Page 1

200 / 300

Installation and Instruction Manual

Evolution House

4-6 Kellet Close

Wigan, WN5 0LP

United Kingdom

Ph: +44 (0) 1942 216 554

Fax: +44 (0) 1942 216 562

Web: www.evolutionaqua.com

Email: info@evolutionaqua.com

Page 2

TABLE OF CONTENTS

Page

Introduction 1

Explanation 2

Installation 3

Gravity Fed Installation 4

Pump Fed Installation 6

Waste Pipe Installation 7

Getting Started 8

Cleaning 9

Kaldnes Biomedia 11

Appendix A 12

Dimensions 13

Page 3

INTRODUCTION

-1-

Thank you for purchasing your Nexus Eazy™ lter. We are sure you will be

delighted with its performance. The Nexus System is supplied gravity fed, though

is easily adapted to become a pump fed unit. For pump fed installations refer to

the relevant pages of this brochure and read thoroughly before installation.

The Nexus Eazy ltration unit has been designed on the principles of minimum

maintenance, high performance and a compact foot print. This design delivers

optimum water quality by using the Kaldnes Moving Bed™ process.

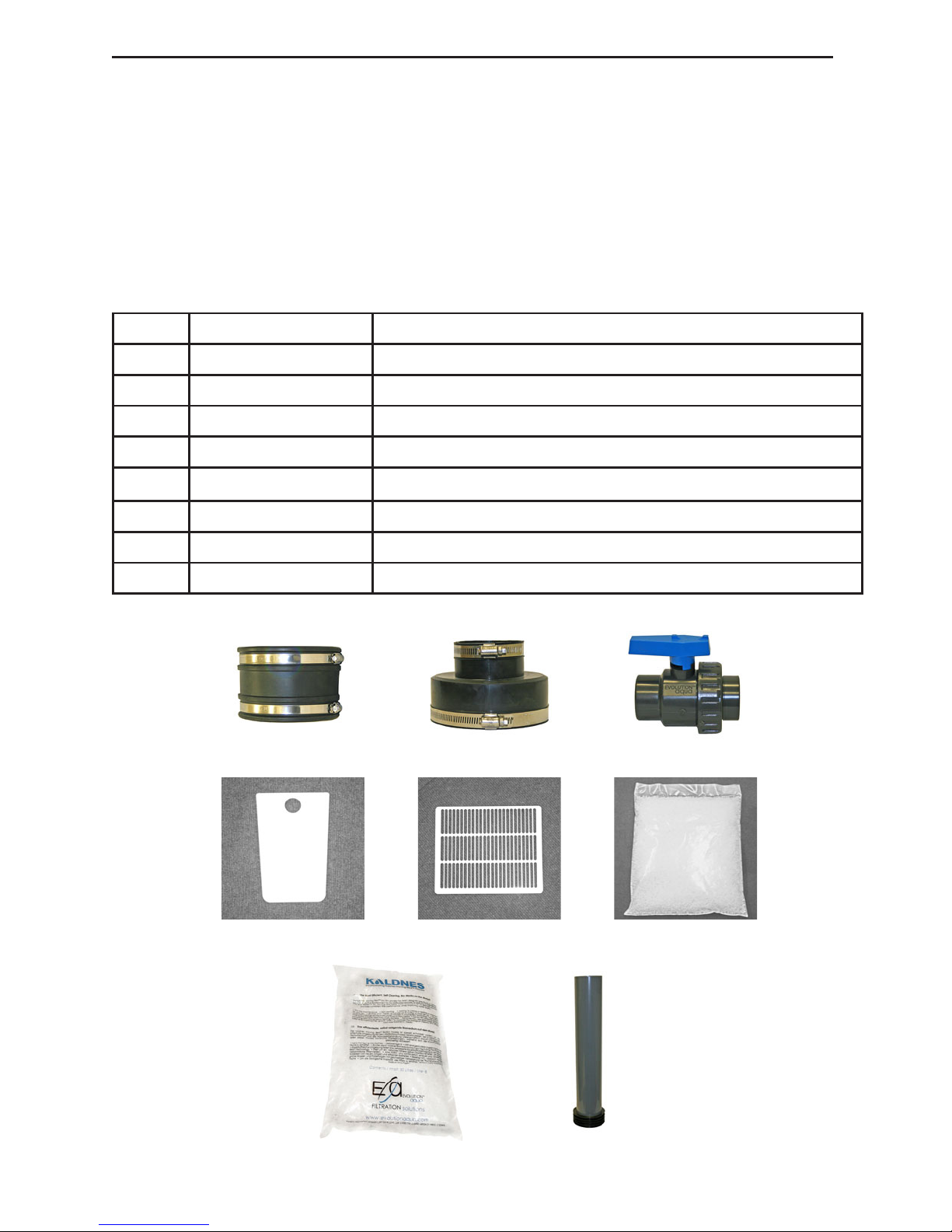

Your Nexus Pack should contain:

Figure Part No Description

1.1 NPC.125 4”-4” (110-125mm) rubber boot

1.2 NAC.1004 4”-2” (122-68mm) rubber boot

1.3 825-50-50 1.5”(50mm) single union ball valve

1.4 1200-400/100-400 inlet slide plate (200/300)

1.5 5000-707 safety outlet grill

1.6 MEDIA30L / 45L bag Kaldnes K1 for Eazy (30L - 200/ 45L - 300)

1.7 MEDIA50L 50L bag Kaldnes K1 (1x Nexus 200, 2x for Nexus 300)

1.8 5000-329 Eazy isolation pipe

Fig 1.4

Fig 1.3Fig 1.2.Fig 1.1

Fig 1.6

Fig 1.8

Fig 1.5

Fig 1.7

Page 4

EXPLANATION

-2-

Basic Operation Nexus:

The Nexus lter is simple yet innovative. Water enters the Nexus via inlet (A) Fig 2

into the inner chamber (B) which works as a basic vortex allowing larger solids to

settle out. The water then passes through the Eazy (C) where the ner particles

are removed and the rst step

in biological treatment takes

place. From the Eazy the water

passes into the outer chamber

(D) where the remainder

of the biological treatment

takes place using the Kaldnes

Moving Bed Process.

The water then passes

through the grill into the

Outlet Chamber (E), where

it is returned to the pond

through the outlet (F). All

waste is discharged through

