EN

USER MANUAL

Models: D43 / T43 / T63

SAFETY

To make the work environment as safe as possible, follow the instructions, possible laws and regulations

and respect the protection, signs and decals that are mounted on or near the machine. Use and service the

system with care.

Each user or operator is responsible to ensure that the safety instruction is followed when using the system.

CAREFULLY READ THE FOLLOWING SAFETY INSTRUCTION

• Each operator shall read and understand this manual before using the system.

• Keep this manual near the system.

• Only use the system when correctly mounted and secured.

• Leave all service work not described in this User Manual to trained personnel.

• Do not remove any covers and do not open any other parts of the system.

• Do not place ngers, hands or other body parts within the working area of the system

and keep away from all moving parts during operation.

• The print head can become very hot, do not touch it until it has cooled off.

• Do not spray water on the system.

• Use protective gloves and safety goggles when using cleaning solvent

• Disconnect the power from the system and call in qualied staff under the following

conditions:

1. The main power cable or plug is damaged or worn.

2. Water or other liquid has been spilled on the system.

3. The system has been dropped or any parts of it has been damaged.

WARNING SIGNS

Depending on type of applicator and conguration, the system can be equipped with warning and instruction

signs. Follow the prompts on these signs and encourage other people around the system to do so as well.

Example: Crush Hazard

RISKS

The recommended solvent to use for cleaning the print head and print roller is isopropyl alcohol, also known

as isopropanol. It is hazardous in case of eye contact, of ingestion, of inhalation and slightly hazardous in case

of skin contact. Isopropyl alcohol is also ammable.

Read, understand and follow the instructions in the Material Safety Data Sheet (MSDS) of the cleaning solvent

prior to use.

