Page 1

AIR SOURCE WATER HEAT PUMP

HIGH TEMPERATURE UNITS

Installation & Instruction Manual

Polaris MT 70 Manual

Page 2

1 Preface

2 Safety Precaution

2.1

2.2

2.3 Warning

2.4 Caution

3 Specification

3.1

3.2

4

5 Installation

5.1

5.2

5.3

5.4

5.6

5.7

5.8

6.Usage

6.1 Function of wire controller

6.2 Usage of wire controller

7.1 Malfunction table

8.Appendix

8.1 Connection of PCB illustration

8.3 Appendix

Marking Description

Icon Description

Performance Parameter List

Outline Dimensional Drawing

Unit Function Description

Installation Space

Installation Schematic Diagram

Model Selection

Selection of the Installation Position

5.5 Installation Mode

Water Pipe Connection

Electrical Wiring

Moving

5.9Trial Operation

7.Maintenance and inspection

8.2 Caution & Warning

CONTENT

1

2

2

2

3

4

5

5

6

7

8

8

8

9

9

10

11

11

13

13

15

15

16

15

27

28

28

30

31

1.Preface

Page 3

1

This manual includes all the necessary information about installation, debugging,

discharging and maintenance. Please read this manual carefully before you open or

maintain the unit.

Read these operating and installation instructions carefully and keep them safe. Should

the equipment change hands, pass these instructions to the subsequent owner. Pass them

to the trained contractors for servicing purposes. Positioning, installation and

commissioning must be carried out by trained personnel working in accordance with these

operating and installation instructions.

When the product is delivered to the users, please check whether there is any damage on

the unit during transportation; If any please talk with the forwarder or the contractor.

If the heat pump unit can just be installed a while latter, please keep it free from damage,

rust or abrasion by following methods.

1. all the access like the water connections must be sealed correctly;

2. the unit must be free from sunshine, and placed under 45℃;

3. the unit must be free from heavy dust to avoid dirty on the evaporator;

4. the unit must be placed free from chaos to avoid accident;

The pictures and drawings in this manual are for your information only. The manufacturer

has the right to chance or improve the product when it is needed, without prior notification

to the users of this device.

1.Preface

It is vital that the below instructions are adhered to at all times to keep the warranty.

—The unit can only be opened or repaired by qualified installer or an authorised dealer.

—Maintenance and operation must be carried out according to the recommended time and

frequency, as stated in this manual.

Page 4

2

2.Safety Precaution

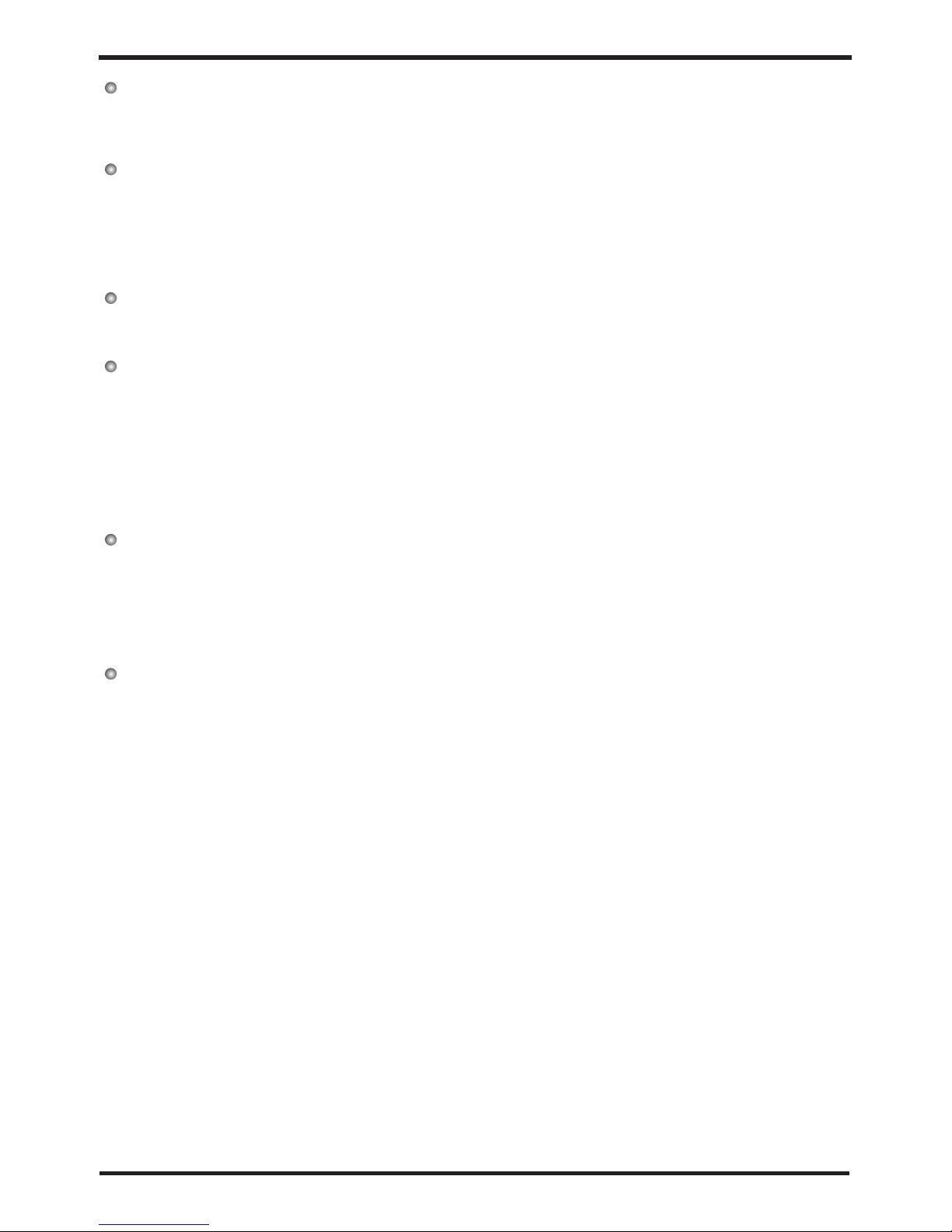

2.1 Marking Description

Marking

Description

Mis-operation (misuse) may cause death or serious injury.

Mis-operation (misuse) may cause personal harm or

material damage.

Warning

Caution

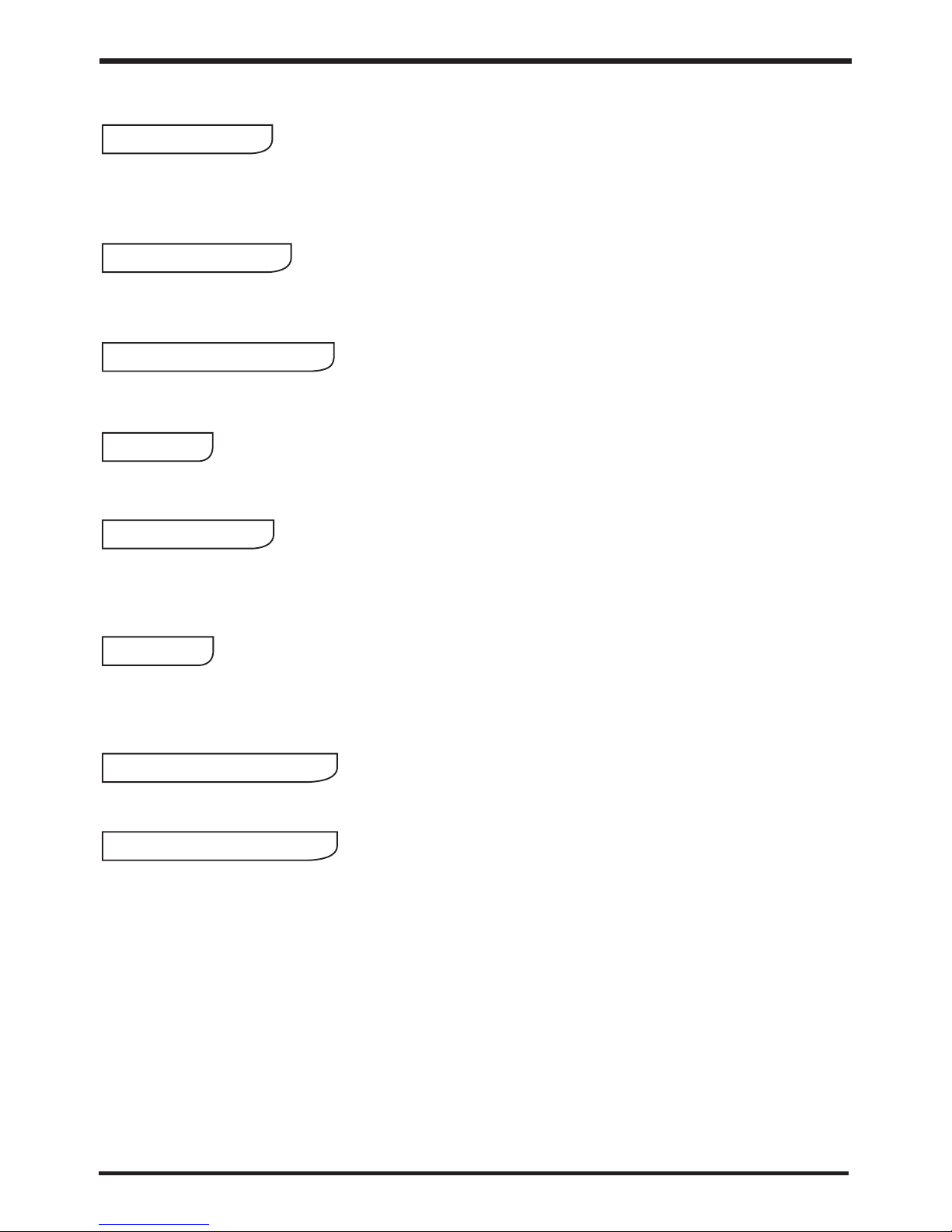

2.2 Icon Description

It indicates prohibition. Detailed prohibitions are represented

by graphics or words in or near the icon.