the waste valves (G). The Eazy

is cleaned by diverting the air

from the Outside chamber to

the Eazy using the valve (H).

Basic Operation Eazy :

The Eazy™ is a stainless steel vessel containing a set volume of static K1 media

(30L for Nexus 200, 45L for Nexus 300) which is located within the centre chamber

of the Nexus. After water enters the Nexus it rotates around the Eazy in the

centre chamber with a downward motion allowing the larger solids to settle

to the bottom of the chamber before passing through the slots of the Eazy into

the static K1 media. After passing through these slots the water ows upwards

through the K1 media where mechanical ltration takes place as small particles

are caught within the K1 media. The water then ows over the slots in the centre

column and into the outer chamber.

Basic Operation Outer Chamber:

The outer chamber of the Nexus contains the Kaldnes Moving Bed Process this

is where the nal stage of biological treatment occurs. Biological breakdown

occurs through different strains of bacteria living on the K1 media. These bacteria

consume Ammonia and Nitrite transforming them into harmless Nitrate. The

amount of Ammonia and Nitrite produced in the pond is dependant on feed

rates and the type of food. For higher feed rates additional K1 media should be

added into the outer chamber (250g/day of average protein content food will

be broken down by 50L of K1).

Fig 2

Page 5

INSTALLATION

-3-

Nexus Setup

This section should be thoroughly read before proceeding with any installation.

Checks to do BEFORE Installation

Check the jubilee clips on the rubber boots are tightened to prevent leaks

Check that the collars on the waste valves are tight

(This is required as some loosening may have occured in transit)

Preparation

Important:

A solid and level base/ground is required. It should be a minimum of 1.2m x

1.0m, to allow easy access to valves and for maintenance purposes. The Nexus

lter needs to be equally supported, this is to prevent possible distortion when it

is full of water. The best option for this would be a level 100 mm thick concrete

plinth. Although decking, paving slabs or well packed gravel would be sufcient

as long as the Nexus sits level and is not allowed to deect under the weight of

the water.

