Everwarm CHK-15-120, CHK-25-120, CHK-50-120, CHF-50, CHF-100 Installation Manual

...

GENERAL

INSTAL

GUIDE

LATION

www.EverWarm.net

THIS PRODUCT SHOULD ONLY BE INSTALLED BY QUALIFIED

PERSONNEL WHO ARE FAMILIAR WITH THE CONSTRUCTION AND

OPERATION OF THE APPARATUS AND ANY RISKS INVOLVED.

READ ALL INFORMATION PROVIDED IN THIS GUIDE BEFORE

ATTEMPTING TO INSTALL THIS PRODUCT.

FOR PART NUMBERS: CHK-15-120, CHK-25-120, CHF-50, CHK-50-120,

CHK-50-240, CHF-100, CHK-100-120, CHK-100-240, CHF-200,

CHK-200-240, CHF-550

THE DOCUMENTATION PROVIDED HEREIN PERTAINS SOLEY TO THE

USE AND INSTALLATION OF EverWarm Radiant Heat FILM, EverWarm

RADIANT FLOORS, OEM ACCESSORIES, AND PRODUCTS

PRODUCED BY CarbonicHeat CORPORATION. SUBJECT MATTER

AND SPECIFICATIONS ARE SUBJECT TO CHANGE.

For updated information on our products please refer to our website

www.EverWarm.net

855.558.5200

416 South Main Street, Suite B-2 Hailey, ID 83333, USA

VERSION 11

TABLE OF CONTENTS

SECTION 1: GENERAL NOTES AND INFORMATION .............4-10

SECTION 2: TOOLS REQUIRED FOR INSTALLATION ............... 11

SECTION 3: INSTALLATION GUIDELINES ........................ 12-20

SUBFLOOR PREPARATIONS ..................... 12

TILE ................................................. 13-16

LAMINATE ............................................ 17

WOOD FLOOR ....................................... 18

CARPET ................................................ 19

LINOLEUM AND VINYL ........................... 20

SECTION 4: INSTALLING HEATING FILM ......................... 21-23

SECTION 5: GENERAL INSTALLATION INSTRUCTIONS ...... 24-32

LAYOU T................................................24

INSTALLING HEATING FILM ......................26

ATTACHING HARNESS .............................27

TESTING CONNECTIONS AND

HEATING FILM; MEASURING OHM’S ..........28

OHM’S READINESS TEST .........................29

APPLYING EDGE SEALING TAPE................29

INSTALLING FLOOR SENSOR .................... 31

ELECTRICAL REQUIREMENTS ...................32

ATTACHIN G T H ERMOSTAT .......................32

SECTION 6: 120 VOLT CONFIGURATION ............................. 33

SECTION 7: 240 VOLT CONFIGURATION ............................ 35

SECTION 8: MULTIPLE ZONES ......................................... 37

SECTION 9: TROUBLESHOOTING ...................................... 38

SECTION 10: WARRANTY ............................................... 39

SECTION 11: NOTES ....................................................... 40

PAGE 41

SECTION 1

GENERAL NOTES & INFORMATION

READ ALL INFORMATION PROVIDED IN THIS GUIDE

BEFORE ATTEMPTING TO INSTALL THIS PRODUCT

The installation of this heating product must be in accordance with both the

manufacturer’s instructions, and the regulations of the authori

ty having

jurisdiction. Failure to do so will result in a voided warranty.

Caution must be taken to guard against risk of electric shock, fire, and bodily

injury during installation of this product.

All floors & subfloors should be prepared in accordance to ANSI & TCNA

specifications. All masonry, adhesives, moisture barriers, and bonding

agents used in the installation must be fully cured (per the manufacturer’s

recommendations - but not less than 28 days) prior to energizing the product

for the first time. All components must be recognized and rated for their use.

NEVER OVERLAP, LAYER, OR STACK THE HEATING FILM ON TOP OF

ANOTHER PIECE OF THE HEATING FILM.

The installation of this heating product must always be connected to a

DEDICATED electrical circuit.

The system shall be installed with a disconnecting means.

