Page 1

Inverter Air Source Water Heat Pump

Installation and Instruction Manual

Page 2

CONTENT

1 Preface

2 Safety Precaution

(1) Mark not es

(2) Icon Not es

(3) Warning

(4) Attenti on

3 Specification

(1) Appeara nce a nd structure of the heat pump

(2) Th e data of unit

(3

) Unit dimen sio n

4 Installation

(1) Applica tio n of heat pump

) Choose a rig ht he at pump unit

(2

(3

) Installa tio n place

(4) Instal lat ion method

(5

) Water loop connectio n

) Power supp ly co nnection

(6

(7

) Location o f the u nit

(8) Transit

(9) Trial Run nin g

5 Use and Operation Instruction of Wire Controller

(1)Main in ter fac e display and function

(2) On and off

(3) Mode switc h

(4) Setting of t arg et te mperature

(5) Temp erature setting

(6) Fast heating

(7) Timer set tin g

(8) Setup in ter fac e

(9) Th e operation of time setting

6 Form of Troubleshooting

(1) Make jud gme nt and troubleshooting

7 Appendix

(1) Appendi x 1

) Appendix 2

(2

(3

) Appendix 3

(4

) Appendix 4

) Appendix 5

(5

) Appendix 6

(6

1

2

2

2

3

4

5

5

6

7

9

9

10

10

10

11

11

11

12

12

13

13

15

15

16

17

18

18

19

20

27

27

28

28

29

30

30

31

32

Page 3

Preface

In order to provide our customers with high quality, strong, reliable and versatile products, this

heat pump is produced by strict design and manufacture standards.

This m anual inc ludes all t he necess ary inf or matio n ab out ins ta llati on , debug gi ng,

disc harging a nd mainte nance. Pl ease re ad t his man ua l caref ul ly befo re y ou open o r

maintain the unit.

The manufacturer of this product will not be held responsible if someone is injured or

the unit is damaged as a result of improper installation, debugging, unnecessary maintenance

which is not in line with this manual.

The un it must be in stalled b y qualifi ed pers on nel.

It is vi ta l that th e below ins tructio ns are adhe red to at a ll t imes to k ee p the war ra nty.

—

The un it can only b e opened or r epaired b y quali fi ed inst al ler or an a ut horis ed d ealer.

—Main tenance a nd operat ion must be c arrie d ou t accor di ng to the r ec ommen de d time an d

freq uency, as stat ed i n this ma nu al.

—Use ge nuine sta ndard spa re parts on ly.

Failure to comply with these recommendations will invalidate the warranty.

The Evo Flex is a high efficiency, energy saving and environmentally friendly equipment, which is

mainly used for house warming. It can work with any kind of indoor unit such fan coil, radiator, or

floor heating pipe, by providing warm or hot water. One unit of monobloc heat pump can also work

with several indoor units.

The Evo Flex is designed to have heat recovery by using a super heater which can provide hot

water for sanitary purposes.

This series of heat pump unit has the following features:

1 Advan ced contr olling

The PC microcomputer based controller is available for the users to review or set the running

parameters of the heat pump. Centralized controlling systems can control several units by PC.

2

Neat Appearance

The heat pump is designed to look neat and subtle. The monobloc one has the water

pump i ncluded w hich is ver y easy for in stallat ion.

3 Flexible installation

The unit has a smart structure with compact body, just a simple outdoor installation is needed.

4 Quiet running

High quality and efficient compressor, fan and water pump is used to ensure low noise level with

insulation.

5 Good heat exchange rate

The heat pump unit uses a specially designed heat exchanger to enhance whole efficiency.

6 Larg e working r ange

This ser ie s of heat p um p is desi gn ed to wor k under diffe re nt work in g condi tions as lo w

as -15 d egrees fo r heating .

1

Page 4

Safety Precaution

To prevent the users and others from the harm of this unit, and avoid

damage on the unit or other property by using the heat pump properly.

Please read this manual carefully and understand the following information

correctly.

Mark Notes

Mark

WARNING

ATTENTION

Icon notes

Icon

Meaning

A wrong o peratio n may lead to d eath or hea vy inju ry o n

peop le.

A wrong o peratio n may lead to h arm on peop le or los s of

mate rial.

Meaning

Proh ibition . What is pro hibited w ill be ne ar by this i co n

Comp ulsory im plement . Th e listed ac tion need t o be taken.

ATTEN TI ON ( inclu de WA R NI NG )

Plea se pay atte ntion to wh at is indic ated.

2

Page 5

Safety Precaution

安装前注意事项

Warning

Installation

Prof essiona l install er

is req uired.

Eart hing is req uired

Operation

PROHIBITION

Shut off the power

Meaning

The he at pump mus t be instal led by qual ified p er sonal s,

to avo id improp er instal lation wh ich can l ea d to wate r

leak age, elec trical sh ock or fire .

Please make sure that the unit and power connection have

good earthing, otherwise it may cause electrical shock.

Meaning

DO NOT put fingers and hands into the fans and evaporator of

the unit, otherwise it may cause injury.

When there is something wrong or a strange smell, the power

supply needs to be shut off to stop the unit. Continuing to run

may cause electrical shortage or fire.

Move and repair

Entrust

Entrust

Prohibit

Meaning

When the heat pump needs to be moved or installed again,

plea se entrus t dealer or q ualifie d perso n to c arry it o ut .

Impr oper inst allatio n will lead t o water lea kage, e le ctric al

shoc k, injury o r fire.

It is prohibited to repair the unit by the user himself,

otherwise electrical shock or fire may occur.

When the heat pump needs to be repaired, please entrust

dealer or qualified person to carry it out. Improper movement or

repair on the unit will lead to water leakage, electrical shock,

injury or fire.

3

Page 6

Safety Precaution

安装前注意事项

ATTENTION

Installation

Inst allatio n Place

Fix th e unit

Need

circ uit break er

Operation

Chec k the

inst allatio n basemen t

Meaning

The unit CANNOT be installed near flammable gas. Once

there is any leakage of the gas, fire can be occur.

Make sure that the basement of the heat pump is strong

enough to avoid the unit moving or falling.

Make sure that there is circuit breaker for the unit, lack of

circuit breaker can lead to electrical shock or fire.

Meaning

Please check the installation basement in a timely period

(

monthly), to avoid any decline or damage on the base which

may hurt people or damage the unit

Swit ch off

the po wer

Proh ibition

Proh ibition

Please switch off the power for cleaning or maintenance.

It is prohibited to use copper or iron as a fuse. The right fuse

must be fixed by

It is pr ohibite d to spray th e flammab le gas to the h eat pum p,

as it ma y cause fir e.

an electrician for the heat pump.