The Airpump should always be situated well above water level to prevent water

siphoning back into the pump should a power failure occur.

Installation Equipment required

Pond Pump, with a maximum actual (taking into account the head loss) 1.

owrate no more than your Nexus model allows see Appendix A on page

12 for specs.

Air Pump to power the Kaldnes K1 Moving Bed, see Appendix A on page 12 2.

for specication of pump size.

Length of hose or braided pipe (10 mm inner diameter) to connect the air 3.

pump to the Nexus

A valve should be tted before and after the Nexus so that the Nexus can be 4.

isolated if required. On Gravity Fed systems this should be a 4 inch (110mm)

ball valve located on the inlet side of the Nexus close to your lter house

wall.

A reducer to connect the 2 inch Nexus rubber boot to your pump.5.

It is highly recommended that a suitably sized UV unit is installed with the 6.

Nexus for removal of single celled algae. UV systems are always installed

after the pump, so on Gravity fed Nexus the UV is after the Nexus and prior

to the Nexus on Pump fed installations.

It is also highly recommended that you t an overow pipe/drain to your 7.

pond.

The Nexus can be installed in either of two ways Gravity Fed or Pump Fed, the

Nexus is shipped complete to be set up in either format with all the necessary

components. The following sections explain how this is done.

Page 6

GRAVITY FED INSTALLATION

-4-

A gravity fed system is where the water level in the Nexus is at the same height as

the water level in the pond, therefore the top of the Nexus should approximately

be at the same height as the top of the pond as shown in Figure 3.

The water on a Gravity fed systems should be fed from a appropriately placed

bottom drain through at least a 4 inch (110mm) pipe with as short a length and

fewer bends as possible (For optimum ow swept bends should be used). At the

end of the bottom drain line before entering the Nexus a valve is required so

that the line can be shut and the Nexus isolated.

For long bottom drains it is recommended that a purge valve line is installed to

remove solids that may settle in your bottom drain line. This should discharge

straight to waste (if possible) or into a suitably sized sump.

It is very important that when laying the bottom drain line that there is no section

where the pipework rises then falls as airlocks can form in this area which will

block ow. Figure 4 below describes what should and shouldn’t be done.

Pipework should be level until reaching the lterhouse where it should ideally go

through a swept bend 90 into the Nexus inlet.

Fig 3

From Pond

To Nexus

From Pond

To Nexus

Fig 4

Page 7

GRAVITY FED INSTALLATION

-5-

* Useful Tip on Getting your water Level right

Getting the water level right in your Nexus is important as if this level is too low

it will affect the ow rate from

your bottom drain as well as the

efciency of your Eazy both in

cleaning and blocking rate. If

the level is too high, you may get

Kaldnes overowing between

chambers. The ideal level is located

just under the top lip of the Nexus

as shown in Figure 5.

The way to measure how high your

Nexus base should be is to measure

the height between your pond

water level and lter bay using a

spirit level or a laser level. And with

a tape measure calculate the appropriate base level.

Gravity Fed Installation Steps

Attach the 4”-4” Boot (Fig 1.1) to the Nexus Inlet (A) then to the 4” bottom 1.

drain pipe by tightening both jubilee clips

Attach the 4”-2” Rubber Boot (Fig 1.2) to the Nexus Outlet (F)2.

Connect the 1.5” Single Union Ball Valve (Fig 1.3) to the 4”-2” Rubber Boot 3.

(Fig 1.2) with the union side facing down towards the pump (depending

on your arrangement you may require an elbow between the boot and

valve)

Connect your water pump to the Single Union Ball Valve (Fig 1.3) on the 4.

union side

Place the 50L K1 media bag into the outside chamber (D) of the Nexus (300 5.

x 2)

Place the K1 bag marked either 30 or 45 into the Eazy basket (C)6.

Connect your air pump to the Nexus air inlet (H) located next to the water 7.

inlet using suitable hosing such as standard 12mm diameter garden hose

Connect your pump outlet to the remainder of your pipework including a 8.

UV steriliser.

Insert the safety exit gill (Fig 1.5) into the exit chamber (E)9.

Connect the waste valves (G) to your waste outlet (Described on Page7)10.

