrode against the workpiece can be disabled in the machine

configuration menu with parameter . In this case the function works as with spotArc, but the spot time

setting range can be selected in the machine configuration menu.

The duration is set in the machine configuration menu using parameter > see 4.7 chapter

EXIT

4s

Figure 4-12

Welding procedure

TIG welding

28

099-00T400-EW501

21.10.2016

Figure 4-13

As an example the process is shown with HF ignition. Arc ignition with lift arc is also possible,

however > see 4.1.6.2 chapter.

Selecting the process activation type for the welding process > see 4.7 chapter.

Up-slope and down-slope times possible for long spot time setting range (0.01–20.0 sec) only.

Press and release torch trigger (tap) to activate the welding process.

Touch the torch gas nozzle and tungsten electrode tip carefully against the workpiece.

Incline the welding torch over the torch gas nozzle until there is a gap of approx. 2–3 mm between the

electrode tip and the workpiece. Shielding gas flows during the set gas pre-flow time . The arc

ignites and the previously set ignition current flows.

The main current phase ends when the set spotArc time elapses.

The welding current decreases to the end current level within the set down-slope time .

The gas post-flow time elapses and the welding process ends.

Press and release the torch trigger (tap) to reactivate the welding process (only for separate

process activation). Touching the welding torch with the tungsten electrode tip again against the

workpiece will initiate the next welding processes.

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

29

4.1.7.6 Non-latched operation, version C

Figure 4-14

1st cycle

• Press torch trigger 1 , the gas pre-flow time elapses.

• HF ignition pulses jump from the electrode to the workpiece. The arc ignites.

• Welding current flows and immediately assumes the set ignition current (search arc at minimum

setting). HF switches off.

2nd cycle

• Release torch trigger 1.

• The welding current ramps up to the main current AMP in the selected up-slope time .

Pressing torch trigger 1 starts the slope from main current AMP to secondary current

AMP%. Releasing the torch trigger starts the slope from the secondary current AMP% and

back to the main current AMP. This process can be repeated as frequently as required.

The welding process is ended by arc interruption in the secondary current (remove the welding

torch from the workpiece until the arc is extinguished).

The slope times and can be set in the Expert menu > see 4.1.20 chapter.

This operating mode must be enabled (parameter ) > see 4.7 chapter.

Welding procedure

TIG welding

30

099-00T400-EW501

21.10.2016

4.1.8 TIG activArc welding

The EWM activArc process, thanks to the highly dynamic controller system, ensures that the power

supplied is kept virtually constant in the event of changes in the distance between the welding torch and

the weld pool, e.g. during manual welding. Voltage losses as a result of a shortening of the distance

between the torch and molten pool are compensated by a current rise (ampere per volt - A/V), and vice

versa. This helps prevents the tungsten electrode sticking in the molten pool and the tungsten inclusions

are reduced. This is particularly useful in tacking and in spot welding.

Selection

EXIT

4s

Figure 4-15

Setting

Parameter setting

The activArc parameter (control) can be adjusted specifically for the welding task (panel

thickness) > see 4.1.20 chapter.

4.1.9 TIG antistick

The function prevents uncontrolled re-ignition following the sticking of the tungsten electrode in the weld

pool by switching off the welding current. In addition, wear at the tungsten electrode is reduced.

After triggering the function the machine immediately switches to the gas post-flow process phase. The

welder starts the new process again at the first cycle. The user can switch the function on or off

(parameter ) > see 4.7 chapter.

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

31

4.1.10 Pulse welding

The following pulse types can be selected:

• Automated pulsing (TIG DC)

• Thermal pulsing (TIG AC or TIG DC)

• Average value pulsing (TIG AC or TIG DC)

• Metallurgical pulsing (TIG DC)

• AC special (TIG AC)

4.1.10.1 Automated pulses

The automated pulses are used with tacking and spot welding of workpieces in particular.

An oscillation in the molten pool is produced by the current-dependent pulse frequency and balance,

which positively influences the ability to bridge the air gap. The pulse parameters required are

automatically specified by the machine control.