4

Page 7

Specification

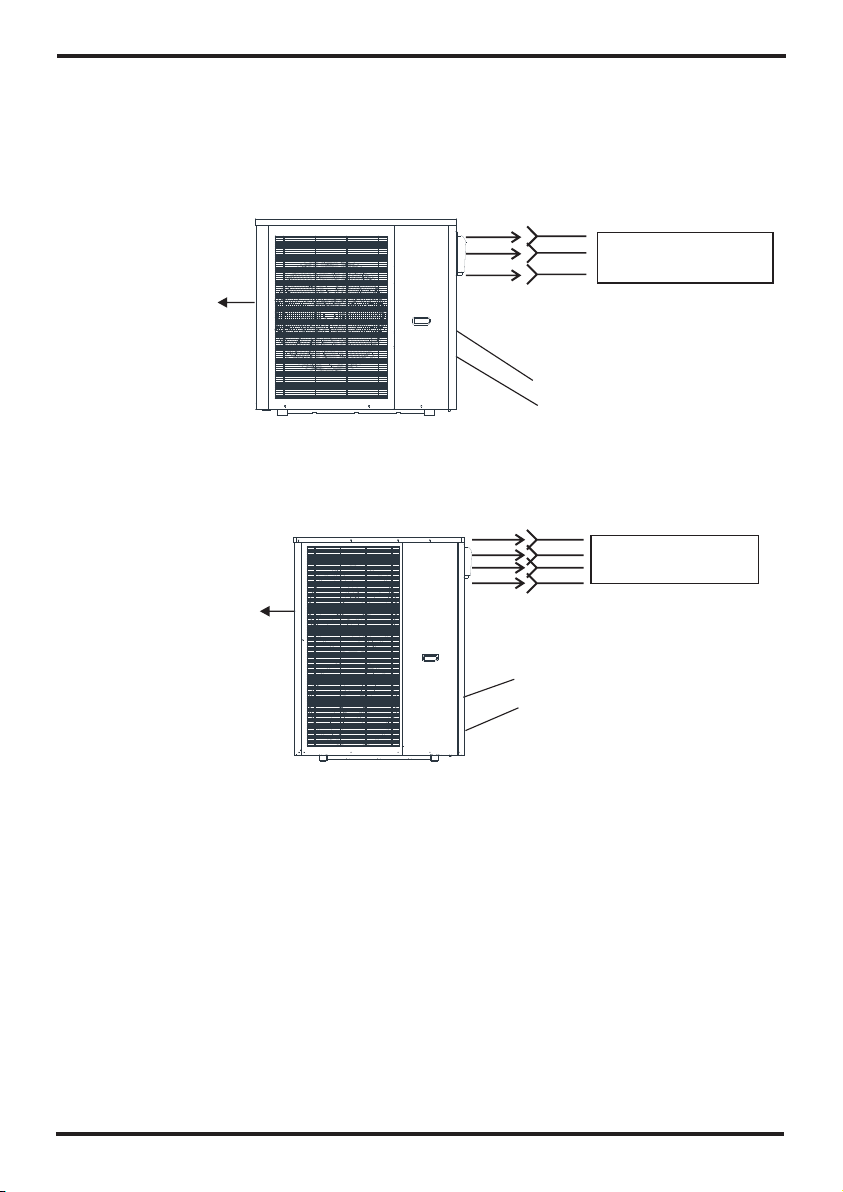

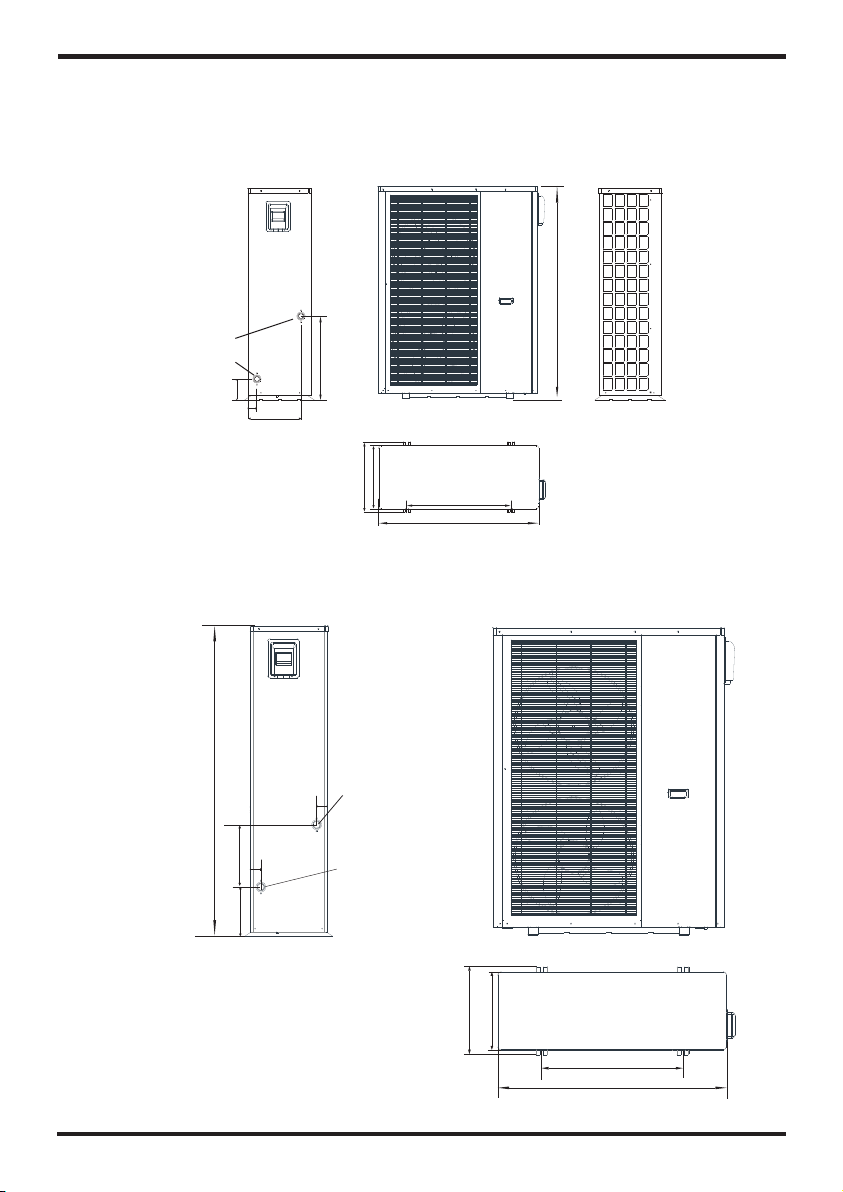

1. Appearance and Structure of the heat pump

Evo Flex 10

Air ou tlet in h orizo ntal

dire ction

Evo Flex 17 & 25

The lo ngest d istan ce of ins talli ng the

remo te cont rolle r is 200 me ters.

Wat er outl et tube

Wat er intl et tube

Remo te Cont rolle r

(Man ually )

Remo te Contro ller

(Man ually)

Air ou tlet in hor izontal

dire ction

The lo ngest dis tance of in stallin g the

remo te contro ller is 200 m eters.

