Freemaq FR Series

Variable Speed Drive

Programming and Software Manual

Variable Speed Drive

Programming and Software Manual

AFE_R1.0

Edition: February 2015

SD7FRMTSW01DI Rev. D

SD700FR SERIES

POWER ELECTRONICS

2

POWER ELECTRONICS

SD700FR

3

Edition of February 2015

This publication could present technical imprecision or misprints. The information here included will be

periodically modified and updated, and all those modifications will be incorporated in later editions.

To consult the most updated information of this product you might access through our website

www.power-electronics.com where the latest version of this manual can be downloaded.

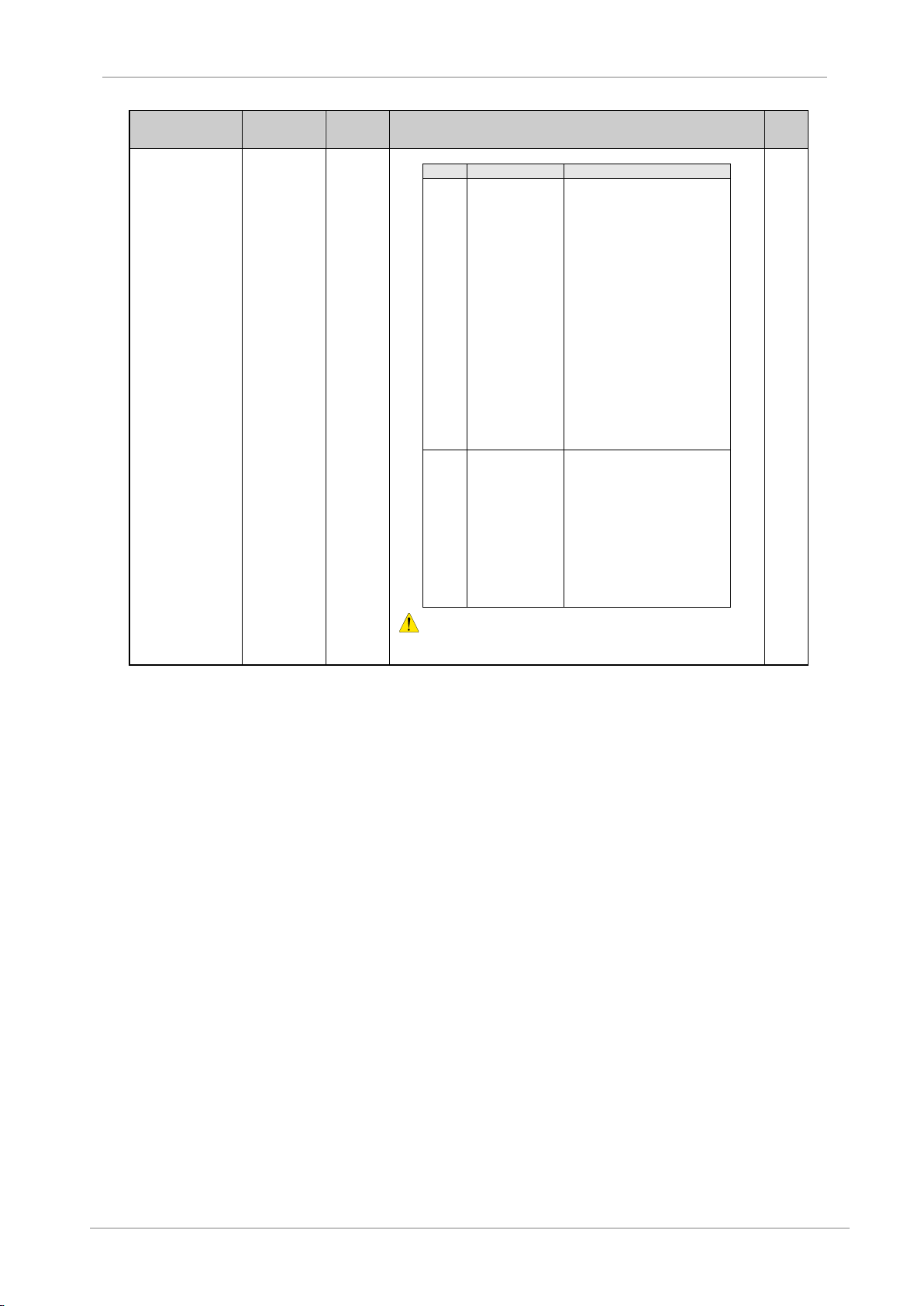

WARNING

This symbol means improper operation may results in serious personal

injury or death.

CAUTION

Identifies shock hazards under certain conditions. Particular attention should

be given because dangerous voltage may be present. Maintenance

operation should be done by qualified personnel

Identifies potential hazards under certain conditions. Read the message and

follow the instructions carefully.

Identifies shock hazards under certain conditions. Particular attention should

be given because dangerous voltage may be present.

SAFETY SYMBOLS

Always follow safety instructions to prevent accidents and potential hazards from occurring.