Figure 4-16

Welding procedure

TIG welding

32

099-00T400-EW501

21.10.2016

4.1.10.2 Thermal pulsing

The operation sequences basically match the standard welding sequences, but there is an additional

switching back and forth between the main current AMP (pulse current) and the secondary current AMP%

(pulse pause current) at the set times. Pulse and pause times and the pulse edges ( and ) are

entered in seconds on the control.

Figure 4-17

The pulse function can also be deactivated if necessary during the up-slope and down-slope

phases (parameter ) > see 4.7 chapter.

Figure 4-18

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

33

Selection

Figure 4-19

Pulse time setting

EXIT

4s

Figure 4-20

Pulse pause setting

EXIT

4s

Figure 4-21

Pulse edge setting

The and pulse edges can be set in the Expert menu (TIG) > see 4.1.20 chapter.

Welding procedure

TIG welding

34

099-00T400-EW501

21.10.2016

4.1.10.3 Average value pulsing

Average value pulsing is a variant of pulsing, with the particularity that the power source will always

maintain the preset average value. This makes this method especially suitable for welding according to

welding procedure specifications.

The parameter must be switched to in the machine configuration menu to enable this pulse

variant. See the "Metallurgical pulsing" pulse variant for other parameter settings.

Once the function is activated, the red signal lights for the main current AMP and secondary current

AMP% light up at the same time.

Average value pulse welding means that the system switches between two currents periodically, an

average current value (AMP), a pulse current (Ipuls), a balance ( ) and a frequency ( ) having been

defined first. The predefined ampere current average value is decisive, the pulse current (Ipuls) is defined

by the parameter as a percentage of the average current value (AMP).

The pulse pause current (IPP) is not set; the machine control calculates the value instead to ensure that

the average value of the welding current (AMP) is maintained. For average value pulsing, the current

is the secondary current only, activated with the torch trigger.

Figure 4-22

AMP = main current (average value), e.g. 100 A

Ipuls = pulse current = x AMP, e.g. 140% x 100 A = 140 A

IPP = pulse pause current

Tpuls = duration of one pulse cycle = 1/ , e.g. 1/100 Hz = 10 ms

= balance = x Tpuls, e.g. 30% x 1 s = 0.3 s

Selection

Figure 4-23

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

35

4.1.10.4 Metallurgical pulsing (kHz pulsing)

Metallurgical pulsing (kHz pulsing) uses the plasma force (arc force) occurring at high currents which

allows you to achieve a constricted arc with concentrated heat input. Unlike thermal pulsing, no times are

set; a frequency and the balance are set instead. The pulsing process also occurs during the upslope and down-slope phase.

Figure 4-24

Selection

Figure 4-25

Welding procedure

TIG welding

36

099-00T400-EW501

21.10.2016

Balance setting

EXIT

4s

Figure 4-26

Frequency setting

EXIT

4s

Figure 4-27

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

37

4.1.10.5 AC special

Is e.g. used to join metal sheets of different thickness.

Figure 4-28

Figure 4-29

The and pulse edges can be set in the Expert menu (TIG) > see 4.1.20 chapter.

Welding procedure

TIG welding

38

099-00T400-EW501

21.10.2016

4.1.11 Welding torch (operating variants)

Different torch versions can be used with this machine.

Functions on the operating elements, such as torch triggers (TT), rockers or potentiometers, can be

modified individually via torch modes.

Explanation of symbols for operating elements:

Symbol

Description

Press torch trigger

Tap torch trigger

Tap and press torch trigger

4.1.11.1 Tap torch trigger (tapping function)

Swiftly tap the torch trigger to change the function.

The torch mode set determines the operating mode of the tapping function.

4.1.12 Torch mode and up/down speed setting

Modes 1 to 6 and 11 to 16 are available to the user. Modes 11 to 16 feature the same function options as

1 to 6, but without the tapping function for the secondary current.

The function options of the individual modes can be found in the corresponding torch type tables.

The torch modes are set using the torch configuration parameters " " in the machine configuration

menu > torch mode " " > see 4.7 chapter.

Only the modes listed are suitable for the corresponding torch types.

