Page 1

EVERPURE

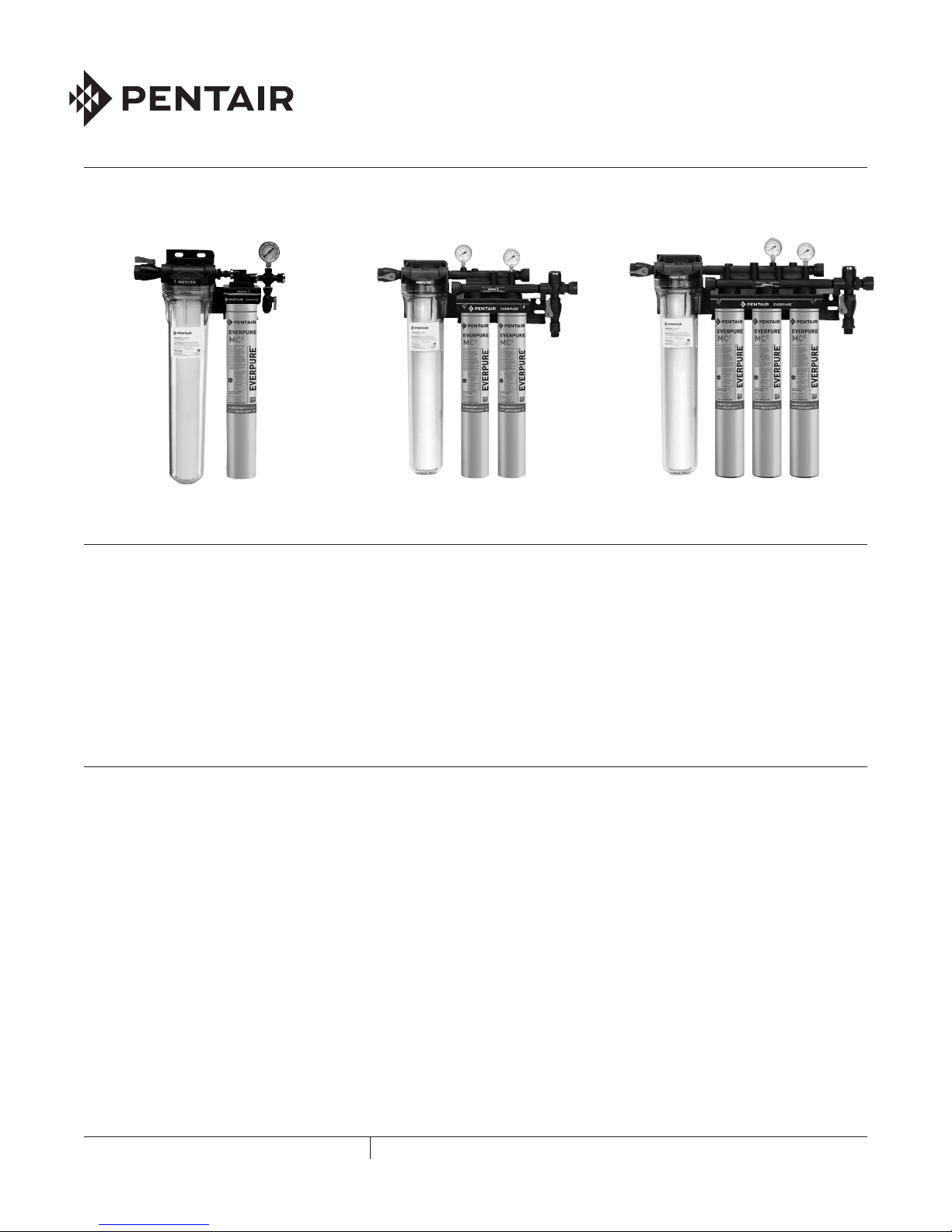

Figure 1 Coldrink 1 System Figure 2 Coldrink 2 System Figure 3 Coldrink 3 System

®

COLDRINK® SERIES FILTER SYSTEMS

SELECT A MOUNTING LOCATION

1. Give consideration to the weight of the unit when

operating (filled with water). Operating weights of the

Coldrink Systems are:

• System 1 - 19 lbs (8.62 kg)

• System 2 - 35 lbs (15.9 kg)

• System 3 - 45 lbs (20.4 kg)

INSTALLATION

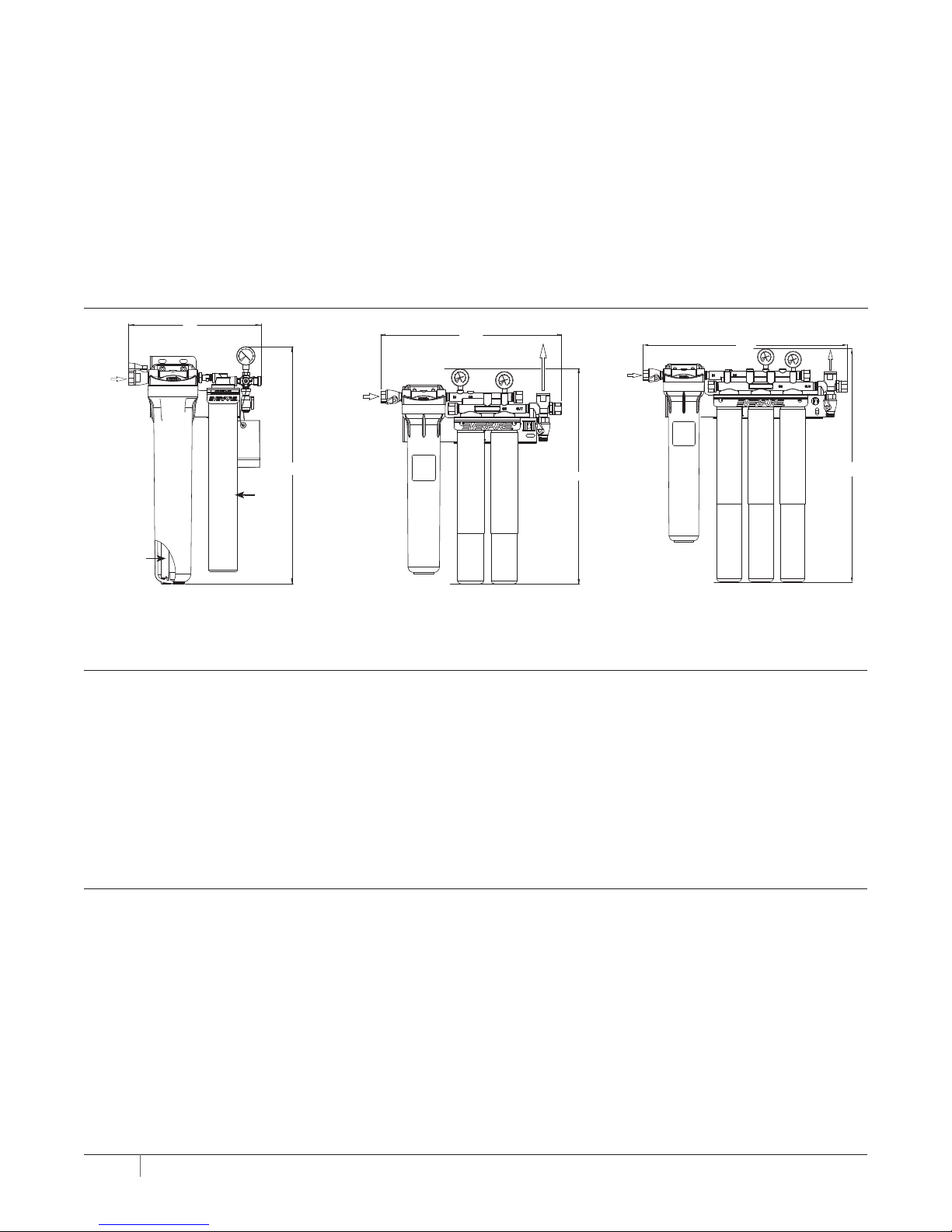

1. Use the predrilled mounting holes in the manifold

bracket as guides. Mark and drill anchor holes. Mount

securely. See Figures 4-6.