Wat er outlet t ube

Wat er intlet t ube

5

Page 8

Specification

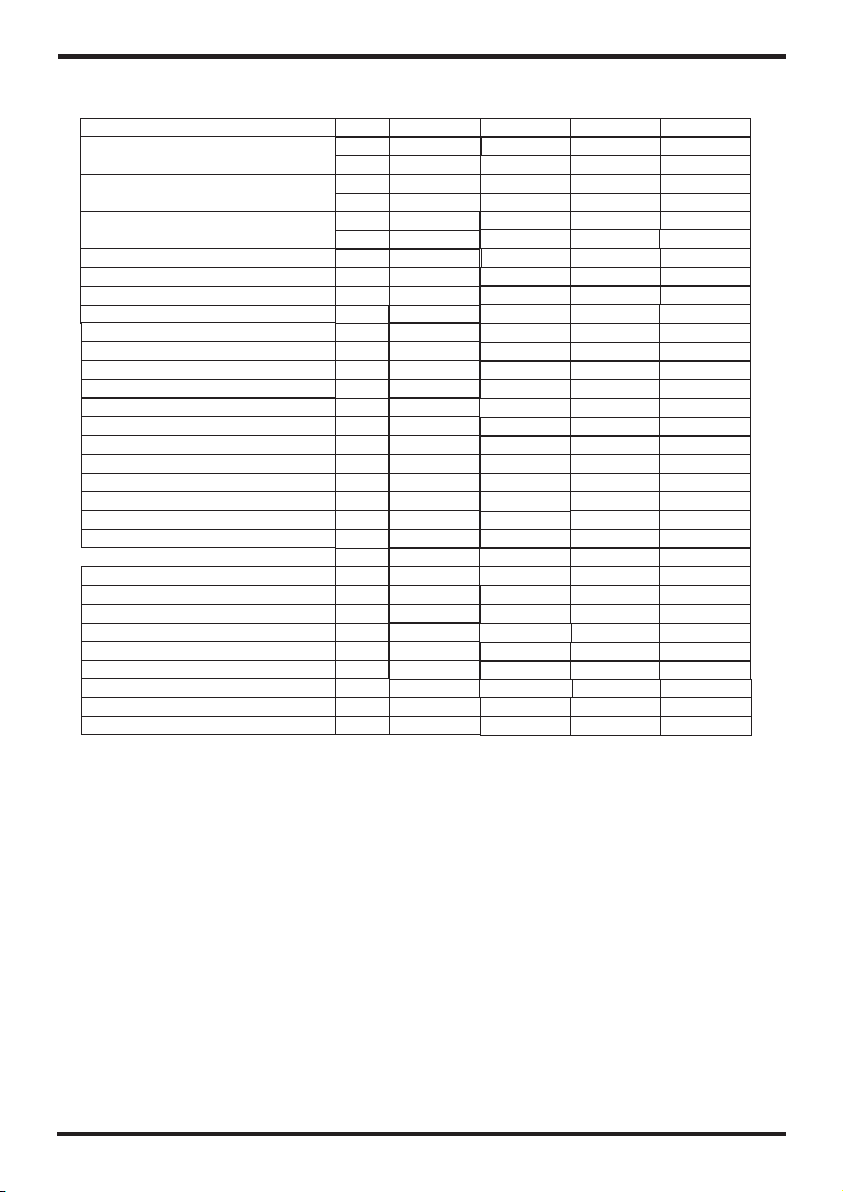

2. The data of unit

Model

Cooli ng C ap ac it y

Heati ng C ap ac it y

Hot Wat er C ap ac it y

Cooli ng P ow er I np ut

Heati ng P ow er I np ut

Hot Wat er P ow er I np ut

Opera ti on E le ct ric Cur re nt (m ax)

Cooli ng C ap ac it y Range

Heati ng C ap ac it y Range

Hot Wat er C ap ac it y Range

Cooli ng P ow er I np ut Rang e

Heati ng P ow er I np ut Rang e

Hot Wat er P ow er I np ut Rang e

Power S up pl y

Compr es so r Qu an tity

Compr es so r Mo de

Fan Qua nt it y

Fan Pow er I np ut

Fan Rot at e Sp ee d

Noise

Water P um p In pu t

water h ea d

Water C on ne ct io n

Water F lo w Vo lu me

Water P re ss ur e Dr op(ma x)

Unit Ne t Di me ns io ns (L/W /H )

Unit Sh ip pi ng D im ensio ns ( L/ W/ H)

Net Wei gh

Shipp in g We ig ht

l

t

Evo Flex

kW

BTU/h

kW

BTU/h

kW

BTU/h

kW

kW

kW

A

kW

kW

kW

kW

kW

kW

W

RPM

dB(A)

kW

m

inch

3

m /h

kpa

mm

mm

kg

kg

10

10

34121

11.5

39240

13.2

45040

3.4

3.4

3.6

15.7

2.0~10

2.5~11.5

4.2~13.2

1.0~3.4

0.8~3.4

1.0~3.6

230V~/50Hz

1

Rotary

1

75

850

54

0.18

12.5

1

1.6

24

953*445*910

1040*490*920

See nameplate

See p ackag e label

17

14.5

49489

16.5

56315

21.6

73702

5.6

5.1

6.2

27

5.0~14.5

5.0~16.5

7.4~21.6

1.6~5.6

1.2~5.1

1.5~6.2

230V~/50Hz

1

Rotary

2

75×2

850

58

0.5

21

1 1/4

2.8

105

996*395*1320

1070*435*1340

See nameplate

See p ackag e label

25

20

68260

25

85325

30

102364

9.0

9.0

8.2

14.0

7.0~20.0

8.0~25.0

11.0 ~3 0. 0

2.5~9.0

2.5~9.0

2.1~8.2

380V/3N~/50Hz

1

Rotary

2

150×2

900

62

0.65

22.5

1 1/4

4.2

71

1175 *4 00*1592

1225*430*1600

See nameplate

See p ackag e label

Cool ing worki ng condit ion:(DB /WB)3 5℃/2 4℃, (Outl et /Inle t) 7℃/ 12℃.

Heat ing worki ng condit ion: (DB/ WB) 7℃/6℃. (Out let/Inl et) 35℃/3 0℃.

Hot Water work ing con di tion: ( DB /WB) 20℃/ 15℃. ( Outle t/ Inlet ) 40℃/ 45℃.

BS EN 14 511-1 -2013 Ai r co nditi oner, whol e liquid co oling mac hine, e le ctric c om press or.

Part 2: Tes t co nditi on P art3: Test m ethod P ar t4:re lated req uiremen ts.

6

Page 9

Specification

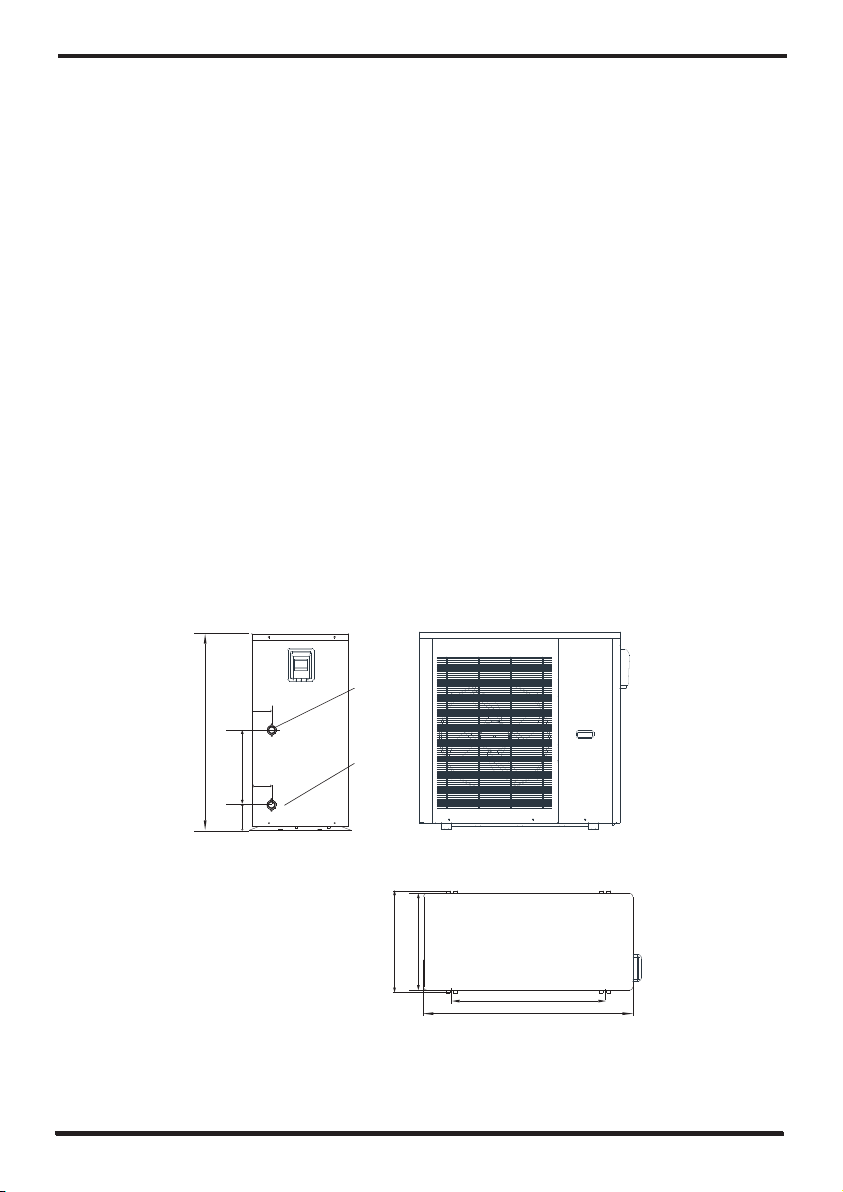

3. Unit dimension

Evo Flex 10

910

338

132

80

80

Wate r outle t 1

Wate r inlet 1

465

445

700

953

7

Page 10

Specification

Evo Flex 17

Wat er outl et 1 1/4' '

Wat er inlet 1 1 /4''

Evo Flex 25

133

1320

525

55

330

395

437

650

996

159 2

320

254

Wate r outle t 1 1/4''

55

55

Wate r inlet 1 1 /4''

450

400

725

117 5

8

Page 11

Installation

Unit fe atures

1. Plate heat exchanger

Use the SWEP efficient heat exchanger with small size and high efficiency.

