Page 1

Page 2

This ma chine has be en engineered to our own rigid safety and performance standards. It

has bee n designed to comply with sanitation and health guidelines recommended by the

Automatic Merchandising H ealth-Industry Council (AMHIC) and it conforms with all other

NAMA safety recommendations.

This machine has be en manufactured in accordance w ith the safety standards of both

Underwriter’s L aboratories and the Canadian Standards Association. To maint ain this

degree of safety and to continue to achieve the level of performance built into th is machine,

it is im portant that installati on and maint enance be p erformed so as to not al ter the ori ginal

construction or wiring and that replacement parts are as specified in the Parts Manual. Your

investment in this equipme nt will be protected by using this Operatos’s Guide and the

Parts Manual in your opera tio n, service and maintena nc e w ork . By fol lowing pre sc rib ed

procedures, machine perf ormance and safety will be preserved.

Crane Merchandising Systems Parts and Support

Parts: 1-800-621-7278 Service:1-800-628-8363

Page 3

TABLE OF C ON TENTS

Initial S e t- up. ......... ........ ........ ........ ........ ........ ........ ........ ........ ........ 1

Power Requ irement s ..... ........ ........ ........ ........ ........ ........ ........ ........ .. 1

Water Requirements......... ........ ................ ........ ........ ........ ........ ....... 1

Final Installation ............................................................................. 2

Install Options................................................................................. 4

Get The Mach i n e Ready To Vend D rinks .... ........ ........ ................ .. 7

Adjus tments and Minor Maintenance......................... ........ ..... 12

Programming The Cold Drink Center...................................... 17

Getting Around ............................................................................. 17

The Displ ay s ....... ........ ........ ........ ........ ........ ........ ........ ........ ........ .. 18

The Func t i o n Keys............ ........ ........ ........ ........ ........ ........ ........ .... 18

Other Keys .................................................................................... 18

Some Conventions:....................................................................... 19

Control Panel Switch Functions Explained.................................. 20

SureVe n d ™............. ........ .............. ........ ........ ........ ........ ........ ........ 21

The Supe r v isor Mode...... ........ ........ ........ ........ ........ ........ ........ ...... 2 2

Programming Procedures.......................................................... 23

Gain A ccess To The Su p ervisor Mo d e.............. ........ ........ ........ ....23

Enter A New Supervisor Code.......................................................23

Enter A Freevend Co d e.... ........ ........ ........ ................ ........ ........ ......23

Enter a N e w D a t a Re ca l l C o d e...................... ........ ........ ................ 2 4

Lock Or Unlock Mode or Payout Keys .........................................24

Set Talker Mode.............................................................................25

Set Print er or DEX Mode.... ........ ........ ........ ........ ........ ........ ........ ...25

Set Dex Options.............................................................................26

Select Printer Baud Rate................................................................26

Select Display Language................................................................27

Selec t Co i n Mechanism ......................... ........ ........ ........ ........ ........27

Selec t Bi l l Validat o r and Option s.......... ................ ........ ........ ........ 2 8

Initial Setup Of NonStandard Bill Validator .................................29

Selec t Card Reader a n d Opt i o n s.......... ........ ................ ........ ........ ..30

Select Monetary Options ...............................................................30

Set Up Winner Mode .....................................................................33

Set Up Mug Discount ....................................................................34

Disable Selections in the Merchandiser .........................................34

Page 4

Set Up Cu p Si z es..................... ........ ........ ........ ........ ................ ......35

Set Up A Drink ..............................................................................36

Factory Default Th row Times an d V o l u mes ....... ........ ........ ..........3 7

Blended D rinks ..... ........ ........ ........ ........ ........ ........ ........ ........ ........ . 3 8

Configure Pump Type....................................................................39

Configure Number of Selections ...................................................40

Set Up Aut o m a t ic Delivery D o o r Op t i o n s.. ........ ........ ........ ........ ...40

Assign Cup Sizes to Selections......................................................41

Turn SureVend™ On or Off ..........................................................42

Option a l o r Mandatory S u reVend™.............. ........ ................ ........ 4 2

Set Up the SureVend™ Anti-Jackpot Timer .................................43

View Software Version..................................................................43

Set the Time of Day.......................................................................44

Set Month, Date, and Year.............................................................44

Set Daylight Savings Time Options...............................................44

Set Tim e-of-Day Inh i b i t V e n d i n g.......... ................ ........ ........ ........4 5

Set Time-of-Day Free Vending .....................................................45

Set Time-of-Day Discount Vending..............................................45

Time Interval Editing.....................................................................46

Select a Standby Message..............................................................48

Select an O u t -o f-Servi ce Me ssage..................... ........ ........ ............48

Select a Freevend Message............................................................49

Edit Custo m Message ........... ........ ........ ........ ........ ........ ........ ........ .4 9

View Machine Configuration Setting............................................51

View Cu p Si z es Assigned to Selec t i o n s.................... ........ ........ ....52

Payout Coins.............................................................................. ....52

Set Prices........................................................................................53

View Non resettabl e Sales and Vend D a t a .......... ........ ........ ...........53

View Data Four Different Ways ....................................................54

View Total Paid Sales....................................................................54

View To tal Sales By D ri n k S ize.............. ........ ........ ................ ......54

View Total Sales By Selection ......................................................54

View To tal Sales By In d i v i d u a l S e l e ction....... ........ ........ ........ ......55

View Tota l Pai d Sales By Pric e Line........ ........ ........ ........ ........ .....55

View To tal Paid Ven d s........ ................ ........ ........ ........ ........ ..........55

Clear All Re settable D ata...... ........ ........ ........ ........ ........ ................ .56

Clear Paid Sales Data Only............................................................56

View Amount in Coin Box ............................................................56

Page 5

View Amount in Validator ............................................................57

View Freevend Sal e s by Time Inte rv a l.. ........ ................ ........ ........57

View Discount Sales by Time Interval ..........................................58

View Free Vends.. ................ ........ ........ ........ ................ ........ ........ ..58

View Winners ................................................................................58

View Time Data.............................................................................59

View To tal Unpaid Sales..... ................ ........ ........ ........ ................ ..6 0

View Total Unpaid Vends .............................................................60

View Number of Test V e n d s .. ........ ........ ........ ........ ........ ........ ....... 6 1

View Number of Mug Ven d s.... ........ ........ ........ ........ ........ ........ .....61

View Number Of Alt Vends..........................................................61

View Machine ID Number.............................................................61

View Cup Ring Cycles Related to SureVend™............................62

View Number of Cup Ring Cy c l e Fai l u res ....... ........ ........ ........ .....62

View Home Switch Us e Related to Su reVend.......... ................ ....62

Test Vend Selections and Verify Credit Added.............................63

Test th e Display....... ........ ........ ........ ........ ................ ........ ........ ......63

Test Dr o p a Cup......... ........ ........ ........ ........ ........ ................ ........ ....64

Test the Automatic Delivery Door.................................................64

Test Throw Stil l Wa t e r .................... ........ ........ ........ ........ ..............64

Test Throw Carbonated Water.......................................................64

Test the S y ru p Pumps ... ........ ........ ........ ........ ........ ........ ........ ........ .6 5

Test th e Ice Maker ........... ........ ........ ................ ........ ........ ........ ......65

Test the Carbonator........................................................................66

Cools an O p e r a t i o n....... ................ ........ ........ ........ ................ ........ ..6 6

Test Various Swit c h es and Sens o rs........... ........ ................ ........ ....68

View SureVend™ Average Calibration Value. .......... ............ ....... 69

View SureVend™ Last Recorded Calibration Value....................69

Test th e Display....... ........ ........ ........ ........ ................ ........ ........ ......70

View Diagnostic Messages............................................................70

Downlo ad Data to a PD CD.................... ........ ........ ........ ........ ........ 7 2

Set Freevend Options.....................................................................73

Page 6

Page 7

Cold Drink Center (327/328) Operato r ’s Guide

Initial Set-up

Power Requirements

This merchandiser requires power as shown in the following table. NOTE: Each

merchandiser should have its own electrical circuit.

Power Requirements

Country Volts Frequency (Hz) Current (Amps)

U.S., Mexico, and Canada 115 60 20

International 230 50 13 - 16

This merchandiser is supplied with a service cord for th e country of use and is terminated in a grounding type plug. The wall receptacle used f or this merchandi ser

must be properly polarized, grounded, and of the correct voltage. Operating the

merchandiser from a sour ce of l ow vol tage will VOID YOUR WARRANTY. Each

merchandiser should have its own electrical circuit and that circuit should be pro

tected with a circuit breaker or fuse conforming to local regulations.

Voltage Ch ec k - Place the leads of a voltmeter across the LINE (LIVE) and NEUTRAL terminals of the wal l receptacle. The voltmeter should indicate 110-130

volts ac for 120 volt, 60 Hz locations, or 220-240 volts ac for 230 volt, 50 Hz loca

tions.

Polarity Check - Pl ace the leads of a voltmeter across the LINE (LIVE) and

GROUND terminals of the wa ll re ceptac le. The voltmeter s hould i ndicat e 110-130

volts ac for 120 volt, 60 Hz locations, or 220-240 volts ac for 230 volt, 50 Hz loca

tions.

-

-

-

Noise Po te nt ia l Che ck - Pla ce the l eads of a vo ltmete r acros s the NEUTRAL and

GROUND terminals of the wall receptacle. The voltmeter should indicate 0 volts

ac. A measurement greate r than 1.5-2.0 volts ac coul d result in problems for the

merchandiser' s electronic circui try caused by electrical noise.

Any deviation from these requirements could result in unreliable performance

from your merchandiser.

Water Requirements

If your location has chemically softe ned water, one of the following steps is

advised:

• Have a non-softened supply line run to the merchandiser

• Contact your local water filter supplier f or information and suggestions

Well water can also be used in the Cold Drink Center. However, you should have

it checked for levels of carbonates and al kalies. Contact your water filter supplier

if these values are relatively high.

Water Pressure

Minimum water pressure: 20 psi (138.0 KPa) at 1/2 gallon/minute

Maximum water pressure: 80 psi (522.0 KPa) at 1/2 gallon/minute

3280020 Page 1 August, 2003

Page 8

Cold Drink Center (327/328) Operator’s Guide

Supply Line Requirements

Locate supply line at the rear of the merchandiser.

Equip the line with a shut-off valve.

Flushing Water Supply Line

Flush the water supply line before connecting it to the merchandiser. A minimum

of five gallons is usually required before connecting the merchand iser to the sup

ply line. To avoi d int roducing possible water line contaminants into the merchandiser, DO NOT flush the merchandiser water system.

Positioning The Merchandiser

You can position thi s merchandiser anywhere in a bank of machines. It can even

be placed on the end flush against a side wall.

Leave enough room in front of the merchandiser for the door to move freely.

BE SURE THE REAR OF THE MERCHANDISER IS AT LEAST 6" AWAY FROM

THE WALL. THIS WILL ENSURE WARM MOIST AIR IS VENTED OUT OF THE

MACHINE'S INTERIOR AND THE REFRIGERATOR CONDENSER FAN IS NOT

OBSTRUCTED.

NOTE

This machine is onl y rated for install ati on in an indoor location.

Final Install ation

1. Connect the merchandi ser to the water supply:

-

a. You will need the following:

• A coil of coppe r tubing wi th outside diamet er of 3/8 inch (9.5 mm) or greater.

The appropriat e plastic tubing may be substituted.

• A 3/8 inch (9.5 mm) flare nut. A 3/8 inch (9.5 mm) male flare is provided.

b. Connect the merchandiser to your water supply.

2. Connect the merchandi ser to the power source:

Power to the merch andiser is controll ed by the main power switch, located on the

power panel.

a. Make sure the main power swi tch is OFF.

b. Connect the merchandi ser’s power cord to your wall outlet .

3. Using a spirit level, level the merchandiser front to back and side to side.

August, 2003 Page 2 3280020

Page 9

Cold Drink Center (327/328) Operato r ’s Guide

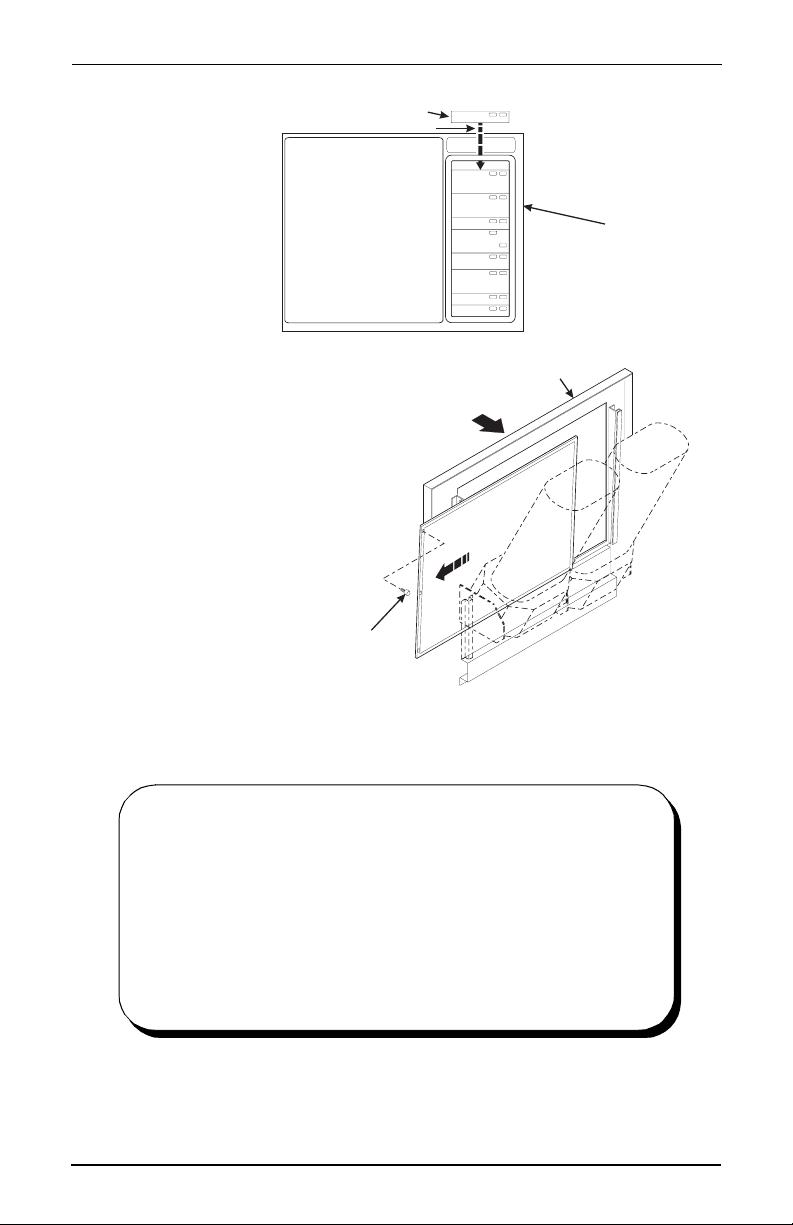

4. Set up the menu

assembly:

a. Swivel the

cup turrets

away from the

door.

b. Remove the

thumb screws

as shown,

and slide out

the menu

assembly.

c. Install selec-

tion inser ts a s

shown.

5. Reinstall the

menu assembly

in the reverse

order of

assembly.

