Page 1

Page 2

CONTENTS

1. Preface

2. Specifications

3. Installation and Connection

3.1 Installation of System

3.2 Swimming Pool Heat Pumps Location

3 .3 Location & minimum clearances

3.4 Swimming Pool Heat Pumps Plumbing

3.5 Swimming Pool Heat Pumps Electrical Wiring

3.6 Initial Start-up of the Unit

4. Usage and Operation

4.1 Function of the controller

4.2 Usage of the controller

4.3 Parameter table

5. Maintenance and Inspection

1

2

5

5

6

6

7

8

8

9

9

11

18

19

5.1 Maintenance

5.2 Trouble Shooting Guide

6. Appendix

7. warranty

8. warranty registration.................................................................................... 25

19

20

21

24

Page 3

1. PREFACE

In order to provide our customers with quality, reliability and versatility, t his p rod uct h as

been made to str ict p rod uct ion s tan dar ds. T his m anu al in clu des a ll th e nec ess ary

info rmatio n abo ut in sta lla tio n, de bug gin g, di sch arg ing a nd ma int ena nce . Ple ase r ead t his

manual carefully before you open or maintain the u nit. The m anu fac tur e of th is pr odu ct wi ll

not be h eld responsible if someone is injured or the unit is damaged, as a result of

improper installation, debugging, or unnecessary maintenance. It i s vit al th at th e

instructio ns wi thi n thi s man ual a re ad her ed to a t all t ime s. Th e uni t mus t be installed by

qualified personnel.

The un it ca n onl y be re paired by qualified installer centr e , per son nel o r an au tho ris ed

dealer.

Maintenance and operation must be carried out according to th e recommended time and

freq uency, as s tat ed in this manual.

Use genuine standard spare parts only.

Fail ure to com ply w ith t hes e rec omm end ati ons w ill invalidate the wa rra nty.

Swimming Pool Heat Pump Unit heats th e swi mmi ng po ol water a nd ke eps the te mpe rat ure

constant. Fo r spl it ty pe un it, T he in doo r uni t can b e Dis cre tel y hid den o r sem i-h idd en to

suit a luxury house.

Our he at pu mp ha s fol low ing c haracteri sti cs:

1 Durable

The he at ex cha nge r is ma de of P VC & Tit ani um tu be wh ich c an wi ths tan d pro lon ged

exposure to swimming pool water.

2 Inst all ati on fl exi bil ity

The un it ca n be in sta lle d out doo rs or i ndo ors .

3 Quie t ope rat ion

The un it co mpr ise s an effi cie nt ro tar y/ sc rol l com pre sso r and a l ow- noi se fa n mot or,

which guarantees its q uie t ope rat ion .

4 Advanced controlling

The un it in clu des m icr o-c omp ute r con tro lli ng, a llo win g all o per ati on pa ram ete rs to b e

set. O per ati on st atu s can b e dis pla yed o n the L CD wi re co ntr oll er. Re mot e con tro lle r can b e

chosen as futu re op tio n.

