RoHS

Compliant

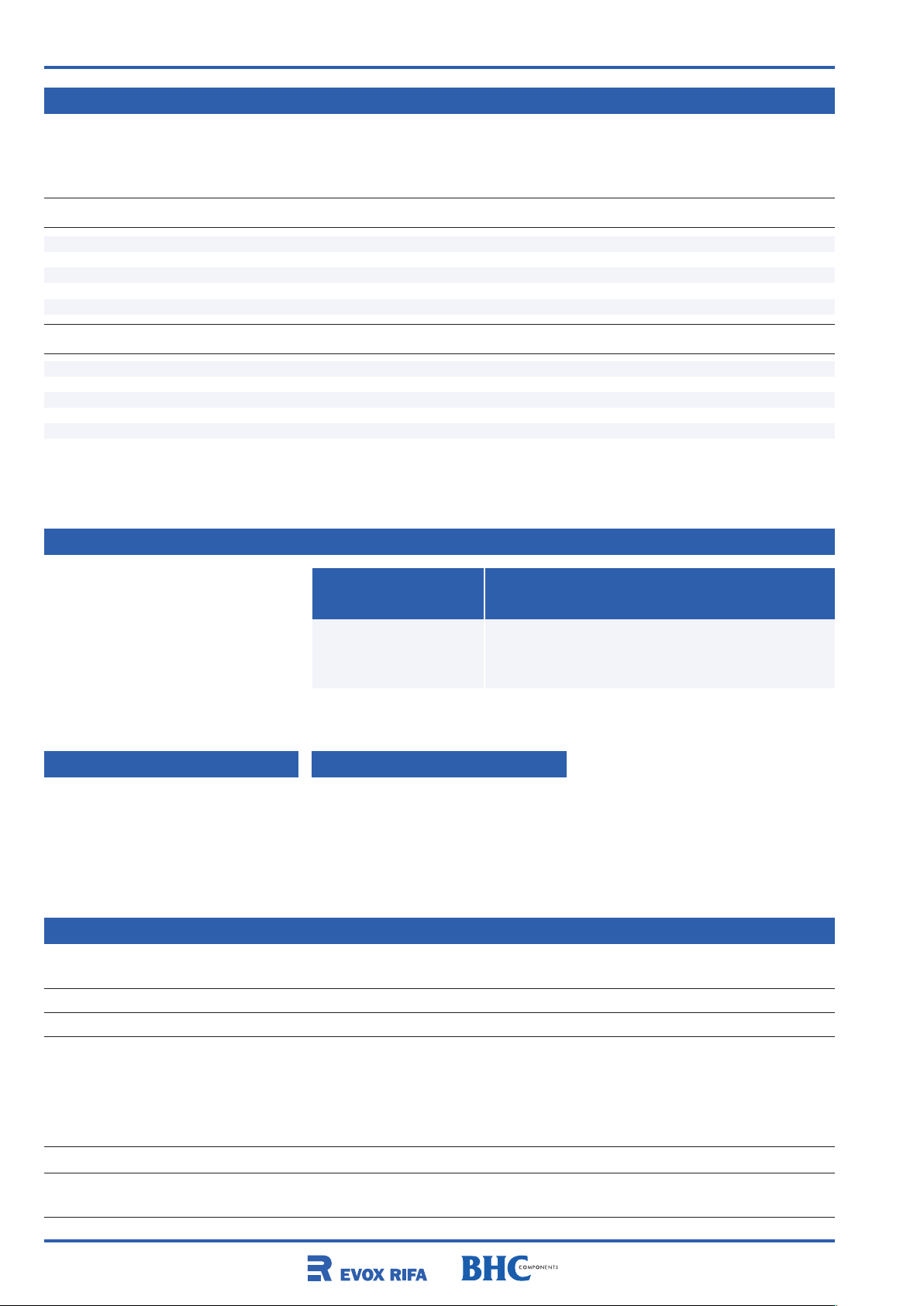

PEG 226 150°c

17.5±0.

5

Ø1±0.0

3

H

3.3±0.5

Ø16±0.5

�

0.8±0.1

15.24±0.1

• Up to 150°C

• Extremely high ripple current

Up to 28A ripple, RMS, Continuous load

• High vibration resistance

APPLICATION BASIC DESIGN

PEG 2 2 6 is a ne w generation o f high

performance axial electrolytic capacitors,

designed for automotive applications with

extremely high demands.

PEG 226 is an el e c t ro l y t ic ca p a c it o r

with outstanding electrical performance.

Polarized, all-welded design, tinned copper

wire leads, negative pole connected to the

case. The PEG 226 winding is housed in a

cylindrical aluminium can with a high purity

alum inium lid and a high quality rubber

SPECIFICATION

Standards IEC 60384-4 Long Life

Grade 40/125/56

Capacitance range 250 - 4700 µF

Capacitance tolerance –10 to +30%, -20 to +20%

Rated voltage 25 - 63 VDC

Temperature range –40 to +150°C

Shelf life at 0V +105°C 5000 h,

+40°C 10 years

Diameter range 16 - 20 mm

Resistance to vibrations 10 - 2000 Hz, 1.5 mm

displacement amplitude or

Remark:

Capacitor in standard version

is without insulation. Polyester

insulation on request

max 20 g 3x22 hours

The capacitors must be clamped by the body.

Life test 2000 h, 150°C (Ø20 case)

1500 h, 150°C (Ø16 case)

Dimensions table PEG 226 (mm)

gasket. Low ESR is a result of a low resistive

electrolyte/ paper system and an all-welded

design. Thanks to its mechanical robustness

the PEG 226 is suitable for use in mobile

and in aircraft installations, operation up to

150°C.

