Page 1

Installation and Instruction Manual

Inverter Air Source Water Heat Pump

Floor heating and Air-con Unit

Hero Series Manual

Page 2

CONTENT

1 Preface

1

3 Specification

5

(3

) Specification data

6

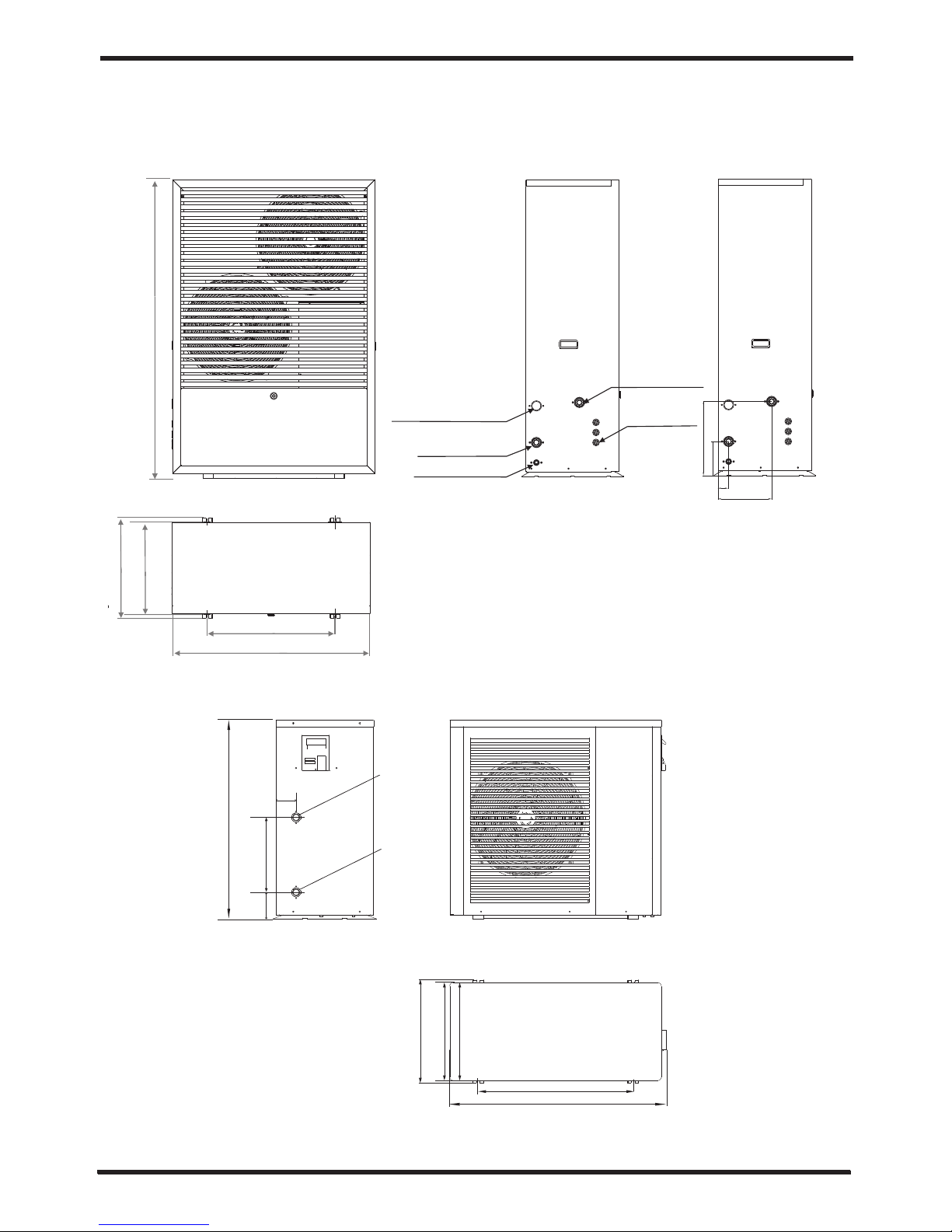

(4) Unit Dimension

7

8

4 Installation

9

12

5 Usage

7 Appendix

22

25

2 Safety Precaution

2

(1) Mark notes

2

(2) Icon Notes

2

(3) Warning

3

(1) Nomenclature of the heat pump

(2) Appearance and Structure of the heat pump

5

5

8

9

9

10

10

1

1

11

12

14

24

24

26

27

10

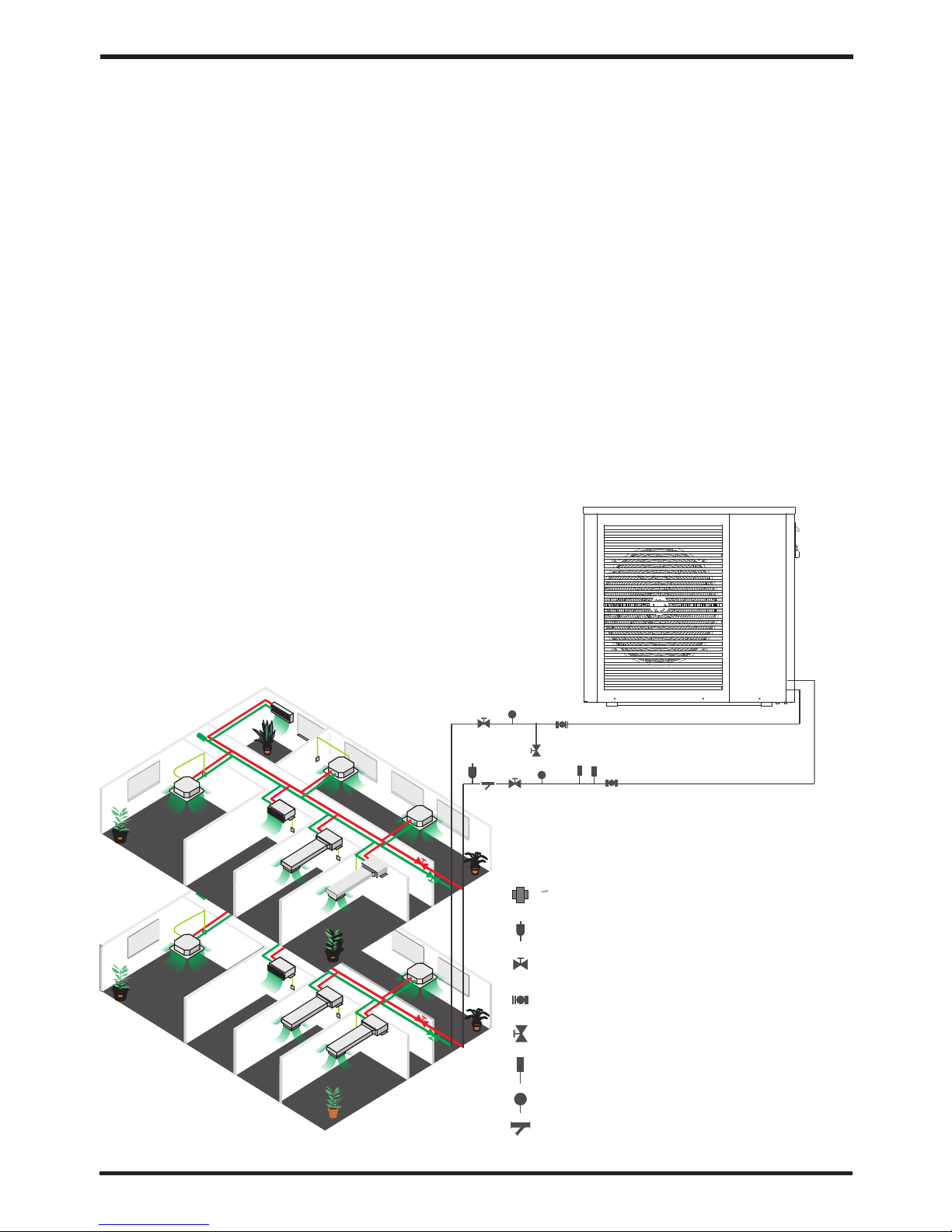

(1) Application of heat pump

(2) Choose a right heat pump unit

(

3) Installation place

(4) Installation method

(

5) Water loop connection

(

6) Power supply connection

(

7) Location of the unit

(8) Transit

(9) Trial Running

(1) Interface

(3) Usage Of Wire Controller

6 Maintenance

(1) Appendix 1

(2) Appendix 2

(

3

) Appendix 3

(

4) Appendix 4

(

5) Appendix 5

(

6) Appendix 6

(

7) Appendix 7

(4) Attention

4

(1) Fault code

(2) Failure and Solution

(5) Electronic Control Error Table

(4) Error Interface

18

20

22

23

26

28

29

4 Quiet running

High quality and efficient compressor, fan and water pump is used to ensure the lo w

noise level with insulation.

5 Good heat exchange rate

Failure to comply with these recommendations will invalidate the warranty.

2 Nice appearance

pump included which is very easy for installation.

3 Flexible installation

1 Advanced controlling

running parameters of the heat pump. Centralized co ntrolling system can control several

units by PC.

It is vital that the below instructions are adhered to at all times to k eep the warranty.

6 Large working range

as -15 degrees for heating.

Preface

12

(2) Function and Display Icon

(6) Controller interfaces and definitions

21

Page 3

The manufacture of this product will not be held responsible if someone is injured or

the unit is damaged, as a result of improper installati on, debugging, unnecessary

maintenance which is not in line with this man ual.

This manual includes all the necessary inf ormation about installation, debugging,

discharging and maintenance. Please re ad this manual carefully before you open or

maintain the unit.

4 Quiet running

High quality and efficient compressor, fan and water pump is used to ensure the lo w

noise level with insulation.

5 Good heat exchange rate

The heat pump unit use special designed heat exchanger to enhance whole efficiency.

The unit must be installed by qualified pers onnel.

—The unit can only be opened or repaired by qualified installer or an authorised dealer.

—Use genuine standard spare parts only.

—Maintenance and operation must be carrie d out according to the recommended time and

frequency, as stated in this manual.

Failure to comply with these recommendations will invalidate the warranty.

2 Nice appearance

The heat pump is designed with beautiful looking. The monobloc one has the water

pump included which is very easy for installation.

3 Flexible installation

The unit has smart structure with compact body, just simple outdoor installation is needed.

