Page 1

Installation and Operation Guide

ROM II and ROM III

REQUIREMENT MAXIMUM MINIMUM

Bacterial Quality Potable Potable

Pressure 125 psig (860 kPa) 40 psig (280 kPa)

Temperature 100˚F (38˚C) 40˚F (4˚C)

Chlorine* 0 ppm (mg/L) 0 ppm (mg/L)

Production Flow Rate: 14.4 gpd (54 Lpd) @ 50 psig (340 kPa); 77˚ F (25˚ C)

Reject Flow Rate: 79.8 gpd (302 Lpd) @ 50 psig (340 kPa); 77˚ F (25˚ C)

*NOTE: Chlorine influent to Cartridge “B”. For Cold Water Use Only.

CONTAMINANT REDUCTION

Contaminant USEPA MCL ROM II Average % Reduction ROM III Average % Reduction

Total Dissolved Solids 187 94.6 94.6

Based on an RO Processor operating at 500 - 2000 mg/ L TDS; 40-70 psi; Neutral pH; Temperature 70 - 74˚ F; and a new Cartridge “B”.

Congratulations on the purchase of your new ROM II or ROM III

Reverse Osmosis Modular Drinking Water System. You and your

family are about to enjoy better tasting, healthier water than

you ever thought possible. The ROM II uses superior design and

contaminant reduction performance of the prefilter cartridge with

a quick-change reverse osmosis cartridge. The ROM III blends the

proven superior design and contaminant reduction performance

of Everpure’s ROM II Processor with a third cartridge for superior

performance in reducing volatile organic chemicals.

The result is the best available combination of technologies to

reduce aesthetic contaminants such as dirt, minerals, tastes and

odors; and health related contaminants such as sodium, heavy

metals and organics (VOC’s).

PARTS SUPPLIED

1. ROM II Head assembly / ROM III Head assembly

2. Cartridge "A" (S-101)

3. Cartridge "B" (TFC RO)

4. Cartridge "C" (VOC#1) (ROM III only)

5. EV312118 - Flow Restrictor Kit ROM II & III

6. EV310876 - Flush plug (1 w/ROM II, 2 w/ROM III)

7. EV305061 - Red 1/4" tubing

8. EV544600 - Blue 3/8" tubing

9. EV311659 - Reducing tee

10. EV311660 - T-link valve

11. EV311588 - Tank Kit

12. EV311652 - Faucet Kit

13. EV312731 - Fitting - Faucet

NOTE: Read and save this manual.

The pages that follow will help you install your system. The

ROM II or ROM III System supplied by Everpure contains a

processor, storage tank, air-gap faucet, and drain connector.

This instruction manual details the installation for a typical

residential reverse osmosis application, but the ROM II or ROM

III System may be used with alternate equipment, such as a water

cooler. Manuals supplied with other components should also be

consulted during the installation. Read all manuals first to get a

clear picture of your project before you begin.

Outlined on page 7 of this manual are several maintenance

procedures you will need to do to guarantee optimum

performance of your system. Page 9 contains a troubleshooting

guide to assist in diagnosing operational problems if they arise.