2. Shut off power to equipment.

3. Connect outlet port of Coldrink System to equipment

served. Always use a NSF approved pipe dope or

plumber tape at all connections. Use a backup wrench

on all fittings while connecting to avoid excessive stress

on the system components.

4. Install a manual shut-off valve leading to the system

for servicing.

5. Connect minimum 3/8” water line to the Coldrink 1

System inlet. Use a minimum 1/2” for Coldrink 2

and 3 Systems.

6. Connect tubing to flushing valve and run to drain. The

cross fitting has a flushing valve installed on the bottom.

2. The location should allow for:

• Minimum clearance of 2-1/2” (6.4 cm) under the

cartridge(s) so it can be lowered for removal

and replacement.

• Adequate space for “in” and “out” water

line connections.

• Be near a drain for flushing and near a 110V outlet

if the accessory (sold separately) EverguardTM Low

Pressure Alarm is used. See Figures 1-6.

NOTE: Some municipal plumbing codes and good

sanitary practices require an air gap at the drain

termination point.

7. Shut off the system inlet valve located on the inlet of the

prefilter head.

8. Check to be sure the o-ring on the prefilter housing is

sufficiently lubricated. Use a good grade of silicone

lubricant, if needed. Position the EC210 Prefilter

Cartridge on guide seat in the bottom of the bowl. Then

thread the bowl into the head by hand. Use a sump

wrench to snug the bowl onto the head.

9. Install the carbon filter cartridge(s) into the filter head(s)

following directions on the cartridge label or as shown in

the Cartridge Change Change Procedure

section illustrations.

10. Turn on inlet water to the filter system and check

for leaks.

FILTRATION & PROCESSING SOLUTIONS

COLD RI NK SERIES INSTAL LAT ION AND OPERAT IO N GUIDE

1

Page 2

21.5"

11. Open the flushing valve and flush the cartridge(s) by

running water through at full force for five (5) minutes.

This will set the filtering media and purge any air and

fines, insuring maximum filter life. See illustrations.

12. After flushing, close the flushing valve, turn on power

to equipment, and plug the LPA (if so equipped) into the

electrical outlet. The system is ready for operation.

DIMENSIONS

14"

INLET

3/8" FNPT

INLET

3/4" FNPT

Check for compliance with state and local laws and regulations. Do not use with water that is microbiologically unsafe

or of unknown quality without adequate disinfection before or

after the system. Systems certified for cyst reduction may be

used on disinfected waters that may contain filterable cysts.

For installations in Massachusetts, the Commonwealth of

Massachusetts Plumbing Code 248 CMR shall be adhered to.

Consult your licensed plumber for installation of the system.

This system and its installation must comply with state and

local regulations.

OUTLET

3/4" FNPT

INLET

3/4" FNPT

25.75"

Outlet

3/4" FNPT

Prefilter

(Inside Sump)

Figure 4 – Coldrink 1

Primary

Filter

Cartridge

25"

Figure 5 – Coldrink 2

25.59"

Figure 6 – Coldrink 3

29.59"

FLUSHING

For maximum life, all carbon filter cartridges must be flushed for five (5) minutes at full flow before use.

ALL NEW CARTRIDGES MUST BE FLUSHED AFTER EACH CARTRIDGE CHANGE BEFORE BEING PUT INTO SERVICE!

If the cartridges are new, have been properly flushed and both needle and follower register inadequate pressure, or the LPA

is sounding, you may be experiencing inadequate water pressure or some restriction may exist in the inlet water line. In either

case, the incoming water pressure must be improved to receive optimum filter life.

COMPLETE CARTRIDGE CHANGE INSTRUCTIONS CAN BE FOUND ON THE FILTER CARTRIDGE LABEL.

Not for residential use. For food service applications only.