This series of heat pump unit owns following features:

1 Advanced controlling

The PC microcomputer based controller is available for the users to review or s et the

running parameters of the heat pump. Centralized co ntrolling system can control several

units by PC.

It is vital that the below instructions are adhered to at a ll times to keep the warranty.

Inverter ir ource ater eat umpa s w h p is a kind of high efficiency, energy saving and

environment friendly equipment, whic h is mainly used for house warming. It can work with

any kind of indoor unit such fan coil, radiato r, or floor heating pipe, by provide warm or hot

water. One unit of monobloc heat pump can also wo rk with several indoor units.

The air source water heat pump unit is designe d to have heat recovery by using super

heater which can provide hot water for sanit ary purpose.

6 Large working range

This series of heat pump is designed to work under different working conditions as low

as -15 degrees for heating.

In order to provide the customers with high quality, strong reliability and good versatility

product, this heat pump is produced by strict design an d manufacture standards.

Preface

1

Page 4

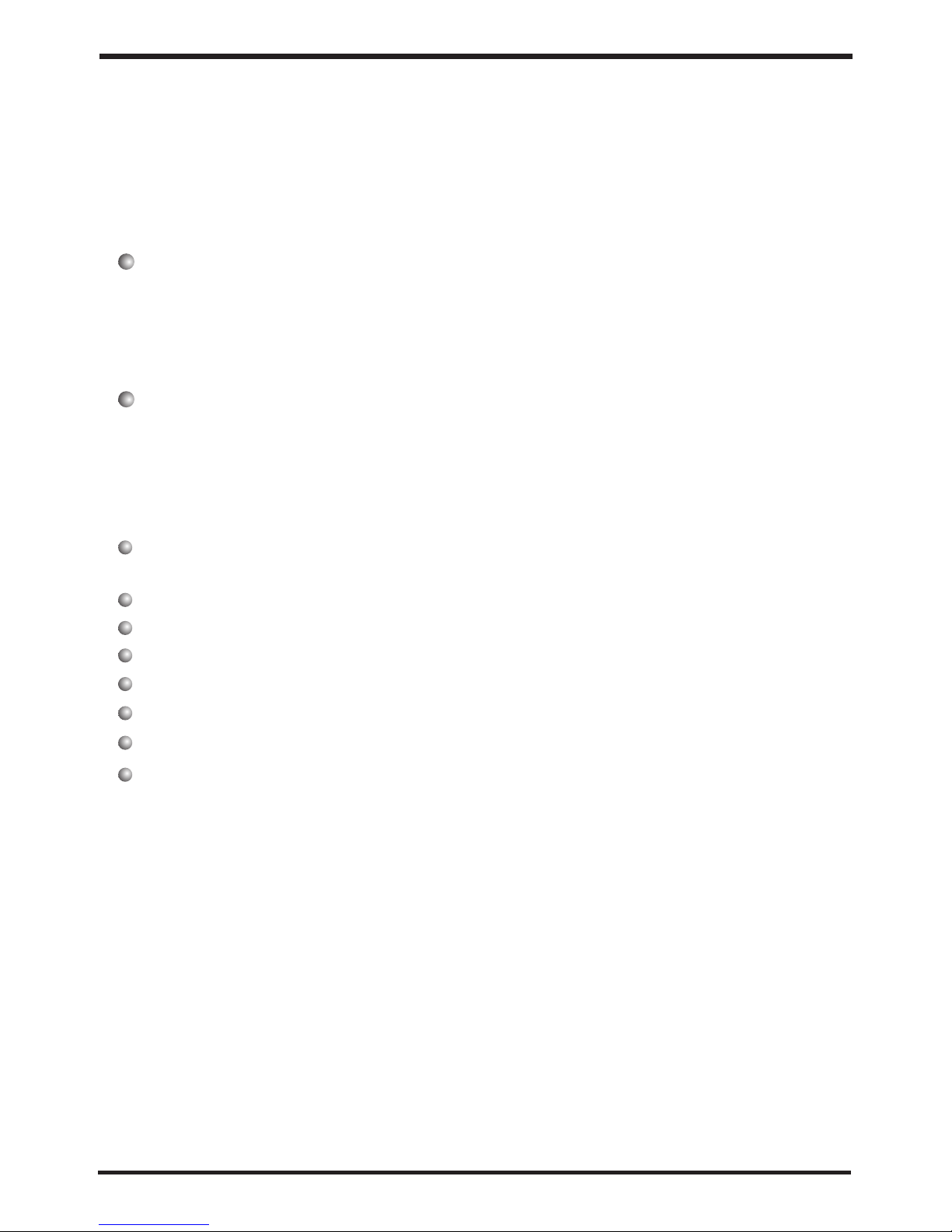

Safety Precaution

Mark

Icon

Meaning

Meaning

A wrong operation may lead to death or heavy injury on people.

A wrong operation may lead to harm on people or loss of material.

Prohibition. What is prohibited will be nearby this icon

Compulsory implement. The listed action need to be taken.

ATTENTION (include WARNING)

Please pay attention to what is indicated.

Mark Notes

Icon notes

WARNING

ATTENTION

To prevent the users and others from the harm of this unit, and avoid damage

on the unit or other property, and use the heat pump properly, please read this

manual carefully and understand the following information correctly.

Safety Precaution

2

Page 5

安装前注意事项

The heat pump must be installed by qualified personals,

to avoid improper installation which can lead to water

leakage, electrical shock or fire.

Please make sure that the unit and power connection

have good earthing, otherwise may cause electrical shock.

Installation

Professional installer

is required.

Earthing is required

Warning

Safety Precaution

Meaning

Operation

Meaning

PROHIBITION

Shut off the power

DO NOT put fingers or others into the fans and evaporator

of the unit, otherwise harm may be occurred.

When there is something wrong or strange smell, the power

supply need to be shut off to stop the unit. Continue to run

may cause electrical short or fire.

Move and repair

Entrust

Prohibit

Entrust

When the heat pump need to be moved or installed again,

please entrust dealer or qualified person to carry it out.

Improper installation will lead to water leakage, electrical

shock, injury or fire.

It is prohibited to repair the unit by the user himself, otherwise

electrical shock or fire may be occur.

When the heat pump need to be repaired, please entrust

dealer or qualified person to carry it out. Improper movement

or repair on the unit will lead to water leakage, electrical

shock, injury or fire.

Meaning

3

Page 6

Switch off

the power

Prohibition

Please switch off the power for clean or maintenance.

It is prohibited to use copper or iron as fuse. The right fuse

must be fixed by electrician for the heat pump.

It is prohibited to spray the flammable gas to the heat pump,

as it may cause fire.

Installation

Operation

Prohibition

安装前注意事项

ATTENTION

Check the

installation basement

Please check the installation basement in a period (one month),

to avoid any decline or damage on the basement, which may

hurt people or damage the unit

Safety Precaution

Meaning

Fix the unit

Installation Place

Need

circuit breaker

The unit CANNOT be installed near the flammable gas.

Once there is any leakage of the gas, fire can be occur.

Make sure that the basement of the heat pump is strong

enough, to avoid any decline or fall down of the unit

Make sure that there is circuit breaker for the unit, lack of

circuit breaker can lead to electrical shock or fire.