SD700FR SERIES

POWER ELECTRONICS

4

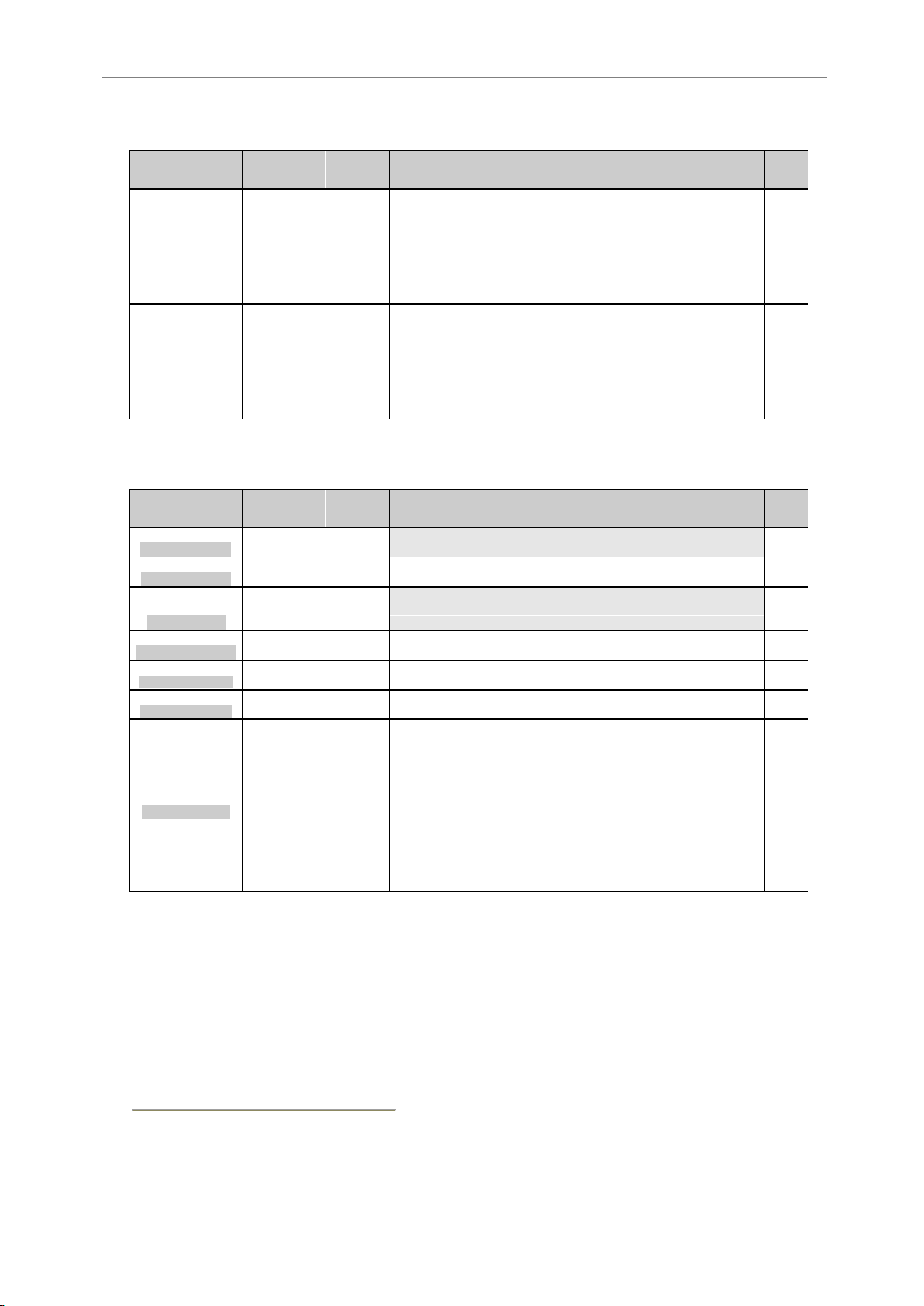

Revisions

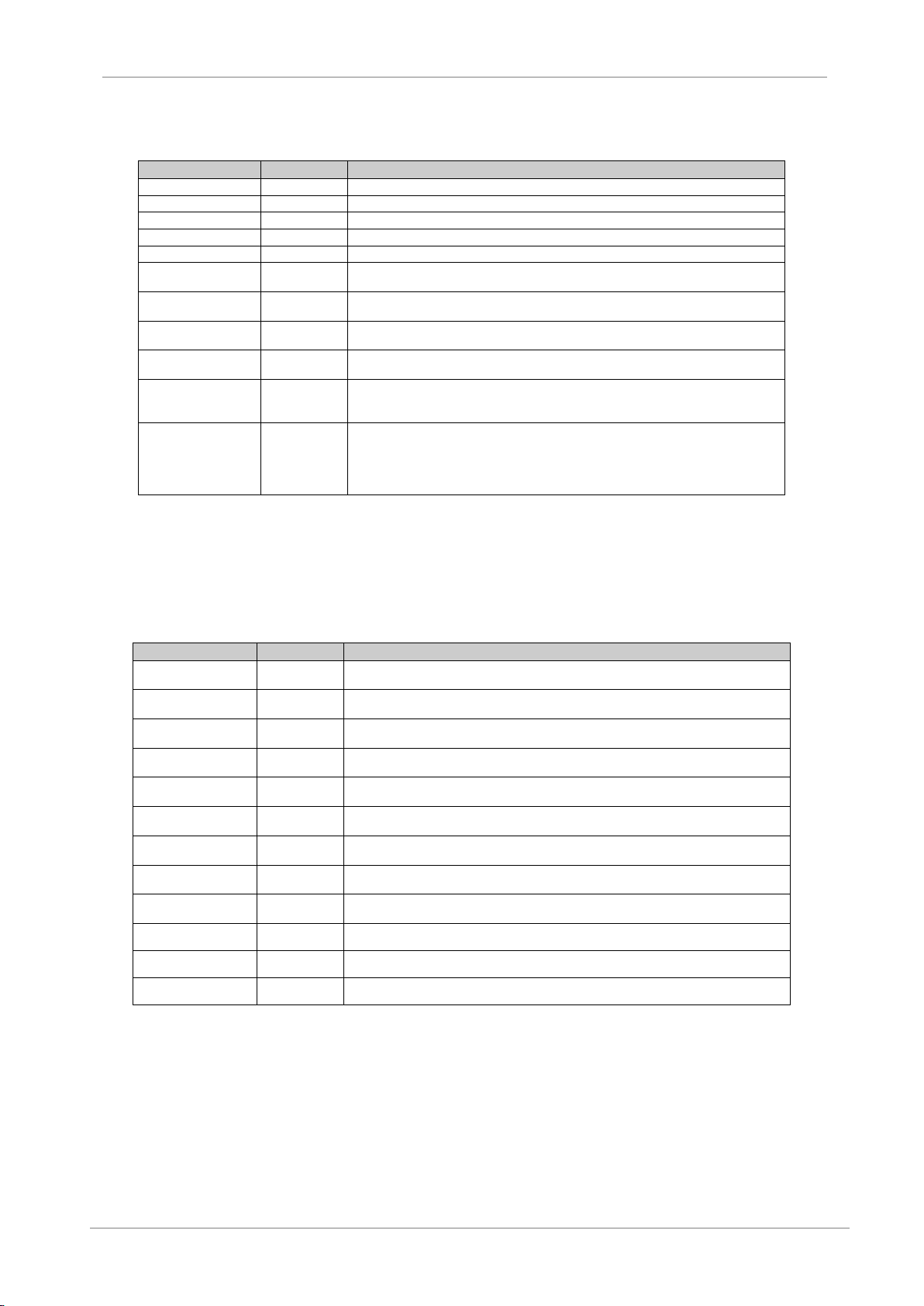

Date Revision Description

27 / 11 / 2012 A First Edition-Software version A.002

03 / 06 / 2013 B Software version A.006

28 / 02 / 2014 C Software version R1.0

19 / 02 / 2015 D Misprints correction

POWER ELECTRONICS

SD700FR SERIES

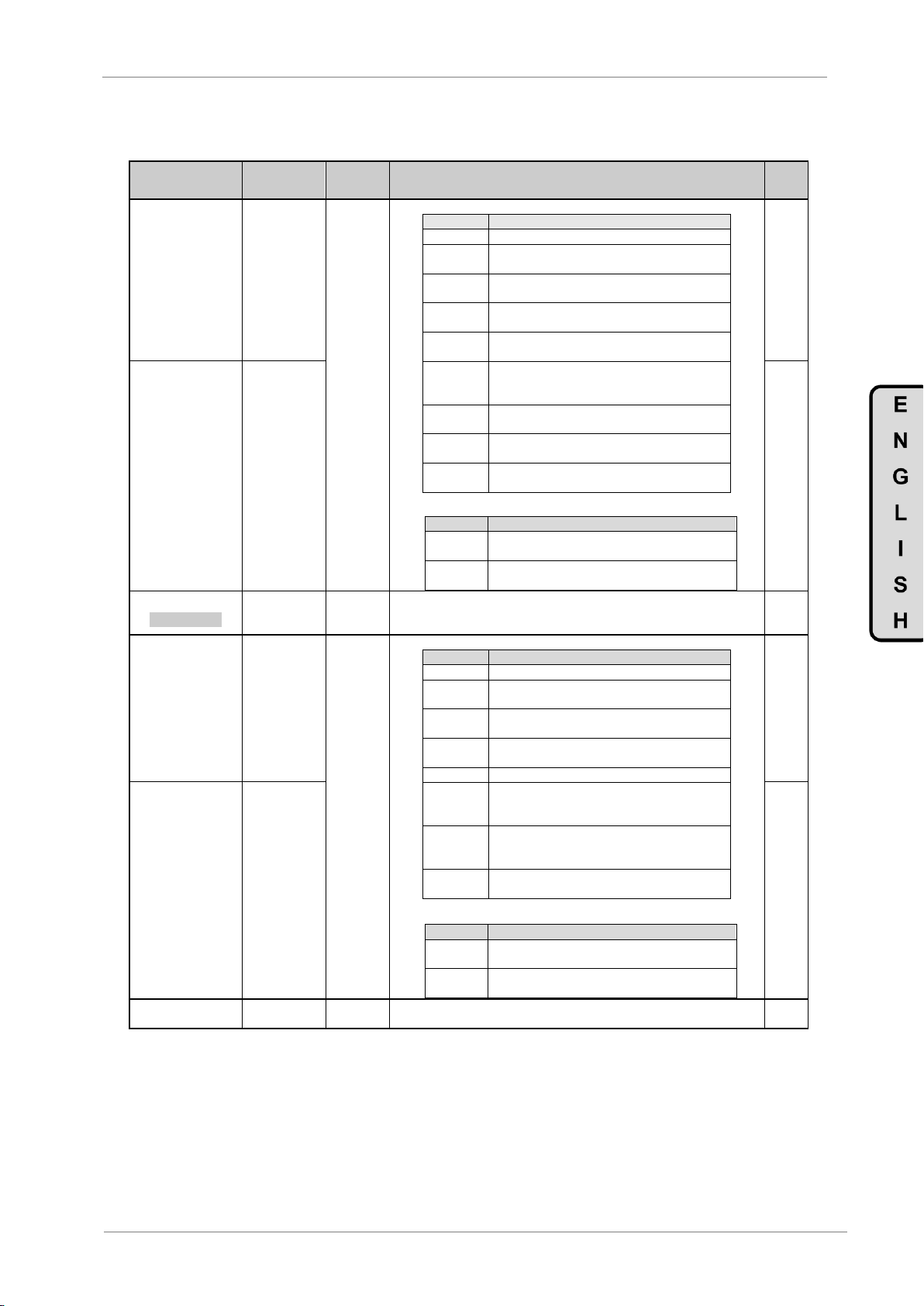

INDEX

5

INDEX

SAFETY INSTRUCTIONS ........................................................................................................... 7

1. DISPLAY UNIT AND CONTROL KEYPAD.......................................................................... 11

1.1. Keypad Unit Description ............................................................................................. 11

2. STATUS MESSAGES .......................................................................................................... 14

2.1. List of Status Messages ............................................................................................. 14

2.2. List of Warning Messages .......................................................................................... 15

3. VISUALIZATION AND STATUS PARAMETERS. GROUP G0 ........................................... 16

3.1. Parameters SV.1 – Motor Visualization ...................................................................... 16

3.2. Parameters SV.2 – Drive Visualization ...................................................................... 17

3.3. Parameters SV.3 – External Visualization .................................................................. 17

3.4. Parameters SV.4 – Internal Visualization ................................................................... 18

3.5. Parameters SV.5 – Programmable Parameters ......................................................... 18

3.6. Parameters SV.6 – Registers ..................................................................................... 19

3.7. Parameters SV.7 – Rectifier ....................................................................................... 19

3.8. Parameters SV.9 – Diagnostic ................................................................................... 19

4. DESCRIPTION OF PROGRAMMING PARAMETERS ........................................................ 20

4.1. Group 1 – G1: Options Menu ..................................................................................... 20

4.2. Group 2 – G2: Motor Nameplate Data ....................................................................... 22

4.3. Group 3 – G3: References ......................................................................................... 23

4.4. Group 4 – G4: Inputs .................................................................................................. 24

4.5. Group 5 – G5: Acceleration and Deceleration Ramps ............................................... 32

4.6. Group 6 – G6: PID Control ......................................................................................... 34

4.7. Group 7 – G7: Start / Stop Mode Configuration ......................................................... 35

4.8. Group 8 – G8: Outputs ............................................................................................... 37

4.9. Group 9 – G9: Comparators ....................................................................................... 41

4.10. Group 10 – G10: Limits .............................................................................................. 45

4.11. Group 11 – G11: Protections ..................................................................................... 46

4.12. Group 12 – G12: Auto Reset ...................................................................................... 48

4.13. Group 13 – G13: Fault History ................................................................................... 49

4.14. Group 14 – G14: Multi-references .............................................................................. 50

4.15. Group 15 – G15: Inch Speeds ................................................................................... 50

4.16. Group 16 – G16: Skip Frequencies ............................................................................ 50

4.17. Group 17 – G17: Brake .............................................................................................. 51

4.18. Group18 _ G18 : Encoder ......................................................................................... 51

