TECHNICAL BULLETIN

Model EWT-3611

Non-Programmable Digital Thermostat

Installer : Save these instructions for future use!

FAILURE TO READ AND FOLLOW INSTRUCTIONS CAREFULLY BEFORE INSTALLING OR

OPERATING THIS CONTROL COULD CAUSE PERSONAL INJURY OR PROPERTY DAMAGE.

DESCRIPTION

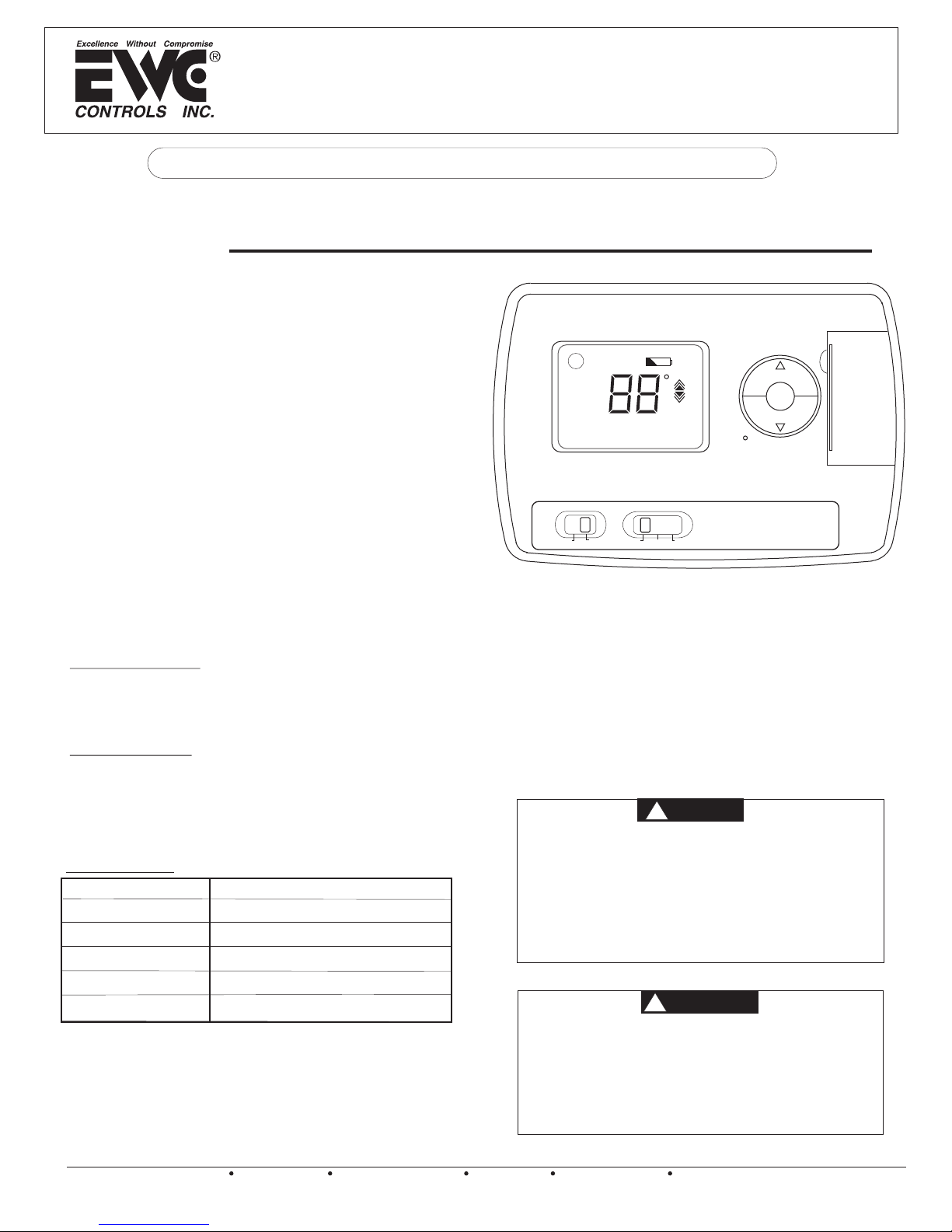

The EWT-3611 is a Non-Programmable Digital Solid State

Thermostat.

Features:

FILTER

l The Thermostat shall be powered by 24 vac and with a

AA battery as backup.

l Compatible Equipment: ULTRA-ZONE Control Panels:

F

SET

TEMP

ST-2E/3E, NCM-300, BMPlus3000 & UZC-4.

COOL

Single Stage Heating and Single Stage Cooling

HEAT

Equipment. Gas, Electric, Oil or Hydronic.

l LCD continuously displays room temperature.