It indicates mandatory (execution).

Detailed mandatory items are represented by graphics or

words in or near the icon.

It indicates caution (including warning).

Detailed cautions are represented by graphics or words in or

near the icon.

To prevent the user himself or others from personal and property damage and ensure correct and

safe use of the unit, please read the important contents described in this Manual carefully. Read the text

with full understanding of the following contents (marking and icon), and follow the following precautions.

Marking

Description

1. The above-mentioned harm in the Description refers to the harm that does not

require hospitalization or long-term treatment, and refers to injuries, burns and electric

shock in general.

2. The above-mentioned material damage refers to losses of property and materials.

2.Safety Precaution

Moving and Repair

Entrust the professionals

for installan

Page 5

3

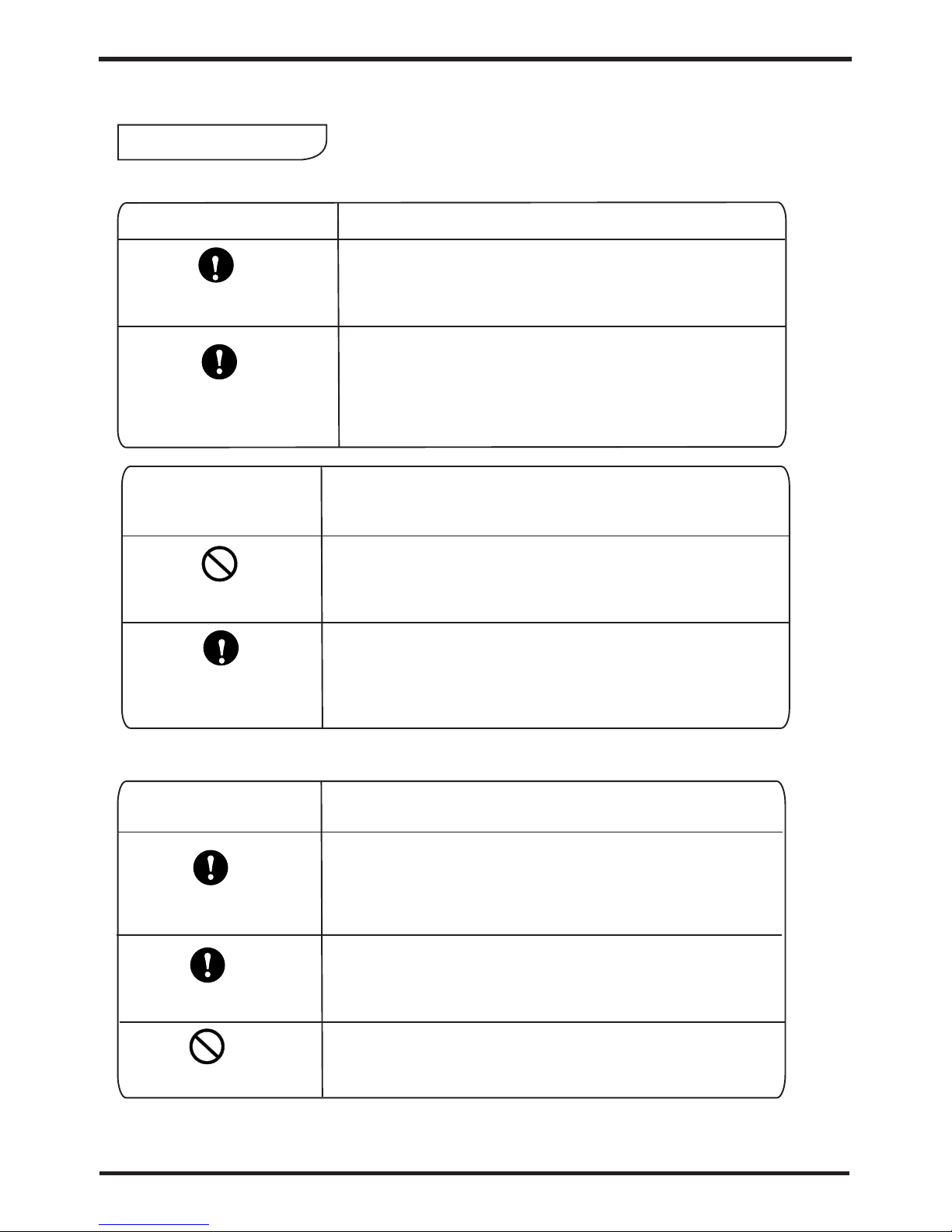

2.Safety Precaution

Please entrust the professionals for installation.

The installation by others may cause installation

imperfections, resulting in water leakage, electric

shock or fire.

Verify whether the grounding is proper.

Improper grounding may cause electric shock.

Installation Warning

Verify the ground wire

2.3 Warning

Description

Use Warning

Description

Prohibit

Cut off the

manual power

Do not put your fingers, sticks and other objects into

the air outlet or the air inlet.

Because the wind wheel operates at high speed inside,

it may cause injury.

When abnormal conditions (burning smell) occur,

immediately cut off the manual power switch to stop

running and contact the dealer.

Continuing abnormal conditions may cause electric

shock or fire.

Moving and Repair

Warning

Entrust

Prohibit

Entrust

If it is necessary to move and re-install the air

conditioning, entrust the dealer or professionals for

implementation.

Improper installation may cause electric shock, fire,

injury, water leakage and other accidents.

It is prohibited to repair the unit by the user himself, otherwise

electrical shock or fire may be occur.

For repair, entrust the dealer or professionals.

Improper repair may cause fire, electrical shock, injury,

water leakage and other accidents.

Entrust the professionals

for installan

Description

Page 6

4

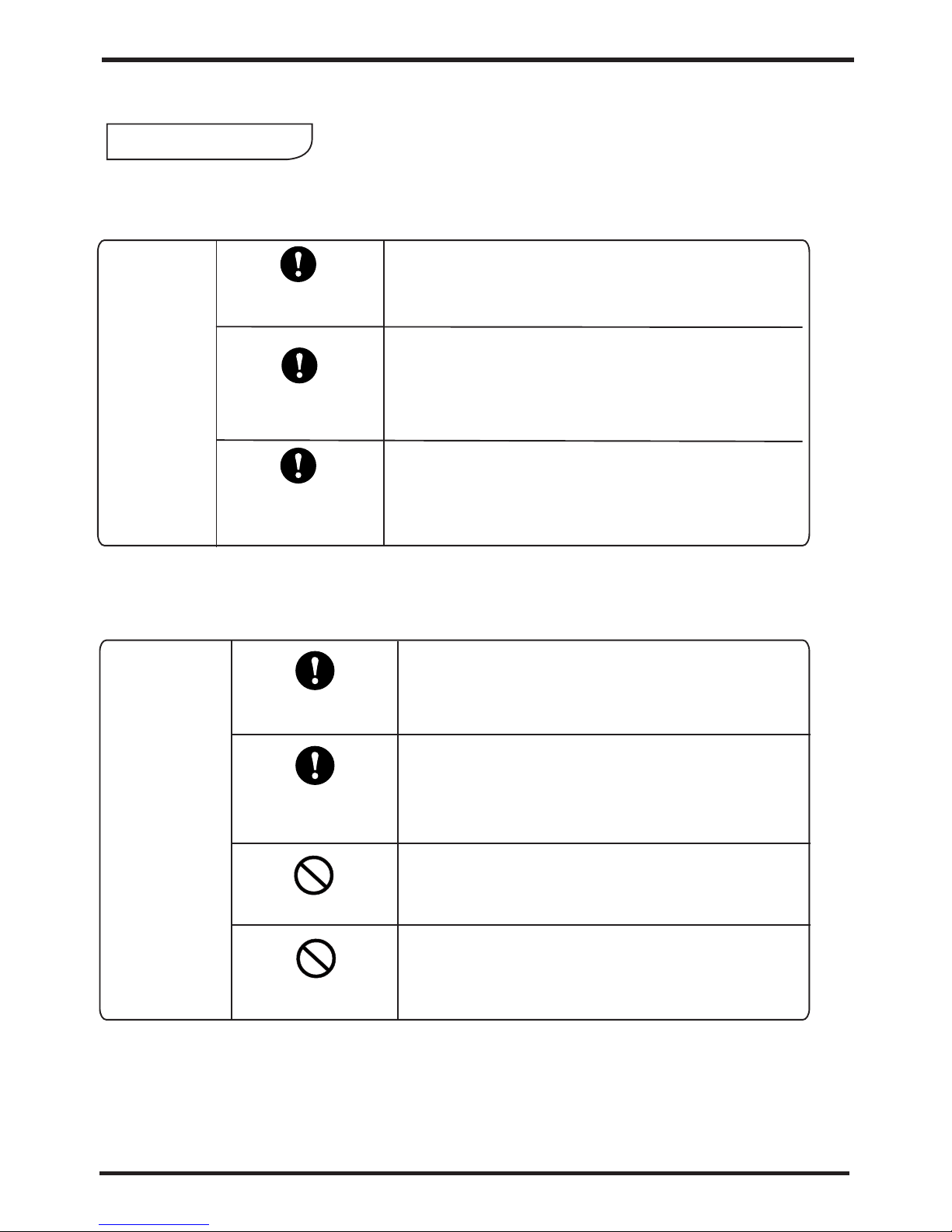

2.Safety Precautions

Use

precautions

Check the

installation bench

Cut off the manual

power switch

Prohibit

Prohibit

For long-term use, check whether the installation

bench is firm and intact.