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

39

4.1.12.1 Standard TIG torch (5-pole)

Standard torch with one torch trigger:

Diagram

Operating

elements

Explanation of symbols

BRT1 = Torch trigger 1 (welding current on/off; secondary

current via tapping function)

Functions

mode

Operating

elements

Welding current On/Off

1

(factory-set)

Secondary current (Latched mode)

Standard torch with two torch triggers:

Diagram

Operating

elements

Explanation of symbols

BRT1 = torch trigger 1

BRT2 = torch trigger 2

Functions

mode

Operating

elements

Welding current On/Off

1

(factory-set)

Secondary current

Secondary current (tapping mode) / (latched mode)

Welding current On/Off

3

Secondary current (tapping mode) / (latched mode)

Up function

Down function

Welding procedure

TIG welding

40

099-00T400-EW501

21.10.2016

Standard torch with one rocker (MG rocker, two torch triggers)

Diagram

Operating

elements

Explanation of symbols

BRT 1 = torch trigger 1

BRT 2 = torch trigger 2

Functions

mode

Operating

elements

Welding current On/Off

1

(factory-set)

Secondary current

Secondary current (tapping mode) / (latched mode)

Welding current On/Off

2

Secondary current (tapping mode)

Up function

Down function

Welding current On/Off

3

Secondary current (tapping mode) / (latched mode)

Up function

Down function

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

41

4.1.12.2 TIG up/down torch (8-pole)

Up/down torch with one torch trigger

Diagram

Operating

elements

Explanation of symbols

TT 1 = torch trigger 1

Functions

Mode

Operating

elements

Welding current on/off

1

(factory-

set)

Secondary current (tapping mode) / (latched mode)

Increase welding current, infinite adjustment (up function)

Reduce welding current, infinite adjustment (down function)

Welding current on/off

2

Secondary current (tapping mode)

Welding current on/off

4

Secondary current (tapping mode) / (Latched mode)

Increase welding current by an increment *

Reduce welding current by an increment *

Welding procedure

TIG welding

42

099-00T400-EW501

21.10.2016

Up/down torch with two torch triggers

Diagram

Operating

elements

Explanation of symbols

TT 1 = torch trigger 1 (left)

TT 2 = torch trigger 2 (right)

Functions

Mode

Operating

elements

Welding current on/off

1

(factory-

set)

Secondary current

Secondary current (tapping mode) / (latched mode)

Increase welding current, infinite adjustment (up function)

Reduce welding current, infinite adjustment (down function)

Welding current on/off

2

Secondary current

Secondary current (tapping mode)

Welding current on/off

4

Secondary current

Secondary current (tapping mode)

Increase welding current by an increment *

Reduce welding current by an increment *

Gas test

4

>

3 s

* > see 4.1.13 chapter

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

43

4.1.12.3 Potentiometer torch (8-pole)

The welding machine needs to be configured for operation with a potentiometer

torch > see 4.1.12.4 chapter.

Potentiometer torch with one torch trigger:

Diagram

Operating

elements

Explanation of symbols

BRT 1 = torch trigger 1

Functions

Mode

Operating

elements

Welding current On/Off

3

Secondary current (tapping mode)

Increase welding current, infinite adjustment

Reduce welding current, infinite adjustment

Potentiometer torch with two torch triggers:

Diagram

Operating

elements

Explanation of symbols

BRT 1 = torch trigger 1

BRT 2 = torch trigger 2

Functions

Mode

Operating

elements

Welding current On/Off

3

Secondary current

Secondary current (tapping mode)

Increase welding current, infinite adjustment

Reduce welding current, infinite adjustment

Welding procedure

TIG welding

44

099-00T400-EW501

21.10.2016

4.1.12.4 Configuring the TIG potentiometer torch connection

DANGER

Risk of injury due to electrical voltage after switching off!

Working on an open machine can lead to fatal injuries!

Capacitors are loaded with electrical voltage during operation. Voltage remains present

for up to four minutes after the mains plug is removed.

1. Switch off machine.

2. Remove the mains plug.

3. Wait for at last 4 minutes until the capacitors have discharged!

WARNING

Risk of accidents due to non-compliance with the safety instructions!

Non-compliance with the safety instructions can be fatal!

• Carefully read the safety instructions in this manual!

• Observe the accident prevention regulations and any regional regulations!

• Inform persons in the working area that they must comply with the regulations!

Test!

Before re-commissioning, it is essential that an "inspection and test during operation" is carried

out conforming to IEC / DIN EN 60974-4 "Arc welding devices - inspection and testing during

operation"!