SELECTION INSERT

INSERT AS SHOWN

VIEW A

VIEW A

DOOR

DISPLAY

ASSEMBLY

6. Load the coin

SLIDE

mechanism:

a. Open the cab-

inet door and

the monetary

THUMB

SCREW

door.

b. Insert coins

into the ir

respective tubes until each tube has been filled.

c. Inspect the tubes for shingl ed coins and correct if necessary.

BRAND NAME LABELS FOR COLD DRINK SELECTIONS

ARE A VAILABLE FROM THE FOLLOWING SOURCES:

National Beverage Screen Printers

609 East Main Street

Williston, SC 29853-5272

Outside South Carolina call: 1-800-325-9021

Inside South Caro li na call: 1-803-266-5272

Fax: 1-803- 266-5 301

The suggested style is: NBS-57

Size: .81 x 2.62

327p0001

3280020 Page 3 August, 2003

Page 10

Cold Drink Center (327/328) Operator’s Guide

SLIDE

Install Options

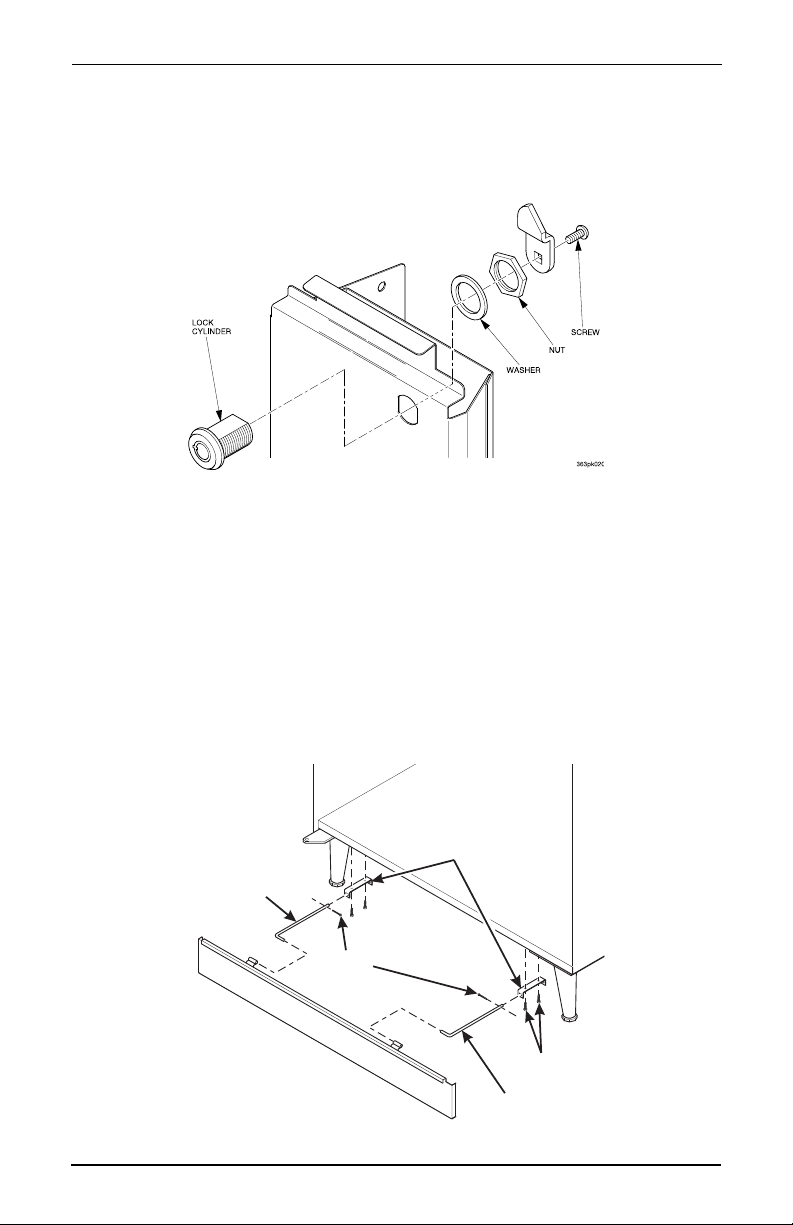

1. Install the coin box lock:

a. Install the l ock cylinder , washer, and nut in the order shown.

b. Tighten the nut.

c. Install the lock bar as shown, and secure with the screw.

2. Mount the base plate brackets:

a. Secure a base plate bracket at each of the remaining pai rs of holes with

two of the hex head screws.

3. Mount the base plate and slides:

a. Insert the short arm of the slides into the hinged tabs of the base plate.

Position the sli de so the notch near the short arm is on the bottom side.

b. Insert the long arms of the slides into the base plate brackets.

c. Insert a cotter pin through the hol e in the back end of each slide . Secure

the pins in place.

d. Push the base plate toward t he me rchandiser cabinet. The front t ab of

the base plate bracket should seat in the notch in the long arm of the

base plate slides.

BASE PLATE

MOUNTING

LEFT HAND

BASE PLATE

SLIDE

COTTER

PIN

August, 2003 Page 4 3280020

BRACKET

HEX HEAD

SCREW

RIGHT HAND

BASE PLATE

Page 11

Cold Drink Center (327/328) Operato r ’s Guide

NOTE

The mounting br acke ts ar e sub ject to d amage when movi ng the

machine with a fork lift. Remove the brackets prior to moving

the machine with a fork lift to prevent damage.

4. Install the water filter cartridge:

IF YOUR MERCHANDISER HAS THE WA TER FILTER OPTION, IT CANNOT BE

OPERA TED WITHOUT A PROPERLY INSTALLED WATER FILTER CAR

TRIDGE.

NOTE

Check the water filter installation record. There is a place to

write the vend number on the cartridge. Local conditi ons m ay

require more frequent replacement.

a. Your filter cartridge is shipped inside the waste pail. Locate it and

remove the wrapping.

b. Install the filter in accordance wit h the appropriate procedure:

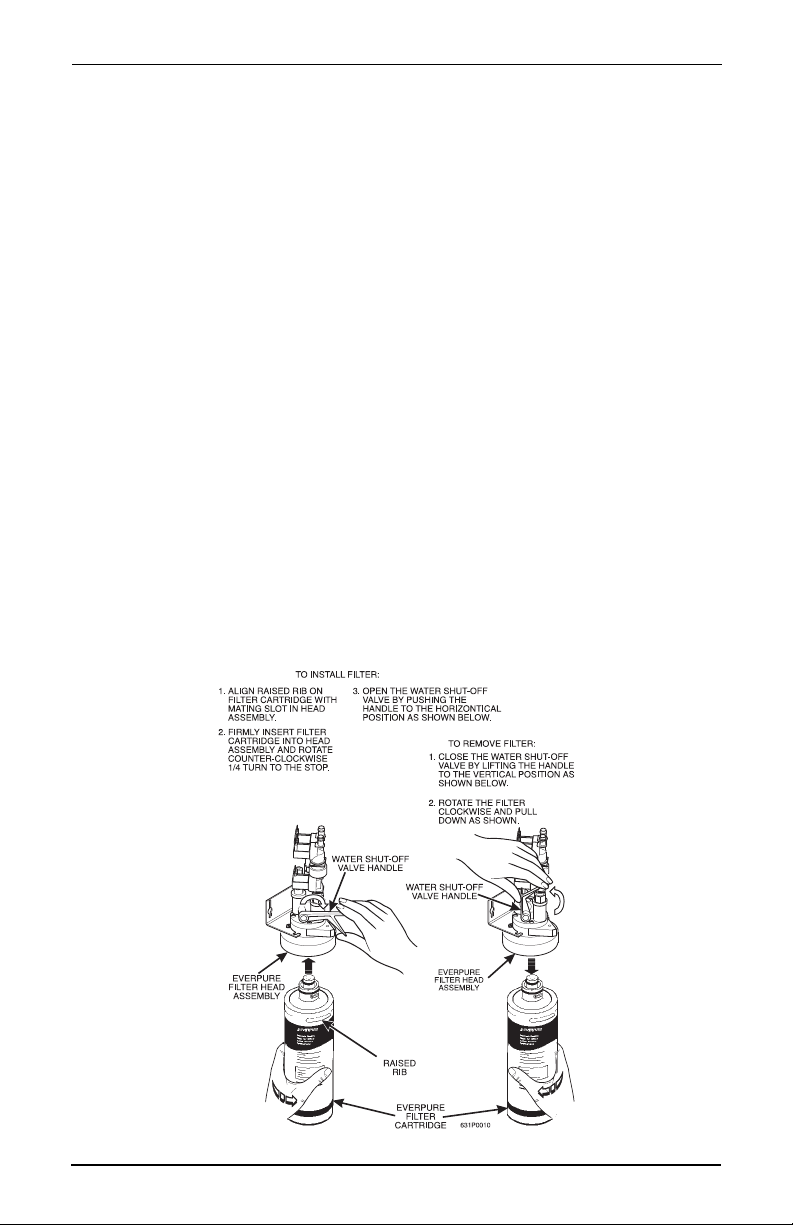

EVERPURE WATER FILTER INSTALLATION

Check the water filter installation record. There is a place to write the vend number on the cartridge. The cartridge is effective for a maximum of 10,000 18 oz.

vends, 11,000 16 oz. vends, 15,000 12 oz. vends, or 20,000 9 oz. vends. Local

conditions may require more frequent replacement.

a. Your filter cartridge is shipped inside the waste pail. Locate it and

remove the wrapping.

b. Gain access to the water filter head assembly, located at the cabinet

back wall above the water bath.

c. Install the filter as shown.

-

3280020 Page 5 August, 2003

Page 12

Cold Drink Center (327/328) Operator’s Guide

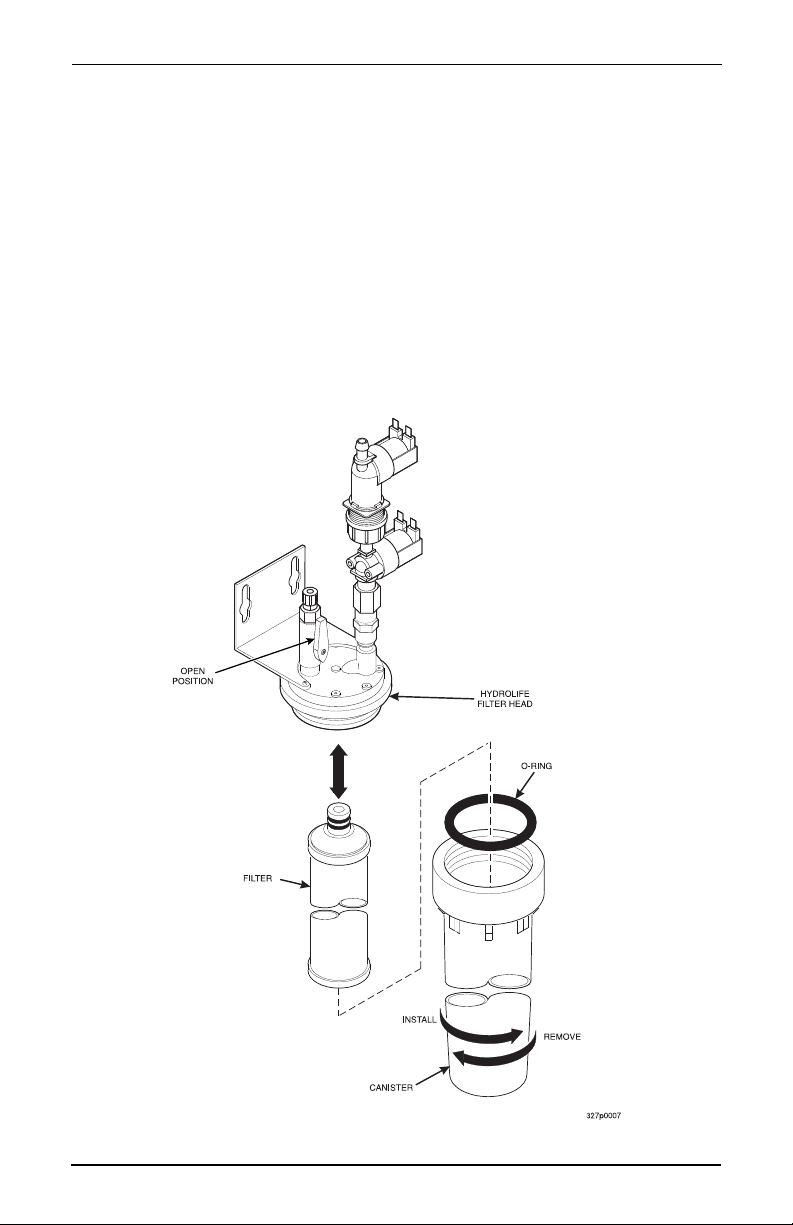

HYDROLIFE FILTER INSTALLATION

a. Place the filter inside the canister. Be sure the o-ring is seated in the

canister just below the threads.

b. Screw the canister and filter assembly onto the filter head until it comes

to a stop.

c. Open the water valve on the inlet line by rotating the handle to the verti -

cal position as shown.

HYDROLIFE FILTER REMOVAL

a. Close the valv e on the inlet line by rotating the handle into the horizonta l

position as shown.

b. Relieve water pressure by performing two or three water throws (See

"T est Throw Still Water" on page 64).

c. Unscrew the filter and canister assem bly from the filter head. Remove

the filter fr om the canister .

August, 2003 Page 6 3280020

Page 13

Cold Drink Center (327/328) Operato r ’s Guide

Get The Machine Rea d y To Vend Drinks

1. Fill the water bath:

a. Open the convenience valve.

b. Fill the water bath level with the carbonator top, or until water runs out

the water bath overfl ow tube.

2. Load and set up cold drink products:

Bag-in-box machines:

a. Place the bag-in-box containers on the lef t hand side of the cabinet with

the fittings facing up.

b. Connect the syrup l ines to the bag-in-box cont ainers. Note that the

syrup lines are mar ked with th e numbers 1 t hrough 8. These cor respond

to the pumps, which provide syrup for selections A through H, respec

tively. Make sure the bag-in-box containers you have installed agree

with these markings.

c. Place connectors inside box.

Syrup tank mach ines:

a. Load syrup into th e tanks.

b. Insert the syr up dip tubes into the tanks and pl ace the lids on the tanks.

Note that the syrup lines are marked with the numbers 1 through 8.

These correspond to the pumps, which provide syrup for selections A

through H, respecti vely. Make sure the syrup tanks you have installed

agree with these markings.

