evoheat 270, PASHW015-270LD Operation & Installation Manual

Operation & Installation Manual

HOT WATER HEAT PUMP

270

Preface

Due to continuous produvct improvement, this manual is be subject to change without prior

notice.

When installing the hot water cylinder, please follow the Instructions as documented in this

manual.

A maintenance programme must be carried out as recommended in this manual to ensure

ongoing reliability.

Failure to comply with these recommendations could void the warranty and cause injury or

death.

It is important that the installation and operational instructions laid out in this manual are

strictly adhered to.

Evo Industries Australia Pty Ltd will not be held responsible for any damages or injuries

caused by the incorrect Installation of this hot water system.

This manual includes all the necessary information regarding the Installation, operation

and maintenance of this product. Please take the time to read it through before installing or

operating the heat pump.

Once the Installation is complete, check that all connections are secure before the power is turned

on.

The installer is to explain to the end user how to operate and maintain the unit in accordance with

this Instruction manual.

Contents

1. Safety Precautions

2. Specifications

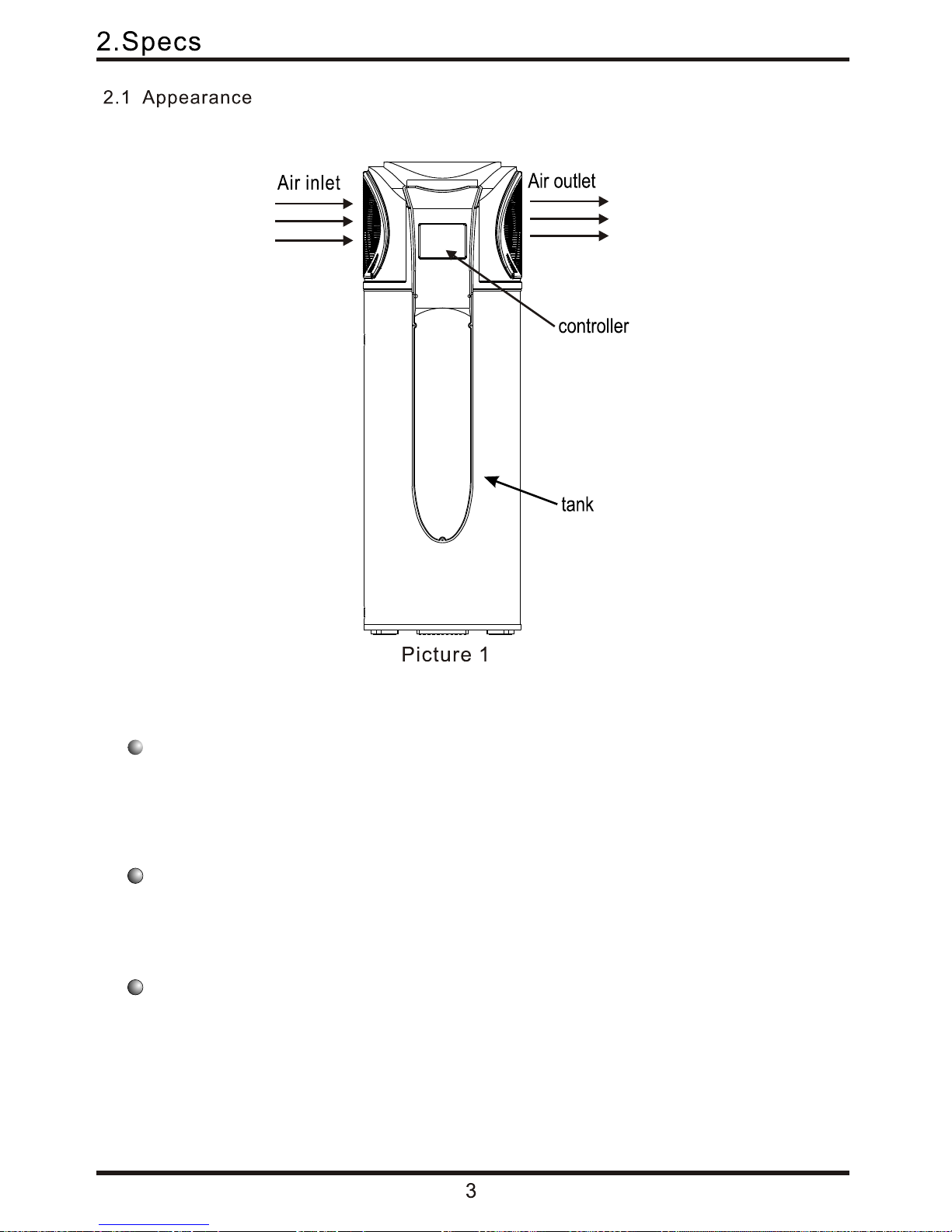

2.1) Appearance

2.2) Characteristics

2.3) Operational Principle

2.4) Dimensions