EV3080-17 Rev H DE09

Page 2

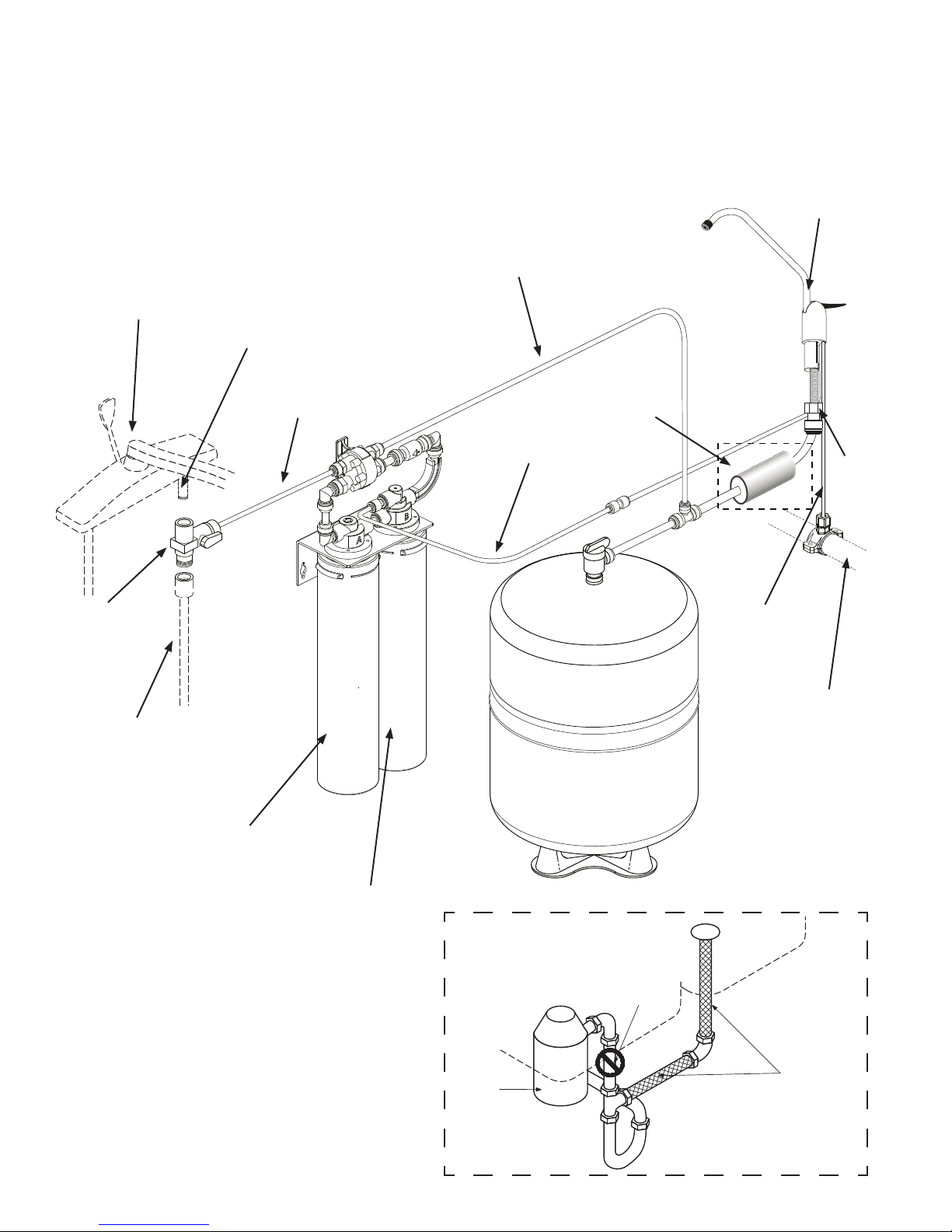

SYSTEM OVERVIEW - ROM II

SINK FAUCET

COLD WATER FAUCET STUB

AIR GAP FAUCET

PRODUCT WATER TUBING

SUPPLY FITTING

(T-LINK)

COLD WATER

SUPPLY TUBE

INLET WATER TUBING TO

ROM PROCESSOR

POST FILTER (OPTIONAL, NOT INCLUDED)

REJECT WATER TUBING (RED)

NUT

DRAIN TUBING

DRAIN CONNECTION

S-101 PREFILTER

CARTRIDGE “A”

TFC RO

CARTRIDGE “B”

NOTE:

All tubing and components represented by dotted lines or

within dotted lines are not supplied with the ROM System.