-

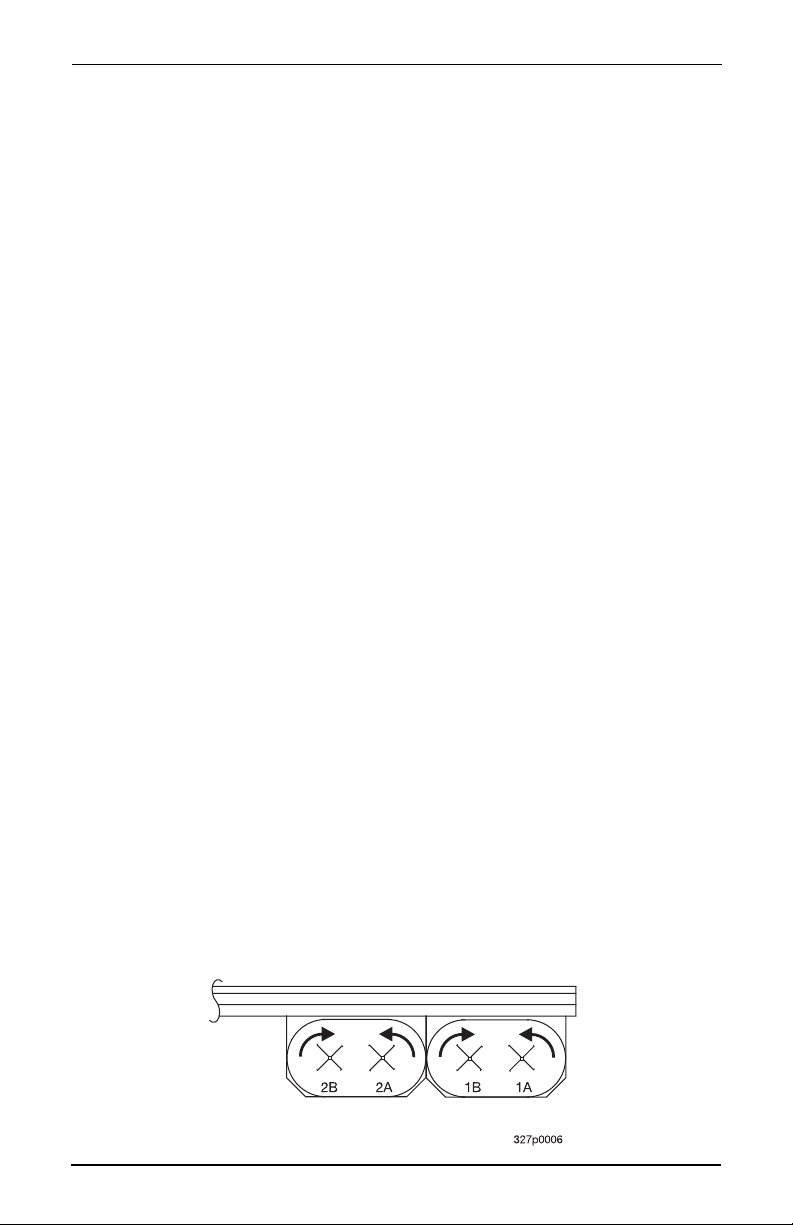

Load the cup mechanism:

NOTE

Use cups that have been designed for use in a cold beverag e

vending machine. Do NOT use cups made of clear

(transpar ent) material.

For single cup size ma chines, the same size cups must be loaded in turrets 1A,

1B, 2A, and 2B. For dual cup size machi nes, small cups are loaded in tu rrets 1A

and 1B; large size cups are loaded in turrets 2A and 2B. The size of cup you

load, and its location, must agree with the available cup mechanisms and

the cup size that you select during pr ogrammi ng. Refer to th e program ming

section (and the sect ion on cup mechanisms) for more information.

a. Support the cup mechanism in the upright posit ion.

b. Push the latch forward to release the cup mechanism. Continue to sup-

port the cup mechanism while you lower it into the loadin g position.

c. Remove the turret cover.

3280020 Page 7 August, 2003

Page 14

Cold Drink Center (327/328) Operator’s Guide

OBSERVE PROPER HYGIENE - DO NOT TOUCH THE CUPS!

d. Open the bottom of the wrap per on a st ack of cups.

e. Insert the wrapped cups into the turret and pull the wrapper out.

DO NOT FILL CUPS ABOVE THE LEVEL MARKED ON THE

OUTSIDE OF THE CUP TURRETS OR ABOVE THE “FILL

LINE” LABEL INSIDE EACH TURRET, OR MOTOR JAMS

WILL OCCUR.

USE ONL Y THE SAME SIZE AND BRAND OF CUPS IN

EACH TURRET; DO NOT INTERMIX!

f. Replace the turret cover after the turrets have been loaded.

g. Be sure the cup mechanism is locked into the upright position.

CABINET

DOOR

CUP MECH

MOUNTING

BRACKET

RETAINING

STRAP

LID

LOAD CUPS

HERE

CUP TURRET

LATCH

CUPS

TOP VIEW

August, 2003 Page 8 3280020

Page 15

Cold Drink Center (327/328) Operato r ’s Guide

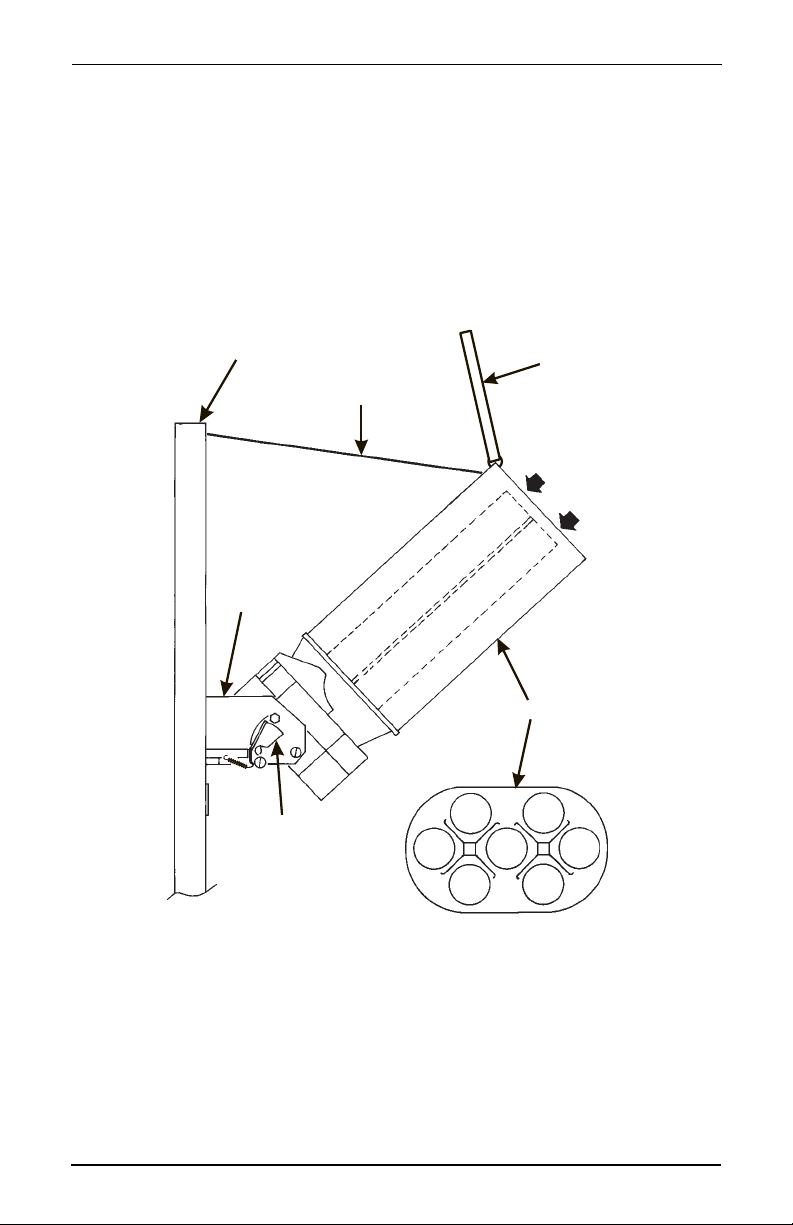

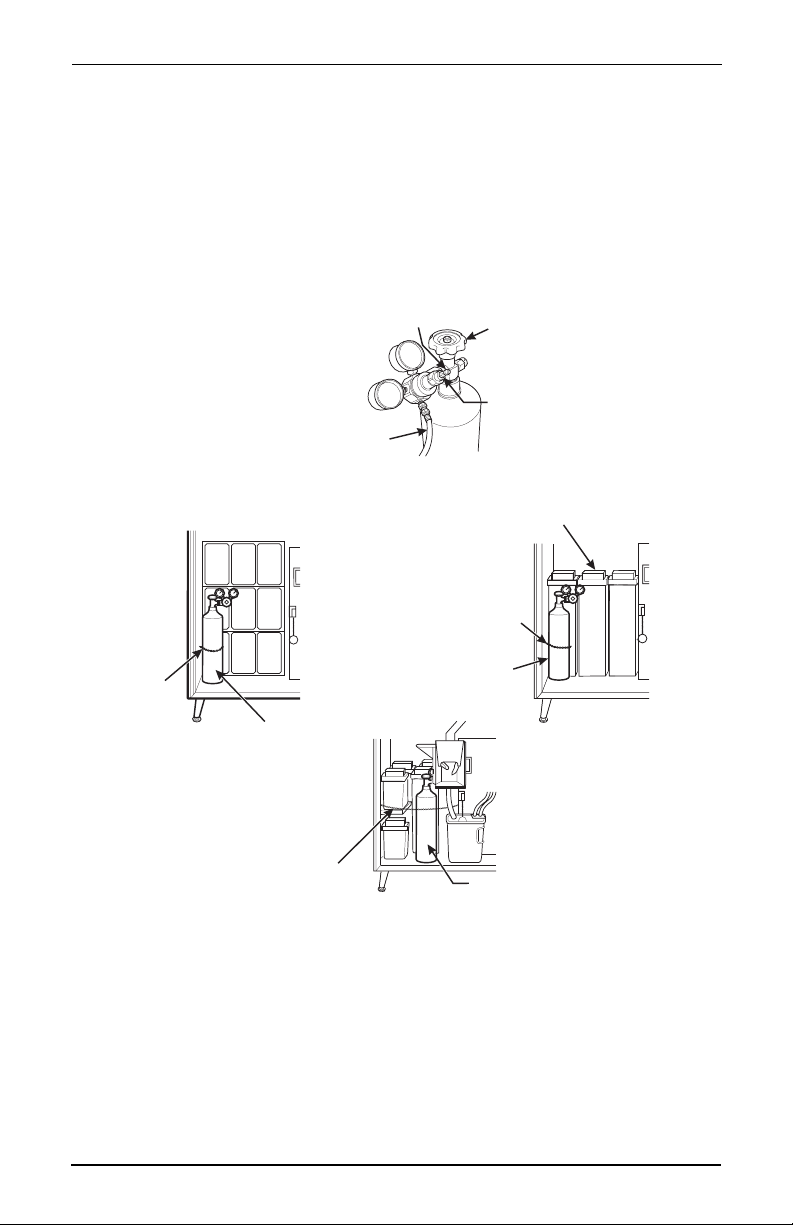

Set up the CO2 tank:

NOTE

A full CO2 tank can be dangerous if it is dropped or mishandled. Handle with car e

and keep the tank lid in place until the tank is properly secured in the

merchandiser.

a. Place the power switch in the OFF position.

b. Install a full CO2 tank on the merchandiser as shown. Secure t he CO2

tank with the retaining chain. (Note the various retaini ng chain configura

tions.)

ADJUSTMENT

SCREW

CO HOSE

2

(REAR OF TANK SHOWN)

CO CYLINDER

2

VALV E

ADJUSTMENT

LOCK NUT

SYRUP TANKS

RETAINING

CHAIN

-

CO CYLINDER

˜

LOCATION 2

2

CO CYLINDER

2

LOCATION 1

327p0008

RETAINING

CHAIN

LOCATION 1

CO CYLINDER

2

RETAINING

CHAIN

c. Remove the CO2 tank lid. Briefly open and close the CO2 cylinder valve

to blow out any foreign matter.

d. Locate the CO2 regulator and flat plastic washer (in a box), and the

tapered plastic washer (in plastic bag).

e. Connect the CO2 hose from the secondary regulator tee fitting to the reg-

ulator. Firmly tighten the fitting.

3280020 Page 9 August, 2003

Page 16

Cold Drink Center (327/328) Operator’s Guide

NOTE

Not using a wrench on the t ank side may damage t he CO2 tank ,

resultin g in per sonal injury.

f. Using two wrenches, tighten the line to the regulator.

g. Insert the flat washer into the regulator nut.

h. Using two wrenches, connect the regulator to th e tank outlet and tighten

in place.

i. Open CO2 tank valve.

j. Adjust the CO2 regulator so that the gauge reads 60 PSI (4.10 bar) .

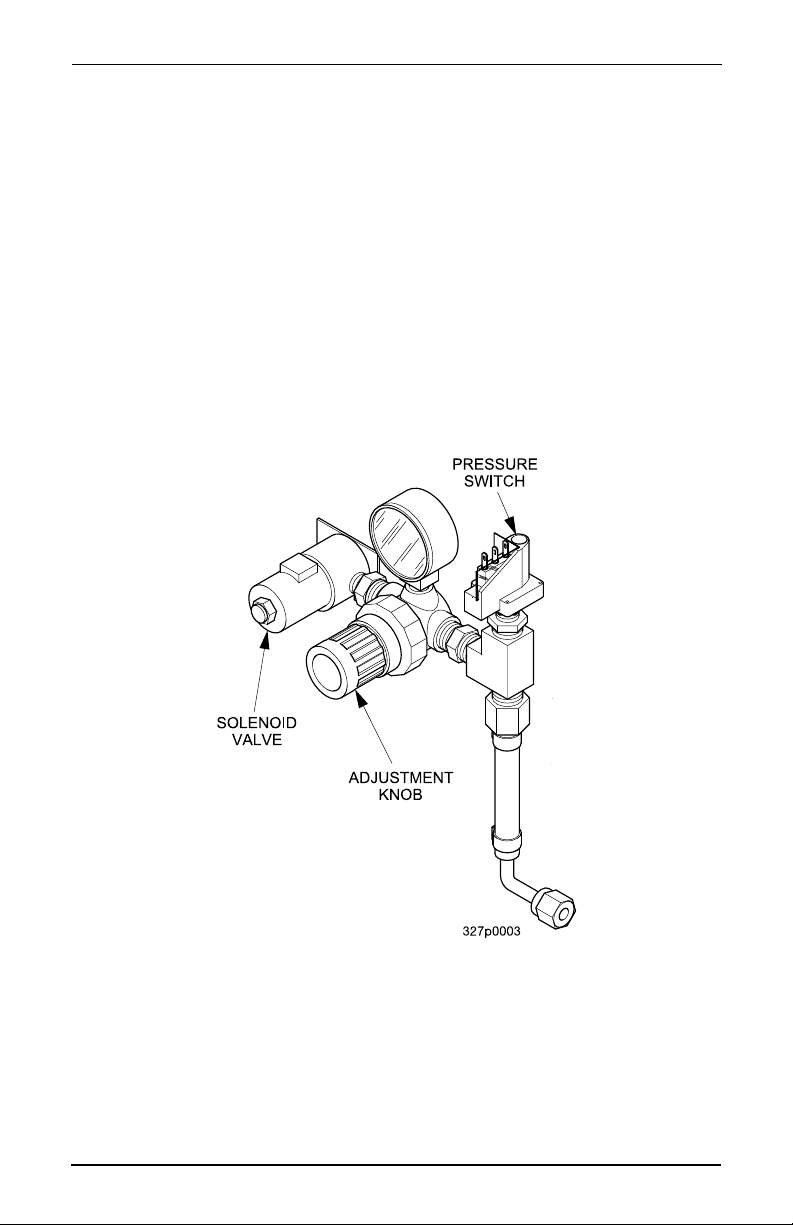

k. The secondary regulator is located behind the monetary p anel on the

right side of the cabi net. Adjust the secondary reg ulator to 40 PSI (2.76

bar).

l. Lock the adjustment screw in place.

m. Remove the water bath cover and actuate the pressure reli ef valve

located on top of the carbonator tank for 3 to 5 seconds.

n. Check for gas leaks al ong the CO2 line.