Meaning

4

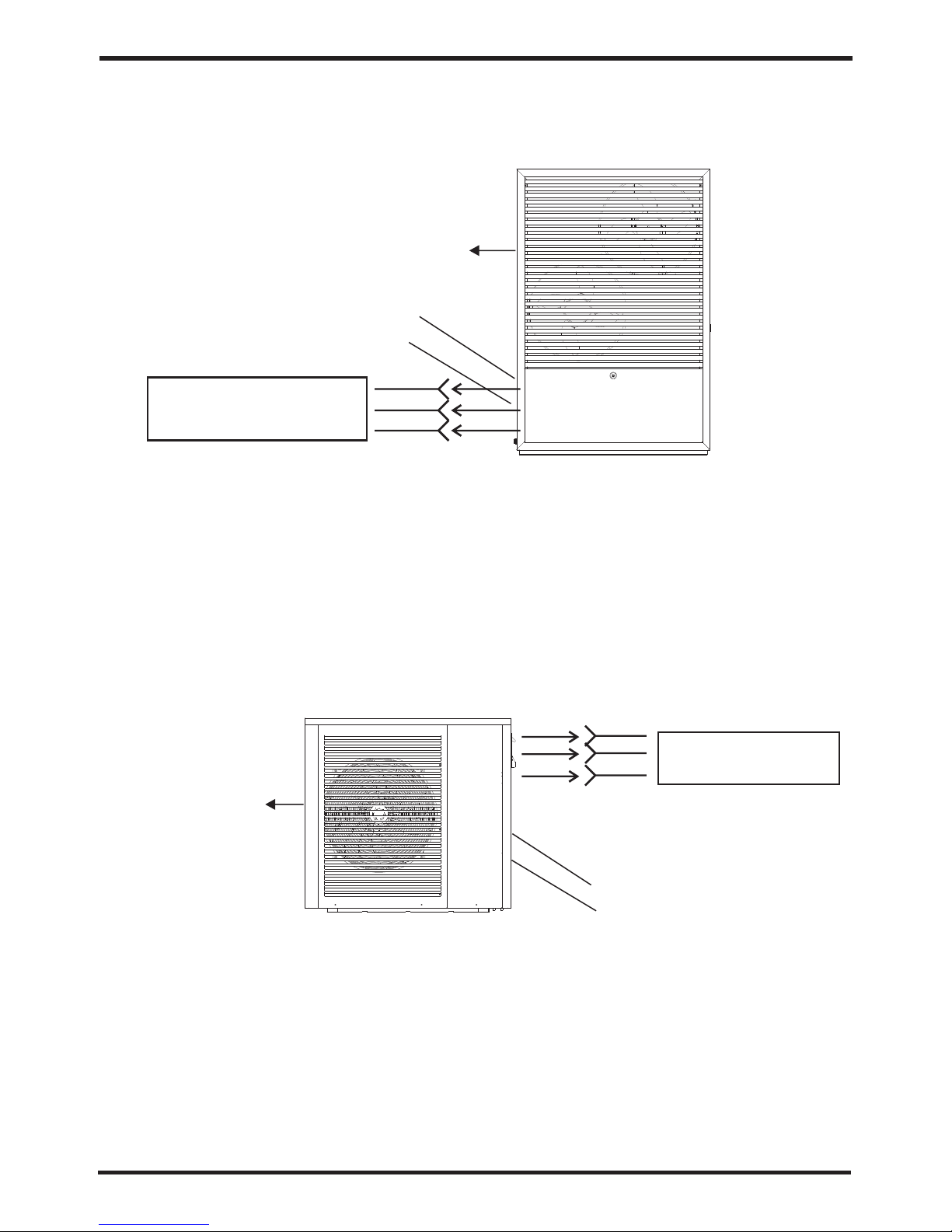

Specification

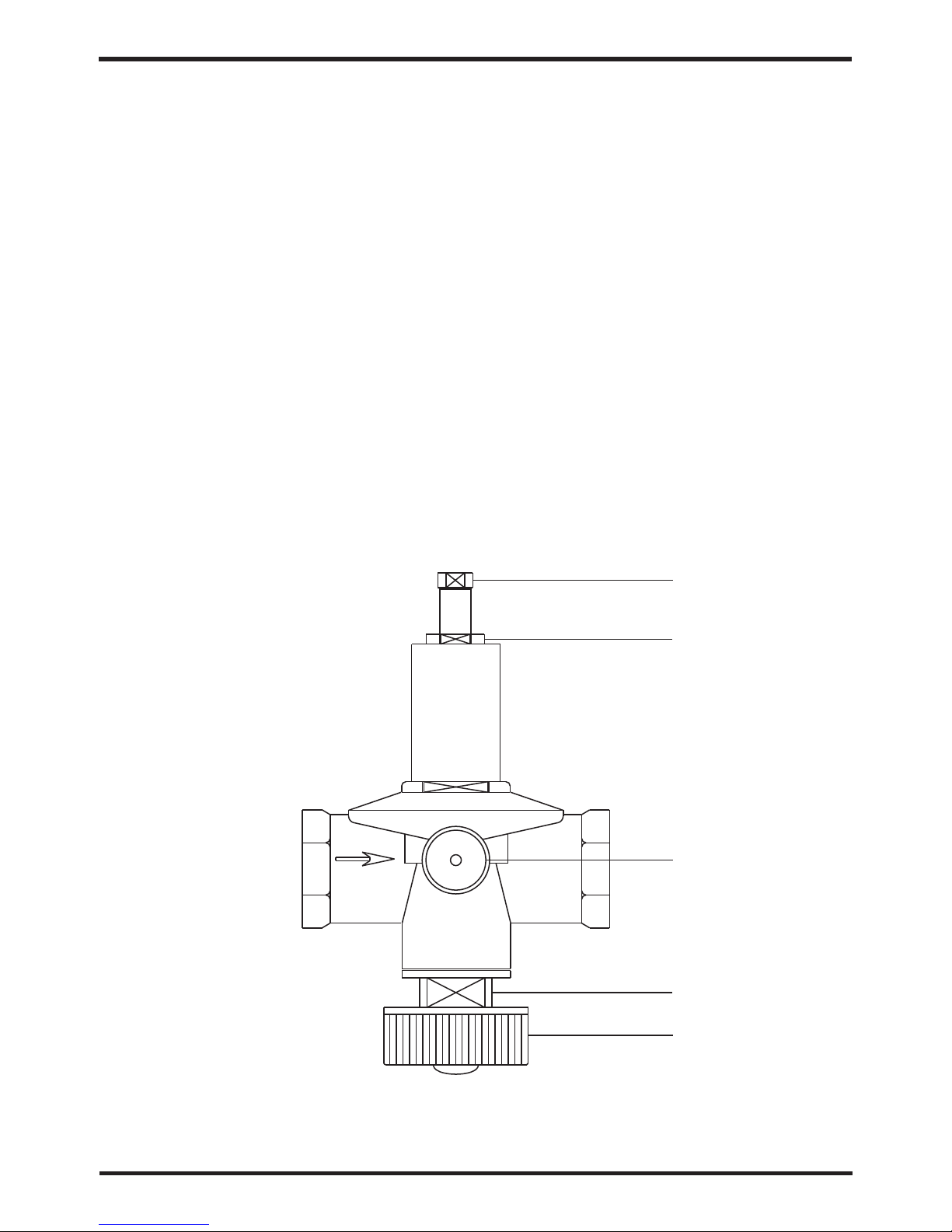

1. Appearance and Structure of the heat pump

The longest distance of installing the

remote controller is 200 meters.

Air outlet in horizontal

direction

Page 7

Specification

1. Appearance and Structure of the heat pump

The longest distance of installing the

remote controller is 200 meters.

Air outlet in horizontal

direction

Water intlet tube

Remote Controller

(Manually)

Water outlet tube

5

Air outlet in horizontal

direction

Water outlet tube

Water intlet tube

The longest distance of installing the

remote controller is 200 meters.

Remote Controller

(Manually)

H15A

H8A

Page 8

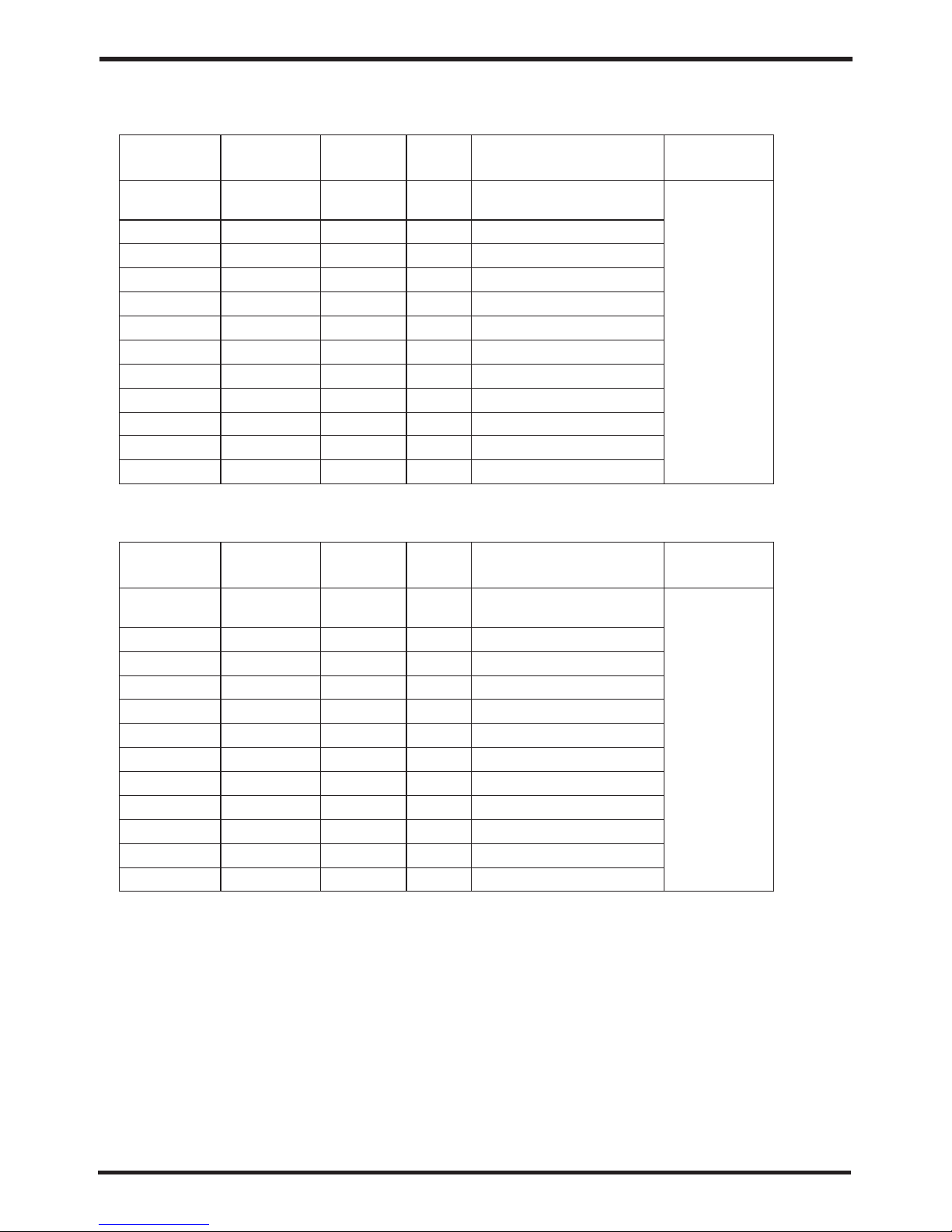

2. The data of unit

Specification

Cooling working condition:(DB/WB)3 5℃/24℃, (Outlet/Inlet) 7℃/12℃.

Heating working condition: (DB/WB) 7℃/6℃. (Outlet/Inlet) 35℃/3 0℃.

BS EN 14511-1-2013 Air conditioner, whole liquid cooling machine, e lectric compressor.

Part2: Test condition Part3:Test method Part4:related requirements.

6

Model

Cooling Capacity

Heating Capacity

Electric Heating Power

Cooling Power Input

Heating Power Input

Operation Electric Current(cooling /heating)

Cooling Capacity Range

Heating Capacity Range

Cooling Power Input Range

Heating Power Input Range

Power Supply

Compressor Quantity

Compressor Model

Fan Quantity

Fan Power Input

Fan Rotate Speed

Noise

Water Pump Input

Max water head

Water Connection

Water Flow Volume

External Pressure

Unit Net Dimensions (L/W/H)

Unit Shipping Dimensions (L/W/H)

Net Weight

Shipping Weight

kW

BTU/h

kW

BTU/h

kW

kW

kW

A

kW

kW

kW

kW

W

RPM

dB(A)

kW

m

inch

3

m /h

m

mm

mm

kg

kg

H15A

10

34000

15

51000

3.0

3.1

3.1

14.1/14.1

6.0~15.0

6.0~18.0

1.6~6.0

1.6~7.0

230V~/50Hz

1

Scrolll

2

110×2

850

58

0.18

12.5

1 1/4

2.5

10

1000*465*1475

1050*510*1500

See nameplate

See packa ge label

H8A

7

23800

9

30600

3.0

2.6

2.6

11.8/11.8

2.0~10

2.5~11.5

1.0~3.4

0.8~3.4

230V~/50Hz

1

Rotary

1

110

850

54

0.18

12.5

1

1.6

10

980*465*900

1010*490*920

See nameplate

See packa ge label

Specification

505

Page 9

7

3 Unit dimension

Specification

Mode ls: H15 A

1000

505

465

647

1475

Wat er inl et 1 1/4' '

Con densa te outl et 1 1/4' '

Wat er outl et 3/4' '

Wat er outl et 1 1/4' '

Wat er pump w ire

369 .5

170

266 .5

51.5

7

Mode ls:H8A

Wat er outl et 1''

Wat er inl et 1''

980

700

465 440

900

338

121

90

Page 10

4 Installation method

2 Choose a right heat pump unit

2.1 Based on the local climate condition, co nstruction features and insulation level,

calculate the required cooling(heati ng) capacity per square meter.