The system should always be disconnected from its power source during

service. This includes service to the thermostat.

All systems MUST be installed with a GFCI compliant thermostat or breaker.

The supply wire or terminals cannot be repaired. If the wire or terminal is

damaged, it must be replaced.

The National Electric Code does not allow the placement of nails, staples, or

other fasteners through the carbon heating or copper bus bar zones.

If a nail or staple is accidentally placed through this area, they must be

removed and securely taped shut.

EverWarm Radiant Heat

EverWarm Radiant Floors

PAGE 5

SECTION 1

1.DO NOT install the Heating Film under large appliances such as

refrigerators, freezers, washers, or dryers (as the heat can be detrimental to

the operation of the appliances).

2.DO NOT install the Heating Film under large, flat-bottomed furniture, built

in cabinetry, vanities, or in any application in which air circulation over the

floor is limited (as the heat can be detrimental to the products).

3.DO NOT install the Heating Film between floor joists under the sub- floor,

in wall cavities, or in ceilings.

4.DO NOT install the Heating Film in food pantries or under floating vanities

(as the heat can be detrimental to the products stored in these areas).

5.DO NOT overlap, layer, or stack the Heating Film on top of another piece

of the Heating Film.

6.DO NOT install the Heating Film over pre-existing linoleum, PVC, or vinyl

floor coverings. (All must be removed, including all pre-existing adhesive,

prior to the installation of the Heating Film).

Prior to installation please consult the local codes. If any of the information in

this guide is not consistent with local codes, the local codes should be

followed. However, electrical wiring is required to be run from a circuit

breaker or other electrical circuit to the control. It is recommended that a

qualified electrician perform these installation steps. Please be aware that

local codes may require that this product and/or the control to

be installed by

an electrician.

Operating the system without a floor covering in place will void the warranty

of the product.

ALL REQUIRED INSPECTIONS MUST BE COMPLETED BEFORE COVERING THE

HEATING FILM INSTALLATION.

PAGE 61

SECTION 1

SPECIFICATIONS FOR HEATING FILM:

Applications: Indoor floor heating.

Listings: UL Listed for U.S. and Canada under

UL 1693 and CAN/CSA C22.2 No.

130.2-93, File No. 20140325E465902, ETL 4007353, CE 120509,

TUV K5140/E112

Controls:Heating Film must be controlled by a

CarbonicHeat approved direct voltage

Floor heat-sensing thermostat.

Voltage:120 VAC Max 100 sq. ft. (9.29 sq.m)

50/60hz,

240 VAC Max 200 sq. ft. (18.58 sq.m)

50/60 Hz

Watts: 15 W/sq. ft. (51 BTU/sq. ft.), 166.1 W/sq.m

Maximum circuit load: 15 Amp

Maximum circuit overload protection: 20 Amp breaker GFCI: (Ground Fault

Circuit Interrupter) required for each circuit (included in the thermostat control).

Maximum bend radius: Not to exceed 90 degrees. Do not crease Heating Film.

Maximum exposure temperature: (Continuous and storage) 150ºF (65.5ºC)

Minimum installation temperature: 50ºF (10ºC)

SKILL REQUIREMENTS:

Installation must be performed by qualified persons, in accordance with local

codes, ANSI/NFPA 70 (NEC Article 424), and CEC Part 1 Section 62 where

applicable. All electrical work must be installed in accordance with Article 424 Part

IX of the National Electric Code (NEC) ANSI/NFPA 70. “STATEMENT OF

NATIONAL ELECTRIC CODE PRODUCT COMPLIANCE (NEC). This product

from EverWarm Radiant Heat™ Corporation is compliant to Article 424, Part

IX of the National Electric Code (NEC), “Electric Radiant Heating Sheets and

Heating Sheet Sets” and as a Heating Sheet Set. Electrical installations must use

a Terminal Junction Assembly manufactured only by CarbonicHeat™ Corporation

per NEC 424.96 (2)”.

THANK YOU FOR SELECTING

EverWarm Radiant Heat®

This informational manual is provided as a guide to installing

EverWarm Radiant Heat Film, including design suggestions,

installation steps, precautions, limitations, and floor covering

guidelines.

