EWM Pico 300 cel, Pico 300 cel VRD, Pico 300 cel pws, Pico 300 cel pws VRD Operating Instructions Manual

Operating instructions

Welding machines for MMA welding

GB

Pico 300 cel

Pico 300 cel VRD

Pico 300 cel SVRD

Pico 300 cel pws

Pico 300 cel pws VRD

Pico 300 cel pws SVRD

099-002032-EW501 29.04.2010

General instructions

CAUTION

Read the operating instructions!

The operating instructions provide an introduction to the safe use of the products.

• Read the operating instructions for all system components!

• Observe accident prevention regulations!

• Observe all local regulations!

• Confirm with a signature where appropriate.

NOTE

In the event of queries on installation, commissioning, operation or special conditions at the

installation site, or on usage, please contact your sales partner or our

customer service department on +49 2680 181-0.

A list of authorised sales partners can be found at www.ewm-group.com.

Liability relating to the operation of this equipment is restricted solely to the function of the equipment. No other

form of liability, regardless of type, shall be accepted. This exclusion of liability shall be deemed accepted by the

user on commissioning the equipment.

The manufacturer is unable to monitor whether or not these instructions or the conditions and methods are

observed during installation, operation, usage and maintenance of the equipment.

An incorrectly performed installation can result in material damage and injure persons as a result. For this reason,

we do not accept any responsibility or liability for losses, damages or costs arising from incorrect installation,

improper operation or incorrect usage and maintenance or any actions connected to this in any way.

© EWM HIGHTEC WELDING GmbH · Dr. Günter-Henle-Str. 8 · D-56271 Mündersbach, Germany

The copyright to this document remains the property of the manufacturer.

Reprinting, including extracts, only permitted with written approval.

Subject to technical amendments.

Contents

Notes on the use of these operating instructions

099-002032-EW501

29.04.2010

3

1 Contents

1

Contents..................................................................................................................................................3

2 Safety instructions.................................................................................................................................5

2.1 Notes on the use of these operating instructions ..........................................................................5

2.2 General..........................................................................................................................................7

2.3 Transport and installation ............................................................................................................10

2.4 Ambient conditions.......................................................................................................................11

2.4.1 In operation...................................................................................................................11

2.4.2 Transport and storage..................................................................................................11

3 Intended use.........................................................................................................................................12

3.1 Applications..................................................................................................................................12

3.1.1 MMA welding................................................................................................................12

3.1.2 TIG (Liftarc) welding.....................................................................................................12

3.2 Overview of device types.............................................................................................................12

3.2.1 Cellulose electrode types (cel) .....................................................................................12

3.2.2 Pole reversing switch (pws)..........................................................................................12

3.2.3 Voltage reducing device (VRD/SVRD).........................................................................12

3.3 Documents which also apply .......................................................................................................13

3.3.1 Warranty.......................................................................................................................13

3.3.2 Declaration of Conformity.............................................................................................13

3.3.3 Welding in environments with increased electrical hazards.........................................13

3.3.4 Service documents (spare parts and circuit diagrams)................................................13

4 Machine description – quick overview ..............................................................................................14

4.1 Pico 300 cel .................................................................................................................................14

4.1.1 Front view.....................................................................................................................14

4.1.2 Rear view......................................................................................................................16

4.2 Machine control – Operating elements........................................................................................18

5 Design and function.............................................................................................................................20

5.1 General........................................................................................................................................20

5.2 Machine cooling...........................................................................................................................20

5.3 Workpiece lead, general..............................................................................................................20

5.4 Transport and installation ............................................................................................................21

5.4.1 Adjusting the length of the carrying strap.....................................................................21

5.5 Mains connection.........................................................................................................................22

5.5.1 Mains configuration ......................................................................................................22

5.6 MMA welding ...............................................................................................................................23

5.6.1 Connecting the electrode holder and workpiece lead..................................................23

5.6.1.1 Pico 300 cel...................................................................................................23

5.6.1.2 Pico 300 cel pws...........................................................................................24

5.6.2 Selecting MMA welding................................................................................................26

5.6.2.1 Arcforce (welding characteristics).................................................................26

5.6.3 Hotstart current and Hotstart time................................................................................27

5.6.4 Antistick........................................................................................................................28

5.6.5 Advanced settings........................................................................................................28

5.6.5.1 Arcforce correction (welding characteristics)................................................28

5.7 TIG welding..................................................................................................................................29

5.7.1 Shielding gas supply (shielding gas cylinder for welding machine).............................29

5.7.1.1 Connecting the shielding gas supply ............................................................30

5.7.2 Connecting a TIG welding torch with rotating gas valve..............................................31

5.7.2.1 Pico 300 cel...................................................................................................31

5.7.2.2 Pico 300 cel pws...........................................................................................32

5.7.3 TIG welding selection...................................................................................................33

5.7.4 TIG arc ignition.............................................................................................................33

5.7.4.1 Liftarc ignition................................................................................................33

Contents

Notes on the use of these operating instructions

4

099-002032-EW501

29.04.2010

5.8 Advanced settings........................................................................................................................34

5.8.1 Arc length restriction (USP)..........................................................................................34

5.8.2 Activating the welding current actual value display......................................................35

5.9 Voltage reducing device (VRD/SVRD).........................................................................................36

5.10 Remote control.............................................................................................................................36

5.10.1 Foot-operated remote control RTF 1............................................................................36

5.10.2 Manual remote control RT 1.........................................................................................36

5.10.3 Manual remote control RT PWS 1................................................................................36

5.11 Dirt filter........................................................................................................................................37

6 Maintenance, care and disposal.........................................................................................................38

6.1 General.........................................................................................................................................38

6.2 Maintenance work, intervals.........................................................................................................38

6.2.1 Daily maintenance tasks...............................................................................................38

6.2.2 Monthly maintenance tasks..........................................................................................38

6.2.3 Annual test (inspection and testing during operation)..................................................38

6.3 Repair Work .................................................................................................................................39

6.4 Disposing of equipment................................................................................................................39

6.4.1 Manufacturer's declaration to the end user..................................................................39

6.5 Meeting the requirements of RoHS..............................................................................................39

7 Rectifying faults....................................................................................................................................40

7.1 Error messages (power source)...................................................................................................40

7.2 Resetting welding parameters to the factory settings..................................................................41

8 Technical data.......................................................................................................................................42

8.1 Pico 300 cel..................................................................................................................................42

9 Accessories, options ...........................................................................................................................43

9.1 Welding torch, electrode holder and workpiece lead...................................................................43

9.2 Remote controls and accessories................................................................................................43

9.2.1 Pico 300 cel pws...........................................................................................................43

9.3 Options.........................................................................................................................................43

9.4 General accessories ....................................................................................................................43

10 Appendix A............................................................................................................................................44

10.1 Overview of EWM branches.........................................................................................................44

Safety instructions

Notes on the use of these operating instructions

099-002032-EW501

29.04.2010

5

Safety instructions

2 Safety instructions

2.1 Notes on the use of these operating instructions

DANGER

Working or operating procedures which must be closely observed to prevent imminent

serious and even fatal injuries.

• Safety notes include the "DANGER" keyword in the heading with a general warning symbol.

• The hazard is also highlighted using a symbol on the edge of the page.

WARNING

Working or operating procedures which must be closely observed to prevent serious

and even fatal injuries.

• Safety notes include the "WARNING" keyword in the heading with a general warning

symbol.

• The hazard is also highlighted using a symbol in the page margin.

CAUTION

Working or operating procedures which must be closely observed to prevent possible

minor personal injury.

• The safety information includes the "CAUTION" keyword in its heading with a general

warning symbol.

• The risk is explained using a symbol on the edge of the page.

CAUTION

Working and operating procedures which must be followed precisely to avoid damaging

or destroying the product.

• The safety information includes the "CAUTION" keyword in its heading without a general

warning symbol.

• The hazard is explained using a symbol at the edge of the page.

NOTE

Special technical points which users must observe.

• Notes include the "NOTE" keyword in the heading without a general warning symbol.