2.5) Technical Data

3. System Features

4. Installation

4.1) Pipeline connection sketch

4.2) Handling and transportation

4.3) Installation clearances

4.4) Cable connection

4.5) Trial running

5. Operation

5.1) Function of wire controller

5.2) Controller Operation

6. Maintenance and repair

7.1) Unit parameters

7. Appendix

6.2) Troubleshooting guide

6.1) Maintenance

7.2) PCB Description

7.3) Detailed parts overview

7.4) Caution

7.5) Earthing methodology

7.6) Use of the P&T valve

Warranty

Contents

Contents

1. Safety Precautions

1

2. Specifications

3

2.1) Appearance

3

2.2) Characteristics

3

2.3) Operational Principle

4

2.4) Dimensions

5

2.5) Technical Data

6

3. System Features

7

4. Installation

8

4.1) Pipeline connection sketch

8

4.2) Handling and transportation

9

4.3) Installation clearances

10

4.4) Cable connection

13

4.5) Trial running

13

5. Operation

14

5.1) Function of wire controller

14

5.2) Controller Operation

16

6. Maintenance and repair

27

7.1) Unit parameters

28

7. Appendix

28

6.2) Troubleshooting guide

27

6.1) Maintenance

27

7.2) PCB Description

28

7.3) Detailed parts overview

29

7.4) Caution

31

7.5) Earthing methodology

32

32

7.6) Use of the P&T valve

33

7.7) Use of the overheating protector

Warranty

34

33

7.8) Draining the water tank

1

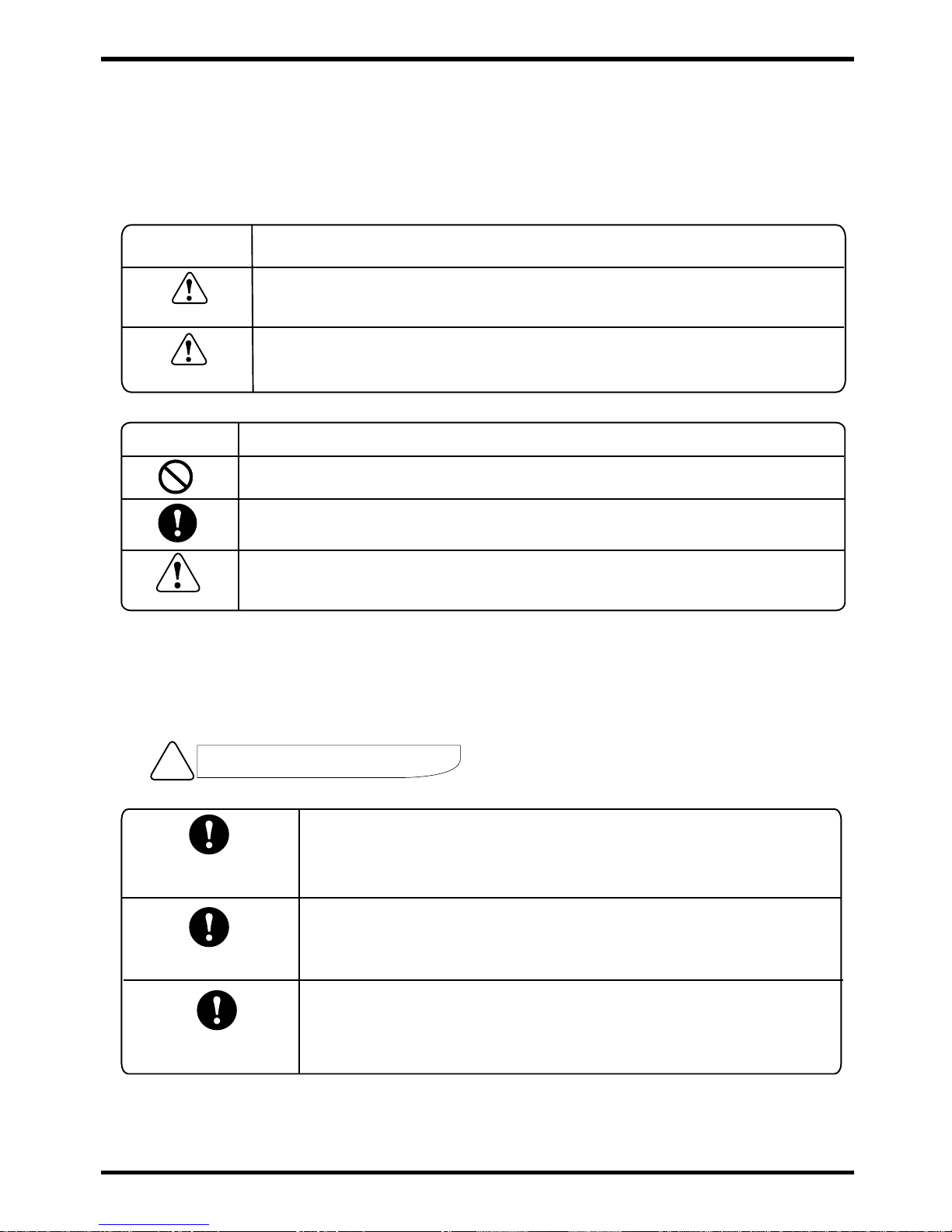

1.Safety Precautions

!