2

GARBAGE

DISPOSAL

DO NOT

CONNECT

DRAIN CONNECTION

HERE

TYPICAL

SINK DRAIN SYSTEM

CONNECT DRAIN

CONNECTION

HERE OR HERE

Page 3

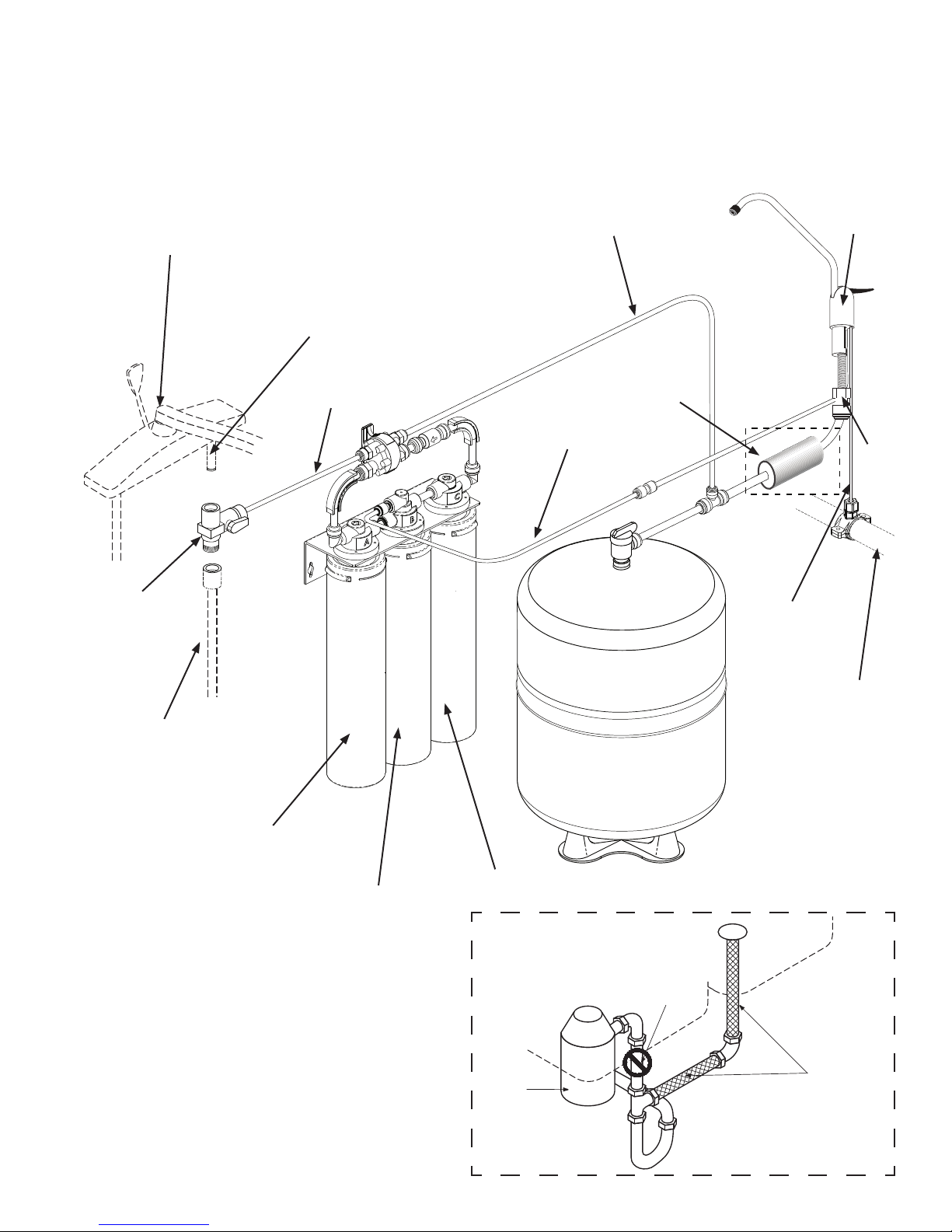

SYSTEM OVERVIEW - ROM III

SINK FAUCET

SUPPLY FITTING

(T-LINK)

COLD WATER FAUCET STUB

INLET WATER TUBING TO

ROM PROCESSOR

PRODUCT WATER TUBING

POST FILTER (OPTIONAL, NOT INCLUDED)

REJECT WATER TUBING (RED)

AIR GAP FAUCET

NUT

DRAIN TUBING

COLD WATER

SUPPLY TUBE

S-101 PREFILTER

CARTRIDGE “A”

TFC RO

CARTRIDGE “B”

NOTE:

All tubing and components represented by dotted lines or

within dotted lines are not supplied with the ROM System.

VOC#1

CARTRIDGE “C”

GARBAGE

DISPOSAL

DO NOT

CONNECT

DRAIN CONNECTION

HERE

DRAIN CONNECTION

TYPICAL

SINK DRAIN SYSTEM

CONNECT DRAIN

CONNECTION

HERE OR HERE

3

Page 4

1. PROCESSING SYSTEM

CAUTION:

CAUTION:

CAUTION:

This water processing system is acceptable for treatment of influent

concentration of no more than 27 mg/L nitrate and 3 mg/L nitrite

in combination measured as N and is certified for Nitrate/Nitrite

Reduction only for water supplies with a pressure of 280kPa (40 psig)

or greater.

The Everpure ROM II and ROM III Processors and their installations

are required to comply with state and local laws and regulations.

This reverse osmosis processor contains a replaceable treatment

component critical for the effective reduction of Nitrate. The product

water should be tested periodically to verify that the processor is

performing satisfactorily. Use the 8-way test strip (PN: EV6500-57) to

determine effluent Nitrate concentrations.

S-101 PREFILTER CARTRIDGE “A”

Cartridge “A” is the first cartridge in the ROM II or ROM III Processor.

It serves two purposes. Most importantly, it adsorbs the chlorine that

is found in most municipal water, keeping that chlorine from damaging

the TFC RO Cartridge “B”.

CONTACT WITH CHLORINE WILL DAMAGE

CARTRIDGE “B”.

Cartridge “A” also does an excellent job of reducing dirt which would

otherwise foul Cartridge “B”.

CHANGING CARTRIDGE “A” REGULARLY IS VERY IMPORTANT.

TFC RO CARTRIDGE “B”

Cartridge “B” is the second cartridge in the ROM II or

ROM III Processor. Cartridge “B” contains the reverse osmosis semipermeable membrane. This membrane is what sets this processor

apart from conventional filter systems. Here is where most of the

dissolved impurities are separated from the water molecules and

flushed down the drain. This cartridge should be replaced periodically

depending on the quality of the product water.

This reverse osmosis system contains a replaceable treatment

component critical for the effective reduction of Total Dissolved Solids

(TDS). The product water should be tested periodically to verify that

the processor is performing satisfactorily. Follow the TDS Performance

Testing procedure found on page 7 of the Maintenance section of this

manual to determine the reduction of TDS.

Replacement of reverse osmosis component should be with one of

identical specifications as defined by the manufacturer, to assure the

same efficiency and contaminant reduction performance.

This processor is not recommended for use with

an ice maker that discharges water to drain as part of the ice

production process.

3. AIR-GAP FAUCET (Supplied)

An air-gap faucet allows the product water to be drawn from the

storage tank when needed. It is NSF Certified for drinking water

use. The air-gap faucet contains a built-in air-gap to prevent cross

contamination. Any additional faucets connected to the system do

not require an air-gap, but must meet state and local health codes.