1

Page 4

2.SPECIFICATION

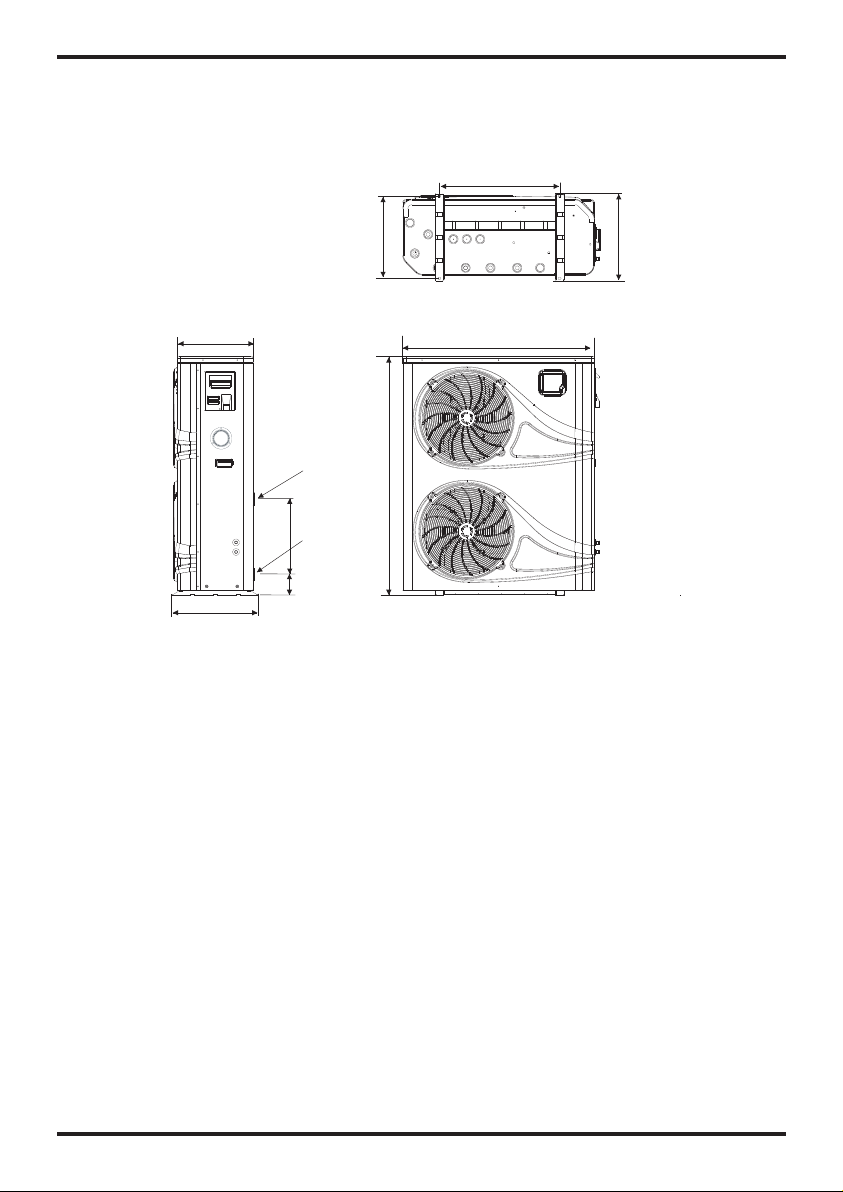

2.2 Th e dime nsio ns for S wimm ing Po ol Hea t Pump U nit

Mode l:F orc e 26

630

unit:mm

395

455

Wat er O ut le t

Φ48.3

Wat er I nl et

440

Φ48.3

103

430

1003

1248

455

3

Page 5

2.SPECIFICATION

Mode l:F orc e 26- 3

395

455

Wat er O ut le t

Φ48.3

Wat er I nl et

440

Φ48.3

103

unit:mm

630

430

1003

1248

455

4

Page 6

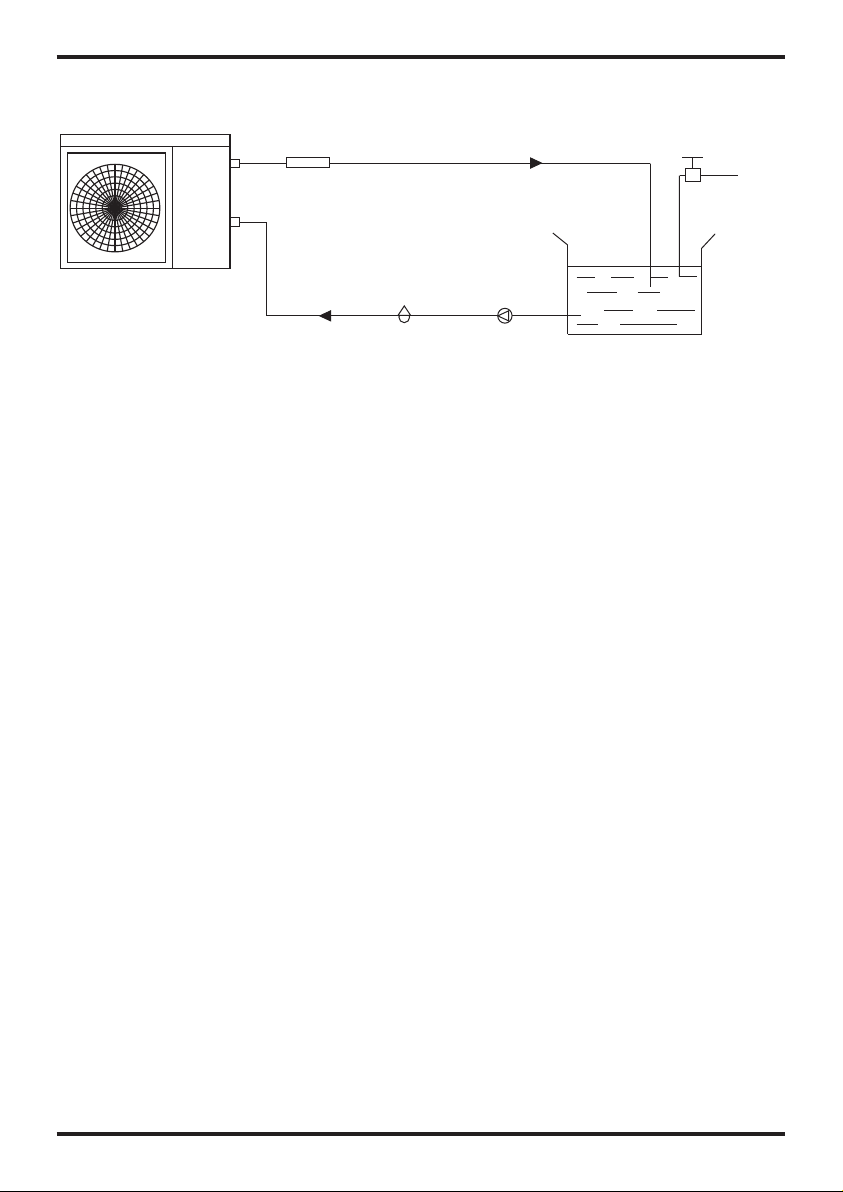

3.INSTALLATION AND CONNECTION

3.1 In sta lla tio n ill ust rat ion

Chlo rin ato r cel l

Wat er in let

Sand f ilt er

(or ot her t ype f ilt er)