Safety instructions

Notes on the use of these operating instructions

6

099-002032-EW501

29.04.2010

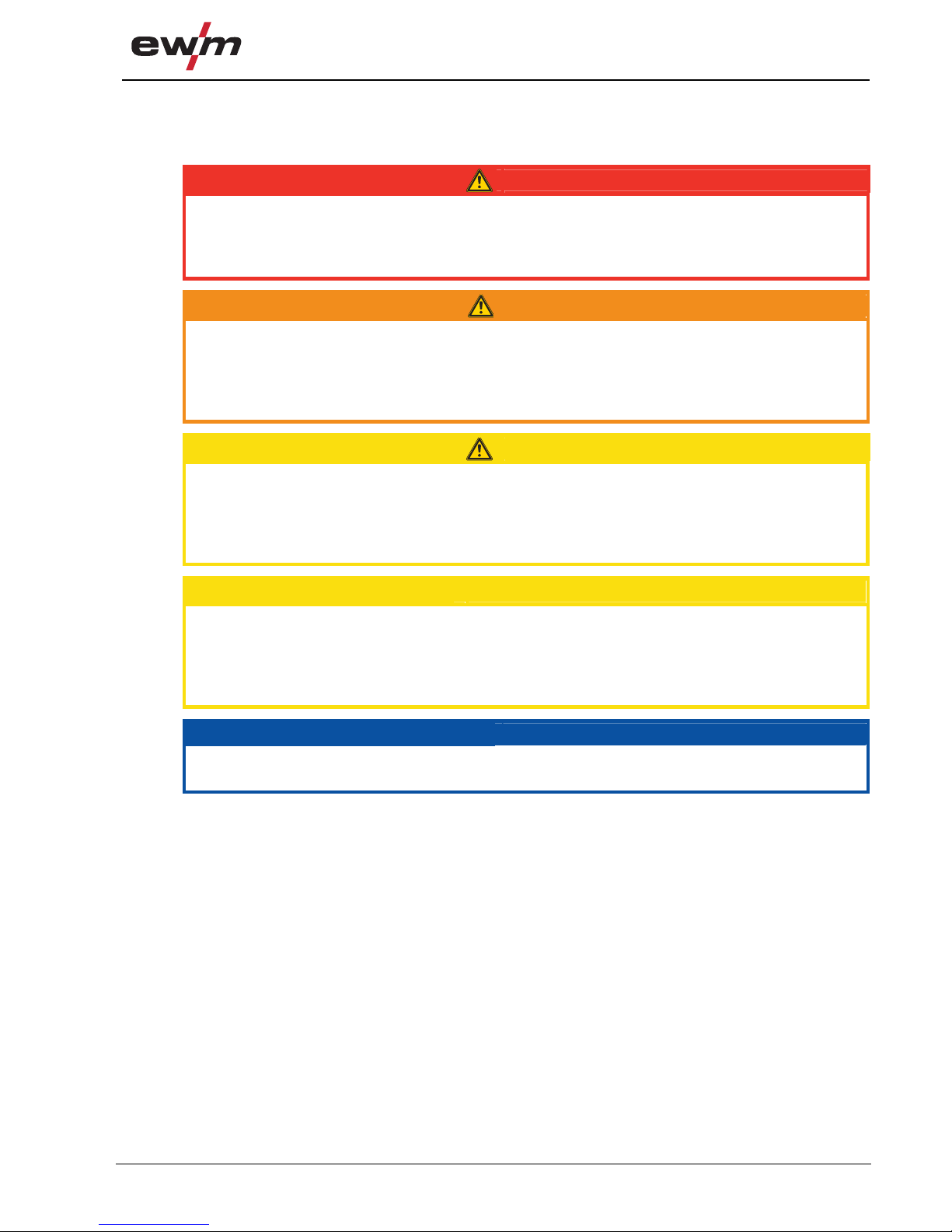

Instructions and lists detailing step-by-step actions for given situatio ns can be recognised via bullet

points, e.g.:

• Insert the welding current lead socket into the relevant socket and lock.

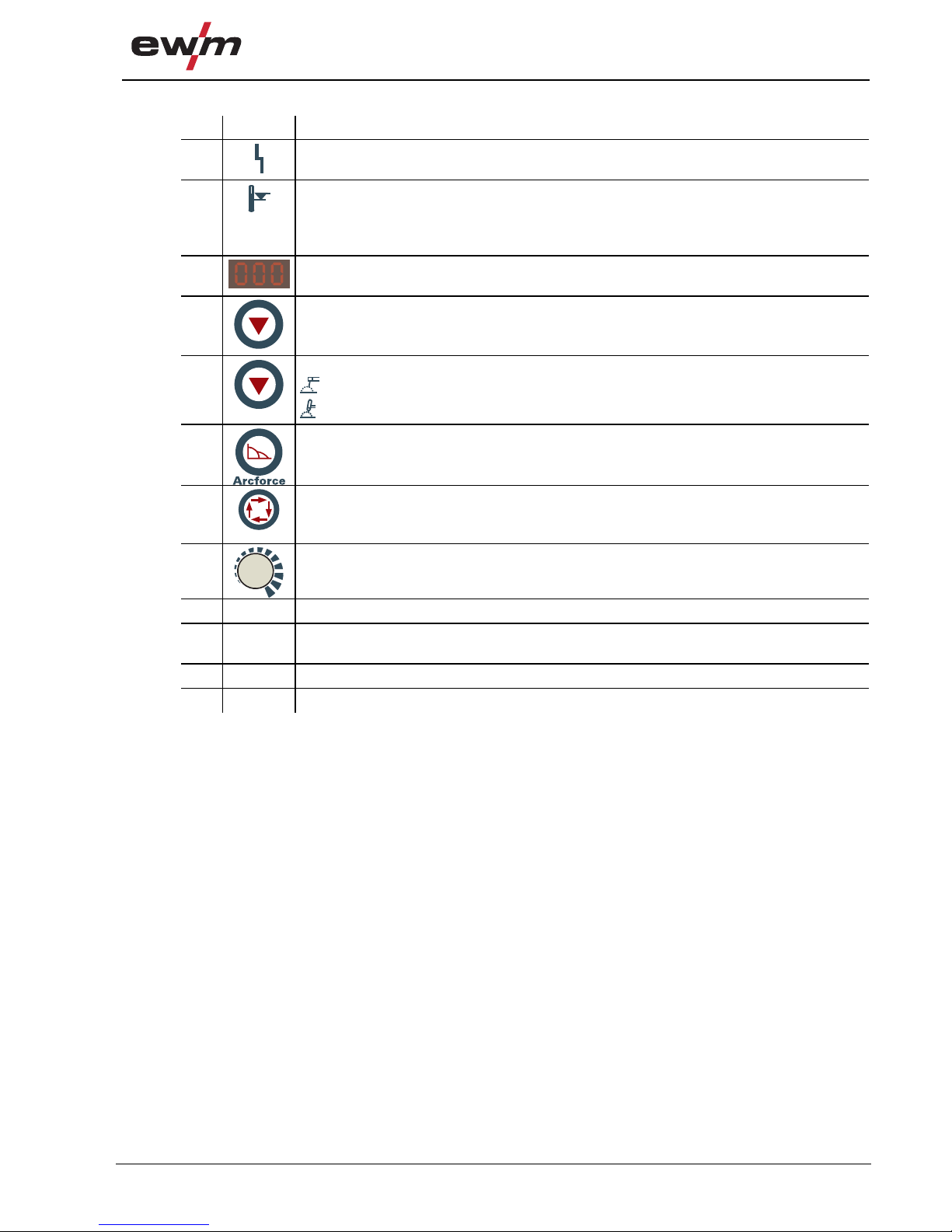

Symbol Description

Press

Do not press

Turn

Switch

0

1

Switch off machine

0

1

Switch on machine

ENTER (enter the menu)

NAVIGATION (Navigating in the menu)

EXIT (Exit the menu)

Time display (example: wait 4s/press)

Interruption in the menu display (other setting options possible)

Tool not required/do not use

Tool required/use

Safety instructions

General

099-002032-EW501

29.04.2010

7

2.2 General

DANGER

Electromagnetic fields!

The power source may cause electrical or electromagnetic fields to be produced which

could affect the correct functioning of electronic equipment such as IT or CNC devices,

telecommunication lines, power cables, signal lines and pacemakers.

• Observe the maintenance instructions! (see Maintenance and Testing chapter)

• Unwind welding lines completely!

• Shield devices or equipment sensitive to radiation accordingly!

• The correct functioning of pacemakers may be affected (obtain advice from a doctor if

necessary).

Do not carry out any unauthorised repairs or modifications!

To avoid injury and equipment damage, the unit must only be repaired or modified by

specialist, skilled persons!

The warranty becomes null and void in the event of unauthorised interference.

• Appoint only skilled persons for repair work (trained service personnel)!

Electric shock!

Welding machines use high voltages which can result in potentially fatal electric shocks

and burns on contact. Even low voltages can cause you to get a shock and lead to

accidents.

• Do not touch any live parts in or on the machine!

• Connection cables and leads must be free of faults!

• Switching off alone is not sufficient!

• Place welding torch and stick electrode holder on an insulated surf ace!

• The unit should only be opened by specialist staff after the mains plug has been unplugged!

• Only wear dry protective clothing!

• Wait for 4 minutes until the capacitors have discharged!

WARNING

Risk of injury due to radiation or heat!

Arc radiation results in injury to skin and eyes.

Contact with hot workpieces and sparks results in burns.

• Wear dry protective clothing (e.g. welding shield, gloves, etc.) according to the relevant

regulations in the country in question!

• Protect persons not involved in the work against arc beams and the risk of glare using safety

curtains!

Explosion risk!

Apparently harmless substances in closed containers may generate excessive pressur e

when heated.

• Move containers with inflammable or explosive liquids away from the working area!

• Never heat explosive liquids, dusts or gases by weldi ng or cutting!

Safety instructions

General

8

099-002032-EW501

29.04.2010

WARNING

Smoke and gases!

Smoke and gases can lead to breathing difficulties and poisoning. In addition, solvent

vapour (chlorinated hydrocarbon) may be converted into poisonous phosgene due to the

ultraviolet radiation of the arc!

• Ensure that there is sufficient fresh air!

• Keep solvent vapour away from the arc beam field!

• Wear suitable breathing apparatus if appropriate!

Fire hazard!

Flames may arise as a result of the high temperatures, stray sparks, glowing-hot parts

and hot slag produced during the welding process.

Stray welding currents can also result in flames forming!

• Check for fire hazards in the working area!

• Do not carry any easily flammable objects such as matches or lighters.

• Keep appropriate fire extinguishing equipment to hand in the working area!

• Thoroughly remove any residue of flammable substances from the workpiece before starting

welding.

• Only continue work on welded workpieces once they have cooled down.

Do not allow to come into contact with flammable material!

• Connect welding leads correctly!

Risk of accidents if these safety instructions are not observed!

Non-observance of these safety instructions is potentially fatal!

• Carefully read the safety information in this manual!