2. Environmentally friendly refrigerant

Using the new generation of environmentally friendly refrigerant R410, which is harmless to the

ozone sphere.

3. Heating in frigid environment.

Optimized designed unit can achieve the heating function normally even when the ambient

temperature is -15℃.

4. Spraying condensation

The water-cooling system will be opened automatically to guarantee the normal operation of

cooling when the ambient temperature is higher than 30℃.

1 Application of heat pump

1.1 Only for air-con

CONNECTING HOSE

GENE RAL VALVE

WATER PUMP

NON-RETURN VALVE

TEMPERATURE METER

THREE-WAY VALVE

EXPANSION TANK

PRESSURE DIFFERENTIAL

BYPASS VALVE

AUTOMATIC REFILL VALVE

out let

inl et

Y-TY PE FILTER

PRES SURE METE R

VENT VALVE

SAFE TY VALVE

1/2'

9

Page 12

Installation

2 Choosing the right unit

2.1 Based on the local climate condition, construction features and insulation level,

calculate the required cooling(heating) capacity per square meter.

2.2 Co nclude th e total cap acity whi ch will b e ne eded by t he c onstr uc tion.

2.3 Acc ording to t he total ca pacity ne eded, c ho ose the r ig ht mode l by c onsul ti ng the he at.

pump f ea tures a s below:

Heat p um p featu res

Cool ing only un it: chille d water out let tem p. a t 5-15 , m ax imum am bi ent tem p. a t 43 .

Heat in g and Coo ling unit: f or coolin g chill ed w ater ou tl et temp . at 5 -15 ,max imum

ambi ent temp. a t 43 . For hea ting, war m water inl et temp . at 4 0-50 , m in imum am bi ent

temp . at - 10 .

Unit a pplicat ion

Evo Flex is used for house, office, hotel,s and so forth which need heating or

cooling separately, with each individual area needing to be controlled.

℃

℃ ℃

3 Installation place

The unit c an b e insta ll ed on any p lace outd oor which c an carry he avy mac hi ne such

as ter ra ce, hou setop, gr ound and so o n.

The location must have good ventilation.

The place is free from heat radiation and other fire flame.

A Some sort of cover is needed in winter to protect the heat pump from snow.

Ther e must be not o bstacle s near the ai r inlet a nd o utlet o f th e heat pu mp .

A place w hich is fre e from stro ng air blow ing.

Ther e must be wat er channe l around th e heat pu mp t o drain t he c onden si ng wate r .

Ther e must be eno ugh space a round the u nit for m ai ntena nc e.

℃ ℃

℃

4 Installation method

The heat p um p can be in st alled o nto the con crete bas ement by ex pansi on s crews , or

onto a s teel fram e with rubb er feet whi ch can be p la ced on th e gr ound or h ou setop .

Make s ure that th e unit is pla ced horiz ontal ly.

10

Page 13

Installation

5 Water loop connection

Plea se pay atte ntion to be low matte rs when t he w ater pi pe i s conne ct ed:

Try to reduce the resistance to the water from the piping.

The piping must be clear and free from dirt and blockage. Water leakage test must be carried

out to ensure there is no water leaking. And then the insulation can be made. Attention that the

pipe must be tested by pressure separately. DO NOT test it together with the heat pump.

There must be an expansion tank on the top point of the water loop, and the water level in the

tank must be at least 0.5 meter higher than the top point of the water loop.

The flow switch is installed inside of the heat pump, check to ensure that the wiring and action

of the switch is normal and controlled by the controller.

Try to avoid air staying inside of the water pipe, and there must be air vent on the top point of

the water loop.

There must be thermometer and pressure meter at the water inlet and outlet, for easy

inspection during running.

6 Power supply connection

Open t he front pa nel, and op en the powe r suppl y ac cess.

The po wer suppl y must go thr ough the wi re acce ss a nd be con ne cted to t he p ower

supp ly termin als in the co ntrolli ng box. Then co nnect the 3 -sign al w ire plu gs o f the

wire c ontroll er and main c ontroll er.

If the o utside wa ter pump is n eeded, pl ease in se rt the po we r suppl y wi re into t he w ire

acce ss also and c onnect to t he water pu mp term in als.

If an ad ditiona l auxilia ry heater i s need to b e co ntrol le d by the he at p ump con tr oller,

the re lay (or pow er) of the au x-heate r must be c on necte d to t he rele va nt outp ut o f

the co ntrolle r.

7 Location of the unit

。

A

Barrier

Air In let

The picture shows the location of horizont al air outl et unit.

B

!

Requ irement s

A>500mm; B>1500mm;

C>1000mm;D>500mm

The mi nimum ven tilatio n distanc e in diag ra m 1.

Barrier

Air Outle t

Attention

11

Main tenance

Spac e

C

Barrier

D

Barrier

Page 14

Installation

8 Transit

When the unit needs to be hung up during installation, an 8

meters cable is needed, and there must be soft material

betw een the cab le and the un it to preve nt dama ge t o

the he at pump cab inet. (Se e picture 1 )

Pict ure 1

WARNING

DO NOT touch the heat exc han ger of the heat pum p wit h fin gers or other obj ect s!

9 Trial Running

Insp ection be fore tria l running

Chec k the indoo r unit, and m ake sure th at the pipe c onnec ti on is rig ht a nd the re le vant

valves are open .

Check the water loop, to ensure that the water inside of the expansion tank is full enough, the

water supply is working wel, the water loop is full of water and without any air. Also make sure

there is good insulation for the water pipe.

Chec k the elect rical wir ing. Make s ure tha t th e power v ol tage is n or mal, th e sc rews ar e

fast ened, the w iring is ma de in line wi th the di ag ram, an d th e earth in g is conn ec ted.

Chec k the heat pu mp unit inc luding al l of the sc re ws and pa rt s of the he at p ump to se e if

they a re in good or der. When po wer on, rev iew the i nd icato r on t he cont ro ller to s ee i f

ther e is any fail ure indic ation. The ga s gauge can b e connect ed to the che ck valv e to

see th e high pres sure(or l ow pressu re) of the sy stem du ri ng tria l ru nning .

Trial run ning

Star t th e heat pu mp by press " " k ey on the con troller. C heck whet her the w at er pump i s

runn ing, if it ru ns normal ly there wi ll be 0.2 MPa o n the wat er p ressu re m eter.

When t he water pu mp runs for 1 m inutes, t he compre ssor wi ll s tart. H ea r wheth er t here is

stra nge sound f rom the com pressor. I f abnorma l sound o cc urs ple as e stop th e un it and

chec k the compr essor. If th e compres sor runs we ll plea se l ook for t he p ressu re m eter

of the r efriger ant.

Then c heck whet her the pow er input an d runni ng c urren t is i n line wi th t he manu al . If not

plea se stop and c heck.

Adju st the valv es on the wat er loop, to m ake sure th at the ho t( cool) w at er supp ly t o each

door i s good and me et the requ irement o f heating (or coo li ng).

Revi ew whethe r the outle t water tem peratur e is stab le .

The pa rameter s of the cont roller ar e set by the fa ctory, it is not a llowed to c hange the n

by use r himself .

12

Page 15

Use and Operation Instruction of Wire Controller

1.Main interface display and function

(1) Po wer on inte rface

1.0

1.0

(2) St arting up i nterfac e

⑨ ⑩

①

Rema rk: the wir e control ler can dis play the te mpera tu re unit a s "℉" or "℃" a ccord in g to

the un it model yo u bought.