Augus t, 2003 Page 10 3280020

Page 17

Cold Drink Center (327/328) Operato r ’s Guide

W

a

s

p

b

t

w

p

t

p

a

d

P

a

o

h

t

i

Is the ratio of syrup to water in a cold drink

BRIX

1. Prime the Syrup System :

Before trying to brix the machine: Operate each syrup valve (increase flow)

to flush any air or water out of the tubin g, pump, or syru p system. This re sid

ual air and water is left in the system from factor y leak testing and machine

setup. If air passes thr ough the syrup val ve, syrup cannot, and the drink wi ll

be weak.

a. Place a cup in the cup delivery compartment.

b. Perform a syrup test thr ow. Refer to "Set Up A Drink" on pag e 36.

Measure the amount of syrup you get.

c. Repeat step b until 1.7 oz (50 ml) of syrup (the proper amount of syrup

for the 12 oz cup) is dispensed.

d. Repeat steps a thr ough c for all the remaining sele ctions in the machine.

e. Remove and discard the cup.

2. Test for Gas Leak s

Now that the pumps are primed, they will not pulse until syr up is called for.

Test the lines for gas leaks as follows:

a. Close the CO2 cylinder valve.

b. Observe the high pre ssure gauge. If the reading on the gauge

decreases, there is a leak in the system.

c. Locate the source of the leak and repair it.

machin e . Als o , to BRIX the machine is to set

up that ratio.

-

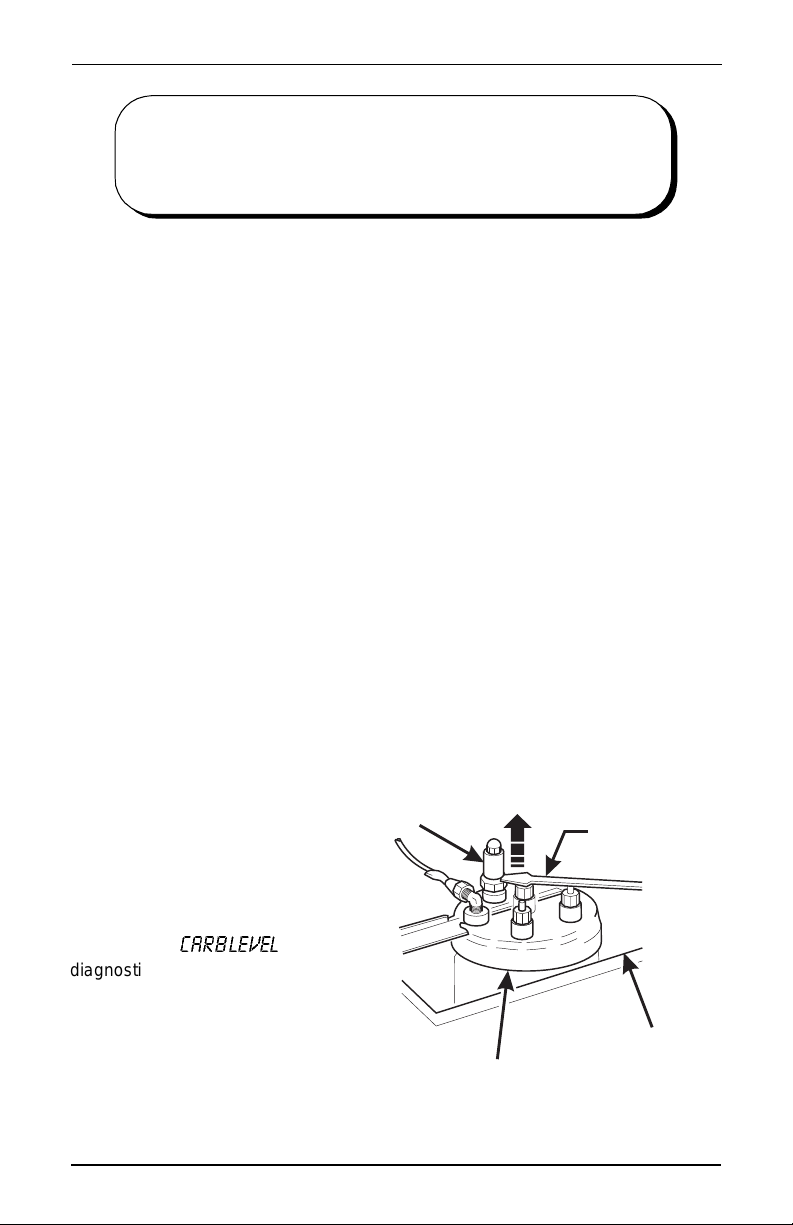

3. Purge the Carbonator of Air

hen a merchandiser is fir st put into service, air may be present in the carbontor. This air will not mix with the water, nor will it be absorbed into the water. A

ressure builds up in the carbonator, the air will be trapped in the top of the caronator and will prev ent

he carbonator from fil ling

ith water. The water

ump will no longer be ab le

o pump against this high

ressure, and it will stop

nd disp lay a

iagnostic message.

urge the carbonat or of

ny trapped air by lif tin g up

n the pressure r elief valve

andle as shown. Once

his condition is cor rected,

t will not happen again as long as the merchandiser is properl y serviced.

3280020 Page 11 August, 2003

`^o_=ibsbi

RELIEF VALVE

CARBONATOR

SCREWDRIVER

WATER BATH

316P0103

Page 18

Cold Drink Center (327/328) Operator’s Guide

Adjustments and Minor Maintenance

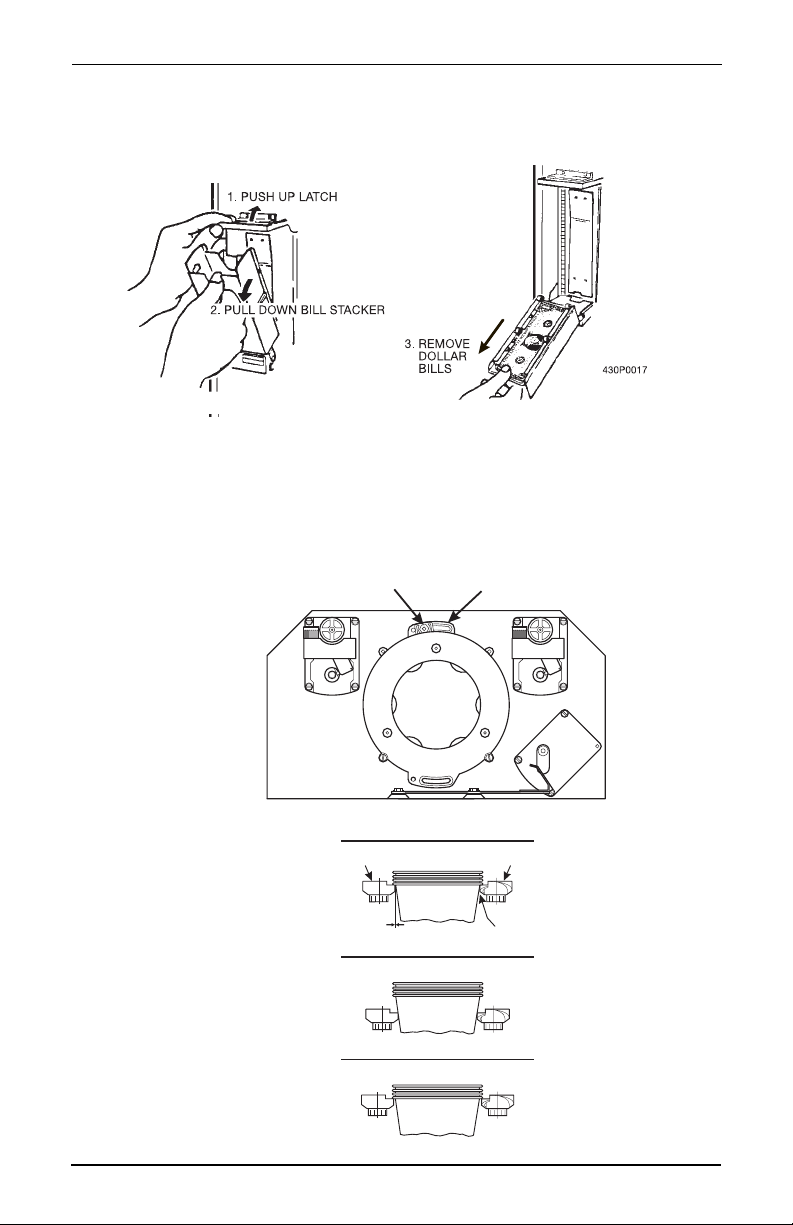

1. Emp ty in g the b ill s tac k e r:

2. Cup mechanism adjustment.

a. Place seven cups in the cup ring.

b. Observe the clear ance as shown in view B.

c. If necessary adjust by first loosening the adjustment arm screw (view A).

d. Move adjustmen t arm until correct clearance is achieved.

e. Hold adjustment arm in pl ace and tighten adjustment arm screw.

LOOSEN SCREW

MOVE ARM

ADJUSTMENT

ARM

View A

VIEW FROM BENEATH

CUP

View B

CAM

This clearance is just

large enough to allow

cup ejection

CORRECT

ADJUSTMENT

ADJUSTED

TOO TIGHT

ADJUSTED

TOO LOOSE

Augus t, 2003 Page 12 3280020

CUP

CAM

This side is snug

against cam

327p0015

Page 19

Cold Drink Center (327/328) Operato r ’s Guide

WATER

C

N

G

SCREW

3. Testing the wate r pump fl ow

The water pump should require between 13 and 21 seconds to completely refill

the carbonator. To check the wat er f low, proceed as f oll ows:

a. Place a cup in the cup station and make sure the waste pail is in place.

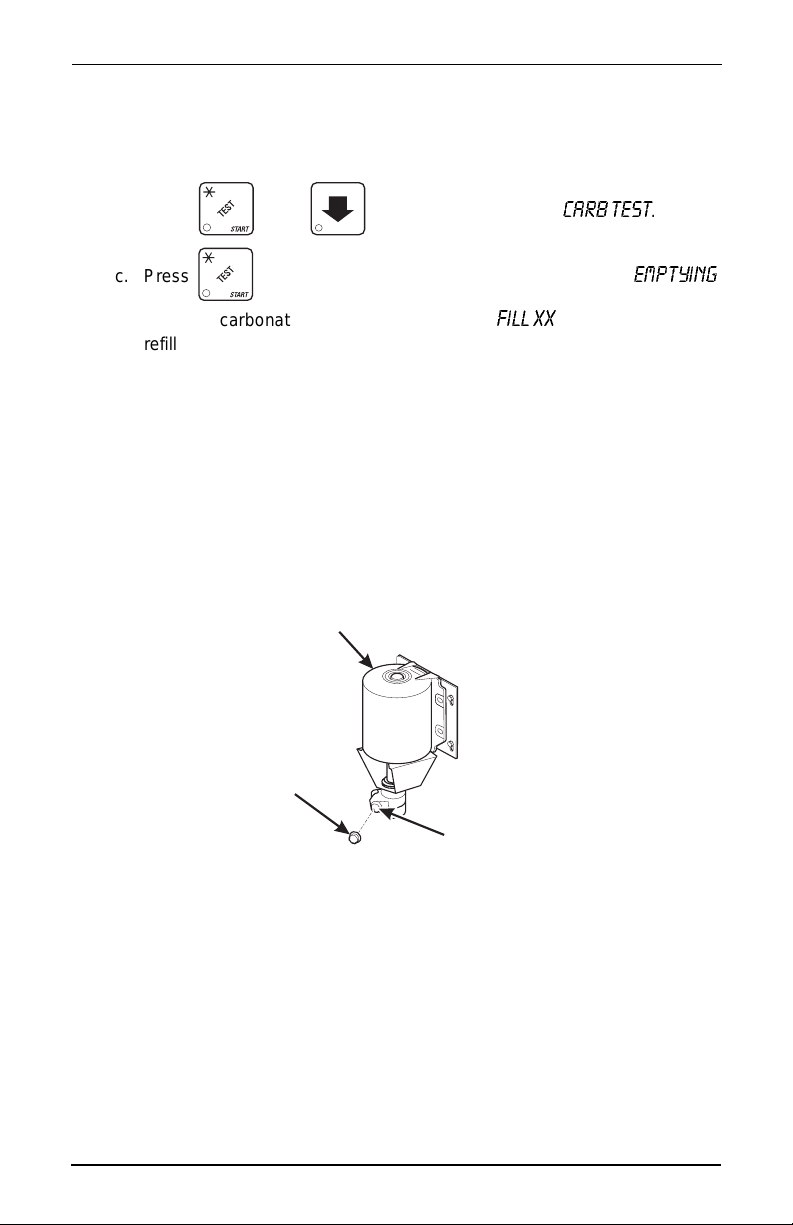

b. Press , then until the display shows:

c. Press . The water pump start s, and t he disp lay shows

while the carbon ator dispenses, then shows

refills.

d. After adjusting the flow, repeat step c until the desired time is achieved.

4. Adjusting the water pump flow:

a. Remove the cap nut to expose the adjustment screw.

b. Turn the adjustment screw:

CLOCKWISE to decrease refill time.

COUNTERCLOCKWISE to increase refill tim e .

NOTE

Failure to replace the cap nut will cause the water pump to leak.

c. Replace the cap nut.

PUMP

AP

UT

cfii=uu

`^o_=qbpq

as the carbonator

.

bjmqvfkd=

ADJUSTIN

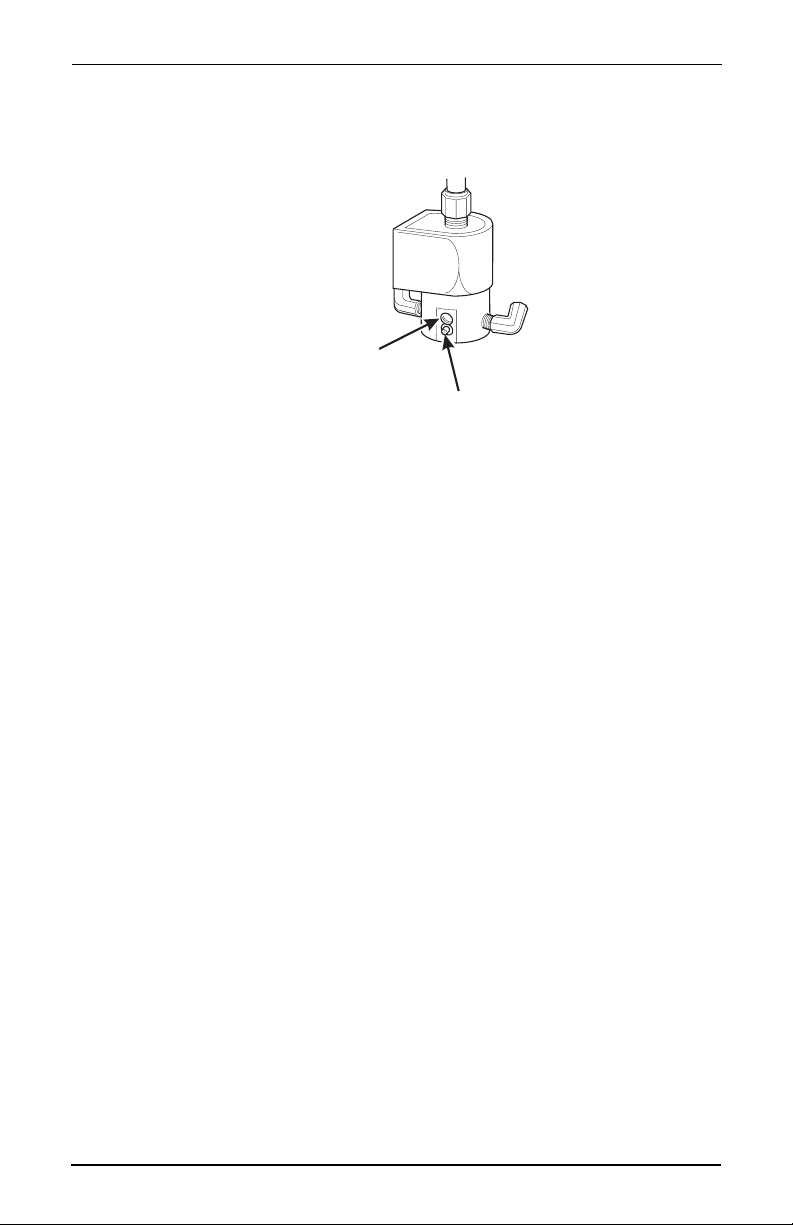

5. Adjusting the water valve:

The water valves are located under the water bath cover.