2.2 Conclude the total capacity which will b e needed by the construction.

2.3 According to the total capacity needed, c hoose the right model by consulting the heat.

pump features as below:

Heat pump features

Cooling only unit: chilled water outlet tem p. at 5-15 , maximum ambient temp. at 43 .

Heating and Cooling unit:for cooling chilled water outlet temp. at 5-15 ,maximum

ambient temp. at 43 . For heating, warm water inlet temp . at 40-50 , minimum ambient

temp. at -10 .

Unit application

a s w h p is used for house, office, hotel, and so forth, which

need heating or cooling separately, with each area need to be control led.

The unit can be installed on any place outdoor which can carry heavy mac hine such

as terrace, housetop, ground and so on.

3 Installation place

Installation

Installation

1 Application of heat pump

1.1 Only for air-con

WATER COUPLING

AUTOMATIC AIR VENT

CHECK-VALVE FOR WATER

FLEXIBLE CONNECTION FOR WATER

DIRTY DRAI N

WATER THERMOMETER

WATER PRESSURE METER

WATER FILTER

8

1. Plate heat exchanger

Use the SWEP efficient heat exchanger with small size a nd high efficiency.

2.Environmentally friendly refrigerant

Use the new generation of environmentall y friendly refrigerant R410, which is harmless to

the ozone sphere.

3. Heating in frigid environment.

Optimized designed unit can achieve the he ating function normally even when the ambient

temperature is -15℃.

4. Spraying condensation

The water-cooling system will be opened automatically to guarantee the normal operation

of cooling when the ambient temperature is higher than 30℃.

Unit features

Page 11

4 Installation method

The heat pump can be installed onto the concrete basement by expansi on screws, or

onto a steel frame with rubber feet which can be p laced on the ground or housetop.

Make sure that the unit is placed horizontal ly.

2 Choose a right heat pump unit

2.1 Based on the local climate condition, co nstruction features and insulation level,

calculate the required cooling(heati ng) capacity per square meter.

2.2 Conclude the total capacity which will b e needed by the construction.

2.3 According to the total capacity needed, c hoose the right model by consulting the heat.

pump features as below:

Heat pump features

Cooling only unit: chilled water outlet tem p. at 5-15 , maximum ambient temp. at 43 .

Heating and Cooling unit:for cooling chilled water outlet temp. at 5-15 ,maximum

ambient temp. at 43 . For heating, warm water inlet temp . at 40-50 , minimum ambient

temp. at -10 .

℃ ℃

℃

℃ ℃

℃

Unit application

a s w h p is used for house, office, hotel, and so forth, which

need heating or cooling separately, with each area need to be control led.

Inve rter ir ource a ter eat ump

There must be enough space around the unit for maintenance.

The place is free from heat radiation and othe r fire flame.

There must be not obstacles near the air inlet a nd outlet of the heat pump.

A place which is free from strong air blowing.

There must be water channel around the heat pu mp to drain the condensing water .

The location must have good ventilation.

The unit can be installed on any place outdoor which can carry heavy mac hine such

as terrace, housetop, ground and so on.

A pall is needed in winter to protect the heat pump from snow.

3 Installation place

Installation

9

Page 12

Installation

9 Trial Running

8 Transit

When the unit need to be hung up during installa tion, a 8

meters cable is needed, and there must be soft material

between the cable and the unit to prevent dama ge to

the heat pump cabinet. (See picture 1)

DO NOT touch the heat exchanger of the heat pump with fingers or other objects!

5 Water loop connection

Please pay attention to below matters when the water pipe is connected:

Try to reduce the resistance to the water from the piping.

The piping must be clear and free from dirty and b locks. Water leakage test must be

carried out to ensure there is no water leakin g. And then the insulation can be made.

Attention that the pipe must be tested by pressure separately. DO NOT test it together

with the heat pump.

The flow switch is installed inside of the hea t pump, check to ensure that the wiring and

action of the switch is normal and controlle d by the controller.

Try to avoid air stayed inside of the water pipe, and there must be air vent on the top

point of the water loop.

There must be thermometer and pressure met er at the water inlet and outlet, for easy

inspection during running.

There must be expansion tank on the top point of t he water loop, and the water level in

the tank must be at least 0.5 meter higher than the top point of the water loop.

6 Power supply connection

Open the front panel, and open the power supply access.

If the outside water pump is needed, please insert the power supply wire into the wire

access also and connect to the water pump term inals.

The power supply must go through the wire acce ss and be connected to the power

supply terminals in the controlling box. Then connect the 3-sign al wire plugs of the

wire controller and main controller.

If an additional auxiliary heater is need to be controlled by the heat pump controller,

the relay (or power) of the aux-heater must be c onnected to the relevant output of

the controller.

7 Location of the unit

Installation

。

The minimum ventilation distance in diag ram 1.

A

B

Barrier

Barrier

Air Inlet

Air Outlet

C

D

Barrier

Maintenance

Space

Barrier

The picture shows the location of horizontal air outlet unit.

Requirements

A>500mm; B>1500mm;

C>1000mm;D>500mm

!

Attention

10

Page 13

Installation

Inspection before trial running

Check the indoor unit, and make sure that the pipe connection is right and the relevant

valves are open .

Check the heat pump unit including all of the sc rews and parts of the heat pump to see if

they are in good order. When power on, review the i ndicator on the controller to see if

there is any failure indication. The gas gauge can be connected to the check valve to

see the high pressure(or low pressure) of th e system during trial running.

Check the water loop, to ensure that the water inside of th e expansion tank is enough, the

water supply is good, the water loop is full of wa ter and without any air. Also make sure

there is good insulation for the water pipe.

Check the electrical wiring. Make sure tha t the power voltage is normal, the screws are

fastened, the wiring is made in line with the di agram, and the earthing is connected.

Trial running

Start the heat pump by press " " key on the controller. Check whether the w ater pump is

running, if it runs normally there will be 0.2 M Pa on the water pressure meter.

When the water pump runs for 1 minutes, the compressor wi ll start. Hear whether there is

strange sound from the compressor. If abnormal sound occurs please stop the unit and

check the compressor. If the compressor runs well please look for the pressure meter

of the refrigerant.

9 Trial Running

Then check whether the power input and runni ng current is in line with the manual. If not

please stop and check.

Review whether the outlet water temperat ure is stable.

The parameters of the controller are set by the factory, it is not allowed to change then

by user himself.

Adjust the valves on the water loop, to make sure that the ho t(cool) water supply to each

door is good and meet the requirement of heati ng(or cooling).

8 Transit

When the unit need to be hung up during installa tion, a 8

meters cable is needed, and there must be soft material

between the cable and the unit to prevent dama ge to

the heat pump cabinet. (See picture 1)

WARNING

DO NOT touch the heat exchanger of the heat pump with fingers or other objects!

Picture 1

11

Page 14

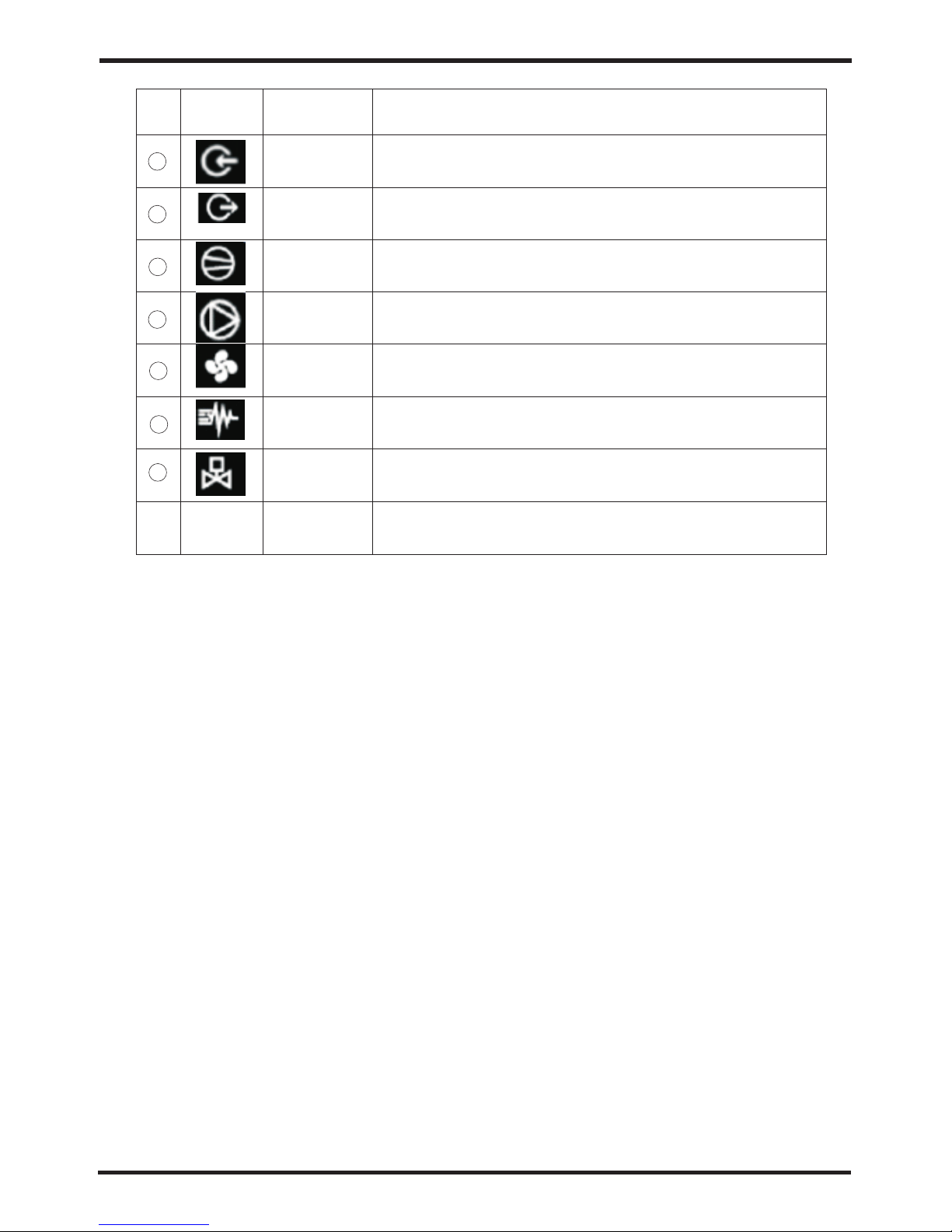

Usage

1.Interface

2.Function and Display Icon

NO.