To prevent personal injury and avoid causing damage to the unit, please take the time to

read the information documented in this manual.

Icon

Meaning

Failure to pay attention to this may lead to serious injury or death.

Failure to pay attention to this may lead to injury or loss of material.

WARNING

INSTALLATION WARNING

Icon

Meaning

Compulsory - The listed action must be implemented.

Please pay attention to what is indicated.

Prohibited (Next to this icon)

The heat pump must be installed by qualified persons. Improper

installation could result in electrical shock /water leakage or fire.

Please ensure that the unit and power connections have a good

earth. Failure to do this may cause electrical shock.

Professional installer

required

Earthing is required

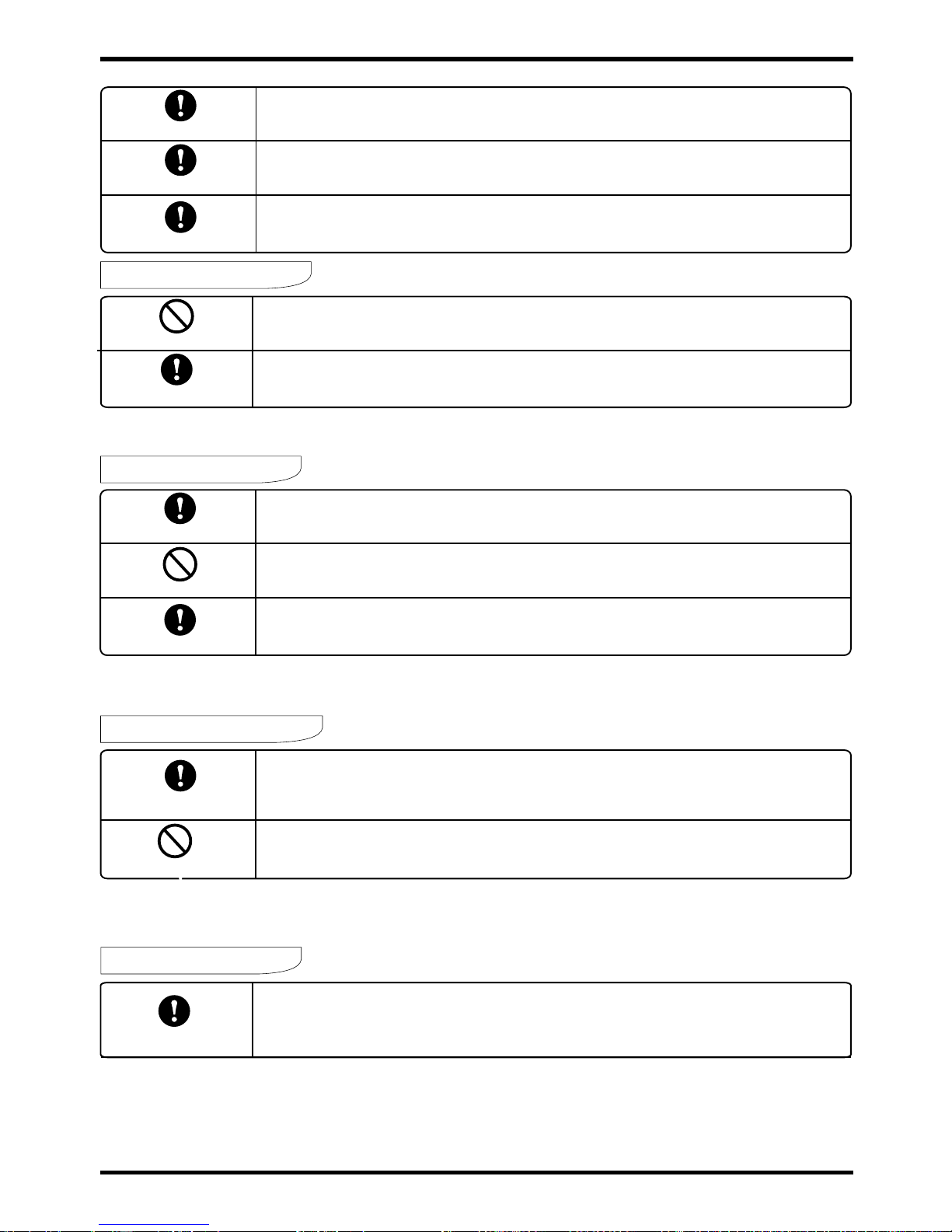

ATTENTION

Check drainage fittings

Before installation, make sure there are no leaks on the plumbing

and drainage fittings.