INSTALLATION PROCEDURE OUTLINE

1. Verify that the water is microbiologically safe.

2. Determine the best location for components.

3. Install the inlet water fitting.

4. Install the drain connection.

5. Mount the ROM Processor.

6. Verify the storage tank air pressure.

7. Position the storage tank.

8. Mount the air-gap faucet.

9. Install the postfilter (Not supplied).

10. Connect the components.

11. Install the Everpure cartridges.

SUGGESTED TOOLS FOR INSTALLATION

Screwdriver

Drill

Center punch

Small adjustable wrench

Safety knife

Eye dropper

Tire pressure gauge (0-20 psi)

Fresh 5-1/4% household liquid chlorine bleach (such as Clorox®)

VOC #1 ORGANICS CARTRIDGE “C” (ROM III ONLY)

Cartridge “C” is an optional third stage of treatment. Its function is

to adsorb any volatile organic chemicals that may get through the

RO membrane. This Cartridge conforms to ANSI/NSF 53 for VOC

reduction. See Performance Date Sheet for individual contaminants

and reduction performance. Cartridge “C” contains granular activated

carbon and should be replaced when Cartridge “A” is replaced.

2. STORAGE TANK

The storage tank stores the water that has been produced by the

ROM II or ROM III Processor. Because the storage tank is precharged

with air pressure to the manufacturer’s specifications, it provides the

pressure needed to deliver the product water to the air-gap faucet.

The storage tank generally contains sufficient pressure to connect

the product water to your remote ice maker. Consult the ice maker

manufacturer for flow rate and pressure requirements for your

ice maker.

4

Page 5

DETAILED INSTALLATION INSTRUCTIONS

CAUTION:

(RefeR to the SyStem oveRview - Page 2 oR 3)

1. VERIFY THAT THE WATER IS MICROBIOLOGICALLY SAFE

Do not use with water that is microbiologically unsafe or of unknown

quality without adequate disinfection before or after the system.

2. DETERMINE THE BEST LOCATION FOR COMPONENTS

The exact placement of the various components of the system

can vary at each installation. The ROM System was designed to

be compact and extremely flexible to allow successful placement

in limited space areas. Try to achieve a good balance between

convenience for today, and future service access.

EVERPURE ROM PROCESSOR

The ROM III Processor measures approximately 12" wide x 17" high

x 4" deep and weighs about 9 pounds when operating. The ROM II

Processor measures approximately 8" wide x 17" high x 4" deep and

weighs about 6 pounds when operating. Either processor can be

mounted under the sink or in the basement. Be sure to leave at least 3"

clearance under the system after it is installed to allow cartridges to

be changed.

FAUCET

Ideally, the air-gap faucet should be mounted on the right or left-hand

back of the sink rim; it could also be mounted in the countertop next

to the sink. Drill a 1

existing spray hose hole.

NOTE: For the air-gap faucet to function correctly, the air-gap faucet

must be mounted on a horizontal surface, with the air-gap faucet base

at or above the sink rim.

NOTE: If an icemaker is to be connected, a 1/4" plastic union tee should

be installed in the line between the faucet and postfilter. The plastic

tubing from the icemaker can then be connected to this tee. Be sure to

use plastic tubing!

NOTE: If the remote equipment (ie: icemaker, water chiller, etc.) is

located greater than 10 feet away from the storage tank, consider

up-sizing the tubing to 3/8 or 1/2" OD to maintain adequate flow and

pressure. Tubing and fittings for this can be purchased at your local

hardware store or home improvement center.

1

⁄8" diameter hole, or you may choose to use an

STORAGE TANK

The storage tank should be placed as close to the air-gap faucet as

possible to maximize the flow rate and for added convenience later.

When full of water, a 3 gallon storage tank will typically weigh 27

pounds. The storage tank operates best in the vertical position, but if

necessary, it will operate in a horizontal position.

NOTE: If the storage tank is positioned in a horizontal position, there is

a chance that air dissolved in the water will not escape and “foaming”

will occur at the air-gap faucet spout.

NOTE: Before connections are made, tubing must be cut square to

ensure a leak free installation. The storage tank and air-gap faucet

tubes should have minimum length and no sharp bends that will

restrict flow.

3. INSTALL THE INLET WATER SUPPLY FITTING

A supply fitting (t-link) has been provided with the system. Close the

cold and hot water inlet valves for the sink faucet. Open both the cold

and hot sides of the sink faucet to relieve all pressure. Be prepared

for any water that may spill out and disconnect the cold water supply

tube from the cold water faucet stub. Attach the supply fitting to the

faucet stub. Connect the supply tube to the supply fitting. Close the

shut-off valve on the supply fitting. Close the hot and cold valves on the

sink faucet. Slowly open the cold and hot inlet valves. Check for leaks

before proceeding. Other plumbing methods may be used to supply the

processor with water, as long as:

• Connections are made to the cold water supply line only

• ¼" O.D. tube connection is made available

• A shut-off valve is installed on the line to the processor

4. INSTALL THE DRAIN CONNECTION

A 1-1/2" drain saddle has been provided with the system.

A typical drain pipe size is 1-1/2" O.D.; some bar or lavatory sink drains

are 1-1/4" O.D. If your drain piping is 1-1/4", purchase a drain saddle

clamp from your local hardware store or home improvement center.

The drain saddle clamp should be installed above the P-trap and on

the vertical or horizontal tailpiece.