② ③ ④

13

⑤

⑧

⑦

⑥

Page 16

Use and Operation Instruction of Wire Controller

Key function

Key nu mber

①

②

③

④

⑤

⑥

⑦

Note :

is def rosting i con, the ma chine is in d efrosti ng mode w he n this ic on i s shown ;

⑧

is hot w ater mode i con, this m achine is i n hot water m ode whe n th is icon i s sh own;

⑨

is hea ting mode i con, this m achine is i n heati ng m ode whe n th is icon i s sh own.

⑩

Key na me

On and o ff

Mode k ey

Temper ature

sett ing

Fast h eating

Tim er settin g

Setu p key

Faul t icon

Key fu nction

Clic k this key to s witch ON or O FF

Red re present s ON, while g rey repre sents OFF

Hot wa ter mode, h eating mo de, cooli ng mode ,

hot wa ter+hea ting mode o r hot water +cool in g mode

can be s elected b y pressin g this key.

Clic k this key to s et the targ et temper ature

Clic k th is key to s ta rt the rap id hea ting

This k ey will be di splayed d uring hea ting

Clic k this key to s et the time r

enab led, whil e green rep resents e nable d

Clic k this key to c heck the un it status , time,fa ctory

para meter, tem peratur e curve, ti mer setti ng and

Mute s etting

This I con will fl ash when th ere is an err or shown up ,

then t he displa y will ente r Failure r ecord i nt erfac e

afte r tapping t his icon.

Whit e represe nts not

14

Page 17

Use and Operation Instruction of Wire Controller

1.2 On and off

As the m ain inter face show s

(1).

In shu tting dow n interfa ce (on/off ke y is in gray st atus),

pres s on/off key ca n st art up th e ma chine .

(2)Note : In starti ng up inter face (on/ off key is in red s tatus),

pres s on/off key ca n sh ut down t he m achin e.

1.3 Mode switch

模式切 换

15

①

②

③

④

⑤

Page 18

Use and Operation Instruction of Wire Controller

In the m ain inter face, the re are five m odes can be s elect ed a fter ta pp ing the m od e key.

(1) ta pping hot w ater mode i con , then t he displa y will chan ge to this mo de inte rf ace;①

(2) ta pping hea ting mode i con , then t he d ispla y wi ll ente r th is mode i nt erfac e;②

(3) ta pping coo ling mode i con ,the n th e displ ay w ill swi tc h to this m od e inter fa ce;③

(4) ta pping hot w ater+he ating mod e icon , the n the dis pl ay will g o in to

hot wa te r+hea ting mode i nterfac e;

(5) ta pping hot w ater+co oling mod e icon , t he n the dis pl ay will c om e to

hot wa te r+coo ling mode i nterfac e;

Note : If what you h ave purch ased is a hea ting-on ly mode l (w ithou t co oling f un ction ),

the "c oo ling" w ill not be sh own on the in terface .

1.4 Setting of target temperatu re

①

④

⑤

②

Take hot w ater + cool ing mode fo r examp le :

Tappin g , the wire c on troll er b ack to ma in i nterf ace;

Tappin g , the targ et t emp of ho t wa ter can b e se t by pop- up k eyboa rd;

Tappin g , the targ et t emp of co ol ing mod e ca n be set by p op-up key board.

①

②

③

16

③

Page 19

Use and Operation Instruction of Wire Controller

1.5 When the target temp is being set, pop-up ke yboard is s hown as

follo wing:

①

②

③

④

Key nu mber

②

③

④

Note : means the ne w target te mp unde r cu rrent s et ting①

Key na me

Retu rn key

Dele te key

Ente r key

Key fu nction

Tappin g this key ca n back to

the ma in interf ace.

Tappin g this key to u ndo

the la st action .

Tappin g this key ca n save you

acti on and back t o the main

inte rface.

17

Page 20

Use and Operation Instruction of Wire Controller

1.6 Fast heating

②

③

①

Unde r the heati ng mode, cl ick the f as t heati ng k ey the a bo ve inte rface wil l appear.

② ③

Clic k to start the f ast hea ti ng and cl ic k to close i t.

1.7 Timer setting

Clic k the timer s etting ke y to enter th e timer set ting and

the in terface d isplay is a s follows :

①

④

①

⑤

②

③

18

⑥

⑦

Page 21

Use and Operation Instruction of Wire Controller

Key nu mber

①

②

③

④

⑤

⑥

⑦

Such a s the above f igure: Un der the sta te of unman ned ope ra tion, i t wi ll star t th e timed

star t-up at 17: 10 and will b e timed shu tdown whe n runni ng t o 20:10 .

Key na me

Retu rn key

Enab le the

time r on

Enab le the

time r off

Hour o f timer on

Minu te of

time r on

Hour o f timer off

Minu te of

time r off

Key co lor

Enab le: Green O N

Disa ble: Gray O FF

Enab le: Red ON

Disa ble: Gray O FF

Key fu nction

Click this key to return to the main

interface.

Clic k this key to s tart or tur n off th e

time d start-u p functio n

Clic k this key to s tart or tur n off th e

time d shutdow n functio n

Hour o f Timer on is sh own

Minu te of Timer on i s shown

Hour o f Timer off is sho wn

Minu te of Timer off is s ho wn

1.8 Setup interface

Clic k th e setup k ey on the mai n interfa ce and the in terface d ispla y is a s follo ws :

①

②

④

⑤

③

19

Page 22

Use and Operation Instruction of Wire Controller

Key nu mber

①

②

③

④

⑤

Key na me

Stat us key

Cloc k key

Mute k ey

Fact ory key

Curv e key

Key fu nction

Clic k this key to g et into the s tatus int erface.

Clic k this key to s et the oper ational t ime funct ion.

Clic k to turn on/ off si lent fu nc tion an d to set timi ng interv al

func tion.

Clic k this key to g et into the f actory in terface .

Clic k this key to l ook up the te mperatu re curve.

1.9 The operation of time setting

Clic k th e clock k ey on the set up interf ace and the i nterfac e displ ay i s as foll ow s:

②

④

①

⑥ ⑤

③

⑦

20

Page 23

Use and Operation Instruction of Wire Controller

Note :

:Cli ck the up and d owm key to se t the month ;

①

:Cli ck the up and d owm key to se t the day;

②

:Cli ck the up and d owm key to se t the year;

③

:Cli ck the up and d owm key to se t the hour;

④

:Cli ck the up and d owm key to se t the minut e;

⑤

:Cli ck the key to c ancel the s etting;

⑥

:Cli ck the key to d etermin e the setti ng,and th e system wi ll be aut om atica ll y

⑦

cali br ated if i t is incorr ect.

1.10 Fault interface

Clic k th e fault i con on the ma in interf ace and the i nterfac e displ ay i s as foll ow s:

①

Note :

①:Fau lt code

②:Fau lt name

③:Occ urrence t ime of the fa ult,Day, mon th a nd year h our: seco nd (s)

④:Cli ck this key t o clear all f ault reco rds

②

③

1.11 Color Display Cal ibratio n

④

Keep c lick quic kly at the bl ank area on a ny interf ace til l yo u hear a lo ng b eep. Then y ou

will e nter the ca librati on interf ace. Clic k "+" to st ar t calib ra tion.

When y ou hear the b eep again , you will fi nish ca li brati on a nd exit

21

Page 24

Use and Operation Instruction of Wire Controller

2. Parameter list and breakdown table

2.1 Electron ic co ntrol fault tab le

Can be j udged acc ording to t he remote c ontroll er fail ur e code an d tr ouble sh ootin g

Pro te ct /faul t

Inl et Tem p. Sens or F ault

Out le t Temp. Sen so r Fault

Wat er Tank Tem p Senso r

AT Sen sor Fau lt

Sucti on Temp. Se ns or Faul t

Coil Temp S ensor

Exh au st t emp Sen so r

Exh au st O verte mp

Sucti on P ressu re s ensor

Fau lt

Exh au st P ressu re s ensor

Fau lt

Low AT pr ot ect io n

Elect ri c Overh ea t Prote ct ion

Commu ni catio n Fa ult

HP Pr ot ectio n

LP Pr ot ectio n

Pri ma ry An ti-fr ee zing Pr ot .