EverWarm Radiant Heat

EverWarm Radiant Floors

PAGE 7

SECTION 1

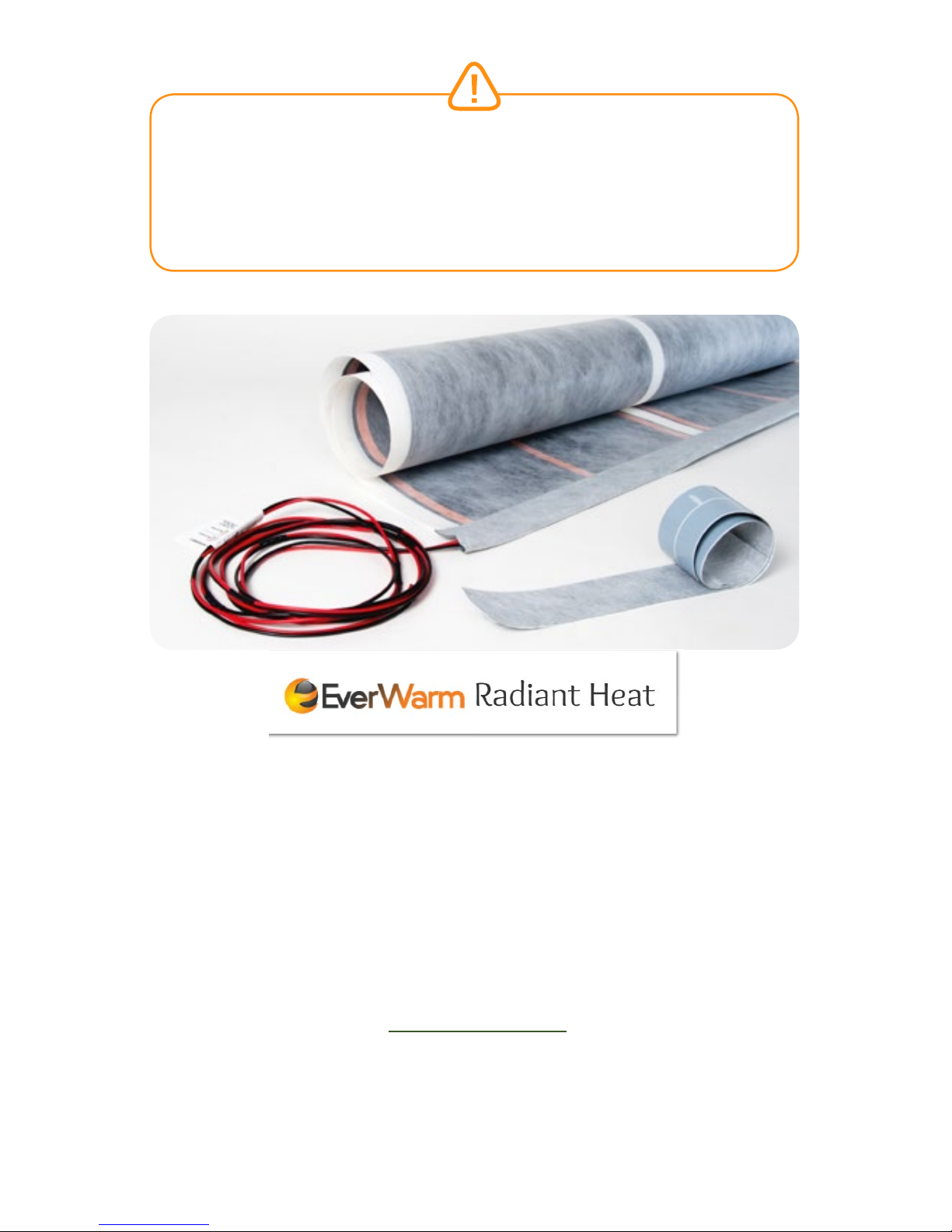

UNDERSTANDING EverWarm Radiant Heat FILM

Carbonic Heating Film is a revolutionary solution to today’s radiant floor

heating applications. The Heating Film is manufactured to make radiant floor

heating more readily available, far more adaptable for unique applications

and designs, and far easier to install than many other radiant floor products.

