Operating instructions

Power sources for automate d a pplications

alpha Q 352, 552 puls MM

Register now!

For your benefit

Jetzt Registrieren

und Profitieren!

www.ewm-group.com

*Details for ewm-warranty

www.ewm-group.com

*

099-005366-EW501 Observe additional system documents! 31.07.2014

CAUTION

Read the operating instructions !

The operating instructions provide an introduction to the safe use of the products.

•

•

•

• Confirm with a signature where appropriate.

NOTE

A list of authorised sales partners can be found at www.ewm-group.com.

General instructions

Read the operating instructions for all system components!

Observe accident prevention regulations!

Observe all local regulations!

In the event of queries on installation, commissioning, operation or special conditions at the

installation site, or on usage, please contact your sales partner or our

customer service department on +49 2680 181-0.

Liability relating to the operation of this equipment is restricted solely to the function of the equipment. No other

form of liability, regardless of type, shall be accepted. This exclusion of liability shall be deemed accepted by the

user on commissioning the equipment.

The manufacturer is unable to monitor whether or not these instructions or the conditions and methods are

observed during installation, operation, usage and maintenance of the equipment.

An incorrectly performed installation can result in material damage and injure persons as a result. For this reason,

we do not accept any responsibility or liability for losses, damages or costs arising from incorrect installation,

improper operation or incorrect usage and maintenance or any actions connected to this in any way.

© EWM AG · Dr. Günter-Henle-Str. 8 · D-56271 Mündersbach, Germany

The copyright to this document remains the property of the manufacturer.

Reprinting, including extracts, only permitted with written approval.

Subject to technical amendments.

31.07.2014

1 Contents

1

Contents .................................................................................................................................................. 3

2 Safety instructions ................................................................................................................................. 6

2.1 Notes on the use of these operating instructions .......................................................................... 6

2.2 Explanation of icons ....................................................................................................................... 7

2.3 General .......................................................................................................................................... 8

2.4 Transport and installation ............................................................................................................ 12

2.4.1 Lifting by crane ............................................................................................................. 13

2.4.2 Ambient conditions ....................................................................................................... 14

2.4.2.1 In operation ................................................................................................... 14

2.4.2.2 Transport and storage ................................................................................... 14

3 Intended use ......................................................................................................................................... 15

3.1 Applications .................................................................................................................................. 15

3.1.1 MIG/MAG standard welding ......................................................................................... 15

3.1.1.1 forceArc ......................................................................................................... 15

3.1.1.2 rootArc ........................................................................................................... 15

3.1.1.3 coldArc .......................................................................................................... 15

3.1.1.4 pipeSolution .................................................................................................. 15

3.1.2 MIG/MAG pulse welding ............................................................................................... 15

3.1.2.1 forceArc puls ................................................................................................. 15

3.1.2.2 rootArc puls ................................................................................................... 15

3.1.2.3 coldArc puls ................................................................................................... 15

3.1.2.4 superPuls ...................................................................................................... 15

3.2 Documents which also apply ....................................................................................................... 16

3.2.1 Warranty ....................................................................................................................... 16

3.2.2 Declaration of Conformity ............................................................................................. 16

3.2.3 Welding in environments with increased electrical hazards ......................................... 16

3.2.4 Service documents (spare parts and circuit diagrams) ................................................ 16

3.2.5 Calibration/Validation .................................................................................................... 16

4 Machine description – quick overview .............................................................................................. 17

4.1 Front view .................................................................................................................................... 17

4.2 Rear view ..................................................................................................................................... 19

4.3 Machine control – Operating elements ........................................................................................ 21

5 Design and function ............................................................................................................................. 23

5.1 General ........................................................................................................................................ 23

5.2 Connection plan ........................................................................................................................... 25

5.2.1 Legend .......................................................................................................................... 26

5.3 Installation .................................................................................................................................... 27

5.4 Machine cooling ........................................................................................................................... 27

5.5 Workpiece lead, general .............................................................................................................. 27

5.6 Notes on the installation of welding current leads ....................................................................... 28

5.7 Welding torch cooling system ...................................................................................................... 30

5.7.1 List of coolants .............................................................................................................. 30

5.7.2 Maximal hose package length ...................................................................................... 30

5.8 Connect the cooling module to the power source ....................................................................... 31

5.9 Mains connection ......................................................................................................................... 32

5.9.1 Mains configuration ...................................................................................................... 32

5.10 Inter m edi ate hos e pack age connection ....................................................................................... 33

5.11 Matching the cable resistance ..................................................................................................... 34

5.12 Connection for workpiece lead .................................................................................................... 36

5.13 Shielding gas supply (shielding gas cylinder for welding machine) ............................................. 37

5.13.1 Connecting the shielding gas supply ............................................................................ 37

5.13.2 Setting instructions ....................................................................................................... 38

Contents

Notes on the use of these operating instructions

099-005366-EW501

3

Contents

Notes on the use of these operating instructions

31.07.2014

5.14 Interfaces...................................................................................................................................... 39

5.14.1 Connecting the RINT X11 robot interface/BUSINT X11 industrial bus interface .......... 39

5.14.2 RINT X12 robot interface .............................................................................................. 39

5.14.3 BUSINT X11 industrial bus interface ............................................................................ 39

5.14.4 Connecting the PC 300.net welding parameterisation software ................................... 41

5.14.5 Connecting the Q-DOC 9000 welding data documentation software ........................... 42

5.14.6 Connecting the WELDQAS welding data monitoring and documentation system ....... 43

5.14.7 Automation interface ..................................................................................................... 44

5.14.8 Sensor Voltage ............................................................................................................. 46

5.15 Protecting welding parameters from unauthorised access .......................................................... 47

5.15.1 Welding data display ..................................................................................................... 47

5.16 Definition of MIG/MAG welding tasks .......................................................................................... 48

5.16.1 Welding task selection .................................................................................................. 49

5.16.1.1 Selecting or defining a new job ..................................................................... 49

5.16.2 forceArc / forceArc puls ................................................................................................ 50

5.16.3 coldArc / coldArc puls ................................................................................................... 51

5.16.4 pipeSolution .................................................................................................................. 52

5.16.4.1 Operating mode ............................................................................................. 53

5.16.5 Welding type ................................................................................................................. 53

5.16.5.1 Program or control voltage mode .................................................................. 53

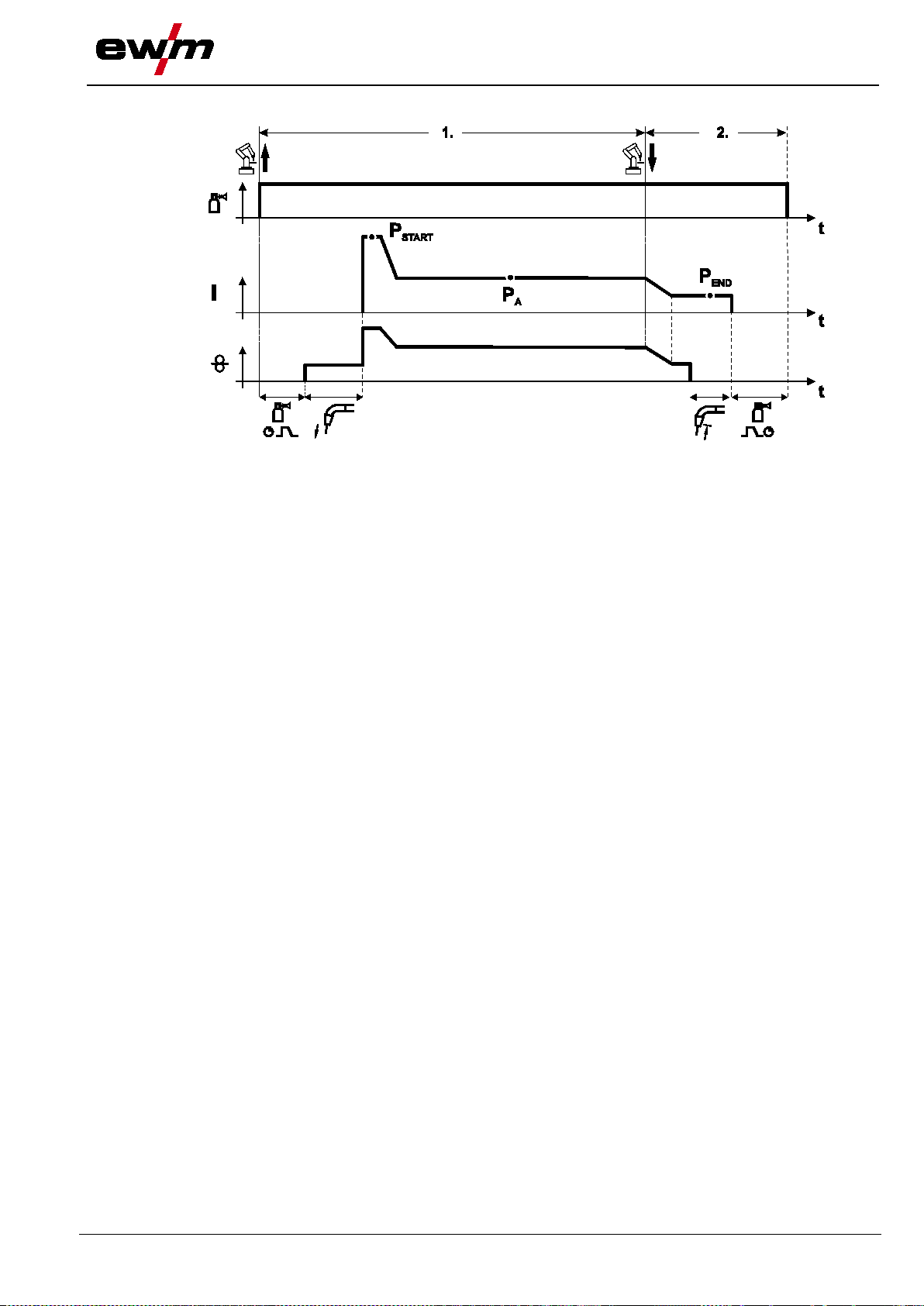

5.16.5.2 Program sequence ........................................................................................ 54

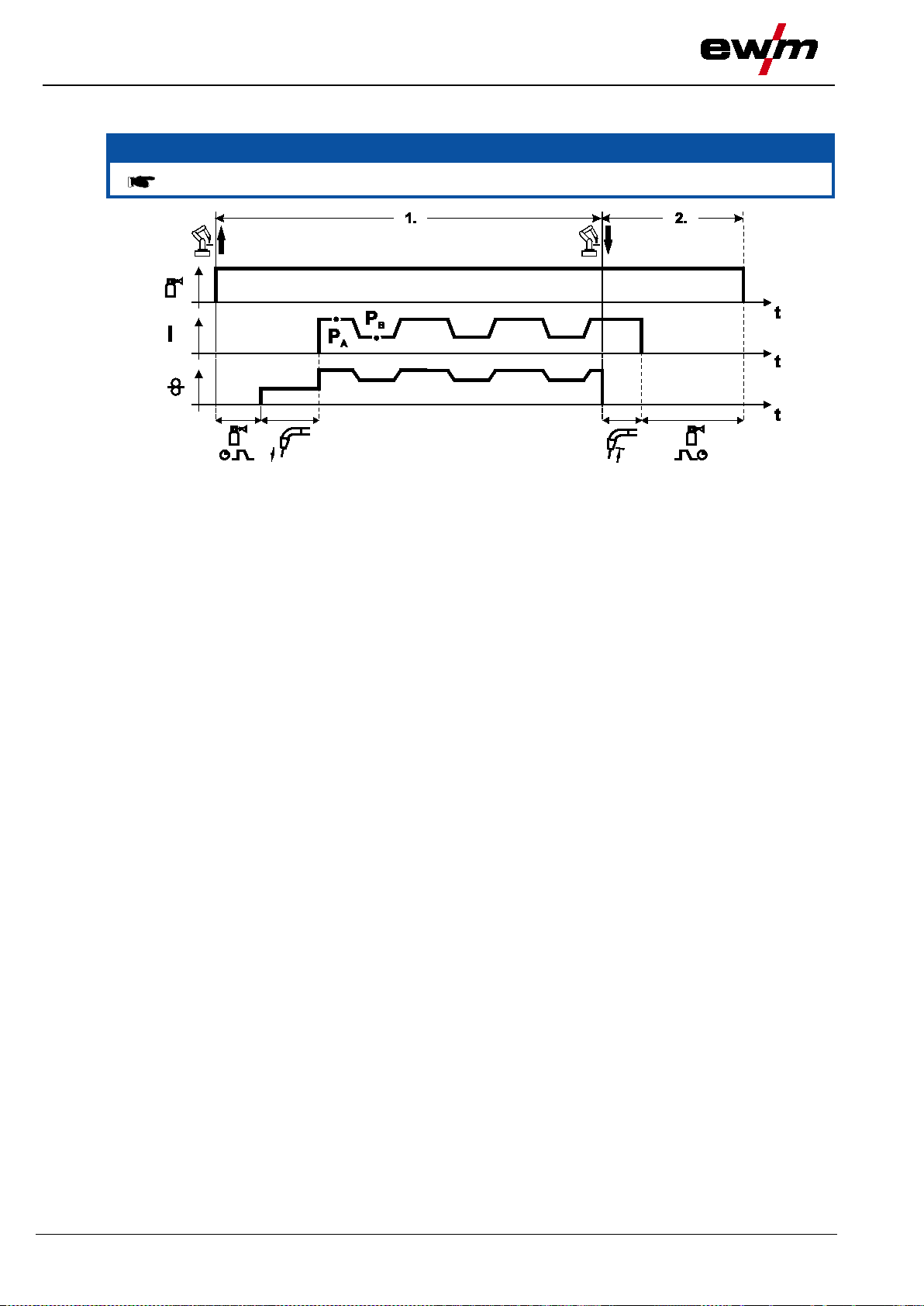

5.16.5.3 superPuls ...................................................................................................... 55