When installing the saddle clamp on a horizontal drain pipe, locate

the hole at the top of the pipe for optimum performance. Once the

location has been determined, drill a 3/8" diameter hole in the drain

pipe. Center the tube connector on the drain saddle clamp over the

hole in the drain pipe. Secure the two halves of the drain saddle

clamp with the hardware provided.

NOTE: Do not connect the processor drain line into the garbage

disposal or dishwasher discharge line. The back pressure caused by

the garbage disposal or dishwasher can back water up into the air-gap

faucet causing it to overflow.

5. MOUNT THE ROM PROCESSOR

A. At this point, you should have already determined where the

ROM Processor will be mounted. Whether under the sink or in the

basement, be sure to leave at least 3" clearance underneath the

processor to allow for cartridge removal. To make your installation

simpler, leave enough access to the processor’s plumbing to allow

you to tighten fittings.

NOTE: Do not install the cartridges at this time.

B. Mount the processor by using the bracket as a template. Attach the

processor to the mounting surface using fasteners intended for use

with the mounting surface material.

REMEMBER THAT THE ROM PROCESSOR WILL WEIGH UP

TO 9 POUNDS WHEN OPERATING.

5

Page 6

6. VERIFY THE STORAGE TANK AIR PRESSURE

CAUTION:

WARNING:

WARNING:

The air precharge in the storage tank should be verified prior to its

installation. Check the air precharge only when the storage tank is

empty (no water). Remove the protective cap from the air valve on the

storage tank. Using a tire pressure gauge (available from a local auto

parts or hardware store) with graduations of 5 PSI or less, test the air

precharge in the storage tank. The pressure should be 9-11 PSI. If the

precharge is above 11 PSI, depress the air valve needle as required

to reduce the pressure to the specified pressure. If the precharge is

below 9 PSI, use a bicycle-type hand pump attached to the air valve to

increase the pressure to the specified pressure. Recheck the pressure

and when it is within the specified range, install the protective cap.

SYSTEM TUBING CONNECTION PROCEDURE

1. Simply push in tube

to attach.

2. Tube is secured in

position.

11. INSTALL THE EVERPURE CARTRIDGES

3. Push in collet to

release tube.

7. POSITION THE STORAGE TANK

It isn’t necessary to have the tank under the sink as long as you can

run tubing from it to the system and the faucet. Be sure the tank rests

on a flat, level base.

8. MOUNT THE FAUCET

The air-gap faucet should be mounted using the hardware provided.

Un-screw the nut from the threaded stem protruding from the base

and remove the support pipe. Route the drain tubes through the hole

in the mounting surface. Inspect the gasket on the base of the faucet

- it should lay flat on the mounting surface and be visible around

the complete circumference of the air-gap faucet base. Attach the

support piece and nut to the threaded stem. Position the base of the

air-gap facuet so the handle is easily accessed. Tighten the nut until

the gasket slighlty compresses and the base does not rotate when the

handle is operated.

Run the red reject water tubing from the ROM Processor’s reject flow

control fitting to the faucet air-gap (or other suitable air-gap). Connect

the outlet of the air-gap faucet to the tube connection on the drain

saddle clamp, using the nut and ferrule provided. Push the tube into

the fitting until it stops, then tighten the nut.

NOTE: If the faucet (or other equipment such as icemakers, water

chillers, etc.) is located greater than 10 feet away from the storage

tank, consider up-sizing the tubing to 3/8 or 1/2" OD to maintain

adequate flow and pressure. Tubing and fiitings for this can be

purchased at you local hardware store or home improvement center.

9. INSTALL THE OPTIONAL POSTFILTER (Not Supplied)

It is recommended that a carbon postfilter be installed with the

system to remove any off-tastes and odors that may be present after

the processed water has been stored. If a postfilter is used, it should

be installed on the tubing between the tank and the faucet. When

the faucet is opened, water should pass from the tank immediately

through the postfilter and out the faucet. Follow instructions from the

manufacturer of the postfilter when installing with the system.

10. CONNECT THE COMPONENTS

The ROM II and ROM III Processors have ttings that accept ¼" OD

plastic tubing.

DO NOT USE COPPER TUBING TO CONNECT

THE COMPONENTS! USE ONLY PLASTIC TUBING. RO

WATER IS VERY PURE AND CAN CREATE A CORROSIVE

CONDITION WHEN IN CONTACT WITH CERTAIN TYPES

OF METAL MATERIALS. THE USE OF ANY TUBING THAT

DOES NOT MEET NSF STANDARDS WILL VOID THE EVERPURE WARRANTY.

Complete all tubing connections at this time. See the drawings below

and on pages 2 and 3 for reference.

Remember that Cartridge “B” requires thorough flushing to remove

the protective storage solution, both now and whenever it is replaced.

Cartridge “A” and Cartridge “C” need flushing to purge air.

A. Remove the packaging from Cartridge “A”. Following the

instructions accompanying the cartridge, install it into the first head

(A) of the processor.

B. Close storage tank shut-off valve.

C. Open air-gap faucet.

D. Install flush plug into head “B” (ROM II & III) and

head “C” (ROM III only).

