Page 1

B E N E F I T S

A P P L I C A T I O N / S I Z I N G

I N S T A L L A T I O N T I P S

O P E R A T I O N T I P S

WS Seri es

Wate r C onditio ners

Water Conditioning fo r Co mmer cial and Lig ht I ndus trial Applications

Available in Sing le T ank Syst em w ith 1” P orti ng

Hardness removal of 30,000 to 45,000 grains at

flow rates up to 12 gallons per minute continuous

Meter initiated regeneration minimizes salt,

water, and electrical costs

Advanced user-friendly controls incorporates

time-tested hydraulically balanced piston,

seal and spacer design to pilot service flow

and regeneration

Large capacity brine tank maximizes time

between refills

Locate equipment on a smooth, level surface

Maintain an air-gap at the end of the drain line

Secure drain line directly over floor drain or

stand pipe

When connecting to a water heater, install a

check valve on the soft water piping to prevent

hot water back-up

When sweating/installing copper piping,

protect the control valve from excessive heat

Check local codes for additional equipment

that may be required, such as backflow

prevention devices (i.e., RPZ)

MRS-20T System: EV9797-92

4MR-1 Cartridge: EV9273-6

WS-30: EV9980-10

WS-45: EV9980-11

9

Check for softened water each time salt is

added, by using a soap or hardness test kit

Use a good quality grade of salt -Solar

or pellet are preferred

Check the salt level on a regular basis

Maintain at minimum salt depth of 6” to

ensure a proper regeneration

On iron bearing waters, use a salt that

contains an iron “fighting” additive, or use

a resin cleaner on a regular basis

Check the water level in the brine tank

If abnormally high - refer to IO guide for

troubleshooting information

Fiberglass reinforced resin vessels with NSF

approved polyethylene liners eliminate worries

about corrosion

Single tank design for simplicity, economy

and space savings

5-cycle control delivers controlled upflow backwash,

downflow brining and slow rinse, rapid rinse, timed

brine refill and downflow service

Reverse Osmosis Pre-treatment

Espresso Machines

Warewashing

Laundry - Linen & Uniform

Boiler Scale Control

Water Heater Scale Protection/Reduction

General Housekeeping

Page 2

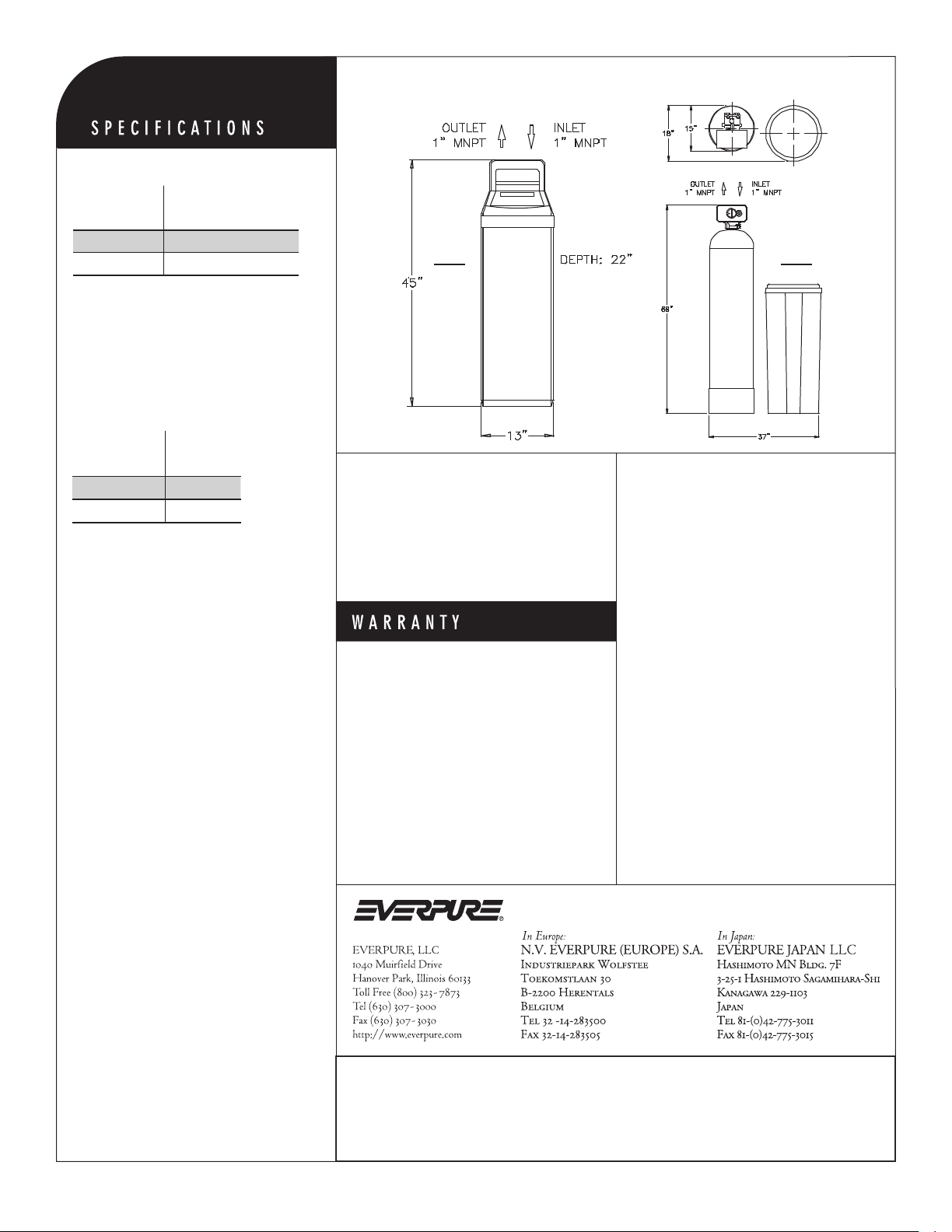

Overall Dimensions (inches):

WS Seri e s

Model

Number

WS-30

WS-45

Inlet Connection:

1” MNPT

Outlet Connection:

1” MNPT

Service Flow Rate (GPM):

Model

Number

WS-30

WS-45

Rated Capacity (grains):

WS-30 30,000

WS-45 45,000

Pressure Requirements:

25-100 PSI (1.7 -6.9 bar) non-shock

Temperature:

40º F to 100º F

Electrical:

115 VAC/60 HZ/1 Phase

Shipping Weight:

WS-30 90 lbs.

WS-45 125 lbs.

Width Depth Height

(A) (B) (C)

13 22 45

34 22 64

Cont. @

15 PSI DP

10

12

WS-30 WS-45

The contaminants or other substances removed or

reduced by this water conditioning system are not

necessarily in your water. Do not use with water that is

microbiologically unsafe or of unknown quality

without adequate disinfection before or after the

system. Systems certified for cyst reduction may be used

with disinfected water that may contain filterable cysts.

Everpure water softening systems are covered by a limited warranty

against defects in material and workmanship for the following periods:

uComplete System - 1 year

uControl Valve - 5 years

uMineral Tank(s) -

u6-13” diameter - 10 years

u14” diameter and larger - 5 years

See printed warranty for details. Everpure will provide a copy of the

warranty upon request.

Operating Weight:

WS-30 500 lbs.

WS-45 550 lbs.

Everpure, LLC

1040 Muirfield Drive

Hanover Park, IL 60133

Ph: 630-307-3000 Fax: 630-307-3030

Loading...

Loading...