NOTE

3280020 Page 13 August, 2003

To prevent personal injury, only turn the adjusting screw when

making adjust ment s. DO NOT l oos en or re move the l imit scr ew

located above the adjusting screw.

NOTE

See "Set Up A Drink" on p age 36, for the procedure and tabl e

for setti ng th ro w s .

Page 20

Cold Drink Center (327/328) Operator’s Guide

(

ADJUSTING SCREW

a. Rotate the adj usting screw 1/8 turn:

CLOCKWISE to decrease water throw.

COUNTERCLOCKWISE to increa s e wa te r th ro w.

b. Repeat the testing steps until the water throw i s as desired.

LIMIT SCREW

SEE WARNING)

6. Testing the syr up throw:

a. Place a graduated flask in the cup station.

b. Refe r to "Set Up A Drink" on page 36, for information on how to se t

your syrup and perform test throws.

c. Test throw syrup and compare the volume of syrup to the suggested vol-

ume in the table for the cup size being vended.

d. If necessary, adju st the syrup valve to obtain the proper volume.

e. Repeat steps c and d for all selections.

NOTE

Software tim es do not control the output volume of diaphragm

pumps; they simply start the motor. The output volume is

controlled with a mechanical adjustment in the pump.

Augus t, 2003 Page 14 3280020

Page 21

Cold Drink Center (327/328) Operato r ’s Guide

E

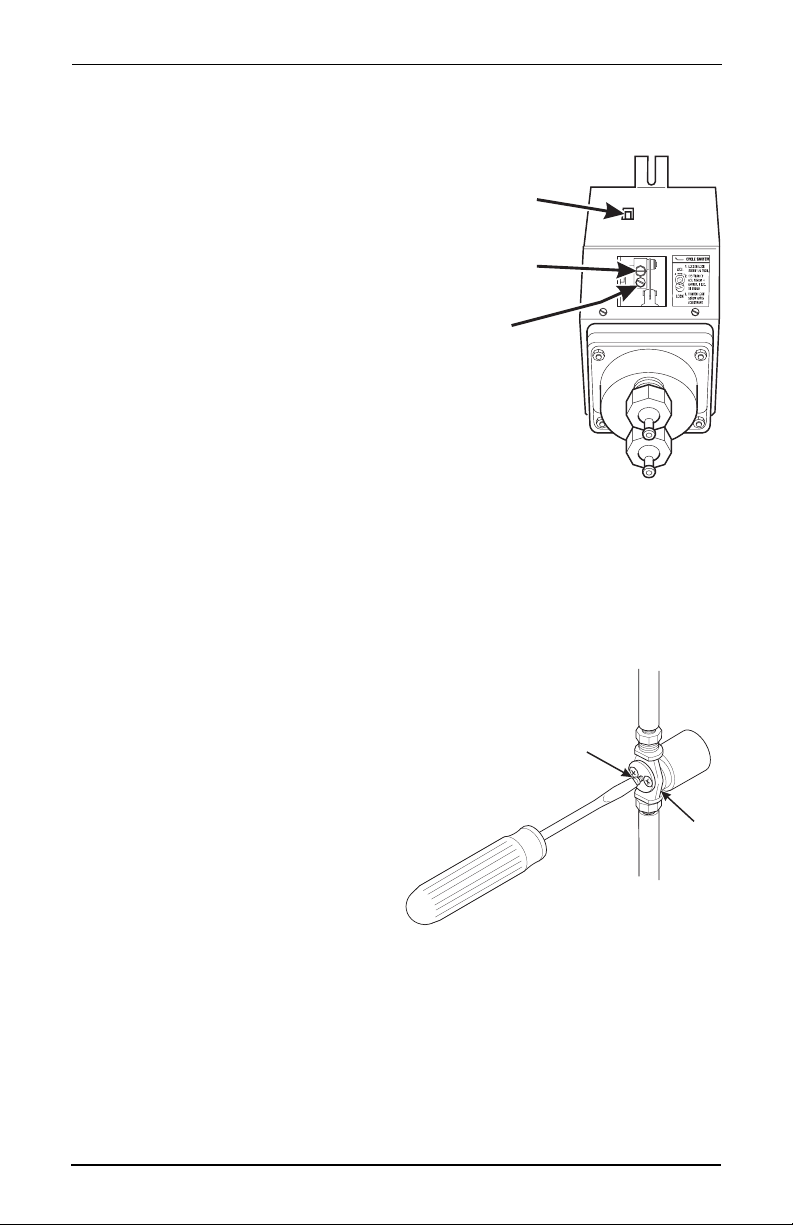

7. Adjusting the Syrup Throw (DIAPHRAGM PUMP):

a. Locate the adjusting block within the syrup pump. Momentarily activate

the prime switch to put the adjusting block into cl ear view.

NOTE

When adjusting th e crank

arm adjuster screw, loosen

the limit screw ¼ turn only.

Loosening the lim it screw

more than ¼ turn may allow

the adjuster screw t o shift

when the limit screw is

tightened. Thi s will resul t in

an inaccurate adjustment.

b. Loosen the limit screw ¼ turn, then turn the adjuster

screw:

CLOCKWISE to decreas e the sy ru p th ro w.

COUNTERCLOCKWISE to increase the syrup throw.

c. Tighten the limit scr ew.

d. Repeat the test and adjustment procedure until the syrup throw is as

desired.

e. Repeat the above steps for each syrup pump.

PRIMING

SWITCH

ADJUSTING

SCREW

LOCK

SCREW

8. Adjusting the Syrup Throw (CO

a. Turn the adjustment screw:

CLOCKWISE to decrease the volume.

COUNTERCLOCKWISE to

increase the volume.

b. Repeat step a for each pump.

2 PUMP)

ADJUSTING

SCREW

VALV

3280020 Page 15 August, 2003

Page 22

Cold Drink Center (327/328) Operator’s Guide

WATER LEVEL

W

T

BUSHING

FLOAT ASSEMBLY

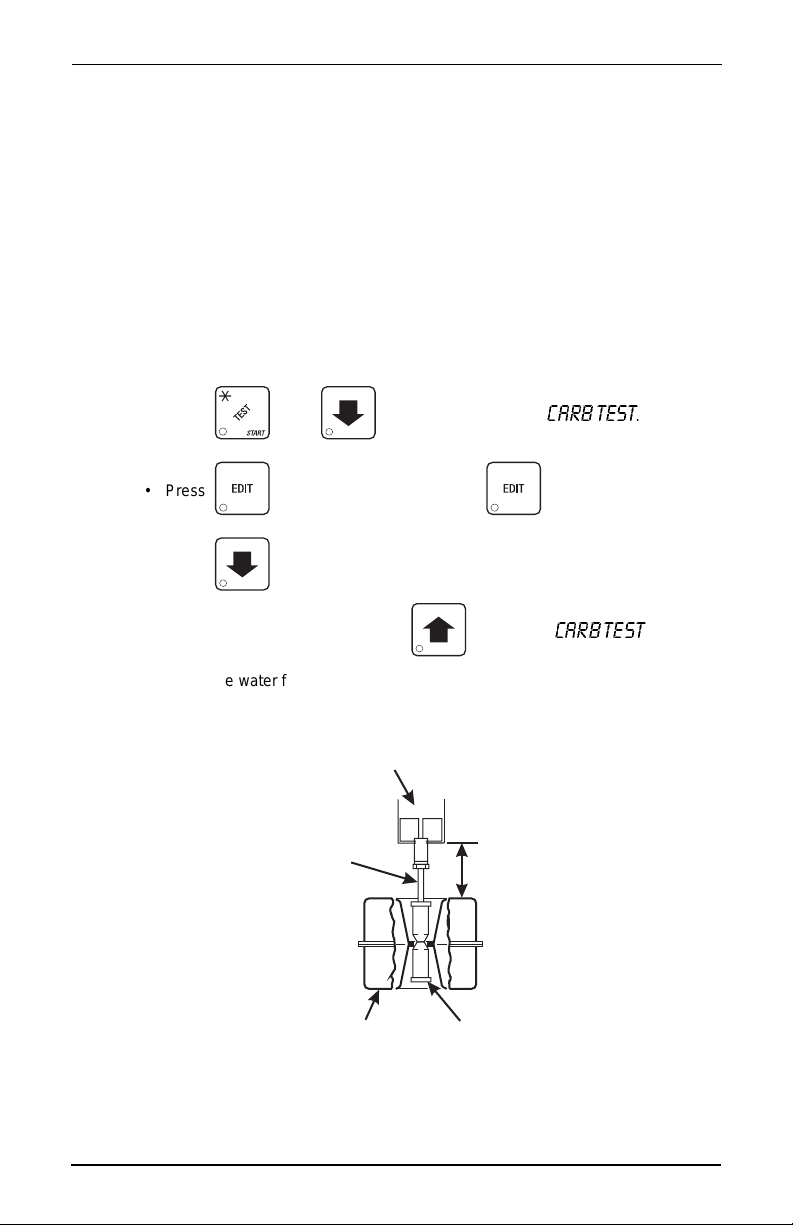

9. Setting the icemaker water level:

A proper level should be maintained within the icemaker. To determine the

water level , a l abel is located on the icemaker that indicates the prop er l evel

in the melt-down tube. The icemaker water level is dependent upon the

feeder cup water level.

a. Set th e M A IN S W I T C H to the OFF (down) position.

b. Remove the water feeder cup cover.

c. Adjust the float shaft bushing:

UP - to raise the water level.

DOWN - to lower the water level.

d. Replace the water feeder cup cover.

e. Check the new water level:

• Set the MAIN SWITCH to the ON (up) position.

•Press , then until the display shows

•Press to dispense still water; press again to stop.

•Press . The feeder cup will refill after you leave the carbonator test.

When the feeder cup is full, press to return to

• When the water flow stops, check the water level in the melt-down tube.

`^o_=qbpq

`^o_=qbpq

f. Repeat steps a thr ough e until the water level is correct.

SWITCH ACTUATOR

˜

ATER FEEDER

FLOAT SHAFT

1¼

.

.

Augus t, 2003 Page 16 3280020

WATER FEEDER

FLOAT SHAF

Page 23

Cold Drink Center (327/328) Operato r ’s Guide

Programming The Cold Drink Center

Getting Around

Getting around the Cold Drink Center software is prett y easy once you know the

features tha t are availa ble to you, and how to use the m. The three mai n part s you

will use are the SERVICE KEYPAD, the SELECTION SWITCH PANEL, and the

DISPLAY.

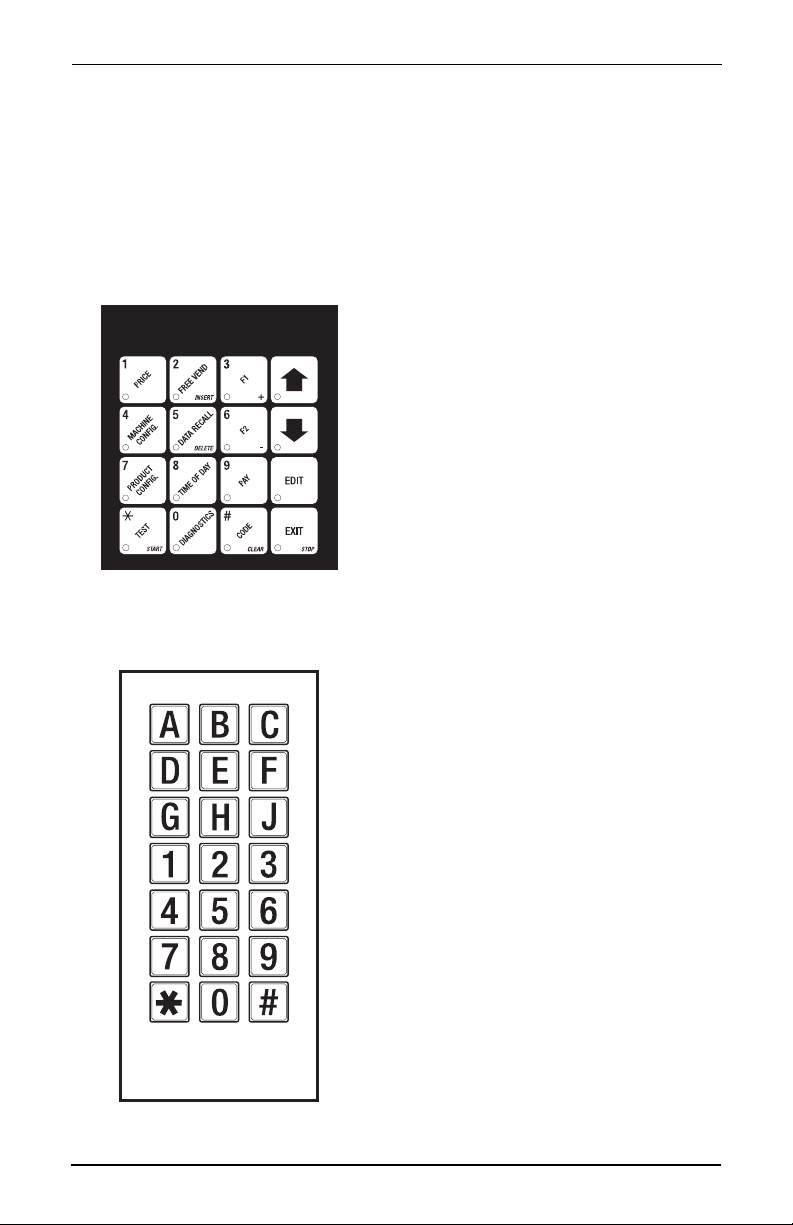

The Service Keypad

For most of your programming jobs,

you will be using the ser vice keypad,

convenientl y located on the monetary

panel. The service keypad has 16

keys. The three columns on the left

are the MODE keys. The right hand

column contains the MOVEMENT

keys.