If installation bench is damaged or weak, the

outdoor unit may fall, causing casualties.

Stop the operation during cleaning, and cut off the

manual power switch.

If the machine does not stop operation, it may

cause injury due to the wind wheel running at a

high speed inside.

Use the appropriate fuse.

If copper or iron wires are used, it may cause

malfunction or fire.

Do not spray the combustible spray directly to

the outdoor unit; otherwise, this may easily

Installation

precaution

Do not install it in a place where flammable gas leak

easily occurs.

Once the flammable gas leaks and stays around the

outdoor unit, this may cause a fire.

Verify whether the leakage protection switch has

been installed.

If the leakage protection switch is not installed, this

may cause electric shock or fire.

Verify whether the installation base is solid.

If the base is not solid, the outdoor unit may fall and

then result in accidents.

2.4 Caution

Verify the

installation site

Verify the

fixing means

Verify the leakage

protection switch

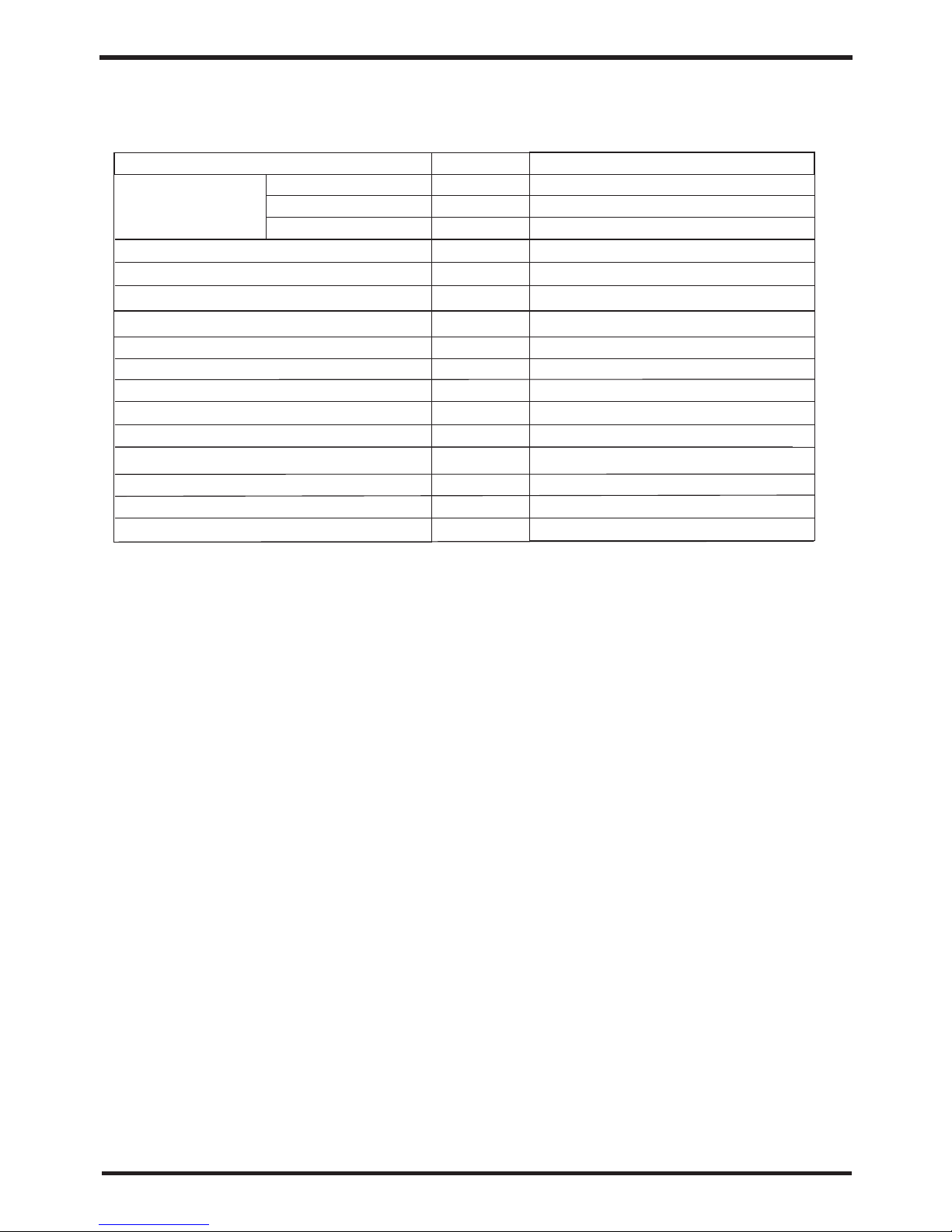

3.Specification

Testing condition: ambient temperature DB/WB 20 C/15 C;

outlet water 65 C, inlet water (return) 55 C;

Recyc led-heatin g

3.1Performance Parameter List

Page 7

5

3.Specification

o o

Testing condition: ambient temperature DB/WB 20 C/15 C;

o o

outlet water 65 C, inlet water (return) 55 C;

117.0

37.5

70.0

AL LH T11 70R13 4

kW

kW

A

Heati ng Output

Power I nput

Runni ng Current

Unit Mo del

Recyc led-heatin g

2

2000×2

920

75

380V/ 3N~/50Hz

(Subj ect to data on the p ackage)

Namep late

W

RPM

dB(A)

mm

mm

kg

kg

Power S upply

Scrol l

Compr essor Typ e

4

Compr essor Quanti ty

Fan Qua ntity

Fan pow er input

Fan spe ed

Noise

Water pipe connection

Unit di mension (L/W /H)

Packa ge size(L/W/ H)

Net Weight

Gross w eight

DN80

Refri gerant Type

R134a

Packa ge

(Subject to drawings o f the h eat p ump )

3.1Performance Parameter List

Page 8

6

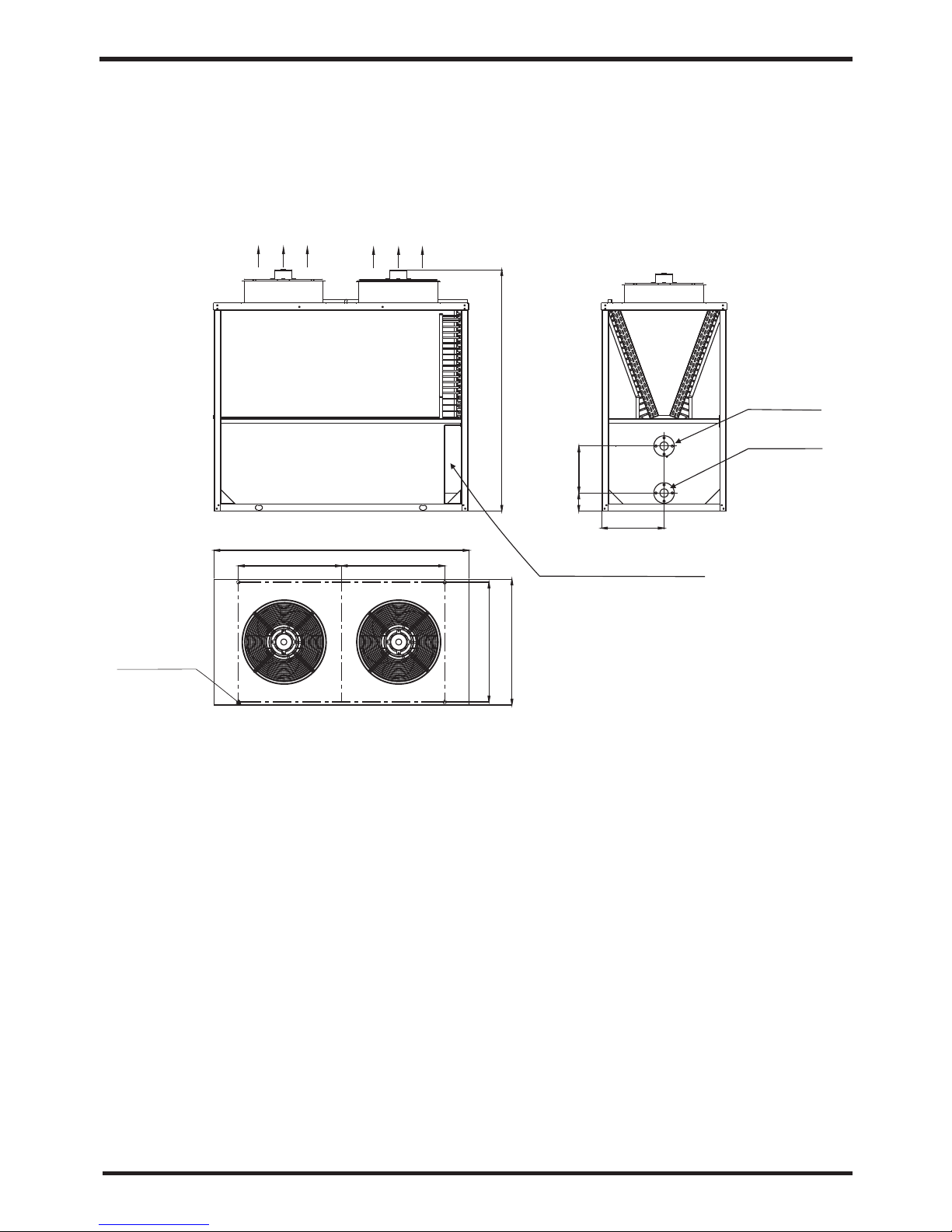

3.2

Outline Dimensional Drawing

3.Specification

Air-out di rec tio n

Installa tio n

Bottom Outlet

Water outlet

DN80 flang e

Electrical co ntr ol box

4-Φ16

2030

2180

900 900

1080

1020

400

175

530

Water inlet

DN80 flang e

Models: AL LHT 1170R13 4

4.Unit Function Description

The unit absorb energy from outside and release the heat according to the heat

exchanger, if the environment temperature is low, the heating capacity will be

attenuation.