• Observe the accident prevention regulations in your country.

• Inform persons in the working area that they must observe the regulations!

CAUTION

Noise exposure!

Noise exceeding 70 dBA can cause permanent hearing damage!

• Wear suitable ear protection!

• Persons located within the working area must wear suitable ear protection!

Safety instructions

General

099-002032-EW501

29.04.2010

9

CAUTION

Obligations of the operator!

The respective national directives and laws must be observed for operation of the

machine!

• National implementation of the framework directive (89/391/EWG), as well as the associated

individual directives.

• In particular, directive (89/655/EWG), on the minimum regulations for safety and health

protection when staff members use equipment during work.

• The regulations regarding work safety and accident prevention for the respective country.

• Setting up and operating the machine according to IEC 60974-9.

• Check at regular intervals that users are working in a safety-conscious way.

• Regular checks of the machine according to IEC 60974-4.

Damage due to the use of non-genuine parts!

The manufacturer's warranty becomes void if non-genuine parts are used!

• Only use system components and options (power source s, welding torches, electrode

holders, remote controls, spare parts and replacement parts, etc.) from our range of

products!

• Only insert and lock accessory components into the relevant connection socket when the

machine is switched off.

Electromagnetic interference!

The machines are intended to be used in industrial areas, according to IEC 60974-10. If

they are used in residential areas, for example, problems may occur with ensuring

electromagnetic compatibility.

• Check whether interference is caused to other machines!

Safety instructions

Transport and installation

10

099-002032-EW501

29.04.2010

2.3 Transport and installation

WARNING

Incorrect handling of shielding gas cylinders!

Incorrect handling of shielding gas cylinders can result in serious and even fatal injury.

• Observe the instructions from the gas manufacturer and in any relevant regulations

concerning the use of compressed air!

• Place shielding gas cylinders in the holders provided for them and secure with fixing

devices.

• Avoid heating the shielding gas cylinder!

CAUTION

Risk of tipping!

There is a risk of the machine tipping over and injuring persons or being damaged itself

during movement and set up. Tilt resistance is guaranteed up to an angle of 10°

(according to IEC 60974-1, -3, -10).

• Set up and transport the machine on level, solid ground.

• Secure add-on parts using suitable equipment.

Damage due to supply lines not being disconnected!

During transport, supply lines which have not been disconnected (mains supply leads,

control leads, etc.) may cause hazards such as connected equipment tipping over and

injuring persons!

• Disconnect supply lines!

CAUTION

Equipment damage when not operated in an upright position!

The units are designed for operation in an upright position!

Operation in non-permissible positions can cause equipment damage.

• Only transport and operate in an upright position!

Safety instructions

Ambient conditions

099-002032-EW501

29.04.2010

11

2.4 Ambient conditions

CAUTION

Installation site!

The machine must not be operated in the open air and must only be set up and operated

on a suitable, stable and level base!

• The operator must ensure that the ground is non-slip and level, and provide sufficient

lighting for the place of work.

• Safe operation of the machine must be guaranteed at all times.

CAUTION

Equipment damage due to dirt accumulation!

Unusually high quantities of dust, acid, corrosive gases or substances may damage the

equipment.

• Avoid high volumes of smoke, vapour, oil vapour and grinding dust!

• Avoid ambient air containing salt (sea air)!

Non-permissible ambient conditions!

Insufficient ventilation results in a reduction in performance and equipment damage.

• Observe the ambient conditions!

• Keep the cooling air inlet and outlet clear!

• Observe the minimum distance of 0.5 m from obstacles!

2.4.1 In operation

Temperature range of the ambient air:

• -20 °C to +40 °C

Relative air humidity:

• Up to 50% at 40 °C

• Up to 90% at 20 °C

2.4.2 Transport and storage

Storage in an enclosed space, temperature range of the ambient air:

• -25 °C to +55 °C

Relative air humidity

• Up to 90% at 20 °C

Intended use

Applications

12

099-002032-EW501

29.04.2010

3 Intended use

This machine has been manufactured according to the latest developments in technology and current

regulations and standards. It must only be operated in line with the instructions on correct us age.

WARNING

Hazards due to improper usage!

Hazards may arise for persons, animals and material objects if the equipment is not used

correctly. No liability is accepted for any damages arising from improper usage!

• The equipment must only be used in line with proper usage and by trained or expert staff!

• Do not modify or convert the equipment improperly!

3.1 Applications

3.1.1 MMA welding

Manual arc welding or, for short, MMA welding. It is characterised by the fact that the arc burns between

a melting electrode and the molten pool. There is no external protection; any protection against the

atmosphere comes from the electrode.

3.1.2 TIG (Liftarc) welding

TIG welding process with arc ignition by means of workpiece contact.

3.2 Overview of device types

3.2.1 Cellulose electrode types (cel)

CEL device types are equipped with special Arcforce characteri stics.

These device types facilitate welding with cellulose electrode types which is safe for vertical-down

welding, especially in the lower output range.

3.2.2 Pole reversing switch (pws)

With PWS device types, the polarity of the welding current connections (pole reversal) can be changed

using a changeover switch on the machine or on the remote control.

Useful function with frequently changing electrode types without time-consuming reconnection of the

welding current connections (also directly at the operating point, in combination with a PWS remote

control).

3.2.3 Voltage reducing device (VRD/SVRD)

The voltage reducing device is a requirement in some countries and in many internal compan y safety

guidelines for power sources.

A distinction is made between two versions:

• VRD (Voltage Reduction Device) or

• SVRD (Slow Voltage Reduction Device)

Both switches meet the European standard (EN 60974-1:2005) and result in an increase in safety in

hazardous environments in particular (such as ship construction, pipe construction, mining).

VRD reduces the open circuit voltage to 12 V within 0.2 s and thus fulfils the Australian standard

(AS 1674.2-2003). SVRD reduces the open circuit voltage within 0.8 s to 12 V and thus fulfils the Russi an

standard (ГОСТ 12.2 007.8).

Intended use

Documents which also apply

099-002032-EW501

29.04.2010

13

3.3 Documents which also apply

3.3.1 Warranty

NOTE

For further information, please see the accompanying supplementary sheets "Machine

and Company Data, Maintenance and Testing, Warranty"!

3.3.2 Declaration of Conformity

The designated machine conforms to EC Directives and standards in terms of its design

and construction:

• EC Low Voltage Directive (2006/95/EC),

• EC EMC Directive (2004/108/EC),

This declaration shall become null and void in the event of unauthorised modifications, improperly

conducted repairs, non-observance of the deadlines for the repetition test and / or non-permitted

conversion work not specifically authorised by the manufacturer.

The original copy of the declaration of conformity is enclosed with the unit.

3.3.3 Welding in environments with increased electrical hazards

In compliance with IEC / DIN EN 60974, VDE 0544 the machines can be used in

environments with an increased electrical hazard.

3.3.4 Service documents (spare parts and circuit diagrams)

DANGER

Do not carry out any unauthorised repairs or modifications!

To avoid injury and equipment damage, the unit must only be repaired or modified by

specialist, skilled persons!

The warranty becomes null and void in the event of unauthorised interference.

• Appoint only skilled persons for repair work (trained service personnel)!

Original copies of the circuit diagrams are enclosed with the unit.

Spare parts can be obtained from the relevant authorised dealer.

Machine description – quick overview

Pico 300 cel

14

099-002032-EW501

29.04.2010

4 Machine description – quick overview

4.1 Pico 300 cel

4.1.1 Front view

Figure 4-1

Machine description – quick overview

Pico 300 cel

099-002032-EW501

29.04.2010

15

Item Symbol Description 0

1

Carrying strap

2 Transport bar

3

Carrying handle

4

Machine control

See Machine control – operating elements chapter

5 Cooling air inlet

6

Connection socket, "+" welding current

• TIG: Connection for workpiece lead

• MMA: Electrode holder or workpiece lead connection

7

Connection socket, 19-pole

Remote control connection

8

Connection socket, “-” welding current

Electrode holder or workpiece lead connection

9

Machine feet

10

Pole reversal changeover switch

The changeover switch is used to switch over the welding current polarity (“+” or “-” ) of

the electrode holder and workpiece lead connection sockets.

= Welding current polarity “+” on connection socket .

= Welding current polarity “-” on connection socket .

11

Connection socket, electrode holder

The welding current polarity (“+” or “-”) are based on the setting of the “Welding current

polarity changeover switch”.

12

Connection socket, workpiece lead

The welding current polarity (“+” or “-”) are based on the setting of the “Welding current

polarity changeover switch".

Machine description – quick overview

Pico 300 cel

16

099-002032-EW501

29.04.2010

4.1.2 Rear view

Figure 4-2

Machine description – quick overview

Pico 300 cel

099-002032-EW501

29.04.2010

17

Item Symbol Description 0

1

Main switch, machine on/off

2 Mains connection cable

3 Cooling air outlet

4

F4

Fuse

Solenoid switch pole reversal fuse

5

F5

Fuse

Solenoid switch pole reversal fuse

Machine description – quick overview

Machine control – Operating elements

18

099-002032-EW501

29.04.2010

4.2 Machine control – Operating elements

Figure 4-3

Machine description – quick overview

Machine control – Operating elements

099-002032-EW501

29.04.2010

19

Item Symbol Description 0

1

Collective interference signal light

For error messages, see the "Rectifying faults" chapter

2

Excess temperature signal light

In case of excess temperature, temperature monitors de-activate the power unit, and

the excess temperature control lamp comes on. Once the machine has cooled down,

welding can continue without any further measures.