YOUR NEXUS IS NOW READY FOR USE

Pump fed installation is where the pump supplies water to the Nexus and water

returns by gravity through a 4” (110mm) pipe. Figure 6 shows an example of a

pump fed system.

Wa ter

Level

Page 8

PUMP FED INSTALLATION

-6-

It important that on the return line back to the pond there is no section of pipe

where the pipe rises then falls as airlocks will form in this section stopping ow an

example of this is shown in Figure 4.

When installing a pump fed Nexus

there is a maximum height difference

that the Nexus base can be below

the pond water level also shown in

the Fig 6. This height is dependant

on the distance between the Nexus

and the return point to the pond,

the table below shows the maximum

heights and distances when using 4” (110mm) pipe.

Important: Essential Action

For Pump fed units it is important that you get the height of the outlet standpipe

correct. The height of this standpipe is very important as it controls the height that

the outer biological chamber of

the Nexus runs at. For a standard

Nexus installation you need to

cut a length of your 4” (110mm)

return pipe: 21” (535mm) for a 200

and 23.2” (590mm) for a 300. This

needs to be inserted into the exit

chamber (E) through the outlet

(F) and then secured using the

4”-4” (110mm) (Fig 1.1) rubber

boot leaving 2” (50mm) below as

shown in Fig 7. 2” (50mm) of pipe

below the boot will allow you to

connect any tting onto your

Nexus such as a valve, elbow or

straight connector. To check that

you have the height of the outlet

pipe correct you can measure

from the top of the standpipe to

Fig 6

Max distance (H) below water

level of Nexus base

Nexus 200 Nexus 300

Next to Pond 350mm 14” 500mm 20”

Within 5m 100mm 4” 250mm 10”

Over 5m At or above water level

Fig 7

Fig 8

Page 9

PUMP FED INSTALLATION

-7-

the top of the Nexus plastic lip as shown in Fig 8. For the 200 the distance needs

to be 110mm and 120mm for the 300.

Pump Fed Installation Steps:

Insert the Exit pipe into the Nexus Outlet (F) and secure using the 4”-4” Boot 1.

(Fig 1.1) as described in previous section page 6.

Connect the 4”- 2” Boot (Fig 1.2) to the Nexus Inlet (A).2.

Connect the Single Union Ball (Fig. 1.3) to the 4”-2” Boot (Fig 1.2) with the 3.

union side towards the pump.

Connect the hose/pipework from your pump to the Single union ball valve 4.

(Fig 1.3) ( If using exi-hose you will require a hose tail).

Connect your 4” pipework from the Exit pipe back to the Pond.5.

Place the 50L K1 media bag into the outside chamber of the Nexus (x2 for 6.

300).

Place the K1 bag marked either 30 or 45 into the Eazy basket (C).7.

Connect your air pump to the Nexus air inlet (H) located next to the water 8.

inlet using suitable hosing such as standard 12 mm diameter garden hose.

Connect the waste valves (G) to your waste outlet (Described Below).9.

Waste Pipe Connection

The waste valves are where the waste from your Nexus is discharged when

cleaning and prior to draining. The 1.5” (50 mm) valve is for the Inner Chamber

(B) and is used for when cleaning the Eazy, while the ¾” (20 mm) valve is for

draining the outer chamber (D)(only when and if required).

Both of these valves can be connected using a waste pipe kit (optional extra) as

shown in Figs 9.1-3 or can just be discharged individually. If the Nexus is located

below your drain height the waste can be either discharged into a sump where

a submersible pump can be used to pump the waste away or an inline pump

can be connected to the wasteline where it can pump directly to waste.

Fig 9.1

As Installed

Fig 9.2

Exit to Left

Fig 9.3

Exit to Right

Page 10

Once your Nexus is installed and plumbed in as described above, you are ready

to ll the Nexus and begin treating your pond water.

To ll your Nexus rst you need to open all your valves before and after the

Nexus. With a pump fed unit you then need to switch on your pump making sure

that the owrate is not too fast (refer to the section below). A gravity fed system

will just ll until it reaches water level.

Once the Nexus is full, you will notice that

the Kaldnes K1 media is positively buoyant

and oating on the water surface. In a

pond containing sh the media can attain

neutral buoyancy in 2-3 hours while in a

newly lled and stocked pond it can take

up to a week for this to occur. For people

installing a Nexus on an existing pond, the

Kaldnes K1 media can be primed before

use, by soaking it in pond water prior to

installation.