E. Open inlet shut-off valve and flush for 3 minutes. Flow will be visible

from the air-gap faucet at this time. Close the inlet shut-off valve.

F. Remove flush plug from head “B” (ROM II & III).

G. Remove the packaging from Cartridge “B”. Install it in the second

head (B).

H. Open the inlet shut-off valve. Allow water to run for 2 hours into your

sink. This purges the protective storage solution from Cartridge “B”

and ensures that when the system is placed into operation, it will

immediately reduce the level (percentage) of all minerals and/or

chemicals. Close the inlet shut-off valve.

INGESTING THE PROTECTIVE SOLUTION MAY CAUSE

IRRITATION OF THE GASTROINTESTINAL TRACT, COLIC, DIARRHEA

OR OTHER SIMILAR SYMPTOMS.

I. For the ROM II installation, skip to step J. For the ROM III installation

only, install Cartridge “C” in the third head (C). Open the inlet shut-off

valve and and observe the flow from the air-gap faucet. (After 16

ounces have been dispensed, close the air- gap faucet.) (15 min

flush based on 1 gallon/2 hours) Close inlet shut-off valve.

EYE PROTECTION AND RUBBER GLOVES SHOULD BE

WORN WHEN HANDLING CHLORINE.

J. Sanitize the storage tank with standard 5¼% liquid chlorine bleach.

Disconnect the product water tubing from the ROM Processor to

the storage tank at the processor connection. Using a clean eye

dropper or other suitable means, place forty (40) drops of liquid

chlorine bleach into the tubing. Reconnect the tubing. Open the inlet

shut-off valve. Open the storage tank shut-off valve. Water will now

start to fill the storage tank. Check all fittings for leaks, tightening

just enough where necessary to stop leakage.

NOTE: It will take approximately 6 hours or more to fill the storage

tank. Remember that the multi-stage treatment of the ROM Processors

produces high quality water at a rate of approximately one gallon

every 2 hours. DO NOT CONSUME THIS WATER.

K. Drain the storage tank by opening the air-gap faucet and letting

the water run until it slows to a drip. This final flush gets all

the air out of the filters and assures that the water will be high

quality. Close air gap faucet as the storage tank begins to refill,

your system will be ready for use.

6

Page 7

MAINTENANCE

The ROM II and ROM III System requires very little maintenance; there

are no weekly or monthly procedures to follow. Regular cartridge

change is the only exception – and an important one.

Remember: Regular cartridge change is the only way your ROM II

or ROM III Reverse Osmosis Modular Drinking Water System will

continue to give you years of uninterrupted high quality water!

The Troubleshooting section in this manual will help you determine

when it is necessary to change cartridges. Unlike most RO systems,

with the ROM II and ROM III System, you can change the

cartridges yourself.

S-101 PREFILTER CARTRIDGE “A”

CHANGE EVERY 6 MONTHS (Based on 3 gallons per day RO product

water usage).

Reduces dirt and protects Cartridge “B” from chlorine.

VOC #1 ORGANICS CARTRIDGE “C” (ROM III ONLY)

CHANGE EVERY 6 MONTHS (Based on 3 gallons per day RO product water usage)

Reduces volatile organic contaminants from the drinking water.

NOTE: Change Cartridges “A” and “C” at the same time.

To change Cartridges “A” and “C”:

1. Shut off the water to the processor.

2. Open the air-gap faucet to drain the storage tank; leave the airgap faucet open.

REFER TO “INSTALL THE EVERPURE CARTRIDGES” FOR

PROPER INSTALLATION AND FLUSHING PROCEDURE.

TFC RO CARTRIDGE “B”

CHANGE ONLY WHEN YOU NOTICE A SIGNIFICANT DROP IN THE

WATER QUALITY OR QUANTITY AND YOU HAVE ALREADY CHANGED

CARTRIDGE “A” AND “C”. UNDER AVERAGE WATER CONDITIONS,

CARTRIDGE “B” SHOULD LAST 2-3 YEARS.

Removes dissolved impurities from the drinking water.

Follow the TDS Performance Testing procedure found here in the

Maintenance section of this manual to determine if Cartridge “B”

should be changed.

To change Cartridge “B”:

1. Shut off the water to the processor.

2. Open the air-gap faucet to drain the storage tank; leave the air-gap

faucet open. Refer to “Install the Everpure Cartridges” for proper

installation and flushing procedure.

SANITIZE STORAGE TANK

SANITIZE WITH EVERY CARTRIDGE CHANGE (EVERY SIX MONTHS)

Ensures good-tasting, high quality water.

To sanitize the storage tank:

1. Shut off the water to the processor.

2. Open the air-gap faucet to drain the storage tank; leave the air-gap

faucet open.

Refer to “INSTALL THE EVERPURE CARTRIDGES” section for storage

tank sanitization procedure.

TDS PERFORMANCE TESTING

To determine the Total Dissolved Solids (TDS) removal performance

of the ROM Processors, and to determine when Cartridge “B” should

be changed, the TDS of the product water produced by the ROM

Processor and the TDS of the inlet water must be measured. The

Everpure TDS Pen, or other conductivity testers, can be used for

these measurements. Follow the instructions with each tester for

proper operation.