3

Three-figure LED display

Display of welding current and voltage, welding parameters, error code

4

Switch display button

AMP Welding current display

VOLT Welding voltage display

5

Welding process button

MMA welding

TIG welding

6

“Arcforce” button (welding characteristics) according to electrode type

7

Select welding parameters button

This button is used to select the welding parameters depending on the welding process

and operating mode used.

8

Welding parameter setting rotary transducer

Setting of welding current and other welding parameter and their values

9 VRD

VRD open circuit voltage reduction

10 AMP%

Hotstart current signal light

50 % to 200 % of the main current

11 sec

Hotstart time signal light (0.1 s to 20 s)

12 AMP

Main current signal light

Design and function

General

20

099-002032-EW501

29.04.2010

5 Design and function

5.1 General

DANGER

Risk of injury from electric shock!

Contact with live parts, e.g. welding current sockets, is potentially fatal!

• Follow safety instructions on the opening pages of the operating instructions.

• Commissioning may only be carried out by persons who have the relevant expertise of

working with arc welding machines!

• Connection and welding leads (e.g. electrode holder, welding torch, workpiece lead,

interfaces) may only be connected when the machine is switched off!

CAUTION

Risk of burns on the welding current connection!

If the welding current connections are not locked, connections and leads heat up and can

cause burns, if touched!

• Check the welding current connections every day and lock by turning in clockwise direction, if

necessary.

CAUTION

Using protective dust caps!

Protective dust caps protect the connection sockets and ther efore the machine against

dirt and damage.

• The protective dust cap must be fitted if there is no accessory component being operated on

that connection.

• The cap must be replaced if faulty or if lost!

5.2 Machine cooling

To obtain an optimal duty cycle from the power components, the following precautions should be

observed:

• Ensure that the working area is adequately ventilated.

• Do not obstruct the air inlets and outlets of the machine.

• Do not allow metal parts, dust or other objects to get into the machine.

5.3 Workpiece lead, general

CAUTION

Risk of burns due to incorrect connection of the workpiece lead!

Paint, rust and dirt on the connection restrict the power flow and may lead to stray

welding currents.

Stray welding currents may cause fires and injuries!

• Clean the connections!

• Fix the workpiece lead securely!

• Do not use structural parts of the workpiece as a return lead for the welding current!

• Take care to ensure faultless power connections!

Design and function

Transport and installation

099-002032-EW501

29.04.2010

21

5.4 Transport and installation

CAUTION

Installation site!

The machine must not be operated in the open air and must only be set up and operated

on a suitable, stable and level base!

• The operator must ensure that the ground is non-slip and level, and provide sufficient

lighting for the place of work.

• Safe operation of the machine must be guaranteed at all times.

5.4.1 Adjusting the length of the carrying strap

NOTE

To demonstrate adjustment, lengthening the strap is shown in the figure. To shorten,

the strap's loops must be inched in the opposite direction.

Figure 5-1

Design and function

Mains connection

22

099-002032-EW501

29.04.2010

5.5 Mains connection

DANGER

Hazard caused by improper mains connection!

An improper mains connection can cause injuries or damage property!

• Only use machine with a plug socket that has a correctly fitted protective conductor.

• If a mains plug must be fitted, this may only be carried out by an electrician in accordance

with the relevant national provisions or regulations (any phase sequence for three-phase

machines)!

• Mains plug, socket and lead must be checked regularly by an electrician!

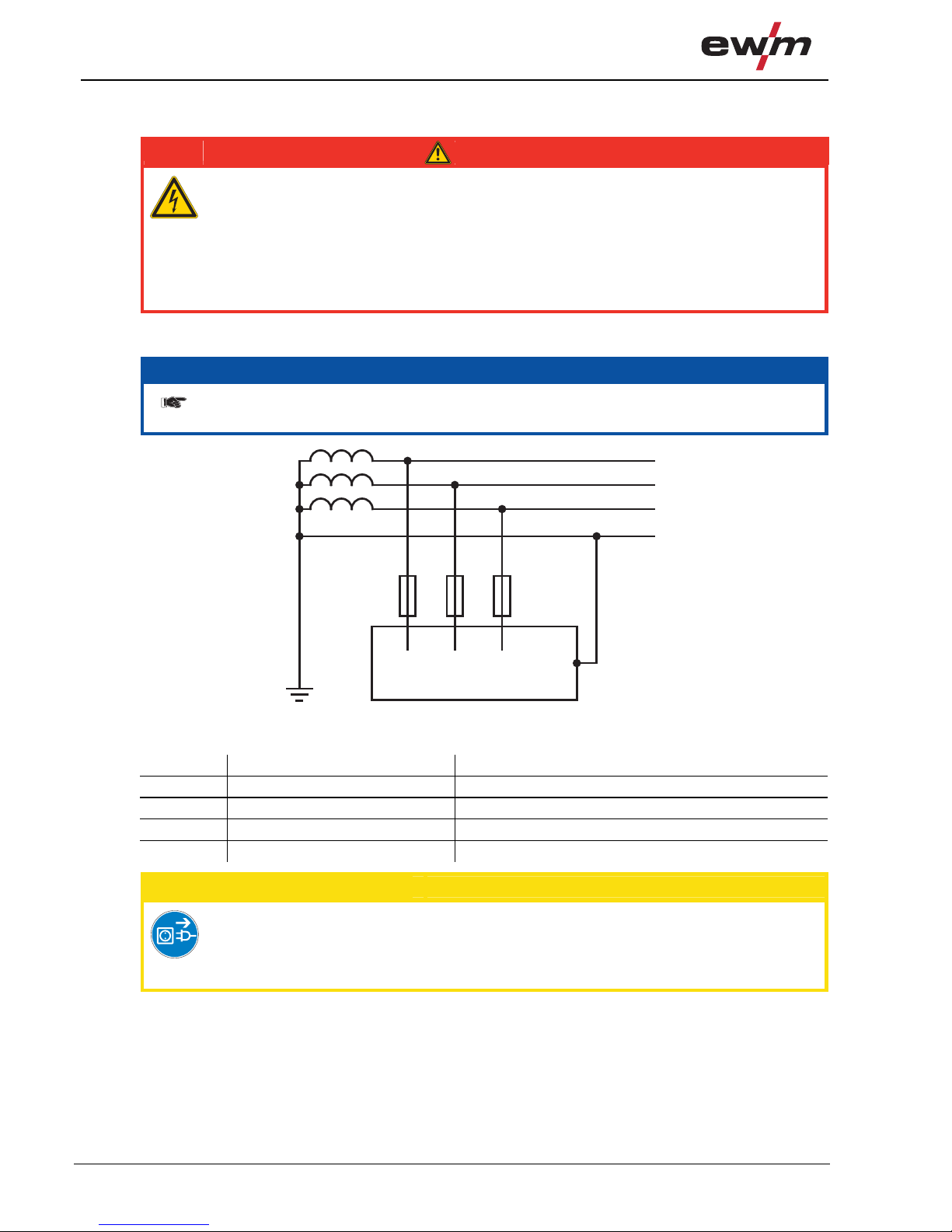

5.5.1 Mains configuration

NOTE

The machine may be connected to TN, TT or IT networks with a protective conductor (as

available).

L1

L3

L2

PE

Figure 5-2

Legend

Item Designation Colour code

L1 Outer conductor 1 black

L2 Outer conductor 2 brown

L3 Outer conductor 3 grey

PE Protective conductor green-yellow

CAUTION

Operating voltage - mains voltage!

The operating voltage shown on the rating plate must be consistent with the mains

voltage, in order to avoid damage to the machine!

• For mains fuse protection, please refer to the “Technical data” chapter!

• Insert mains plug of the switched-off machine into the appropriate socket.

Design and function

MMA welding

099-002032-EW501

29.04.2010

23

5.6 MMA welding

CAUTION

Risk of being crushed or burnt.

When replacing spent or new stick electrodes

• Switch off machine at the main switch

• Wear appropriate safety gloves

• Use insulated tongs to remove spent stick electrodes or to move welded workpieces and

• Always put the electrode holder down on an insulated surface.

NOTE

Polarity depends on the instructions from the electrode manufacturer given on the

electrode packaging.

5.6.1 Connecting the electrode holder and workpiece lead

5.6.1.1 Pico 300 cel

Figure 5-3

Item Symbol Description 0

1

Electrode holder

2

Connection socket for "+" welding current

Electrode holder or workpiece lead connection

3

Workpiece

4

Connection socket, “-” welding current

Workpiece lead or electrode holder connection

• Insert cable plug of the electrode holder into either the "+" or "-" welding current connection socket and

lock by turning to the right.

• Insert cable plug of the workpiece lead into either the "+" or "-" welding current connection socket and

lock by turning to the right.

Design and function

MMA welding

24

099-002032-EW501

29.04.2010

5.6.1.2 Pico 300 cel pws

NOTE

+ / -

The pole reversal changeover switch allows the welding current polarity (+/-) to be

changed without unplugging the electrode holder or workpiece leads. Changeover can

also be carried out using a suitable remote control (PWS). The polarity cannot be

changed during welding!

Figure 5-4

Design and function

MMA welding

099-002032-EW501

29.04.2010

25

Item Symbol Description 0

1

Electrode holder

2

Connection socket, electrode holder

The welding current polarity (“+” or “-”) are based on the setting of the “Welding current

polarity changeover switch”.

3

Workpiece

4

Connection socket, workpiece lead

The welding current polarity (“+” or “-”) are based on the setting of the “Welding current

polarity changeover switch".