Wat er ou tle t

Pool

Wat er pu mp

Valve

Wat er su ppl y

Insta llat ion it ems:

The fa cto ry on ly pr ovi des t he ma in un it an d the w ate r uni t; the other items in the illustration

are necessary spare parts for th e wat er sy ste m ,th at pr ovi ded b y use rs or t he in sta lle r.

Atten tion :

Please follow the se steps w hen using for t he fi rst t ime

1.Op en va lve a nd ch arge water.

2.Ma ke sure th at th e pum p and t he wa ter -in p ipe h ave b een fill ed wi th wa ter.

3.Cl ose the va lve a nd start t he un it.

ATTN: I t is ne ces sar y tha t the water-in pipe is hi ghe r tha n the pool surface.

The sc hemati c dia gram is fo r ref ere nce o nly. P lea se ch eck t he wa ter i nle t/outlet label on the

heat pump while plumbing installation.

5

Page 7

3.INSTALLATION AND CONNECTION

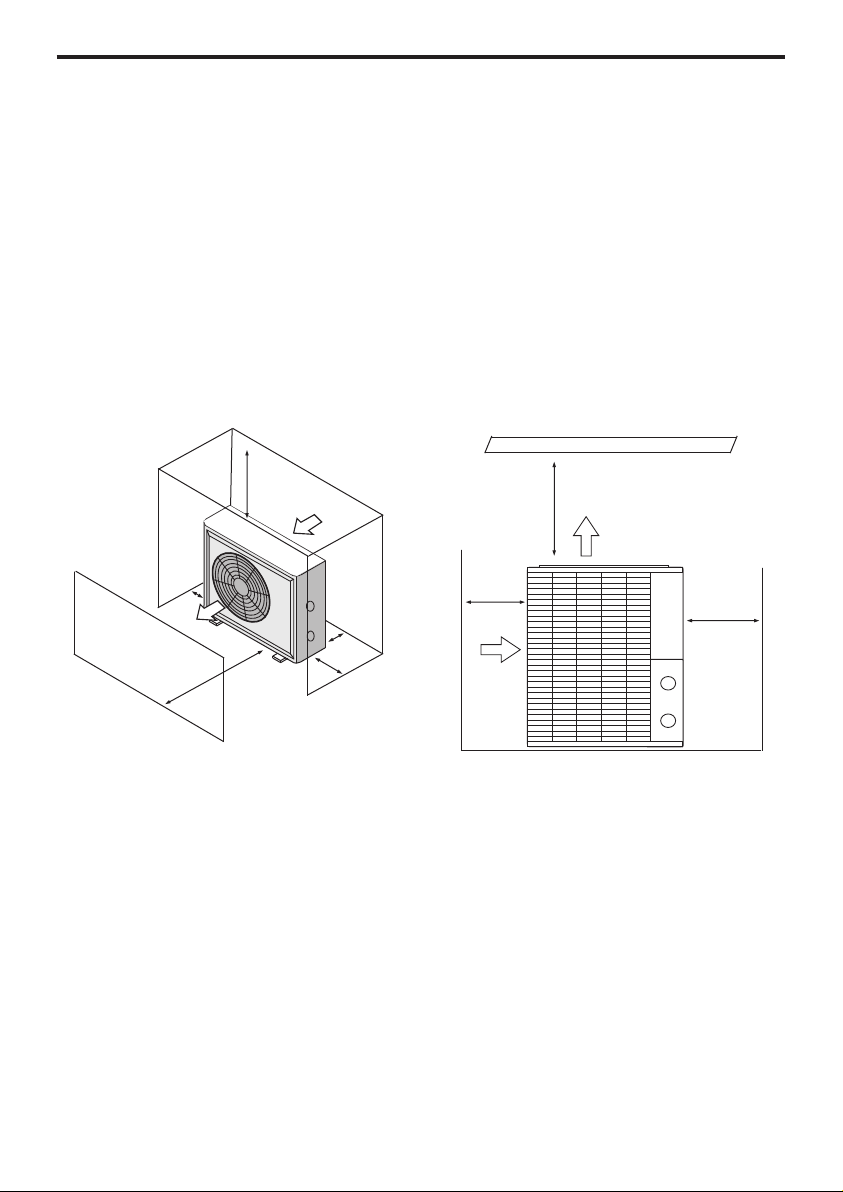

3.2 Swimming Pool Heat Pumps Location

Before installation it is very important to ensure 4 variables are carefully checked to allow

the unit to operate correctly:

• Adequate Air Flow

• Correct water flow volume

• Correct electrical connection & supply

• Heater condition

*For indoor pools please consult the supplier.