4.19. Group 19 – G19: Fine Tuning .................................................................................... 52

4.20. Group 20 – G20: Communication Buses .................................................................... 55

4.21. Group 21 – G21: Networks ........................................................................................ 58

4.22. Group 22 – G22: Rectifier .......................................................................................... 60

5. MODBUS COMMUNICATION .............................................................................................. 62

5.1. Supported Modbus Function Codes ........................................................................... 62

5.2. Addressing Modes ..................................................................................................... 63

5.3. Remote Control Functions ......................................................................................... 64

5.4. Summary of Modbus Addresses ................................................................................ 65

6. FAULT MESSAGES. DESCRIPTION AND ACTIONS ........................................................ 78

6.1. Description of Fault List .............................................................................................. 78

7. COMMONLY USED CONFIGURATIONS ............................................................................ 85

7.1. Start / Stop Commands and Speed Reference by Keypad ........................................ 85

7.2. Start / Stop Commands by Terminals and Speed Reference by

7.3. Start / Stop Commands by Terminals and Speed Reference by

7.4. Start / Stop Commands by Terminals and Seven Speed References

8. CONFIGURATION REGISTER ............................................................................................ 90

Analogue Input ........................................................................................................... 85

Motorized Potentiometer ............................................................................................ 87

Selectable by Digital Inputs ........................................................................................ 88

SD700FR SERIES

POWER ELECTRONICS

6

INDEX

POWER ELECTRONICS

SD700FR SERIES

SAFETY INSTRUCTIONS

7

Do not remove the metal cover while the power is applied or the unit is in operation.

Otherwise electric shock could occur.

Do not run the drive with the front cover removed.

Otherwise, you may get an electric shock due to the high voltage terminals or exposure of charged

capacitors.

The drive does not remove the voltage from the input busbars of the drive. Before working on the

drive, isolate the whole drive from the supply.

Do not remove the cover except for periodic inspections or wiring, even if the input power is not

applied.

Otherwise, you may access to the charged circuits and may get an electric shock.

Wiring and periodic inspections should be performed at least 10 minutes after disconnecting the

input power. To remove the front cover check that the DC Link red LED is off, then remove the

terminals metallic cover and check with a multimeter the following measures:

Measure between the output power busbars U, V, W and the cabinet and check that the

voltage is around 0V.

Measure that the DC link terminals +, - and chassis voltage are below 30VDC.

Otherwise, you may get an electric shock.

Operate the switches with dry hands.

Otherwise, you may get an electric shock.

Do not use cables with damaged insulation.

Otherwise, you may get an electric shock.

Do not subject the cables to abrasions, excessive stress, heavy loads or pinching.

Otherwise, you may get an electric shock.

Do not make any insulation or voltage withstand tests on the motor with the drive connected.

SAFETY INSTRUCTIONS

IMPORTANT!

Read this manual carefully to maximise the performance of this product and to ensure its safe

use.

Power Electronics accepts no responsibility or liability for any damage resulting from

inappropriate use of the equipment.

In this manual, safety messages are classified as follows:

WARNING

SD700FR SERIES

POWER ELECTRONICS

8

SAFETY INSTRUCTIONS

Install the drive on a non-flammable surface. Do not place flammable material nearby.

Otherwise fire could occur.

Disconnect the input power if the drive is damaged.

