Everpure Coldrink series, Coldrink 1, Coldrink 3, Coldrink 2 User Manual

EVERPURE

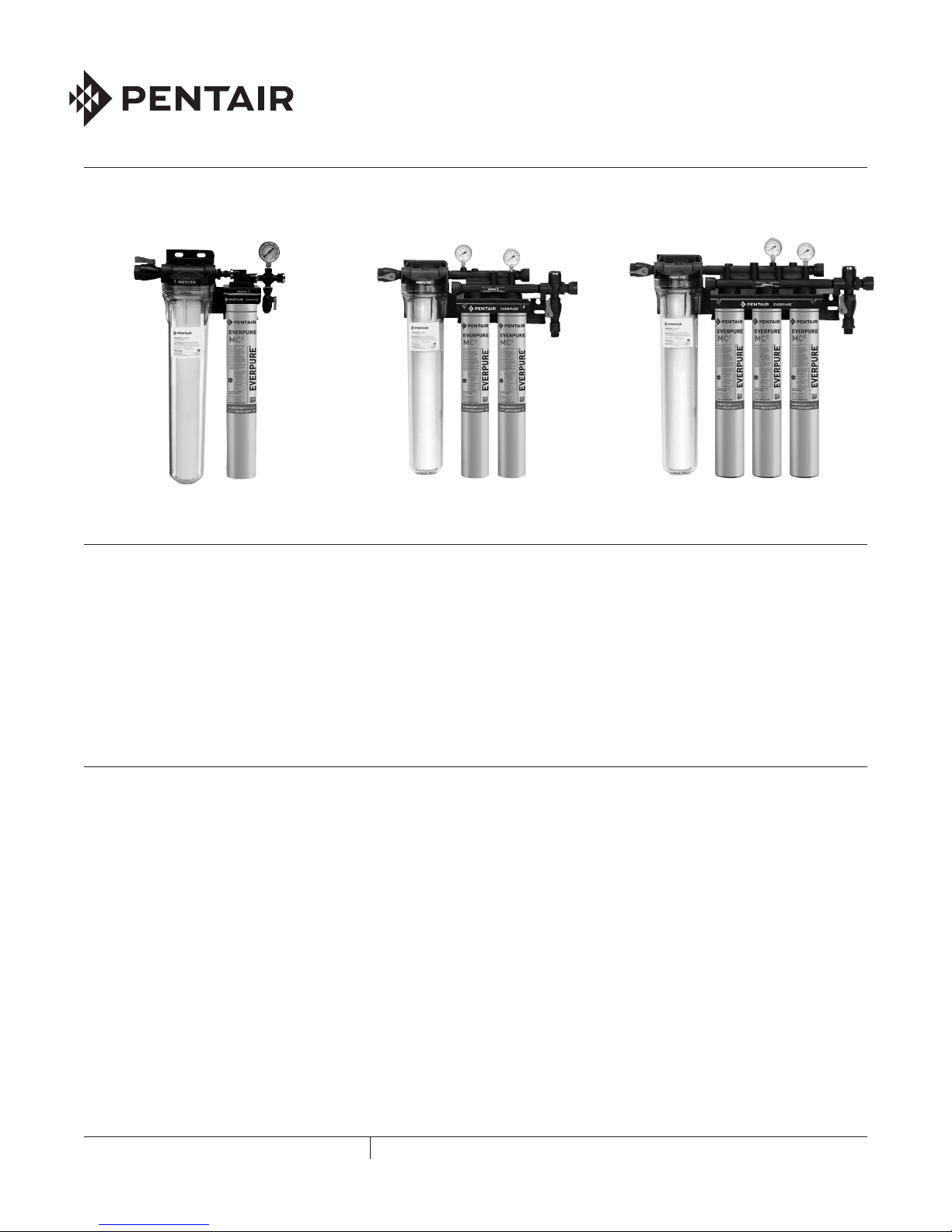

Figure 1 Coldrink 1 System Figure 2 Coldrink 2 System Figure 3 Coldrink 3 System

®

COLDRINK® SERIES FILTER SYSTEMS

SELECT A MOUNTING LOCATION

1. Give consideration to the weight of the unit when

operating (filled with water). Operating weights of the

Coldrink Systems are:

• System 1 - 19 lbs (8.62 kg)

• System 2 - 35 lbs (15.9 kg)

• System 3 - 45 lbs (20.4 kg)

INSTALLATION

1. Use the predrilled mounting holes in the manifold

bracket as guides. Mark and drill anchor holes. Mount

securely. See Figures 4-6.