DO N

OT place the unit in an enclosed area, where the units discharge air can be

re-ci

rculated. In an enclosed area take measures to evacuate the cold waste air out

of the room. Conversely make sure there is adequate air entering the room to supply

the heat pump.

Air in let

500mm

700m m

Air ou tle t

2000mm

800mm

300mm

Air ou tle t

1000mm

0mm

250

3.3 Location & minimum clearances

Evo rec

ommend the heat pump should ONLY be installed in a location with appropriate ventilation. See

above for minimum airflow clearances.

The Evo pool heat pump should be installed with a minimum clearance of at least 3.5m to the water’s

edge. Furthermore, EvoHeat recommend installing the heat pump no greater than 7.5 meters away from

the water’s edge due to heat loss from the piping. If you do not have a location with these suggested

clearances, please contact our EvoHeat Tech Support Specialist on 1300 859 933 to discuss

appropriate installation locations.

The heat pump should be installed a maximum of 5m below the water level of the pool/spa.

Make sure the heat pump is not located where large amounts of water may run-off from a roof into the

unit. Sharp sloping roofs without gutters will allow excessive amounts of rain water mixed with debris

from the roof to be forced through the unit. A water deflector may be needed to protect the heat pump.

If installing the heater on an existing pump/filtration system the heater must be installed AFTER the

filter and BEFORE the chlorinator/sanitizer.

The heat pump should be installed on a flat level surface.In the event that a suitable location is

unavailable contact Evo Industries for specialist technical advice.

700m m

Air in let

Page 8

3.INSTALLATION AND CONNECTION

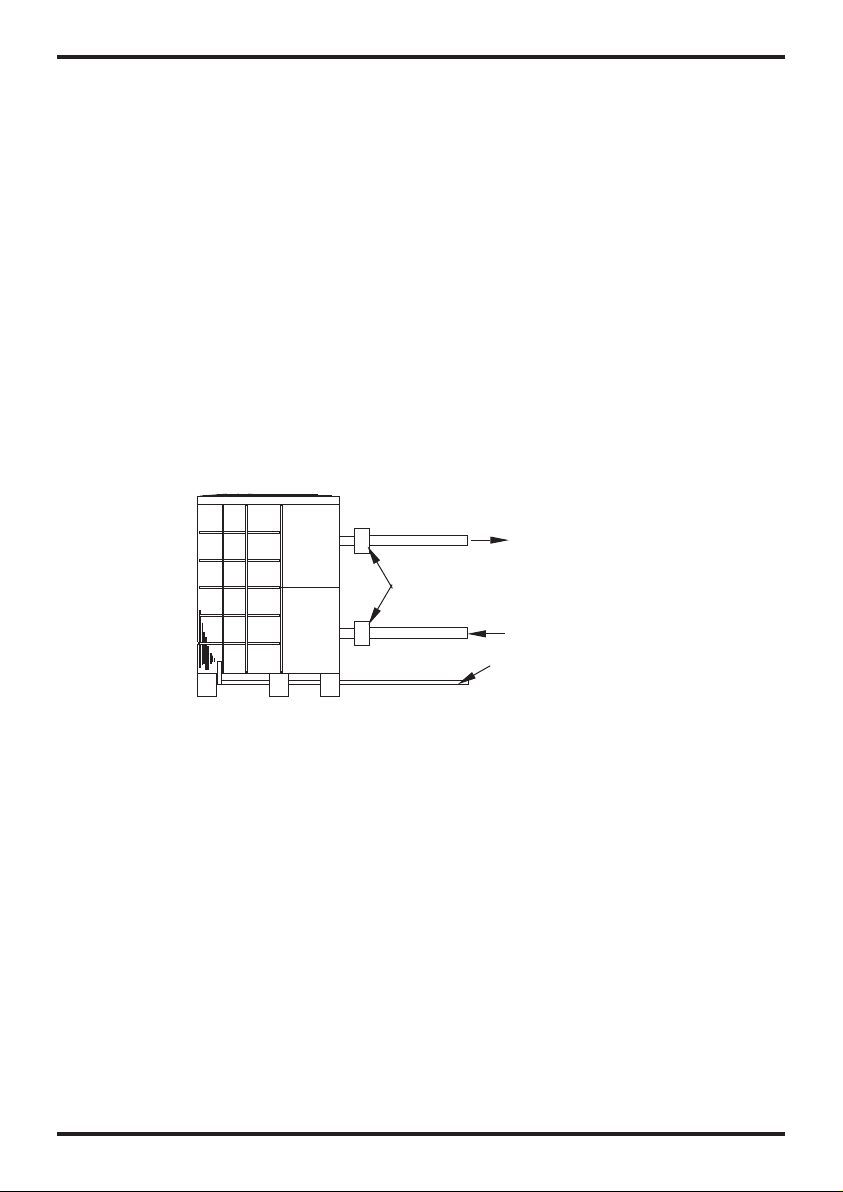

3.4 Swi mmin g Pool H eat Pu mps Pl umbi ng

The Sw imming Pool H eat Pump s exclusive rated flo w tit ani um he at ex cha nge r req uir es no

special plumbing arrangements except bypass(please set the flow rate according to the

nameplate). The w ate r pre ssu re dr op is l ess t han 1 0kP a at ma x. Fl ow ra te. S inc e the re is n o

residual heat or fl ame Temper atu res , Th e uni t doe s not n eed c opp er he at si nk pi pin g. PV C

pipe can be run straight into t he un it.