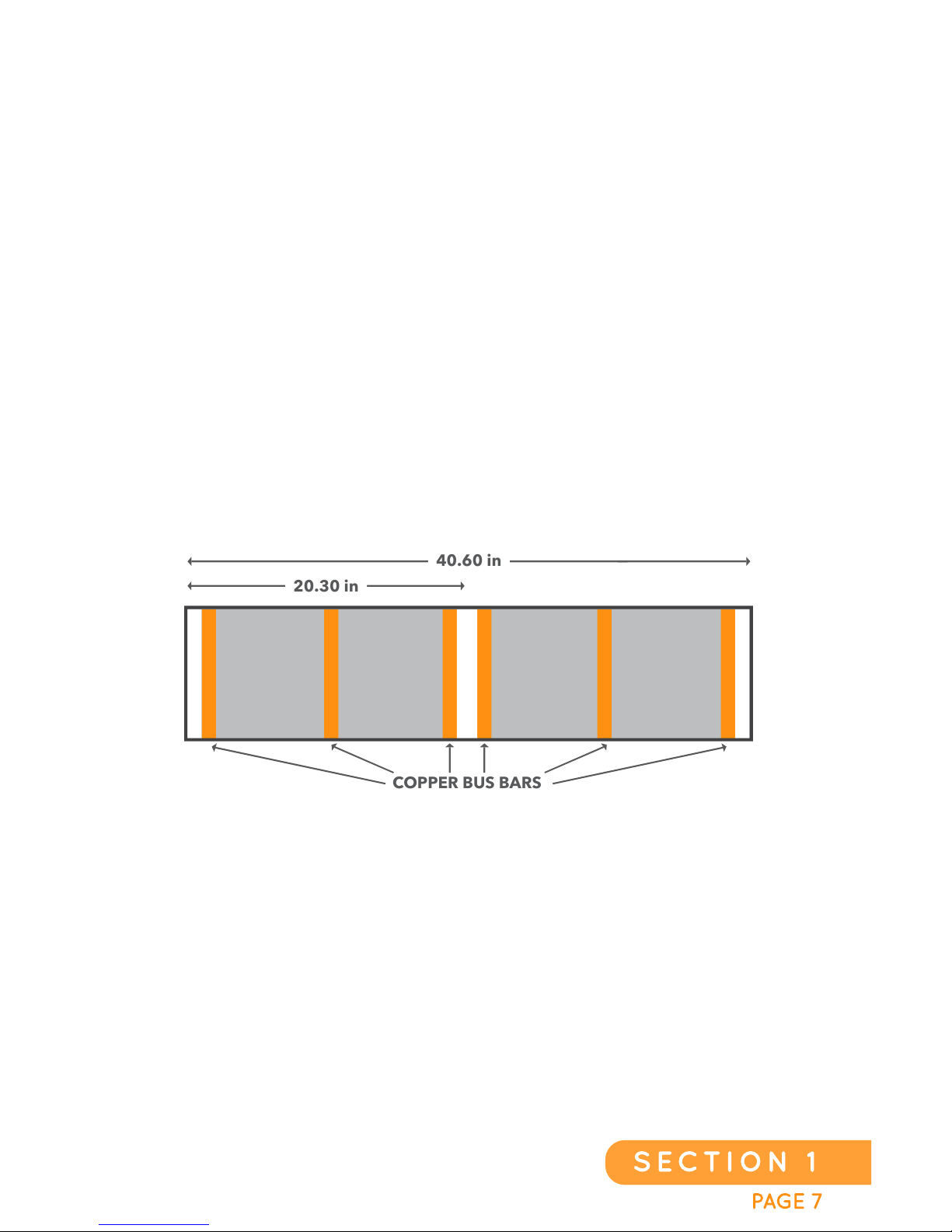

Carbonic Heating Film is 40.6 inches wide (but can be cut to half the width if

desired for certain applications) and is available in many lengths to

accommodate your specific needs. The Heating Film may be cut to any

length with the use of scissors, a razor knife, or other cutting instruments. It

can also be cut at any angle needed for each application, including the

cutting of a hole for an electrical outlet, toilet flange, or floor register.