5.16.6 MIG/MAG functional sequences / operating modes ..................................................... 56

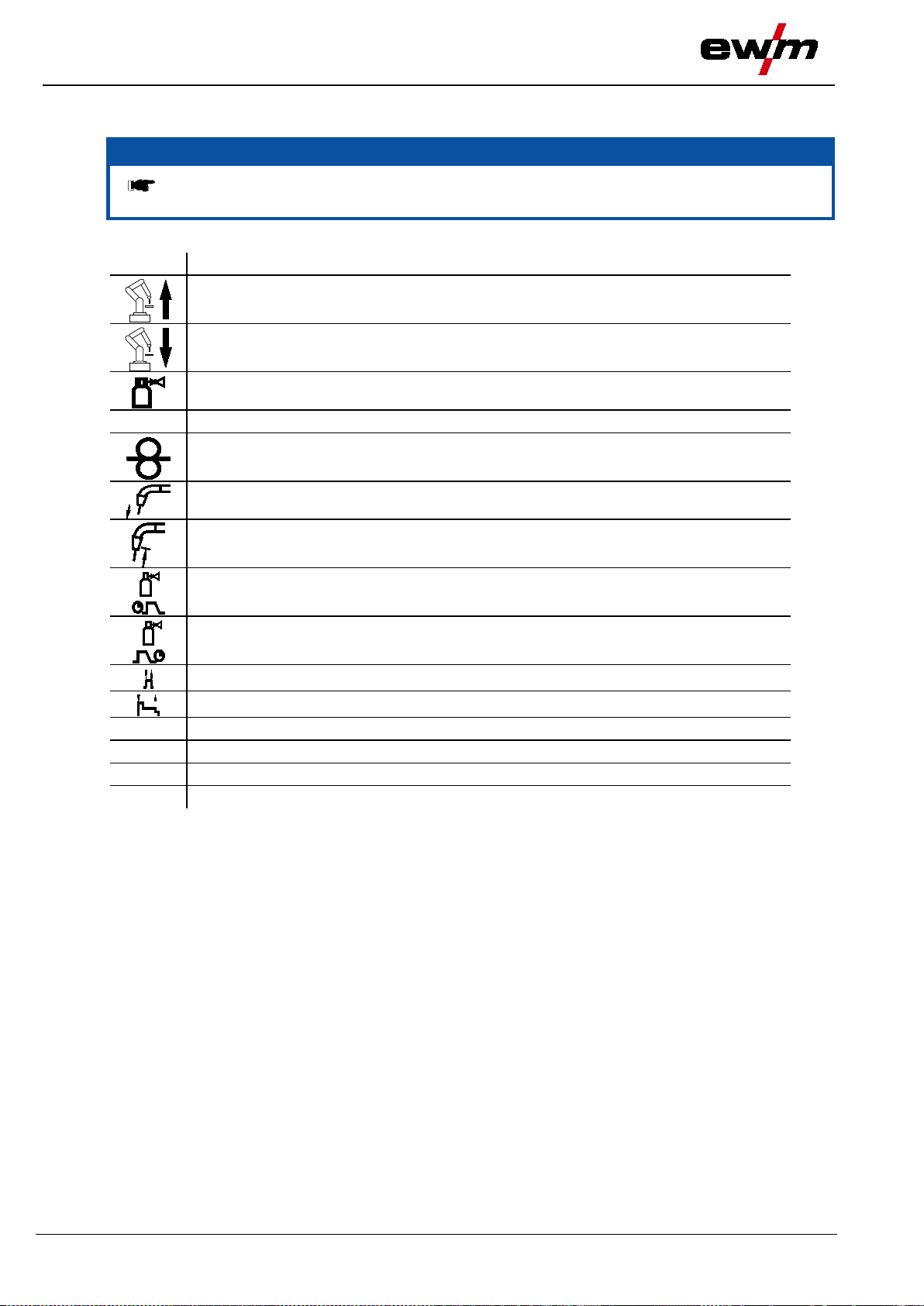

5.16.6.1 Explanation of signs and functions ................................................................ 56

5.16.7 MIG/MAG program sequence ("Program steps" mode) ............................................... 61

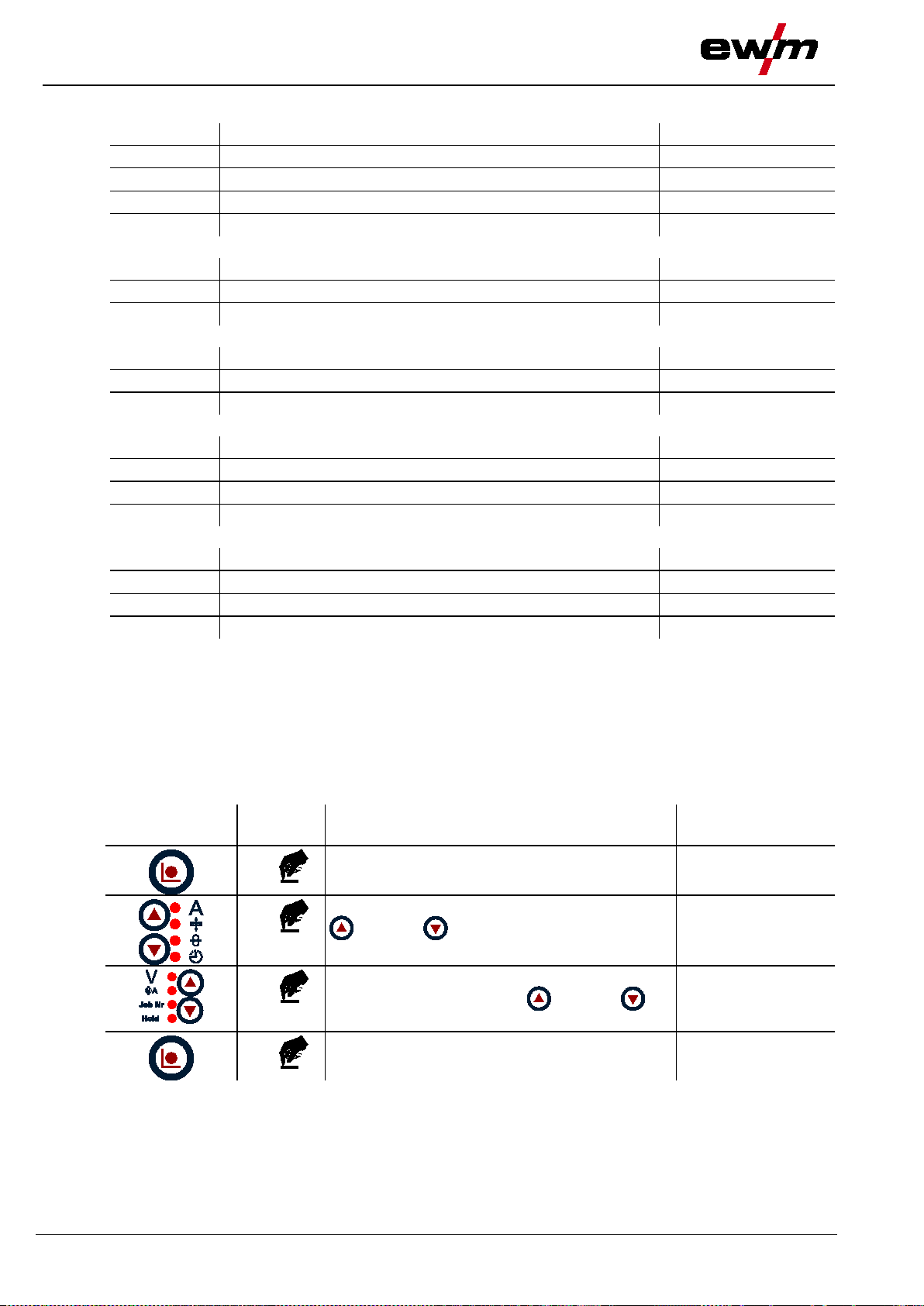

5.16.8 Selection ....................................................................................................................... 61

5.16.9 MIG/MAG overview of parameters for M3.1x ............................................................... 61

5.16.10 Main program A mode .................................................................................................. 62

5.16.10.1 Selection ........................................................................................................ 62

5.16.11 MIG/MAG overview of parameters for M3.1x ............................................................... 63

5.17 "Special Mode" mode ................................................................................................................... 64

5.17.1 Selection ....................................................................................................................... 64

5.17.2 Switching the Hold function on and off ......................................................................... 65

5.17.3 Wire feed speed switching (absolute / relative) ............................................................ 65

5.17.4 Resetting JOBs to status on delivery (Reset ALL) ....................................................... 65

5.17.5 Exiting "Special Mod e" afte r makin g changes .............................................................. 65

5.18 "JOB Info" mode ........................................................................................................................... 66

5.19 Operating time counter ................................................................................................................. 66

5.20 Organising welding tasks (Mode "JOB Manager") ....................................................................... 67

5.20.1 Creating a new JOB in the memory or copying a JOB ................................................. 67

5.20.2 Loading an existing job ................................................................................................. 68

5.20.3 Resetting an existing JOB to the factory setting (Reset JOB) ...................................... 68

5.21 Expert parameters ........................................................................................................................ 69

5.21.1 Selecting expert model parameters .............................................................................. 69

5.21.2 Selecting variables (5 model points) ............................................................................. 69

5.21.3 Setting parameters ....................................................................................................... 69

4

099-005366-EW501

31.07.2014

6 Maintenance, care and disposal ......................................................................................................... 70

6.1 General ........................................................................................................................................ 70

6.2 Maintenance work, intervals ........................................................................................................ 70

6.2.1 Daily maintenance tasks............................................................................................... 70

6.2.1.1 Visual inspection ........................................................................................... 70

6.2.1.2 Functional test ............................................................................................... 70

6.2.2 Monthly maintenance tasks .......................................................................................... 71

6.2.2.1 Visual inspection ........................................................................................... 71

6.2.2.2 Functional test ............................................................................................... 71

6.2.3 Annual test (inspection and testing during operation) .................................................. 71

6.3 Maintenance work ........................................................................................................................ 71

6.4 Disposing of equipment ............................................................................................................... 72

6.4.1 Manufacturer's declaration to the end user .................................................................. 72

6.5 Meeting the requirements of RoHS ............................................................................................. 72

7 Rectifying faults ................................................................................................................................... 73

7.1 Checklist for rectifying faults ........................................................................................................ 73

7.2 Error messages ............................................................................................................................ 75

7.3 Error messages (RC-Panel) ........................................................................................................ 77

7.3.1 Interface for automated welding ................................................................................... 78

7.4 Display machine control software version ................................................................................... 79

7.4.1 Resetting JOBs to status on delivery (Reset ALL) ....................................................... 79

7.5 Vent coolant circuit ....................................................................................................................... 80

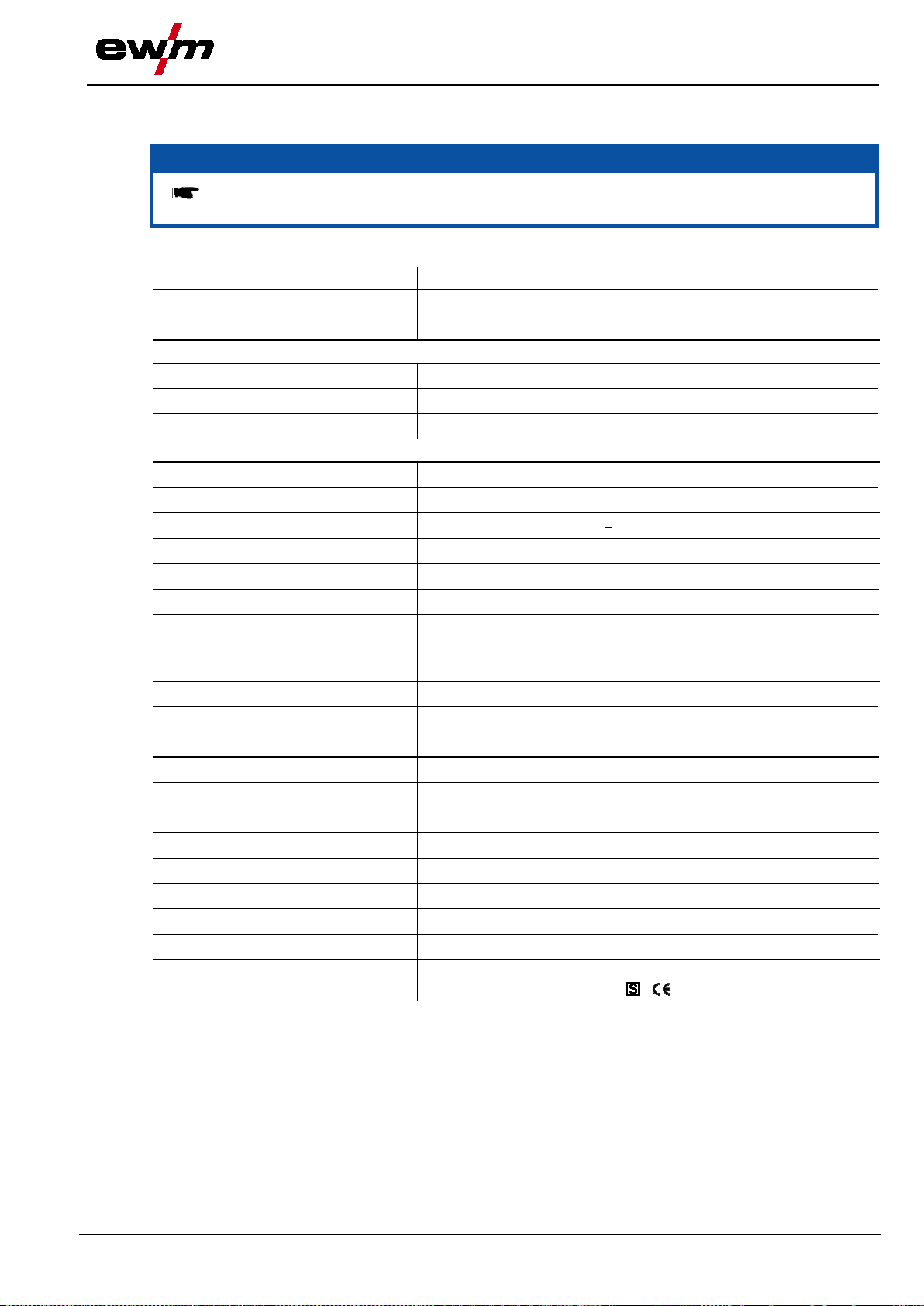

8 Technical data ...................................................................................................................................... 81

8.1 alpha Q 352, 552 Puls ................................................................................................................. 81

9 Accessories .......................................................................................................................................... 82

9.1 Connection cables, connection sockets....................................................................................... 82

9.2 General accessories .................................................................................................................... 82

9.3 Options ......................................................................................................................................... 82

9.4 Transport systems ....................................................................................................................... 82

9.5 Interfaces ..................................................................................................................................... 82

9.6 Computer communication ............................................................................................................ 82

9.7 Cooling units ................................................................................................................................ 83

9.8 Wire feed units ............................................................................................................................. 83

10 Circuit diagrams ................................................................................................................................... 84

10.1 alpha Q 352, 552 Puls ................................................................................................................. 84

11 Appendix A ........................................................................................................................................... 86