Location: Co nne ct th e uni t in th e poo l pum p dis cha rge (return ) line downstream of al l fil ter

and pool pumps, and upstream of any chl ori nators , ozo nat ors o r che mic al pu mps .

Stan dard model have slip glue fitti ngs w hich accept 32mm or 50 mm PVC pipe fo r

connection to the p ool o r spa f ilt rat ion p ipi ng. B y usi ng a 50 N B to 40 NB yo u can p lum b 40N B

Give s erious cons ideration to add ing a q uick cou pler fit tin g at th e uni t inl et an d out let t o all ow

easy draining of unit for winterizing and to provide easier access should servicing be

required.

To pool

PVC COUPL ER

RECOMME NDE D(P rov ide d)

From p ump

COND ENS ATION

DRAIN

BARB FTG

Condensation: Since the H eat pump c ool s down the a ir about 4 -5℃, wat er ma y con den se on

the fi ns of t he ho rse sho e sha ped evaporator. If the r ela tiv e hum idi ty is v ery h igh , thi s cou ld

be as mu ch as seve ral l itr es an h our. The wa ter w ill r un do wn th e fin s int o the b ase pan a nd

drain out through the barbed plastic con densation drain fit tin g on th e sid e of th e bas epa n.

This f itt ing i s des ign ed to a cce pt 20 mm cl ear v iny l tub ing w hic h can b e pus hed o n by ha nd

and run to a suita ble d rain. It i s eas y to mi sta ke th e con den sat ion f or a wa ter l eak i nsi de th e

unit.

NB: A quick way to verify that the wa ter i s con den sat ion i s to sh ut of f the unit and keep the

pool pump running. If the water st ops r unn ing o ut of t he ba sep an, i t is co nde nsa tio n. AN

EVEN QUIC KER WAY IS to TEST THE D RAI N WATER FOR CHLORINE - if the is no chlorine

present, the n it' s con den sat ion .

7

Page 9

3.INSTALLATION AND CONNECTION

3.5 Swi mming Pool Heat Pumps El ectr ical W irin g

NOTE : Alth oug h the u nit h eat e xch ang er is e lec tri cal ly is ola ted f rom t he re st of t he un it, i t

simply prevents the fl ow of e lec tri cit y to or f rom t he po ol wa ter. G rou ndi ng th e uni t is st ill

required to prote ct yo u aga inst sho rt ci rcu its i nsi de th e uni t. Bo ndi ng is a lso r equ ire d.

The un it ha s a sep ara te mo lde d-i n jun cti on bo x wit h a sta nda rd el ect ric al co ndu it ni ppl e

already in place. Just remove the screws and the fro nt pa nel , fee d you r sup ply l ine s in

thro ugh the co ndu it ni ppl e and wire-nut the electric sup ply w ires to th e thr ee co nne cti ons

already in the junction box (fou r con nec tio ns if t hre e pha se) . To comp let e ele ctr ica l hoo kup ,

connect Heat Pump b y electr ical conduit, UF c abl e or ot her s uit abl e mea ns as s pec ifi ed (a s

permitted by l oca l electr ical author iti es) t o a ded ica ted AC p ower sup ply b ranch circuit

equipped with the p roper ci rcuit br eak er, disconnect or time d elay fus e pro tec tio n.

Disconnect - A disconnect means (circuit breaker , fu sed or un-fused switc h) sh oul d be

located with in si ght of and r ead ily a cce ssible from the un it, T his i s com mon p rac tic e on

commercial and residential air conditioners and heat pumps. It prevents rem ote ly- ene rgi zing

unatten ded e qui pment an d permits tur nin g off p owe r at th e uni t whi le th e uni t is be ing

serviced.

3.6 Ini tial s tart up of th e Unit

NOTE - In or der f or th e uni t to he at th e poo l or sp a, th e fil ter p ump m ust b e run nin g to

circulate water t hro ugh t he he at ex cha nge r.

Star t up Pr oce dur e - Afte r ins tal lat ion i s com ple ted , you s hou ld fo llo w the se st eps :

1. Turn on your filter p ump. Che ck fo r wat er le aks a nd ve rify flo w to an d fro m the p ool .

2. Turn on the electri cal power supply to the u nit , the n pre ss th e key O N/O FF of w ire

controller, It sho uld s tar t in se ver al se con ds.