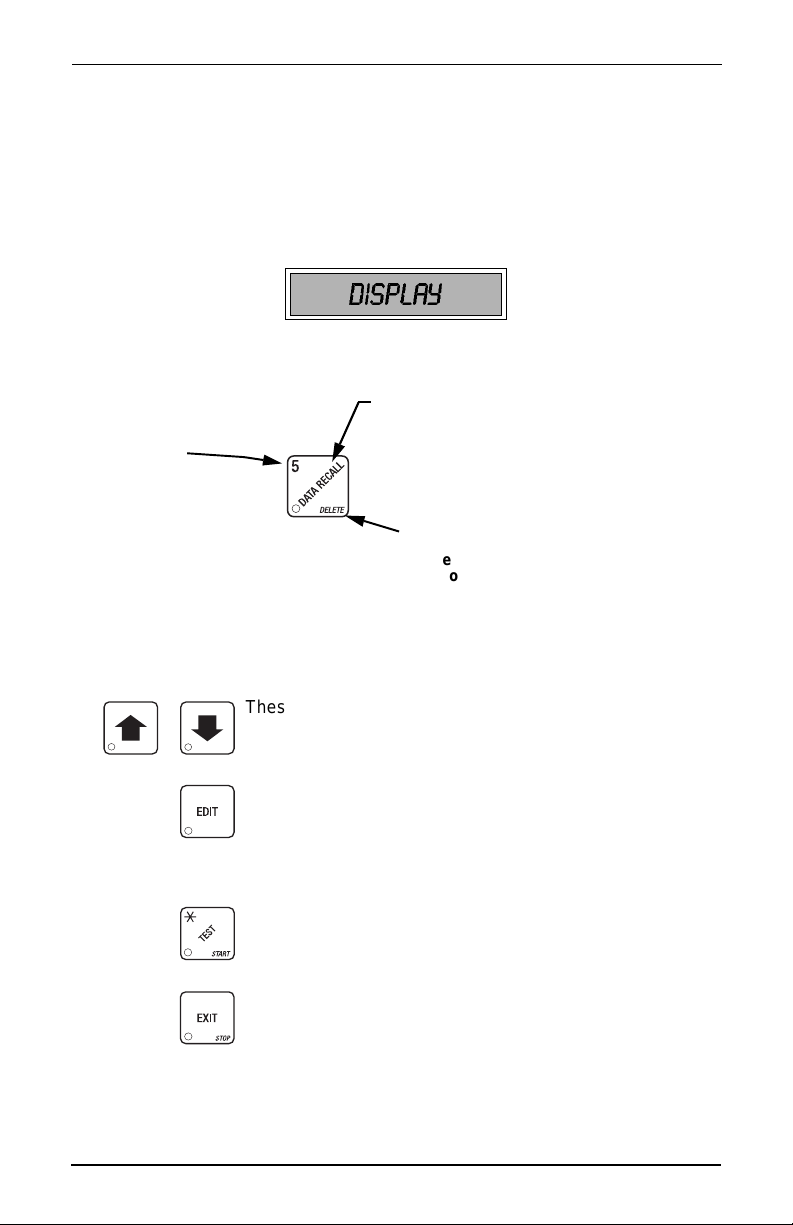

he Selection Switch Panel

The selection switch panel is also

located on the monetary panel. Unlike

the service keypad, it is accessible

when the cabinet door is cl osed.

These are the keys the customer will

use to make selections. You can also

use these keys during programming

procedures.

3280020 Page 17 August, 2003

Page 24

Cold Drink Center (327/328) Operator’s Guide

T

Y

e

P

e

y

g

s

le,

er

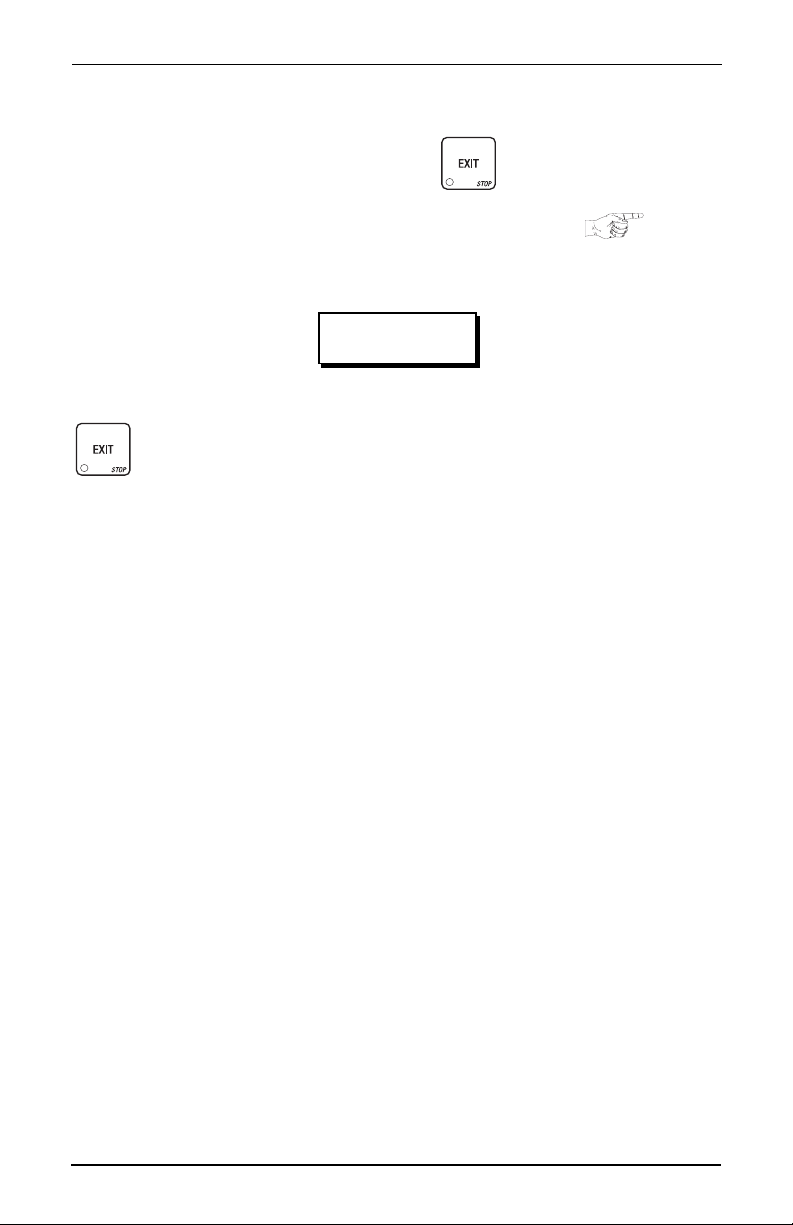

The Displays

The 10-characte r displ ay perfor ms two functions , and is ref erred to in this book as

"the display":

• I t shows the customer 's sel ecti on an d how much credi t is i n the mac hi ne, as

well as the ready, service, and time of day messages.

• I t provides informatio n and feedback to the service person during maintenance.

DISPLAY

The Function Keys

The keys on the control panel can be used for up to three things:

THE PRIMARY PURPOSE

This is the main job of the key. From the standb

message, it w ill allow yo u to en ter a prog rammin

HE NUMBER

ou might be asked to

nter a numerical value.

ressing this key will

nter a "5".

Other Keys

The MOVEMENT keys on the control pan el let you m ove insi de a mode, and back

and forth between modes .

mode. In this example, you can view stored sale

data.

THE SECONDARY PURPOSE

This is the key's "second job". For examp

this key can be used to delete a charact

when you are edi ting cu sto m messages.

These keys are your "leg s", which let you move up and

down the list of tasks. They let you continue from one step

to the next in programming procedures.

This is your "activa te" or " choose" key. It "opens a door" to

additional information and lets you begin a programming

task once you are inside of a mode. Sometimes, it is used

as a toggle switch to show you your choices during a programming task.

This key can be used before running a function, or to

choose “ALL” in a multiple selection.

This is your "end" key. Pressing it one or more times will

move you back to the start of the mode, or all the way back

to the standby message.

Augus t, 2003 Page 18 3280020

Page 25

Cold Drink Center (327/328) Operato r ’s Guide

Some Conventions:

All programming procedures assume that you are starting with the standby mes-

sage showing in the display. If not, just press until you get there.

Each programming procedure is highli ghted by a pointing hand: so it will

stand out.

Definitions and helpful information will appear in shadow boxes:

Helpful Hint

When you see the word CONTINUE at the end of a function, it means to press

until you return to the standby message.

3280020 Page 19 August, 2003

Page 26

Cold Drink Center (327/328) Operator’s Guide

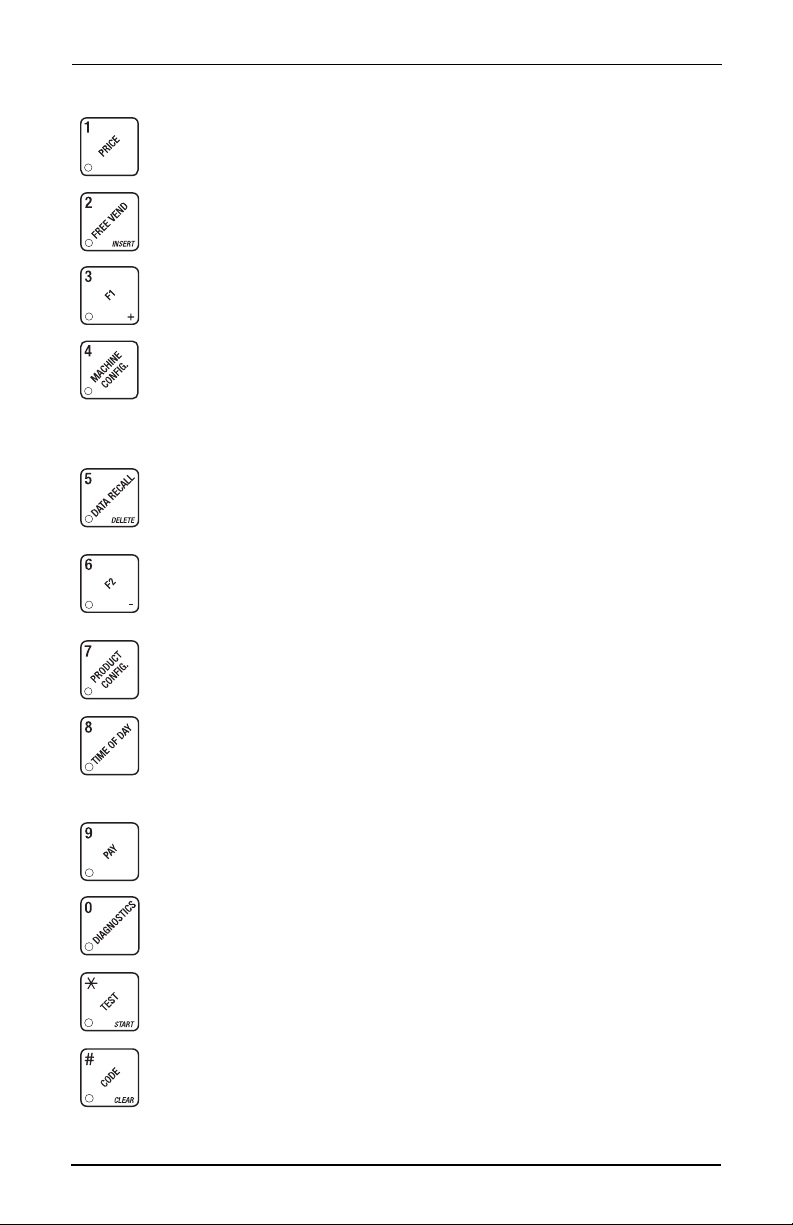

Control Panel Switch Functions Explained

Press this button t o put your machine into the Price Setting m ode.

You can see maximum and minimum mac hine prices, and change

prices for entire machine, entire tray, or indi vidual selection.

Press this button t o set up how t he Free Vend mode will oper ate.

Press this button to view the software version number, machine and

accessory configuration, and active selection status.

Press this button t o:

• Select display language

• Select coin mechanism and

options

• Select bill validat or and options

Press this button t o:

• View total sales and vends by

whole machine, selection, or

drink size

Press this button t o:

• Download data into your portable data collection device (PDCD),

OR

• Set printer baud rate, dependi ng upon which device you are using

Press this button t o:

• Set machine configurati on

• Set which selections are acti ve

• Select card reader and

options

• Select monetary options

• Set winner feature

• Set mug discount option

• Cl ear resettable data

• View or set machine ID

Press this button t o:

• Set time of day

• Set day, month, year

• Select display messages

• Edit messages

Press this button to pay one or more coins from the coin mechanism.

Press this button to see any fault or condition that may place the

machine out of service

Press this button t o:

• Pe rf orm TEST VENDS

• Test machine functions

Press this button t o:

• En ter the SUPERVISOR mode

• Change the SUPERVISOR

access code

Augus t, 2003 Page 20 3280020

• Set message scrolling speed

• Set up time of day intervals

for inhibit, freevend, and discount vending

• Test displays

• Lock and unlock access to

functions

• Set free vend code

Page 27

Cold Drink Center (327/328) Operato r ’s Guide

SureVend™

SureVend™ ensures that a cup is always available in the cup station before any

money is collect ed or product delivered. The sens ing system is a beam of infra

red light across the cup station that is broken by the cup when it falls into position.

The SureVend™ software monito rs the cup station sensor during the time the cup

ring is cycled and for three seconds afterward. If a cup is not detected, the soft

ware will first determine if a second cup ring with the same size cups exist s and

will then tr y to dr op a c up from t he s econd ri ng. I f the s econd ring also fai ls t o drop

a cup or is not usable, the sof twa re will rep eat the at tempt f rom the firs t cup ri ng to

attempt to clear any j ams in t he cup delivery area . Each ring wi ll be t ried up to two

times. If a cup is still not detected by the infra red sensor then several things hap

pen:

• Any ring that failed twice in a row is placed temporarily out-of-service for a

length of time that is determined by the user,

• The customer's credit is eit her restored for another vend att em pt or is

returned au toma ti c ally,

• Three beeps sound and the message

another size cup r ing is available), or the message

the event that no other cups are avail able. The customer may always get a

refund by pressi ng the coin return button.

INSERT MUG

message if de sired (see

Spec ial rules exist to protect both the customer and the operat or from loss. First

and foremost, th e customer is protected because no drink is spoiled nor money

lost because a cup fails to fall to the cup station. The customer is given every

chance to get his original choice of cup size by tr ying at least twice per ring to

eject a cup. If two rings are available with the same cup size, the system will alt er

nately try to vend a cup fr om each ri ng until the cup is delivered or both rings are

placed out-of-service.

is the default messa ge. You may customize this

"Edit Custom Message" on page 49

for more information).

SELECT ANOTHER SIZE

NOTE

flashes (if

IN S ERT M UG

flashes in

-

-

-

-

The operator is prot ected by the anti-j ackpot program of the system . It is conceivable that a customer could prevent cups from reachi ng the sensing area of the

cup station in order to steal the cups and then get a refund for the vend. Under

the SureVend™ Anti-Jackpot system, the operator can lose no more than two

cups in a row per ring. Then that ring is temporarily placed out-of-service both to

protect t he custo mer an d to di scou rage th eft . T he amoun t of ti me th at the cup r ing

is out-of-service is programmable from 0 to 99 minutes. After the time has

elapsed, th e cup ring wi ll retur n to servi ce but the co unt of the two failure s is kept.