1.Safety Precautions

Installation position

Circuit breaker required

OPERATION WARNING

Shut off the power

MOVE AND REPAIR

OPERATION ATTENTION

Shut off the power

USAGE WARNING

Usage warning

1.Safety Precautions

2

Installation position

Fixing the unit

Circuit breaker required

The unit MUST NOT be installed near flammable gas.

Ensure that the base you are installing on is level and stable.

This unit requires a circuit breaker. failure to do so could result in an

electrical shock or fire.

OPERATION WARNING

Prohibited

Shut off the power

Do not put fingers or any other objects into the fan. Children should be

kept clear of this appliance.

In the event of a unit malfunction please shut the power off and contact your service

engineer.

MOVE AND REPAIR

Important

If the heat pump needs to be relocated or installed again, only use an authorised

dealer or qualified persons.

It is prohibited for the end user to repair the unit . Failure to use a qualified

technician may lead to serious injury and/or damage to the unit.

Should the heat pump need to be repaired, only use an authorised dealer or

qualified technician.

Prohibited

Important

OPERATION ATTENTION

Shut off the power

Turn the power off before cleaning the unit.

Prohibited

Do not spay flammable aerosols onto the unit, as this could result in a fire.

USAGE WARNING

Usage warning

Danger - High temperature water and hot fittings. Do not touch.

Setting the water temperature too high can cause burns and scalds.

Do not attempt to repair yourself - contact Evoheat for advice.

Smart and efficient unit

The operational costs can be up to 75% less than that of an electric water heater, and can

be installed in locations which are unsuitable for solar hot water heating.

2.2 Characteristics

Easy to operate

Featuring an easy to use timer for both start and stop operations, with a controller to set the

desired water temperature.

Safe and environmentally friendly

Produces no harmful gases along with no open flame, making the unit safe to work with

when installing.