5

Pole reversal changeover switch

The changeover switch is used to switch over the welding current polarity (“+” or “-” ) of

the electrode holder and workpiece lead connection sockets.

= Welding current polarity “+” on connection socket .

= Welding current polarity “-” on connection socket .

• Insert cable plug on the electrode holder into the welding current socket “ ” and lock by turning to

the right.

• Insert cable plug on the workpiece lead into the welding current socket “

” and lock by turning

to the right.

Design and function

MMA welding

26

099-002032-EW501

29.04.2010

5.6.2 Selecting MMA welding

Operating

element

Action Result

Select MMA welding process

The

signal light lights up in green

Set welding current

5.6.2.1 Arcforce (welding characteristics)

During the welding process, arcforce prevents the electrode sticking in the weld pool with increases in

current. This makes it easier to weld large-drop melting electrode types at low current strengths with a

short arc in particular.

NOTE

The selectable electrode characteristics on the machine control are guideline values.

Every characteristic can also be optimised for the relevant electrode types and their

welding properties (see chapter "Arcforce correction").

The electrode types used must be selected on the machine control to achieve the optimum

welding properties of the electrode types.

Control element Action Result

x x

The corresponding signal light displays the selection.

Electrode type allocation

Item Electrode type

a)

rutile

b)

rutile basic

c)

basic and

rutile/cellulose

d)

cellulose

Figure 5-5

Design and function

MMA welding

099-002032-EW501

29.04.2010

27

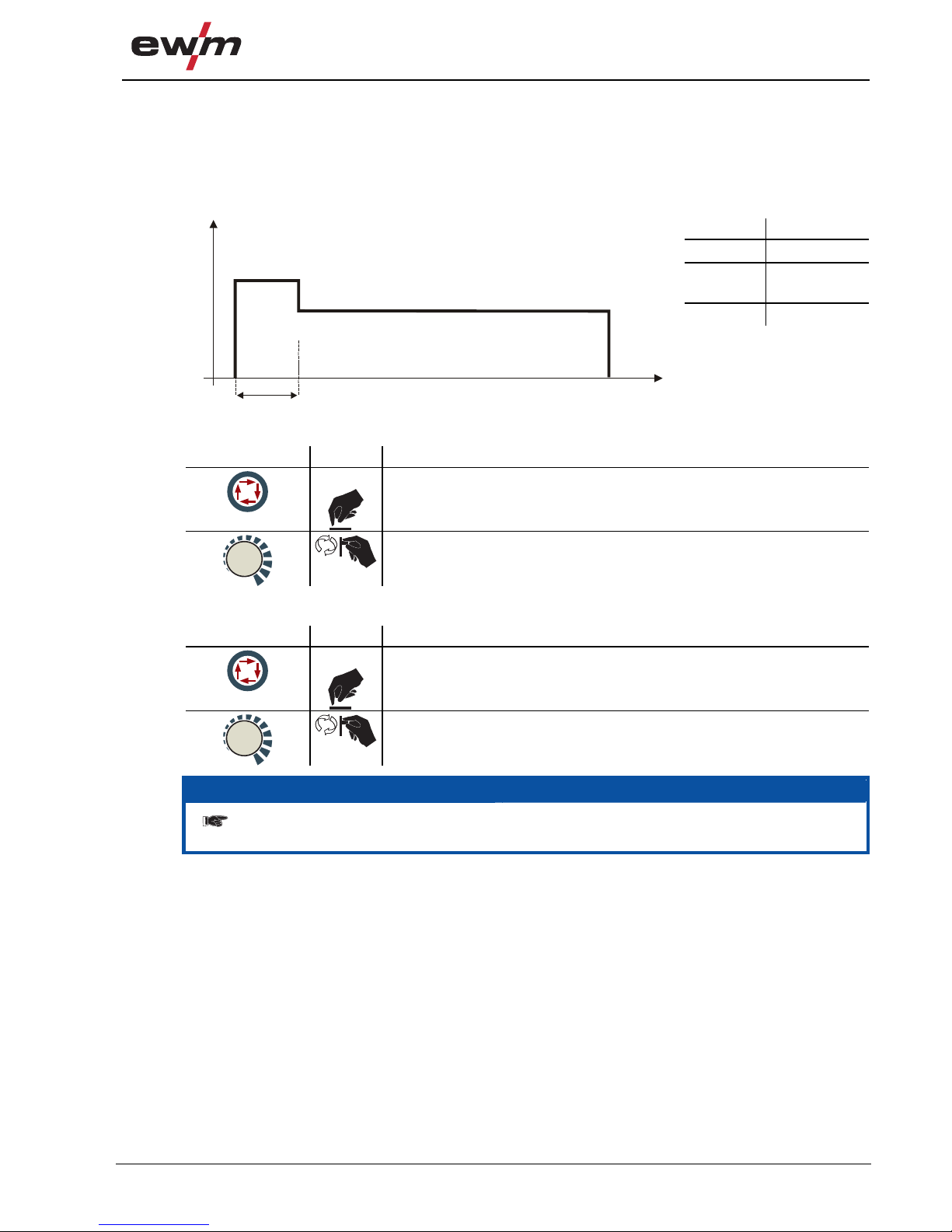

5.6.3 Hotstart current and Hotstart time

The hotstart device uses an increased ignition current to improve arc ignition. The parameters for

the hotstart current and time can be adjusted individually.

When the stick electrode has been struck, the arc ignites at the adjusted hotsta rt current AMP% (factory

setting: 120 % of main current)

and welds at this current until the hotstart time in seconds has elapsed

(factory setting: 1 second). The hotstart current then reduces to the main current set.

Symbol Meaning

AMP Main current

AMP% Hotstart

current

sec Hotstart time

t

AMP%

AMP

I

sec

Figure 5-6

Hotstart current

Control element Action Result

n x

Signal light AMP% lights up

Hotstart current is set as a percentage of the main current

(50 % to 200 %)

Hotstart time

Control element Action Result

n x

Signal light sec lights up

Hotstart time is set

(0.1 s to 20 s)

NOTE

After a waiting time of approx 5 s, the display changes back to the main current set and

the signal light AMP comes on.

Design and function

MMA welding

28

099-002032-EW501

29.04.2010

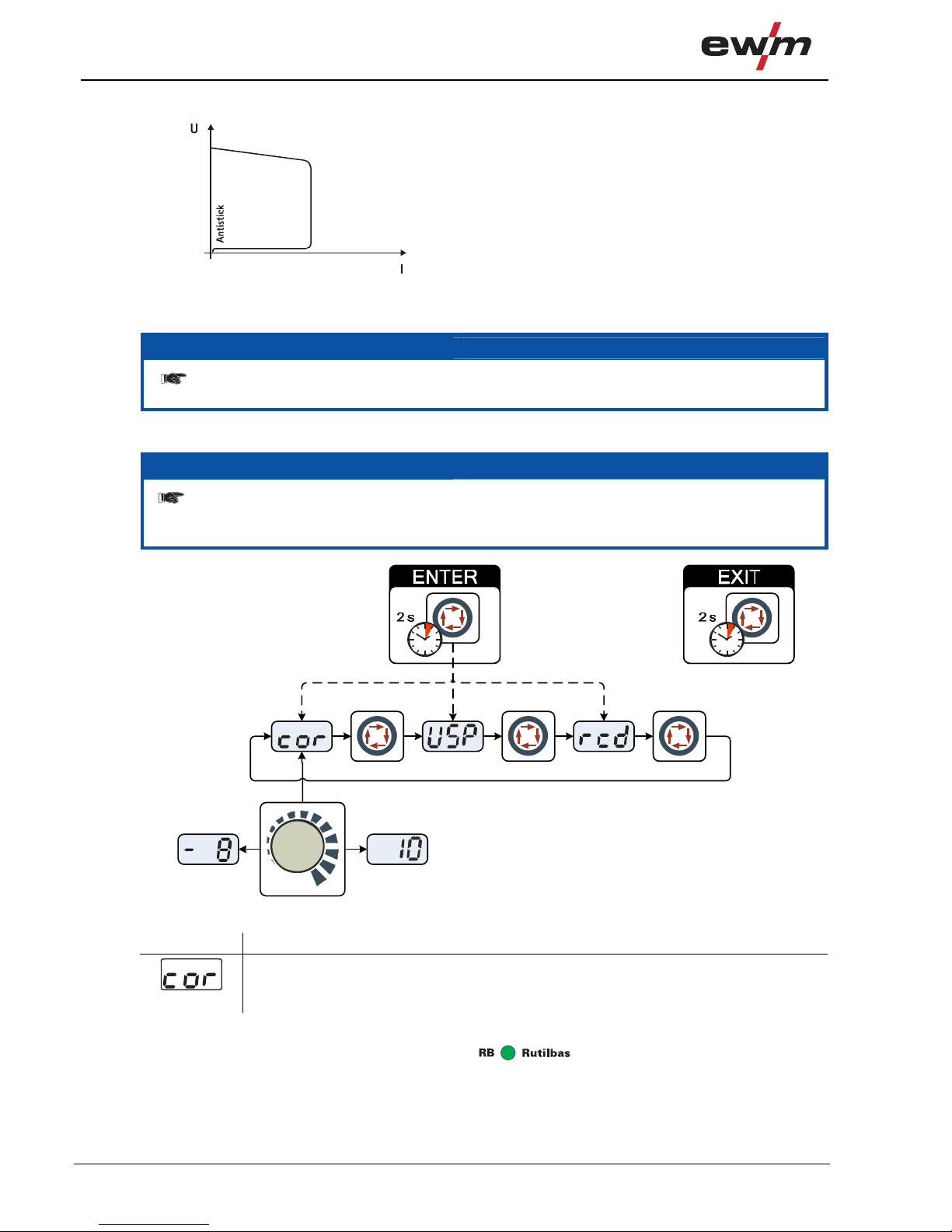

5.6.4 Antistick

Anti-stick prevents the electrode from annealing.