Heating capacity

3 minutes protection

When the unit stop, if you restart the unit or turn on the manual switch, the unit will not run

in 3 minutes, it's the protection for the compressor.

If the environment temperature is too high, the unit will stop running to protect the

compressor.

Defrosting

Under the heating mode, the unit will defrost automatic to make sure the heating

efficiency (it will last 2-10 minutes).

Working condition

In order to use the unit correctly, please run the unit at environment temperature -7℃-43.

The unit includes sophisticated electronic devices, prohibited to use water from lake,

untreated river water and groundwater!

Power off

If the power supply is off, the unit will stop running. If the running unit is disturbed by

lightning, car radio, power grid fluctuations please cut off the manual power switch , and

then power on, press the on / off button.

leakage current protection

There is a leakage current action protection comes with the power supply wire.

Electric heating protection

When the water temperature reach 94℃, electric heating fuse will melt off (can not be

restored).

Hight pressure protection

Page 9

7

4.Unit Function Description

The unit absorb energy from outside and release the heat according to the heat

exchanger, if the environment temperature is low, the heating capacity will be

attenuation.

Heating capacity

3 minutes protection

When the unit stop, if you restart the unit or turn on the manual switch, the unit will not run

in 3 minutes, it's the protection for the compressor.

If the environment temperature is too high, the unit will stop running to protect the

compressor.

Defrosting

Under the heating mode, the unit will defrost automatic to make sure the heating

efficiency (it will last 2-10 minutes).

Working condition

In order to use the unit correctly, please run the unit at environment temperature -7℃-43.

The unit includes sophisticated electronic devices, prohibited to use water from lake,

untreated river water and groundwater!

Power off

If the power supply is off, the unit will stop running. If the running unit is disturbed by

lightning, car radio, power grid fluctuations please cut off the manual power switch , and

then power on, press the on / off button.

leakage current protection

There is a leakage current action protection comes with the power supply wire.

Electric heating protection

When the water temperature reach 94℃, electric heating fuse will melt off (can not be

restored).

Hight pressure protection

Page 10

8

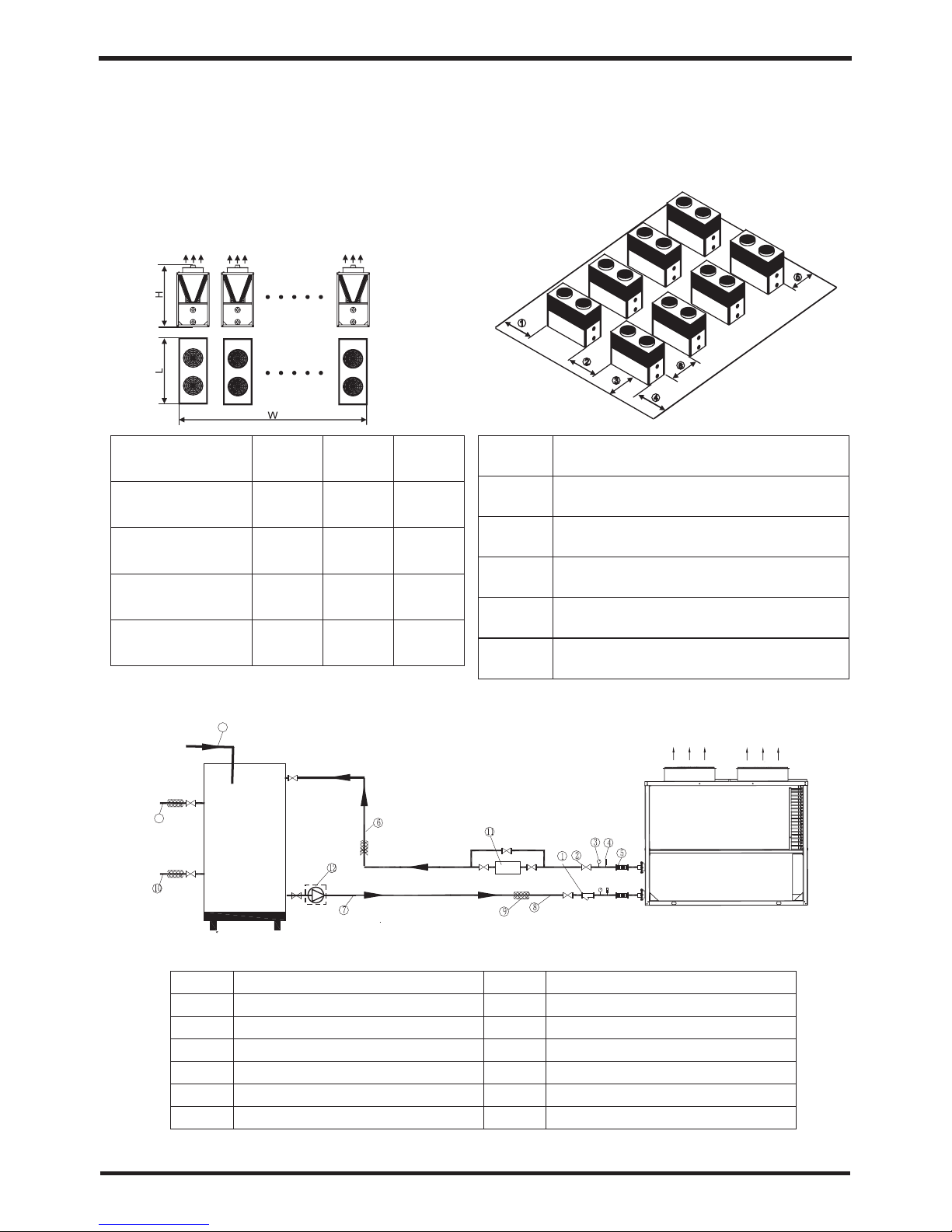

5.Installation

5.2 Installation Schematic Diagram

1

3

5

7

Y-type filter

Thermometer (0-100℃)

Connecting hose

Hot Water Circulating Pipe

2

4

6

8

Shut-off valve

Pressure gauge (0-1.0MPa)

Hot Water Circulating Pipe

Water supply pipes

Water Tank

Air-out di r

e

cti

on

1

3

8

Thermal insulation

Hot Water Supply Pipe

Electric auxiliary heater

Water pump

Hot Water Return Pipe

9

10

11

12

13

5.1Installation Space

2180

2180

2180

2180

3160

5240

7320

9400

2030

2030

2030

2030

Dimensions

Outline Dimensional

Drawing - Parallel Units

Schematic Diagram of Unit

Installation Position

Air-out direction

Parallel Mode

Double-

connected unit

Tripartite-

connected

Quadruple-

connected

Quintuplicate-

connected unit

L(mm)

L(mm) L(mm)

1

2

3

4

5

6

Maintenance space above 1800mm

Unit spacing above 1500mm

Maintenance space above 1500mm

Maintenance space above 1500mm

Maintenance space above 1800mm

Maintenance space above 1000mm

5.Installation

5.3 Model Selection

(1)Make comprehensive consideration of the required refrigerating (heating) capacity per unit

area according to climatic conditions, building use and heat preservation;

(2)Calculate the total load according to the unit load and the total area;

(3)Select the appropriate unit based on the total load and the application scope of the unit.

(4)Application occasions:

5.4Selection of the Installation Position

Page 11

9

5.Installation

5.3 Model Selection

(1)Make comprehensive consideration of the required refrigerating (heating) capacity per unit

area according to climatic conditions, building use and heat preservation;

(2)Calculate the total load according to the unit load and the total area;

(3)Select the appropriate unit based on the total load and the application scope of the unit.

(4)Application occasions:

5.4Selection of the Installation Position

The unit can be installed on balconies, roofs, floors, or any other places easy to install

and reliable for load-bearing;

Air circulated places;

Places without thermal radiation or other heat sources;

Install a snow shed in winter;

Places without obstruction near the suction inlet or the exhaust outlet;

Places where the exhaust outlet is free from heavy winds;

Drainage channels shall be equipped around the machine to drain the condensed

water;

Enough space should be remained around the machine.

Page 12

10

5.Installation

5.5 Installation Mode

The unit is directly secured to the cement base with the expansion bolts.

Use channel steel to make the installation base, place shockproof rubber pads on

the ground or the roof, and ensure that the unit is placed levelly.

Air-out direction

1500mm

Figure 1 Installation Schematic Diagram of Snow Shed

To ensure the proper functioning of the unit in cold

areas in winter, the snow shed must be installed

during the engineering installation.