Temperature set point is displayed when it is being

changed.

fan

l Temperature display can be configured in °F or °C.

l The Thermostat can be set between 45°F and 95°F.

on

auto

l Backlit display.

l The thermostat terminal block has the following

terminals: Y, R, G, W, RC/O, RH/B and C.

(Shown with Front Cover Removed)

lAir Filter Replacement Monitor.

Contents:

Electrical Ratings

19-30VAC 60 Hz

1.0 Amp (Max load per terminal)

1 EWT-3611 Thermostat

2 Plastic Wall Anchors

2 #8 x 1” Screws

1 TB-234 Technical Bulletin

Thermal Ratings

Set point Temperature Range 45°F to 95°F

Operating Ambient Temperature 30°F to 99°F

Storage Temperature Range 14°F to 140°F

Do not use circuits exceeding specified voltage. Higher

voltage will damage control and could cause shock or

Technical Data

Power

Working Environment

Range

Shell

Dimension

Connection Interface

24VAC, 50/60Hz + AA Battery

32°F~120°F

5~95%RH(non-condensing)

Fire Retardant PC ABS

3.5x5.1x1.2 in (HxWxD)

Each terminal is capable of accepting

2 x 18 AWG solid copper wires.

fire hazard.

Do not short out terminals on gas valve or primary control

to test. Shorted or incorrect wiring will damage thermostat

and could cause personal injury and/or property damage.

Thermostat installation and all components of the system

shall conform to Class 2 circuits per the NEC code.

This product does not contain mercury. However, this

product may replace a unit which contains mercury.

EWC Controls Inc. would like to advise all technicians

and consumers that all mercury thermostats should

be recycled. You can take your mercury thermostat

to your local HVAC wholesaler for recycling.

SPAN

system

cool

off

heat

WARNING

!

ATTENTION

!

Reset

Fig. 1

TB-234 090375A0234 Rev. B

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- info@ewccontrols.com

Copyright © 2009 EWC Controls All Rights Reserved

1

INSTALLATION

The installer should be an experienced and trained

HVAC contractor. Failure to read and follow

instructions carefully before installation or

operation could damage this control or cause

property damage. Test the finished installation for

proper operation.

CAUTION

!

To prevent electrical shock and/or equipment damage,

disconnect electric power to system at main fuse or

circuit breaker box until installation is complete.

Mount the EWT-3611 Thermostat about 5 feet above the

floor in an area with good air circulation at average

temperature. DO NOT install the thermostat where it can

be affected by:

drafts or dead spots behind doors and in corners

hot or cold air from ducts

radiant heat from sun or appliances

concealed pipes and chimneys

on surfaces such as an outside wall, that are a

different temperature then the room air

temperature.