If the electrode sticks in spite of the Arcforce device, the

machine automatically switches over to the minimum

current within about 1 second to prevent the electrode

from overheating. Check the welding current setting

and correct according to the welding task!

Figure 5-7

5.6.5 Advanced settings

NOTE

To enable the greatest possible breadth of applications, the following parameters can

be adjusted or optimised for the welding task.

5.6.5.1 Arcforce correction (welding characteristics)

NOTE

To change the advanced setting parameters, hold down the "Welding parameters" button

for 2 seconds after selecting the welding process.

The following diagram shows the setting options.

Figure 5-8

Display Setting/selection

Arcforce correction (setting -8 to 10, factory setting 0)

• Increase value > harder arc

• Decrease value > softer arc

Example:

You are using a rutile/basic electrode type and set "

" accordingly on the machine control.

When welding the electrode type, you specify a hard or aggressive arc. You should now change the

arcforce setting in the direction of "less arcforce – softer arc" until the required result is achieved.

Design and function

TIG welding

099-002032-EW501

29.04.2010

29

5.7 TIG welding

5.7.1 Shielding gas supply (shielding gas cylinder for welding machine)

WARNING

Incorrect handling of shielding gas cylinders!

Incorrect handling of shielding gas cylinders can result in serious and even fatal injury.

• Observe the instructions from the gas manufacturer and in any relevant regulations

concerning the use of compressed air!

• Place shielding gas cylinders in the holders provided for them and secure with fixing

devices.

• Avoid heating the shielding gas cylinder!

CAUTION

Faults in the shielding gas supply.

An unhindered shielding gas supply from the shielding gas cylinder to the welding torch

is a fundamental requirement for optimum welding results. In addition, a blocked

shielding gas supply may result in the welding torch being destroyed.

• Always re-fit the yellow protective cap when not using the shielding gas connection.

• All shielding gas connections must be gas tight.

NOTE

Before connecting the pressure reducer to the gas cylinder, open the cylinder valve

briefly to expel any dirt.

Design and function

TIG welding

30

099-002032-EW501

29.04.2010

5.7.1.1 Connecting the shielding gas supply

• Secure the shielding gas cylinder using a securing chain.

Figure 5-9

Item Symbol Description 0

1

Pressure reducer

2

Shielding gas cylinder

3

Output side of the pressure reducer

4

Cylinder valve

• Tighten the pressure reducer screw connection on the gas bottle valve to be gas-tight.

• Screw the shielding gas connection of the welding torch to the pressure reduce r on the shielding gas

cylinder.

• Slowly open the gas cylinder valve.

• Open the rotating valve on the welding torch

Before each welding process, the rotating valve must be opened; after the welding process, it

must be closed.

• Set the required amount of shielding gas on the pressure reducer, about 4 - 15 l/min depending on the

current strength and the material.

Rule of thumb for gas flow rate:

Diameter of gas nozzle in mm corresponds to gas flow in l/min.

Example: 7 mm gas nozzle corresponds to 7 l/min gas flow

Design and function

TIG welding

099-002032-EW501

29.04.2010

31

5.7.2 Connecting a TIG welding torch with rotating gas valve

5.7.2.1 Pico 300 cel

Figure 5-10

Item Symbol Description 0

1

Workpiece

2

Connection socket for "+" welding current

Workpiece lead connection

3

Output side of the pressure reducer

4

Welding torch

5

Connection socket, "-" welding current

Welding current lead connection for TIG welding torch

• Insert the welding current plug on the welding torch into the welding current connection socket and

lock by turning to the right.

• Insert the cable plug on the work piece lead into the "+" welding current connection socket and lock by

turning to the right.

• Screw the shielding gas connection of the welding torch to the pressure reduce r on the shielding gas

cylinder.

Design and function

TIG welding

32

099-002032-EW501

29.04.2010

5.7.2.2 Pico 300 cel pws

NOTE

For machines with pole reversal switch (PWS), the welding current polarity is changed

as follows after selecting “TIG welding process”:

• Electrode holder connection socket = welding current polarity “-” ,

• Workpiece lead connection socket = welding current polarity “+”.

Figure 5-11

Item Symbol Description 0

1

Output side of the pressure reducer

2

Welding torch

3

Connection socket, TIG welding torch

4

Workpiece

5

Connection socket, workpiece lead

• Insert the welding current plug of the welding torch into the connection socket and lock by turning

to the right.

• Insert cable plug on the workpiece lead into the welding current socket “

” and lock by turning

to the right.

• Screw the shielding gas connection of the welding torch to the pressure reduce r on the shielding gas

cylinder.

Design and function

TIG welding

099-002032-EW501

29.04.2010

33

5.7.3 TIG welding selection

Control element Action Result

x x

TIG welding signal light

lights up

Main current setting

5.7.4 TIG arc ignition

5.7.4.1 Liftarc ignition

a) b) c)

Figure 5-12

The arc is ignited on contact with the workpiece:

a) Carefully place the torch gas nozzle and tungsten electrode tip onto the workpiece (liftarc current

flowing, regardless of the main current set).

b) Incline the torch towards the torch gas nozzle until there is a gap of approx. 2-3mm between the tip of

the electrode and the workpiece (arc ignites, current increases to the main current set).

c) Lift off the torch and swivel to the normal position.

Ending the welding process: Remove the torch from the workpiece until the arc goes out.

Design and function

Advanced settings

34

099-002032-EW501

29.04.2010

5.8 Advanced settings

NOTE

To enable the greatest possible breadth of applications, the following parameters can

be adjusted or optimised for the welding task.

5.8.1 Arc length restriction (USP)

Figure 5-13

Display Setting/selection

Arc length restriction

on Function switched on (TIG, factory setting)

off Function switched off (MMA, factory setting)

Design and function

Advanced settings

099-002032-EW501

29.04.2010

35

5.8.2 Activating the welding current actual value display

The welding current can be displayed as a setpoint value or an actual value on the welding data display.

The factory setting is that the welding current is displayed as a setpoint value (parameter "rcd" = off).

After switching over to the actual value display (parameter "rcd" = on), the following is displayed:

• The setpoint value is displayed in open circuit mode (when no welding current is flowing)

• If welding current is flowing, the welding data display switches over to the actual value

• After welding, the setpoint value is displayed once more

Figure 5-14

Display Setting/selection

Power display switching

on Actual value display

off Setpoint value display (factory setting)

Design and function

Voltage reducing device (VRD/SVRD)

36

099-002032-EW501

29.04.2010

5.9 Voltage reducing device (VRD/SVRD)

The signal light (VRD open circuit voltage reduction) indicates when the voltage reduction device has

been activated. This then ensures that the open circuit voltage between the electrode holder and the

workpiece is reduced to the permissible values.

The voltage reducing device is a requirement in some countries and in many internal compan y safety

guidelines for power sources.

A distinction is made between two versions:

• VRD (Voltage Reduction Device) or

• SVRD (Slow Voltage Reduction Device)

Both switches meet the European standard (EN 60974-1:2005) and result in an increase in safety in

hazardous environments in particular (such as ship construction, pipe construction, mining).

VRD reduces the open circuit voltage to 12 V within 0.2 s and thus fulfils the Australian standard

(AS 1674.2-2003). SVRD reduces the open circuit voltage within 0.8 s to 12 V and thus fulfils the Russi an

standard (ГОСТ 12.2 007.8).

5.10 Remote control

NOTE

The remote control is operated on the 19-pole remote control connection socket.

5.10.1 Foot-operated remote control RTF 1

Features

• Infinitely adjustable welding current (0% to 100%) depending on the preselected

main current on the welding machine.

5.10.2 Manual remote control RT 1

Functions

• Infinitely adjustable welding current (0% to 100%) depending on the preselected

main current on the welding machine.

5.10.3 Manual remote control RT PWS 1

Functions

• Infinitely adjustable welding current (0% to 100%) depending on the preselected

main current at the welding machine

• Pole reversing switch, suitable for machines with PWS function

Design and function

Dirt filter

099-002032-EW501

29.04.2010

37

5.11 Dirt filter

NOTE

These accessory components can be retrofitted as an option, see Accessories chapter.

The dirt filter can be used in places with unusually high levels of dirt and dust in the ambient air.

The filter reduces the duty cycle of the welding machine via the reduced flow of cooling air. The

filter must be disassembled and cleaned regularly depending on the level of dirt (blow out with

compressed air).

1

2

3

Figure 5-15

Item Symbol Description 0

1

4 fixing screws for dirt filter

2

Dirt filter with fixing plate

3 Cooling air inlet

• Fix dirt filter with 4 fixing screws on the front of the casing (cooling air inlet) of the welding machine.

Maintenance, care and disposal

General

38

099-002032-EW501

29.04.2010

6 Maintenance, care and disposal

DANGER

Risk of injury from electric shock!

Cleaning machines that are not disconnected from the mains can lead to serious injuries!

• Disconnect the machine completely from the mains.

• Remove the mains plug!

• Wait for 4 minutes until the capacitors have discharged!

6.1 General

When used in the specified environmental conditions and under normal operating condition s, this

machine is largely maintenance-free and requires a minimum of care.