3. Afte r run nin g a few m inu tes m ake s ure t he ai r lea vin g the t op( sid e) of t he un it is

cooler(Between 5-10 ℃)

4. Wit h the u nit o per ati ng tu rn th e fil ter p ump o ff. The u nit s hou ld al so tu rn off au tom ati cal ly,

5. Allow the unit and po ol pump to r un 24 hours per day until desired pool water emperature is

reached. When the w ate r-i n tem per atu re re ach s ett ing , The u nit j ust s huts off. The un it wi ll

now automati cal ly re sta rt (a s lon g as yo ur po ol pu mp is r unn ing )wh en th e poo l tem per atu re

drops more tha n 2℃bel ow set tem peratu re.

Tim e Del ay- The unit is equipped with a 3 mi nut e bui lt- in so lid s tat e res tar t del ay in clu ded t o

protect cont rol c irc uit c omp one nts a nd to e lim ina te re sta rt cy cli ng an d con tac tor c hat ter.

This t ime d ela y wil l automa tic all y res tar t the u nit a ppr oxi mat ely 3 m inu tes a fte r eac h con tro l

circuit inte rru pti on. E ven a b rie f pow er in ter rup tio n wil l act iva te th e sol id st ate 3 m inu te

restart dela y and p revent the unit fr om st art ing u nti l the 5 m inu te co unt dow n is co mpl ete d.

Power interruptions during the delay period will have no effe ct on t he 3 mi nut e cou ntd own .

8

Page 10

4. USAGE AND OPERATION

9

Page 11

4. USAGE AND OPERATION

Page 12

4. USAGE AND OPERATION

11

Page 13

4. USAGE AND OPERATION

12

Page 14

4. USAGE AND OPERATION

13

Page 15

4. USAGE AND OPERATION

14

Page 16

4. USAGE AND OPERATION

15

Page 17

4. USAGE AND OPERATION

16

Page 18

4. USAGE AND OPERATION

17

Page 19

4. USAGE AND OPERATION

3. Para mete r tabl e

Meaning

Heating inlet tar get temp .

Cooling inlet target temp.

Auto i nlet tar get t emp .

Remark:

The wi re co ntr oll er ca n dis pla y the t emp era tur e uni t as "℉" or "℃" a cco rdi ng to t he un it

Mode l you bought.

27℃

27℃

27℃

Remar k Defau lt

Adjustable

Adjustable

Adjustable

18

Page 20

5. MAINTENANCE AND INSPECTION 5

5.1 Ma intena nce

Check the wate r sup ply d evi ce and the r ele ase ofte n. You should avoid the condition of no

wate r or air enteri ng into sy ste m, as t his w ill i nfl uen ce un it' s per for man ce an d rel iab ili ty.

You sh oul d cle ar th e poo l/s pa fi lte r reg ula rly t o avo id da mag e to th e uni t as a re sul t of th e

dirty of cl ogg ed fi lte r.

The ar ea around the u nit shou ld be dry, cl ean a nd we ll ve nti lat ed. C lea n the s ide h eat ing

exchanger regularly to maintain good heat exchange as conserve energy .

The op eratio n pre ssure of the refri ger ant syst em sh oul d onl y be se rvi ced b y a cer tif ied

tech nician .

Check the power sup ply and cable connection ofte n,. Sho uld t he un it be gin t o ope rat e

abnormally, swit ch it o ff a nd co nta ct th e qua lif ied t ech nic ian .

Discharge all water in the water pump and water syst em ,s o tha t fre ezi ng of t he wa ter i n the

pump or water sy ste m doe s not o ccu r. You should discharge the water at the botto m of

wate r pump if th e uni t wil l not b e use d for a n ext end ed pe rio d of ti me. You should check the

unit thoroughly and fi ll th e sys tem w ith w ate r ful ly be for e usi ng it f or th e fir st ti me af ter a

19

Page 21

5. MAINTENANCE AND INSPECTION

5.2 Trouble S hoo tin g Gui de

The co mmon fai lur e cause and solution.

20

Page 22

6.APPENDIX

1.Con nection of P CB ill ustr atio n

OUT1 OUT2

3

FUSE

4

T5AL 250 V

OUT 3

OUT 4

OUT 5

AC- N

CN1

CN2

PC1001

GND

12V

NET

Connections explanation:

Symbol

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

OUT1

OUT2

OUT3

OUT4

OUT5

AC-N

NET GND 12 V

DI01 G ND

DI02 G ND

DI03 G ND

DI04 G ND

DI05 G ND

DI06 G ND

AI01 G ND

AI02 G ND

AI03 G ND

AI04 G ND

AI05 G ND

AI06 G ND

CN1

CN2

CN6

CN19

5V CN1 6 GN D

CN19

CN6

3

4

GND

DI0 1

GND

GND

DI0 2

DI0 3

GND

GND

DI0 4

DI0 5

CN4

GND

AI0 6

GND

AI0 5

GND

AI0 4

GND

AI0 3

GND

AI0 2

GND

AI0 1

+5V

CN1 6

GND

DI0 6

GND

CN3

Meaning

Compressor of sys tem 1(220 -23 0VAC)