Secon da ry A n ti -fr ee zi ng P ro t.

Flow Sw it ch Prot ec tion

Compr es sor Ove rc urren t

Shutd ow n Fault

Anti- fr eezin g Pr ot

DC Fan Mo to r 1 Failu re

DC Fan Mo to r 2 Failu re

DC Fan Mo to r Comms F ai lure

Fau lt

displ ay

The t em p. S ensor i s br oken

P01

or sh or t ci rcuit

The t em p. S ensor i s br oken

P02

or sh or t ci rcuit

The t em p. S ensor i s br oken

P03

or sh or t ci rcuit

The t em p. S ensor i s br oken

P04

or sh or t ci rcuit

The t em p. S ensor i s br oken

P17

or sh or t ci rcuit

The t em p. S ensor i s br oken

P153

or sh or t ci rcuit

The t em p. S ensor i s br oken

P181

or sh or t ci rcuit

The t em p. S ensor i s br oken

P182

or sh or t ci rcuit

PP2

The p re ss ure Sen so r is brok en

PP1

The p re ss ure Sen so r is brok en

The e nv ir onmen t te mp. is lo w

TP

The c om pr essor i s ov erloa d

E04

Commu ni cat ion f ai lure be tw een

E08

wire co nt rolle r an d mainb oa rd

The h ig h- prees ur e switc h is

E11

bro ke n

Low pre ss ure1 pr ot ectio n

E12

The a mb ie nt temp . Is l ow

E19

The a mb ie nt temp . Is l ow

E29

No wate r/ littl e wa ter in

E032

water s ys tem

The c om pr essor i s ov erloa d

E051

Wat er fl ow i s no t enoug h

E171

1. Mo to r is i n locke d- rotor s ta te

2.T he w ir e conne ct ion bet we en

F03 1

DC-fa n mo tor mod ul e and fan

motor i s in b ad cont ac t

1. Mo to r is i n locke d- rotor s ta te

2.T he w ir e conne ct ion bet we en

F03 2

DC-fa n mo tor mod ul e and fan

motor i s in b ad cont ac t

Speed c on trol mo du le and ma in

E081

board c om munic at ion fai l

Reaso n

Elimi na tion me th ods

Check o r ch ange th e te mp. Sen so r

Check o r ch ange th e te mp. Sen so r

Check o r ch ange th e te mp. Sen so r

Check o r ch ange th e te mp. Sen so r

Check o r ch ange th e te mp. Sen so r

Check o r ch ange th e te mp. Sen so r

Check o r ch ange th e te mp. Sen so r

Check o r ch ange th e te mp. Sen so r

Check o r ch ange th e pr essur e Se nsor

or pres su re

Check o r ch ange th e pr essur e Se nsor

or pres su re

Check w he ther th e sy stem of t he c ompre ss or

runni ng n ormal ly

Check t he w ire con ne ction b et ween

remot e wi re cont ro ller an d ma in boar d

Check t he p ressu re s witch a nd c old cir cu it

Check t he p ressu re s witch a nd c old cir cu it

Check t he p ipe wat er f low and w at er pump

Check w he ther th e sy stem of t he c ompre ss or

runni ng n ormal ly

Check t he p ipe wat er f low and w he ther

water s ys tem is ja mm ed or not

1.C ha ng e a new fan m ot or

2.C he ck t he wire c on necti on a nd make s ur e

the y ar e in g ood con ta ct

1.C ha ng e a new fan m ot or

2.C he ck t he wire c on necti on a nd make s ur e

the y ar e in g ood con ta ct

Check t he c ommun ic ation c on necti on

22

Page 25

Use and Operation Instruction of Wire Controller

Frequency conversion board fault table :

Prote ct ion/f au lt

IPM O ve rc urren t Sh utdow n Fa ult

Compr es sor Acti va tion Fa il ure

PFC Fa ult

DC Bus Ov er load

DC Bus Un de rload

AC In pu t Un derlo ad

AC In pu t Ov erloa d

Input v ol tage Sa mp le Faul t

Commu ni catio n Fa ilure b et ween

DSP and P FC

Commu ni catio n Fa ult (DS P)

Commu ni catio n Fa ult

(In ve rt er Boar d)

IPM O ve rh eat Sto p

Wea k Ma gneti sm Al arm

Inp ut v ol tage La ck ing Pha se

IPM C ur re nt Samp le F ault

Senso r Fa ult of Mo du le/Ra di ator

IGB T Pow er Devic e Ove rhear Ala rm

Ove rl oa d Alarm

AC In pu t Ov erCur re nt Alarm

EEP RO M Fa ult Alar m

Destr oy ed EEPR OM Ac tivat io n

Ban Alar m

LP 15 V Un derlo ad F ault

IGB T Po wer Dev ic e Overh ea t Fault

Fau lt

displ ay

F00

IPM I np ut c urren t is l arge

Lac k of phas e, step o r drive h ardwa re

F01

dam ag

F03

The P FC c ir cuit pr ot ectio n

DC bus vo lt age<D c bu s

F05

Ove rl oa d-vol ta ge prot ec tion va lu e

DC bus vo lt age<D c bu s

F06

Under lo ad-vo lt age pro te ction v al ue

The i np ut v oltag e is u nderl oa d, caus in g

F07

the i np ut c urren t is l ow

The i np ut v oltag e is o ver, cau si ng the

F08

input c ur rent is t o hi gh

F09

The i nput vo ltage s ampli ng faul t

F10

DSP and P FC conn ec t fault

DSP and I nvert er b oard co mm unica ti on

F11

fai lu re

Commu ni cat ion f ai lure be tw een

F12

inver te r board

F13

The I PM modu le is ove rheat

Compr es sor mag ne tic for ce i s not

F14

enoug h

F15

The i np ut v oltag e lo st phas e

F16

IPM s ampli ng elec trici ty is fau lt

F17

The t ra ns ducer i s ov erhea t

F20

The t ra ns ducer i s ov erhea t

The c om pr essor i np ut curr en t is too la rg e

F21

F22

Inp ut c ur rent is t oo l arge

F23

MCU e rror

F24

MCU e rror

F25

The V 15 V is o verlo ad o r under vo ltage

T

F26

Reaso n

and mai nb oard

ransd uc er temp er ature i s to o high

Elimi na tion me th ods

Check a nd a djust t he c urren t

measu re ment

Check t he m easur in g volta ge c heck

reque nc y conve rs ion boa rd h ardwa re

Che ck th e PF C sw it ch tu b e s ho rt ci rc u i t

or no t

Check t he i nput vo lt age mea su remen t

Check t he i nput vo lt age mea su remen t

Check t he i nput vo lt age mea su remen t

Check a nd a djust t he c urren t

measu re ment

Check a nd a djust t he c urren t

measu re ment

Check t he c ommun ic ation c on necti on

Check t he c ommun ic ation c on necti on

Check t he w ire con ne ction b et ween

remot e in verte r bo ard and m ai n board

Check a nd a djust t he c urren t

measu re ment

Check a nd m ea sure th e vo lt age

adjus tm en t

Check a nd a djust t he c urren t

measu re ment

Check a nd a djust t he c urren t

measu re ment

Check a nd a djust t he c urren t

measu re ment

Check a nd a djust t he c urren t

measu re ment

Check a nd a djust t he c urren t

measu re ment

Check t he V 15 V in pu t vol ta ge i n ra ng e

13.5v ~1 6.5v or not

Check a nd a djust t he c urren t

measu re ment

2.2 Parameter list

Meaning

Refr igerati on target t emperat ure set poi nt

Heat ing the tar get tempe rature se t point

23

Default

12℃

40℃

Remarks

Adju stable

Adju stable

Page 26

Use and Operation Instruction of Wire Controller

3. Interface drawin

3.1 Controller interface diagram and definition

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

5V

DI5-PWM

D05-PWM

DI4-PWM

D04-PWM

DI3-PWM

D03-PWM

DI2-PWM

A02

D02-PWM

DI1-PWM

A01

D01-PWM

DI10

DI09

DI08

DI0 7

DI06

DI05

DI04

DI0 3

DI02

DI0 1

AI2 2

AI2 1

AI2 0

AI1 9

AI1 8

AI1 7

AI1 6

AI1 5

AI1 4

AI1 3

AI12

AI11

AI1 0

AI0 9

AI0 8

A

AI0 7

AI0 6

AI0 5

AI04(5 0K)