When your Nexus is full it is time to turn on your airpump to circulate the media

making sure the valve to the outer chamber (bottom valve) is open and the

valve to the Eazy (top valve) is closed, as per gure 10. Once your media

has achieved neutral buoyancy it will move and circulate around the outer

chamber as shown in Fig 11.

Importance of Flowrate

The owrate through your Nexus affects

how your Nexus runs in two different

ways. You will visually notice straight

away that the levels in both the inner

and outer chamber will run at different

heights depending on the owrate.

Because of this the owrate also helps

determine the interval between when

the Eazy needs to be cleaned though

this is mainly dependant on the type of

food you are feeding and the amount

of algae in your pond.

The owrate of your pump can be adjusted by slightly opening or closing the

valve after your pump. For Gravity Fed systems if the level in the outside chamber

is dropping (when your eazy is clean) your owrate is too fast and needs to

be slowed down. While with Pump fed systems, if your inner chamber level is

rising quickly (when easy is clean) and overowing into the outer chamber your

owrate is too fast.

GETTING STARTED

-8-

Fig 10

Fig 11

Page 11

CLEANING

-9-

Gravity Fed

With a gravity setup, the level in the outer chamber (D) will lower as the Eazy

becomes dirty and the K1 in the Eazy will rise. By looking into the inner stainless

steel column on the Eazy you can see what height the water is passing through

the Eazy into the outer chamber. When the water level becomes low on the

steel slots and high turbulence is seen the Eazy should be cleaned.

Stop the circulation pump.1.

Wait a short period of time to allow the water levels within the Nexus to 2.

stabilise.

Close off the feed to the biological chamber by inserting the isolation pipe 3.

into the centre of the “Eazy”, ensuring that the rubber ange engages within

the Nexus centre spigot Fig 12.

Close the inlet to the Nexus by inserting inlet slide-plate (Fig1.4) supplied with 4.

your Nexus. Your Eazy is now isolated from the rest of the system.

Now clean the Eazy as in described in “Cleaning the Eazy” on page 10.5.

Remove the Nexus inlet slide-plate allowing the nexus to rell.6.

Remove the Isolation pipe.7.

Restart your pump.8.

Pump Fed

With a pump fed setup the level in the inner chamber (B) rises when the Eazy

becomes more blocked, the Eazy has to be cleaned before this level gets too

high and overows into the outer chamber (D).

Reduce ow to Nexus by closing single union ball valve most of the way, 1.

leaving valve partially open.

Close off the feed to the biological chamber by inserting the Isolation pipe 2.

into the centre of the “Eazy”, ensuring that the rubber ange engages within

the Nexus centre column Fig 12.

Watch the level in the inner chamber rise until the water level reaches the 3.

1” (25mm) below the top of the Eazy outer drum, then close the single union

ball valve. It is essential that this water level is maintained to allow efcient

cleaning.

Switch off the pond pump.4.

Now clean the Eazy as in described in “Cleaning the Eazy”5.

Open the single union ball valve and start pump.6.

Once the water level in inner chamber (B) reaches the level in the outer 7.

chamber (D) remove the isolation pipe.

Page 12

Once you have your Eazy ready to be cleaned as described in the previous

section you are ready to clean your Eazy as explained below.

Open the top air valve to the Eazy then close the bottom valve to the outer 1.

chamber as shown in Fig 13. The Kaldnes in the “Eazy” shall start to aerate

within a few minutes as shown in Fig 14.

After the “Eazy” has been aerating for a minimum of three minutes, open the 2.

1.5” (50mm) waste valve (G) to drain waste from the inner Nexus chamber.

Once the central chamber has drained it is recommended you give a quick 3.

clean to the inner chamber and outer stainless steel of the Eazy with a hose

then close the 1.5” waste valve.

Gravity Fed - Remove inlet slide-plate (Gravity Fed) until level stabilises then 4.

replace slide plate.

Pump Fed - Open single union ball valve and start pump allowing inner 5.

chamber to rell until the water cleaning level is reached as in Fig 14. Then

close valve and switch of pump.