The amount of TDS rejected by the processor is expressed as a

percentage. A 92% reduction means that 92% of the dissolved solids

have been removed from the inlet water by the processor. To calculate

the percent reduction, use the following equation:

Inlet TDS - Product TDS

x 100 = % reduction

Inlet TDS

The Inlet TDS is the total dissolved solids content of the water going

into the processor, and the Product TDS is the total dissolved solids

content of the high quality product water.

Example: If the Inlet TDS is measured to be 600 ppm and the Product

TDS is measured to be 48 ppm, then:

600 ppm - 48 ppm

x 100 = 92% reduction

600 ppm

The indication of TDS reduction is done by following the procedure

outlined below:

1. Open the faucet and run product water for 60 seconds to ensure a

fresh sample.

2. Rinse a clean cup several times with product water and then collect

enough water to measure with the TDS Pen.

3. Following the operating instructions with the TDS Pen, measure and

record the Product TDS.

4. Rinse the cup several times with water from the same inlet water

source that the ROM Processor is connected to, and then collect

enough water to measure with the TDS Pen.

NOTE: Make sure that the water you collect is the same as the inlet

water to the ROM Processor.

5. Following the operating instructions with the TDS Pen, measure and

record the Inlet TDS.

6. Using the equation above, and referring to the example given,

calculate the percent reduction for your processor. Cartridge “B”

should be replaced when the percent reduction falls below 90%.

7

Page 8

CALCULATIONS:

Formula:

Example:

TDS test date:

/ /

TDS test date:

/ /

TDS test date:

/ /

TDS test date:

/ /

TDS test date:

/ /

TDS test date:

/ /

Inlet TDS - Product TDS

Inlet TDS

600 ppm - 48 ppm

600 ppm

ppm - ppm

ppm

ppm - ppm

ppm

ppm - ppm

ppm

ppm - ppm

ppm

ppm - ppm

ppm

ppm - ppm

ppm

x 100 = % reduction

0.92 x 100 = 92%

x 100 = % reduction

x 100 = % reduction

x 100 = % reduction

x 100 = % reduction

x 100 = % reduction

x 100 = % reduction

INDEX NUMBER PART NUMBER DESCRIPTION QUANTITY

1 EV3079-42 Dual RO Header OR 1

EV3079-43 Triple RO Header 1

2 EV3079-26 Shut-off Valve 1

3 EV3103-91 Check Valve 1

4 EV9273-77 Cartridge “A” (S-101) 1

5 EV9273-70 Cartridge “B” (TFC RO) 1

6 EV9273-79 Cartridge “C” (VOC #1) (Rom iii oNLy) 1

7 EV3115-84 Flow restrictor 1

8 EV3103-10 Reducer, 3/8" stem x 1/4" tube 1

Not shown EV6500-57 8 Way Test Kit

ROM II

3

2

1

8

ROM III

1

7

3

2

4

5

8

1/4" red tubing

Detail of flow restrictor assembly.

6

4

5

(Inserts into upper port of head B)

Page 9

TROUBLESHOOTING:

PROBLEM PROBABLE CAUSE REMEDY

I. Not enough drinking water: A. Storage tank pressure too low. a. Add air to increase precharge to 10 psi.

B. Demand greater than unit’s specified output. b. Consult dealer for optional large tank for more

C. Not enough incoming water. c. Clogged inlet tubing; clean out or replace.

D. Not enough water pressure. d. Same as (c) above, or change in household

E. Plugged Cartridge “A”. e. Replace Cartridge “A”.

F. Plugged Cartridge “C”. (ROM III only) f. Replace Cartridge “C”. (ROM III only)

G. Cartridge “B” fouled with sediment. g. Replace Cartridge “A” and Cartridge “B”.

H. Product water check valve failure. h. Replace check valve fitting.

I. Plugged flow control. i. Clean/replace flow control fitting; replace

II. Bad tasting drinking water: A. All of 1 above except (b). a. All of 1 above except (b).

B. Foreign matter in storage tank. b. Clean, sanitize and flush storage tank.

C. Postfilter exhausted. c. Replace postfilter.

D. Leakage around Cartridge “B” O-rings. d. Relubricate/replace O-rings.

E. Product line and reject connections are reversed. e. Check lines and make correct connections.

F. Cartridge “B” needs replacing. f. Replace Cartridge “B”.

G. Storage tank bladder is ruptured. g. Replace storage tank and check precharge

III. External Leakage: A. Loose fittings. a. Check all fittings for tightness.

IV. Overflow at faucet air-gap — gurgling sounds: A. Drain tube plugged. a. Clean drain tubing of debris.

B. Drain tubing not in continuous downward slope. c. Rid drain tubing of loops or low spots.

C. Tubing connections reversed at faucet. d. Change tubing connections.

D. Insufficient drain. e. Clean drain pipe/find alternate drain.

V. “Foaming” at faucet tip: A. Storage tank is positioned on side (dissolved air

cannot escape).

VI. “Foaming” at air-gap: A. Drain tubing connected to same drain line as

dishwasher, etc.

B. When sink is full of soapy water and plug is

pulled, it can backup at air-gap.