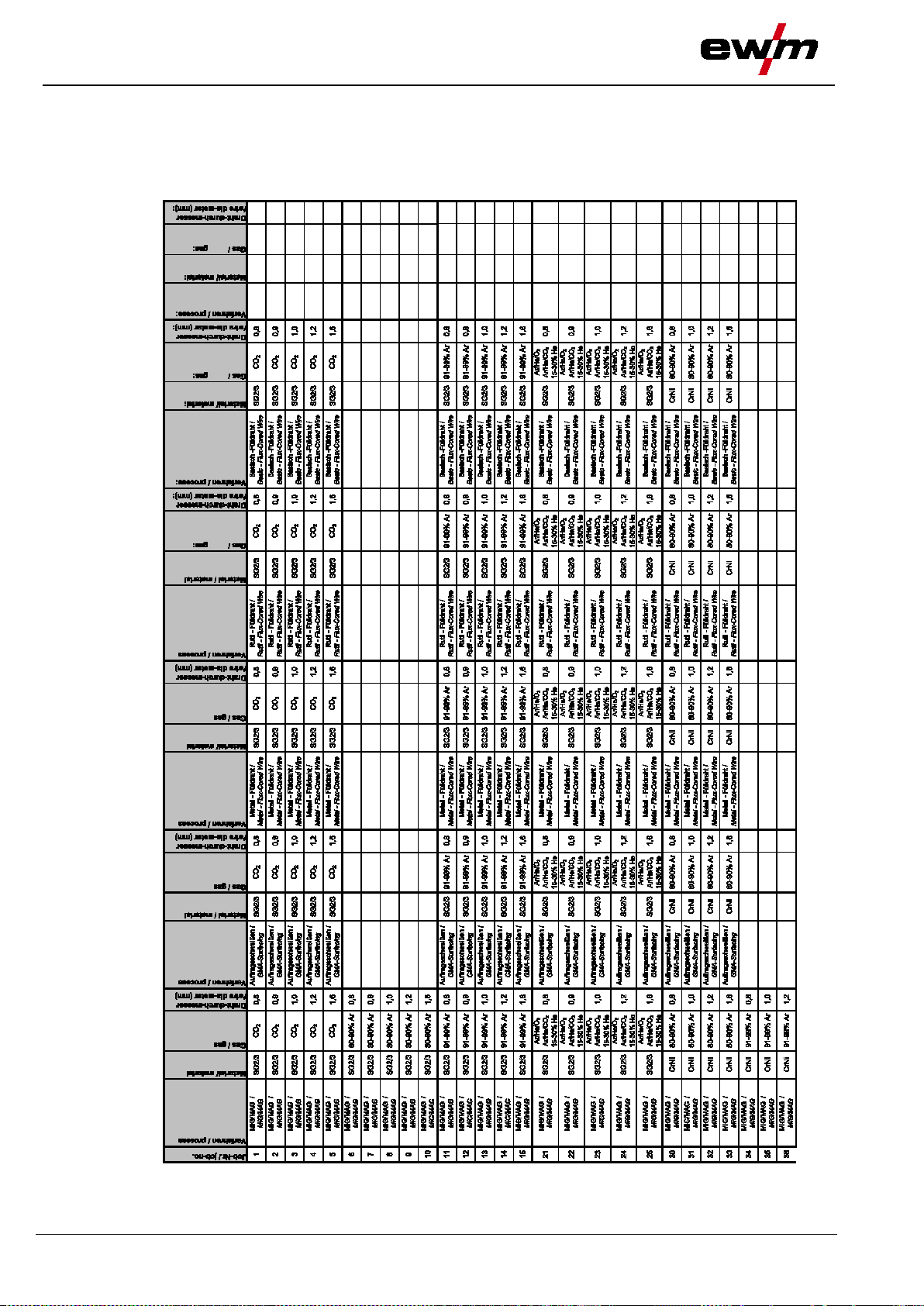

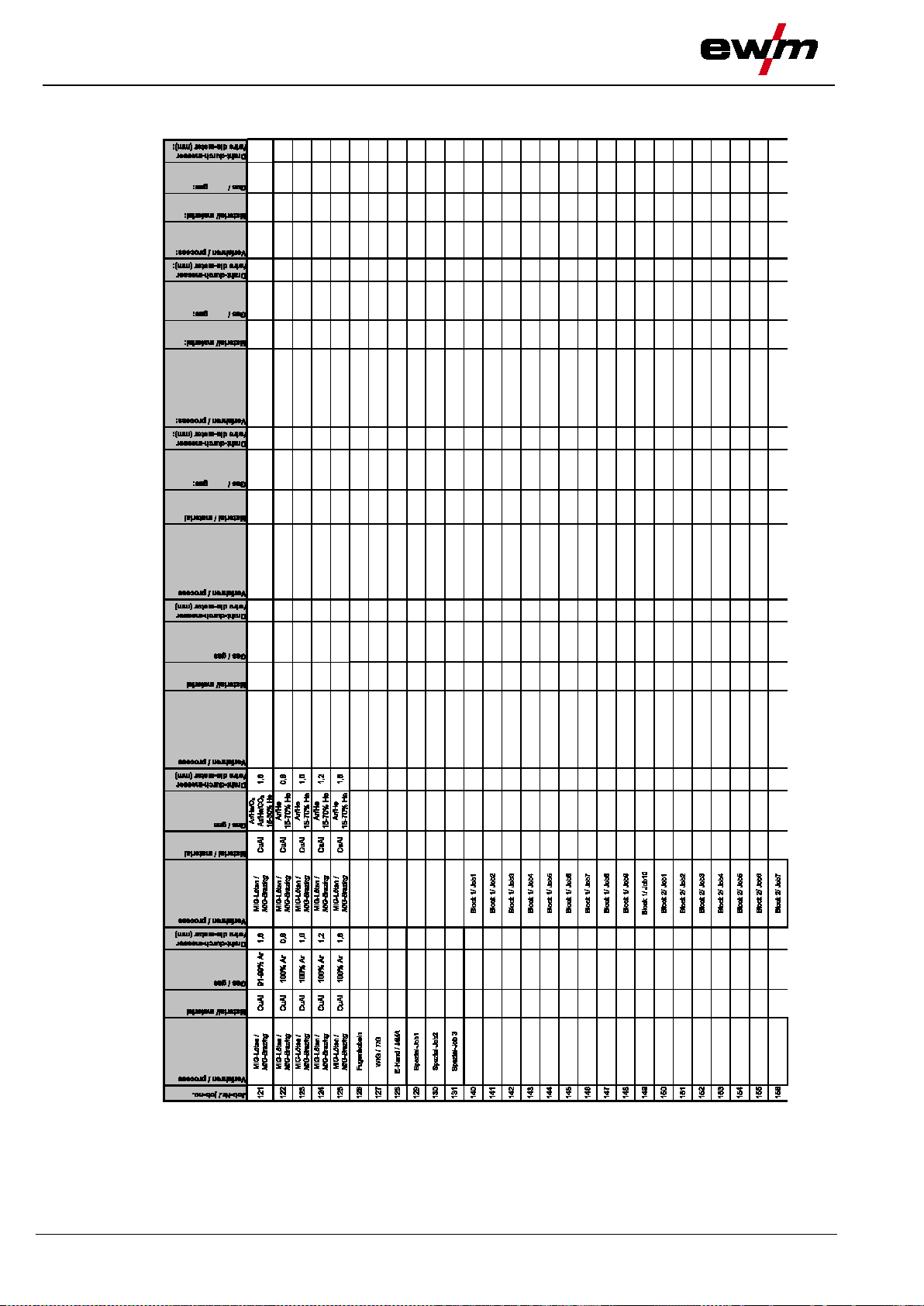

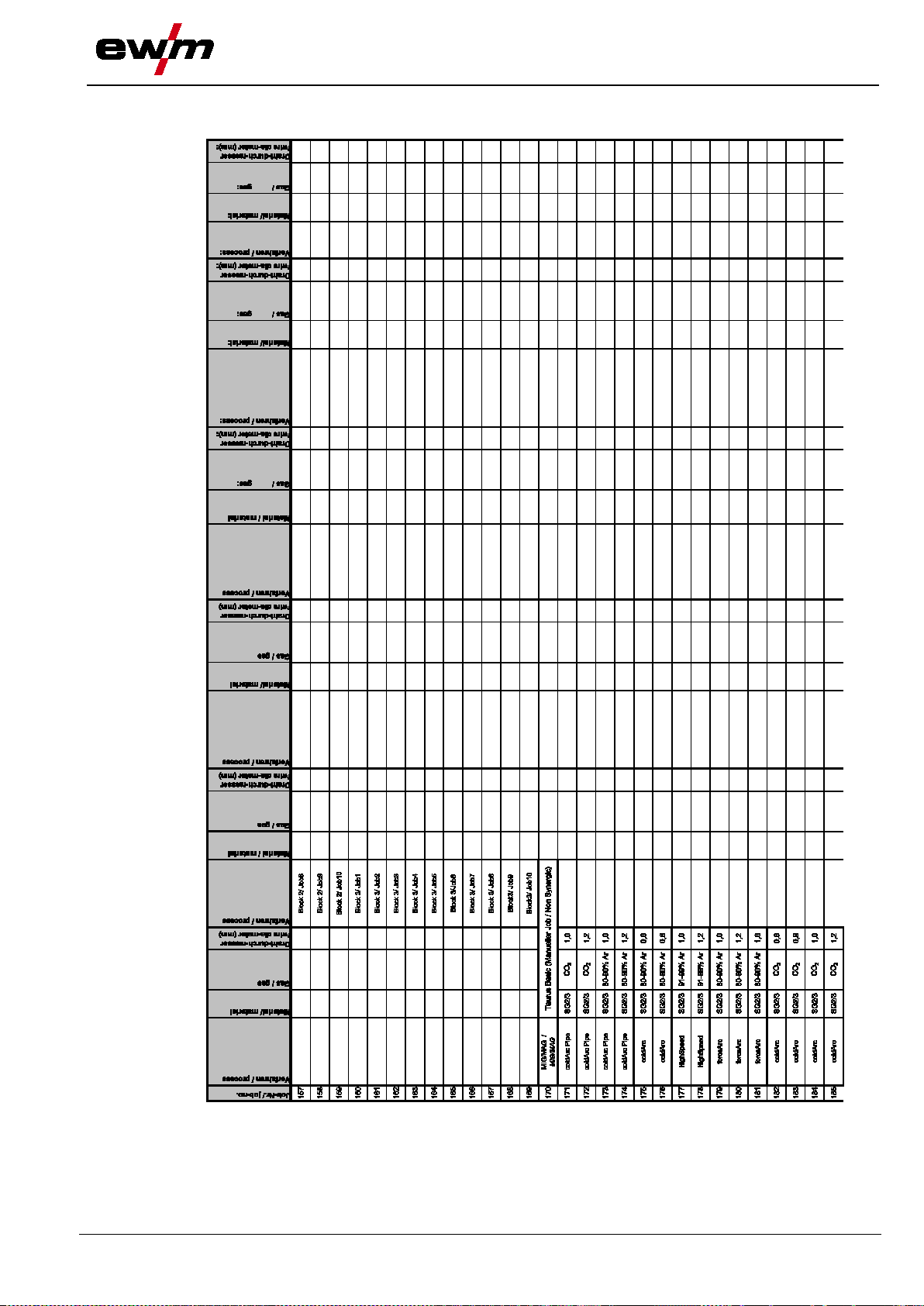

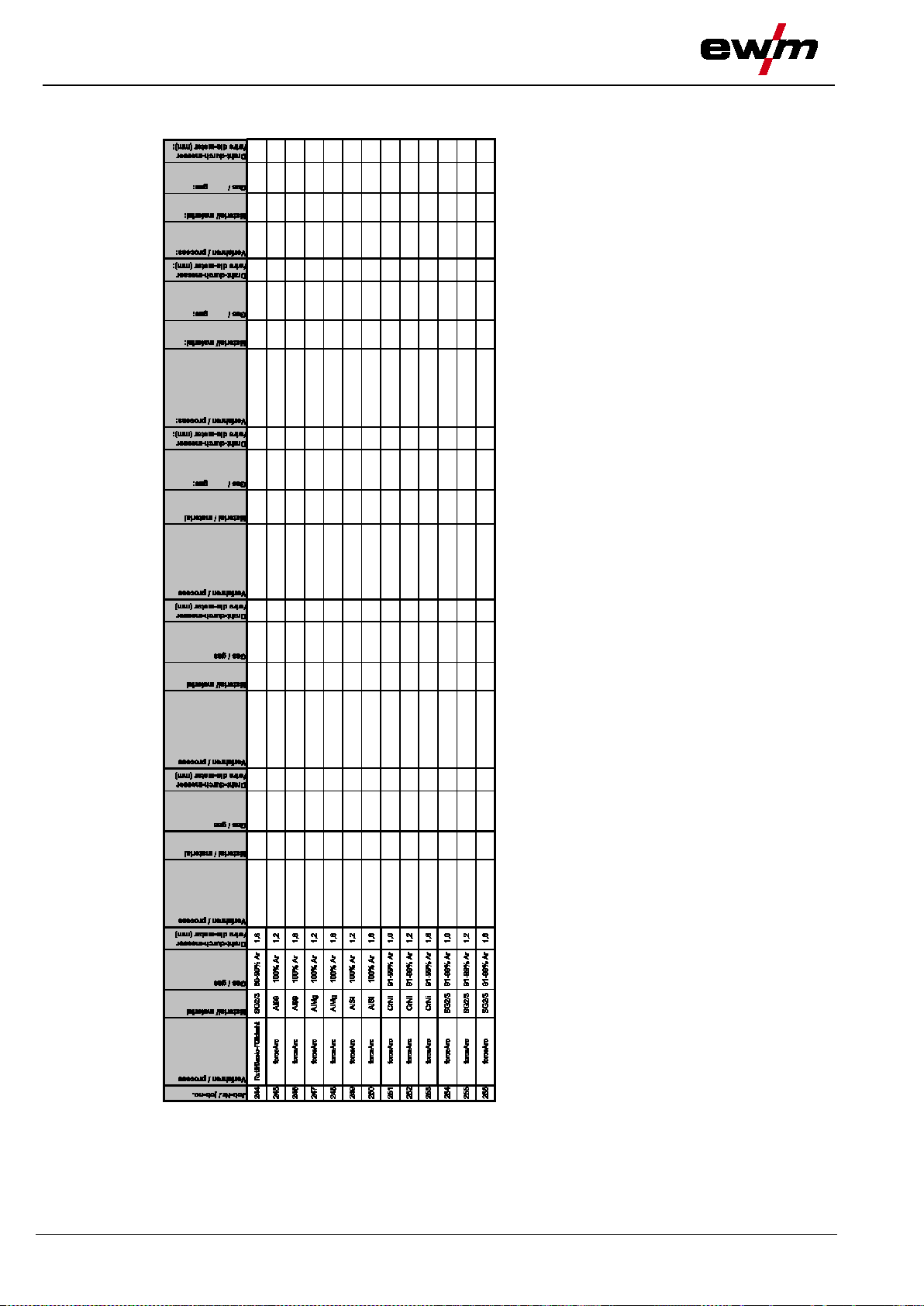

11.1 JOB-List ....................................................................................................................................... 86

12 Appendix B ........................................................................................................................................... 95

12.1 Overview of EWM branches ........................................................................................................ 95

Contents

Notes on the use of these operating instructions

099-005366-EW501

5

Safety instructions

Notes on the use of these operating instructions

31.07.2014

DANGER

Working or operating procedures which must be closely observed to prevent imminent

• The hazard is also highlighted using a symbol on the edge of the page.

WARNING

Working or operating procedures which must be closely observed to prevent serious

• The hazard is also highlighted using a symbol in the page margin.

CAUTION

• The risk is explained using a symbol on the edge of the page.

CAUTION

Working and operating procedures which must be followed precisely to avoid damaging

• The hazard is explained using a symbol at the edge of the page.

NOTE

• Notes include the "NOTE" keyword in the heading without a general warning symbol.

2 Safety instructions

2.1 Notes on the use of these operating ins tr uc t ions

serious and even fatal injuries.

• Safety notes include the "DANGER" keyword in the heading with a general warning symbol.

and even fatal injuries.

• Safety notes include the "WARNING" keyword in the heading with a general warning

symbol.

Working or operating procedures which must be closely observed to prevent possible

minor personal injury.

• The safety information includes the "CAUTION" keyword in its heading with a general

warning symbol.

or destroying the product.

• The safety information includes the "CAUTION" keyword in its heading without a general

warning symbol.

Special technical points which users mu st observe.

Instructions and lists detailing step-by-step actions for given situations can be recognised via bullet

points, e.g.:

• Insert the welding current lead socket into the relevant socket and lock.

6

099-005366-EW501

31.07.2014

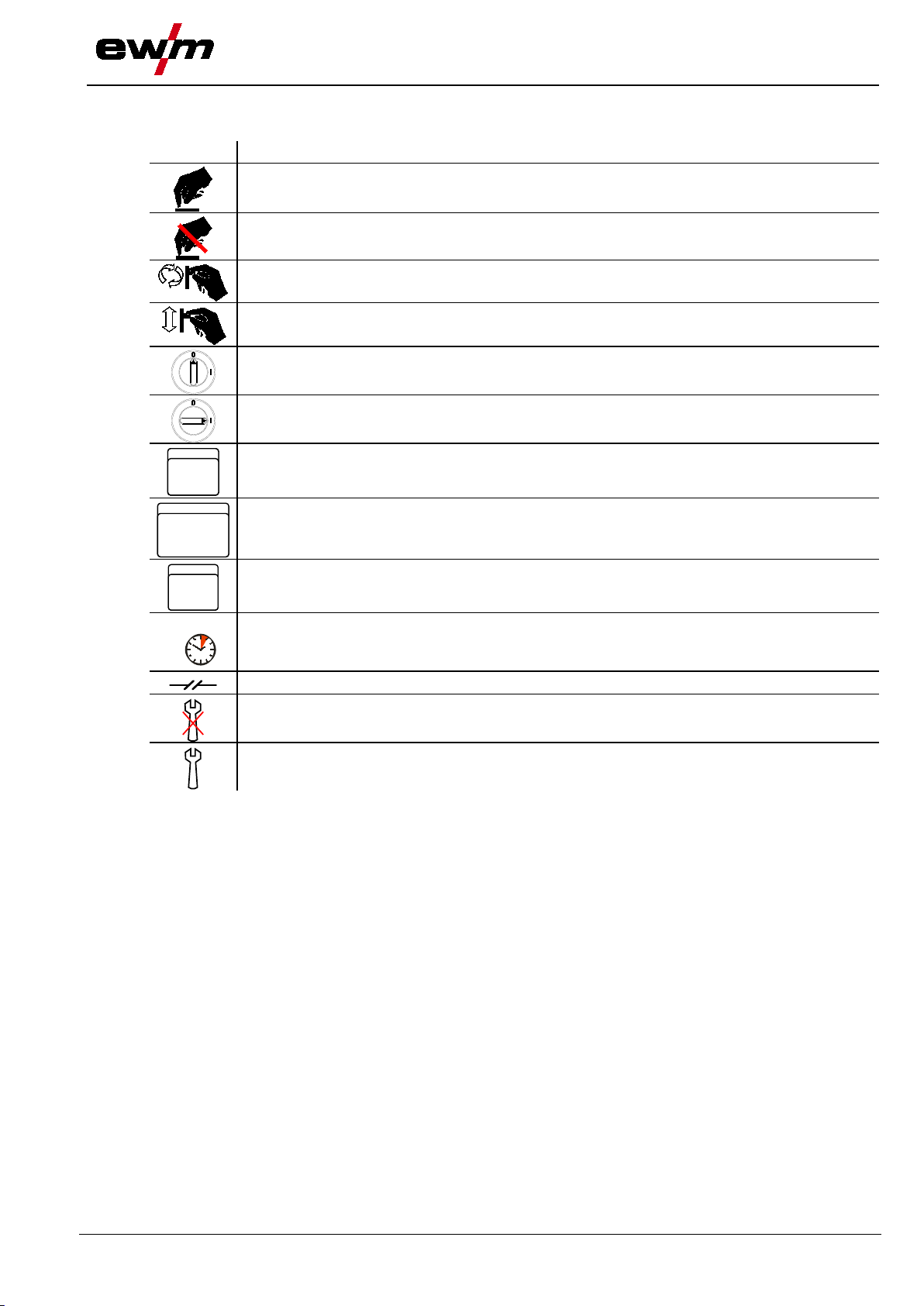

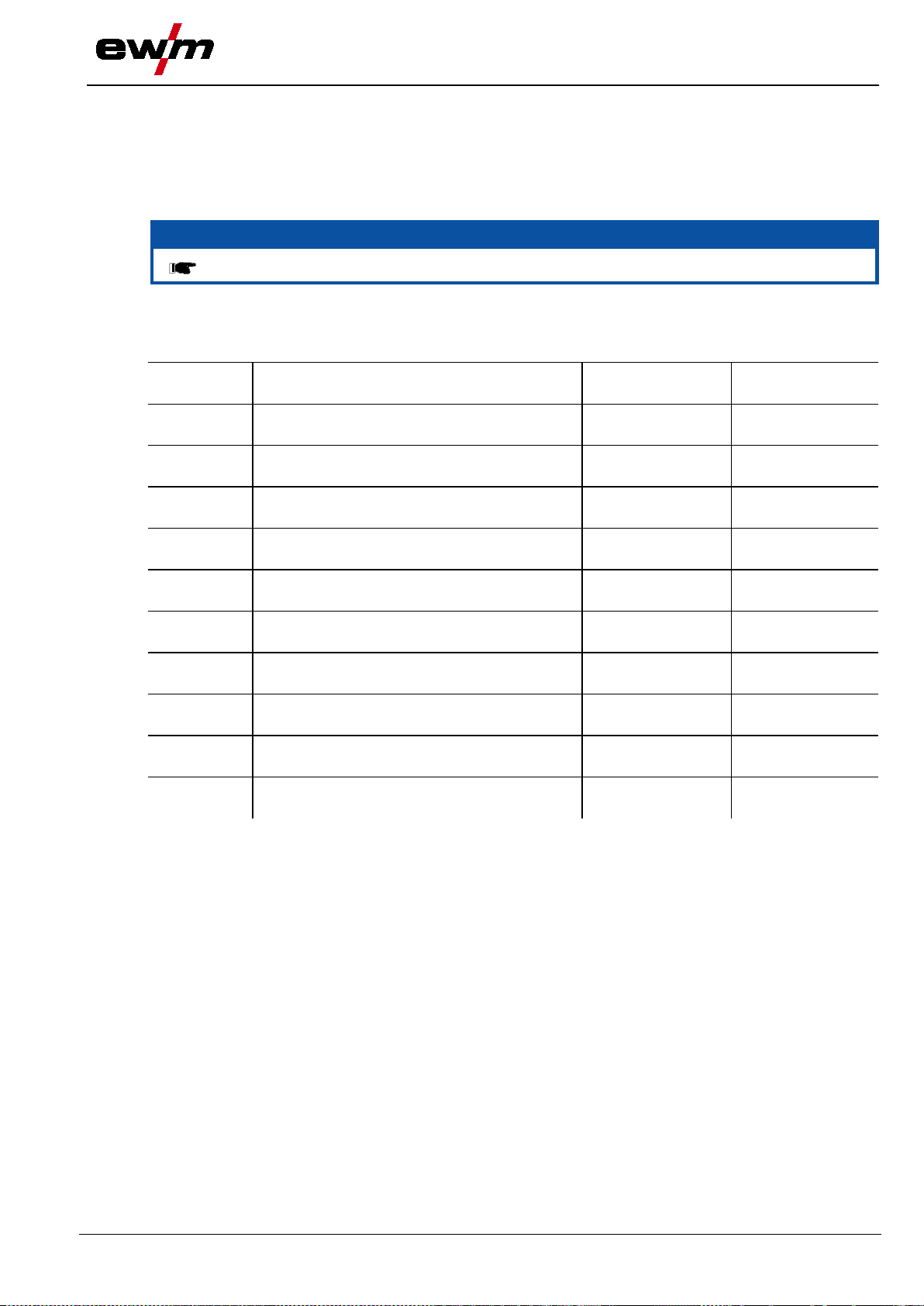

Symbol

Description

Turn

Switch on machine

ENTERENTER

ENTER (enter the menu)

NAVIGATION

EXIT

EXIT (Exit the menu)

4 s

Interruption in the menu display (other setting options possible)

Tool not required/do not use

2.2 Explanation of icons

Press

Do not press

Switch

Switch off machine

Safety instructions

Explanation of icons

NAVIGATION (Navigating in the menu)

Time display (example: wait 4s/press)

Tool required/use

099-005366-EW501

7

Safety instructions

General

31.07.2014

DANGER

Electric shock!