The Eazy should now be aerating again. After the Eazy has boiled for another 6.

few minutes open the waste valve again.

Repeat steps 1-6 until the water after aerating is fairly clean7.

Close the airvalve to the Eazy and re-open the valve to the outer chamber8.

Go back to previous instruction for pump or gravity fed.9.

CLEANING THE EAZY

-10-

Figures 12-14

Starting Clockwise

from Above

Page 13

The Kaldnes Moving Bed™ process, has

been scientically tried and tested in sh

farming and waste treatment for over 10

years. Developed by Professor Halvard

Ødergard at Trondheim University of Science

and Technology the Kaldnes Moving Bed™ bio lm process has been designed

specically to create the most effective environment for the nitrication process

to take place. The media is engineered in a wheel shape and is slightly positively

buoyant, allowing a small amount of water ow created by adding air to the

process) to circulate the media throughout the vessel.

Oxygen and food (ammonia and nitrite) gives the bacteria the means to grow,

whilst the Kaldnes media provides maximum surface area for the bacteria to

colonise and produce bio lm. It is this process, which removes harmful ammonia

and nitrite from the water. As the Kaldnes media chaotically circulates within

the bio tank, it causes old dead bacteria/bio lm on the outside, to be removed

making space for new younger heavier feeding bacteria/bio lm to colonise.

Within the wheel, is a protected surface, which enables colonies of bacteria

to naturally follow their life cycle, maturing and dying, in turn fuelling the latter

stages of nitrication conversion process. It also assists in the breakdown of

any small particles passing through from the mechanical stage. Therefore, the

Kaldnes media maintains both a young biolm & a maturing bio lm providing a

more consistent lter performance, whilst improving water quality, encouraging

healthier Koi and aiding in reducing green water and blanket weed. Due

to chaotic movement of Kaldnes K1 media, the process is self-cleaning and

requires no maintenance. This allows the lter to reach optimum effectiveness

without the disturbance of periodic maintenance, avoiding unnecessary loss

of bacteria within the lter preventing high levels of ammonia and nitrite within

the water. The other major benet of Kaldnes K1 media is the huge ‘active’

surface area available for the bacteria to grow on compared to other types of

media. This feature allows for smaller lter design, e.g. the Nexus, whilst providing

increased biological efciency.

KALDNES K1 MEDIA

-11-

Mature media

at high feeding loads

Mature media

at low feeding loads

Virgin media

Page 14

Appendix A

-12-

Specication Nexus Eazy 200 Nexus Eazy 300

10,000 Litres/hr 13,000 Litres/hr

Max Flow Rate 2,200 UK Gallons/hr 2,859 UK Gallons/hr

2,640 US Gallons/hr 3.431 US Gallons/hr

Kaldnes Media 50 ltrs bio/ 30 ltrs Eazy 100 ltrs bio/ 45 ltrs Eazy

Max Capacity 150 ltrs bio / 30 ltrs Eazy 300 ltrs bio / 45 ltrs Eazy

18,000 Litres 34,000 Litres

Max Pondsize 4,000 UK Gallons 7,500 UK Gallons

4,800 US Gallons 9,000 US Gallons

Rec. Airpump Airpump 70 -75 Airpump 95+

Volume lter Nexus Eazy 200 Nexus Eazy 300

105 Litres 205 Litres

Chamber B 23 UK Gallons 45 UK Gallons

28 US Gallons 54 US Gallons

405 Litres 635 Litres

Chamber D 89 UK gallons 139 UK Gallons

107 US Gallons 168 US Gallons

510 Litres 840 Litres

Total volume 112 UK Gallons 185 UK Gallons

135 US Gallons 222 US Gallons

Total K1 Media in Chamber D Recommended Airpump

50 - 75 Litres Airpump 70 - 75

75 - 100 Litres Airpump 95

100 - 150 Litres Airpump 130

150 + Litres Airpump 150

Page 15

Appendix B

-13-

225

315

850

270

W a ter

Level

1025

480

380

425

480

950

1010

785

735

1110

D 960

W a ter

Level

370

1260

315

1320

D 1110

370

1430

320

Page 16

Page 17

Page 18

Page 19

Page 20

Loading...

Loading...