Otherwise, it could result in a secondary accident or fire.

After stopping the drive, it will remain hot for a couple of minutes. Touching hot parts may result in

skin burns.

Do not apply power to a damaged drive or to a drive with parts missing even if the installation is

complete. Otherwise, you may get an electric shock.

It is not permitted to weld the cabinet; this can damage the electronic sensitive equipment inside.

Do not allow lint, paper, wood chips, dust, metallic chips or other foreign matter into the drive.

Otherwise fire or accident could occur.

RECEPTION

The SD700FR are carefully tested and perfectly packed before delivering.

In the event of transport damage, please ensure that you notify the transport agency and POWER

ELECTRONICS: 902 40 20 70 (International +34 96 136 65 57) or your nearest agent, within 24hrs

from receipt of the goods.

UNPACKING

Make sure model and serial number of the variable speed drive are the same on the box, delivery

note and unit.

Each variable speed drive is delivered with Hardware and Software technical manuals.

RECYCLING

Packing of the equipments should be recycled. For this, it is necessary to separate different

materials included (plastic, paper, cardboard, wood ...) and deposit them on proper banks.

Waste products of electric and electronic devices should be selectively collected for your correct

recycling company.

EMC

The drive is intended to be used in industrial environment (Second Environment), it achieve

compliance with C3 category defined in IEC/EN 61800-3 standard following the installation

recommendation within this manual.

Select communication and control system according to the drive EMC environment. Otherwise,

systems could suffer from interferences due to a low EMS level.

CAUTION

WARNINGS

POWER ELECTRONICS

SD700FR SERIES

SAFETY INSTRUCTIONS

9

SAFETY

Before operating the drive, read this manual thoroughly to gain and understanding of the unit. If

any doubt exists then please contact POWER ELECTRONICS, (902 40 20 70 / +34 96 136 65

57) or your nearest agent.

Wear safety glasses when operating the drive with power applied or the front cover is removed.

Handle and transport the drive following the recommendations within this manual.

Install the drive according to the instructions within this manual and the local regulations.

Do not place heavy objects on the drive.

Ensure that the drive is mounted vertically and keeping the minimum clearances distances.

Do not drop the drive or subject it to impact.

The SD700FR drives contain static sensitive printed circuits boards. Use static safety

procedures when handling these boards.

Avoid installing the drive in conditions that differ from those described in the Environmental

Ratings section.

CONNECTION PRECAUTIONS

To ensure correct operation of the drive it is recommended to use a SCREENED CABLE for the

control wiring.

The motor cable should comply with the requirements within this manual. Due to increased

leakage capacitance between conductors, external ground fault protection threshold value

should be adjusted ad hoc.

Do not disconnect motor cables if input power supply remains connected.

The internal circuits of the SD700FR Series will be damaged if the incoming power is connected

and applied to output terminals (U, V, W).

Do not use power factor correction capacitors banks, surge suppressors, or RFI filters on the

output side of the drive. Doing so may damage these components.

Always check whether the DC Link red LED is OFF before wiring terminals. The capacitors may

hold high-voltage even after the input power is disconnected.

TRIAL RUN

Verify all parameters before operating the drive. Alteration of parameters may be required

depending on application and load.

Always apply voltage and current signals to each terminal that are within levels indicated within

this manual.

OPERATION PRECAUTIONS

When the Auto Restart function is enabled, keep clear of driven equipment, as the motor will

restart suddenly after the fault reset.

The “STOP / RESET” key on the keypad is active only if the appropriate function setting has

been made. Pushing this button the drive will NOT perform a safe stop. It is available STO

optional board, which installed with a separate EMERGENCY pushbutton, will disconnect the

power and will be unable to generate torque in the motor with high reliability.

If a fault is reset with the reference signal still active, the drive will unexpectedly restart. Verify

that it is permissible for this to happen. Otherwise, it may lead to injury to people.

Do not modify or alter internal wiring and spare parts without Power Electronics supervision.

Before programming or operating the SD700FR Series, initialise all parameters back to factory

default values.

SD700FR SERIES

POWER ELECTRONICS

10

SAFETY INSTRUCTIONS

EARTH CONNECTION

Ground the drive and adjoining cabinets to ensure a safety operation and to reduce

electromagnetic emission.

Connect the input PE terminal only to the dedicated PE terminal of the drive. Do not use the

case or the chassis screw for grounding.

Ground the drive chassis through the dedicated and labelled terminals. Use appropriate

conductors to comply with the local regulations. The ground conductor should be connected first

and removed last.

Motor ground cable must be connected to the PE output terminal of the drive and not to the

installation’s ground. We recommend that the section of the ground conductor (PE) should be

equal or greater than the active conductor (U, V, W).

If the user decides to use shielded motor cable, ensure a correct 360º shield bonding in both the

drive cabinet and the motor terminal box.