VII. Bad smell from drinking water: A. Postfilter exhausted or Cartridge “C” exhausted. a. Replace postfilter and/or Cartridge “C”.

B. Cartridge “A” exhausted. b. Replace Cartridge “A”.

C. Storage tank needs disinfection. c. Clean, sanitize and flush storage tank.

VIII. Fast flow to drain: A. Defective flow control. a. Replace flow control fitting; consult factory.

IX. Black specks in product water: A. Carbon fines. a. Flush or replace postfilter.

X. Low faucet pressure: A. Low precharge in storage tank. a. Increase storage tank precharge.

B. Postfilter plugged. b. Replace or flush postfilter.

XI. Flow control plugged: A. Extremely high mineral content feed water. a. Higher flow rate flow control fitting needed;

B. Iron or iron-bacteria fouled. b. Clean/replace flow control fitting if plugged and

storage capacity.

pressure; increase household water pressure.

Cartridge “A” if necessary.

pressure.

a. Mount tank in upright position.

a. Find different drain for tubing.

b. Find different drain for tubing.

consult factory.

pretreat source for iron removal; consult factory.

9

Page 10

NOTES:

Page 11

Page 12

LIMITED WARRANTY

You have just purchased one of the nest water treatment units made. As an expression of our condence in Everpure products,

this product is warranted against defects in material and workmanship to the original end-user when installed in accordance with

Everpure specications. The warranty period commences from the date of purchase** and is administered as follows:

For a period of ONE YEAR Replaceable elements (i.e., lter and water treatment cartridges)*

For a period of FIVE YEARS The entire system (excluding replaceable elements)

*This is for material and workmanship, not lter or water treatment cartridge life.

** PROOF OF PURCHASE REQUIRED.

The unit must be used in operating conditions that conform to Everpure’s recommended design guidelines. This warranty will not

apply if the unit has been modied, repaired or altered by someone not authorized by Everpure.

If a part described above is found defective within the specied period, you should notify Everpure technical service at the

phone number listed below. Any part found defective within the terms of this warranty will be repaired or replaced (at Everpure’s

discretion) by your local dealer (labor not covered). Any repaired or replaced warranty item will be incorporated under the original

warranty terms of the existing system.

We are not responsible for damage caused by accident, re, ood, freezing, Act of God, misuse, misapplication, neglect, oxidizing

agents (such as chlorine, ozone, chloramines and other related components), alteration, installation or operation contrary to

our printed instructions, or by the use of accessories or components which do not meet Everpure’s specications. Refer to the

specications section in the Installation and Operating manual for approved application parameters.

Our product performance specications are furnished with each water treatment unit. TO THE EXTENT PERMITTED BY LAW,

EVERPURE DISCLAIMS ALL IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR PARTICULAR PURPOSE; TO THE EXTENT REQUIRED BY LAW, ANY SUCH IMPLIED WARRANTIES ARE LIMITED

IN DURATION TO THE PERIOD SPECIFIED ABOVE FOR THE ENTIRE WATER TREATMENT UNIT. As a manufacturer, we do not

know the characteristics of your water supply or the purpose for which you are purchasing this product. The quality of water

supplies may vary seasonally or over a period of time, and your water usage rate may vary as well. Water characteristics can also

differ considerably if this product is moved to a new location. For these reasons, we assume no liability for the determination of

the proper equipment necessary to meet your requirements, and we do not authorize others to assume such obligations for us.

Further, we assume no liability and extend no warranties, express or implied, for the use of this product with a non-potable water

source or a water source which does not meet the conditions for use described in the owner’s guide or performance data sheet

for this product. OUR OBLIGATIONS UNDER THIS WARRANTY ARE LIMITED TO THE REPAIR OR REPLACEMENT (AT EVERPURE’S

DISCRETION) OF THE FAILED PARTS OF THE WATER TREATMENT UNIT, AND WE ASSUME NO LIABILITY WHATSOEVER FOR

DIRECT, INDIRECT, INCIDENTAL, CONSEQUENTIAL, SPECIAL, GENERAL OR OTHER DAMAGES.

Some states do not allow the exclusion of implied warranties or limitations on how long an implied warranty lasts, so the above

limitation may not apply to you. Similarly, some states do not allow the exclusion of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specic legal rights, and you may also have other

rights which vary from state to state. Consult your telephone directory for your local independently operated Everpure dealer, or

write Everpure for warranty and service information.

For sales, replacement components, and service, contact your Everpure dealer or:

Pentair Residential Filtration, LLC: 5730 North Glen Park Rd • Milwaukee, Wisconsin 53209 • 262.238.4400 • 800.279.9404

Everpure Europe NV: Toekomstlaan 30 • B-2200 Herentals • Belgium • Ph. +32 14 28 35 00 • Fx. +32 14 28 35 05

Everpure Japan, Inc: Hashimoto MN Bldg. 7F • 3-25-1 Hashimoto Sagimihara-Shi • Kanagawara 229-1103 Japan • Tel. 81-(0)42-775-3011 • Fax. 81-(0)42-775-3015

©2009 Pentair Residential Filtration, LLC Printed in U.S.A. EV3080-17 Rev H DE09

12

Loading...

Loading...