Wat er pu mp(22 0-2 30VAC)

4way valve (220-230VAC)

High speed of fan motor(220-230VAC)

Low speed of fan moto r(220-230VAC)

Neutral wire

Wire c ontrol ler

On/O ff Sw itch(i npu t)(no us e)

Flow s witch (i npu t)( n orm al cl ose )

Low pressure protect

High pressure protect

No use

No use

Suction temp .(i npu t)

Wat er in t emp .(i npu t)

Wat er ou t tem p.( inp ut)

Temp. Of coil ( input)

Ambient temp.(i npu t)

Adjustable fan sp eed/Ex haust te mpe rature

Primary transfo rmer

Secondary transformer

With out u se

Electronic expansion valve

Flow m ete r

21

Page 23

6.APPENDIX

Cauti on & Warni ng

1. The u nit c an on ly be r epa ire d by qu ali fie d ins tal ler c ent re pe rso nne l or an a uth ori sed

deal er.(fo r Eur ope m ark et)

2. Thi s app lia nce i s not i nte nde d for u se by p ers ons ( inc lud ing c hil dre n) wi th re duc ed ph ysi cal

sens ory or men tal c apa bil iti es, o r lac k of ex per ien ce an d kno wledge, unl ess they h ave been

give n supervision or instruction concerning use of the appliance by a person responsible for

thei r saf ety. (for Europe market)

Chil dren should be supervised to ensure that they do not play with the a ppl ian ce.

3. Ple ase make sure that the un it an d pow er co nne cti on ha ve go od ea rth ing , oth erw ise m ay

caus e electr ica l shock.

4. If th e sup ply c ord i s dam age d, it m ust b e rep lac ed by t he ma nuf act ure r or ou r ser vic e age nt

or sim ila rly q ual ifi ed pe rson in order to avoid a hazard.

5. Dir ective 2 002 /96 /EC ( WEE E):

The sy mbol depicting a cros sed-out was te bi n tha t is un der nea th th e app lia nce i ndi cat es

that t his p rod uct , at th e end o f its u sef ul li fe, m ust b e han dle d sep ara tel y fro m dom est ic

wast e, mu st be t ake n to a re cyc lin g cen tre f or el ect ric a nd el ect ron ic de vic es or h and ed

back t o the d eal er wh en pu rch asing an equivalent appliance.

6. Dir ective 2 002 /95 /EC ( RoH s): T his p rod uct i s com pli ant w ith d ire cti ve 20 02/ 95/ EC (R oHs )

conc erning restrictio ns fo r the u se of h arm ful s ubs tan ces i n ele ctr ic an d ele ctr oni c dev ice s.

7. The u nit C ANN OT be ins tal led n ear t he fl amm abl e gas . Onc e the re is a ny le aka ge of t he ga s

, fire c an be o ccu r.

8. Mak e sure tha t the re is c irc uit b rea ker f or th e uni t, la ck of c irc uit b rea ker c an le ad to

elec tri cal s hoc k or fi re.

9. The h eat p ump l oca ted i nsi de th e uni t is eq uip ped w ith a n ove r-l oad p rot ect ion s yst em. I t

does n ot al low f or th e uni t to st art f or at l eas t 3 min ute s fro m a pre vio us st opp age .

10. Th e uni t can o nly b e rep air ed by t he qu ali fie d per son nel o f an in sta lle r cen ter o r an

auth ori zed d eal er. (fo r Nor th America market)

11. Ins tal lat ion m ust b e per for med i n acc ord anc e wit h the N EC/ CEC b y aut hor ize d per son o nly.

(for No rth America market)