If the previous problem was theft, then the next vend attempt from that ring will be

successful and the count of the two previous failures will be erased. If the prob

lem is an actual system failure, then the third failure will permanently place that

cup ring out of service until a service technician visits the machine.

3280020 Page 21 August, 2003

-

Page 28

Cold Drink Center (327/328) Operator’s Guide

An induced SureVend™ failure cann ot cause an alternate vend from a sele cted

small cup to a large cup at the sma ll cup pri ce. This protects the oper ator from

customers try ing to get large cup dri nks at a small cup pr ice. (SureVend™ will not

automatically switch to a different cup size in mid-vend because it cannot be

ensured that cor rect change will be returned for the new price.)

To tu rn Sur e Vend™ off, see "Turn SureVend™ On or Off" on page 42.

The Supervisor Mode

The supervisor is allowed to do things that a normal user cannot, like controlling

access to certain modes. The supervisor can lock out any of the programming

modes to any one who does not have t he r ight "ke y". On ce a s uper visor enter s the

proper code, he or she will be able to:

• Change the supervisor access code

• Lock out any or all of the service keypad modes

• Set whether data is cleared with or after being downloaded into a

portable data collection device

• Grant or deny access to data items during DATA RECALL

• Modify the machine configuration

Augus t, 2003 Page 22 3280020

Page 29

Cold Drink Center (327/328) Operato r ’s Guide

Programming Procedures

GAIN ACCESS TO THE SUPERVISOR MODE

1. Press . The display shows:

digit supervisor code within 6 seconds to gain access.

A new machine has a factory- set supervisor code of 0000.

When you have entered the right code, you will hear two beeps and see

UNLOCKED

2. CONTINUE.

in the display.

ENTER CODE

NOTE

. You must enter the fo ur-

ENTER A NEW SUPERVISOR CODE

1. Follow the steps in "Gain Access T o The Supervisor Mode" on page 23.

2. Press . The display shows

current super visor code. Use the number keys to enter a new code.

If you enter a n ew code, be sure to keep a writt en record of it.

There is no other way to access the SUPERVISOR mode.

3. CONTINUE.

SUPER XXXX

NOTE

. The X's represent the

ENTER A FREEVEND CODE

(Supervisor Mode Only)

1. Follow the steps in "Gain Access T o The Supervisor Mode" on page 23.

2. Press , then until the display shows

represent the current freevend code. Use the number keys to enter a new

code. If the code is anything other than "0000", it must be entered after the

key lock is turned in order to enable free vends.

3. CONTINUE.

3280020 Page 23 August, 2003

FREE XXXX

. The X's

Page 30

Cold Drink Center (327/328) Operator’s Guide

ENTER A NEW DATA RECALL CODE

(Supervisor Mode Only)

If the prop er non-z ero code is entered , sale s and n on-res etta ble sales d ata can be

viewed without opening the machine’s door.

1. Follow the steps in "Gain Access T o The Supervisor Mode" on page 23

2. Press , then until the display shows

represent the currently entered code. Use the number keys to enter a new

code, if desired.

NOTE

A code of 0000 disables this feature.

Usage:

In ready mode, enter the 4-digit code. When the correc t code is entered, the nonresettabl e sales total is displayed. Press # to view the tot al number of vends.

Enter a lett e r ke y (e x.

and 0 (ex.

show the lar ge cup tot al). Press # to cycl e t hrough the com plet e selec tion l ist . The

display will remain active for 9 seconds.

3. CONTINUE.

0B

) to view the sales tot al f or that product, regular size cup (

B

) to view the sales tot al for that product. Press a letter key

NR XXXX

. The X's

1 B

will

LOCK OR UNLOCK MODE OR PAYOUT KEYS

(Supervisor Mode Only)

1. Follow the steps in "Gain Access T o The Supervisor Mode" on page 23.

2. Press , then until the display shows either #

UNLOCKED

maintenance keypad.

3. Press to change between loc ked and unlocked. When anyone other

. To see if a key is locked or unl ocked, press that key on the

LOCKED

or #

than the supervi sor tries to enter a locked mode, the di splay shows

EXAMPLES: Press , then to lock the function. Now, non-super vi-

sors cannot vi ew any sales data. If you want non-supervisors to view data but not

be able to clear data, leave the

Mode keys and cannot be locked out:

4. CONTINUE.

Augus t, 2003 Page 24 3280020

key unlocked, but do lock .

NOTE

LOCKED

.

Page 31

Cold Drink Center (327/328) Operato r ’s Guide

SET TALKER MODE

(Supervisor Mode Only)

1. Follow the steps in "Gain Access T o The Supervisor Mode" on page 23.

2. Press , then until the display shows

3. Press to turn the talker option ON or OFF.

NOTE

Talker hardware must be installe d for thi s to work.

TALK ON or TALK OFF.

SET PRINTER OR DEX MODE

(Supervisor Mode Only)

1. Follow the steps in "Gain Access T o The Supervisor Mode" on page 23.

2. Press , then until the display shows:

PRINTER

- means that data will be sent directly to a printer,

DEX ONLY

DEX+CLR

DEX NR

3. Press to change bet ween the three choices.

4. CONTINUE.

- data remains in memory after it is downloaded into a port able

data collection device (PDCD),

- resettable data is cleared after it is download ed int o a PDCD.

- a special DEX option. All sales data will become non-re settable.

Consult your DEX supplier before choosing this option.

3280020 Page 25 August, 2003

Page 32

Cold Drink Center (327/328) Operator’s Guide

SET DEX OPTIONS

1. Follow the steps in "Gain Access T o The Supervisor Mode" on page 23.

2. Press , then until the di splay sho ws one of two reset tabl e bil l

valida to r to ta ls tra n sm itted to the DEX de v ic e:

CA 304 = N.C.

mat. For example: 200 for two dollars. (This is the default setting.)

CA 304 = N.O.

count format. For example: 2 for two dollars.

3. Press to switch between the two choices. Consult your DEX

handheld suppli er for the proper settings for your machine.

If the bill count is incorrect, the CA304 setting may be wrong. Try anot her setting.

4. Press until the display shows one of the following two options:

- the value of bills in the stacker will be transmitted in a cash for-

- the value of bills in the stacker will be transmitted in a dollar

NOTE

LAST.VND.ON

LAST.VND.OFF

5. Press to switch between the two choices.

6. CONTINUE.

- the DEX device will transmit the date and time of the last vend

for each selection.

- the DEX device will NO T transmit the date and t ime of the last

vend for each selec tion. (This is the default set ting)

SELECT PRINTER BAUD RATE

(Printer mode only)

BAUD

RATE

1. Press . One of the following is displ ayed:

BAUD 1200 BAUD 2400 BAUD 4800 BAUD 9600

2. Press until the correct baud rate for your printer is displayed.

3. CONTINUE.

The speed of data tr ansfer, expressed in bits per second.

Your printer can receive data at a certain rate, and you must

tell the machine what that rate is.

Augus t, 2003 Page 26 3280020

Page 33

Cold Drink Center (327/328) Operato r ’s Guide

SELECT DISPLAY LANGUAGE

1. Press . The current LANGUAGE is shown in the display. Press

to choose the desired language. Y our choices are:

ENGLISH, DEUTSCH, FRANCAIS, ESPANOL, PORTUGUES, SWEDISH, NEDERLANDS

FINNISH

.

2. CONTINUE.

, or

SELECT COIN MECHANISM

1. Press , then press until the curr ent COIN MECHANISM is

shown in the di splay. Press to choose the de si red coi n mecha nis m.

Your choices are:

MDB MECH, DUMB MECH, EXEC MECH

2. Proceed to "Select Mo neta ry Options " on p age 30, to cu sto mize your co in

mechanism choice.

Depending upon your choice of coin mechanisms, some

displays ma y not appear.

3. CONTINUE.

, or

NOTE

NO MECH

3280020 Page 27 August, 2003

Page 34

Cold Drink Center (327/328) Operator’s Guide

SELECT BILL VALIDATOR AND OPTIONS

1. Press , then press until one of the following is displayed:

NO DBV

SER.1. 2.5.10.20

PULSE DBV

MDB.1.2.5.10.20

MDB.

<*>

BILL SELECTION METHOD:

The standard $1, $2, $5, $10 and $20 bills are enabled by pre ssing th e 1, 2, 5, 6,

or 7 key(s), respectively, to display which bill (s) will be accepted.

1. Press to choose the desired optio n.

2. CONTINUE.

- No bil ls will be accepted or there is no bill validator installed

(you can exit the function).

- The seri al bi ll validator is selected and will accept $1, $2,

$5, $10, and $20 bills. Use BILL SELECTION METHOD

below to change the bills that will be acc e pte d .

- The pulse bi ll validator will accep t $1 bills.

- A standard MDB bill valid a to r is sele c te d . It wi ll accept $1,

$2, $5, $10 and $20 bil ls . Use BILL SELECTION METHOD

below to change the bills that will be acc e pte d .

- An MDB bill validator that accepts non-standard bills or

tokens is connect ed and operating. Press to enter

list of bills. See "Initial Setup Of NonSt andard Bill V alida-

tor" on page 29.

Augus t, 2003 Page 28 3280020

Page 35

Cold Drink Center (327/328) Operato r ’s Guide

INITIAL SETUP OF NONSTANDARD BILL VALIDATOR

1. Connect the bil l validator, and follow the steps in "Select Bill Validator and

Options" on page 28, to select

screens.

MDB.=

<*> will not be an option yet. Exit the bill validator set up by

MDB.1.2.5.10.20

in the bill validator selection

pressing

2. Press , then press until

3. Press .

validator channel 1, the

the validator will accept $1.00 bills.

4. Press to toggle the bill accep tance ON or

5. Press and to scroll through the list of ot her denominations

and to set them to ON or

6. Press to move up to the top level screen.

If a denomination does not display in the scroll li st of available

denominations, check the binary switc h settings for the

validator. If the binary switch for a given denomin ation is set to

“off”, it will not display in the list of denominations.

. Bill information is now collected from the validator.

MDB.=

<*> displays.

1. 1. 00 O N

will display. The firs t nu m b e r (1.) indicates bill

1. 00

is the bill denominat ion, and ON indicates th at

OFF

.

OFF

.

NOTE

7. CONTINUE.

3280020 Page 29 August, 2003

Page 36

Cold Drink Center (327/328) Operator’s Guide

SELECT CARD READER AND OPTIONS

1. Press , then press until the current card reader is shown in

the display. Your choi ces are:

NO CARD, DUMB CARD

2. Press to choose the desired card reader.

3. Press until one of the following is displayed (not available if

is selected abov e):

REVALUE.ON

REVALUE.OFF

4. Press to display the desired choice.

5. CONTINUE.

- Allows credit to be transferred onto the card

==J==

, or

Credit cannot be transferred to the card

M DB CARD

.

SELECT MONETARY OPTIONS

This function lets you:

Set change return criteria

Set currency accept ance on low

change

Set overbuy options

Set last bill stacking options

Set declining balance

NO CARD

Depending on the coi n mec h and bill validator select ed, some options below may

not be available.

1. Press , then press until the display shows

X.XX represents the largest denomination coin or bill that will be changed

without a purchase. Any non-zero value h ere will return all escrowed co ins.

(Each coin denomination that the coin mech has a tube for is called an

ESCROWED coin because it can be retur ned.) When the coin return button

is pressed, all coins inserted will be retur ned provided there is a coin mech

tube for each of tho se coins, EXCEPT in the forced vend mode.

Augus t, 2003 Page 30 3280020

CH ANGE X.XX

.

Page 37

Cold Drink Center (327/328) Operato r ’s Guide

Some examples:

CHANGE 0.00

CHANGE .25

less than .25 denomi nation or have a payout tube. Acceptance of a dollar

coin will not cause a For ce V end i f the coi n mechanism has a dol lar coi n pay

out tube. Otherwise, accepting a dollar coin or accept ing and stacking of a

dollar bill w ill cause a Force Vend.

CHANGE 1.00

be changed without purchase. All escrowed coins are returned.

Use the keypad to enter a value for the change number.

2. Press until one of th e foll owing is displa y e d :

ACC

=

<

A C C.STK X. XX

- Forced vend; NO change returned without a purchase.

- Returns change without purchase if all accept ed coins are

- Bills and non-escrowed coins less than or equal to $1.00 will

$$ X.XX

-Accept any bill of value $X.XX or less, regardless of available

change. Hold the last bill that meets or exceeds maxim um

price in escro w. (This setting is normally used.)

-Accept any bill of value $X.XX or less, regardless of available

change. Immediately stack the last bil l.

-

Example: If setting is

ting will immediately stack the second $1.00 bill inserted .

3. Press to display the desired choice.

4. The value of "X.XX" has two purposes:

a. The value of "X.XX " te lls th e mac h in e ho w big a bill o r co in to acc ep t

even though there i s not enough change in the coin mech to cover al l

possible paybacks.

For example, ent er 1.00. Therefore, the machi ne will take a dollar bill or

coin even though there is less than $1.00's worth of change. Entering

5.00 tells the machine to take a five even though th ere is less than

$5.00's worth of change, and so forth.

This could cause a customer to be short-changed.

Entering 0.00 means that bills or coins not held in escrow or in a tube will

only be accepted if there is enough change to cover them.

b. The value of "X.XX" tell s the machine how much th e customer i s allowed

to overbuy a product . The customer will be short-changed when an

overbuy occu rs.

ACC.STK 1.00

NOTE

and maximum price is $1.50. This set-

3280020 Page 31 August, 2003

Page 38

Cold Drink Center (327/328) Operator’s Guide

Example:

For a value of $0.25: if there is no change in the machine and t he customer

inserts a $1. 00 bill, the customer can purc hase a product for $0.75 even

though the change cannot be paid back. The customer wil l be shortchanged. Normally a purchase will not be approved unless all change can

be paid.

Entering 0.00 means that the vend will only be approve d when the correct change can be returned (overbuy disabled).

5. Press until the display shows:

USE EXACT CHANGE

mechanism falls below the value of "X.XX". Enter a value with t he num ber

keys. For example, if

message is dis played wh en l ess tha n a do llar 's wor th of c hange is in the coin

mechanism.

DECLINING

BALANCE :

6. Press until one of th e foll owing is displa y e d :

DECLINE.ON

DECLINE.OFF

7. Press to display the desired choice.

8. Press until one of th e foll owing is displa y e d :

FAIL=CASH

FAIL=CREDIT

- If the customer’s primary selection is unavailable, they will be

when the amount of available change in the coin

LOW.MSG 1.00

Once credit is established, multiple

vends may occur until the coin

return is pressed.

- More than one vend is allowed, with a decl ining balance.

- A declining balance is not allowed.

able to collect a full refund by pressing the change return button.

- If the customer’s prima ry sel ection is unavail able, they will be

able to make an alternate selection, but not get a full refund.

This option only avail able if SureV end is ON.

LOW.MSG X.XX

is displayed, the

NOTE:

. The display will show

USE EXACT CHANGE

9. CONTINUE.

Augus t, 2003 Page 32 3280020

Page 39

Cold Drink Center (327/328) Operato r ’s Guide

SET UP WINNER MODE

At preselected int ervals, a customer may receive a

WINNER

1. Press , then press until one of the following is displayed:

refund for a selection. You can select the interval and

qualif yi ng se l ections.