2. Shut off power to equipment.

3. Connect outlet port of Coldrink System to equipment

served. Always use a NSF approved pipe dope or

plumber tape at all connections. Use a backup wrench

on all fittings while connecting to avoid excessive stress

on the system components.

4. Install a manual shut-off valve leading to the system

for servicing.

5. Connect minimum 3/8” water line to the Coldrink 1

System inlet. Use a minimum 1/2” for Coldrink 2

and 3 Systems.

6. Connect tubing to flushing valve and run to drain. The

cross fitting has a flushing valve installed on the bottom.

2. The location should allow for:

• Minimum clearance of 2-1/2” (6.4 cm) under the

cartridge(s) so it can be lowered for removal

and replacement.

• Adequate space for “in” and “out” water

line connections.

• Be near a drain for flushing and near a 110V outlet

if the accessory (sold separately) EverguardTM Low

Pressure Alarm is used. See Figures 1-6.

NOTE: Some municipal plumbing codes and good

sanitary practices require an air gap at the drain

termination point.

7. Shut off the system inlet valve located on the inlet of the

prefilter head.

8. Check to be sure the o-ring on the prefilter housing is

sufficiently lubricated. Use a good grade of silicone

lubricant, if needed. Position the EC210 Prefilter

Cartridge on guide seat in the bottom of the bowl. Then

thread the bowl into the head by hand. Use a sump

wrench to snug the bowl onto the head.

9. Install the carbon filter cartridge(s) into the filter head(s)

following directions on the cartridge label or as shown in

the Cartridge Change Change Procedure

section illustrations.

10. Turn on inlet water to the filter system and check

for leaks.

FILTRATION & PROCESSING SOLUTIONS

COLD RI NK SERIES INSTAL LAT ION AND OPERAT IO N GUIDE

1

21.5"

11. Open the flushing valve and flush the cartridge(s) by

running water through at full force for five (5) minutes.

This will set the filtering media and purge any air and

fines, insuring maximum filter life. See illustrations.

12. After flushing, close the flushing valve, turn on power

to equipment, and plug the LPA (if so equipped) into the

electrical outlet. The system is ready for operation.