Welding machines use high voltages which can result in potentially fatal electric shocks

• Wait for 4 minutes until the capacitors have discharged!

necessary).

Do not carry out any unauthorised repairs or modifications!

• Appoint only skilled persons for repair work (trained service personnel)!

WARNING

Risk of accidents if these safety instructions are not observed!

• Inform persons in the working area that they must observe the regulations!

safety curtains!

2.3 General

and burns on contact. Even low voltages c an cause you to get a shock and lead to

accidents.

• Do not touch any live parts in or on the machine!

• Connection cables and leads must be free of faults!

• Switching off alone is not sufficient!

• Place welding torch and stick electrode holder on an insulated surface!

• The unit should only be opened by specialist staff after the mains plug has been unplugged!

• Only wear dry protective clothing!

Electromagnetic fields!

The power source may cause electrical or electromagnetic fields to be produced which

could affect the correct functioning of electronic equipment such as IT or CNC devices,

telecommunication lines, power cables, signal lines and pacemakers.

• Observe the maintenance instr uc tions "See 6 Maintenance, care and disp osal chapter"!

• Unwind welding leads completely!

• Shield devices or equipment sensitive to radiation accordingly!

• The correct functioning of pacemakers may be affected (obtain advice from a doc tor if

To avoid injury and equipment damage, the unit must only be repaired or modified by

specialist, skilled persons!

The warranty becomes null and void in the event of unauthorised interference.

Non-observance of these safety instructions is potentially fatal!

• Carefully read the safety information in this manual!

• Observe the accident prevention regulations in your country.

Risk of injury due to radiation or heat!

Arc radiation results in injury to skin and eyes.

Contact with hot workpieces and sparks results in burns.

• Use welding shield or welding helmet with the appropriate safety level (depending on the

application)!

• Wear dry protective clothing (e.g. welding shield, gloves, etc.) according to the relevant

regulations in the country in question!

• Protect persons not involved in the work against arc beams and the risk of glare using

8

099-005366-EW501

Safety instructions

General

31.07.2014

WARNING

excessive pressure

• Never heat explosive liquids, dusts or gases by welding or cutting!

Smoke and gases!

• Wear suitable breathing apparatus if appropriate!

• Connect welding leads correctly!

Danger when coupling multiple power sources!

AC welding, as a minor error in operation can cause the welding voltages to be combined.

CAUTION

Noise exposure!

• Persons located within the working area must wear suitable ear protection!

Explosion risk!

Apparently harmless substances in closed containers may generate

when heated.

• Move containers with inflammable or explosive liquids away from the working area!

Smoke and gases can lead to breathing difficulties and poisoning. In addition, solvent

vapour (chlorinated hydrocarbon) may be converted into poisonous phosgene due to

the ultraviolet radiation of the arc!

• Ensure that there is sufficient fresh air!

• Keep solvent vapour away from the arc beam field!

Fire hazard!

Flames may arise as a result of the high temperatures, stray sparks, glowing-hot parts

and hot slag produced during the welding process.

Stray welding currents can also result in flames forming!

• Check for fire hazards in the working area!

• Do not carry any easily flammable objects such as matches or lighters.

• Keep appropriate fire extinguishing equipment to hand in the working area!

• Thoroughly remove any residue of flammable substances from the workpiece before

starting welding.

• Only continue work on welded workpieces once they have cooled down.

Do not allow to come into contact with flammable material!

Coupling multiple power sources in parallel or in series has to be carried out by

qualified personnel and in accordance with the manufacturer's guidelines. Before

bringing the power sources

that they cannot exceed the maximum allowed open circuit voltage.

• Connection of the machine

• When decommissioning individual power

to be safely disconnected from the welding system as a whole. (Danger due to inverse

voltages

!)

• Do not couple welding machines with pole reversing switch (PWS series) or machines for

Noise exceeding 70 dBA can cause permanent hearing damage!

• Wear suitable ear protection!

into service for arc welding operations, a test has to verify

may be carried out by qualified personnel only!

sources, all mains and welding current leads have

099-005366-EW501

9

Safety instructions

General

31.07.2014

CAUTION

• Regular checks of the machine according to IEC 60974-4.

machine is switched off.

Damage to the machine due to stray welding c urrents!

Stray welding currents can destro y protective earth conductors, damage equipment and

not in use!

the machine can be connected.

Obligations of the operator!

The respective national directives and laws must be observed for operation of the

machine!

• National implementation of the framework directive (89/391/EWG), as well as the

associated individual directives.

• In particular, directive (89/655/EWG), on the minimum regulations for safety and health

protection when staff members use equipment during work.

• The regulations regarding work safety and accident prevention for the respective country.

• Setting up and operating the machine according to IEC 60974-9.

• Check at regular intervals that users are working in a safety-conscious way.

Damage due to the use of non-genuine parts!

The manufacturer's warranty becomes voi d if non-genuine parts are used!

• Only use system components and options (power sources, welding torches, electrode

holders, remote controls, spare parts and replacement parts, etc.) from our range of

products!

• Only insert and lock accessory components into the relevant connection socket when the

electronic devices and cause overheating of components leading to fire.

• Make sure all welding leads are securely connected and check regularly.

• Always ensure a proper and secure electrical connection to the workpiece!

• Set up, attach or suspend all conductive power source components like casing, transport

vehicle and crane frames so they are insulated!

• Do not place any other electronic devices such as drillers or angle grinders, etc., on the

power source, transport vehicle or crane frames unless they are insulated!

• Always put welding torches and electrode holders on an insulated surface when they are

Mains connection

Requirements for connection to the public mains network

High-performance machines can influence the mains quality by taking current from the mains

network. For some types of machines, connection restrictions or requirements relating to the

maximum possible line impedance or the necessary minimum supply capacity at the interface

with the public network (Point of Common Coupling, PCC) can therefore apply. In this respect,

attention is also drawn to the machines' technical data. In this case, it is the responsibility of

the operator, where necessary in consultation with the mains network operator, to ensure that

10

099-005366-EW501

Safety instructions

General

31.07.2014

CAUTION

10, welding machines are grouped in two electromagnetic

• Shielding from other equipment in the surrounding area or the entire welding system

EMC Machine Classification

In accordance with IEC 60974compatibility classes "See 8 Technical data chapter":

Class A machines are not inten ded for use in reside nt ial areas where the power supply comes

from the low-voltage public mains network. When ensuring the electromagnetic compatibility of

class A machines, difficulties can arise in these areas due to interference not only in the supply

lines but also in the form of radiated interference.

Class B machines fulfil the EMC requirements in industrial as well as residential areas,

including residential areas connected to the low-voltage public mains network.

Setting up and operating

When operating arc welding systems, in some cases, electro-magnetic interference can occur

although all of the welding machines comply with the emission limits specified in the standard.

The user is responsible for any interference caused by welding.

In order to evaluate any po s s ible problems with electromagnetic compatibility in the

surrounding area, the user must consider the following: (see also EN 60974-10 Appendix A)

• Mains, control, signal and telecommunication lines

• Radios and televisions

• Computers and other control systems

• Safety equipment

• The health of neighbouring persons, especially if they have a pacemaker or wear a hearing

aid

• Calibration and measuring equ ipm ent

• The immunity to interference of other equipment in the surrounding area

• The time of day at which the welding work must be carried out

Recommendations for reducing interference emission

• Mains connection, e.g. additional mains filter or shielding with a metal tube

• Maintenance of the arc welding equipment

• Welding leads should be as short as possible and run closely together along the ground

• Potential equalization

• Earthing of the workpiece. In cases where it is not possible to earth the workpiece directly,

it should be connected by means of suitable capacitors.

099-005366-EW501

11

Safety instructions

Transport and installation

31.07.2014

WARNING

Incorrect handling of shielding gas cylinders!

• Avoid heating the shielding gas cylinder!

CAUTION

There is a risk of the machine tipping over and injuring persons or being damaged itself

• Fix external wire feed units during transport (avoid uncontrolled rotation)!

• Disconnect supply lines!

CAUTION

• Only transport and operate in an upright position!

2.4 Transport and installation

Incorrect handling of shielding gas cylinders can result in serious and even fatal injury.

• Observe the instructions from the gas manufacturer and in any relevant regulations

concerning the use of compressed air!

• Place shielding gas cylinders in the holders provided for them and secure with fixing

devices.

Risk of tipping!

during movement and set up. Tilt resistance is guaranteed up to an angle of 10°

(according to EN 60974-A2).

• Set up and transport the machine on level, solid ground!

• Secure add-on parts using suitab le equip ment !

• Replace damaged wheels and their fixing elements!

Damage due to supply lines not being disconnected!

During transport, supply lines which have not been disconnected (mains supply leads,

control leads, etc.) may cause hazards such as connected equipment tipping over and

injuring persons!

Equipment damage when not operated in an upright position!

The units are designed for operation in a n u p rig h t position!

Operation in non-permissible positions can cause equipment damage.

12

099-005366-EW501

31.07.2014

WARNING

Risk of injury during lifting by crane!

or mount-on components.

Craning principle

• Avoid lateral loading of the lifting eyes!

2.4.1 Lifting by crane

When lifting the machine by crane, persons may be severely injured by falling machines

• Simultaneous lifting of system components such as power source, wire

feeder or cooling unit

be lifted separately!

• Remove any supply leads and accessories before lifting by crane

hose package

remote control,etc.)!)

• Properly close and lock all casing covers and protective caps

lifting by crane!

• Use the correct number of hoisting equipment of the right size and

right capacity! Observe craning principle (see figure)!

• For machines with lifting eyes: always lift all lifting eyes simultaneously!

• When using retrofitted craning frames etc.: always use at least two

lifting points positioned as far apart as possible – observe option

description.

• Avoid any jerky movements!

• Ensure that the load is

chain slings of the same length only!

• Stay outside the danger zone underneath the machine!

• Observe the regulations regarding occupational safety and accident

prevention for the respective country.

Safety instructions

Transport and installation

is not allowed. Each system component has to

(e.g.

, wire spool, shie ld in g gas cylinder, toolbox, wire feeder,

before

distributed evenly! • Use chain hoists and

Risk of injury due to unsuitable lifting eye!

In case of improper use of lifting eyes or the use of unsuitable lifting eyes, persons can

be seriously damaged by falling equipment or add-on components!

• The lifting eye must be completely screwed in!

• The lifting eye must be positioned flat onto and in full contact with the supporting surfaces!

• Check that the lifting eyes are securely fastened before use and check for any damage

(corrosion, deformation)!

• Do not use or screw in damaged lifting eyes!

099-005366-EW501

13

Safety instructions

Transport and installation

31.07.2014

CAUTION

Installation site!

CAUTION

• Avoid ambient air containing salt (sea air)!

Non-permissible ambient conditions!

• Observe the minimum distance of 0.5 m from obstacles!

2.4.2 Ambient conditions

The machine must not be operated in the open air and must only be set up and

operated on a suitable, stable and level base!

• The operator must ensure that the ground is non-slip and level, and provide sufficient

lighting for the place of work.

• Safe operation of the machine must be guaranteed at all times.

Equipment damage due to dirt accumulation!

Unusually high quantities of dust, acid, corrosive gases or substances may damage the

equipment.

• Avoid high volumes of smoke, vapour, oil vapour and grinding dust!

Insufficient ventilation results in a reduction in performance and equipment damage.

• Observe the ambient conditions!

• Keep the cooling air inlet and outlet clear!

2.4.2.1 In operation Temperature range of the ambient air:

• -25 °C to +40 °C

Relative air humidity:

• Up to 50% at 40 °C

• Up to 90% at 20 °C

2.4.2.2 Transport and storage Storage in an enclosed space, temperature range of the ambient air:

• -30 °C to +70 °C

Relative air humidity

• Up to 90% at 20 °C

14

099-005366-EW501

31.07.2014

WARNING

• Do not modify or convert the equipment improperly!

3 Intended use

Hazards due to improper usage!

Hazards may arise for persons, animals and material objects if the equipment is not

used correctly. No liability is accepted for any damages arising from improper u sag e!

• The equipment must only be used in line with proper usage and by trained or expert staff!

3.1 Applications

3.1.1 MIG/MAG standard welding

Metal arc welding using a wire electrode whereby gas from an external source surrounds the arc and the

molten pool to protect them from the atmosphere.

3.1.1.1 forceArc

Heat-reduced, directionally stable and powerful arc with deep penetration for the higher performance

range. Non-alloyed, low-alloy and high-alloy steels and high-tensile fine-grained steels

3.1.1.2 rootArc

Short arc with perfect weld modelling capabilities for effortless gap bridging and positional welding

3.1.1.3 coldArc

Heat-reduced, low-spatter short arc for high dimensional stability welding and brazing, plus root welding

with excellent gap bridging capab iliti es .

3.1.1.4 pipeSolution

Reduced-energy MAG welding. X-ray-proof welding of pipelines and pipework without lack of fusion. Root

pass and fill and final pass with or without air gap. Low- and high-alloy steels with solid and cored wires.

3.1.2 MIG/MAG pulse welding

Welding process for optimum welding results when joining stainless steel and aluminium thanks to

controlled drop transfer and targeted, adapted heat input.

3.1.2.1 forceArc puls

Effective addition to the forceArc arc, perfect for welding final passes in all performance classes and all

positions.

3.1.2.2 rootArc puls

The perfect enhancement for focused heat input for the higher performance range

3.1.2.3 coldArc puls

The optimum enhancement for the higher performance range, with focused heat input exactly where the

heat is required.

3.1.2.4 superPuls

The EWM superPuls function enables automatic switching between two operating points in a process.

Intended use

Applications

099-005366-EW501

15

Intended use

Documents which also apply

31.07.2014

NOTE

For further information, please see th e accompanying supplementary sheets "Machine

and Company Data, Maintenance and Testing, Warranty"!

The designated machine conforms to EC Directives and standards in terms of its design

and construction:

•

• EC EMC Directive (2004/108/EC),

This declaration shall become null and void in the event of unauthorised modifications, improperly

conducted repairs, non

conversion work not specifically authorised by the manufacturer.

The original copy of the declaration of conformity is enclosed with the unit.

In compliance with

environments with an increased electrical hazard.

DANGER

• Appoint only skilled persons for repair work (trained service personnel)!

3.2 Documents which also apply

3.2.1 Warranty

3.2.2 Declaration of Conformity

EC Low Voltage Directive (2006/95/EC),

-observance of the deadlines for the repetition test and / or non-permitted

3.2.3 Welding in environments with increased electrical hazards

IEC / DIN EN 60974, VDE 0544 the machines can be used in

3.2.4 Service documents (spare parts and circuit diagrams)

Do not carry out any unauthorised repai rs o r modifications!

To avoid injury and equipment damage, the unit must only be repaired or modified by

specialist, skilled persons!

The warranty becomes null and void in the event of unauthorised interference.

Original copies of the circuit diagrams are enclosed with the unit.

Spare parts can be obtained from the relevant authorised dealer.