Caution

5.6 Water Pipe Connection

5.7 Electrical Wiring

5.Installation

Page 13

5.6 Water Pipe Connection

Note the following items during connection of water inlet and outlet pipes:

`

Minimize the resistance of the water pipe outside the unit.

The entire piping system should be clean and free of dirt and rust to prevent pipe

clogging. Test for leakages after the pipes are installed to ensure that the entire

piping system is free of leakage, and then coat with the insulating layer.

The pipeline should be conducted with a pressure test separately, rather than

together with the air conditioning main engine.

An expansion water tank should be installed at the highest point of the water

distribution pipeline, where the highest point of the water level in the expansion water

tank is at least 0.5 meters higher than the water distribution pipe.

Flexible joints should be used between the unit interface and the field piping to

reduce the vibration spread to both buildings and equipment. Both the pipe and the

fittings must be independently supported, but should not be supported by the unit.

The thermometer and the pressure gauge should be installed at the water inlet and

outlet pipes of the unit to facilitate the inspection during operation.

Drainage interfaces should be installed at all low positions of the water system (the

unit has a drain port to facilitate drainage; interfaces will be added in other positions

on site) so that the water in the system will be completely drained if it is not used in

winter; automatic exhaust valves should be installed at all high positions so as to

facilitate to exhaust the air from the pipeline. No insulation is provided for both the

exhaust valves and the drain port for easy maintenance.

5.7 Electrical Wiring

Open the panel, and open the power line hole

Thread the power line through the hole and connect it to the power line terminal; and

the three-core control line of the remote controller shall be plugged with the three-core

signal line on the main board according to the wiring diagram.

For an external water pump, thread the power line of the water pump through the hole

and connect it to the water pump terminals.

If it is necessary to automatically control the auxiliary heat source, connect the control

output signal of the auxiliary heat source to the start switch of the auxiliary heat source.

If it is necessary to automatically control mode of the air conditioning terminal, connect

the mode control signal to the mode control switch on each indoor air conditioning

terminal.

5.Installation

11

Page 14

5.Installation

12

The master air switch

3

5

Wire controller

3

5 5

3

5

3

Wire controller

Wire controller

Wire controller

Power cablee

Model

(R,S,T,N, ground)

576S-V

Three-core signal line

2

3×0.5mm

Notes:

(1) The unit uses the three-phase power supply, and the cable specification in the

table above refers to the cable specification of each phase.

2

(1)Both the neutral line and the ground line use the 4mm cables, and both the

2

three-core signal line and the defrosting coordination line use the 0.5mm wires.

2 2

3×16 mm +2×2 5mm

5.8 Moving

5.Installation

5.9Trial Operation

5.9.1 Check prior to trial operation

Page 15

5.8 Moving

Warning

Do not touch the radiating fins behind the machine

by hand or with other objects!

Picture 2

When lifting is needed, use four sling wires

longer than 8m for lifting; during the lifting, use the

special lifting hole (hook) on the unit base. Pads

shall be provided at the contact between the

housing and the sling to prevent the damage to the

housing, as shown in Figure 2.

5.Installation

5.9Trial Operation

Check the piping system. Check whether the expansion water tank is filled with sufficient

water and whether the water supply for supplement is normal. Check whether the entire

piping system is full of water and whether the air is completely exhausted. Check

whether all valves in the system are opened. Check whether the pipelines are well

insulated.

Check the power distribution system. Check whether all power supplies have normal

voltage. Check whether screws of each power distribution part are locked, and whether

the power is distributed to the circuit according to the distribution wiring diagram. Check

whether the ground line is well connected.

Check the water chilling unit. Check whether all fastening screws and screws on the

mechanical parts of the unit are firm. Check whether there is any fault indication on the

operation lights on the outdoor control main board. Connect the pressure gauge to the

fluoridated inlet to detect the system pressure during operation.

5.9.1 Check prior to trial operation

13

Page 16

5.Installation

Turn on the machine with on the remote controller, and then immediately

check whether the water pump operates normally; if it is normal, observe the water

flow switch and the water pressure gauge of the water system: when the water flow

switch is in the ON state, the water pressure gauge shall show the water pressure of

about 0.2MPa.

After the water pump has operated for some time, the compressor will start. Judge

whether there is any abnormal sound in the unit during operation with the sense of

hearing; if there is any abnormal sound, immediately cut off the power and check the

unit; if there is no abnormal sound, continue the operation and then note whether

the pressure of the refrigerating system is normal.

Check whether the input power and the current of the unit are consistent with the

performance data list in the Manual; in case of incompliance, stop the unit for check.

Adjust the water supply valve in each room, so that the temperature of each room

meets the use requirements.

Observe whether the outlet water temperature is normal.

Parameters of the remote controller have been set in the factory, and the user shall

not adjust it without permission.

5.9.2 Trial Operation

14

6.Usage

6.1 Function of wire controller

Page 17

6.Usage

Welcome

V1.0

v1.0

Loading .. .. ..

Press the button to set the clock,

the timer on or timer off

Press this button to check button function

or system state.

Press this button to confirm current operation.

ON/OFF

Press this button to start up/shut off the unit,

cancel current operation or back to upper interface.

HELP

MODE

CLOCK

Button Name

Function

6.1 Function of wire controller

Press this key to select the upward option or increase

the parameter value.

Press this key to select the downward option or

decrease the parameter value.

Up

Down

15

Page 18

16

6.Usage

6.2.1 The way to use

You can use “ ”at any interface, it will show relevant button function of current interface.

You can press “ ”to exit the "help" interface.

For example:

Press “ ”at main interface, system will show all button function; Press “ ”at clock

interface, system will show“ ”、 “ ” 、“ ”and“ ”button function.

ON:Heating

Inle t temp .: 35.0℃

Outl et t emp.: 65. 0℃

1.

Pres si ng this key c ould turn

on/o ff the u nit, canc el t he

curr en t opera ti on or retur n

to the f or mer inter face.

Press“ ”

This s ym bol means

you ca n pa ge up

2.

Pres si ng this key c ould

sele ct t he upward o ption or

incr ea se the valu e of a

cert ai n paramet er.

3.

Pres si ng this key c ould

sele ct t he down wa rd option

or dec re ase the val ue of a

cert ai n paramet er.

4.

Pres si ng this key c ould

swit ch u nit mode, e nter

into t he n ext inter face or

save s et tings.

5.

Pres si ng this key c ould set

the sy st em time, or t ime for

regu la r shutd ow n or

rest ar t.

6.

Pres si ng this key c ould

chec k th e unit stat e or

show y ou t he key

func ti ons.

Mode

Both are OK when system show ON or OFF

ON:Eco.heating

Inle t te mp.: 25.0℃

Outl et t emp.: 25. 0℃

31/0 3/ 2011 09:10 THU.

Press“ ”

Press“ ”

Press“ ”

Press“ ”

Press“ ”

Press“ ”

6.2 Usage of wire controller

In the boot state

In the boot state

2016 /0 7/20 08:4 0 MON.

6.Usage

Press “ ”at clock interface, the screen shows as follow:

Both are OK when system shows ON or OFF

6.2.2 Starting up and shutting down

Page 19

17

6.Usage

Press “ ”at clock interface, the screen shows as follow:

Date: 20/07/2016

Time: 08:40

Week: Monday

Timer

Date format

Both are OK when system shows ON or OFF

Press“ ”

to enter

1. Up or down arrow

selects items

2. Clock key changes

status

3. On/off key exits

Press“ ”to show

relevant button function

Press“ ”

to exit

6.2.2 Starting up and shutting down

Press “ ”in the shutdown state for 1s to start up the system;

Press “ ”in the startup state for 1s to shut down the system.

For example:

Press“ ”

for 1s

Running state

MODE

(By actual state)

Month

Date

Time Week

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

OFF:Heating

Inle t te mp.: 25.0℃

Outl et t emp.: 25. 0℃

Year

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

In the shutdown state

In the startup state

2016 /0 7/20 08 :4 0 MON.

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

2016 /0 7/20 08:4 0 MON.

2016 /0 7/20 08 :4 0 MON.

2016 /0 7/20 08:4 0 MON.

Page 20

6.Usage

6.2.3 The operation of system state

At any interface, you can enter system working state by pressing“ ”twice, press“ ”

(pageup)or “ ” (p aged own)to s elec t the ne edin g para mete r, pres s“ ”to enter, and

press “ ”to exit.

For example:

Press“ ”

Temperature

Switch

Output

Press“ ”

T01 In le t water 55. 0℃

T02 Ou tl et water 65 .0℃

T03 Amb ie nt 30.5℃

T04 Co il 1 3 0.5℃

T05 Co il 2 4 5.5℃

T06 Su ct ion L1 65.5℃

T07 Su ct ion H1 25.5℃

T08 De ic e 1 65.5℃

Press“ ”

Press“ ”

Press“ ”

ON:Heating

In l et t e mp. : 25. 0℃

Outl et t emp.:25 .0℃

1.

Pres si ng this key c ould turn

on/o ff the u nit, canc el t he

curr en t opera ti on or retur n

to the f or mer inter face.

Temperature

Switch

Output

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

2016 /0 7/20 08:4 0 MON.

2015 /0 7/20 08:4 0 MON.

18 19

6.Usage

6.2.4 The operation of parameter

At main interface, press“ ”or“ ”to enter parameter setting interface, press

“ ”(increasing)or“ ”(decreasing)can change parameter value, press“ ”to save the

setting and exit . Press“ ”can not save the setting but exit.(You can refer to parameter table

to set relevant temperature.)