POWER ELECTRONICS

SD700FR SERIES

DISPLAY UNIT AND CONTROL KEYPAD

11

1. DISPLAY UNIT AND CONTROL KEYPAD

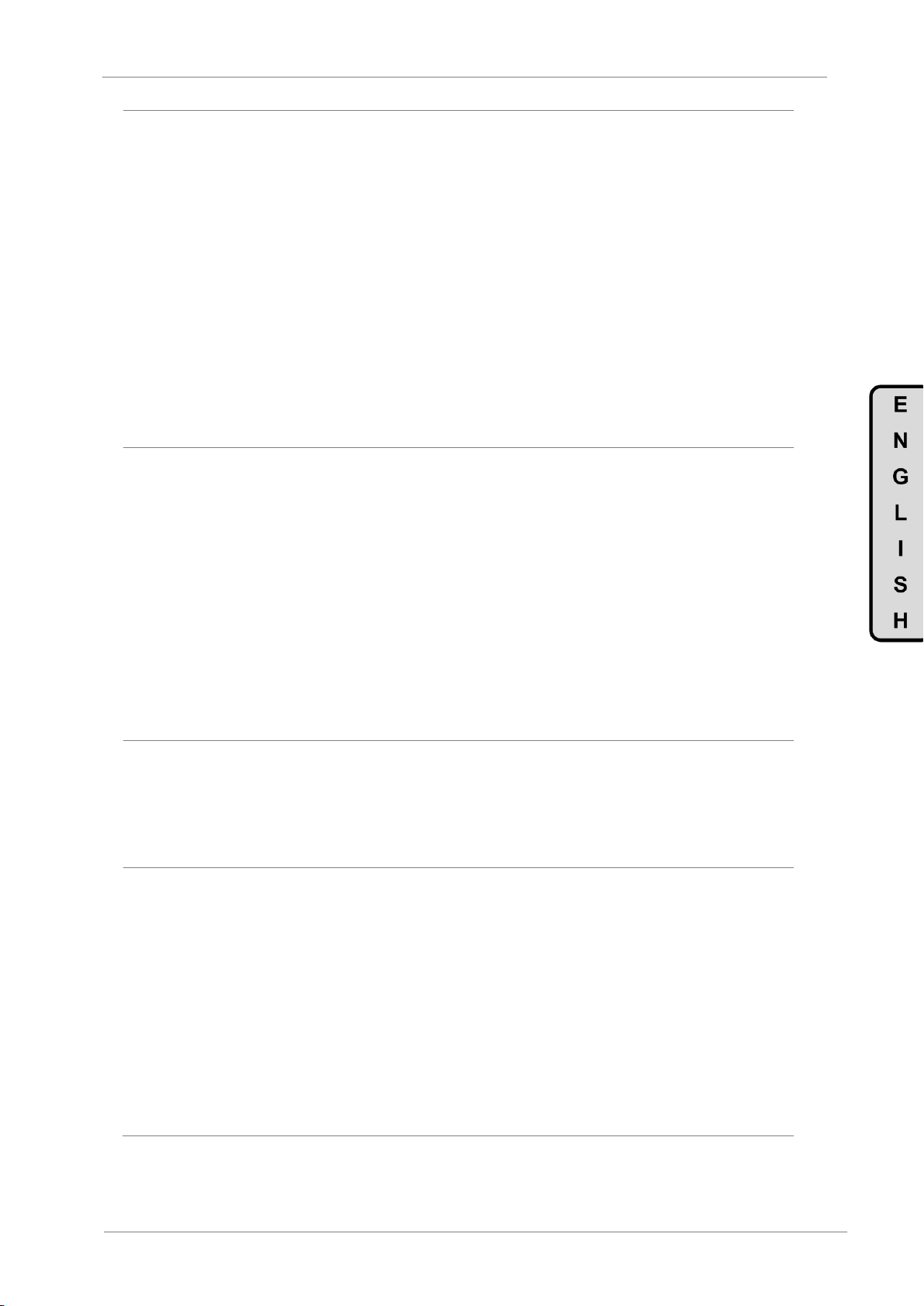

1.1. Keypad Unit Description

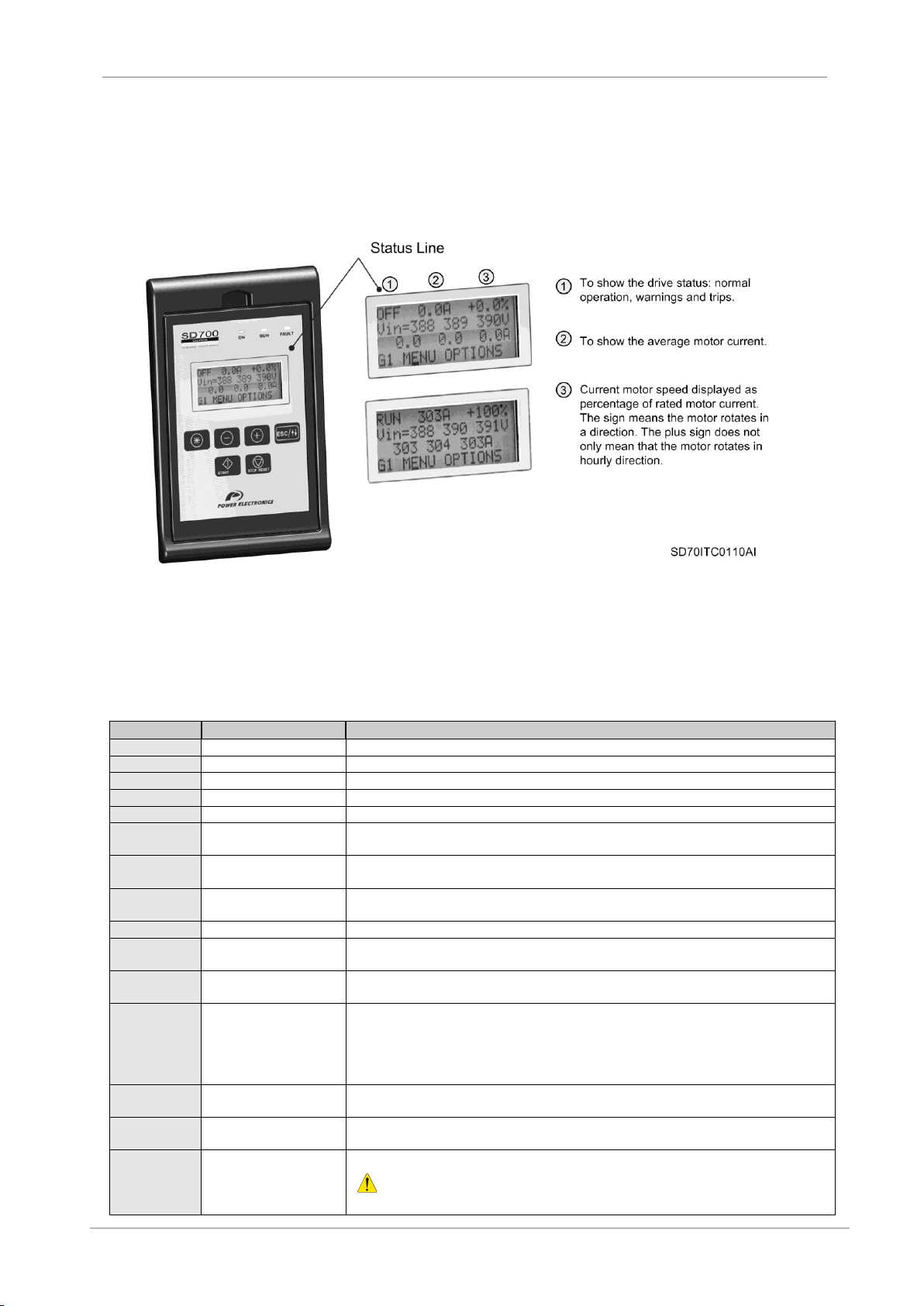

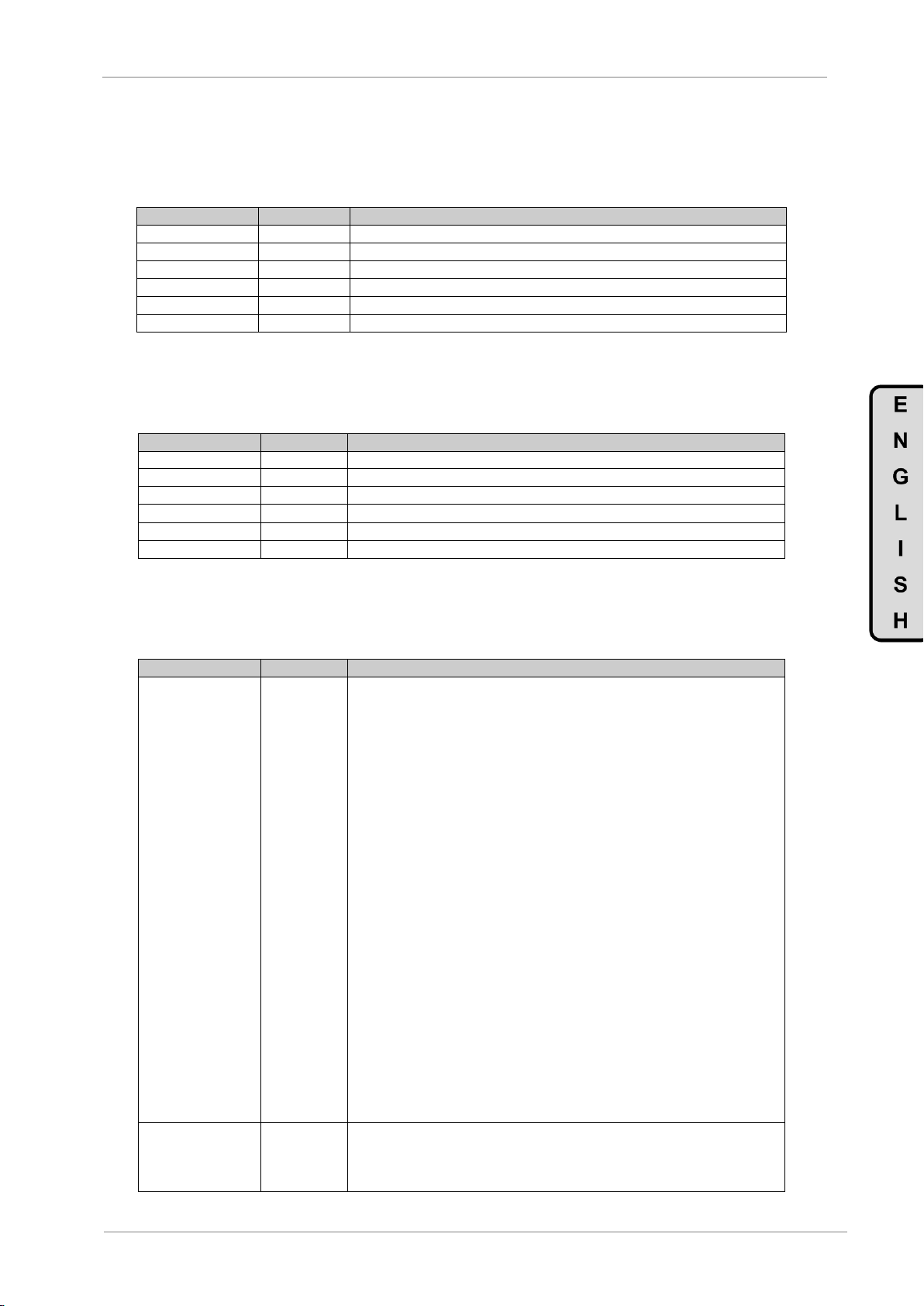

The display of the SD700FR is removable for remote installation, as the illustration shows. There are

three leds on the display which indicate the drive operational status, one LCD screen with 4 lines of

16 characters each and keys for control and parameter setting.

Figure 1.1 Display Unit and Keypad

1.1.1. LEDs for Status Indication

Leds offer an easy method of identifying if the SD700FR is powered up, if the drive is supplying

output voltage, or if the drive has tripped.

Led ON: Yellow colour. When it is lit, indicates equipment is powered up. When it is blinking,

it indicates that the drive gets any warning.

Led RUN: Green colour. When it is lit, indicates the motor is powered by the SD700FR.

When it is blinking, it indicates that only one of the power bridges is switching.