3.2.5 Calibration/Validation

We hereby confirm that this machine has been tested using calibrated measuring equipment, as

stipulated in IEC/EN 60974, ISO/EN 17662, EN 50504, and complies with the admissible tolerances.

Recommended calibration i nter v al: 12 months

16

099-005366-EW501

Machine description – quick overview

31.07.2014

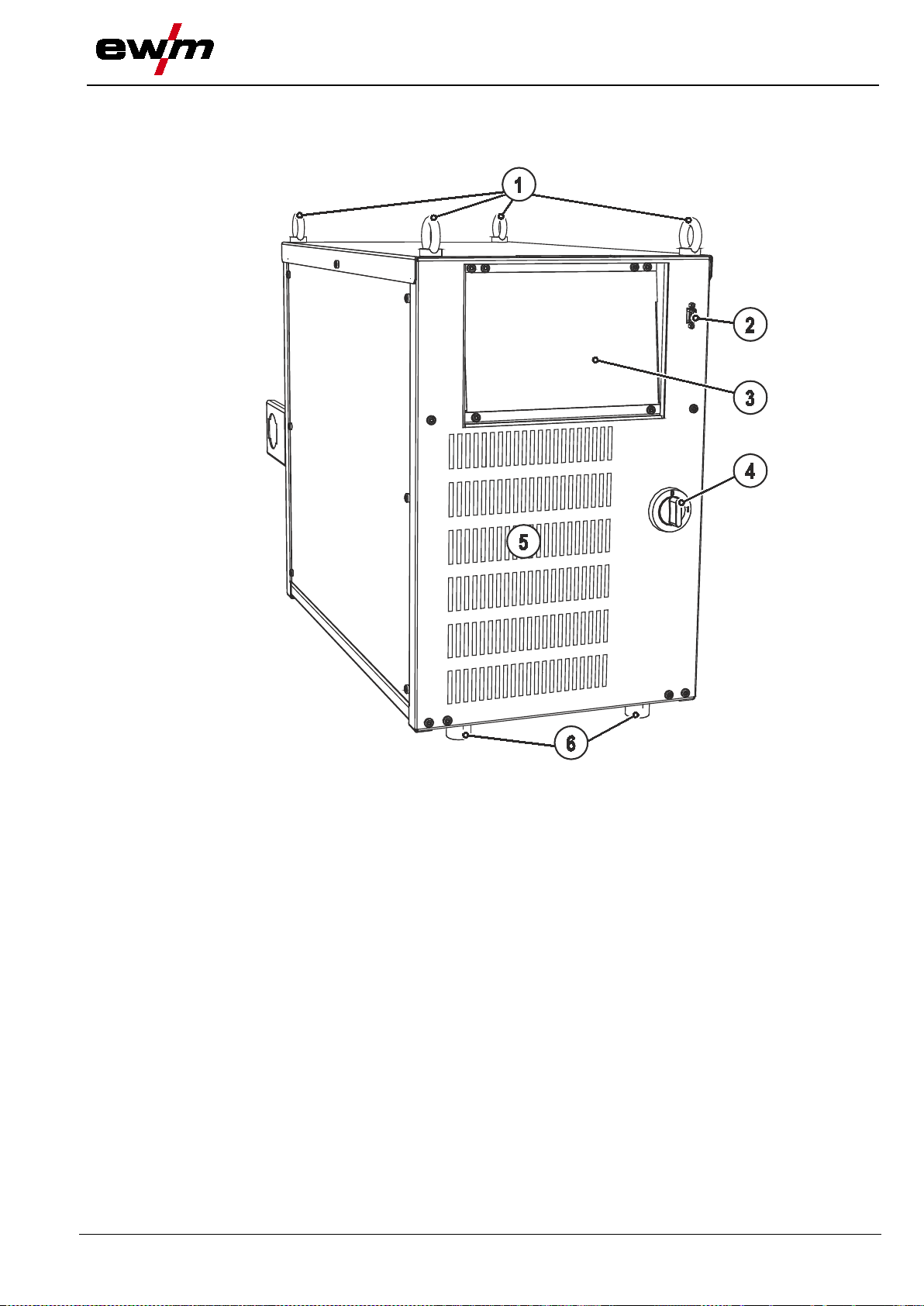

4 Machine description – quick overview

4.1 Front view

Front view

Figure 4-1

099-005366-EW501

17

Machine description

– quick overview

Front view

31.07.2014

Item

Symbol

Description 0

Lifting lug

"See 4.3 Machine control – Operating elements chapter“

Main switch, machine on/off

5 Cooling air inlet

Machine feet

1

2

PC interface, serial (D-Sub connection socket, 9-pole)

3

4

6

Machine control

18

099-005366-EW501

31.07.2014

4.2 Rear view

Machine description – quick overview

Rear view

Figure 4-2

099-005366-EW501

19

Machine description

– quick overview

Rear view

31.07.2014

Item

Symbol

Description 0

Interfaces (customer specific)

7-pole connection socket (digital)

For connecting digital accessory components

7-pole connection socket (digital)

Wire feed unit connection

welding torch and the power source

Welding current connection on wire feed unit

press to reset a triggered fuse

11 Connection socket, 5-pole

Intermediate hose package strain relief

14

1

• RINTX12 robot interface

• BUSINTX11 industrial bus inter fac e

2

3

4

5

6

7

8

9

10 Mains connection cable

19-pole mechanised welding interface (analogue)

"See 5.14.7 Automation interface chapter"

8-pole connection socket

Cooling unit control lead

12-pole connection socket (analogue)

Connection socket for analogue control signals (collision protection, etc. ) between the

Connector plug, welding current "+"

Connection socket, “-” welding current

Workpiece connection

Key button, automatic cutout

Wire feed motor supply voltage fuse

Cooling unit voltage supply

12

13 Cooling air outlet

Machine feet

20

099-005366-EW501

Machine description – quick overview

31.07.2014

NOTE

as in the power source!

Item

Symbol

Description 0

Buttons switching digital display, left

Selection of further welding parameters in lower programming levels.

Display, 16-digit

Display of all welding parameters and their values

Switching of the digital display Buttons, right

Standard welding

(program steps mode, main program A mode, JOB Manager, JOB Info)

4.3 Machine control – Operating elements

The device controller may be install ed both in an external wired remote Control as well

Machine control – Operating elements

1

2

3

4

Figure 4-3

Welding current (nominal, actual and hold values)

Material thickness (nominal value)

Wire speed (nominal, actual and hold values)

Operating hour counter

Welding voltage (nominal / actual values)

Motor current (actual value)

JOB number

After each completed welding process, the last parameter values used for the

welding process are shown on the display in the main program; the signal

light is on.

Status

Display of the current parameters specified by the robot control.

Non-latched

Special, non-latched

Pulse welding

5

Button, Mode

Select further programming levels

099-005366-EW501

21

Machine description

– quick overview

Machine control

31.07.2014

Item

Symbol

Description 0

Key switch for protection against unauthorised use

Button, "Program sequence"

the welding process.

the welding process.

"ENTER" button

Superpuls

Button, "Program A" (operating point)

Dynamics (signal light flashing)

– Operating elements

6

Position “1” > changes possible,

Position “0” > changes not possible.

"See 5.15 Protecting welding parameters from unauthorised access chapter".

7

8

9

"JOB Manager" button (organise welding tasks)

During operation, the current position in the program sequence is shown.

Outside, the values can be selected and welding parameters changed by means of the

rotary dial.

Button, "Program selection 8 to 15"

Display the selected program during the welding process and select program outside

Display information on the current welding task selected

Define new welding task

Copy welding task

Display information on any welding task (job)

Gas pre-flows (0.0 to 20.0 sec)

Start program (WFstart 0% to 200% / Ustart)

Start time (0.0 to 20.0 sec)

Current program display

End program (0% to 200%)

End time (0.0 to 20.0 sec)

Wire burn-back (2 to 500)

Gas post-flow time (0.0 s to 20.0 s)

10

11

12

Button, "Program selection 0 to 7"

Display the selected program during the welding process and select program outside

Confirmation, e.g.: of JOB parameters

Wire speed

Voltage correction

22

099-005366-EW501

General

31.07.2014

WARNING

Risk of injury from electric shock!

interfaces) may only be connected when the machine is switched off!

CAUTION

Not all active parts of the welding current circuit can be shielded from direct contact. To

• Always place torches and electrode holders on an insulated surface!

if necessary.

Risk of injury due to moving parts!

• Keep casing covers or protective caps closed during operation!

• Keep all casing covers or protective caps closed during operation!

Risk from electrical current!

surface before starting work and during breaks.

5 Design and function

Design and function

5.1 General

Contact with live parts, e.g. weldin g current sockets, is potentially fatal!

• Follow safety instructions on the opening pages of the operating instructions.

• Commissioning may only be carried out by persons who have the relevant expertise of

working with arc welding machines!

• Connection and welding leads (e.g. electrode holder, welding torch, workpiece lead,

Insulate the arc welder from welding voltage!

avoid any associated risks it is vital for the welder to adhere to the relevant safety

regulations. Even low voltages can cause a shock and lead to accidents.

• Wear dry and undamaged protective clothing (shoes with rubber soles/welder's gloves

made from leather without any studs or braces)!

• Avoid direct contact with non-insulated connection sockets or connectors!

Risk of burns on the welding current connection!

If the welding current connections are not locked, connections and leads heat up an d

can cause burns, if touched!

• Check the welding current connections every day and lock by turning in clockwise direction,

The wire feeders are equipped with moving parts, which can trap hands, hair, clothing

or tools and thus injure persons!

• Do not reach into rotating or moving parts or drive components!

Risk of injury due to welding wire escaping in an unpredictable manner!

Welding wire can be conveyed at very high speeds and, if conveyed incorrectly, may

escape in an uncontrolled manner and i n jure persons!

• Before mains connection, set up the complete wire guide system from the wire spool to the

welding torch!

• Remove the pressure rollers from the wire feeder if no welding torch is fitted!

• Check wire guide at regular intervals!

If welding is carried out alternately using different methods and if a welding torch and

an electrode holder remain connected to the machine, the open-circuit/welding voltage

is applied simultaneously on all cables.

• The torch and the electrode holder should therefore always be placed on an insulated

099-005366-EW501

23

Design and function

General

31.07.2014

CAUTION

• Accessory components are detected automatically after the power source is switched on.

NOTE

Observe documentation of other sy stem components when connecting!

Damage due to incorrect connection!

Accessory components and the power source itself can be damaged by incorrect

connection!

• Only insert and lock accessory components into the relevant connection socket when the

machine is switched off.

• Comprehensive descriptions can be found in the operating instructions for the relevant

accessory components.

Using protective dust caps!

Protective dust caps protect the connection sockets and therefore the machine against

dirt and damage.

• The protective dust cap must be fitted if there is no accessory component being operated

on that connection.

• The cap must be replaced if faulty or if lost!

24

099-005366-EW501

31.07.2014

3~

AC

Cool 82

M drive 4 Rob 2

AC

Fassförderung

7

pol

12

pol

5

pol

8

pol5pol

SPS / CU / ROB

19

pol

RINTX12

BUSINTX11

7

pol

12

pol

7

pol

19

pol

19

pol

AIR

AIR

8

pol

AIR

HP

HP

HP

5.2 Connection plan

Design and function

Connection plan

099-005366-EW501

Figure 5-1

25

Design and function

Connection plan

31.07.2014

Shielding gas

Welding torch coolant

Cooling water input

3~

AC

19

pol

19-pole mechanised welding interface

12

pol

Wire feed unit control lead (12-pole)

7

pol

Wire feed unit control lead/RINTX12, BUSINTX11 (7-pole)

5

pol

Cooling unit supply voltage connection (5-pole)

8

pol

Cooling unit control lead (8-pole)

AIR

HP

5.2.1 Legend

Wire feed

Welding current (minus potential, workpiece)

Cooling water output

Welding machine supply voltage

Welding current (plus potential)

Euro torch connector

Compressed air connection to clean the welding torch nozzles

Hose package (HP = hose package)

26

099-005366-EW501

31.07.2014

CAUTION

Installation site!

• Safe operation of the machine must be guaranteed at all times.

CAUTION

• Take care to ensure faultless power connections!

5.3 Installation

The machine must not be operated in the open air and must only be set up and

operated on a suitable, stable and level base!

• The operator must ensure that the ground is non-slip and level, and provide sufficient

lighting for the place of work.

5.4 Machine cooling

To obtain an optimal duty cycle from the power components, the following precautions should be

observed:

• Ensure that the working area is adequately ventilated.

• Do not obstruct the air inlets and outlets of the machine.

• Do not allow metal parts, dust or other objects to get into the machine.

5.5 Workpiece lead, general

Design and function

Installation

Risk of burns due to incorrect connection of the workpiece lead!

Paint, rust and dirt on the connec tion restrict the power flow and may lead to stra y

welding currents.

Stray welding currents may cause fires and injuries!

• Clean the connections!

• Fix the workpiece lead securely!

• Do not use structural parts of the workpiece as a return lead for the welding current!

099-005366-EW501

27

Design and function

Notes on the installation of welding current leads

31.07.2014

NOTE

Incorrectly installed welding current leads can cause faults in the arc (flickering).

Lay the workpiece lead and hose package of power sources without HF igniter

(MIG/MAG) for as long and as close as possible in parallel.

long as possible in parallel with a distance of 20 cm to avoid HF sparkover.

Always keep a distance of at least 20 cm to leads of other power sources to avoid

interferences.

5.6 Notes on the installation of wel ding current leads

Lay the workpiece lead and hose package of power sources with HF igniter (TIG) for as

Figure 5-2

28

099-005366-EW501

Design and function

31.07.2014

NOTE

Use an individual welding lead to the workpiece for each welding machine!

NOTE

packages. Avoid loops!

Always keep leads as short as possible!

Lay any excess cable lengths in meanders.

Figure 5-3

Fully unroll welding current lead s, torch hose packages and intermediate hose

Notes on the installation of welding current leads

Figure 5-4

099-005366-EW501

29

Design and function

Welding torch cooling system

31.07.2014

CAUTION

Coolant mixtures!

• When changing the coolant, the entire volume of liquid must be changed.

that the frost protection is adequate to prevent damage to the machine or the accessory

• Replace coolant as necessary if frost protection is inadequate!

NOTE

The disposal of coolant must be carr ied o u t according to official regulations and

• Recommended cleaning agent: water, if necessary with cleaning agent added.

Coolant

Temperature range

KF 23E (Standard)

-10 °C to +40 °C

KF 37E

-20 °C to +10 °C

Pump 3.5 bar

Pump 4.5 bar

drive (example. miniDrive)

intermediate drive (example: miniDrive)

5.7 Welding torch cooling s yst e m

Mixtures with other liquids or the use of unsuitable coolants result in material damage

and renders the manufacturer's warranty void!

• Only use the coolant described in this manual (overview of coolants).

• Do not mix different coolants.

Insufficient frost protection in the welding torch coolant!

Depending on the ambient conditions, different liquids are used for cooli n g the welding

torch "See 5.7.1 List of coolants

Coolants with frost protection (KF 37E or KF 23E) must be checked regularly to ensure

components.

• The coolant must be checked for adequate frost protection with the TYP 1 frost protection

tester "See 9 Accessories chapter".

chapter".

observing the relevant safety data sheets (German waste code number: 70104)!

• Coolant must not be disposed of together with household waste.

• Coolant must not be discharged into the sewerage system.

5.7.1 List of coolants

The following coolants may be used "See 9 Accessories chapter":

5.7.2 Maximal hose package length

Machines with or without separate wire feeder

Compact machines with additional intermediate

Machines with separate wire feeder and additional

Data as a rule refer to the entire hose package length

including welding torch. The pump output is shown on the type plate (parameter: Pmax).