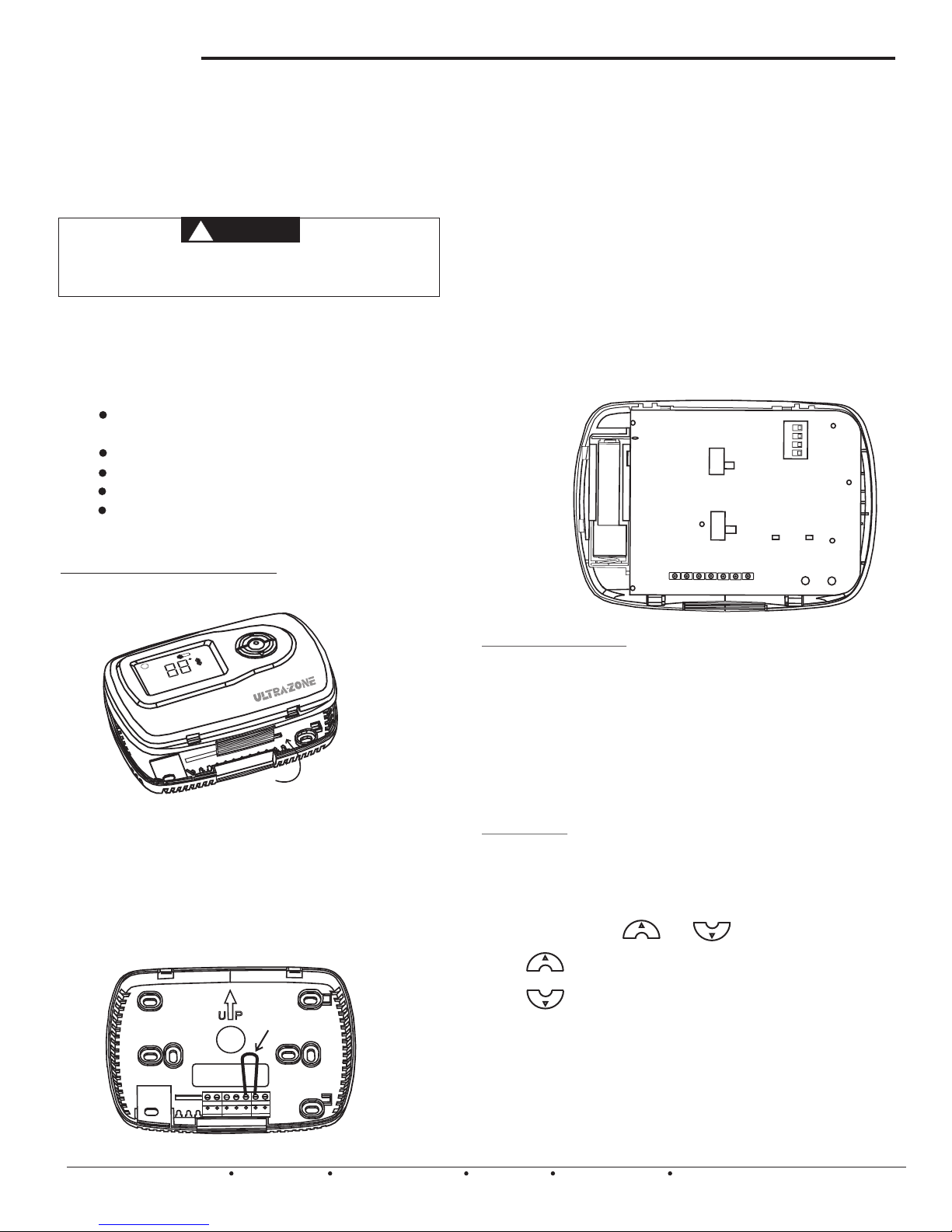

In order for this thermostat to control your system, the system type

must be specified by the selector switch on the circuit board inside

the thermostat. There is also a selector switch for your choice of

Fahrenheit or Celsius display. See figure 4.

Fan Mode Selector (HG-HE switch)

The factory position is in the “HG” position. Leave it in this position if

you have a gas furnace or an oil burner. If you have an electric

furnace or hot water coil change the position to “HE”.

System Selector (STANDARD - HEAT PUMP switch)

The factory position for this switch is in the STD position. Leave it in

this position if you have ANY system that uses gas, oil, electric or hot

water heating.

If you have a single stage Heat Pump, the thermostat can be

configured to the Heat Pump mode by moving the switch to the “HP”

position. This thermostat model does not have auxiliary or

emergency heat features, therefore it cannot be used on heat pump

systems that require these functions.

4

3

H

P

S

T

D

H

E

H

G

DP

2

ON

1

F

AHRENHEIT

C

Mount wallplate and Thermostat

Remove the wallplate from your thermostat by pressing the

release tab on the bottom of the thermostat. See Figure 2.

R

E

T

IL

F

F

T

E

S

P

M

E

T

N

A

P

S

L

O

CO

EAT

H

Figure 2

®

Position wallplate on the wall and pull the wires through the

large opening. Level the unit for appearance. Mark the

mounting holes for the provided wall anchors.

Drill holes with a 3/16” bit and gently tap anchors into holes

until flush with the wall.

Reposition wallplate to wall, pulling wires through the large

opening. Insert mounting screws provided into the wall

anchors and tighten. See figure 3.

Jumper

RH/B

RC/O

C

G

W

R

Y

Changing the battery:

Figure 4

One fresh AA alkaline battery should provide about one year of

service. However, when the battery becomes drained, the thermostat

will not function. At your earliest convenience, you need to replace

the battery with one new AA alkaline battery.

NOTE: If you remove or replace the battery, the temperature set point

and Span settings will reset back to the factory default settings.

NOTE: If you plan to be away from the premises over 30 days, we

recommend that you replace the old battery with a new alkaline

battery prior to leaving.

Span Setting

Your thermostat is set at the factory to cycle at 2°F (1°C) above and

below the set temperature. (Span = 2) This setting has been

designed to provide a comfortable room temperature under most

conditions. However, if you find your system cycling too fast or too

slow, the Span can be adjusted to modify the cycle time.

Press and hold BOTH and keys for three seconds.

SPAN will be displayed on the LCD.

Press to raise the Span to 3. This setting increases cycle

time by allowing your system to run longer cycles.

Press to lower the Span to 1. This setting decreases the

cycle time by causing your system to run shorter cycles.

The Span settings remain the same for both HEAT and COOL, and

can be changed in any System Switch position. Any loss of 24vac

and/or battery power will default the Span back to the factory default

setting of 2.