Led FAULT: Red colour. When it is blinking, indicates the equipment is in fault status.

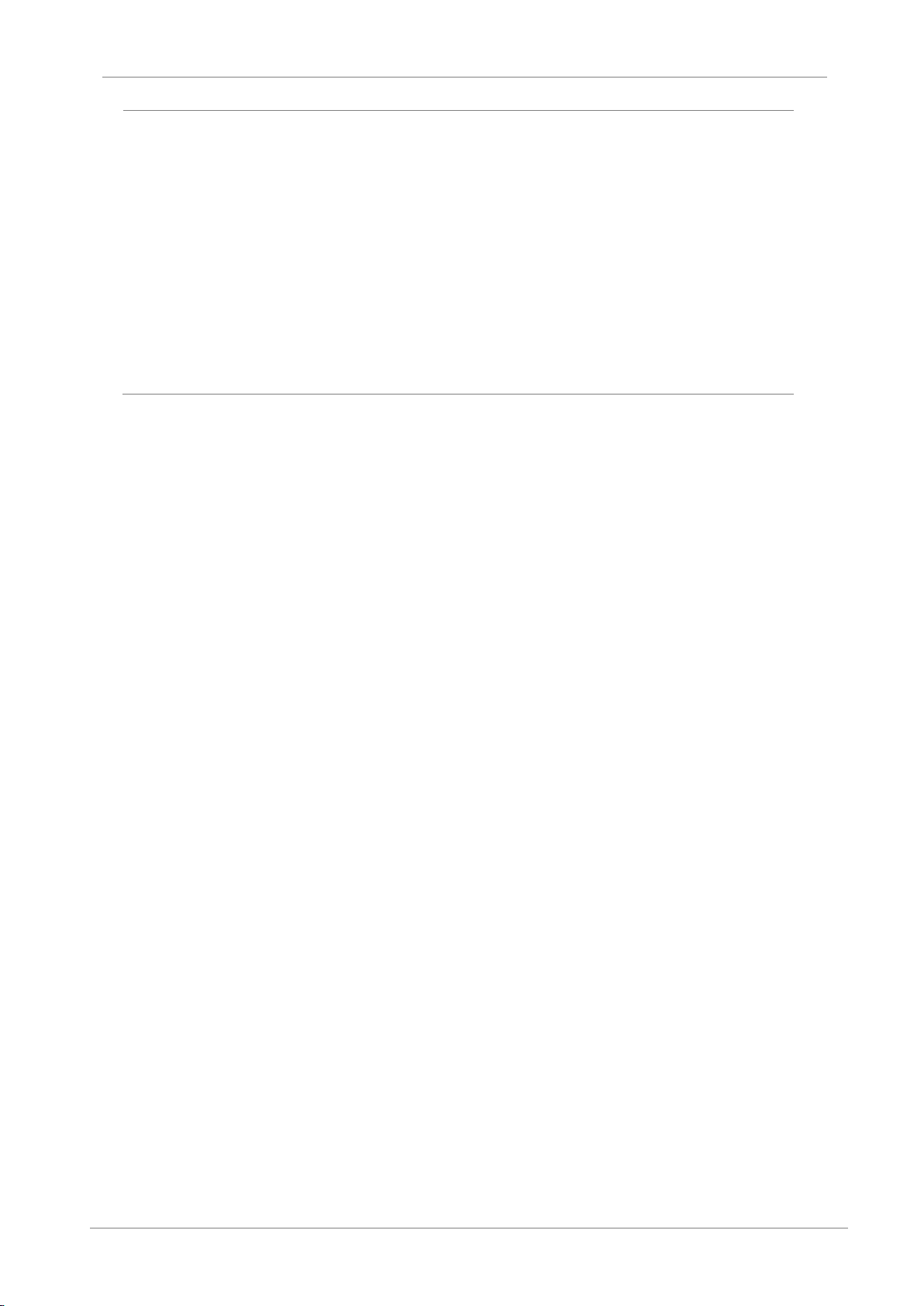

Figure 1.2 Status Visualization

SD700FR SERIES

POWER ELECTRONICS

12

DISPLAY UNIT AND CONTROL KEYPAD

1.1.2. Alphanumeric LCD Display

SD700FR display has a LCD screen of four lines with sixteen characters each (16x4). Each line

has different functions.

Status Line: It is the top line.

It is always present and shows the SD700FR

status (STR – Start, STP – Stop, etc…).

It also shows the output current and the

motor speed.

It is not configurable by the user.

Visualization Line 1: It is the second

line of the screen. It is always present

and allows the selection of variables from

the visualization menu.

It is configurable by the user.

Visualization Line 2: It is the third

line of the screen. It is always present

and allows the selection of variables from

the visualization menu.

It is configurable by the user.

Programming Line: It is the fourth line.