Icon

Key name

Key functions

1

2

3

4

On/Off

Mode

Up

Down

Long press "Mode", to switch between cooling

and heating

In the state of defrosting, the icon Def is on

In the state of cooling, the icon Cool is on

In the state of heating, the icon Hot is on

5

Fan Speed

Short press "Fan Speed", to enter the Query interface

6

7

8

In OFF state, long pr ess "ON/OFF", to en te r the Startup inter fa ce

In ON state, long pre ss " ON/OFF", to ent er t he Shutdown inter fa ce

Short press "UP", to modify the temperature or clock

Short press "DOWN", to modify the temperature or clock

12

Cooling

Heating

Def

Usage

Page 15

Usage

13

NO.

Icon

Key name

Key functions

9

10

Outlet

Electric

Heating

4-way valve

Outlet icon

When the Electric Heating starts up, in the main

display area, the Electric Heating status icon i s on , an d

when the Electric Heating shuts down, the icon is off.

When the 4-way valve starts up, in the main display ar ea ,

the 4-way valve status icon is on, and when the 4-way

valve shuts down, the icon is off.

Inlet

Inlet icon

Compressor

When the compressor starts up, in the main display

area, thecompressor status icon is on, and when

the compressor shuts down, the icon is off.

Pump

When the Pump starts up, in the main display area, the

Pump status icon is on, and when the Pump shuts down,

the icon is off.

Fan

When the Fan starts up, in the main display area, the

Fan status icon is on, and when the Fan shuts down,

the icon is off.

11

12

13

14

15

Page 16

14

Usage

3.Usage Of Wire Controller

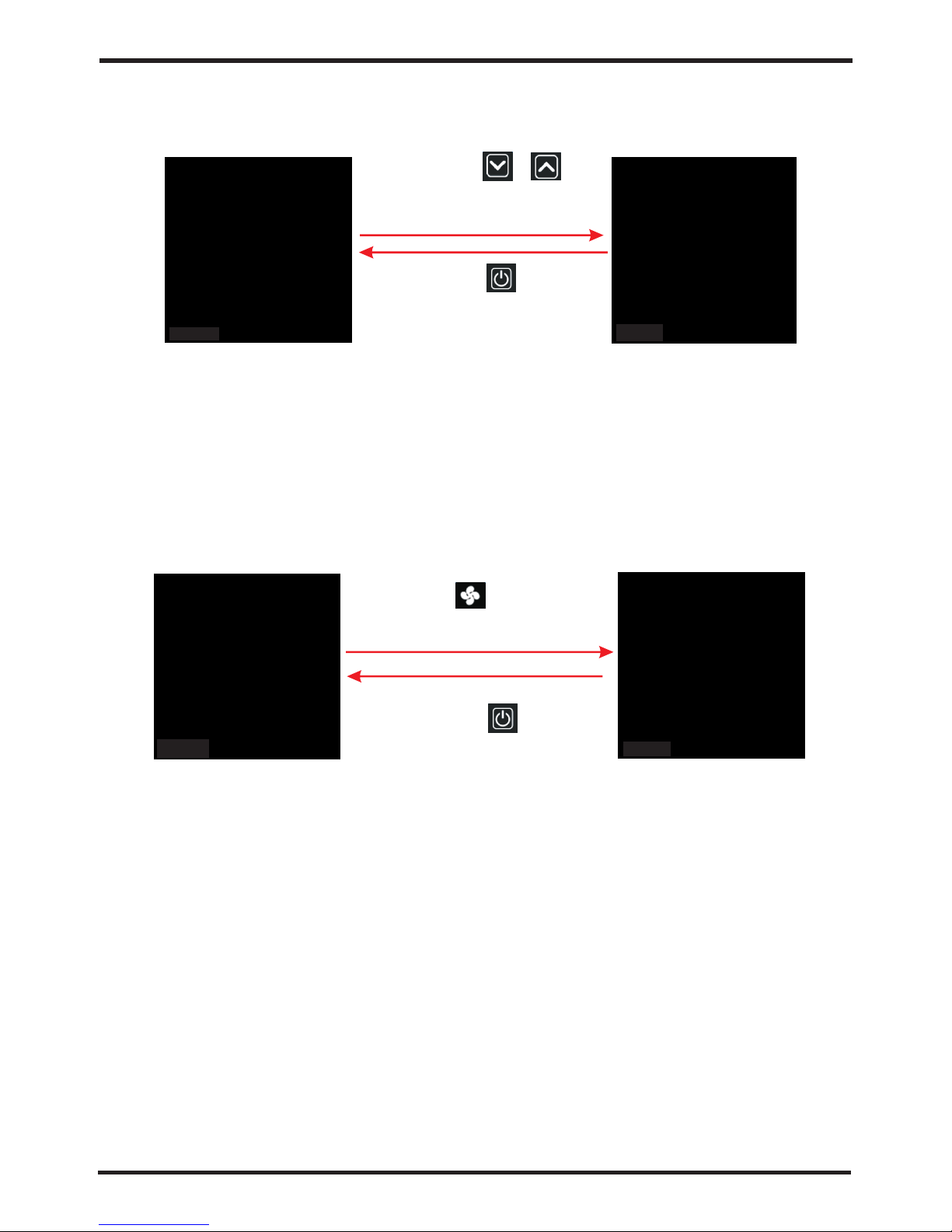

3.1 Startup & Shutdown

Note: the Startup & Shutdown operation can only be performed in the main interface.

1

enter the S tartup

interfa ce

Long pres s for

second to

For 1 minut e without

operati on, scree n out

Short pre ss any key,

back to the S tartup

interfa ce

3.2 Mode

In the main interface, long press for " "1 second, to switch between t he cooling

and heating modes.

Cooling Interface

Heating Interface

Note: 1) Without Thermostat, wired controller can be used for Startup & Shutdown;

2) With Thermostat, wired controller can only be used for Shutdown, and cannot

be used for Startup;

3) When using the remote control, wired controller is shown as below:

Startup Interface

Shutdown Interface

Def Interface

(heating mode only)

1

enter the S hutdown

interfa ce

Long pres s for

second to

Usage

Note: In the temperature setting interface, for 20 seconds without operation, the system

will automatically record the setting, and back to the main inte rface.

Page 17

15

Usage

Set tempe rature fl ashing

Note: In the temperature setting interface, for 20 seconds without operation, the system

will automatically record the setting, and back to the main inte rface.

Note: In the query parameter interface, it cannot automatically back to the main interface.

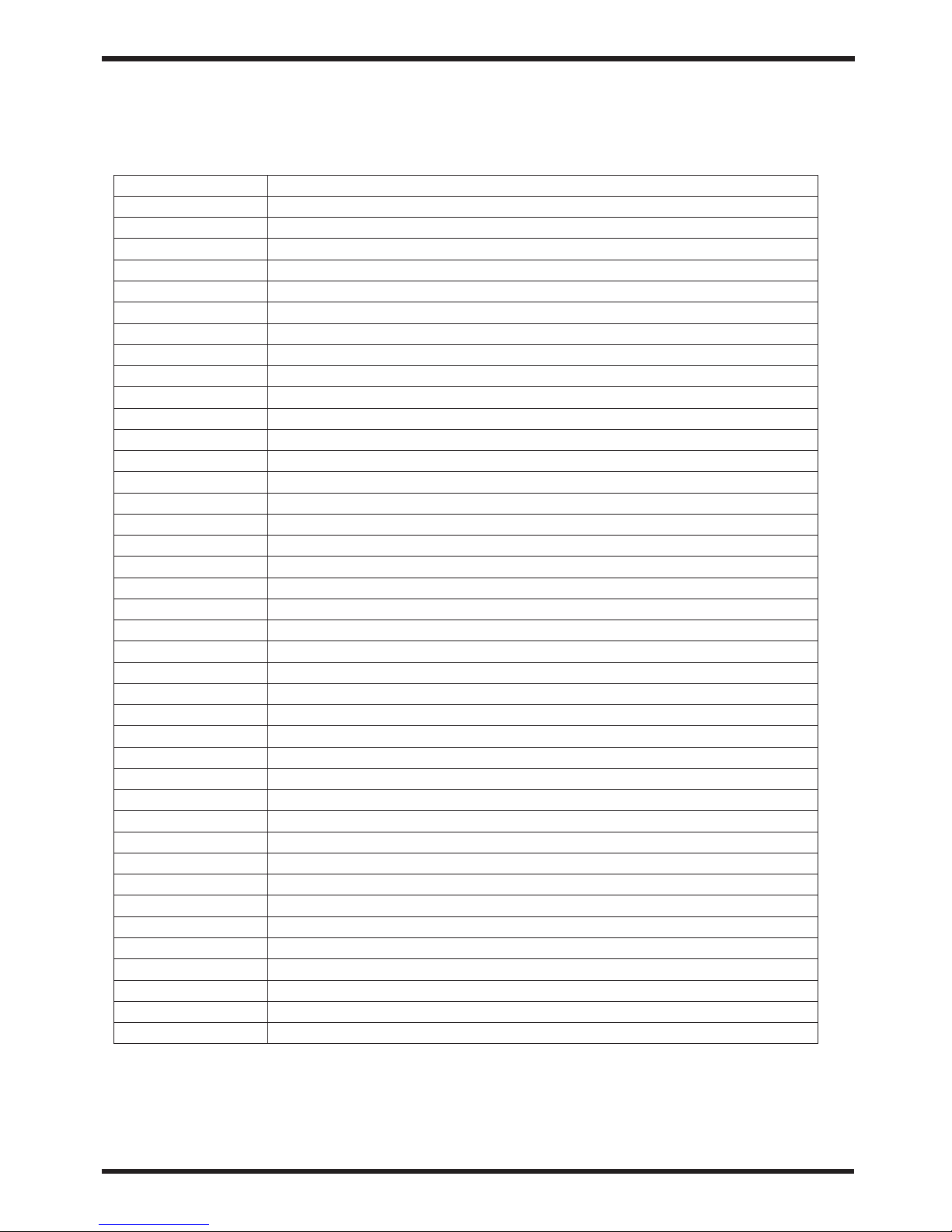

3.3 Temperature

Short press or to

enter thetemperature

setting interface

Short press , back

and save

3.4 State parameter query

Short press ,

to enter the Query interface;

Short press

Page 18

16

3.5 State query list:

Usage

State No

U01

U02

U03

U04

U05

U06

U07

U08

U09

U10

U11

U12

U13

U14

State Name

Inlet Temperature

Outlet Temperature

Suction Temperature

Discharge Temperature

Ambient Temperature

Coil Temperature

Low Pressure

High Pressure

Electronic Expansion Valve Steps

Compressor Actual Frequency

Compressor Setting Frequency

Suction gas Superheating/10

Discharge gas Superheating

Fan 1 Set Speed

U15

Fan 2 Set Speed

Usage

Note: In the clock setting interface, for 20 seconds without operation, the system

will automatically record the setting, and back to the main inte rface.