AI03(5 0K)

AI0 2

AI0 1

485-B 1

CAN-H

CAN-L

GND

12V

485-B 2

485-A 1

GND

12V

PC8002

485-B 3

GND

485-A 3

12V

CN4

T5AL250V

FUSE

CN2

CN3

CN1

RO 18

RO 17

RO 16

RO 15

RO 14

RO 13

RO 12

RO 11

RO 10

RO 09

RO 08

RO 07

RO 06

RO 05

RO 04

RO 03

RO 02

RO 01

L

N

485-A 2

12V

24

Page 27

Use and Operation Instruction of Wire Controller

Main board of the input and output interface instructions below

Number

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Sign

RO 01

RO 02

RO 03

RO 04

RO 05

RO 06

RO 07

RO 08

RO 09

RO 10

RO 11

RO 12

RO 13

RO 14~ RO18

AC-L

AC-N

AI01

AI02

AI03

AI04

AI05

AI06

AI07

AI08

AI09 -AI20

AI21

AI22

DI01

DI02

DI03

DI04

DI05

DI06

DI07

485_ A1

485_ B1

485_ A2

485_ B2

485_ A3

485_ B3

Mean ing

Comp ressor ( ou tput 220- 230VAC)

Wat er pump ( out put 220 -2 30VAC)

4-wa y valve ( out put 220-2 30VAC)

Fan ( ou tput 220- 230VAC)

Rese rved

Anti -freezi ng Heater ( output 22 0-230VAC)

Cran kshaft He ater( out put 220-2 30VAC)

Spra y Val ve ( outpu t 22 0-230 VAC)

Elec tric Auxil iary Heat er( outpu t 220-2 30 VAC)

Rese rved

Alar m( output 2 20-230VAC)

Hot wa ter pump

Elec tromagn etic thre e-way val ve

Rese rved

Live w ire ( input 2 20-230VAC)

Neut ral wire ( in put 220-2 30VAC)

Wat er inlet temperature( )inpu t

Water output temperature( )inpu t

Syst em Exhaus t tempera ture (inpu t)

Rese rved

Syst em suctio n tempera ture (inpu t)

Syst em coil tem peratur e( input)

Ambi ent tempe rature( in put)

Wat er tank Tempera ture ( inpu t )

Rese rved

Suct ion press ure input

Exha ust press ure input

Syst em high pre ssure inpu t( )

Syst em low pres sure inp ut( )

Wat er flow swi tch inpu t( )

Emer gency swi tch input( )

Mode s witch inpu t( )

Mast er-slav e machine s witch in pu t( )

Elec tric heat ing overl oad prote ction s wi tch inpu t( )

Freq uency con version b oard comm unica ti ons

Comm unicate w ith wire co ntrolle r and DC fa n mo dule

Rese rved

25

Page 28

Use and Operation Instruction of Wire Controller

41

42

43

44

12V

5V

CN1

CN2- CN4

12V( output)

5V(o utput)

Elec tronic ex pansion v alve

Rese rved

26

Page 29

Form of Troubleshooting

A.

Make judgment sand troubleshooting by reference to the following form

Fail ure

Heat pu mp

canno t

be star te d

Wat er pump i s

runni ng w ith

high no is e or

witho ut w ater

Heat pu mp

capac it y is low,

compr es sor

do not st op

High co mp resso r

exhau st

Low pre ss ure

probl em

of th e sy st em

Compr es sor do

not run

High no is e of

compr es sor

Fan d o no t ru n

The c om pr essor

runs bu t he at

pump ha s no t

heati ng o r

cooli ng c apaci ty

Low out le t water

tem pe ra ture

Low wat er f low

prote ct ion

Poss ible caus es for the fa ilure

1 Wro ng p ower su pp ly

2 pow er s up ply cab le l oose

3 cir cu it b reake r op en

1 lac k of w at er in the p ip ing

2 much air in the water loop

3 water va

4 dir t an d bl ock on th e wa ter fil te r

1 lac k of r ef riger an t

2 bad i ns ul ation o n wa ter pip e;

3 low h ea t ex chang e ra te on air s id e

exc ha ng er;

4 lac k of w at er flow

1 too m uc h re frige ra n

2 low h ea t ex chang e ra te on air s id e

exc ha ng er

1 lac k of g a

2 blo ck o n fi lter or c ap illar y

3 lac k of w at er flow

1 pow er s up ply fai lu r

2 com pr es sor con ta ctor br ok en

3 pow er c ab le loos e

4 pro te ct ion on co mp resso r

5 wro ng s et ting on r et urn wat er t emp.

6 lac k of w at er flow

1 liq ui d re frige ra nt goes i nt o compr es so r

2 com pr es sor fai lu re

1 fai lu re o n fan rel a

2 fan m ot or b roken

1 no ga s in t he h eat pum p;

2 hea t ex ch anger b ro ken;

3 com pr es sor fai lu re.

1 low w at er f low rat e;

2 low s et ti ng for th e de sired w at er temp .;

1 lac k of w at er in the s ys tem;

2 fai lu re o n flow sw it ch

lves closed

;

t

s

e

y

Solu tions

1 shu t of f the pow er a nd chec k po wer sup pl y;

2 che ck p ow er cabl e an d make ri gh t conne ct io n

3 che ck f or t he caus e an d repla ce t he fuse o r

cir cu it b reake r

1 che ck t he w ater su pp ly and ch ar ge wate r

to th e pi pi ng;

2 dis ch ar ge the ai r in t he wate r lo op;

3 ope n th e va lves in w at er loop ;

4 cle an t he w ater fi lt er.

1 che ck f or t he gas le ak age and r ec harge t he

ref ri ge rant;

2 mak e go od i nsula ti on on wat er p ipe;

3 cle an t he a ir side h ea t excha ng er;

4 cle an t he w ater fi lt er

1 disch ar ge the re du ndant g a

2 cle an t he a ir side h ea t excha ng er

1 che ck t he g as leak ag e and rec ha rge fre on ;

2 rep la ce f ilter o r ca pilla ry ;

3 cle an t he w ater fi lt er and di sc harge t he a ir in

wat er l oo p.

1 che ck o ff the po we r suppl y;

2 rep la ce c ompre ss or cont ac tor;

3 tig ht en t he powe r ca ble;

4 che ck t he c ompre ss or exha us t temp. ;

5 res et t he r eturn w at er temp .;

6 cle an t he w ater fi lt er and di sc harge t he a ir i n

wat er l oo p.

1 bad eva po ratio n, c heck th e ca use for b ad

eva po ra tion an d ge t rid of th is

2 use n ew c om press or ;

1 rep la ce t he fan re la y

2 rep la ce f an moto r.

1 che ck s ys tem lea ka ge and re ch arge re fr ig era nt ;

2 fin d ou t th e cause a nd r eplac e th e heat

exc ha ng er;

3 rep la ce c ompre ss or.

1 cle an t he w ater fi lt er and di sc harge t he a ir in

wat er l oo p.

2 res et t he d esire d wa ter tem pe ratur e.

1 cle an t he w ater fi lt er and di sc harge t he a ir in

wat er l oo p.

2 rep la ce t he flow s wi tch.

s

;

;

27

Page 30

Appendix

Appendix 1 Install sketch map

S

pecial installation( expandable water tank)

Pre ssure

lea kage

val ve

Technical request:

1.Each connection must be connected tightly and have no leakage.

2.the arrowhead orientation of automatic filled- water

must accord with water supply.