6.2.5 The operation of clock

At main interface, press“ ”to enter clock setting interface, select the needing parameter

and press“ ”,at this time, parameter value flashing, press“ ”(increasing)or“ ”

(Decreasing) can change parameter value, then press“ ”to save, press“ ”can cancel the

setting or back to the main interface.(“timer setting”refer to timer operation)

Page 21

6.Usage

6.2.4 The operation of parameter

At main interface, press“ ”or“ ”to enter parameter setting interface, press

“ ”(increasing)or“ ”(decreasing)can change parameter value, press“ ”to save the

setting and exit . Press“ ”can not save the setting but exit.(You can refer to parameter table

to set relevant temperature.)

Heating set point:

75.0℃

Press“ ”

or“ ”

Press“ ”

or“ ”

Press“ ”

to save the

setting

6.2.5 The operation of clock

At main interface, press“ ”to enter clock setting interface, select the needing parameter

and press“ ”,at this time, parameter value flashing, press“ ”(increasing)or“ ”

(Decreasing) can change parameter value, then press“ ”to save, press“ ”can cancel the

setting or back to the main interface.(“timer setting”refer to timer operation)

Press“ ”

to enter clock

interface

Press“ ” to select

the needing parameter

Date: 16/07/2016

Time: 05:55

Week: Thursday

Timer

Date format

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

2016 /0 7/20 08 :4 0 MON.

2016 /0 7/20 08 :4 0 MON.

Heating set point:

75.5℃

2016 /0 7/16 05:5 5 TH U.

Page 22

20

6.Usage

Press“ ”to select

needing parameter

Press“ ”

Hour bit flashing

Press“ ”

or“ ”

Press“ ”

to save the

hour value

Hour bit flashing

Minute bit flashing

Press“ ”

or“ ”

Press“ ”

to exit

The time has been changed

Tips:The setting of date and week is the same with clock;

If there is no operation in 10s, system will remember parameter setting automatic

and back to the main interface.,

As follow :

Date: 16/07/2016

Time: 05:55

Week: Thursday

Timer

Date format

Date: 16/07/2016

Time: 05:55

Week: Thursday

Timer

Date format

Date: 16/07/2016

Time: 06:55

Week: Thursday

Timer

Date format

Date: 16/07/2016

Time: 06:55

Week: Thursday

Timer

Date format

Date: 16/07/2016

Time: 06:41

Week: Thursday

Timer

Date format

Date: 16/07/2016

Time: 06:41

Week: Thursday

Timer

Date format

Minute bit flashing

Press“ ”

to save the

minute value

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

2015 /0 7/16 06 :4 1THU.

6.Usage

6.2.6 The operation of timer

You can set four timer on and timer off according to you needing.

At main interface, press “ ”to enter timer setting, press “ ”to select “Timer”, then

press“ ”to enter timer setting interface,(timer setting:you can set four timer on and timer

off, and the time you set can from Monday to Sunday.),the operation is the same with clock

setting.

For example:

A. Timer setting

Page 23

21

6.Usage

6.2.6 The operation of timer

You can set four timer on and timer off according to you needing.

At main interface, press “ ”to enter timer setting, press “ ”to select “Timer”, then

press“ ”to enter timer setting interface,(timer setting:you can set four timer on and timer

off, and the time you set can from Monday to Sunday.),the operation is the same with clock

setting.

For example:

Hour bit flashing

No operation

in 10s

It has been changed

Press“ ”

to enter clock

interface

Press“ ”to

select "Timer"

Timer zone

Daily timer

Press“ ”

to enter Timer

interface

A. Timer setting

Press“ ”

to enter Timer

setting interface

Date: 16/07/2016

Time: 06:55

Week: Thursday

Timer

Date format

Date: 16/07/2016

Time: 05:55

Week: Thursday

Timer

Date format

Date: 16/07/2016

Time: 05:55

Week: Thursday

Timer

Date format

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

2015 /0 7/20 06 :5 5 MON.

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

2015 /0 7/20 05 :5 5 MON.

Page 24

22

6.Usage

Press“ ”

to enter Timer

setting interface

Timer1:00:00-00:00

Timer2:00:00-00:00

Timer3:00:00-00:00

Timer4:00:00-00:00

Press“ ”

Hour bit flashing

Hour bit flashing

Press“ ”

or“ ”

Press“ ”

Minute bit flashing

Timer1:07:30-00:00

Timer2:00:00-00:00

Timer3:00:00-00:00

Timer4:00:00-00:00

Press“ ”

or“ ”

Press“ ”

Press“ ”

Press“ ”

Timer1:00:00-00:00

Timer2:00:00-00:00

Timer3:00:00-00:00

Timer4:00:00-00:00

Timer1:07:00-00:00

Timer2:00:00-00:00

Timer3:00:00-00:00

Timer4:00:00-00:00

Timer1:07:00-00:00

Timer2:00:00-00:00

Timer3:00:00-00:00

Timer4:00:00-00:00

Timer1:07:30-00:00

Timer2:00:00-00:00

Timer3:00:00-00:00

Timer4:00:00-00:00

Timer1:07:30-22:00

Timer2:00:00-00:00

Timer3:00:00-00:00

Timer4:00:00-00:00

Timer1:07:30-22:00

Timer2:00:00-00:00

Timer3:00:00-00:00

Timer4:00:00-00:00

Minute bit flashing

Hour bit flashing

Hour bit flashing

Minute bit flashing

Press“ ”

or“ ”

6.Usage

Tips:1) The operation of Tim er2 , Time r3, Ti mer4 is the same with Timer1;

2) Timer1 :07:30-22:0 0 mea ns sy stem starts up at 7:30, and shut down a t 22: 00 au tomaticly;

3) If there is no operation in 10s, system will memory parameter setting automaticl y.

B. The operation of daily timer

Page 25

23

6.Usage

Press“ ”

Press“ ”

to back to upper

interface

Press“ ”

to back to

upper interface

Tips:1) The operation of Tim er2 , Time r3, Ti mer4 is the same with Timer1;

2) Timer1 :07:30-22:0 0 mea ns sy stem starts up at 7:30, and shut down a t 22: 00 au tomaticly;

3) If there is no operation in 10s, system will memory parameter setting automaticly.

Press“ ”

to enter clock

interface

Press“ ”to

select "Timer"

Press“ ”

to enter timer

interface

B. The operation of daily timer

Press“ ”

Timer1:07:30-22:00

Timer2:00:00-00:00

Timer3:00:00-00:00

Timer4:00:00-00:00

Timer zone

Daily timer

Date: 16/07/2016

Time: 05:55

Week: Thursday

Timer

Date format

Date: 20/07/2016

Time: 05:55

Week: Monday

Timer

Date format

Timer zone

Daily timer

Press“ ”

to back to

upper interface

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

2015 /0 7/20 05 :5 5 MON.

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

2015 /0 7/20 05:5 5 MON.

Date: 20/07/2016

Time: 05:55

Week: Monday

Timer

Date format

Page 26

24

6.Usage

Press“ ”

Mon. :Timer1

Tue .: Timer1+ Tim er3

Wed.: ON

Thu. : Timer3+ Time r1

Fri. : Timer4

Sat. : Timer2+ Time r4

Sun. : OFF

Press“ ”

to enter

“Daily timer ”

Press“ ”

Press“ ”

Flashing

Press“ ”

or“ ”

Press“ ”

Flashing

Press“ ”

or“ ”

Press“ ”

Press“ ”

to back to

upper interface

Timer zone

Daily timer

Mon. :Timer1

Tue .: Timer1+ Tim er3

Wed.: ON

Thu. : Timer3+ Time r1

Fri. : Timer4

Sat. : Timer2+ Time r4

Sun. : OFF

Mon. :Timer1

Tue .: Timer1+ Tim er3

Wed.:O N

Thu. : Timer3+ Time r1

Fri. : Timer4

Sat. : Timer2+ Time r4

Sun. : OFF

Mon. :Timer1

Tue .: Timer1+ Tim er3

Wed.:O N

Thu. : Timer3+ Time r1

Fri. : Timer2

Sat. : Timer2+ Time r4

Sun. : OFF

Mon. :Timer1

Tue .: Timer1+ Tim er3

Wed.:O N

Thu. : Timer3+ Time r1

Fri. : Timer2+Timer4

Sat. : Timer2+ Time r4

Sun. : OFF

Mon. :Timer1

Tue .: Timer1+ Tim er3

Wed.:O N

Thu. : Timer3+ Time r1

Fri. : Timer2+Timer3

Sat. : Timer2+ Time r4

Sun. : OFF

Mon. :Timer1

Tue .: Timer1+ Tim er3

Wed.:O N

Thu. : Timer3+ Time r1

Fri. : Timer2+Timer3

Sat. : Timer2+ Time r4

Sun. : OFF

6.Usage

Tips:The Timer operations of Monday, Tuesday, Wednesday, Thursday, Saturday, Sunday is

the same with Friday.

Monday:OFF : means Monday Timer hasn't been set, and the running state is the same with

Sunday at 24:00, for example, if system is running at 24:00 on Sunday, then

it will be running the whole day on Monday, and vice versa;

Wednesday:ON : means system will be running the whole day on Wednesday

Thursday:OFF : means system will be off the whole day on Thursday;

Saturday:Timer1+Timer2 : means the time to start up and to shut down is according to Timer1

and Timer2.

If there is no operation in 10s, system will memory the parameter setting automaticly and back

to main interface.