OVERVIEW

D43

3

2

T43/ T63

9

4

5

6

7

8

1

10

1 - Print head handle

2 - Print head

3 - Inner paper guide

4 - Status beacon

5 - Outer paper guide

6 - Rewinder paper

pinch

7 - Rewinder pinch

release

8 - Rewind unit

9 - Ribbon rewind

shaft

10 - Ribbon unwind

shaft

D43/ T43/ T63

11 - Power switch

11

OVERVIEW

TOUCH PANEL

3

4

5

5

1 - Start / Stop button

2 - Active message

button

3 - Menu bar

4 - Layout preview

5 - Test print button

2

1

6 - Active messages

popup window

6

CONTROL PANEL

7 - Reset button

7

5

1 - Test print button

2 - Reset button

3 - Stop button

4 - Start button

5 - Status LEDs

4

23

1

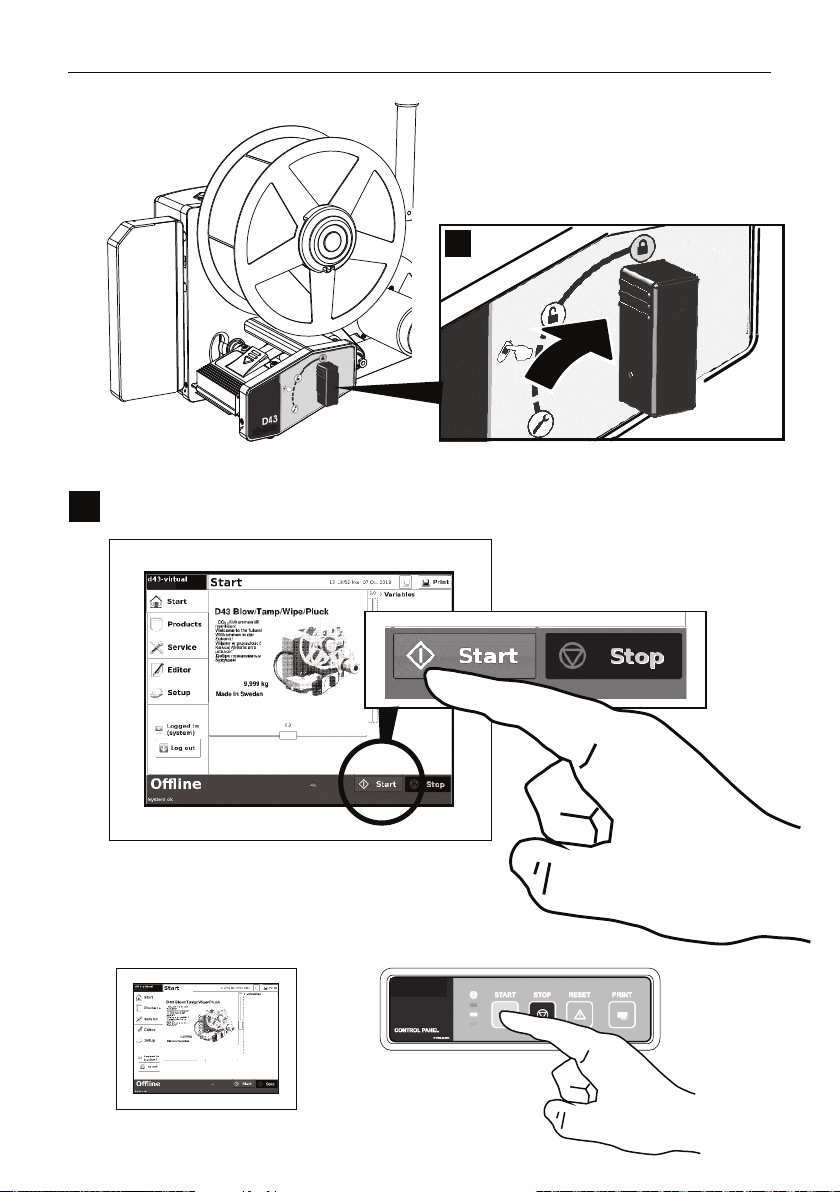

OPERATION

CHANGING LABELS

1

2

3

4

OPERATION

5 6

7 8

CHANGING LABELS

9

10

11

40cm

OPERATION

12

13 14

15

CHANGING LABELS

17

16

OR

OPERATION

CHANGING RIBBON (T43/T63)

1

CHANGING LABELS Step 1-5

2

3

5 6

4

CHANGING RIBBON

7

8

9

10

11

OPERATION

CHANGING RIBBON

12

Always use a bobbin between the ribbon

and the ribbon rewind shaft

13

3x

14

LABEL WIDTH SETTING

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

CHANGING LABELS Step 6-17

1

1 2 3 4 5 6 7 8 9 10 1 2 3

LABEL WIDTH SETTING

2

11cm+0mm=110mm

3

OPERATION

4

RIBBON WIDTH SETTING (T43 / T63)

1

LABEL LENGTH SETTING (BLOW APPLICATOR)

1

blow

1 2 3 4 5 6 7 8 9 10

60mm

label lenght (mm)

100 90 80 70 60 50 40

11cm+0mm=110mm

CLEANING

CLEANING PRINT HEAD AND PRINT ROLLER

1

2

Isopropanol

Isopropyl alcohol

Paper tissue or cloth

(clean and soft)

3

Isopropanol

Isopropyl alcohol

Paper tissue or cloth

(clean and soft)

*

*

* PLEASE READ THE SAFETY INSTRUCTIONS BEFORE USE!

BASIC TROUBLESHOOTING

TEXT ON LABEL BAD QUALITY / STRIPES

1 2 3 4 5 6

TEXT WRONG POSITIONED ON LABEL (WIDTH)

1 2 3 4 5 6

TEXT WRONG POSITIONED ON LABEL (LENGTH)

1 2 3 4 5 6

- Verify that correct label quality and correct ribbon quality

is used.

- Clean the print head (see CLEANING)

If not OK, contact your service engineer to replace the print

head

- Check that correct label size is used for the print job

selected

- Verify the paper position (see LABEL WIDTH SETTING)

If not OK, contact your service engineer to correct the

layout

- Check that correct label size is used for the print job

selected

- Clean the print roll, print head and print head profile

(see CLEANING)

If not OK, contact your service engineer to replace the

print roll

LABEL NOT APPLIED OR MISPOSITIONED ON PRODUCT/BOX

- Clean the print roll, print head and print head profile (see

CLEANING)

?

- If using round or non rectangular labels, verify the paper

guide position (see LABEL WIDTH SETTING)

If not OK, contact your service engineer

PAPER OUT ALARM AFTER PAPER CHANGE

- Clean print roll, print head and print

head profile (see CLEANING)

If not OK, contact your service

engineer to replace the print roll

IN CASE OF OTHER FAULTS

1. Do not turn off the machine

2. Note the time and symptom

3. Contact your service engineer

Artikel Nr. P101174-000

Loading...

Loading...