12. US E SUP PLY WIRE S SUI TAB LE FO R 75℃.

13. Ca uti on: S ing le wa ll he at ex cha nge r, not suit abl e for p ota ble w ate r con nec tio n.

22

Page 24

6.APPENDIX

(2) Cable s peci fica tion

1. Single phase unit

Nameplate

maximum

current

No more

than 1 0A

10~16A

16

~25A

25

~32A

32

~40A

40

~63A

63~75A

75~101A

101~123A

123~148A

148~186A

186~224A

2. Three pha se unit

Nameplate

maximum

current

No more

than 1 0A

10~16A

16

~25A

25

~32A

32

~40A

40

~63A

63~75A

75~101A

101~123A

123~148A

148~186A

186~224A

Phase line

2×1.5m m

2×2.5m m

2×4mm

2×6mm

2×10mm

2×16mm

2×25mm

2×25mm

2×35mm

2×50mm

2×70mm

2×95mm

Phase line

3×1.5m m

3×2.5m m

3×4mm

3×6mm

3×10mm

×

16mm

3

×

25mm

3

3×25mm

3×35mm

3×50mm

3×70mm

3×95mm

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Earth line

1.5m m

2.5m m

4mm

6mm

10mm

16mm

mm

25

mm

25

35mm

50mm

70mm

95mm

Earth line

1.5m m

2.5m m

2

4mm

2

6mm

10mm

16mm

mm

25

mm

25

35mm

50mm

70mm

95mm

Creepage protector

MCB

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

30mA less than 0.1 sec

20A

32A

30mA less than 0.1 sec

40A

30mA less than 0.1 sec

40A

30mA less than 0.1 sec

63A

30mA less than 0.1 sec

80A

30mA less than 0.1 sec

100A

30mA less than 0.1 sec

125A

30mA less than 0.1 sec

160A

30mA less than 0.1 sec

30mA less than 0.1 sec

225A

30mA less than 0.1 sec

250A

30mA less than 0.1 sec

280A

Creepage protector

MCB

30mA less than 0.1 sec

20A

30mA less than 0.1 sec

32A

30mA less than 0.1 sec

40A

30mA less than 0.1 sec

40A

30mA less than 0.1 sec

63A

80A

30mA less than 0.1 sec

100A

30mA less than 0.1 sec

30mA less than 0.1 sec

125A

30mA less than 0.1 sec

160A

225A

30mA less than 0.1 sec

30mA less than 0.1 sec

250A

30mA less than 0.1 sec

280A

Signal line

×

n 0.5mm

Signal line

×

n 0.5mm

2

2

When th e unit w ill be i nsta lled a t outd oor, pl ease u se the c able w hich c an aga inst UV.

23

Page 25

EVOHEAT Pump Warranty

1. The titanium heat exchanger tubing is guaranteed against corrosion for a period of twenty five

(25) years from the date of purchase when used with chlorine, salt, bromine or sea water. (*25 year

warranty on the titanium heat exchanger is valid for Evo heat pumps purchased post 15.05.2018. If

purchased prior please refer to your original operating manual for warranty details).

2. The compressor is guaranteed for five (5) years from the date of purchase.

3. All other parts are guaranteed for two (2) years from the date of purchase.

4. This warranty covers all labour for twelve (12) months from the date of purchase.

5. This warranty excludes any defect or injury caused by or resulting from misuse, abuse, neglect,

accidental damage, improper voltage, vermin infestation, incompetent installation, any fault not

attributable to faulty manufacture or parts, any modifications which affect the reliability or

performance of the unit.

6. This warranty does not cover the following:

a. Natural Disasters (hail, lightening, flood, fire etc.)

b. Rust or damage to paintwork caused by a corrosive atmosphere

c. When serviced by an unauthorized person without the permission of Evo Industries

d. When a unit is installed by an unqualified person

e. Where a unit is incorrectly installed

f. When failure occurs due to improper or faulty installation

g. Failure due to improper maintenance (refer Operating Instructions)

h. ‘No Fault Found’ service calls where the perceived problem is explained within the

Operation Instructions

i. Costs associated with delivery, handling, freighting, or damage to the product in transit.

7. If warranty service is required you should:

a. contact Evo Industries Australia on 1300 85 99 33 or via our Contact page on our web

site

b. provide a copy of your receipt as proof of purchase

c. have completed the online warranty registration or provide a completed warranty card.

8. Home service is available within the normal operating area of your Evo Industries authorized

Service Centre. Service outside this area will incur a traveling fee. Unless otherwise specified to the

purchaser, the benefits conferred by this express warranty and additional to all other conditions,

warranties, rights and remedies expressed or implied by the Trade Practices Act 1974 and similar

consumer protection provisions contained in legislation of the States and Territories and all other

obligations and liabilities on the part of the manufacturer or supplier and nothing contained herein

shall restrict or modify such rights, remedies, obligations or liabilities

24

Page 26

Warranty Registration

To register your Warranty, please enter the following details or go online at https://evoheat.com.au/warrantyregistration/ to register directly at our website.

Fields with a star (*) must be filled in. For information about what Evo Industries Australia will do with your

personal details, please refer to our Privacy Disclaimer on our website.

Family Name: * ___________________________________________________________________

Given Name: * ___________________________________________________________________

Preferred Title: *___________________________________________________________________

Age Group: * 18-24 25-34 35-44 45-54 55-64 64+

Street Address: * ___________________________________________________________________

Suburb: * ________________________________________________________________________

Postcode: * _______________________________________________________________________

State: * _________________________________________________________________________

Email: * _________________________________________________________________________

Please tell us about which EvoHeat product you bought, who you bought it from and what you will be using it

for.

Product & Model: *_________________________________________________________________

Serial Number:* ____________________________________________________________________

Authorised Installer:* _______________________________________________________________

Date Purchased: *__________________________________________________________________

Date Installed:* ____________________________________________________________________

Receipt Number: *_________________________________________________________________

Company you bought it from: *_______________________________________________________

Did you purchase the item when you purchased your pool?: ________________________________

If you purchased it after the pool, how many years did you wait?: ____________________________

What size is your pool or spa?: ________________________________________________________

Why did you choose an EVOHEAT product? ____________________________________________

Code:20151021-0003

Loading...

Loading...