3.The pressure of automatic filled-water has been

set,and please do not remove screw.

aut omati c

fil l-wat er

val ve

1/2'

9

15

4

1

outle t

inlet

234

6

13

5

5

9

11

10

8

7

1/2'

4

12

13

4

14

4

6

Remark

1 main unit

2 connecting h ose

l

3 pressure met er

4 general valv

e

5 three-way va lve

6 Y-type filter

7 safety valv

e

9 vent valve

10 automatic r efi ll valve

11 pres sure differential by pas s valve

12 drain valve

13 Non-retur n val ve

14 water pump

15 fan coil

8 expansion ta nk

Installation request:

1 The fa ctory only offers main u nit ( 1)in the legend, and t he ot her modules

which are indi spe nsable fittin gs, a re pr ovided by users o r ins tallation com pan y.

2 Automatic ref ill v avel(10)is instal led o n the t op point of the wat er sy stem。

3 The qu antity propor tio n of general vave l(4)and t hre e-way valve(5)is

referred to th e tec hnical regula tio n, and there is three- way v alve installe d on th e

farthest pla ce of w ater systemso o n.

28

Page 31

Appendix

Appendix 2:

The installation explanation of automatic filled-water

1 When automatic filled-water valve is installed,the arrowhead orientation of inlet water must

accord with the orientation of valve ;

2 Automatic filled-water has been adjusted in advance to 1.5bar;

3 If readjust the pressure of inlet water,please operate as follows:

* open the screw cap(C);

* If reduce the pressure of water supply,pease unscrew the pressure to adjust the screw(B);

* If increese the pressure of waer supply,please screw down the pressure to adjust the screw (B)

4 When the system need fill water at first,wrest the handle(A) of filled-water.Then the handle(A)

can return(close) when the system is full of water.

5 Automatic filled-water Valve need clean in a periodic time and then you must close the tap,

unscrew the plug(D),remove the inside filter net.Please assemble them again after cleaning.

NOTICE:There are two connections for water pressure meter in the central section of

automatic filled-water,where the water pressure meter can be connected directly

and display the set pressure.The screw cap(C) must be tweaked after adjusting

the filled-water pressure.

B

C

1/2'

1/4'

D

A

29

Page 32

Appendix

Appendix 3:

The installation explanation of the leakage pressure valve.

1 The acti on p ressu re o f leaka ge p ressu re valve 'i s more than 3 bar(val ve is open),

but th e pr essur e can not be ad justed.

2 The valv e wi ll open a ut omati ca lly to ma ke sure tha t the water l oop of air- con syste m

is saf e wh en the wa ter press ure in the ba ckwater s ide is high er than t he s et pres su re.

outle t

inlet

Appendix 4:

The way of assistant heat source connection

Unit p ro vides t he connec tion of ass istant he at source w hich ca n no t be only f or g as-fi re d

boil er,but als o for elect ronic boi ler or wa rm -net pi pe f or city a cc ordin gl y.

The wa y to the conn ection is a s follows :

1)wate r chiller a nd heat pum p+assis tant gas- fired b oi ler

wate r chiller a nd heat pum p

inl et

out let

cab le

contr ol w ire

Thr ee-wa y valve

gas-f ir ed boil er

inlet

outle t

2)wate r chiller a nd heat pum p+assis tant el ec troni c bo iler

wate r chiller a nd heat pum p

inl et

out let

cab le

elect ro nic boi le r

inlet

outle t

30

Page 33

Appendix

Appendix 5、

1. The uni t ca n only be r ep aired b y qu alifi ed instal ler centr e personn el or an au th orise d

deal er.(for Euro pe market)

2. This ap pl iance i s no t inten de d for use b y persons ( includi ng childr en) wit h re duced p hy sical

sens ory or ment al capabi lities, o r lack of exp erien ce a nd know le dge, un le ss they h av e been

give n supervi sion or ins tructio n concern ing use o f th e appli an ce by a per so n respo ns ible fo r

thei r sa fety. (for Eu ro pe mark et)

Chil dren shou ld be super vised to en sure that t hey do no t pl ay with t he a pplia nc e.

3. Ple ase make su re that the u nit and pow er connec tion ha ve g ood ear th ing, ot he rwise m ay

caus e electri cal shock .

4. If th e su pply co rd is damag ed, it must b e replace d by the manu factu re r or our se rv ice age nt

or sim ilarly qu alified p erson in or der to avoi d a hazar d.

5. Dir ective 20 02/96/E C (WEEE):

The sy mbol depi cting a cro ssed-ou t waste bin t hat is un de rneat h th e appli an ce indi ca tes

that t hi s produ ct, at the en d of its usef ul life, mu st be handl ed sepa ra tely fr om d omest ic

wast e, must be ta ken to a recy cling cen tre for ele ctric and e lectr on ic devi ce s or hand ed

back t o th e deale r when purc hasing an e quivale nt appl ia nce.

6. Dir ective 20 02/95/E C (RoHs): Thi s product i s complia nt with dir ective 20 02/95 /E C (RoHs )

conc erning re stricti ons for the u se of harmf ul substa nces in e le ctric a nd e lectr on ic devi ce s.

7. The uni t CA NNOT be ins ta lled ne ar t he flam ma ble gas . On ce ther e is a ny leak age of the ga s

, fire c an b e occur.

8. Mak e sure that t here is cir cuit brea ker for the u nit, lack o f circu it b reake r ca n lead to

elec trical sh ock or fire .

9. The hea t pu mp loca te d insid e th e unit is e quipped w ith an over -load pro tecti on s ystem . It

does n ot allow fo r the unit to s tart for at l east 3 minu tes from a pr evious st oppag e.

10. The un it c an only b e re paire d by the qual ified per sonnel of a n install er cent er o r an

auth orized de aler. (for No rth Americ a market)

11. Insta ll ation m us t be perf or med in ac cordanc e with the NE C/CEC by au thorize d perso n on ly.

(for No rth Americ a market)

12. US E SUPPLY WI RES SUI TABLE F OR 75℃.

13. Ca ution: Si ngle wall h eat excha nger, no t su itabl e fo r potab le w ater co nn ectio n.

Caution & Warning

31

Page 34

Appendix

Appendix 6、Cable specification

1. Single phas e uni t

Name plate

maxi mum

curr ent

No more

than 1 0A

10~1 6A

16

~25A

25

~32A

32

~40A

40

~63A

63~7 5A

75~1 01A

101~ 123A

123~ 148A

148~ 186A

186~ 224A

Phas e line

2×1.5m m

2×2.5m m

2×4mm

2×6mm

2×10mm

2×16mm

2×25mm

2×25mm

2×35mm

2×50mm

2×70mm

2×95mm

2. Thr ee phase unit

Name plate

maxi mum

curr ent

No more

than 1 0A

10~1 6A

16

~25A

25

~32A

32

~40A

40

~63A

63~7 5A

75~1 01A

101~ 123A

123~ 148A

148~ 186A

186~ 224A

Phas e line

3×1.5m m

3×2.5m m

3×4mm

3×6mm

3×10mm

×

16mm

3

×

25mm

3

3×25mm

3×35mm

3×50mm

3×70mm

3×95mm

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Eart h line

1.5m m

2.5m m

4mm

6mm

10mm

16mm

25

25

35mm

50mm

70mm

95mm

Eart h line

1.5m m

2.5m m

4mm

6mm

10mm

16mm

mm

25

mm

25

35mm

50mm

70mm

95mm

mm

mm

2

2

MCB

2

20A

2

32A

2

40A

2

40A

2

63A

2

80A

2

100A

2

125A

2

160A

2

225A

2

250A

2

280A

MCB

2

20A

2

32A

40A

40A

2

63A

2

80A

2

100A

2

125A

2

160A

2

225A

2

250A

2

280A

Cree page prot ector

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

Cree page prot ector

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

30mA le ss than 0.1 s ec

Sign al line

×

n 0.5mm

Sign al line

×

n 0.5mm

2

2

When t he unit wil l be instal led at outd oor, ple as e use the c ab le whic h ca n again st U V.

32

Page 35

Code: 20 18101 8- 0001

Loading...

Loading...