There are some points, which should be observed, to guarantee fault-free operation of your welding

machine. Among these are regular cleaning and checking as descri bed below, depending on the pollution

level of the environment and the length of time the unit is in use.

6.2 Maintenance work, intervals

6.2.1 Daily maintenance tasks

• Mains supply lead and its strain relief

• Welding current cables (check that they are fitted correctly and secured)

• Gas tubes and their switching equipment (solenoid valve)

• Operating, message, safety and adjustment devices (Functional test)

• Other, general condition

6.2.2 Monthly maintenance tasks

• Casing damage (front, rear and side walls)

• Transport elements (strap, lifting lugs, handle)

• Selector switches, command devices, emergency stop devices, voltage re ducing devices, message

and control lamps

6.2.3 Annual test (inspection and testing during operation)

NOTE

The welding machine may only be tested by competent, capable personsl.

A capable person is one who, because of his training, knowledge and experience, is

able to recognise the dangers that can occur while testing welding power sources as

well as possible subsequent damage and who is able to implement the required safety

procedures.

For further information, please see the accompanying supplementary sheets "Machine

and Company Data, Maintenance and Testing, Warranty"!

The former term of repetition test has been replaced due to a change in the corresponding standard with

“Inspection and testing during operation”.

In addition to the regulations on the test given here, the relevant local laws and regulations must also be

observed.

Maintenance, care and disposal

Repair Work

099-002032-EW501

29.04.2010

39

6.3 Repair Work

DANGER

Do not carry out any unauthorised repairs or modifications!

To avoid injury and equipment damage, the unit must only be repaired or modified by

specialist, skilled persons!

The warranty becomes null and void in the event of unauthorised interference.

• Appoint only skilled persons for repair work (trained service personnel)!

Repair and maintenance work may only be performed by qualified authorised personnel; otherwise the

right to claim under warranty is void. In all service matters, always consult the dealer who supplied the

machine. Return deliveries of defective equipment subject to warranty may only be made through your

dealer. When replacing parts, use only original spare parts. When ordering spare parts, please quote the

machine type, serial number and item number of the machine, as well as the type designation and item

number of the spare part.

6.4 Disposing of equipment

NOTE

Proper disposal!

The machine contains valuable raw materials, which should be recycled, and

electronic components, which must be disposed of.

• Do not dispose of in household waste!

• Observe the local regulations regarding disposal!

6.4.1 Manufacturer's declaration to the end user

• According to European provisions (guideline 2002/96/EG of the European Parliament and the Council

of January, 27th 2003), used electric and electronic equipment may no longer be placed in u nsorted

municipal waste. It must be collected separately. The symbol depicting a waste container on wheels

indicates that the equipment must be collected separately.

This machine is to be placed for disposal or recycling in the waste separation systems provided for this

purpose.

• According to German law (law governing the distribution, taking b ack and environmentally correct

disposal of electric and electronic equipment (ElektroG) from 16.03.2005), used machines are to be

placed in a collection system separate from unsorted municipal waste. The publi c waste management

utilities (communities) have created collection points at which used equipment from private households

can be disposed of free of charge.

• Information about giving back used equipment or about collections can be obtained from the

respective municipal administration office.

• EWM participates in an approved waste disposal and recycling system and is registe red in th e Used

Electrical Equipment Register (EAR) under number WEEE DE 57686922.

• In addition to this, returns are also possible throughout Europe via EWM sales partners.

6.5 Meeting the requirements of RoHS

We, EWM HIGHTEC Welding GmbH Mündersbach, hereby co nfirm that all products supplied by us which

are affected by the RoHS Directive, meet the requirements of the RoHS (Directive 2002/95/EC).

Rectifying faults

Error messages (power source)

40

099-002032-EW501

29.04.2010

7 Rectifying faults

All products are subject to rigorous production checks and final checks. If, despite this, something fails to

work at any time, please check the product using the following flowchart. If none of the fault rectification

procedures described leads to the correct functioning of the product, please inform you r autho rised

dealer.

7.1 Error messages (power source)

NOTE

A welding machine error is indicated by the collective fault signal lamp (A1) lighting up

and an error code (see table) being displayed in the machine control display. In the event

of a machine error, the power unit shuts down.

• If multiple errors occur, these are displayed in succession.

• Document machine errors and inform service staff as necessary.

Error message Possible cause Remedy

"E 1" Electronics error Switch the machine off and back on again. If the

error persists, inform the service dept.

"E 2" Temperature error Allow machine to cool down.

"E 3" Electronics error See “E 1”.

"E 4" Electronics error See “E 1”.

"E 5" Electronics error See “E 1”.

"E 6" Balancing error in voltage

recording

"E 7" Balancing error in current

recording

Switch off the machine, place the electrode holder

in an insulated position and switch the machine

back on. If the error persists, inform the service

dept.

"E 8" Error in one of the electronics

supply voltages

Switch the machine off and back on again. If the

error persists, inform the service dept.

"E 9" Mains undervoltage Switch off the machine and check the mains

voltage.

"E10" Secondary excess voltage Switch the machine off and back on again. If the

error persists, inform the service dept.

"E11" Mains excess voltage Switch off the machine and check the mains

voltage.

"E12" Voltage reduction error (VRD) Switch the machine off and back on again. If the

error persists, inform the service dept.

Rectifying faults

Resetting welding parameters to the factory settings

099-002032-EW501

29.04.2010

41

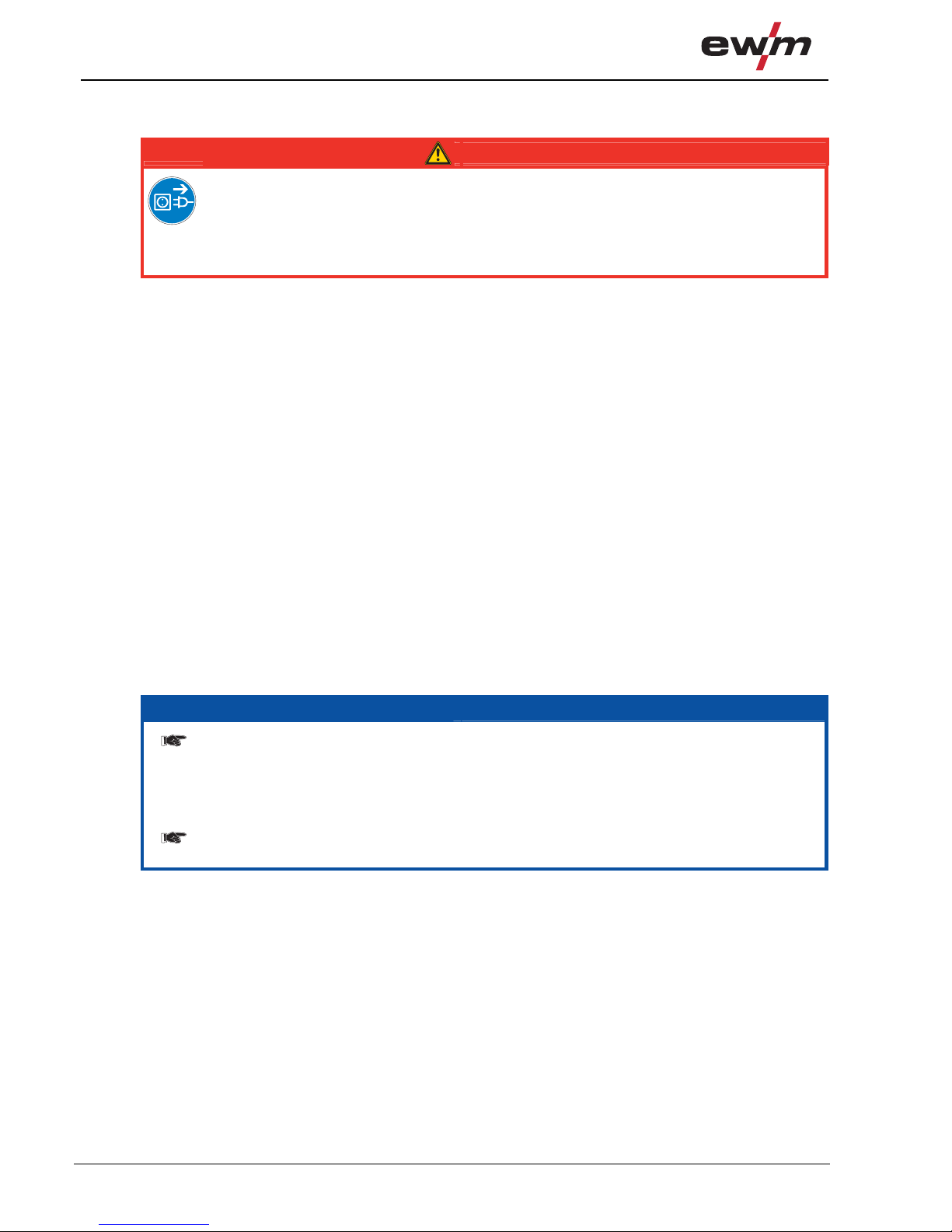

7.2 Resetting welding parameters to the factory settings

NOTE

All customised welding parameters that are stored will be replaced by the factory

settings.

0

1

0

1

AMP

VOLT

Figure 7-1

Display Setting/selection

Calibration

The machine will be calibrated for approx 2 seconds each time it is switched on.

Initialising

All customised welding parameters that are stored will be replaced by the factory

settings.