Page 27

25

6.Usage

Press“ ”

to back to upper

interface

Press“ ”

to back to

upper

interface

If " " has been shown, it means

timer on/off has been set

Tips:The Timer operations of Monday, Tuesday, Wednesday, Thursday, Saturday, Sunday is

the same with Friday.

Monday:OFF : means Monday Timer hasn't been set, and the running state is the same with

Sunday at 24:00, for example, if system is running at 24:00 on Sunday, then

it will be running the whole day on Monday, and vice versa;

Wednesday:ON : means system will be running the whole day on Wednesday

Thursday:OFF : means system will be off the whole day on Thursday;

Saturday:Timer1+Timer2 : means the time to start up and to shut down is according to Timer1

and Timer2.

If there is no operation in 10s, system will memory the parameter setting automaticly and back

to main interface.

Timer zone

Daily timer

Date: 20/07/2016

Time: 05:55

Week: Monday

Timer

Date format

Press“ ”

to back to upper

interface

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

2015 /0 7/20 05 :5 5 MON.

Page 28

26

6.Usage

6.2.7 Keyboard lock

To avoid mis-operations, please lock the controller after parameter setting.

At the main interface, pressing “ ”for 5 seconds,the keyboard will be locked.

When the keyboard is locked, pressing“ ”for 5 seconds, the keyboard will be unlocked.

NOTES:

When the unit is in alarming state, the key lock can be removed automaticly.

Press“ ”

Locked

6.2.8 Malfunction display

There will be malfunction code showing on the controller screen when relative malfunction

occurs.

You can refer to the malfunction table to find out the failure cause and solution.

For example:

P01

Inlet water temp.

Failure

Failure number:1

Malfunction code

Malfunction

Failure number

press“ ”

or“ ”can check

next malfunction

Parameter table

Meaning

Set-point of heating target temp.

Default

Remarks

Ajustable

70℃

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

2015 /0 7/20 05 :5 5 MON.

ON:Heating

Inle t te mp.: 35.0℃

Outl et t emp.: 65. 0℃

2015 /0 7/20 05 :5 5 MON.

7.1 Malfunction table

You can refer to the malfunction table to find out the failure cause and solution.

7.Maintenance and inspection

Page 29

7.1 Malfunction table

Power on

P01

P02

P15(sys te m1 ), P2 5(syste m2 )

P35(sys te m3 ), P4 5(syste m4 )

P04

Malf un ction

Disp la y

Reas on

Reso lu tion

Normal wo rk in g

Outlet te mp . Se ns or f ailure

Inlet tem p. S en so r fa ilure

You can refer to the malfunction table to find out the failure cause and solution.

Wat er f low is not en ou gh

and low dif fe re ntial pre ss ur e

Communi ca ti on f ai lure betw ee n

wire cont ro ll er a nd m ain board

The prote ct io n sy st em is failu re

Wat er f low is not en ou gh

The ambie nt t em p. I s lo w

No water/ li tt le w at er in water

system

The high- pr ee su re s witch is br ok en

Electri ca l- he at i s over heat

The temp. S en so r is b ro ken or

short cir cu it

Check or ch an ge t he t em p. Sensor

Check or ch an ge t he t em p. Sensor

Check or ch an ge t he t em p. Sensor

Check or ch an ge t he t em p. Sensor

Check or ch an ge t he t em p. Sensor

Check or ch an ge t he t em p. Sensor

Check or ch an ge t he t em p. Sensor

Check or ch an ge t he t em p. Sensor

The low-p re es ur e sw itch is bro ke n

Wat er f low is not en ou gh

The ambie nt t em p. I s lo w

Check the p re ss ur e sw itch and co ld c ir cu it

Check the p re ss ur e sw itch and co ld c ir cu it

Check the p ip e wa te r fl ow and wate r pu mp

Check or ch an ge e le ct rical-h ea t

Check the p ip e wa te r fl ow and whet he r

water sys te m is j am me d or not

Check the p ip e wa te r fl ow and whet he r

water sys te m is j am me d or not

Check the p ip e wa te r fl ow and whet he r

water sys te m is j am me d or not

Check eac h pr ot ec ti on point of t he s ys te m

Check the w ir e co nn ec tion betw ee n

remote wi re c on tr ol ler and mai n bo ar d

/

/

The temp. S en so r is b ro ken or

short cir cu it

The temp. S en so r is b ro ken or

short cir cu it

The temp. S en so r is b ro ken or

short cir cu it

The temp. S en so r is b ro ken or

short cir cu it

The temp. S en so r is b ro ken or

short cir cu it

The temp. S en so r is b ro ken or

short cir cu it

The temp. S en so r is b ro ken or

short cir cu it

Ambient t em p. F ai lu re

System 1/ 2/ 3/ 4

Coil temp . Fa il ur e

System 1/ 2/ 3/ 4 ab so rb

Temp. Failu re

System 1/ 2/ 3/ 4 an ti -freeze

Temp. Failu re

Using sid e sy st em 1 / 2/ 3/4

Anti-fr ee ze t em p. F ailure

System 1/ 2/ 3/ 4 co il i nlet

Temp. Failu re

System 1/ 2/ 3/ 4 hi gh

Pressur e pr ot ec ti on

System 1/ 2/ 3/ 4 lo w

Pressur e pr ot ec ti on

Wat er f low failu re

Electri c- he at er

Overhea t pr ot ec ti on

Wat er i nlet and ou tl et

Temp. Too big

System 1/ 2/ 3/ 4 an ti -freeze

Protect io n

System 1/ 2/ 3/ 4 so ur ce side

Anti-fr ee ze p ro te ction

System 1/ 2/ 3/ 4 us in g side

Anti-fr ee ze p ro te ction

Anti-fr ee ze p ro te ct level 1

Anti-fr ee ze p ro te ct level 2

System pr ot ec ti on

Communi ca ti on f ai lure

P17(sys te m1 ), P2 7(syste m2 )

P37(sys te m3 ), P4 7(syste m4 )

P19(sys te m1 ), P2 9(syste m2 )

P39(sys te m3 ), P4 9(syste m4 )

P191(sy st em 1) ,P 291(sys te m2 )

P391(sy st em 3) ,P 491(sys te m4 )

P151(sy st em 1) ,P 251(sys te m2 )

P351(sy st em 3) ,P 451(sys te m4 )

E11( sy st em 1) ,E21(sy st em 2)

E31(sys te m3 ), E4 1(syste m4 )

E12(sys te m1 ), E2 2(syste m2 )

E32(sys te m3 ), E4 2(syste m4 )

E03

E04

E06

E06

E17(sys te m1 ), E2 7(syste m2 )

E37(sys te m3 ), E4 7(syste m4 )

E171(sy st em 1) ,E 271(sys te m2 )

E371(sy st em 3) ,E 471(sys te m4 )

E19

E29

E05

E08

Wat er f low is not en ou gh

and low dif fe re ntial pre ss ur e

Check the p ip e wa te r fl ow and whet he r

water sys te m is j am me d or not

7.Maintenance and inspection

27

Page 30

28

8.1 Connection of PCB illustration

Connections explanation:

Meaning

Live line

Null line

Compressor 1 output(220VAC)

Compressor 2 output(220VAC)

Compressor 3 output(220VAC)

Compressor 4 output(220VAC)

High speed /souce pump output(220VAC)

Low speed output (220VAC)

Water pump output(220VAC)

4-way valve output(220VAC)

Electric heater output(250VAC)

Spray valve output(220VAC)

Alarm system output(220VAC)

Emergency switch output

Mode indicator output

Emergency switch input

System 1 high pressure protection input

System 2 high pressure protection input

System 3 high pressure protection input

System 4 high pressure protection input

System 1 low pressure protection input

System 2 low pressure protection input

System 3 low pressure protection input

System 4 low pressure protection input

Water flow switch protection input

Electric heater overload protection input

Symbol

L

N

RO 01

RO 02

RO 03

RO 04

RO 05

RO 06

RO 07

RO 08

RO 09

RO 10

RO 11

DI/DO 1

DI/DO 2

DI/DO 3

DI 01

DI 02

DI 03

DI 04

DI 05

DI 06

DI 07

DI 08

DI 09

DI 10

RO 01

L

L

L

N

N

PC8001

RO 02

RO 03

RO 04

RO 05

RO 06

RO 07

RO 08

RO 09

RO 10

RO 11

GND

NET

12V

5V

0-10V

GND

GND

AI 01

AC12V

AC12V

RS485B

RS485A

AI 02

AI 03

AI 04

AI 05

AI 06

AI 07

AI 08

AI 09

AI 10

AI 11

AI 12

AI 13

AI 14

AI 15

AI 16

DI 01

DI 02

DI 03

DI 04

DI 05

DI 06

DI 07

DI 08

DI 09

DI 10

DI/ DO01

DI/ DO02

DI/ DO03

DI 11

CN 3

CN2

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Meaning

System protection signal

Water input temperature input

Water output temperature output

System 1 fan coil temperature input

System 2 fan coil temperature input

System 3 fan coil temperature input

System 4 fan coil temperature input

Ambient temperature input

System 1 antifreeze temperature input

System 2 antifreeze temperature input

System 3 antifreeze temperature input

System 4 antifreeze temperature input

System 1 suction temperature input

System 2 suction temperature input

System 3 suction temperature input

System 4 suction temperature input

No use

Connecting to the remote controller

System 1 electric expansion valve output

System 2 electric expansion valve output

Symbol

DI11

AI 01

AI 02

AI 03

AI 04

AI 05

AI 06

AI 07

AI 08

AI 09

AI 10

AI 11

AI 12

AI 13

AI 14

AI 15

AI 16

GND

NET

12V

RS485A

RS485B

AC12V

AC12V

CN2

CN3

NO.