• For detailed instructions, please see the standard operating instructions for the welding

machine.

When connecting a potentiometer torch, jumper JP27 on PCB T320/1 inside the welding machine

should be unplugged.

Welding torch configuration

Setting

Prepared for TIG standard or up/down torch (factory setting)

JP27

Prepared for potentiometer torches

JP27

Figure 4-30

For this torch type the welding machine has to be set to torch mode 3 > see 4.1.12 chapter.

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

45

4.1.12.5 RETOX TIG torch (12-pole)

For machines with 12-pole torch connection socket only.

Diagram

Operating elements

Explanation of symbols

TT= torch trigger

Functions

Mode

Operating

elements

Welding current on/off

1

(ex works)

TT 1

Secondary current

TT 2

Secondary current (tapping function)

TT 1 (tapping)

Increase welding current (up function)

TT 3

Reduce welding current (down function)

TT 4

Modes 2 and 3 are not used with this type of torch or, respectively, are not appropriate.

Welding current on/off

4

TT 1

Secondary current

TT 2

Secondary current (tapping function)

TT 1 (tapping)

Raise welding current in stages (setting the first increment)

TT 3

Decrease welding current in stages (setting the first decrement)

TT 4

Switchover between Up-Down and JOB changeover

TT 2 (tapping)

Increase JOB number

TT 3

Decrease JOB number

TT 4

Gas test

TT 2 (3 s)

Welding current on/off

6

TT 1

Secondary current

TT 2

Secondary current (tapping function)

TT 1 (tapping)

Increase welding current, infinite adjustment (up function)

TT 3

Reduce welding current, infinite adjustment (down function)

TT 4

Switchover between Up-Down and JOB changeover

TT 2 (tapping)

Increase JOB number

TT 3

Decrease JOB number

TT 4

Gas test

TT 2 (3 s)

Welding procedure

TIG welding

46

099-00T400-EW501

21.10.2016

4.1.13 Up/down operation in modes 4 and 14

By tapping the relevant torch trigger the current can be roughly adjusted. Holding the torch trigger will

cause an infinite adjustment of the welding current.

This function is only available when using up/down torches in modes 4 and 14!

Figure 4-31

The parameter for setting the reach can be found in the machine configuration

menu > see 4.7 chapter.

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

47

4.1.14 Alternating current waveforms

Selection

EXIT

4s

Figure 4-32

Display

Setting/selection

Alternating current waveforms

------- Rectangular (ex works)

------- Trapezoidal

------- Sine

AC welding with rectangular current waveform (ex works)

Highest energy input

Alternating current welding with trapezoidal current waveform

An all-rounder, suitable for most applications

Alternating current welding with sinusoidal current waveform

Low noise level

Welding procedure

TIG welding

48

099-00T400-EW501

21.10.2016

4.1.15 Ramp function

4.1.15.1 Foot-operated remote control responsiveness

With the foot-operated remote control the welding current can be infinitely adjusted during the welding

process. The maximum main current has to be set at the machine before starting to weld. Within the

preset range the main current can be set by adjusting the pressure on the pedal.

Linear responsiveness (ex works)

Welding current changes linearly.

Figure 4-33

Logarithmic responsiveness

Welding current changes logarithmically.

This setting is especially suited for welding with low currents, e.g. for thin panels. The logarithmic

responsiveness enables a more precise dosing.

Figure 4-34

The logarithmic responsiveness is set in the machine configuration menu. The parameter must be set

to > see 4.7 chapter.

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

49

4.1.15.2 RTF 1 foot-operated remote control

Figure 4-35

Symbol

Meaning

Actuate foot-operated remote control (start welding process)

Operate foot-operated remote control (set welding current according to application)

Release foot-operated remote control (end welding process)

The parameter can be changed in the machine configuration menu > see 4.7 chapter.

Welding procedure

TIG welding

50

099-00T400-EW501

21.10.2016

4.1.16 Automatic AC frequency

Automatic AC frequency can be selected for JOBs 1–7 only. The left stop in the frequency functional

sequence is used for activation, displayed as .

The signal light comes on when the function is activated.

The machine control adjusts or sets the AC frequency in relation to the set main current. The lower the

welding current, the higher the frequency and vice versa. This ensures a concentrated, directionally

stable arc is achieved when welding currents are low. The load from the tungsten electrode is minimised

when the welding currents are high, ensuring a higher service life.