3.6 Clock Setting

3.6.1 Time Setting

3.6.2 Set and cancel the timing

(if connected to the thermostat, the timing function is not available)

Page 19

17

Usage

Note: In the clock setting interface, for 20 seconds without operation, the system

will automatically record the setting, and back to the main inte rface.

3.6 Clock Setting

3.6.1 Time Setting

Long press +

at the same time for

two seconds

Short press

for flashing by

the hour

Short press or

to change flashing

by the hour

Short press

for flashing by

the minute

Short press or

to change flashing

by the minute

Short press

back to the main interface

3.6.2 Set and cancel the timing

(if connected to the thermostat, the timing function is not available)

Long press

to enter "ON1" time

setting interface "ON1"

time setting interface

Short press

to enter " OFF1"

time setting

interface

Short press

for flashing by the hour

to enter "ON1" hour setting

Short press

or to set hour

For flashing by the hour

or the minute

short press

to cancel "ON1" timing

Short press again

Page 20

18

4 Error Interface

Usage

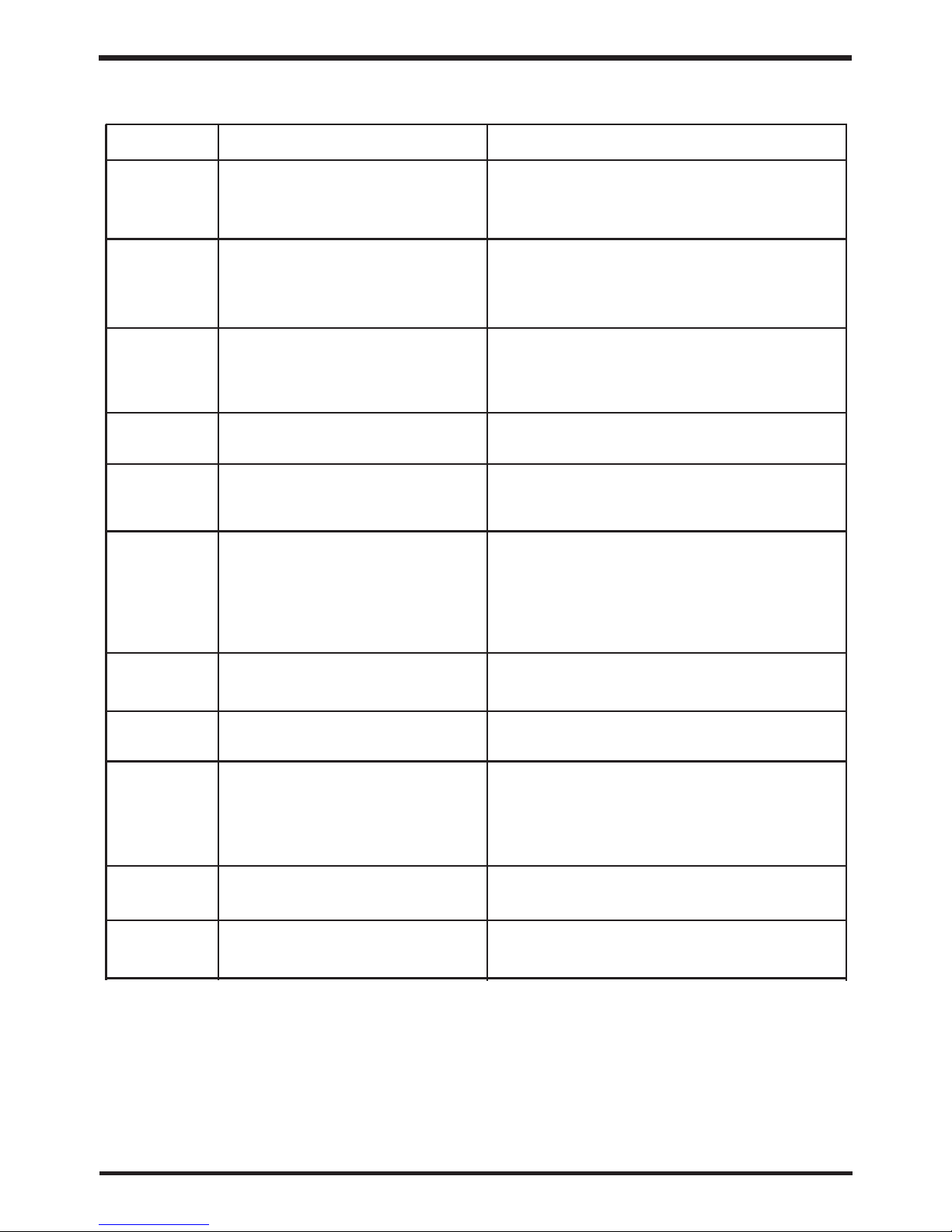

Error Code

Note:

On the Error Interface, short press "ON/OFF", back to the main interface, a nd short press

"UP" or "DOWN" to display multiple errors.

On the main interface, short press "ON/OFF" to back to the Error Interface. For 10

seconds without operation, automatically back to the Error Interface.

1).

2).

4.1 Interface

Error No.

Error Quantiy

Usage

5 Electronic Control Error Table

Page 21

19

Usage

We can use Error Code to find the cause and the solution.

Protection/Error

Error Code

Standby

Normal Startup

Inlet Temperature Error

Outlet Temperature Error

Ambient Temperature

Suction Temperature Error

Discharge Temperature Error

Low Pressure Sensor Erro

High Pressure Sensor Erro

High Pressure Protection

Low Pressure Protection

Flow Switch Protection

Winter Def Protection I

Winter Def Protection II

Def Protection

Dischange High Temperature Protection

Pump Working Environment Protection

AC Input low voltage protection

AC Input over-current protection shutdown

AC Input over-current protection alarm

None

P01

P02

P04

P07

P08

PP1

PP2

E01

E02

E03

E19

E20

E07

P81

E44

E21

E22

E23(blank)

5 Electronic Control Error Table

None

DC bus over-voltage protection

DC bus low-voltage protection

IPM over-current protection

IPM overheating protection

Radiator temperature sensor error

Power component overheating protection shutdown

Power component overheating protection alarm

IPM current sampling

Compressor over-current protection shutdown

Compressor over-current protection alarm

Input voltage phase

Compressor start-up error

Communication error between DSP and communication board

Communication error between DSP with PFC

Input voltage sampling

EEPROM Error

Compressor weak magnetic protection

PFC Error

Communication error between drive and ma in board

Communication error between main board a nd wired controller

E08

EE 8

E45

E41

E40

E39

E38

E37

E36

E35

E34(blank)

E33

E32

E31(blank)

E30

E29

E28

E27

E25

E24

Page 22

PC8002

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

N

L

RO 01

RO 02

RO 03

RO 04

RO 05

RO 06

RO 07

RO 08

RO 09

RO 10

RO 11

RO 12

RO 13

RO 14

RO 15

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

5V

12V

GND

485_B

485_A

CAN_L

GND

12V

CAN_H

12V

GND

485_B

485_A

CN

1

CN

2

CN7

CN3

CN

4

CN

9

DI5 _PWM

DO5 _PWM

DI4 _PWM

DO4 _PWM

DI3 _PWM

DO3 _PWM

DI2 _PWM

A02

DO2 _PWM

DI1 _PWM

A01

DO1 _PWM

DI1 0

DI0 9

DI0 8

DI0 7

DI0 6

DI0 5

DI0 4

DI0 3

DI0 2

DI0 1

AI2 2

AI2 1

AI2 0

AI1 9

AI1 8

AI1 7

AI1 6

AI1 5

AI1 4

AI1 3

AI1 2

AI1 1

AI1 0

AI0 9

AI0 8

AI0 7

AI0 6

AI0 5

20

6 Controller interfaces and definition s

Usage

6.1 Main bo ard interface s

Usage

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Page 23

AI0 8

AI0 7

AI0 6

AI0 5

AI0 4

AI0 3

AI0 2

AI0 1

Usage

21

D01-D 02_ PWM

DI0-D I2_ PWM

NO.

Main board Instruction

NO.