2. Specs

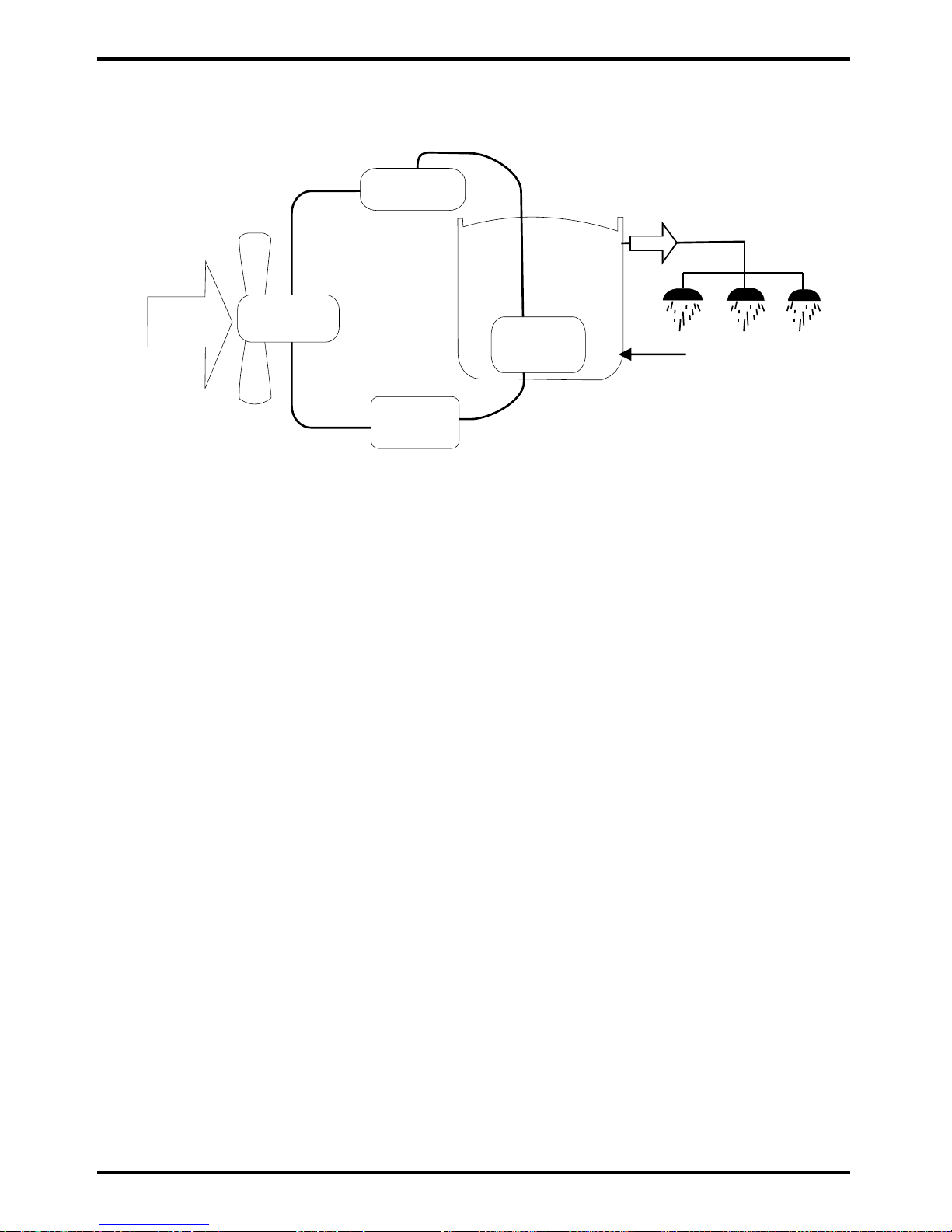

2.3 Operational Principle

Heat Pump System Theory:

(1) Using a small power input to drive the compressor, the power used is Q1.

(2) While the unit is running, the power that comes ambient air is Q2 (from the refrigerant

transformation).

(3) The energy that the water gets from the unit is Q3.

(4) According to the law of conservation of energy:

﹛ Sum of input power = sum of output power Q1+Q2 = Q3

﹛ In standard working conditions, the power that heat pump gets from the environment is about

3.2 times the power input, Q2 = 3.2 x Q1

so: Q3 = Q1+Q2 = Q1+3.2Q1= 4.2Q1

Which means you can get 4.2Q1 from heat pump if you spend Q1 energy. Which means the

energy that you can get from heat pump after using 1 kW of electricity is equal to the energy that

you get from electrical element heater after using 4.2 kW of electricity. This makes the hot water

heat pump is one of the most energy efficient heating equipment available on the market today..

4

2. Specs

2.3 Operational Principle

4

Air from

outside

Hot water

Low temp.

Compressor

Compressor

Thermal

expansion

valve

Water supply

Tank

Picture 2

Air

exchanger

Water

exchanger

Heat Pump System Theory:

(1) Using a small power input to drive the compressor, the power used is Q1.

(2) While the unit is running, the power that comes ambient air is Q2 (from the refrigerant

transformation).

(3) The energy that the water gets from the unit is Q3.

(4) According to the law of conservation of energy:

﹛ Sum of input power = sum of output power Q1+Q2 = Q3

﹛ In standard working conditions, the power that heat pump gets from the environment is about

3.2 times the power input, Q2 = 3.2 x Q1

so: Q3 = Q1+Q2 = Q1+3.2Q1= 4.2Q1

Which means you can get 4.2Q1 from heat pump if you spend Q1 energy. Which means the

energy that you can get from heat pump after using 1 kW of electricity is equal to the energy that

you get from electrical element heater after using 4.2 kW of electricity. This makes the hot water

heat pump is one of the most energy efficient heating equipment available on the market today..