Pump 3.5 bar: Pmax = 0.35 MPa (3.5 bar)

Pump 4.5 bar: Pmax = 0.45 MPa (4.5 bar)

30 m 60 m

20 m 30 m

20 m 60 m

30

099-005366-EW501

Design and function

31.07.2014

NOTE

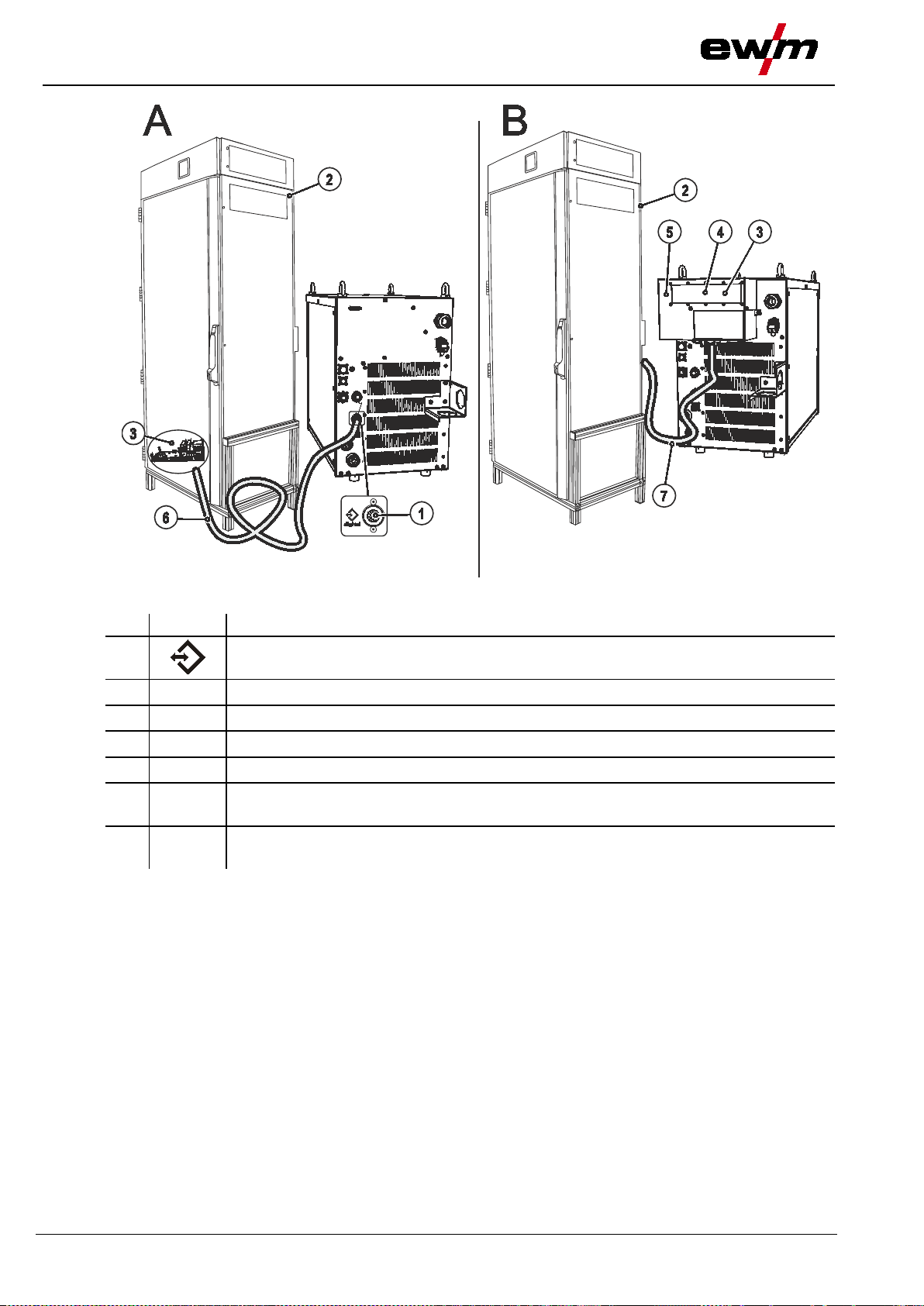

Item

Symbol

Description 0

2 Connection socket, 5-pole

5.8 Connect the cooling module t o t he power s ource

Please note the relevant documentation of the accessory components.

Connect the cooling module to the power source

1

• Insert and lock the 8-pole control lead plug on the cooling module into the 8-pole connection socket on

the welding machine.

• Insert and lock the 5-pole supply plug on the cooling module into the 5-pole connection socket on the

welding machine.

099-005366-EW501

8-pole connection socket

Cooling unit control lead

Cooling unit voltage supply

Figure 5-5

31

Design and function

Mains connection

31.07.2014

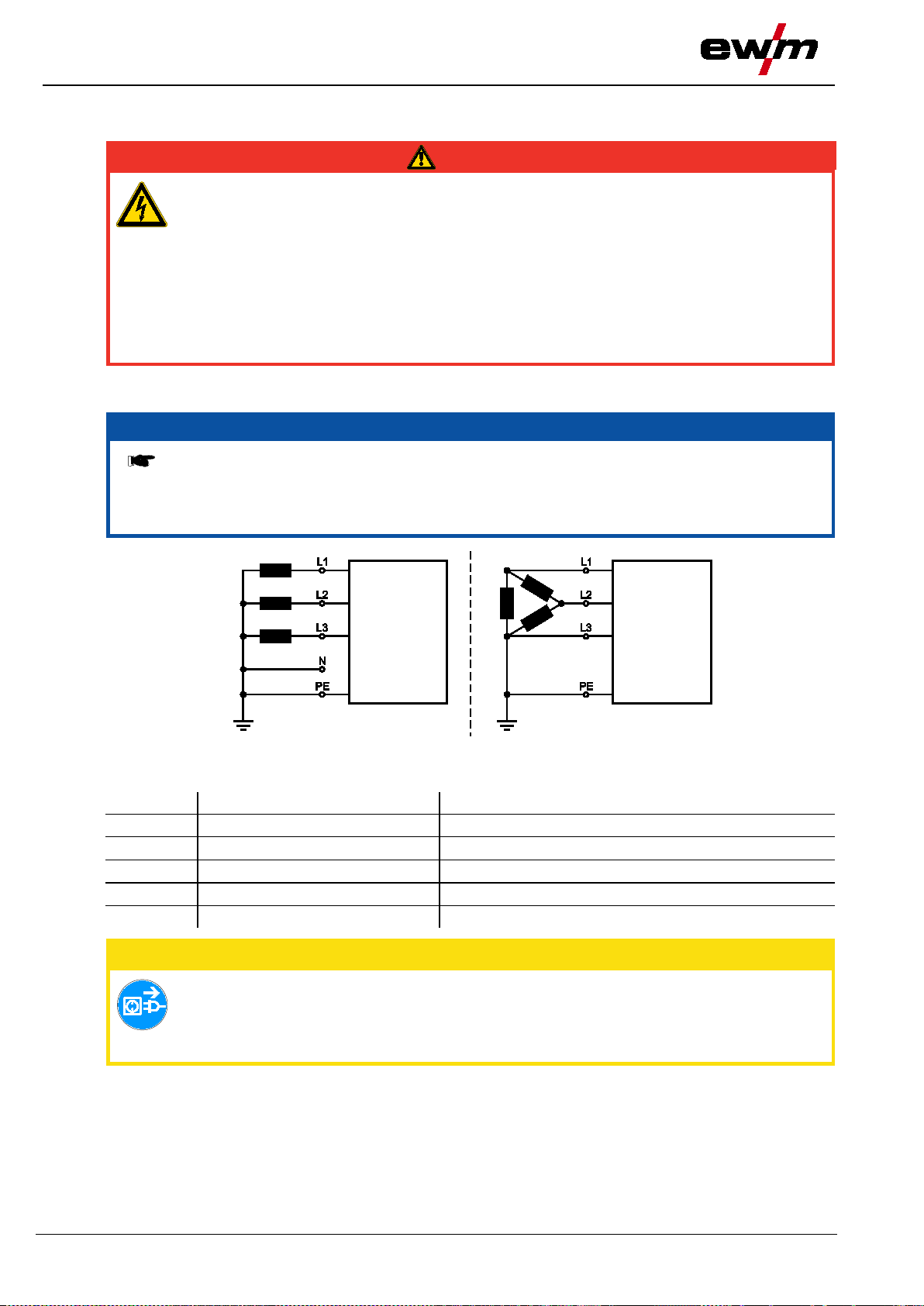

DANGER

Hazard caused by improper mains connection!

protection class 1.

NOTE

The machine may be connected to:

e.g. the outer conductor

Item

Designation

Colour code

L1

Outer conductor 1

brown

L2

Outer conductor 2

black

L3

Outer conductor 3

grey

N

Neutral conductor

blue

PE

Protective conductor

green-yellow

CAUTION

• For mains fuse protection, please refer to the “Technical data” chapter!

5.9 Mains connection

An improper mains connection can cause injuries or damage property!

• Only use machine with a plug socket that has a correctly fitted protective conductor.

• If a mains plug must be fitted, this may only be carried out by an electrician in accordance

with the relevant national provisions or regulations!

• Mains plug, socket and lead must be checked regularly by an electrician!

• When operating the generator always ensure it is earthed as stated in the operating

instructions. The resulting network has to be suitable for operating devices according to

5.9.1 Mains configuration

• a three-phase system with four conductors and an earthed neutral conductor

• a three-phase system with three conductors of which any one can be earthed,

Figure 5-6

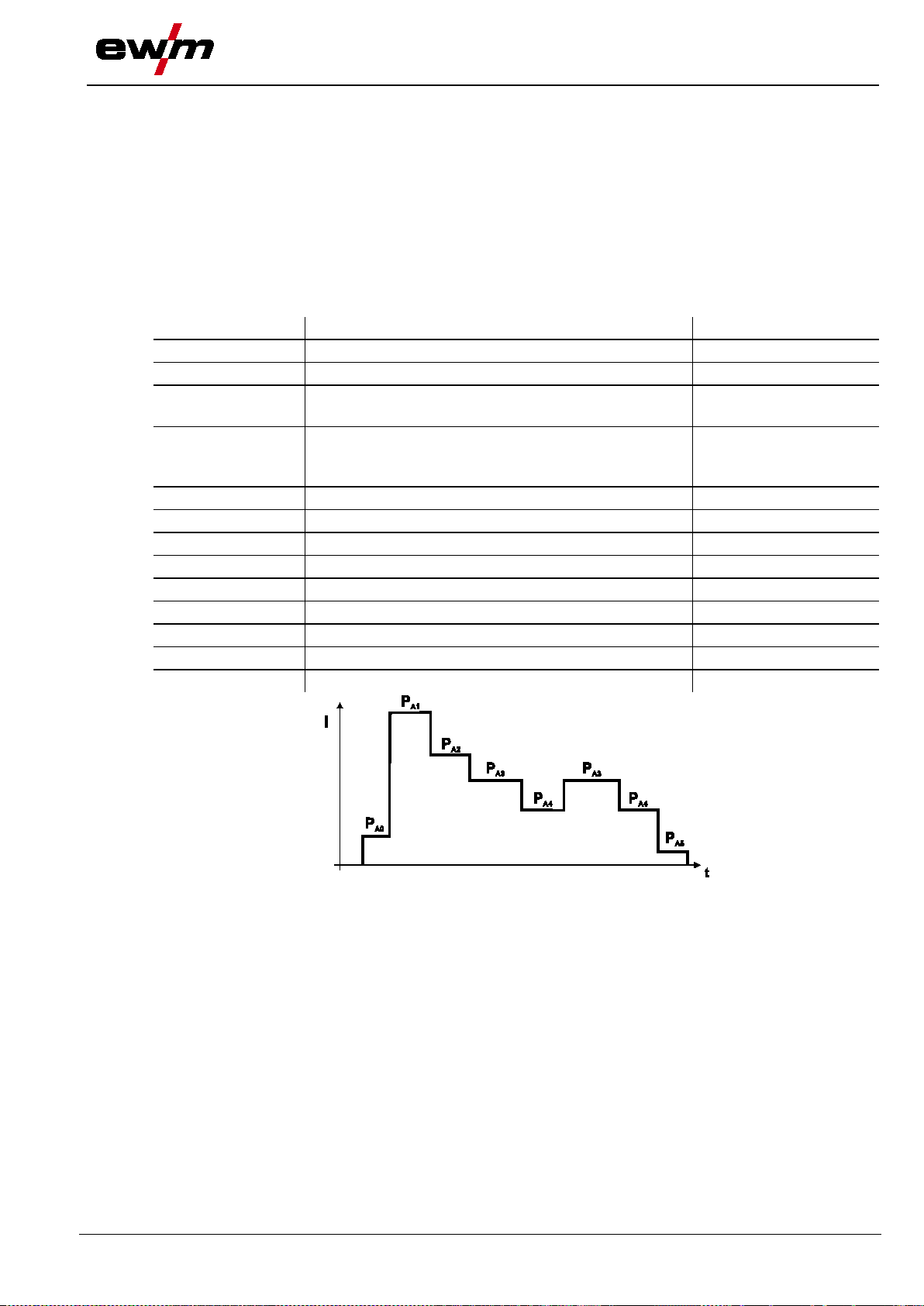

Legend

Operating voltage - mains voltage!

The operating voltage shown on the rating plate must be consistent with the ma ins

voltage, in order to avoid damage to the machine!

• Insert mains plug of the switched-off machine into the appropriate socket.

32

099-005366-EW501

31.07.2014

NOTE

shielding cored wire) are welded using ne gative polarity.

• Observe the information from the electrode manufacturer!

Item

Symbol

Description 0

Intermediate hose package strain relief

7-pole connection socket (digital)

Wire feed unit connection

12-pole connection socket (analogue)

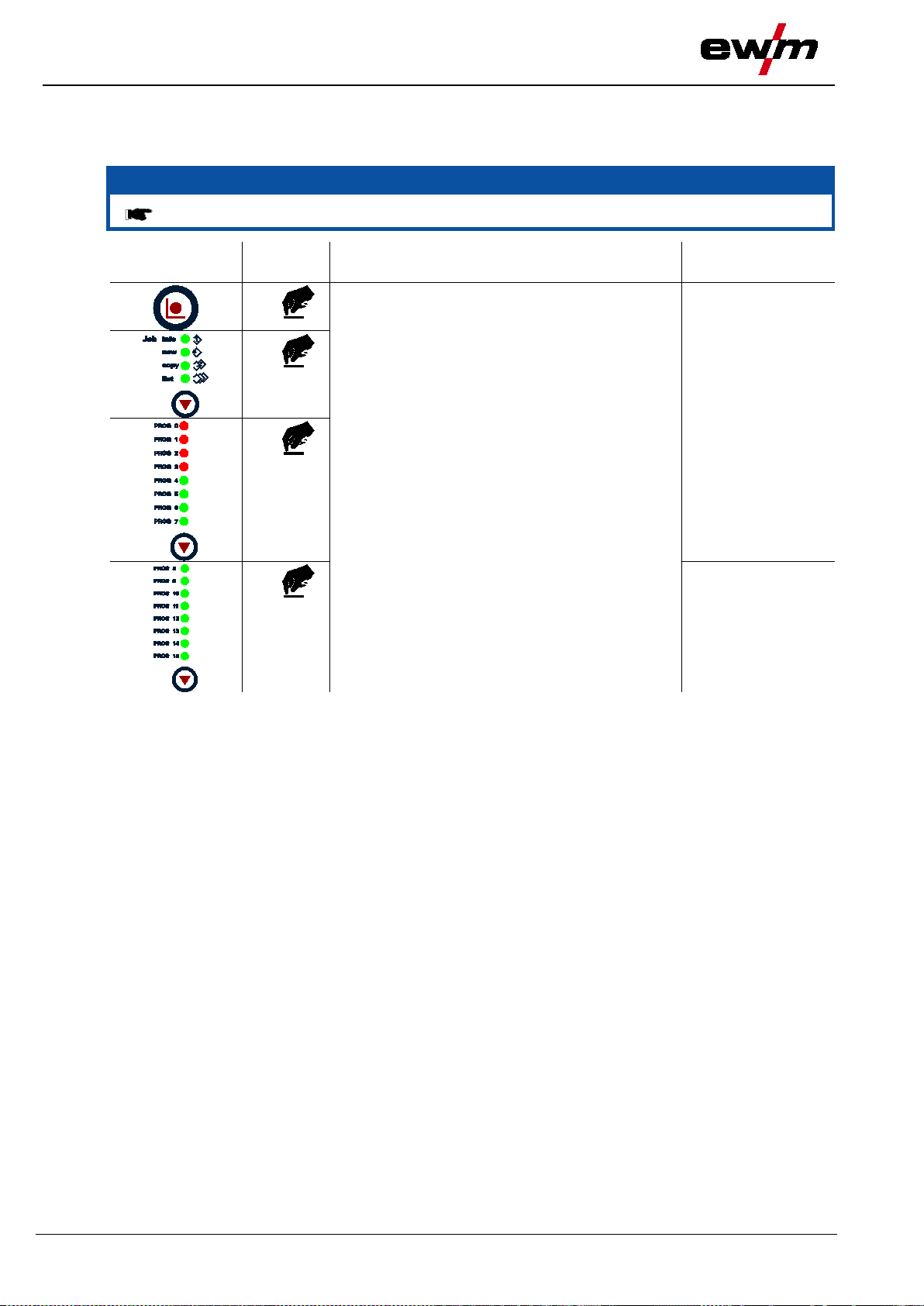

welding torch and the power source

Connection socket, “+” welding current

• MIG/MAG welding:

Welding current to wire feed/torch

Connection socket, “-” welding current

• MIG/MAG cored wire welding:

Welding current to wire feed/torch

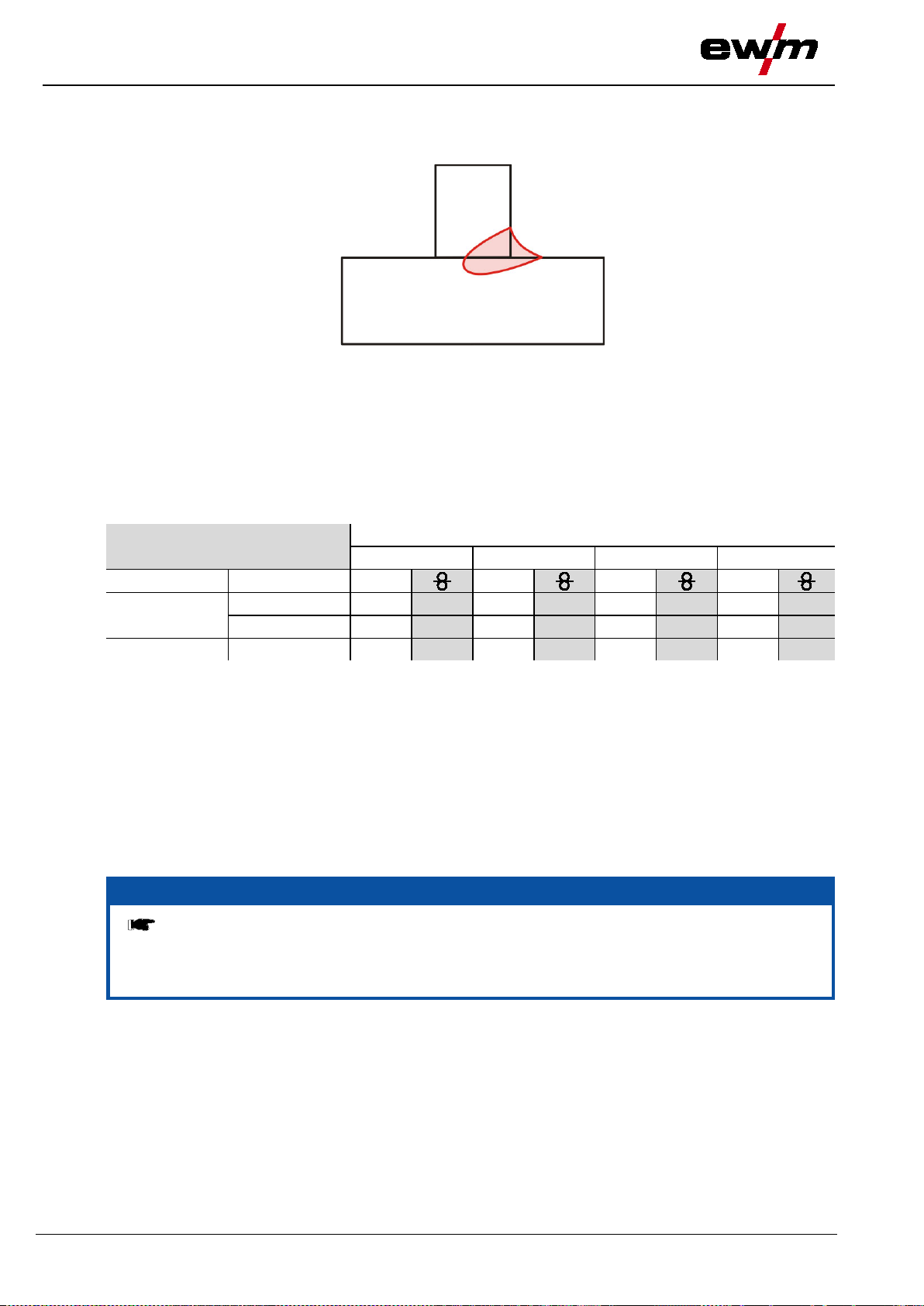

5.10 Intermediate hose package connection

Note the polarity of the welding curren t!

Some wire electrodes (e.g. self-

In this case, the welding current lead should be connected to the "-" welding current

socket, and the workpiece lead should b e connected to the "+" welding current socket.

Design and function

Intermediate hose package connec t ion

1

2

3

Connection socket for analogue control signals (collision protection, etc. ) between the

4

5

• Insert the end of the tube package through the intermediate tube package strain relief and lock by

turning to the right. If applicable, follow the instructions from the third party manufacturer of the strain

relief.

• Insert the welding current plug of the wire feeder unit in the "+" welding current connection socket and

lock by turning to the right.

• Insert the wire feed control lead plug into the 7-pole connection socket (digital) and lock.

• Insert the analogue control signal cable plug into the 12-pole (analogue) connection socket and lock

by turning to the right.

099-005366-EW501

Figure 5-7

33

Design and function

Matching the cable resistance

31.07.2014

2

3

4

1

l

0

50mm

l

0

A

RINT X12

BUSINT X11

1 x

n x

l

0

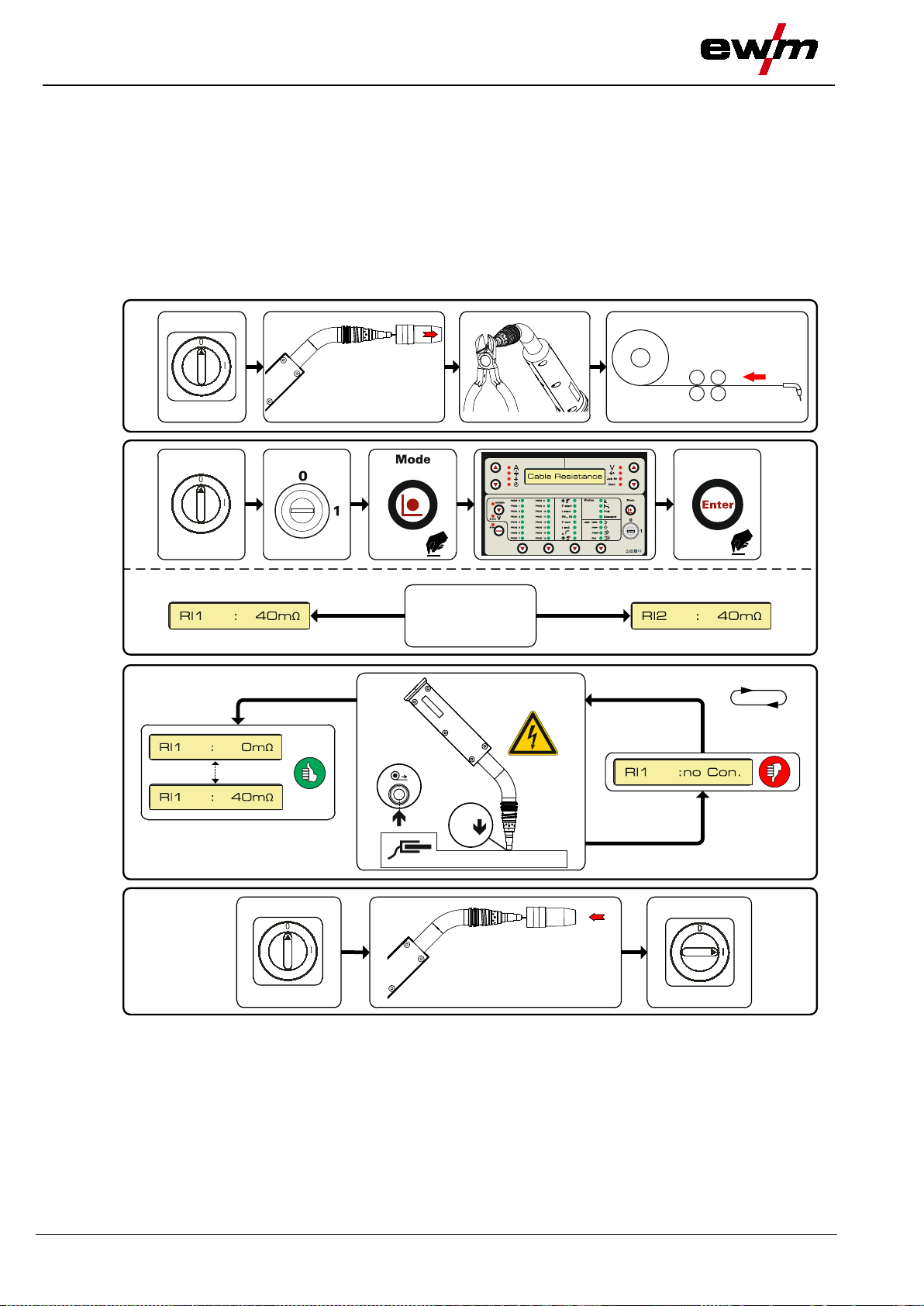

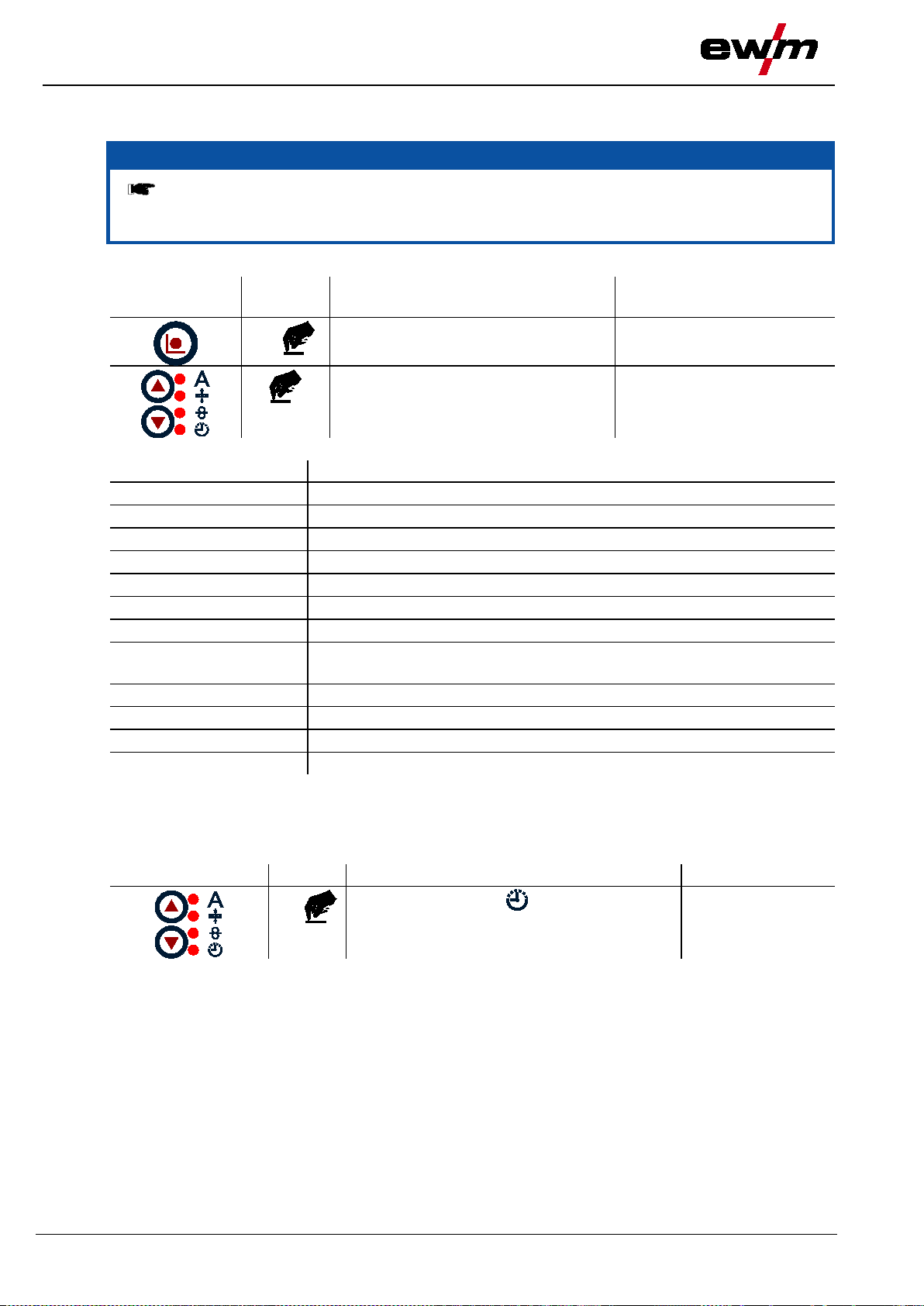

5.11 Matching the cable resistance

The resistance value of cables can either be set directly or it can be matched using the power source.

The factory setting of the power sources is 8 m-ohm. This value correponds to a 5 m earth cable, a 1.5 m

intermediate hose package and a 3 m water-cooled welding torch. With other hose package lengths, it is

necessary to carry out a +/- voltage correction to optimise welding properties. The voltage correction

value can be set close to zero by means of re-matching the cable resistance. It is recommended to match

the electric cable resistance after replacing accessories such as torches or intermediate hose packages.

In case a second wire feeder is used the (rL2) parameter has to be adjusted. For all other configurations it

is sufficient to match the (rL1) parameter.

Figure 5-8

34

099-005366-EW501

tance

31.07.2014

1 Preparation

• Switch off the welding mac hine.

• Unscrew the gas nozzle of the welding torch.

• Cut off the welding wire to be flush with the contact tip.

• Retract the welding wire a bit (approx. 50 mm) on the wire feeder. Now there should be no more

welding wire in the contact tip.

2 Configuration

• Switch on the welding machine

• At the machine control, turn the key switch to the "1" position.

• Press the "Mode" push-button until the "Cable Resistance" parameter is shown on the machine control

display.

• Confirm the parameter by the" Enter " push-button.

• In case of welding systems with a second power circuit – if two wire feeders are to be operated from a

single power source, for example – a second alignment with parameter Rl2 must be performed. To do

so, switch the wire feeder using the appropriate interface.

3 Alignment/measurement

• Place the welding torch contact tip on a cleansed part of the workpiece with light pressure and press

the inching button at the torch or wire feeder for approx. 2 seconds; this function can also be selected

via the interface. Short-circuit current flows briefly, which is used to determine and display the cable

resistance. The value can be between 0 mΩ and 40 mΩ. The new value is immediately saved without

requiring any further confirmati on. If "no Con." is shown on the display, measurement failed. The

measurement must be repeated.

4 Restoring welding standby mode

• Switch off the welding machine.

• Screw the gas nozzle onto the welding torch.

• Switch on the welding machine

• Insert the welding wire.

Design and function

Matching the cable resis

099-005366-EW501

35

Design and function

Connection for workpiece lead

31.07.2014

NOTE

shielding cored wire) are welded using ne gative polarity.

• Observe the information from the electrode manufacturer!

Item

Symbol

Description 0

Connection socket, "+" welding current

• MIG/MAG cored wire welding:

Workpiece connection

"-" welding current connection socket

• MIG/MAG welding:

Workpiece connection

5.12 Connection for workpie c e l ead

Note the polarity of the welding curren t!

Some wire electrodes (e.g. self-

In this case, the welding current lead should be connected to the "-" welding current

socket, and the workpiece lead should b e connected to the "+" welding current socket.

1

2

• Insert the plug on the workpiece lead into the "-" welding current connection socket and lock.

36

Figure 5-9

099-005366-EW501

Design and function

31.07.2014

WARNING

• Avoid heating the shielding gas cylinder!

CAUTION

Faults in the shielding gas supply.

• All shielding gas connections must be gas tight.

NOTE

Before connecting the pressure regulator to the gas cylinder, open the cylinder valve

briefly to expel any dirt.

5.13 Shielding gas supply (shie lding gas cylinder for welding machi ne )

5.13.1 Connecting the shielding gas supply

Incorrect handling of shielding gas cylinders!

Incorrect handling of shielding gas cylinders can result in serious and even fatal injury.

• Observe the instructions from the gas manufacturer and in any relevant regulations

concerning the use of compressed air!

• Place shielding gas cylinders in the holders provided for them and secure with fixing

devices.

An unhindered shielding gas supply fro m th e shielding gas cylinder to the welding

torch is a fundamental requirement fo r optimum welding results. In addition, a blocked

shielding gas supply may resul t in the welding torch being destroyed.

• Always re-fit the yellow protective cap when not using the shielding gas connection.