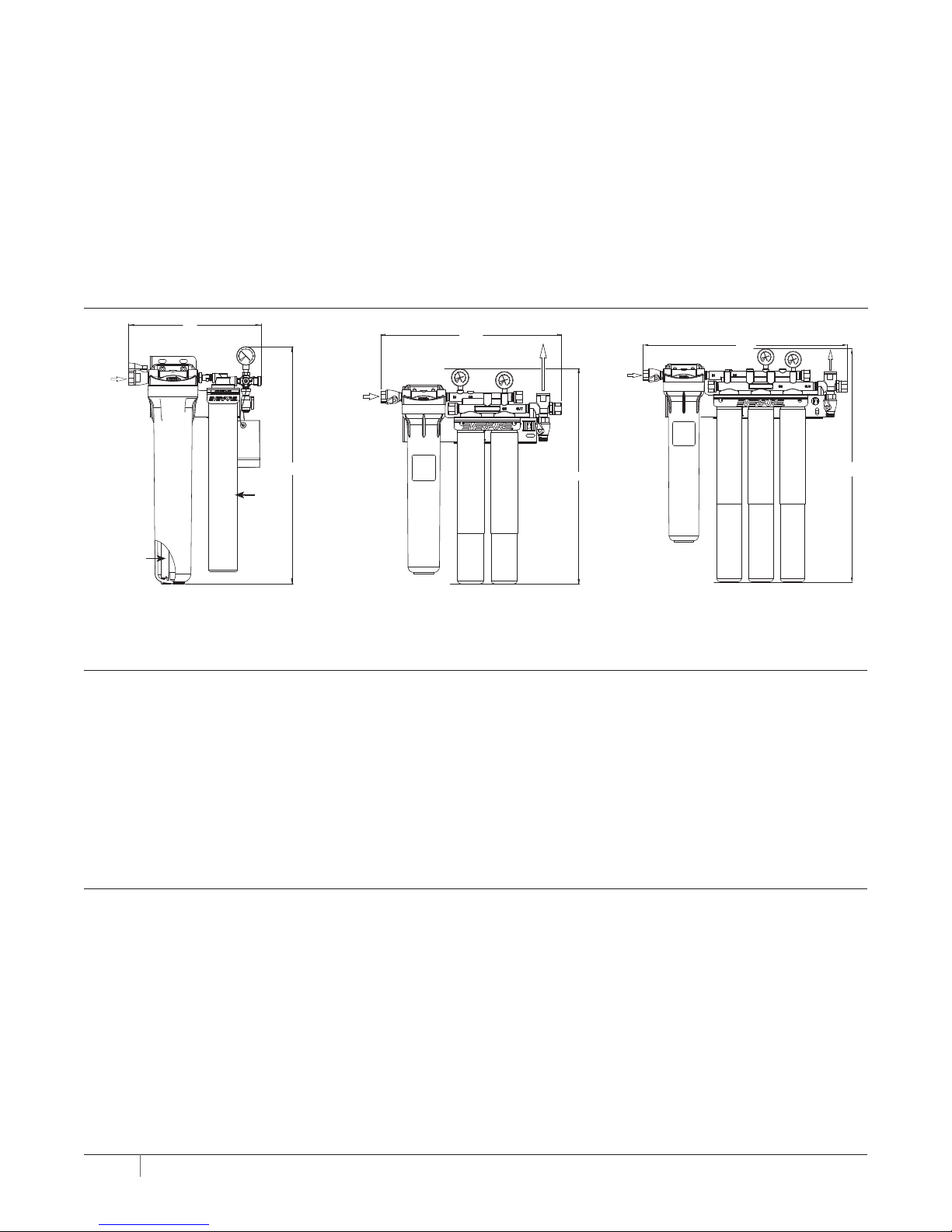

DIMENSIONS

14"

INLET

3/8" FNPT

INLET

3/4" FNPT

Check for compliance with state and local laws and regulations. Do not use with water that is microbiologically unsafe

or of unknown quality without adequate disinfection before or

after the system. Systems certified for cyst reduction may be

used on disinfected waters that may contain filterable cysts.

For installations in Massachusetts, the Commonwealth of

Massachusetts Plumbing Code 248 CMR shall be adhered to.

Consult your licensed plumber for installation of the system.

This system and its installation must comply with state and

local regulations.

OUTLET

3/4" FNPT

INLET

3/4" FNPT

25.75"

Outlet

3/4" FNPT

Prefilter

(Inside Sump)

Figure 4 – Coldrink 1

Primary

Filter

Cartridge

25"

Figure 5 – Coldrink 2

25.59"

Figure 6 – Coldrink 3

29.59"

FLUSHING

For maximum life, all carbon filter cartridges must be flushed for five (5) minutes at full flow before use.

ALL NEW CARTRIDGES MUST BE FLUSHED AFTER EACH CARTRIDGE CHANGE BEFORE BEING PUT INTO SERVICE!

If the cartridges are new, have been properly flushed and both needle and follower register inadequate pressure, or the LPA

is sounding, you may be experiencing inadequate water pressure or some restriction may exist in the inlet water line. In either

case, the incoming water pressure must be improved to receive optimum filter life.

COMPLETE CARTRIDGE CHANGE INSTRUCTIONS CAN BE FOUND ON THE FILTER CARTRIDGE LABEL.

Not for residential use. For food service applications only.

CARTRIDGE CHANGE DETERMINATION

Replace the prefilter cartridge whenever it becomes excessively dirty (observed visually or by flow restriction). Follow the

change instructions provided with the cartridge. Replace carbon filter cartridges when capacity is reached, or when flow

becomes inadequate, but at least annually. All carbon filter cartridges on multiple cartridge systems should be changed at

the same time. The system pressure gauge or accessory (sold separately) EverguardTM Low Pressure Alarm (LPA) provide

quick, simple means of determining when the filter cartridge(s) should be checked. Installed on the system outlet manifold,

the gauge or LPA can be used to monitor both dynamic (flowing) and static (line) pressure. The cartridge(s) should be changed

when the pressure gauge needle is in the red area while equipment is in operation, and yet the needle shows adequate line

pressure between cycles. Observe the needle during the next equipment on cycle. If the needle registers adequate pressure,

it can be assumed that the temporary low-pressure condition was caused by a brief power failure or other incoming pressure

disruption. If the low pressure condition is not due to an external condition, check/change the prefilter first. If the low pressure

condition is still not corrected, change the carbon filter cartridges.

2 COLD RI NK SERIES INSTAL LAT ION AND OPERAT IO N GUIDE

Loading...

Loading...