CARTRIDGE CHANGE DETERMINATION

Replace the prefilter cartridge whenever it becomes excessively dirty (observed visually or by flow restriction). Follow the

change instructions provided with the cartridge. Replace carbon filter cartridges when capacity is reached, or when flow

becomes inadequate, but at least annually. All carbon filter cartridges on multiple cartridge systems should be changed at

the same time. The system pressure gauge or accessory (sold separately) EverguardTM Low Pressure Alarm (LPA) provide

quick, simple means of determining when the filter cartridge(s) should be checked. Installed on the system outlet manifold,

the gauge or LPA can be used to monitor both dynamic (flowing) and static (line) pressure. The cartridge(s) should be changed

when the pressure gauge needle is in the red area while equipment is in operation, and yet the needle shows adequate line

pressure between cycles. Observe the needle during the next equipment on cycle. If the needle registers adequate pressure,

it can be assumed that the temporary low-pressure condition was caused by a brief power failure or other incoming pressure

disruption. If the low pressure condition is not due to an external condition, check/change the prefilter first. If the low pressure

condition is still not corrected, change the carbon filter cartridges.

2 COLD RI NK SERIES INSTAL LAT ION AND OPERAT IO N GUIDE

Page 3

REPLACEMENT PARTS

Contact your local Pentair® Everpure® dealer for system

replacement parts.

DESCRIPTION PART NUM BER

Outlet Pressure Gauge EV3114-09

Inlet Pressure Gauge

(Coldrink 3 & 4)

EV3114-09

Inlet/flushing Valve EV3114-07

O-ring for Prefilter EV3112-40

Prefilter Bowl EV3112-38

PRESSURE GAUGES

System Tested and Certified by NSF International against NSF/ANSI

Standard 42 and 53 for the reduction of:

Standard No. 42 —

Aesthetic Effects

Bacteriostatic Effects

(MC2 and XC2 only)

Chemical Reduction

Standard No. 53 —

Health Effects

Mechanical Filtration

Cyst (MC, MC2, XC, XC2 only)

Asbestos (MC and MC2 only)

Taste and Odor

Chlorine

Mechanical Filtration

Nominal Particulate Class I

(MC, MC2, XC, XC2 only)

Low Inlet

Pressure

CARTRIDGE CHANGE PROCEDURE

E-Series Pre filter Cartri dge Change

1. Shut of f power t o equipment . Shut off

inlet w ater ahea d of syste m.

Everpure Carbo n Filter Cartridge

Change

1. Shut of f power to eq uipment. S hut off

inlet w ater ahea d of syste m.

2. Push re d relief v alve. Unsc rew bowl .

Remov e prefilt er cartr idge.

2. Open fl ushing val ve to relie ve press ure.

3. Hold he ad firmly an d push upwa rd. Turn

cart ridge to le ft until i t stops.

Adequate Inlet

Pressure

3. Clean b owl wit h filtered w ater only ; NO

SPECIAL CLEANERS.

4. Feel he ad o-ring. I f dry, lubr icate wit h

high qua lity sil icone lubr icant.

4. Pull ca rtridg e downwar d and out of he ad.

5. Hold he ad firmly. A lign cart ridge lug w ith

label . Insert n ew cartr idge firm ly

into he ad.

Low Outlet

Pressure

5. Inst all new pre filter car tridge in b owl.

Hand ti ghten bow l onto head .

6. Turn car tridge ri ght 90˚ unti l

rota tion stop s.

7. Repea t steps 3-6 f or remaini ng

cartridges.

Adequate Outlet

Pressure

6. Turn on wa ter. Turn on pow er to

equipment.

Flushing

8. With f lushing v alve fully o pen, open in let

wate r at full for ce for five m inutes. C lose

flus hing valve .