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

485 connection

12V power input

8.Appendix

. Connection of PCB illustration

Connections explanation:

8.Appendix

Page 31

29

. Connection of PCB illustration

Connections explanation:

1

2

3

4

No.

Symbol

Meaning

System1 mangtic valve outlet(220-230VAC)

System 2 economizer outlet temp.failure(input)

7

8

9

10

11

12

13

14

15

5

6

Ambient temp.(input)

RO02

RO04

RO03

RO01

AI03 GND

AI04 GND

AI05 GND

AI06 GND

AI07 GND

AI08 GND

AI09 GND

System 2 exhaust temp.(input)

System 1 exhaust temp.(input)

System 2 economizer inlet temp.failure(input)

System 1 economizer inlet temp.failure(input)

System 1 economizer outlet temp.failure(input)

Wire controller

System 2 economizer outlet temp.failure(input)

16

17

18

19

Ambient temp.(input)

NET GN D 12V

DI01 GND

AI01 GND

AI02 GND

AI03 GND

AI04 GND

AI05 GND

AI06 GND

AI07 GND

AI08 GND

AI09 GND

System 2 exhaust temp.(input)

System 1 exhaust temp.(input)

System 2 economizer inlet temp.failure(input)

System 1 economizer inlet temp.failure(input)

System 1 economizer outlet temp.failure(input)

System 2 anti-freeze temp.(input)

System 1 anti-freeze temp.(input)

Mode/conmunication

System2 mangtic valve outlet(220-230VAC)

System1 alert outlet(220-230VAC)

System2 alert outlet(220-230VAC)

CC01

CC02

CC03

CC04

System1 mangtic valve inlet(220-230VAC)

System2 mangtic valve inlet(220-230VAC)

System1 alert inlet(220-230VAC)

System2 alert inlet(220-230VAC)

9

10

11

12

13

14

15

CN2

BHB10

CN3

RLY1RLY2RLY3RLY4

CN5

CN6

12V

NET

GND

DI01

AI01

AI02

AI03

AI04

AI05

AI06

AI07

AI08

CT1 CT2

CN4

GND

GND

GND

GND

GND

GND

GND

GND

GND

CC01

AI09

GND

CC02 RO01 RO02RO03RO04 CC0 3 CC 04

8.Appendix

Page 32

30

8.Appendix

1. The unit can only be repaired by qualified installer centre personnel or an authorised

dealer.(for Europe market)

2. This appliance is not intended for use by persons (including children) with reduced physical

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. (for Europe market)

Children should be supervised to ensure that they do not play with the appliance.

3. Please make sure that the unit and power connection have good earthing, otherwise may

cause electrical shock.

4. If the supply cord is damaged, it must be replaced by the manufacturer or our service agent

or similarly qualified person in order to avoid a hazard.

5. Directive 2002/96/EC (WEEE):

The symbol depicting a crossed-out waste bin that is underneath the appliance indicates

that this product, at the end of its useful life, must be handled separately from domestic

waste, must be taken to a recycling centre for electric and electronic devices or handed

back to the dealer when purchasing an equivalent appliance.

6. Directive 2002/95/EC (RoHs): This product is compliant with directive 2002/95/EC (RoHs)

concerning restrictions for the use of harmful substances in electric and electronic devices.

7. The unit CANNOT be installed near the flammable gas. Once there is any leakage of the gas

, fire can be occur.

8. Make sure that there is circuit breaker for the unit, lack of circuit breaker can lead to

electrical shock or fire.

9. The heat pump located inside the unit is equipped with an over-load protection system. It

does not allow for the unit to start for at least 3 minutes from a previous stoppage.

10. The unit can only be repaired by the qualified personnel of an installer center or an

authorized dealer. (for North America market)

11. Installation must be performed in accordance with the NEC/CEC by authorized person only.

(for North America market)

12. USE SUPPLY WIRES SUITABLE FOR 75℃.

13. Caution: Single wall heat exchanger, not suitable for potable water connection.

8.2 Caution & Warning

1. The unit can only be repaired by qualified installer centre personnel or an authorised

dealer.(for Europe market)

2. This appliance is not intended for use by persons (including children) with reduced physical

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. (for Europe market)

Children should be supervised to ensure that they do not play with the appliance.

3. Please make sure that the unit and power connection have good earthing, otherwise may

cause electrical shock.

4. If the supply cord is damaged, it must be replaced by the manufacturer or our service agent

or similarly qualified person in order to avoid a hazard.

5. Directive 2002/96/EC (WEEE):

The symbol depicting a crossed-out waste bin that is underneath the appliance indicates

that this product, at the end of its useful life, must be handled separately from domestic

waste, must be taken to a recycling centre for electric and electronic devices or handed

back to the dealer when purchasing an equivalent appliance.

6. Directive 2002/95/EC (RoHs): This product is compliant with directive 2002/95/EC (RoHs)

concerning restrictions for the use of harmful substances in electric and electronic devices.

7. The unit CANNOT be installed near the flammable gas. Once there is any leakage of the gas

, fire can be occur.

8. Make sure that there is circuit breaker for the unit, lack of circuit breaker can lead to

electrical shock or fire.

9. The heat pump located inside the unit is equipped with an over-load protection system. It

does not allow for the unit to start for at least 3 minutes from a previous stoppage.

10. The unit can only be repaired by the qualified personnel of an installer center or an

authorized dealer. (for North America market)

11. Installation must be performed in accordance with the NEC/CEC by authorized person only.

(for North America market)

12. USE SUPPLY WIRES SUITABLE FOR 75℃.

13. Caution: Single wall heat exchanger, not suitable for potable water connection.

8.3Appendix 9

(1) Caution & Warning

8.Appendix

Page 33

31

1. The unit can only be repaired by qualified installer centre personnel or an authorised

dealer.(for Europe market)

2. This appliance is not intended for use by persons (including children) with reduced physical

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. (for Europe market)

Children should be supervised to ensure that they do not play with the appliance.

3. Please make sure that the unit and power connection have good earthing, otherwise may

cause electrical shock.

4. If the supply cord is damaged, it must be replaced by the manufacturer or our service agent

or similarly qualified person in order to avoid a hazard.

5. Directive 2002/96/EC (WEEE):

The symbol depicting a crossed-out waste bin that is underneath the appliance indicates

that this product, at the end of its useful life, must be handled separately from domestic

waste, must be taken to a recycling centre for electric and electronic devices or handed

back to the dealer when purchasing an equivalent appliance.

6. Directive 2002/95/EC (RoHs): This product is compliant with directive 2002/95/EC (RoHs)

concerning restrictions for the use of harmful substances in electric and electronic devices.

7. The unit CANNOT be installed near the flammable gas. Once there is any leakage of the gas

, fire can be occur.

8. Make sure that there is circuit breaker for the unit, lack of circuit breaker can lead to

electrical shock or fire.

9. The heat pump located inside the unit is equipped with an over-load protection system. It

does not allow for the unit to start for at least 3 minutes from a previous stoppage.

10. The unit can only be repaired by the qualified personnel of an installer center or an

authorized dealer. (for North America market)

11. Installation must be performed in accordance with the NEC/CEC by authorized person only.

(for North America market)

12. USE SUPPLY WIRES SUITABLE FOR 75℃.

13. Caution: Single wall heat exchanger, not suitable for potable water connection.

8.3Appendix 9

(1) Caution & Warning

8.Appendix

Page 34

32

(2) Cable specification

When the unit will be installed at outdoor, please use the cable which can against UV.

8.Appendix

1. Single phase unit

10~16A

16

~25A

25

~32A

32

~40A

40

~63A

63~75A

75~101A

101~123A

123~148A

148~186A

186~224A

Phase line

MCB

Creepage protector

Signal line

2

×

n 0.5mm

Nameplate

maximum

current

Earth line

No more

than 10A

2

2×1.5mm

2

2×2.5mm

2

2×4mm

2

2×6mm

2

2×10mm

2

2×16mm

2

2×25mm

2

2×25mm

2

2×35mm

2

2×50mm

2

2×70mm

2

2×95mm

20A

32A

40A

40A

63A

80A

100A

125A

160A

225A

250A

280A

2

1.5mm

2

2.5mm

2

4mm

2

6mm

2

10mm

2

16mm

2

mm

25

2

mm

25

2

35mm

2

50mm

2

70mm

2

95mm

30mA less than 0.1 sec

10~16A

16

~25A

25

~32A

32

~40A

40

~63A

63~75A

75~101A

101~123A

123~148A

148~186A

186~224A

Phase line

MCB

Creepage protector

Signal line

2

×

n 0.5mm

Nameplate

maximum

current

Earth line

No more

than 10A

20A

32A

40A

40A

63A

80A

100A

125A

160A

225A

250A

280A

2

1.5mm

2

2.5mm

2

4mm

2

6mm

2

10mm

2

16mm

2

mm

25

2

mm

25

2

35mm

2

50mm

2

70mm

2

95mm

2. Three phase unit

2

3×1.5mm

2

3×2.5mm

2

3×4mm

2

3×6mm

2

3×10mm

2

×

16mm

3

2

×

25mm

3

2

3×25mm

2

3×35mm

2

3×50mm

2

3×70mm

2

3×95mm

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

Note:

Page 35

Note:

Page 36

Code : 20 17080 3- 0003

Loading...

Loading...