Technical data

Pico 300 cel

42

099-002032-EW501

29.04.2010

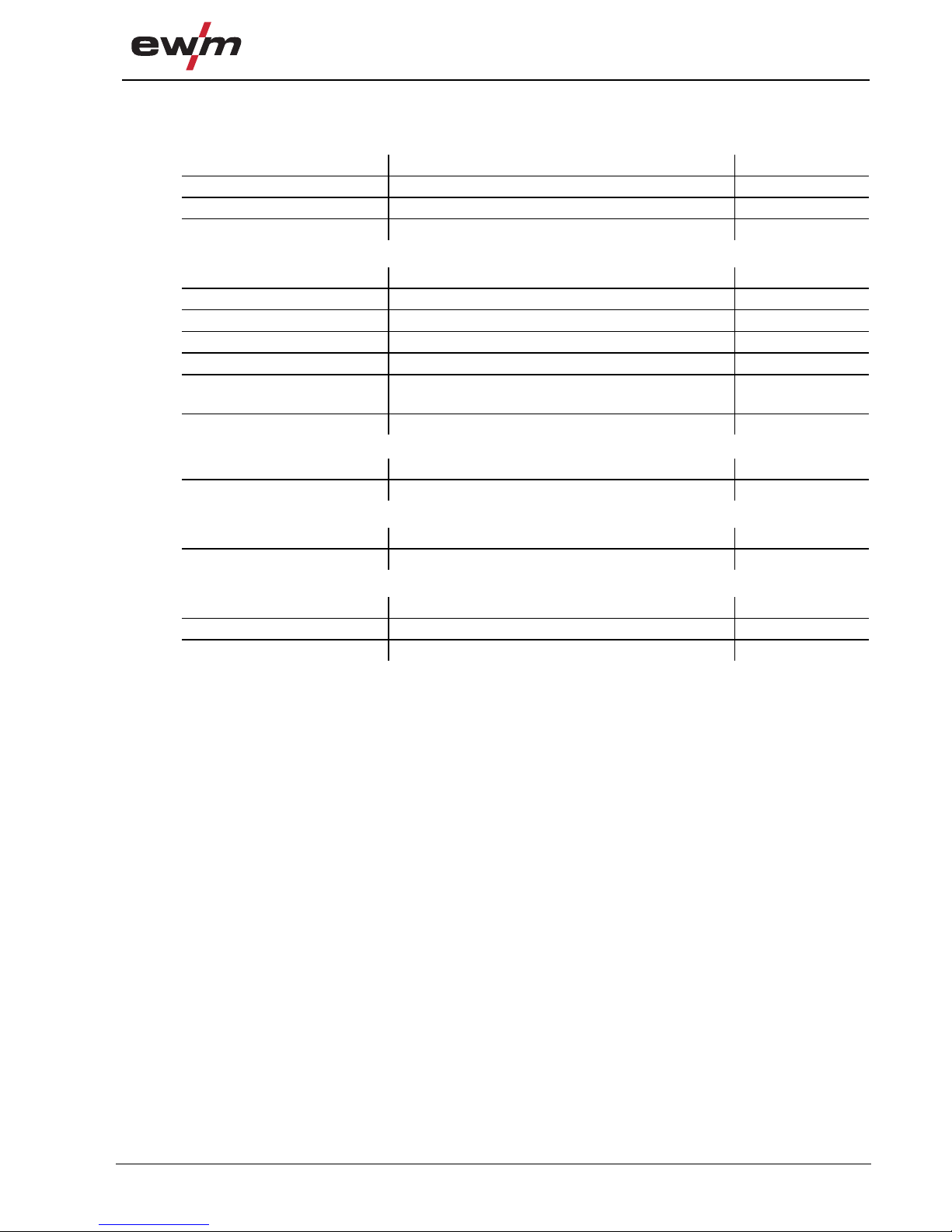

8 Technical data

8.1 Pico 300 cel

NOTE

Performance specifications and guarantee only in connection with original spare and

replacement parts!

MMA TIG

Current setting range 10 A-300 A 5 A-300 A

Voltage setting range 20.4 V-32.0 V 10.4 V-22.0 V

Duty cycle at 25 °C

30%

40%

60%

100%

300 A

250 A

190 A

300 A

260 A

200 A

Duty cycle at 40 °C

25%

30%

60%

100%

300 A

220 A

170 A

300 A

240 A

190 A

Load alternation

10 min. (60% DC ∧ 6 min. welding, 4 min. pause)

Open circuit voltage 99 V

Open circuit voltage (VRD) 12 V

Open circuit voltage (SVRD) 12 V

Mains voltage (tolerances) 3 x 400 V (+20% to -25%)

Frequency 50/60 Hz

Mains fuse (safety fuse, slow-blow) 16 A

Mains connection lead H07RN-F4G1,5

Max. connected load 12.1 kVA 8.3 kVA

Recommended generator rating 16.4 kVA

cosϕ at Imax

0.99

Insulation class/protection classification H/IP 23

Ambient temperature

-20 °C to +40 °C

Machine cooling/torch cooling Fan/gas

Workpiece lead 35 mm2

Dimensions L/W/H 515 x 185 x 350 mm

Dimensions L/W/H (pws) 515 x 185 x 445 mm

Weight 16.5 kg

Weight (pws) 23.5 kg

Constructed to standards

IEC 60974-1, -10

/

Accessories, options

Welding torch, electrode holder and workpiece lead

099-002032-EW501

29.04.2010

43

9 Accessories, options

9.1 Welding torch, electrode holder and workpiece lead

Type Designation Item no.

EH50 4M Electrode holder 092-000004-00000

WK50QMM 4M KL Workpiece cable, clamp 092-000003-00000

TIG 26V 4M ABITIG 26 V 4 m BCC-1 BHC-01 094-010979-00000

9.2 Remote controls and accessories

Type Designation Item no.

RT1 Remote control current 090-008097-00000

RA5 19POL 5M Remote control e.g. connection cable 092-001470-00005

RA10 19POL 10M Remote control e.g. connection cable 092-001470-00010

RA20 19POL 20M Remote control e.g. connection cable 092-001470-00020

RTF1 19POLE 5M Foot-operated remote control current with

connection cable

094-006680-00000

RV5M19 19POLE 5M Extension cable 092-000857-00000

9.2.1 Pico 300 cel pws

Type Designation Item no.

RT PWS1 Remote control vertical-down current, pole reversal 090-00819 9-00000

9.3 Options

Type Designation Item no.

ON FILTER Retrofit option, contamination filter for ai r inlet 092-001856-00000

9.4 General accessories

Type Designation Item no.

DM1 32L/MIN Manometer pressure reducer 094-000009-00000

5POLE/CEE/16A/M Machine plug 094-000712-00000

Appendix A

Overview of EWM branches

44

099-002032-EW501

29.04.2010

10 Appendix A

10.1 Overview of EWM branches

www.ewm-group.com

www.ewm-tv.de

EWM SCHWEISSTECHN IK-HANDELS-GMBH

Sachsstraße 28

50259 Pulheim · Deutschland

Tel: · Fax:+49 2234 697-047 -048

www.ewm-grwm-group.com/handel · nl-koeln@ewm-group.com

EWM HIGHTECWELDING s.r.o.

Tr. 9 718. kvetna

407 53 Ji ík ovř ·Tschechische Republik

Tel: + · Fax:420 412 358-551 -20

www.ewm-group.com/cz · info.cz@ewm-group.com

EWM HIGHTECWELDING UK Ltd.

Unit B CoopiesWay2

Coopies Lane Industrial Estate

Morpeth · Northumberland · NE JN· Großbritannien61 6

Tel: · Fax:+44 1670 505875 -514305

www.ewm-group.com/uk · info.uk@ewm-group.com

EWM HIGHTECWELDING (Kunshan) Ltd.

10 Yuanshan Road,Kunshan

New & High-tech Industry Development Zone

Kunshan · Jiangsu · ·Volksrepublik China215300

Tel: + · Fax:86 512 57867-188 -182

www.ewm-group.com/cn · info.cn@ewm-group.com

EWM HIGHTECWELDING GmbH

Dr.Günter-Henle-Straße 8

56271 Mündersbach

Deutschland

Tel: +49 2680 181-0 · Fax: -244

www.ewm-group.com · info@ewm-group.com

EWM SCHWEISSTECHN IK-HANDELS-GMBH

In der Florinskaul 14-16

56218 Mülheim-Kärlich · Deutschland

Tel: +49 261 988898-0 · Fax: -244

www.ewm-group.com/handel · nl-muelheim@ewm-group.com

EWM HIGHTECWELDING GmbH

Niederlassung Nord

Lindenstraße a1

38723 Seesen-Rhüden · Deutschland

Tel: · Fax:+49 5384 90798-0 -20

www.ewm-group.com/handel · nl-nord@ewm-group.com

EWM HIGHTECWELDING SALES s.r.o.

Prodejní a poradenské centrum

Tyr

š

ova 2106

256 01 Bene ov u Prahy · Tschechische Republik

š

Tel: · Fax:+420 317 729-517 -712

www.ewm-group.com/cz · sales.cz@ewm-group.com

EWM HIGHTECWELDING GmbH

Scharnsteinerstraße 15

4810 Gmunden · Österreich

Tel: · Fax:+43 7612 778 02-0 -20

www.ewm-group.com/at · info.at@ewm-group.com

EWM HIGHTECWELDING FZCO

Regional Off

ice M

iddle East

JAFZAView 18 14 05F · P.O. Box 262851

Jebel Ali Free Zone · Dubai · Vereinigte Arabische Emirabische Emirate

Tel: · Fax:+971 4 8857-789 -500

www.ewm-group.com/me · info.me@ewm-group.com

Loading...

Loading...