9. Turn on po wer to equi pment

3 COLD RI NK SERIES INSTAL LAT ION AND OPERAT IO N GUIDE

Page 4

OPERATING SPECIFICATIONS

COMBINED MODEL NAME REPLACEMENT CARTRIDGE

FLOW RATE CAPACITY

GPM LPM GALLONS LITRES

Coldrink System 1 - MC MC 1.67 6.3 9,000 34,000

Coldrink System 1 - MC

2

MC

2

1.67 6.3 12,000 45,420

Coldrink System 1 - XC XC 1.67 6.3 12,000 45,420

Coldrink System 1 - XC

2

XC

2

1.67 6.3 12,000 45,420

Coldrink System 1 - 4CB5 4CB5 1.67 6.3 6,000 22,710

Coldrink System 1 - 7CB5 7CB5 2.5 9.4 10,000 67,850

Coldrink System 2 - MC MC 3.3 12.6 18,000 68,000

Coldrink System 2 - MC

2

MC

2

3.3 12.6 18,000 68,000

Coldrink System 2 - XC XC 3.3 12.6 24,000 90,840

Coldrink System 2 - XC

2

XC

2

3.3 12.6 24,000 90,840

Coldrink System 2 - 4CB5 4CB5 3.3 12.6 12,000 45,420

Coldrink System 2 - 7CB5 7CB5 5.0 18.9 20,000 75,700

Coldrink System 3 - MC MC 5.0 18.9 27,000 102,000

Coldrink System 3 - MC

2

MC2 5.0 18.9 27,000 102,000

Coldrink System 3 - XC XC 5.0 18.9 36,000 136,260

Coldrink System 3 - XC

2

XC

2

5.0 18.9 36,000 136,260

Coldrink System 3 - 4CB5 4CB5 5.0 18.9 18,000 68,000

Coldrink System 3 - 7CB5 7CB5 7.5 28.2 30,000 113,550

* For individual cartridge specifications, refer to cartridge literature.

Temperature

35-100°F (2-38°C)

Pressure

10-125 psi (0.7-8.6 bar), non-shock

For cold water use only.

The term ‘bacteriostatic’ indicates that the system limits the passage or growth of bacteria that may already exist in the

incoming water. It does not mean that the water leaving the system is safer to drink than the water entering the system.

EPA Est. No. 002623-IL-002

FILTRATION & PROCESSING SOLUTIONS

EVERPURE-SHURFLO WORLD HEADQUARTERS, 1040 MUIRFIELD DRIVE, HANOVER PARK, IL 60133 USA • WWW.EVERPURE.COM

800.942.1153 MAIN (US ONLY) • 800.942.1153 (US ONLY) • 630.307.3000 MAIN • 630.307.3030 FAX • CSEVERPURE@PENTAIR.COM EMAIL

PENTAIR AUSTALIA/NEW ZEALAND, 1-21 MONASH DRIVE, DANDENONG SOUTH, VIC 3175, AUSTRALIA

1300.576.190 TEL • AU.EVERPURE@PENTAIR.COM EMAIL

EVERPURE-SHURFLO CHINA, 21F CLOUD 9 PLAZA , NO 1118, SHANGHAI , 200052, CHINA

86.21.3211.4588 TEL • 86.21.3211.4580 FAX • CHINA.WATER@PENTAIR.COM EMAIL

EVERPURE-SHURFLO INDIA, G REEN BOULEVARD, B-9/A, 7TH FLOOR - TOWER B SECTO R 62, NO IDA - 201301

91.120.419.9444 TEL • 91.120.419.9400 FAX • INDIACUSTOMER@PENTAIR.COM EMAIL

EVERPURE-SHURFLO EUROPE, PENTAIR WATER BELGIUM BVBA, INDUS TRIEPARK WOL FSTEE, TOEKOMSTLAAN, 30 B-2 200 HERENTALS, BELGI UM

+32.(0).14.283.500 TEL • +32.(0).14.283.505 FAX • SALES@EVERPURE-EUROPE.COM EMAIL

EVERPURE-SHURFLO JAPAN INC., HASHIMOTO MN BLDG. 7F, 3-25-1 HASHIMOTO, MIDORI-KU, SAGAMIHARA-SHI KANAGAWA 252-0143, JAPAN

81.(0)42.775.3011 TEL • 81.(0)42.775.3015 FAX • INFO@EVERPURE.CO.JP EMAIL

EVERPURE-SHURFLO SOUTHEAST ASIA, 390 HAVE LOCK ROAD, #04-01, KI NG’S CE NTRE, SINGA PORE 169662

65.6795.2213 TEL • FAX: 65.6795.2219 FAX • CSEVERPURE@PENTAIR.COM EMAIL

All Pentair trademarks and logos are owned by Pentair, Inc. or its affiliates. All other registered and unregistered trademarks and logos are the property of their

respective owners. Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice.

Pentair is an equal opportunity employer.

© 2014 Pentair Filtration Solutions, LLC. All Rights Reserved.

EV3112-79 Rev G MY14

Loading...

Loading...