WINNER OFF

WIN XXX

2. Press to display the desired choice.

If you selected

3. The display shows

occur per each winner vend. For example, an interval number of 50 means

that a winner can happen any one time during the next 50 vends. Usi ng the

number keys, enter an interval number between 10 and 9999.

4. Press . The display shows

represent whi ch sel ection s are al lowed wi nners. Press th e appropr ia te lette r

key to enabl e a selection, press the key again to disable it. For example,

pressing A, C, and E will cause the display to look like this:

=

A

*.

ADVANCED OPTIONS:

•Press to enable all selections.

•Press to deactivate all sel ections.

Winner function is disabled.

Winners are allowed at cert ain intervals, represented by "XXX".

WINNER OFF

- C - E - - - , meaning that all A, C, and E selections can have a win ner.

, you can exit the functio n.

WIN XXX

. XXX represents the number of vends that must

==

- - - - - - - -

*

=

. The dashes in the display

•Press 0 or 1 to set winner selections by cup size.

NOTE

If displaying WINNER by selection, press once to

redisplay wi ldcard (

3280020 Page 33 August, 2003

=

.

ABC

*

....) selections.

Page 40

Cold Drink Center (327/328) Operator’s Guide

AN EXAMP L E . . .

You want to enable winners on all selections except E and F. Do the f ollowing:

a. Press . The letters

the dashes.

b. Press "E" and "F". The letters

dashes.

This is a two-part screen. Pr ess to display selections

5. CONTINUE.

A

through J appear in the display instead of

E

and

F

in the display are replaced by

NOTE

Y Z _ _ _ 8 9

*.

.

SET UP MUG DISCOUNT

You can establish a discount for customers who use their own mug.

1. Press , then press until the display sho ws

example shows the exis ting discount amount is zero.

2. Enter a discount amount. This will be i n cents, for example press or

5 to enter a discount amount of 5 cents.

3. CONTINUE.

MUG DSC .00

. This

DISABLE SELECTIONS IN THE MERCHANDISER

1. Press , then press until the display shows something li ke:

LK. ABCDEF

not available for vending. An availabl e selection has its l etter replaced by a

blank space.

2. Press the appropr iat e letter to toggle the displ ay on or off.

3. CONTINUE.

Augus t, 2003 Page 34 3280020

. This display means that all regular size selections (A - F) are

NOTE

Press to lock all selections; press to unlock al l

selections . Press to display the second screen.

Page 41

Cold Drink Center (327/328) Operato r ’s Guide

SET UP CUP SIZES

Make sure the cup sizes you select agree with the cup s you have actually loaded

during setup.

1. Press then until the displ ay shows

currently select ed drin k size f or the cu ps in tur ret 2 (n ormall y large c up s), " Y"

is the current l y selec ted dri nk si ze for the cups i n turr ets 1A and 1B ( normall y

regular cups).

2. Press to cycle t hrough t he avail able #1 cup ring si zes; p ress

to cycle through the available #2 cup ring sizes.

3. Any changes made to the cup sizes must be "locked in". There are two

ways to d o this:

a. If you are keepi ng some cup sizes the sam e, or putting the cups in differ-

ent cup rings, press and hold . The display momentarily shows

CLEARING

old throw times to the new cup r ing, if possible.

b. If you are loading all different size cups, or want to load all new default

times, press and hold

CLEARING

tory default times for all cup sizes, clearing any custom throw tim es you

have estab li shed. (See

on page 37.)

, two beeps sound, then shows

. The display momentarily shows

, two beeps sound, then shows

"Factory Default Throw Times and Volumes"

NOTE

Machines with diaphragm pumps (see "Configure Pump

T ype" on page 39) can only vend one cup size.

FINISHED

FINISHED

X OZ Y

. "X" is the

. This will reassign the

. This will r eload the fac-

4. CONTINUE.

3280020 Page 35 August, 2003

Page 42

Cold Drink Center (327/328) Operator’s Guide

SET UP A DRINK

Be sure that the cup sizes you set in "Set Up Cup Sizes" on page 35, agree wit h

the cup size s ac tuall y in y our m achine. All procedu res for se tti ng up the drink s ar e

similar, so this example wil l demonstrate how to set up the A selection, regular

size drink.

1. Press , then press until the display shows

star (

) represent s the selection (A, B, etc.). The dash (-) represents the

*

size of the selection.

2. Press A. (If you were setting up the A selection for the large size drink, you

would press 1 fir s t, then A.) The display shows something similar to:

CLD. A 12.00

A selection is 12.00 seconds. Enter a new time if desired.

3. Press . The display shows

currently set carbonated water throw time for the A selection is 12.00

seconds. Enter a new time i f desi red. A v alue of .00 will lock out carbona tion

for the selection.

4. Pressing after each display will cause the following screens to

appear:

SRP. A

PCT. A

ICE. A

ICE. A+

OPTIONS:

. This means that the currently set still water throw time for the

CRB. A 12.00

View and change the settings for syrup

View and change the setti ngs for percentage of carbonation (0-100) .

A value of 100 will lock out non-carbonation for the selection.

View and change the settings for ice throw time

View and change the settings for extra ice throw time

. This means that the

SETUP --

*. The

a. At any of the precedi ng disp lay s, you c an press to test throw that

item.

b. At any of the preceding displays, you can press * or # (on the selection

switch panel) to step through a list of that item 's throw times for other

selections where that item is active. For example, pressing # at the

CLD. A

display will show the throw time for either

ing on how the drink size s are se t up). This is a handy way to move fr om

one selection to another without going to the

NOTE

If you try to set up a selection that is not configured, the

screen w ill re ma in in the d is pl a y.

Augus t, 2003 Page 36 3280020

CLD. 1A

SETUP

or

CLD. B

screen first.

SETUP

(depend-

Page 43

Cold Drink Center (327/328) Operato r ’s Guide

Special Selections:

Ice and Cup 8-4 (small cup)

1-8-4 (large cup)

Carbonated Water 9-3 (small cup)

1-9-3 (large cup)

Non-Ca rb . Wate r 9-4 (small cup )

1-9-4 (large cup)

5. CONTINUE.

FACTORY DEFAULT THROW TIMES AND VOLUMES

Syrup Throw

Cup Size

Volume

Still and Carb.

Water

Time

Volume

Time

Ice Extra Ice

Time

Volume

Volume

oz mL oz mL sec oz mL sec oz g sec oz g sec

5 148 0.7 21 3.40 3.6 107 5.10 1.5 42 1.85 2.0 57 2.50

7 210 1.0 30 4.80 5.0 150 7.20 1.5 42 1.85 2.0 57 2.50

8 237 1.1 33 5.30 5.7 169 8.10 1.5 42 1.85 2.0 57 2.50

9 270 1.4 40 6.40 6.7 200 9.60 1.5 42 1.85 2.0 57 2.50

10 295 1.5 45 7.20 7.5 222 10.70 2.0 57 2.50 2.0 57 2.50

12 355 1.7 50 8.00 8.4 250 12.00 2.0 57 2.50 3.0 85 3.50

16 473 2.3 69 11.00 11.7 345 16.60 3.0 85 3.50 3.7 105 4.50

18 532 2.7 79 12.60 13.3 395 19.00 3.0 85 3.50 3.7 105 4.50

20 590 3.0 88 14.00 15.0 439 21.00 3.0 85 3.50 3.7 105 4.50

NOTE: For all cup sizes...

Carbonation per centage is 100%;

Blend mixture percentage is 50%.

(milliliters (mL) and cubi c centimeters (cc) are equivalent)

Time

3280020 Page 37 August, 2003

Page 44

Cold Drink Center (327/328) Operator’s Guide

BLENDED DRINKS

In addition to regul ar syrup drinks, specialty drinks can be produced by blending

two syrups in a si ngle drink. An example of this would be Iced Tea with Lemon.

Use the regular tea syr up with t he lemonade syr up t o make tea with lemon. Other

well-known combinations are Lemon Pepsi or Cherry Coke.

NOTE

These types of drinks are only available on machines using the CO2

pumps, becau se of t he need to control the syrup throw ti m e. The throw

volume of a diaphragm pump cannot be controlled elect ronically, so the

needed adjustment is not available with that type of machine.

1. Press , then until the display shows

drink you want to blend (X, Y, and Z are valid), then press to view

the diffe rent screens of the recipe.

Most screens are similar to normal drink set ups, such as cold water

(

CLD . X

), carbonated water (

that you will NOT normally see are the percentage plus (

selection (

needed only for the blended drinks.

Percentage plus is wher e y ou wil l sel ect th e amoun t of e ach s yrup yo u want

to use. For example, se t per centage plus to .80 (

the syrup will be divided 80% from t he first valve, and 20% from the second.

Val ve selection is how you decide which syrups to mix together . (Obviously, you will need to know which valves dispense which syrups.)

2. Press until som et h ing like

change the valve sel ection for the first syrup in the mix.

3. Press until som et h ing like

change the valve selection for the second syru p in the mix. In the examples

above, the drin k is configured so that 80% comes from syrup valve 1 and

20% comes from syrup val ve 2.

4. Set the remaining screens as you would for a normal drink .

MIX . X

) screens. On these screens, you will add information

CRB . X

), and syrup (

MIX . 1X V1

MIX . 1X V2

SETUP --

SYR . X

PCT . X .80

displays. Press to

displays. Press to

*. Select the

). The setup screens

PCT . X+

) and valve

). This means

Augus t, 2003 Page 38 3280020

Page 45

Cold Drink Center (327/328) Operato r ’s Guide

Spritz Drink s

Spr it z drinks are special versions of blended drinks that require a sl ightly differe nt

setup. The idea is to disp ense a cold water drink with just a hint of flavoring. An

example would be water with lem on. You can easily do this with a blended setup

by doing the following:

1. Set up all times as you would wi th a wate r only drink.

2. Set the

3. Set the

4. Alter the syrup time r so that the total syrup throw is only a fraction of a

normal throw (1 or 2 seconds).

5. An alternate technique is to set the first val ve to t he desired flavor, then set

percent plus to 100%. Eit her way, all the syrup comes from only one va lve,

and the throw time can be adjusted to taste.

1. Press , then until the display shows one of the foll owing:

MIX . X

and

PCT . X+

MIX . X+

screen to 50 % .

screens to dispense from the same valve.

CONFIGURE PUMP TYPE

(Supervisor Mode Only)

GAS PUM P

DIAPH. 50 HZ

DIAPH. 60 HZ

NOTE: Machines with diaphragm pumps can only vend one cup si ze.

2. Press to select the type of pumps in your machine.

If you select

puts the machine into m ug only vending. If the machine wi ll not drop cups,

3. CONTINUE.

3280020 Page 39 August, 2003

- The machine is configured for CO2 pumps.

- The machine is configured for 50 Hz diaphragm pumps.

- The machine is configured for 60 Hz diaphragm pumps.

NOTE

GAS PUMP

ensure that this setting is not the source of the pr oblem.

and press , a decimal will display. This setting

Page 46

Cold Drink Center (327/328) Operator’s Guide

CONFIGURE NUMBER OF SELECTIONS

(Supervisor Mode Only)

1. Press , then until the display shows one of the foll owing:

SIX SELECT

EIGHT SEL

2. Press to configure the number of sel e ctions in your machine.

3. CONTINUE.

- The machine can vend six selec ti ons.

- The machine can vend eight selecti ons.

SET UP AUTOMATIC DELIVERY DOOR OPTIONS

(Supervisor Mode only)

1. Press then until the display shows one of the following:

DOOR ON

DOOR ON -

DOOR OFF

2. Press to select the desired opt ion.

3. CONTINUE.

+ The door opens at th e beginning of the vend.

The door opens at the end of the vend.

The door does not open automatically.

Augus t, 2003 Page 40 3280020

Page 47

Cold Drink Center (327/328) Operato r ’s Guide

ASSIGN CUP SIZES TO SELECTIONS

(Supervisor Mode Only)

You can load up to two different sizes of cup s in your machine (see "Set Up Cup

Sizes" on page 35). You m ay not alwa ys want a cert ain se lecti on to use al l of the

cup sizes in your machine.

1. Press , then until the display shows something like this:

0. ABCDEF

available for all selections (A - F).

2. Press the appropr iat e letter to toggle the displ ay on or off. A selec ti o n th a t

doesn't vend the displayed size cup has its letter replaced by a blank sp ace.

Press to display all select ions; press to clear all selections.

3. Press to display remaini ng selections.

4. Press . The display shows something like this:

1. ABCDEF

able for all selections (A - F).

5. Press the appropr iat e letter to toggle the displ ay on or off. A selec ti o n th a t

doesn't vend the displayed size cup has its letter replaced by a blank sp ace.

Press to display all selections; press to clear all selections.

. This display means that the smaller of the two cup sizes (0) is

NOTE

NOTE

If you have only one cup size in your machi ne, you will not see

the next display.

. This display means that the larger of the two cup si zes (1) is avail-

NOTE

6. Press to display remaini ng selections.

To vend a cup only, press 1, 2, 3 (large si ze) or 2, 3 (regular size).

7. CONTINUE.

3280020 Page 41 August, 2003

Page 48

Cold Drink Center (327/328) Operator’s Guide

TURN SUREVEND™ ON OR OFF

1. Press then until the display shows one of the following:

SURE.V OFF

SURE.V ON

2. Press to switch between the two choices.

3. CONTINUE.

: None of the SureV end™ functions are available . Use this if the

SureV end™ system is not instal led, or there is some reason you

do not want to use it (for exam ple in a high cup theft situati on).

. The SureVend™ system is operative. All of the Sur eVend™

functions ar e available.

OPTIONAL OR MANDATORY SUREVEND™

1. Press then until the display shows one of the following:

OPT’N SURE.V

MUST SURE.V

: The machine revert s to home switch operation of the ring

motors if the SureVend™ system cannot operate normally

because of an obstruction in the cup station or for any other

reason.

: The vending machine is operational only if the SureVend™

system is determined to be working. Otherwise, the machine

will go temporarily out of service until the blockage or other

error is corrected.

2. Press to switch between the two choices.

3. CONTINUE.

Augus t, 2003 Page 42 3280020

Page 49

Cold Drink Center (327/328) Operato r ’s Guide

SET UP THE SUREVEND™ ANTI-JACKPOT TIMER

1. Press then until the display shows

XX represents how many mi nutes Sur eV end™ will be di sabled f or eit her cup

ring. The same value applies to the two timers (one on each ring).

2. Enter a number using ei ther keypad.

If any cup ring motor fails to deliver a cup on two consecutive attempts, the

cup ring goes out of service. After the time set in step 2 has elapsed, the

cup ring goes bac k in s ervic e and is gi ven one more c hanc e to del iver a cup.

If cup delivery is again unsuccessful, t he ring goes out of service until the

machine is serviced. A successful delivery on any cup ring wil l reset the

failed attempts for that particular cup ring. If both cup rings perform three

consecutive faile d attempt s (and t he SureVend™ sensor is determined to be

working), the enti re machine goes into the "mug only" mo de until the

machine is serviced. If either cup ring performs three consecutive failed

attempts with the other cup ring in anti-jac kpot timer mode, the entire

machine will be in "mug only" mode (assuming SureVend is working) until

the preset time elapses (one more attempt will be made to deliver a cup) or

the machine is serv iced by a route operator.

NOTE

A setting of 00 will disable this feat ure. A setting of 99 will

disable the ring until the next service call.

NOTE

If the cup sizes are the same, the machine alternates ring motor cycles until

either a cup is detected or both rings reach two consecutive failed attempts.