It is used to display and / or set different

parameters within the SD700FR. Figure 1.3 Detail of Display Lines

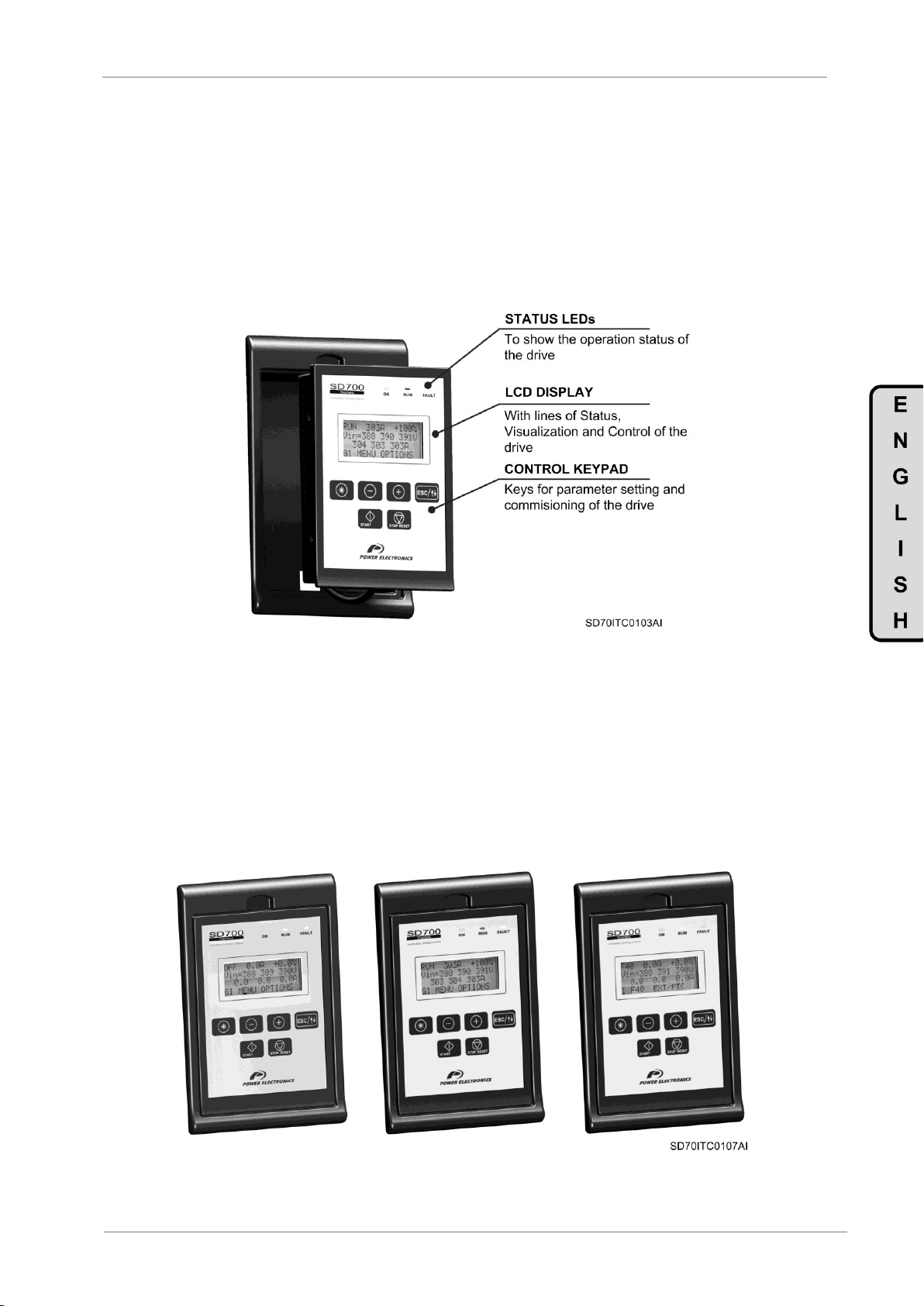

1.1.3. Control Keys

Function keys have multiple uses and can be operated individually or in combination with other

keys:

It allows access to different parameters groups and sub-groups; it displays code

explanations and allows adjustment of parameter values in combination with

other keys. If a group has no sub-groups, it allows direct access to the

parameters of the group.

To modify numeric parameters:

& Simultaneously pushed, the value will increase.

& Simultaneously pushed, the value will decrease.

To modify parameters of numbered options:

Pushing this key, the extended explanation will appear.

& Simultaneously pushed will ascend the user

through the varying options.

& Simultaneously pushed will descend the user

through the varying options.

It allows upward movement through the parameters groups and allows

navigation for different parameters within a parameter group. It also allows the

increase of parameters value.

It allows downward movement through the parameters groups and allows

navigation for different parameters within a parameter group. It also allows the

decrease of parameters value.

POWER ELECTRONICS

SD700FR SERIES

DISPLAY UNIT AND CONTROL KEYPAD

13

When pushed for 2 seconds (approx.) it allows navigation between the

programming line and visualisation lines available to the user. It also offers the

possibility of escaping back to the previous sub-group or group.

To start the drive from the keypad when the control has been set as local

control (check drive configuration).

To stop the drive from the keypad when the control has been set as local

control. In the case of tripping this key can be used to reset the drive, if local

control is enabled. The drive will not perform an Emergency Stop and the drive

will not be disconnected from the power supply.

In the following figure you can see a programming example where you can observe the operation

explained previously.