Radial version

See page 39

D x L Case D d L L1 b±2 Weight

code ±0.5 ± 0.03 ±1 min Box approx (g)

16 × 27 F 16 1.0 26.5 33 40 8

16 × 35 G 16 1.0 34.5 41 40 11

20 × 27 H 20 1.0 26.5 33 40 13

20 × 35 J 20 1.0 34.5 41 40 20

20 × 43 L 20 1.0 42.5 49 40 24

ARTICLE TABLE PEG 226 (150°C)

CR D × L I

Tc=125°C Tc=140°C Tc=150°C Ta=125°C Ta=125°C 20°C 20°C 125-150°C code

≥ 5 kHz ≥ 5 kHz ≥ 5 kHz ≥ 5 kHz ≥ 5 kHz 100 Hz 100 kHz 5-100 kHz

µF mm A A A A A mW mW mW

* I

RAC

* I

RAC

* I

RAC

** IAC(max)*** ESR (max) ESR (max) ESR (max) Article

RAC

25 VDC (UR )

1500 16x27 16.8 10.6 4.7 5.9 7.4 72 36 12.7 PEG226HF4150M

2200 16x35 19.2 12.1 5.4 7.2 9.1 51 26 9.7 PEG226HG4220M

2200 20x27 22.2 14.0 6.3 7.1 9.1 50 25 10.6 PEG226HH4220Q

3300 20x35 25.8 16.3 7.3 8.9 11.3 34 17 7.8 PEG226HJ4330Q

4700 20x43 28.5 18.0 8.1 10.3 13.1 25 13 6.4 PEG226HL4470Q

* Capacitor mounted with low thermal resistance path (heat-sink). Maximum ripple current continuous operation.

** Rated ripple current, continuous operation at natural convection (∅20 case 4000 h, ∅16 case 3000 h).

*** Max ripple current, at natural convection (∅20 case 2000 h, ∅16 case 1500 h)

37

PEG 226

ARTICLE TABLE PEG 226 (150°C)

CR D × L I

Tc=125°C Tc=140°C Tc=150°C Ta=125°C Ta=125°C 20°C 20°C 125-150°C code

≥ 5 kHz ≥ 5 kHz ≥ 5 kHz ≥ 5 kHz ≥ 5 kHz 100 Hz 100 kHz 5-100 kHz

µF mm A A A A A mW mW mW

* I

RAC

* I

RAC

* I

RAC

** IAC(max)*** ESR (max) ESR (max) ESR (max) Article

RAC

40 VDC (UR)

800 16x27 16.2 10.2 4.6 5.6 7.2 100 36 13.6 PEG226KF3800Q

1200 16x35 18.6 11.8 5.3 7.0 8.8 69 26 10.3 PEG226KG4120Q

1500 20x27 22.8 14.4 6.5 7.3 9.3 57 22 10.0 PEG226KH4150Q

2200 20x35 25.7 16.2 7.3 8.9 11.2 41 17 7.9 PEG226KJ4220Q

2700 20x43 27.9 17.6 7.9 10.1 12.8 32 13 6.7 PEG226KL4270Q

63 VDC (UR)

250 16x27 11.5 7.3 3.3 4.0 5.1 227 53 26.9 PEG226MF3250Q

370 16x35 13.6 8.6 3.9 5.1 6.4 155 37 19.2 PEG226MG3370Q

470 20x27 17.3 10.9 4.9 5.5 7.0 125 32 17.5 PEG226MH3470Q

680 20x35 20.0 12.7 5.7 6.9 8.7 87 23 13.0 PEG226MJ3680Q

900 20x43 22.2 14.0 6.3 8.1 10.2 67 18 10.6 PEG226ML3900Q

* Capacitor mounted with low thermal resistance path (heat-sink). Maximum ripple current continuous operation (see below).

** Rated ripple current, continuous operation at natural convection (∅20 case 4000 h, ∅16 case 3000 h).

*** Max ripple current, at natural convection (∅20 case 2000 h, ∅16 case 1500 h)

RIPPLE CURRENT SPECIFICATION AND OPERATIONAL LIFE

The ripple current specification (see table

above) is given at case temperature (Tc)

and at ambient temperature (Ta). To be able

FREQUENCY

100 Hz 300 Hz 1 kHz 5 kHz 100 kHz

to operate at specified ripple current at

temperature Tc, the capacitor needs to be

mounted with low thermal resistance path

to application chassis.

Correction factor (Corr) 0.35 0.57 0.80 1.00 1.04

(Typical value)

Frequency correction factor, for ripple

current (Corr), see table to the right:

For operational life time calculation, please

see pages 148 to 149.

RELIABILITY

Estimated field failure rate: < 2 ppm/year.

The expected failure rate, for this capacitor

range, is based on field experience for capacitors with structural similarity. This failure

rate is valued during first year of operation.

Rated leakage current, IRL (µA)

Rated voltage, UR (V)

Rated capacitance, CR (µF)

I

RL

LEAKAGE CURRENT

= 0.003 x CR x UR + 4

Expected failure rate thereafter: < 1 ppm/y.

(Until end of specified operational life)

ORDERING INFORMATION

For further ordering information please see page 8.

P E G 2 2 6 K F 3 8 0 0 Q E 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Capacitance tolerances: E1: Packed in boxes

Pos. 13: Q: –10 to +30%

M: -20 to +20%

Quantities and weights

CASE CODE F G H J L

Weight approx (g) 8 11 13 20 24

Standard box quantity 125 100 150 125 100

38

Loading...

Loading...