The use of a foot-operated remote control reduces manual intervention by the user during the welding

process to a minimum.

Figure 4-36

Selection

<

Figure 4-37

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

51

4.1.17 AC commutation optimisation

The AC commutation assistance function can help to increase process stability when welding materials

such as pure aluminium. If half-wave failures should occur during the welding process, the parameter can

be increased, counteracting half-wave failures.

The parameter must first be switched on in the machine configuration menu > see 4.7 chapter. The

parameter value can then be selected and set in the Expert menu > see 4.1.20 chapter.

4.1.18 Simultaneous welding on both sides, synchronisation types

This function is important, if two power sources are used to simultaneously weld on both sides, as is

sometimes required for welding thick aluminium materials in the PF position. This ensures that, with

alternating currents, the positive and negative pole phases are present on both power sources

simultaneously, thus avoiding the arcs negatively influencing each other.

4.1.19 Synchronisation via mains voltage (50Hz / 60Hz)

Phase sequences and rotating magnetic fields in the supply voltages must be the same for both welding

machines. If this is not the case, the energy input into the weld pool will be negatively affected.

Some machine types can be optionally retrofitted with a rotary switch to set the phase position (ON

NETSYNCHRON). Use this rotary switch to correct the phase difference in increments of 60° (0°, 60°,

120°, 180°, 240° and 300°). Optimum phase correction will directly achieve better welding results.

The synchronisation via mains voltage function is enabled in the Expert menu (TIG). The parameter

must be set to (signal light Netsync lights up) > see 4.1.20 chapter.

Welding procedure

TIG welding

52

099-00T400-EW501

21.10.2016

4.1.20 Expert menu (TIG)

The expert menu includes functions and parameters which are either not set on the machine control, or

which do not require regular setting.

ENTER (Enter the menu)

• Keep the control button pressed for 2 s.

NAVIGATION (Navigate the menu)

• Parameters are selected by turning the main control button or pressing the "Parameter

selection left/right" push-button.

• Change parameters by pressing (parameter selection) and turning (parameter setting) the

main control button.

EXIT (Exit the menu)

• The machine will return automatically to the ready-to-operate status after 4 sec.

ENTER

4s

NAVIGATION

A

A

B

A

B

A

B B

A

A

A

B

B

A

A

A

B

A

B

B

B

A

B

A

A

B

A

B

A

A

A

B

A

A

A

B

B

EXIT

4s

A

A

A

A

A

A

A

B

A

A

Figure 4-38

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

53

Display

Setting/selection

Expert menu

Slope time (main current to secondary current)

Slope time (main current to secondary current)

Slope time (main current to secondary current)

Slope time (main current to secondary current)

Amplitude balance

activArc parameter

Parameter also adjustable after TIG activArc welding is activated.

AC commutation optimisation > see 4.1.17 chapter

------- Function enabled

------- Function disabled (ex works)

Filler wire process (cold/hot wire)

------ filler wire activated

------ filler wire deactivated (factory setting)

Hot wire process (start signal for hot wire power source)

------- Function enabled

------- Function disabled (ex works)

Wire/pulse function (wire feeding behaviour when using pulsed TIG welding)

Wire feeding can be disabled during pulse pauses (not the case for automated

pulsing or kHz pulsing).

------- Function disabled

------- Function enabled (ex works)

Filler wire diameter (manual setting)

Setting the wire diameter between 0.6 mm to 1.6 mm.

The character "d" preceding the wire diameter on the display (d0.8) indicates a preprogrammed characteristics (correction operating mode "KORREKTUR”).

If there is no characteristics for the selected wire diameter, the parameters have to be set

manually (manual operating mode “MANUELL“).

To select the operating mode > see 4.3.1.2 chapter.