Shielding gas supply (shielding gas cylinder for welding machine)

099-005366-EW501

37

Design and function

Shielding gas supply (shielding gas cylinder for welding machine)

31.07.2014

Item

Symbol

Description 0

Pressure regulator

Shielding gas cylinder

3

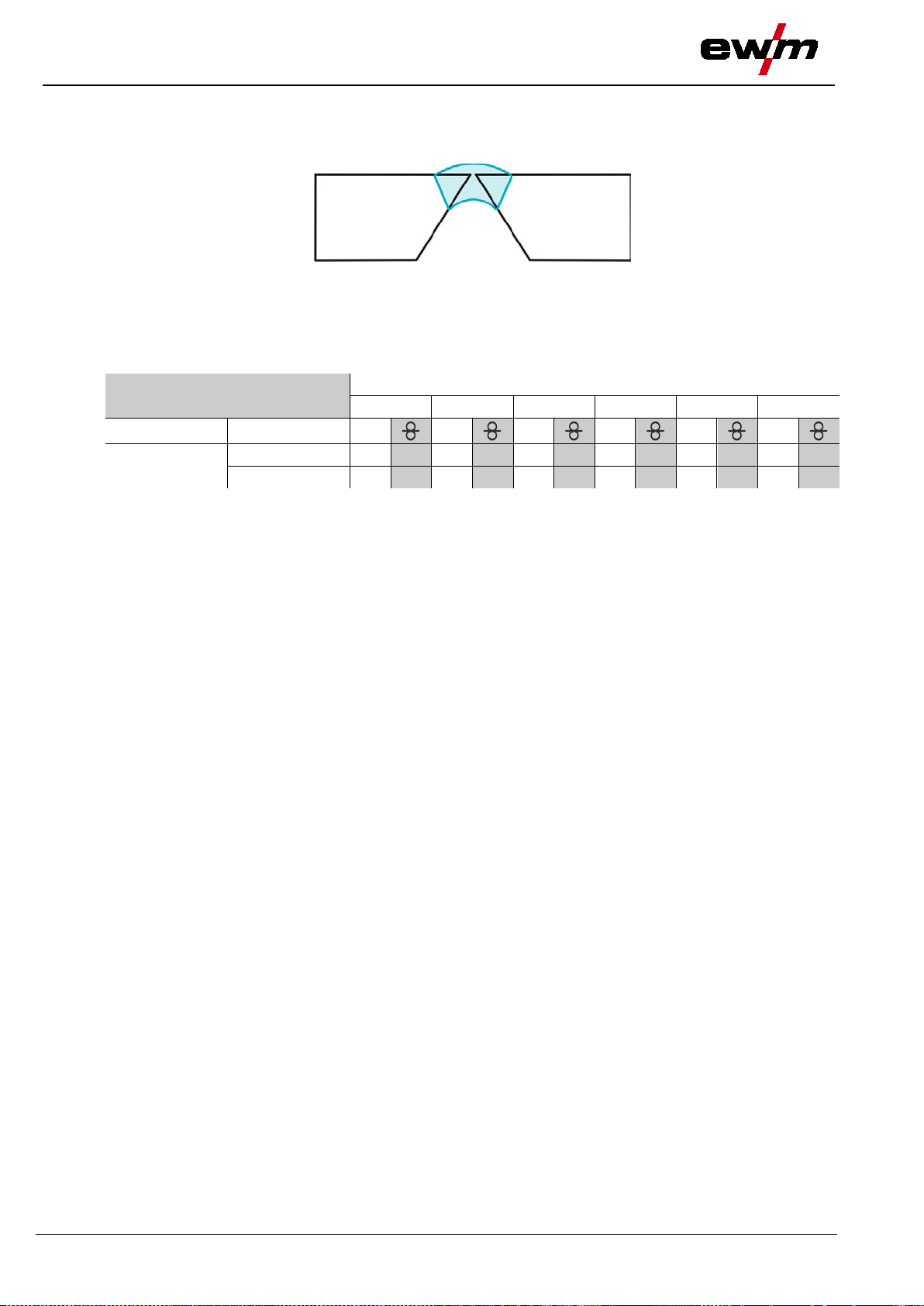

Welding process

Recommended shielding gas quantity

MAG welding

Wire diameter x 11.5 = l/min

MIG brazing

Wire diameter x 11.5 = l/min

MIG welding (aluminium)

Wire diameter x 13.5 = l/min (100 % argon)

TIG

Gas nozzle diameter in mm corresponds to l/min gas throughput

Shielding gas

Factor

75% Ar/25% He

1.14

50% Ar/50% He

1.35

25% Ar/75% He

1.75

100% He

3.16

NOTE

• Adjust the shielding gas quantity to suit the welding task!

1

2

Output side of the pressure regulator

4

Cylinder valve

• Place the shielding gas cylinder in the cylinder holder and secure it from tipping over using the

securing chain!

• Before connecting the pressure regulator to the gas cylinder, open the cylinder valve briefly to blow out

any dirt.

• Mount the pressure regulator on the gas cylinder valve.

• Screw gas hose connection crown nut onto the output side of the pressure regulator.

• Screw the gas hose connection nipple onto the G¼" connection nipple.

• Tighten gas hose on pressure regulator to be gas tight.

• Fit the gas hose and G1/4" crown nut onto the relevant connection on the welding machine, and fit the

wire feed unit (if present on this version).

5.13.2 Setting instructions

Figure 5-10

Helium-rich gas mixtures require a higher gas volume!

The table below can be used to correct the gas volume calculated where necessary:

Incorrect shielding gas setting!

If the shielding gas setting is too low or too high, this can introduce air to the weld p o o l

and may cause pores to form.

38

099-005366-EW501

Design and function

31.07.2014

CAUTION

machine is switched off.

• Accessory components are detected automatically after the power source is switched on.

NOTE

Only one variant can ever be operated at any one time.

5.14 Interfaces

5.14.1 Connecting the RINT X11 robot interface/BUSINT X11 industrial bus interface

Damage due to the use of non-genuine parts!

The manufacturer's warranty becomes void if non-genuine parts are used!

• Only use system components and options (power sources, welding torches, electrode

holders, remote controls, spare parts and replacement parts, etc.) from our range of

products!

• Only insert and lock accessory components into the relevant connection socket when the

Damage due to incorrect connection!

Accessory components and the power source itself can be damaged by incorrect

connection!

• Only insert and lock accessory components into the relevant connection socket when the

machine is switched off.

• Comprehensive descriptions can be found in the operating instructions for the relevant

accessory components.

Interfaces

The interfaces can be operated directly on the power source in a separate interface casing or externally,

e.g. in a robot control cabinet or via a data cable.

5.14.2 RINT X12 robot interface

The standard digital interface for mechanised applications

(optional, retrofitting on the machine or external fitting by the customer)

Functions and signals:

• Digital inputs: start/stop, operating modes, JOB and program selection, inching, gas test

• Analogue inputs: control voltages, e.g. for welding performance, welding current, etc.

• Relay outputs: process signal, ready for welding, system composite fault, etc.

5.14.3 BUSINT X11 industrial bus interface

The solution for integration into mechanised production lines, with for example

• Profibus

• CAN-Open, CAN DeviceNet

• Interbus systems with copper and optical fibre connection (FSMA/Rugged Line)

099-005366-EW501

39

Design and function

Interfaces

31.07.2014

Item

Symbol

Description 0

For connecting digital accessory components

Robot interface, Tetrix / Phoenix / alpha Q, RINT X12

Industrial bus interface, Tetrix / Phoenix / alpha Q, BUSINT X11

5

Connection between switching cabinet and power source

Connection lead

Connection between interface casing and switching cabinet

1

2

3

4

6

7

7-pole connection socket (digital)

Switching cabinet

Interface casing

Connection cable, 7-pole

Figure 5-11

40

099-005366-EW501

Design and function

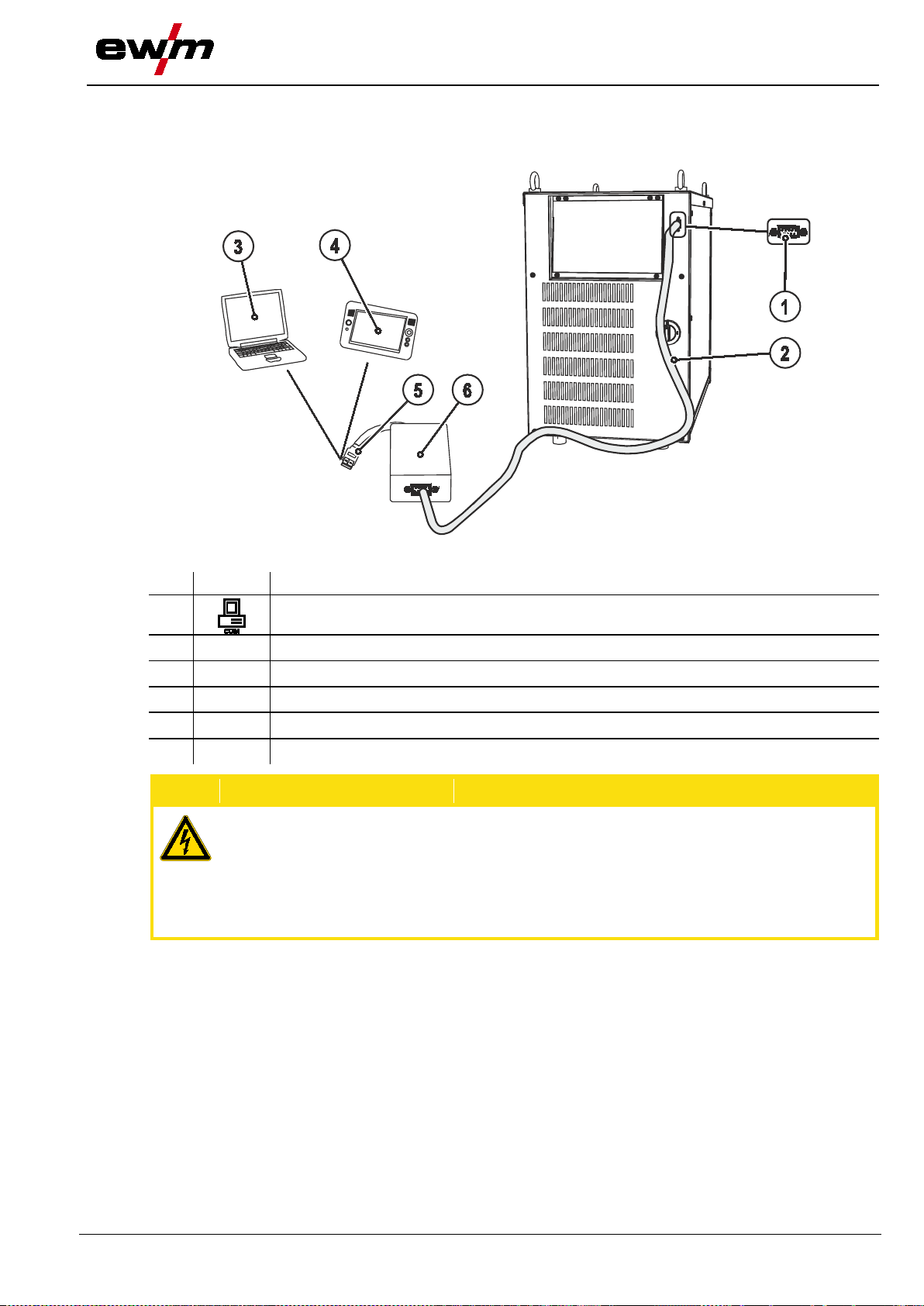

31.07.2014

Item

Symbol

Description 0

PC interface, serial (D-Sub connection socket, 9-pole)

2

3

RC300 tablet PC

USB connection

6

CAUTION

Equipment damage or faults may occur if the PC is connected incorrectly!

5.14.4 Connecting the PC 300.net welding parameterisation software

Create all welding parameters quickly on the PC and easily transfer them to one or more welding

machines (accessories, set consisting of software, interface, connection leads)

Interfaces

1

Connection cable, 9-pole, serial

Windows PC

4

5

SECINT X10 USB

Not using the SECINT X10USB interface results in equipment damage or faults in signal

transmission. The PC may be destroyed due to hi gh frequency ignition pulses.

• Interface SECINT X10USB must be connected between the PC and the welding machine!

• The connection must only be made using the cables supplied (do not use any additional

extension cables)!

Figure 5-12

099-005366-EW501

41

Design and function

Interfaces

31.07.2014

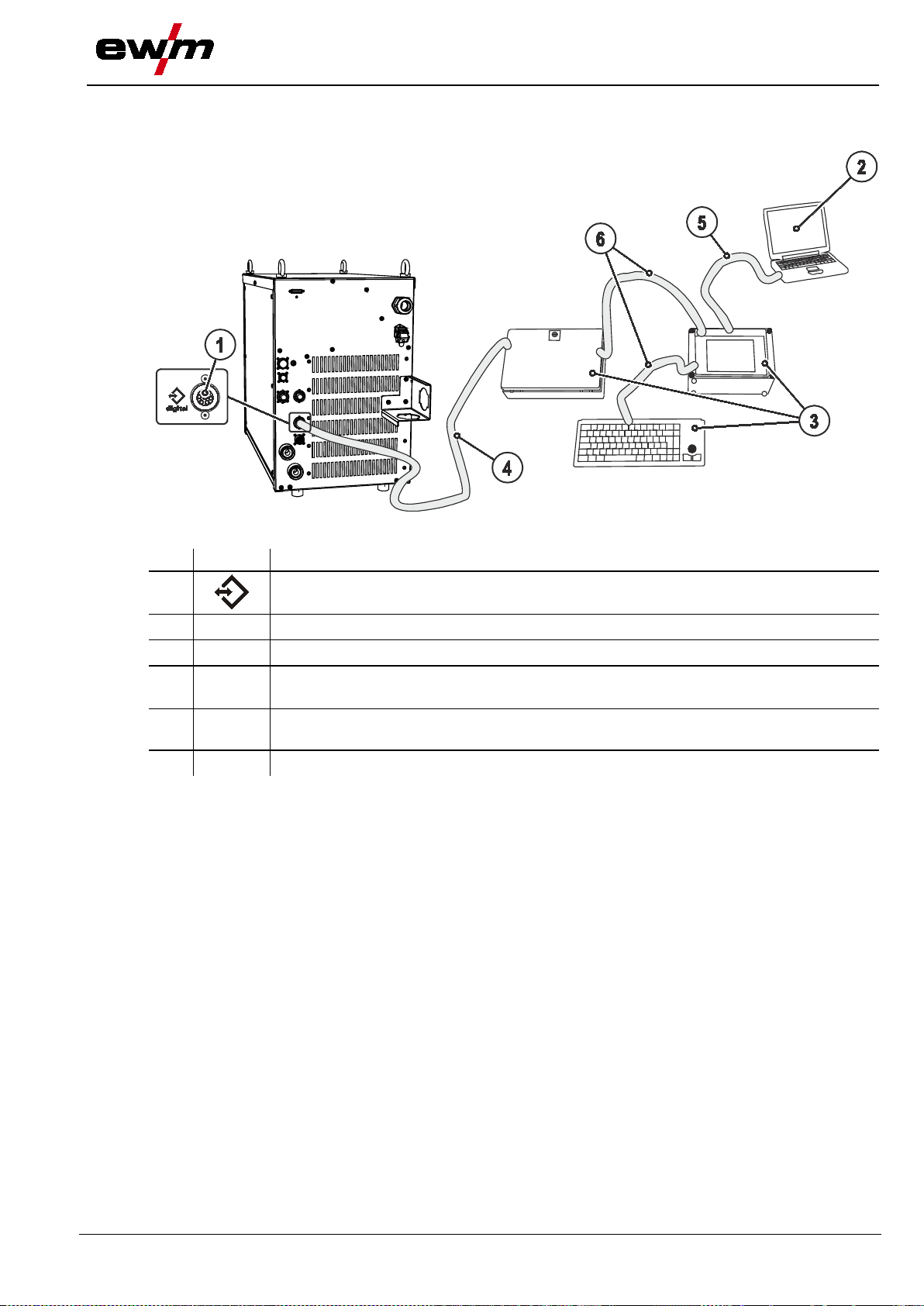

Item

Symbol

Description 0

For connecting digital accessory components

Windows PC

RC300 tablet PC

4

5

Connection cable, 7-pole

Connection between switching cabinet and power source

CAUTION

Equipment damage or faults may occur if the PC is connected incorrectly!

extension cables)!

5.14.5 Connecting the Q-DOC 9000 welding data documentation software

(Accessories: Set consisting of software, interface, connection leads)

The ideal tool for welding data documentation of, for example:

welding voltage and current, wire speed and motor current.

1

Figure 5-13

7-pole connection socket (digital)

2

3

SECINT X10 USB

Connection cable, 9-pole, serial

6

PCINT X10

7

Not using the SECINT X10USB interface results in equipment damage or faults in signal

transmission. The PC may be destroyed due to hi gh frequency ignition pulses.

• Interface SECINT X10USB must be conn ec ted betw een the PC and the welding machine!

• The connection must only be made using the cables supplied (do not use any additional

42

099-005366-EW501

Design and function

31.07.2014

Item

Symbol

Description 0

For connecting digital accessory components

WELDQAS welding data monitoring and docum entation system

Connection cable, 7-pole

Connection between switching cabinet and power source

cables

5.14.6 Connecting the WELDQAS welding data monitoring and documentation system

Network-compatible welding data monitoring and documentation system for digital power sources.

Interfaces

1

2

3

4

5

6

7-pole connection socket (digital)

Windows PC

Integration option of WELDQAS into existing network systems via network

Connection cable included as standard with WELDQAS

Figure 5-14

099-005366-EW501

43

Design and function

Interfaces

31.07.2014

CAUTION

• Use shielded control leads only.

WARNING

No function of the external interr u p t equipment (emergency stop switch)!

• Disconnect jumper 1 on PCB T320/1 (Tetrix / forceTig) or M320/1 (Phoenix / alpha Q)!

5.14.7 Automation interface

The welding power sources feature a very high safety standard.

This safety standard is also maintained when peripheral equipment is connected for mechanised welding,

if this peripheral equipment meets the same criteria, particularly with regard to isolation from the mains

supply.

This is guaranteed by the use of transformers conforming to VDE 0551.

The welding machines are equipped for mechanised operation as standard.

For the simplest possible mechanised applications, control inputs and galvanically isolated relay contacts

are available on the interface for mechanised welding.

Equipment damage due to unshielded contro l leads!

Unshielded control leads can cause damage to the power source and accessory

components.

Figure 5-15

If the emergency stop circuit has been realised using an external interrupt equipment

via the interface for automated welding, the machine must be configured for this setup.

If this is not observed, the power source will ignore the external interrupt equipment

and will not shut down!

44

099-005366-EW501

Design and function

31.07.2014

Pin

Input/output

Designation

Note

Cable screen connection

B

Output

REGaus

15 V = no welding current

E/R

Not-Aus

contact!

F

Output

0V

I>0 to the user

+U

act

J

K

Output

SYN_A1

Seam tracking synchronising signal

Start/stop

Switch to potential-free

Power supply

N

Power supply

S

Output

0V

+I

act

box, collision switch

V