2. Specifications

5

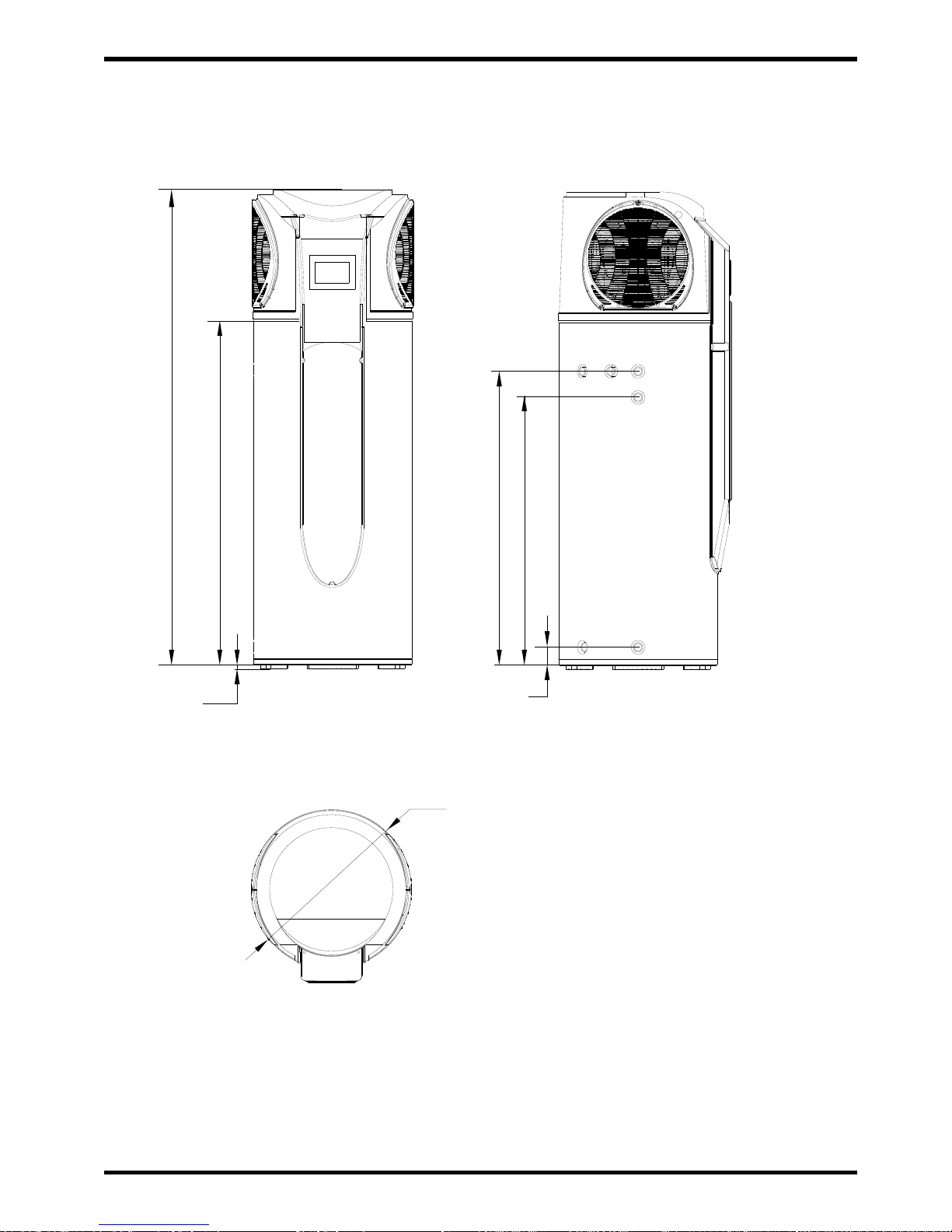

2.4 dimensions

unit-mm

MODEL: EVOHEAT 270

2. Specifications

2.5 performance parameters

Working Temp Range

(1).Ambient temperature is -7deg to 43deg(Heat Pump)

(2).The max temperature of water tank is 70

Measurement conditions:

Instant heating: Ambient temperature15DB/13WB,Water inlet 15 Water outlet 45

Operating parameters

The range of the operating water pressures: 0.15~0.7MPa

Picture 3

¦640

16

99

1435

1955

1194

1094

2. Specifications

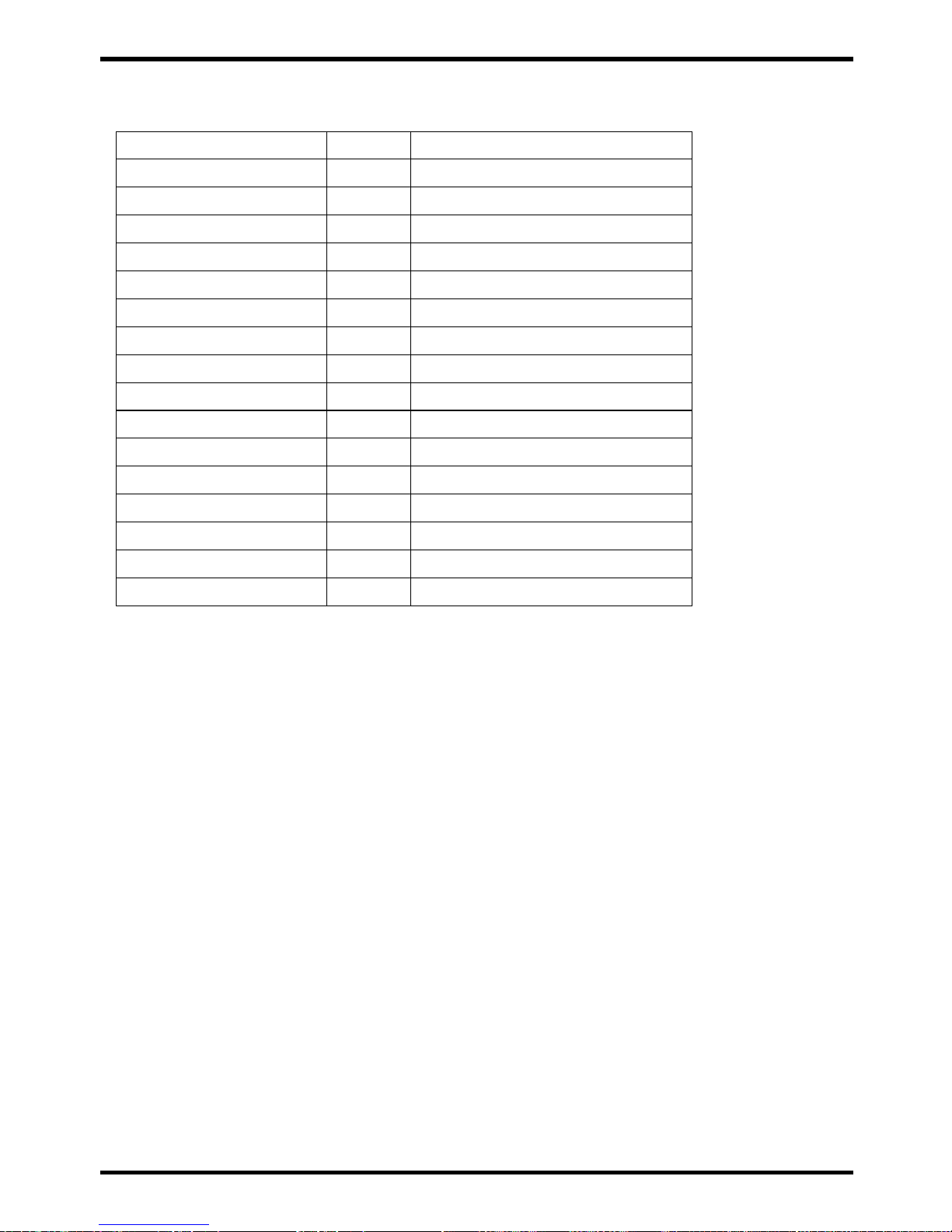

2.5 performance parameters

6

Working Temp Range

(1).Ambient temperature is -7deg to 43deg(Heat Pump)

(2).The max temperature of water tank is 70

Measurement conditions:

Instant heating: Ambient temperature15DB/13WB,Water inlet 15 Water outlet 45

Operating parameters

The range of the operating water pressures: 0.15~0.7MPa

Model

Heating capacity

Water tank capacity

Power input

Running current

Power supply

Compressor Number

Compressor

Rated outlet water Temp.

Air volume

Nosie

Water inlet/outlet size

*Hydroboost Power heat

Net dimensions

Shipping dimensions

Net weight

Shipping weight

kW

kW

A

Deg C

3

m /h

dB(A)

inch

kW

mm

mm

kg

kg

EVOHEAT270 (PASHW015-270LD)

3.4 Heat Pump

270

0.94 Heat Pump

3.92 Heat Pump + 6.5 Hydroboost

240V~/50Hz

1

rotary

55

450

49

3/4

1.5

See the drawing

135

175

720x760x2040

3.Operation

3 min safety protect

If the unit stops and you re start the unit or turn it on manually, the unit will not start to run

again for approx 3 minutes. This is a protection feature to safe guard the compressor.

In low ambient conditions the heating output decreases. See page __ for further

information.

Heating capacity

In order to use the unit correctly, please run the unit at environment temperature -7→-43→.

The unit includes sophisticated electronic devices, prohibited to use water from lake, untreated

river water and groundwater!

Working conditions

Defrosting

In heating mode the unit will defrost automatically, maximizing the heating efficiency (Lasting 2 10 minutes).

The fan motor will stop running whilst the unit is defrosting.

Overheating protection

When the water temperature reaches 75deg C, the power of the unit will be cut and must be

manually reset. See page __ for more information.

Water pressure protectiontemperature or

A P&T valve MUST be installed in the tank. When the tank pressure reaches 0.85MPa or

when the tank temperature reaches 93deg C, the P&T valve will open automatically so as

to reduce the pressure or temperature decrease.