There are a few things to know about the structure of the Heating Film.

Electrical current-conducting copper bus bars run down the length of the

Heating Film (2 bus bars are required to create heat - see drawing). Should a

copper bus bar be cut during the installation of the product, you may repair it

by either adding an “Adder” at the end or by installing a “Jumper” at the cut

point. More about these later.

Under no circumstances should the active areas (gray) of the Heating Film

be allowed to overlap itself or an adjacent piece of the Heating Film. The

product includes three areas (the two white outer edge strips and the white

center “Cut Line” strip) suitable for nailing and stapling to sub-floor, if

deemed necessary, for the designed installation of the product. These strips

are non-conductive and non-heat generating. All fasteners used to secure

the Heating Film to the sub-floor (excluding adhesives), including staples or

nails that are to be used, must only be placed through these designated

areas and not in the active carbon (gray) heating areas. Failure to do so will

cause problems with the system and/or damage the Heating Film and

associated areas including the building structure. The Heating Film can be

installed with either side facing up.

40.60 in

COPPER BUS BARS

20.30 in

PAGE 81

SECTION 1

EXPECTED FLOOR TEMPERATURE

Heating performance is never guaranteed. EverWarm Radiant Heat is

designed to deliver 15 W/sq. ft., with an average attainable temperature

between 75°F (23.9°C) and 104°F (40°C), depending upon the subfloor, the

layers of materials included in the floor installation, and the type of flooring

used. The attainable floor temperature is dependent on how well the floor is

insulated, the temperature of the floor prior to start up, and the overall

thermal drain of the floor mass. Insulation is recommended under the

Heating Film for best performance.

WIRING ASSEMBLIES

Since this is a high voltage product, a connection system is required for

power. A “Harness” is used to connect the Heating Film to a thermostat and

power supply, and a Harness is used to connect multiple pieces of Heating

Film in certain installations. EverWarm Radiant Heat Harnesses, Adders,

and Jumpers are manufactured for either 120V or 240V applications. The

wiring assemblies are designed for maximum efficiency and will work well

for almost any layout requirements. It is important to note that there are six

crimping terminals per sheet for the 120v Harness and four crimping

terminals per sheet for the 240v Harness.

THERE ARE THREE TYPES OF WIRING ASSEMBLIES:

1. Harnesses (J, J2, J3, J4): Harnesses

are used for connecting sheet(s) of Heating

Film with a 12 foot long “cold lead” that is

run to a thermostat, or to connect to

another sheet of Heating Film. Harnesses

are available in 120 volt and 240 volt

configurations. For a single panel 120 volt

application a “J-120” (J indicates one sheet,

and 120 is the voltage) would be required.

For a dual sheet would be required.

For a dual sheet configuration using 240 volts a “J2-240” (J2 indicates two

sheets, and 240 is the voltage) would be required. Connections for a three

sheet system would require a J3. A J4 Harness will connect four sheets of

Heating Film together. If there are three and a half sheets needed, a J4 can

be used by trimming off the unused portion of the Harness.

HARNESS

EverWarm Radiant Heat

EverWarm Radiant Floors

PAGE 9

SECTION 1

2. Adders (A, A2, A3, A4): Adders are

used to attach one sheet of Heating Film

to another, when a thermostat cold lead

connection is not required. Adders are

available in 120 volt and 240 volt

configurations. To add a single sheet

of Heating Film to a 120 volt system, an

“A-120” (A indicates one additional

sheet, 120 indicates the voltage) would

be required. To add two sheets to an

existing sheet, use an A2. To add three sheets, an A3 will be required.

An A4 will connect up to four sheets to an existing sheet or sheet set.

3. Jumper (JP-60): A Jumper can be

used to reconnect a copper bus bar if it

has been cut for completion of the

layout. The Jumper is sixty (60”) inches

in length and can be used on both 120

volt and 240 volt systems. They are

helpful for going through door ways,

around corners, around posts, and

around columns. Jumpers can also be

used around cut outs for floor ports

such as receptacles, registers, and floor ports.