Main board Instruction

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

N

L

RO 01

RO 02

RO 03

RO 04

RO 05

RO 06

RO 07

RO 08

RO 09

RO 10-RO 18

AI 01

AI 02

AI 03

AI 04

AI 05

AI 06

AI 07

AI 08-AI 20

AI 21

AI 22

DI 01

DI 02

DI 03

DI 04

DI 05

DI 06

DI 07

DI 08-DI 10

A 01-A 02

12V

485-B

485-A

GND

CAN-L

CAN-H

CN1

CN2-CN4

Power Null Wire

Power Live Wire

Not Used

Pump

4-way valve

Fan

Not Used

Def Heating

Crankshaft Heating

Spray Valve

Auxiliary Electric Heating

Not Used

Inlet Temperature Sensor

Outlet Temperature Sensor

Discharge Temperature Sensor

Not Used

Suction Temperature Sensor

Coil Temperature Sensor

Environment Temperature Sens or

Not Used

Suction pressure input

Discharge pressure input

High voltage switch input

Low voltage switch input

Flow switch input

Emergency switch input

Mode Switch

Master and slave switch

Electri c heating o verload

protect ion switc h

Not Used

Not Used

Not Used

Not Used

Wired Controller 12V

Wired Controller 485-B

Wired Controller 485-A

Wired Controller GND

Not Used

Not Used

Electronic Expansion Valve A

Not Used

Page 24

22

A. Form of Troubleshooting

Check whe ther ther e is fault on

pressur e switch or r efriger ant loop

Check whe ther syst em compre ssor

is in norma l operati on

Protect ion/fau lt

Standby

Normal bo oting

Wat er inlet te mp. senso r error

Ambient tem p. sensor e rr or

Antifre ezing pro tection

Wat er flow pro tection

Cause

Wat er inlet te mp sensor i s in open

circuit o r short cir cuit

Check and rep lace temp . se nsor

Wat er outlet t emp senso r is in

open circ uit or shor t circuit

Ambient t emp senso r is in open

circuit o r short cir cuit

Check and rep lace temp . se nsor

Check and rep lace temp . se nsor

Way o f troublesh ooting

Abnormal co mmunica ti on betwee n

remote cont roller an d ma inboard

Flow is inade quate

Check wat er flow , and w hether

water sys tem is dama ged

Ambient tem peratur e is t oo low

Ambient tem peratur e is t oo low

There is no or li ttle wate r in w ater syst em

Check wat er flow , and w hether

water sys tem is dama ged

Fault

display

NO

NO

P01

P02

P04

P07

P08

High-pr essure pr otectio n

Low-pre ssure pro tection

E01

E03

E02

Suction t emp. sens or is in open

circuit o r short cir cuit

Check and rep lace temp . se nsor

Exhaust t emp. Sens or is in open

circuit o r short cir cuit

Check and rep lace temp . se nsor

High-pres sure swit ch i s disconn ec ted

Low-press ure switc h is d isconne ct ed

E07

E19

E29

Compresso r load is too l ar ge

Suction p ressure s ensor is in o pen

circuit o r short cir cuit

Exhaust p ressure s ensor is in o pen

circuit o r short cir cuit

Winter Le vel I antif reezing

protect ion

PP2

Input volta ge is too low, r es ulting in

too high inpu t current

Input curre nt is too hig h, e xceedin g

effec ti ve value fo r pr otectio n current hal t

DC bus voltag e>DC bus over vo ltage

halt pro tection val ue

DC bus voltag e<DC bus over vo ltage

halt pr otection va lue

IPM current i s too large

Temperature o f IPM modul e is t oo high

Sensor is in sh ort circu it o r open circ ui t

Temperature o f power com po nent is

too high

Fault of curr ent sampl in g

Compresso r current i s to o high

Input volta ge is in defa ul t phase

Default pha se, step ou t or h ardware

damage on act uator

Fault of DSP and commu ni cation bo ard

Fault of DSP and PFC

Fault of curr ent sampl in g

Chip error

Inadequat e magneti c fo rce of comp re ssor

Check and r eplace ex haust pre ssure

sensor

Check and r eplace su ction pre ssure

sensor

Check and m easure in put volta ge

Check and m easure in put curre nt

Check and m easure bu s voltage

Check and m easure bu s voltage

Check and m easure cu rrent as we ll

as adjus t

Check and m easure cu rrent as we ll

as adjus t

Check and r eplace se nsor

Reduce te mperatu re and chec k

c ompon ent

Check and m easure cu rrent as we ll

as adjust

Check and m easure vo ltage as we ll

as adjust

Check and m easure vo ltage and

check fre quency bo ard hardw are

Check com municat ion conne ction

Check com municat ion conne ction

Check com municat ion conne ction

Check and m easure cu rrent as we ll

as adjust

P181

E21

E22

E24

E25

E27

E28

E29

E30

E32

E33

E35

E36

Wat er inlet te mp.sens or error

Suction t emp. sens or error

Exhaust t emp. sens or error

Suction p ressure s ensor err or

Exhaust pre ssure sen so r error

Winter Le vel II anti freezin g

protect ion

AC input unde rvoltag e

protectio n

Exhaust ove r heat

protectio n

AC input over current

protectio n halt

DC bus over voltage

protect ion

DC bus unde rvoltag e

protect ion

IPM overc urrent pr otectio n

IPM modul e overhea t

protect ion

Radiato r tempera ture

sensor er ror

Power com ponent ov erheat

protect ion halt

IPM current s ampling

Compres sor overc urrent

protect ion hault

Input vol tage defa ult phase

Failure o f compres sor

booting

Fault of comm unicati on

between DSP and PFC

Fault of co mmunica tion

between D SP and

communi cation bo ard

Input volta ge sampli ng

Fault of EEPR OM

Compresso r flux weak en ing

protectio n alarm

Fault o f com mun ication be twe en

actua tor a nd Pc 8002

Check whe ther ther e is fault on

pressur e switch or r efriger ant loop

Check whe ther chip i s damaged a nd

replace c hip

PP1

E37

E38

E39

E40

E41

EE8

Form of Troubleshooting

Form of Troubleshooting

B. Or make judgment and troubleshooting by reference to the following form

Heat pump

cannot

be starte d

Wat er pump is

running w ith

high nois e or

without w ater

Heat pump

capacit y is low,

compres sor

do not stop

High comp ressor

exhaust

Low press ure

problem

of the syst em

Compres sor do

not run

High nois e of

compres sor

Fan do not ru n

The compr essor

runs but he at

pump has no t

heating o r

cooling c apacity

Low outle t water

tempera ture

Low water f low

protect ion

Page 25

Form of Troubleshooting

B. Or make judgment and troubleshooting by reference to the following form

Failure

Possible causes for the failure

Solutions

Heat pump

cannot

be starte d

1 Wrong p ower supp ly

2 power sup ply cable l oose

3 circuit b reaker op en

1 shut off the power a nd check po wer suppl y;

2 check pow er cable an d make righ t connect io n

3 check for t he cause an d replace t he fuse or

circuit b reaker

Wat er pump is

running w ith

high nois e or

without w ater

1 lack of wat er in the pip ing

2 much air in t he water lo op

3 water vav les close d

4 dirt and bl ock on the wa ter filte r

1 check the w ater supp ly and char ge water

to the pipi ng;

2 dischar ge the air in t he water lo op;

3 open the va lves in wat er loop;

4 clean the w ater filt er.

Heat pump

capacit y is low,

compres sor

do not stop

1 lack of ref rigeran t;

2 bad insul ation on wa ter pipe;

3 low heat ex change ra te on air sid e

exchang er;

4 lack of wat er flow

1 check for t he gas leak age and rec harge the

refrige rant;

2 make good i nsulati on on water p ipe;

3 clean the a ir side hea t exchang er;

4 clean the w ater filt er

High comp ressor

exhaust

1 too much re frigera nt

2 low heat ex change ra te on air sid e

exchang er

1 dischar ge the redu ndant gas

2 clean the a ir side hea t exchang er

Low press ure

problem

of the syst em

1 lack of gas

2 block on fi lter or cap illary

3 lack of wat er flow

1 check the g as leakag e and recha rge freon ;

2 replace f ilter or ca pillary ;

3 clean the w ater filt er and disc harge the a ir in

water loo p.

Compres sor do

not run

1 power sup ply failu re

2 compres sor conta ctor brok en

3 power cab le loose

4 protect ion on comp ressor

5 wrong set ting on ret urn water t emp.

6 lack of wat er flow

1 check off the powe r supply;

2 replace c ompress or contac tor;

3 tighten t he power ca ble;

4 check the c ompress or exhaus t temp.;

5 reset the r eturn wat er temp.;

6 clean the w ater filt er and disc harge the a ir i n

water loo p.

High nois e of

compres sor

1 liquid re frigera nt goes int o compres so r

2 compres sor failu re

1 bad evapo ration, c heck the ca use for bad

evapora tion and ge t rid of this ;

2 use new com pressor ;

Fan do not ru n

1 failure o n fan relay

2 fan motor b roken

1 replace t he fan rela y;

2 replace f an motor.

The compr essor

runs but he at

pump has no t

heating o r

cooling c apacity

1 no gas in the h eat pump;

2 heat exch anger bro ken;

3 compres sor failu re.

1 check sys tem leaka ge and rech arge refr ig erant ;

2 find out th e cause and r eplace th e heat

exchang er;

3 replace c ompress or.

Low outle t water

tempera ture

1 low water f low rate;

2 low setti ng for the de sired wat er temp.;

1 clean the w ater filt er and disc harge the a ir in

water loo p.

2 reset the d esired wa ter tempe rature.

Low water f low

protect ion

1 lack of wat er in the sys tem;

2 failure o n flow swit ch

1 clean the w ater filt er and disc harge the a ir in

water loo p.

2 replace t he flow swi tch.