Wire return

• Increase value = more wire return

• Decrease value = less wire return

Simultaneous AC welding on both sides, synchronisation types

------- Function disabled (ex works)

------- Synchronisation via mains voltage (50 Hz/60 Hz)

Ignition type (TIG)

------- HF start active (ex works)

------- Lift arc ignition active

Welding procedure

TIG welding

54

099-00T400-EW501

21.10.2016

4.1.21 Aligning the cable resistance

To ensure optimum welding properties, the electric cable resistance should be aligned again whenever an

accessory component such as the welding torch or the intermediate hose package (AW) has been

changed. The resistance value of the cables can be set directly or can be aligned by the power source. In

the delivery state the cable resistance is set to the optimum values. To optimise the welding properties for

other cable lengths, an alignment process (voltage correction) is necessary.

2

3

4

1

l0l

0

+

+

Tetrix

Classic

Tetrix

Smart

Comfort

Synergic

B

A

+

Tetrix

Comfort 2.0

RT50 7POL

Figure 4-39

Welding procedure

TIG welding

099-00T400-EW501

21.10.2016

55

1 Preparation

• Switch off the welding machine.

• Unscrew the gas nozzle from the welding torch.

• Unfasten the tungsten electrode and extract.

2 Configuration

• Activate the rotary knob while switching on the welding machine at the same time.

• Release rotary knob.

• You can now use the rotary knob (rotate and press) to select the parameter rL > see 4.7 chapter.

3 Alignment/measurement

• Applying slight pressure, press the welding torch with the collet against a clean, purged location on the

workpiece and then press the torch trigger for approx. 2 seconds. A short-circuit current will flow

briefly, which is used to determine and display the cable resistance. The value can be between 0 mΩ

and 60 mΩ. The new value is immediately saved without requiring further confirmation. If no value is

shown on the right-hand display, then measurement failed. The measurement must be repeated.

4 Restoring welding standby mode

• Switch off the welding machine.

• Lock the tungsten electrode in the collet again.

• Screw the gas nozzle onto the welding torch.

• Switch on the welding machine.

Welding procedure

MMA welding

56

099-00T400-EW501

21.10.2016

4.2 MMA welding

4.2.1 Welding task selection

It is only possible to change the basic parameters when no welding current is flowing and any

possible access control is disabled > see 4.5 chapter.

The welding task is selected using the buttons on the machine control on the welding machine.

Signal lights (LED) display the welding parameter selection.

Set the welding task in the following order:

Figure 4-40

Welding procedure

MMA welding

099-00T400-EW501

21.10.2016

57

4.2.2 Hotstart

The hot start device ensures that stick electrodes ignite more effectively thanks to a greater hot start

current. After selecting the stick electrode, the arc ignites with the hot start current for the preset hot

start time and then reverts to the main current (AMP).

The parameter values for hot start current and time can be optimised for the electrode types used.

Figure 4-41

4.2.2.1 Hotstart current

EXIT

4s

Figure 4-42

4.2.2.2 Hotstart time

EXIT

4s

Figure 4-43

Welding procedure

MMA welding

58

099-00T400-EW501

21.10.2016

4.2.3 Arcforce

During the welding process, arcforce prevents the electrode sticking in the weld pool with increases in

current. This makes it easier to weld large-drop melting electrode types at low current strengths with a

short arc in particular.

EXIT

4s

Figure 4-44

4.2.4 Antistick

Anti-stick prevents the electrode from annealing.

If the electrode sticks in spite of the Arcforce device, the machine

automatically switches over to the minimum current within about 1

second to prevent the electrode from overheating. Check the welding

current setting and correct according to the welding task!

Figure 4-45

4.2.5 Welding current polarity reversal (polarity reversal)

This function can be used to reverse the welding current polarity electronically.

For example, when welding with different electrode types for which different polarities are stipulated by

the manufacturer, the welding current polarity can be switched easily on the control.

-

+

~

Figure 4-46

Welding procedure

MMA welding

099-00T400-EW501

21.10.2016

59

4.2.6 Pulse welding

Pulse welding means that the system switches between two currents periodically with a pulse current

(Ipuls), a pulse pause current (IPP), a balance ( ) and a frequency ( ) having been defined first.

Figure 4-47

AMP = main current, e.g. 100 A

Ipuls = pulse current = x AMP, e.g. 140% x 100 A = 140 A

IPP = pulse pause current = 1–200% of AMP

Tpuls = duration of one pulse cycle = 1/ , e.g. 1/100 Hz = 10 ms

= balance = x Tpuls, e.g. 30% x 1 s = 0.3 s

Selection

Figure 4-48