ADDER

JUMPER

PAGE 101

SECTION 1

EDGE SEALING TAPE

It is critical to seal any cut that is made to the gray

area of the Heating Film. The Edge Sealing Tape

comes in one length (42 inches), but in two

different widths, 4.8 inches wide and 2.4 inches

wide. The wider Edge Sealing Tape (4.8 inches

wide) is used to seal the edge of the Heating Film

to which the wiring Harness, or Adder is attached.

The narrower Edge Sealing Tape (2.4 inches wide)

is used to seal any cut edges where there is no

attached wiring Harness, Adder, or any other cuts (including holes cut in

between the copper bus bars) that have been made to the Heating Film during

the installation process. The Edge Sealing Tape is a highly-adhesive

fleece-backed butyl tape. The fleece backing that is the same as that used on

EverWarm Radiant Heat Film, making the Edge Sealing Tape compatible with

all types of adhesives.

REMEMBER: THE EDGE SEALING TAPE MUST BE USED ON ANY GRAY EDGE,

OR GRAY AREA OF THE HEATING FILM THAT HAS BEEN CUT.

THERMOSTATS

EverWarm Radiant Heat offers a variety of direct line voltage thermostats in

both programmable and non-programmable models. All EverWarm Radiant

Heat thermostats in the United States are GFCI-protected (required by the

NEC). Each thermostat includes a floor sensor, which EverWarm Radiant

Heat requires for each installation. Each thermostat senses both ambient air

and floor temperatures, enabling installers to set the floor temperature to the

flooring manufacturer’s desired set point, along with maximizing the potential

comfort of the room’s environment. The maximum load allowed on a standard

thermostat is 15 amps. The maximum amount of total Heating Film allowable

per circuit translates to the following:

110-120VAC: 31.25 LINEAR FT = 100 FT2 PER ZONE (1 THERMOSTAT)

220-240VAC: 62.5 LINEAR FT = 200 FT2 PER ZONE (1 THERMOSTAT)

Installations that require a larger amount of Heating Film per thermostat (over

200 square feet per zone) will require the use of a “master” thermostat that

controls a “slave” power unit. Up to 2000 square feet of Heating Film can be

installed and combined using 10 slave units. Up to 10 Slave Units can be

controlled by one Master Thermostat.

EverWarm Radiant Heat

Radiant Floors

EverWarm Radiant Floors

PAGE 11

SECTION 2

Digital Multi-Meter

Wire Stripper

Wire Cutters

Wire Crimper

Broom/Dust Pan

Scissors

Tape Measure

Flex Heat Crimping Tool

(Pa r t# C HP-01)

TOOLS REQUIRED FOR

INSTALLATION

TOOLS NEEDED WHEN INSTALLING THE

EverWarm Radiant Heat HEATING

SYSTEM

PAGE 121

SECTION 3

INSTALLATION GUIDELINES:

THE FOLLOWING SECTION OUTLINES THE PREPARATION

REQUIRED PRIOR TO INSTALLING THE HEATING FILM.

FLOOR PREPARATION

1. Ensure slab or wood sub-floor is structurally sound (follow TCNA

installation guidelines for sub-floor rigidity).

2. Concrete slab must be free of waxy or oily films and curing compounds

(when present, mechanical scarifying is necessary). If these chemicals

are present, water will bead. If the sealer is left on the floor, the mortar

for the tiles won’t adhere. Remove sealer with a floor sander using

medium-grit sandpaper.

3. There should not be any protrusions sticking up from the sub-floor that

could impact or cause damage to the Heating Film such as nails, rebar,

or any other potentially damaging material.

4. Level the floor per TCNA guidelines. Allow the compound to dry

following manufacturer’s recommendations.

5. Mop or sponge the floor with clean water to remove any traces of dust.

6. Make sure the floor is completely dry before installing EverWarm

Radiant Heat Film.

EverWarm Radiant Heat

Loading...

Loading...