2

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- info@ewccontrols.com

Copyright © 2009 EWC Controls All Rights Reserved

Figure 3

WIRING

ST-3E

ZONE2

T’STAT

C

W

Y

R

ZONE1

T’STAT

C

W

Y

R

R1

O

B

G

C

RH/B

RC/O

W

G

R

Y

C

RH/B

Y

W

G

R

RC/O

Figure 5

1

1

36

T

EW

1

1

36

T

EW

NCM-300

Gas/Elec. 1H/1C

NON-ZONED

HYDRO OR OIL

1 HEAT/ 1 COOL

AIR HANDLER

C

W

G

R

Y

ZONE

T’STAT

C

R

W/E

Y

G

O/B

C

Jumper

RH/B

RC/O

W

G

R

Y

1

61

3

EWT-

Figure 7

ISOLATION CIRCUIT

REQUIRED

C

RH/B

RC/O

W

G

R

Y

611

WT-3

E

NON-ZONED

HEAT PUMP

1 HEAT/ 1 COOL

HEAT

PUMP

C

O

G

R

Y

C

W

G

R

Y

AIR HANDLER

This thermostat model does not have auxiliary or emergency

heat features, therefore it cannot be used on heat pump

systems that require these functions.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- info@ewccontrols.com

Copyright © 2009 EWC Controls All Rights Reserved

C

RH/B

RC/O

W

G

R

Y

611

T-3

EW

Figure 6

NON-ZONED

GAS OR OIL

1 HEAT/ 1 COOL

COMPRESSOR

C

Y

T

TO

BOILER OR

CIRCULATOR CONTROL

NO ISOLATION CIRCUIT

REQUIRED

GAS FURNACE

C

W

G

R

Y

T

Figure 8

C

RH/B

RC/O

W

G

R

Y

11

6

-3

T

W

E

Figure 9

3

OPERATION

This thermostat will operate on a full 24vac (R&C) power supply. If

desired, one battery (AA) may be used as a backup power supply

in the event of a power failure. If a full 24vac is not available, then

use one AA battery as the primary power supply.

Start-up

The LCD will show the factory default display of 70°F (21°C)

when the battery is first installed. The temperature will update

after a few seconds.

System Selector Switch

system

off

cool

heat

the thermostat. You may select COOL, OFF or HEAT. NOTE:

Anytime you install or remove the thermostat from the wallplate,

slide the System Selector to the OFF position.

Fan Switch

fan

on

auto

with normal operation of your system. In a normal gas or oil

furnace, the fan will be turned on by the furnace after its warm-up

delay. For electric heat, air conditioning, and heat pump operation,

the fan will turn on with the system. To run the fan continuously,

slide the fan switch to the ON position.

The System Selector Switch on the front of the

thermostat determines the operating mode of

The Fan Switch should normally be located in the

AUTO position. The fan will be turned on along

Filter Monitor

Your thermostat also keeps a record of the number of hours

your filter has been in use. To maximize your system

performance and energy efficiency, change or clean your filter

regularly.

When the total fan time reaches 400 hours, you need to clean or

change your system filter, “FILTER” will flash continuously until

the counter is reset to zero.

Press the center button to review filter usage. “FILTER”

displays with the total number usage in hours.

To reset the Filter Monitor counter, press and hold the

center button for 3 seconds when the filter monitor day shows.

Backlighting

Your thermostat has an electro-luminescent lamp that backlights

the display for easy viewing in the dark.

When any key is pressed, the display is illuminated.

The display will remain illuminated for 5 seconds after the last key

is pressed.

NOTE: If the thermostat is in a Low battery warning condition, the

backlight will not operate. Replace with 1 new AA alkaline battery

to restore the backlight function.

Review Current Set-Point Temperature

Press either the up or down key once to see the set-point

temperature. The factory default is 68°F (20°C) with the System

Switch in HEAT, and 78°F (26°C) with the System Switch in

COOL.

Setting New Set-Point Temperature

Press either or once and display the set-point

temperature.

Press either or again to change your desired setpoint temperature. Hold the key down for over 2 seconds to fast

advance the set-point temperature.

Auto Shut Off

Your thermostat will automatically shut off in HEAT mode if the

room temperature rises above 95°F (35°C). It will shut off in COOL

mode if the room temperature drops below 45°F (7°C).

Note that if your system has malfunctioned and no longer

responds to thermostat controls, the Auto shut off will have no

effect.

Troubleshooting

PROBLEM SOLUTION

No display Check power to thermostat

or 24vac and/or battery

Dim Display

Fan does not Check HG/HE Switch for correct position

operate properly

Heating or Wait and see if 4 min. time dalay is activated

Cooling does not Check “System Switch” for correct position

operate properly Check Wiring

Thermostat

permanently reads

HI, LO, E1 or E2.

Thermostat is faulty

Replace Thermostat

4

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- info@ewccontrols.com

Copyright © 2009 EWC Controls All Rights Reserved

Loading...

Loading...