23

Page 26

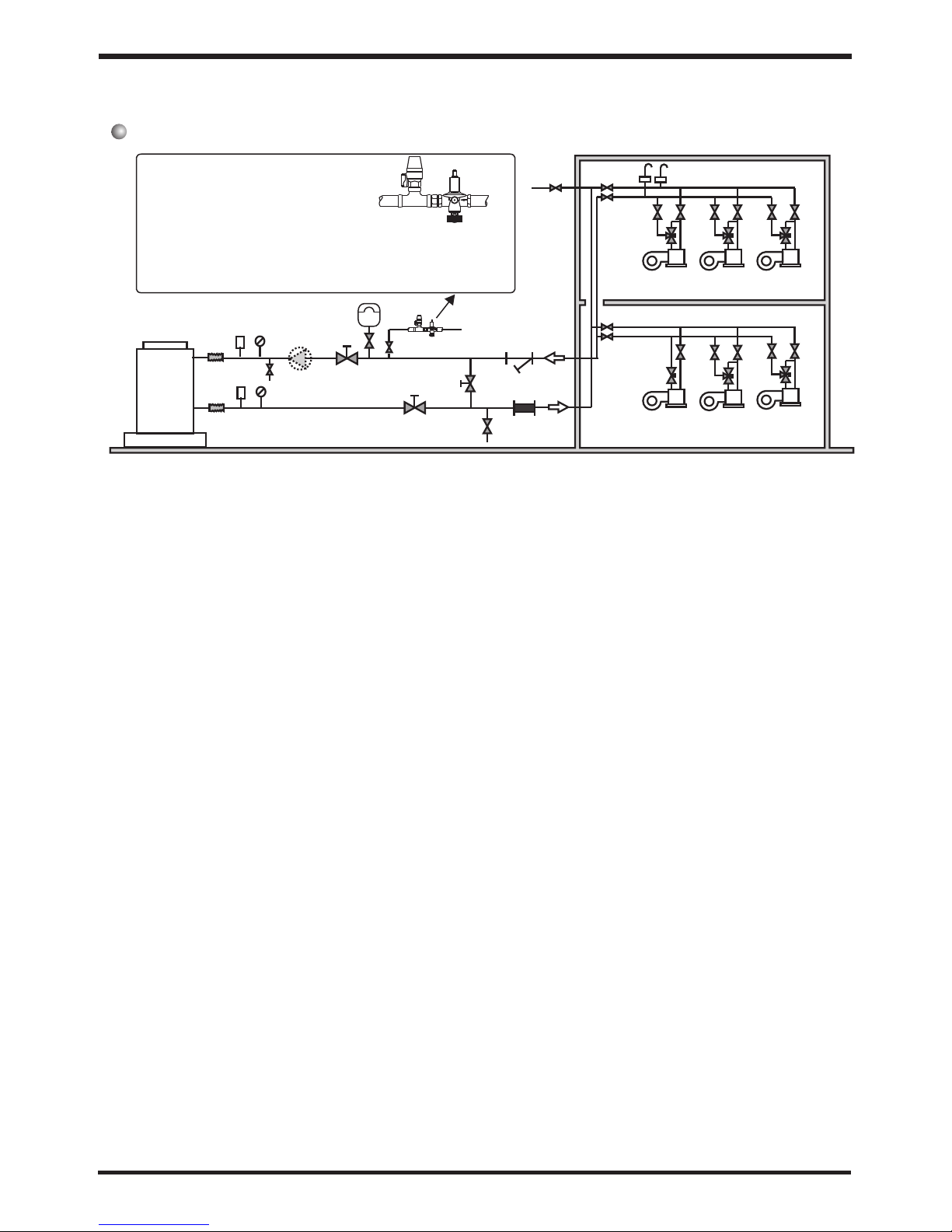

Especial installation( expandable water tank)

Appendix 1 Install sketch map

Appendix

Remark

1 main unit

2 fan coil

3 rubber flexible connection

4 thermometer

5 manometer

6 Y type filter

8 ball valve

10 bypass valve

1/2'

Technical request:

1.Each connection must be connected tightly and have no leakage.

2.the arrowhead orientation of automatic filled- water

must accord with water supply.

3.The pressure of automatic filled-water has been

set,and please do not remove screw.

autom ati c

fill- wat er

valve

Press ure

leaka ge

valve

2

14

15

13

17

Installation request:

1 The factory only offers main unit (1)in the legend, and the other modules

which are indispensable fittings, are provided by users or installation company.

2 The unit which of code contains the letter "B" ,has water pump inside and need

not install water pump outside (16)

3 Automatic ventilation(15)is installed on the top point of the water system。

4 The quantity proportion of two-way valve(13)and three-way valve(14)is

referred to the technical regulation, and there is three-way valve installed on the

farthest place of water system.

5 The ball valve (17) is used when it is swashed, filled water in the water system

and so on.

1

3

4

5

10

12

18

16

20

6

11

19

Conne ct supp ly pi pe

1/2'

inlet

outlet

8

11 drain valve

12 filter

13 two-way valve

14 three-way valve

15 automatic ventilation

16 water pump

17 ball valve

18 ball valve

19 expandable water tank

20 automatically filled-water

24

Appendix 2:

The installation explanation of automatic filled-water

Appendix

Page 27

Appendix 2:

The installation explanation of automatic filled-water

1 When automatic filled-water valve is installed,the arrowhead orientation of inlet water must

accord with the orientation of valve ;

2 Automatic filled-water has been adjusted in advance to 1.5bar;

3 If readjust the pressure of inlet water,please operate as follows:

* open the screw cap(C);

* If reduce the pressure of water supply,pease unscrew the pressure to adjust the screw(B);

* If increese the pressure of waer supply,please screw down the pressure to adjust the screw (B)

4 When the system need fill water at first,wrest the handle(A) of filled-water.Then the handle(A)

can return(close) when the system is full of water.

5 Automatic filled-water Valve need clean in a periodic time and then you must close the tap,

unscrew the plug(D),remove the inside filter net.Please assemble them again after cleaning.

NOTICE:There are two connections for water pressure meter in the central section of

automatic filled-water,where the water pressure meter can be connected directly

and display the set pressure.The screw cap(C) must be tweaked after adjusting

the filled-water pressure.

B

C

1/4'

D

A

1/2'

Appendix

25

Page 28

Appendix 3:

The installation explanation of the leakage pressure valve.

1 The action pressure of leakage pressure valve 'is more than 3bar(valve is open),

but the pressure can not be adjusted.

2 The valve will open automatically to make sure that the water loop of air-con system

is safe when the water pressure in the backwater side is higher than t he set pressure.

Appendix

Appendix 4:

The way of assistant heat source connection

Unit provides the connection of assistant heat source which ca n not be only for gas-fired

boiler,but also for electronic boiler or wa rm-net pipe for city accordingly.

The way to the connection is as follows:

2)water chiller and heat pump+assistant el ectronic boiler

electro nic boile r

inlet

cable

water chiller and heat pump

gas-fir ed boiler

inlet

outlet

1)water chiller and heat pump+assistant gas-fired b oiler

Three -wa y val ve

control w ire

outle t

water chiller and heat pump

inlet

cable

outle t

inlet

outlet

outlet

inlet

26

Appendix

Appendix 5、

Note:

Connect frequency water pump

(PWM control) to reserved interface

as required and controller will be able

to automatically control water pump.

Page 29

Appendix

27

Appendix 5、

Ways of connection to remote controller

The following ways of connection to control system ar e optional based on user demand:

A. Simultaneously connect remote controller and n etworking interface:

PC8002

+12

NET

GND

Remote

controller

WiFi module

Note:

1、In the mode of unit operation, it is necessary to complet e value setting by remote controller.

2、It is advised to control equipment by mobile terminal a fter connection to WiFi module.

B. Connect with external water pump:

Note:

Connect frequency water pump

(PWM control) to reserved interface

as required and controller will be able

to automatically control water pump.

GND

Y 3

Frequency

water pump

Main controller

L

N

C. Connect to room temperature controller:

Note:

1、The way is applicable to special requireme nts of users;

2、Connect 485 signal wire to reserved termin al after determining the use of room

temperature controller.

R S4 8 5+

R S4 8 5-

PC8002

Room

temperature

controller

Page 30

Appendix 6、

Caution & Warning

1. The unit can only be repaired by qualified installer centre personnel or an au thorised

dealer.(for Europe market)

2. This appliance is not intended for use by persons (including children) with reduced physical

sensory or mental capabilities, or lack of experien ce and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. (for Europe market)

Children should be supervised to ensure that they do no t play with the appliance.

3. Please make sure that the unit and power connection have good earthing, otherwise may

cause electrical shock.

4. If the supply cord is damaged, it must be replaced by the manufactu rer or our service agent

or similarly qualified person in order to avoid a hazard.

5. Directive 2002/96/EC (WEEE):

The symbol depicting a crossed-out waste bin that is underneath the appliance indicates

that this product, at the end of its useful life, must be handled sepa rately from domestic

waste, must be taken to a recycling centre for electric and electr onic devices or handed

back to the dealer when purchasing an equivalent appliance.

6. Directive 2002/95/EC (RoHs): This product is compliant with directive 2002/95 /EC (RoHs)

concerning restrictions for the use of harmful substances in e lectric and electronic devices.

7. The unit CANNOT be installed near the flammable gas. Once there is any leakage of the gas

, fire can be occur.

8. Make sure that there is circuit breaker for the unit, lack of circu it breaker can lead to

electrical shock or fire.

9. The heat pump located inside the unit is equipped with an over-load protecti on system. It

does not allow for the unit to start for at least 3 minutes from a previous stoppage.

10. The unit can only be repaired by the qualified personnel of an installer cent er or an

authorized dealer. (for North America market)

11. Installation must be performed in accordance with the NEC/CEC by authorized perso n only.

(for North America market)

12. USE SUPPLY WIRES SUI TABLE FOR 75℃.

13. Caution: Single wall heat exchanger, no t suitable for potable water connection.

Appendix

28

When the unit will be installed at outdoor, ple ase use the cable which can against UV.

Appendix

1. Single phase unit

2. Three phase unit

Page 31

Appendix 7、Cable specification

When the unit will be installed at outdoor, ple ase use the cable which can against UV.

Appendix

29

1. Single phase unit

10~16A

16

~25A

25

~32A

32

~40A

40

~63A

63~75A

75~101A

101~123A

123~148A

148~186A

186~224A

Phase line

MCB

Creepage protector

Signal line

2

×

n 0 . 5 m m

Nameplate

maximum

current

Earth line

No more

than 10A

2

2×1.5mm

2

2×2.5mm

2

2×4mm

2

2×6mm

2

2×10mm

2

2×16mm

2

2×25mm

2

2×25mm

2

2×35mm

2

2×50mm

2

2×70mm

2

2×95mm

20A

32A

40A

40A

63A

80A

100A

125A

160A

225A

250A

280A

2

1.5mm

2

2.5mm

2

4mm

2

6mm

2

10mm

2

16mm

2

mm

25

2

mm

25

2

35mm

2

50mm

2

70mm

2

95mm

30mA less than 0.1 sec

10~16A

16

~25A

25

~32A

32

~40A

40

~63A

63~75A

75~101A

101~123A

123~148A

148~186A

186~224A

Phase line

MCB

Creepage protector

Signal line

2

×

n 0 . 5 m m

Nameplate

maximum

current

Earth line

No more

than 10A

20A

32A

40A

40A

63A

80A

100A

125A

160A

225A

250A

280A

2

1.5mm

2

2.5mm

2

4mm

2

6mm

2

10mm

2

16mm

2

mm

25

2

mm

25

2

35mm

2

50mm

2

70mm

2

95mm

2. Three phase unit

2

3×1.5mm

2

3×2.5mm

2

3×4mm

2

3×6mm

2

3×10mm

2

×

16mm

3

2

×

25mm

3

2

3×25mm

2

3×35mm

2

3×50mm

2

3×70mm

2

3×95mm

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

30mA less than 0.1 sec

Page 32

Code:20 160612- 0003

Loading...

Loading...