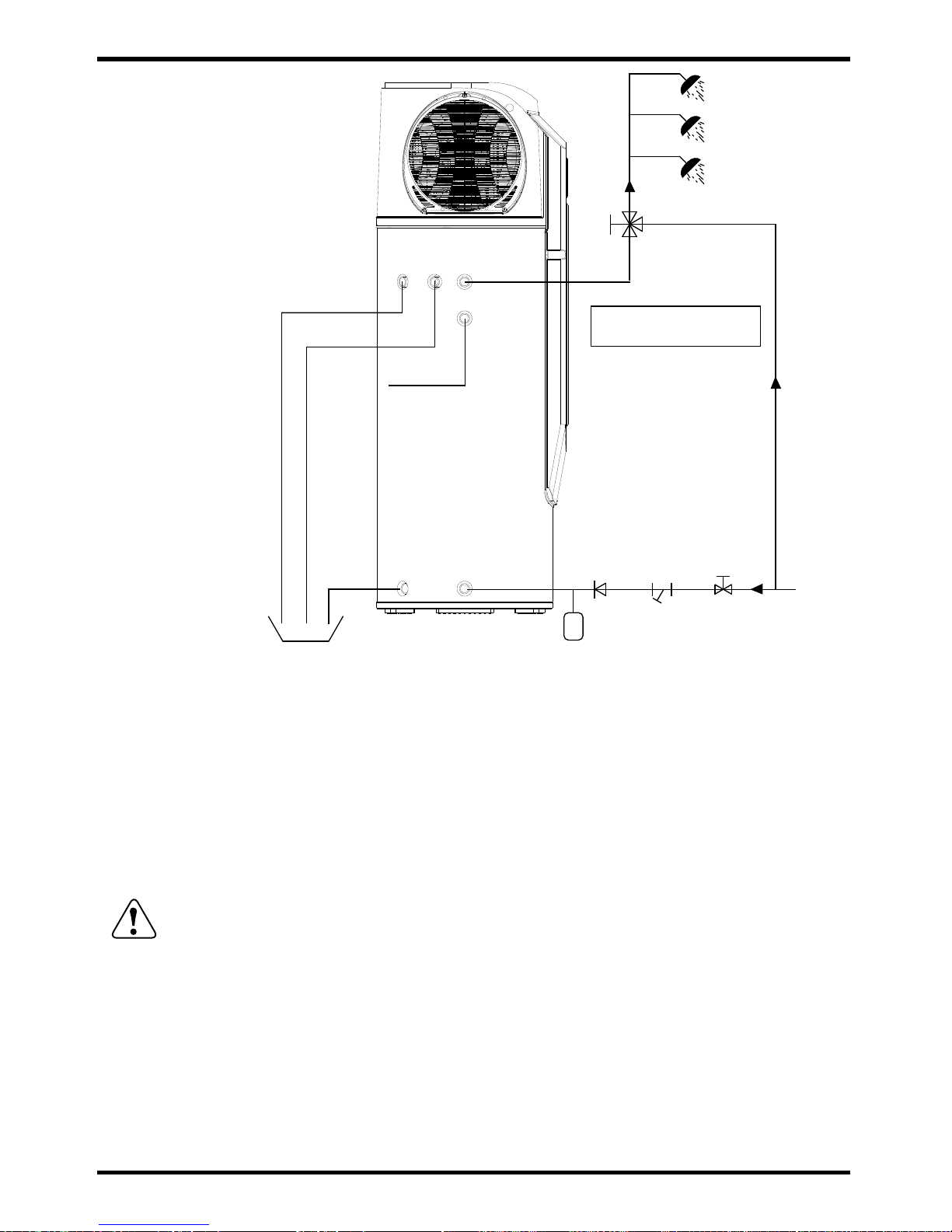

4.1 Pipeline connection sketch

4. Installation

7

Sanitech high temp sanitization

The Evoheat 270 is fitted with Sanitech. the Sanitech system will heat the tank water to 70

degrees for one 30min period every week at midnight. Please be aware of very high

temperature water outlet at this time.

8

4.1 Pipeline connection sketch

4. Installation

Picture 4

ATTENTION

Pipeline connection explanation

Installation of the water inlet or outlet pipes: The specification of the water inlet and

outlet thread is BSP3/4”(internal thread).Pipes must be heat-resistant and durable.

Installation of the pipe for P&T valve: The spec of the valve connecting thread is

BSP3/4”(internal thread).After installation, please confirm that the plumbing outlet is

exposed to the air. When flexible plumbing is connected to the pressure relief

outlet of this valve, please confirm that the plumbing is vertical and exposed to the

air.

Water Inlet

Y-shaped Filter

Tap Water

Thermal expansion tank

(if required)

Barrel-drain

Drainpipe

Condensate Outlet

P&T Valve

Water Outlet

Notice:

Tempering valve required

Magnesium

Anode

ATTENTION: The P&T valve attached to the unit MUST be installed, or it will cause

damage to the unit and pose a serious risk to passersby.

Installation MUST comply with AS/NZS3500.4 and all other relevant Australian

Standards and Industry Codes.

Do not use stainless steel fittings to connect directly with other metals to prevent

galvanic corrosion.

If installed outdoors all fittings and insulation must be weather resistant

.

9

4. Installation

4.2 Freight and Transportation

As a rule, the unit should be stored and/or transported in its shipping container in an upright

position and without water charge. For transport over short distances, and provided due care

is exercised, an inclination angle of up to 30 degrees is permitted. During transport and

storage, ambient temperatures of - 10 to +60deg C are permissible.

4.2.1 Transport using a forklift

When transported by a fork lift, the unit must remain mounted on the pallet. The lifting speed

should be kept to a minimum. Due to its top-heaviness, the unit must be secured against

tipping over. To prevent any damage or injury, the unit must be placed on a level surface.

4.2.2 Manual transport

For the manual transport, the wooden pallet can be used for bottom part.

Using ropes or carrying straps, a second or third handling configuration is possible. With this

type of handling, care must be taken that the maximum permissible inclination angle of 60

degrees is not exceeded. If transport in an inclined position cannot be avoided, the unit should

be left to rest at least one hour after it has been moved into final position before operation.

CAUTION! High center of gravity, Place on a level surface!

Picture 5

4. Installation

Before installation, please ensure that you leave space as shown below for maintenance

The unit must be installed on the ground on a solid level surface capable of holding the full weight of

the unit.

4.2A Recommended household size

The below recommendations are based on heat pump only mode.

Higher occupancy levels are able to be achieved with the

Hydroboost heater activated

Notice: High usage of hot water and other factors could affect this

recommendation.Please consult your dealer if you have special requirements.

Household Size

Up to 6 people

model

Evoheat 270

Loading...

Loading...