Figure 1.4 Example of parameters navigation

SD700FR SERIES

POWER ELECTRONICS

14

STATUS MESSAGES

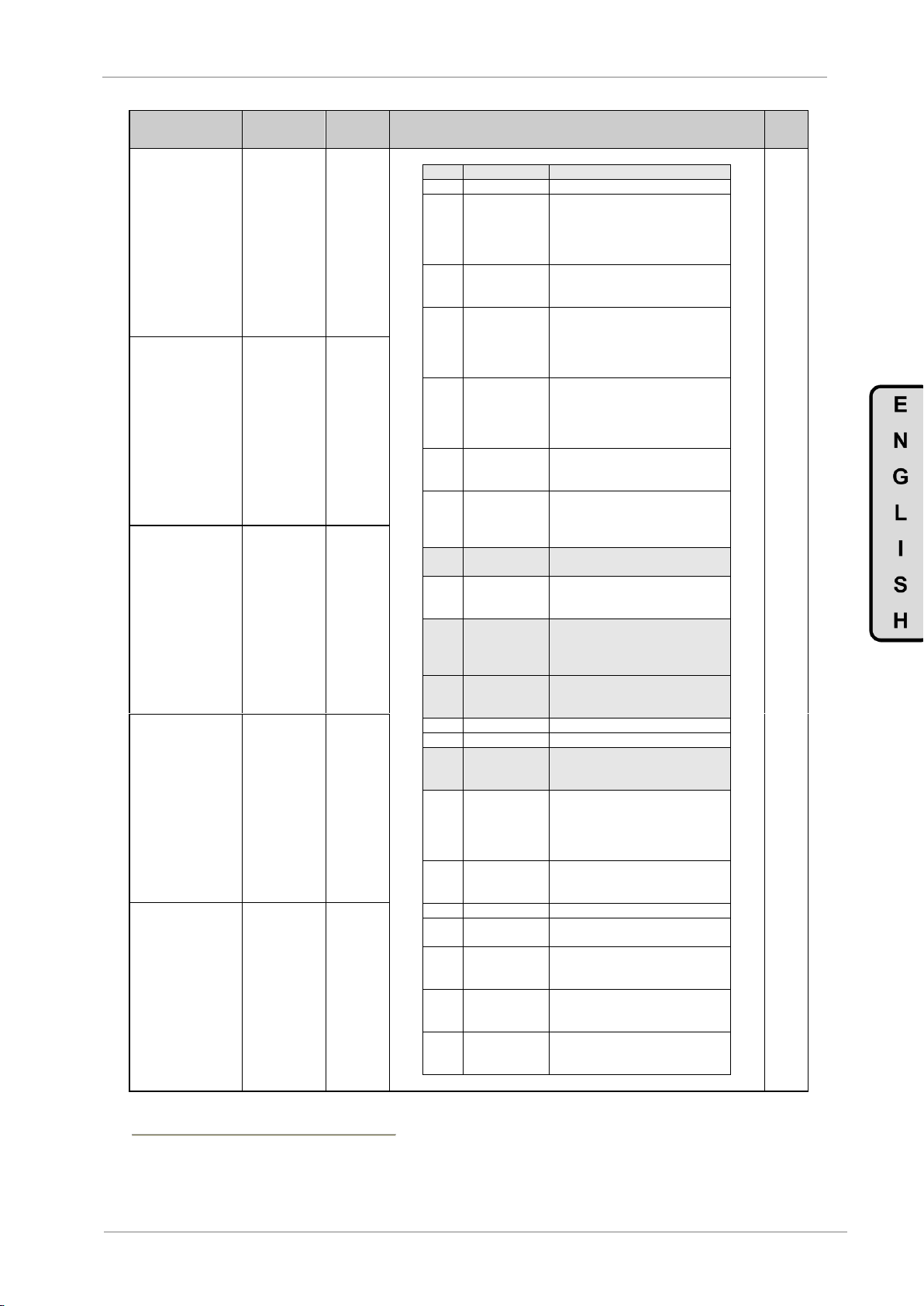

Screen

Name

Description

OFF

Deactivated power

Drive power is deactivated.

ON

Activated power

Drive power is activated.

ACL

Accelerating

Drive is increasing the output frequency. Motor increasing in speed, it is accelerating.

RUN

Running

Drive is operating at reference speed. Operation at steady status.

DEC

Decelerating

Drive is decreasing the output frequency. Motor decreasing in speed, it is decelerating.

SPG

Stopping

Drive is decreasing the output frequency due to a stop command. Motor is stopping by ramp

until zero speed is reached.

EST

Free run stop when a

fault occurs

Drive is stopping by free run stop after a fault occurs (emergency stop). Motor stopping time

is determined by inertia as the drive output has turned off.

SPN

Flying start

‘Flying start’ operation must be configured if required. The SD700FR will search for the actual

motor shaft speed once the drive has received a start command.

DCB

DC brake

SD700FR is applying DC current injection to stop the motor.

TBR

DC brake ON delay

Drive is applying a delay time before DC current injection is active. When this time is

elapsed, the DC brake will be active.

DLY

Start Delay Time

When a delay time has been set in order to start the equipment, after the start command has

been activated, this message will be displayed until this time has elapsed.

IN1

Inch speed 1

SD700FR is working according to inch speed 1 command and ‘Start + Inch speed 1' mode is

active. When operated in this mode the "Start + Inch speed 1" command is dominant over

other inputs programmed for "Start" functionality. Therefore if one input is configured as

‘Start’ and it is deactivated; in spite of this deactivated input, the drive will start when ‘Start +

Inch speed 1' command is received. This is also valid for Inch speed 2 and 3.

IN2

Inch speed 2

SD700FR is working according to inch speed 2 command. ‘Start + Inch speed 2' mode is

active.

IN3

Inch speed 3

SD700FR is working according to inch speed 3 command. ‘Start + Inch speed 3' mode is

active.

HEA

Non condensing current

is activated

SD700FR is injecting DC current to prevent moisture condensing within the motor.

CAUTION: Although the motor is not running there is dangerous voltage. Run Led will

be lit during this process. Be careful to avoid damages and personal injury.

2. STATUS MESSAGES

The upper line of the display corresponds to the status line. In this line we can display the equipment

status, motor current (A) and the motor speed (%). It is always displayed and it is not programmable by the

user.

Figure 2.1 Status Line Description

Note: The user can access to the information displayed in status line via Modbus communication. See section ‘Modbus

Communication’.

2.1. List of Status Messages

POWER ELECTRONICS

SD700FR SERIES

STATUS MESSAGES

15

Screen

Name

Description

MOL

Motor overload

This message will appear when motor thermal model is increasing the estimated motor

temperature.

MOC

Motor over-current

Motor current is higher than the rated current value.

DOC

Drive over-current

This message will appear if the output current is higher than 125% of the nominal current.

ILT

Current limitation

Current limit algorithm has been activated.

TLT

Torque limitation

Torque limit algorithm has been activated.

VLT

Voltage limitation

A high DC Link voltage level has been detected and the voltage limit control algorithm has

been activated to protect the drive.

ACO

Asymmetric current

Asymmetry in output currents of the drive has been detected.

AVO

Output voltage

imbalance

Asymmetry in output voltage of the drive has been detected.

AVI

Input voltage imbalance

Asymmetry in input voltage of the drive has been detected.

OVV

High input voltage

Input voltage of the equipment is reaching a dangerous level. The value is above the set

value (protections settings).

UNV

Low input voltage

Input voltage of the equipment is reaching a dangerous level. The value is below the set

value (protections settings).

S1L

Speed limit 1 reached

Motor speed has reached speed limit 1.

S2L

Speed limit 2 reached

Motor speed has reached speed limit 2.

IPR

Current input protection

Input current has reached the 100% of the rated current.

IIB

Input current imbalance

Inverse input current has reached the 75% of the fault threshold “R19 I IM BIN”.

IGF

Input ground fault

Ground fault current has reached the 75% of the ground fault threshold.”R20 GRND INPUT”.

TRB

Temperature rectifier

bridge

The rectifier’s IGBTs have reached 90ºC.

CCM

CAN communication

module

Some CAN frames from the fiber optics communication have been lost.

FPS

Fan Power Supply

The rectifier’s fan power supply has a failure. The fault “R34 IGBT TEMP” will reduce its

threshold value from 110ºC up to 90ºC, in order to protect the drive components.

PLL

Phase Locked Loop

The rectifier is synchronizing to the grid.

SWM

Software Mismatch

SW version not compatible

DWA

Diagnostic Warning

Active

Some Diagnostic Board is reporting a warning.

LCL

Contactor LCL

The LCL feedback is not correctly.

2.2. List of Warning Messages

SD700FR SERIES

POWER ELECTRONICS

16

VISUALIZATION AND STATUS PARAMETERS. GROUP G0

Screen

Units

Description

Sp Ref = +000%

% motor speed

It shows the present reference value of speed which is applied to the motor.

Mtr Speed = +0rpm

rpm

It shows the motor speed in revs per minute.

Mtr Sp = +0.0%

%

It shows the motor speed in %. It corresponds with the third field of the status line

OFF 0.0A +0.0%

Mtr Freq = +0.0Hz

Hz

It shows the frequency being applied to the motor.

Mtr Vout = 0V

V

It shows the present voltage applied to the motor.

Mtr Iout = 0.0A

A

It shows the present current flowing to the motor. It corresponds with the second field of the

status line OFF 0.0A +0.0%

Mtr Torqe = 0.0%

% motor torque

It shows the present torque applied to the motor.

Mtr Pfactr = 0.0

-

It shows the power factor of the motor.

Mtr Pwr = +0.0kW

kW

It shows the instantaneous power consumption of the motor.

0.0A 0.0A 0.0A

A

It shows the instantaneous current of each phase of the motor (U, V and W).

Vmt= 0 0 0V

V

It shows the instantaneous voltage applied to the motor terminals.

PTC Motor = 0

-

It shows if the motor PTC (temperature sensor) is connected.

X: PTC Connected.

0: PTC Not Connected.

Motor Temp = 0.0%

% Motor heat

It shows the estimated motor temperature. A level of 110% will cause F25 trip (motor

overload).

Enco. Pulso =0

pulses

It shows the encoder pulses.

Clsped = 0 rpm

rpm

Real speed mesured by the encoder.

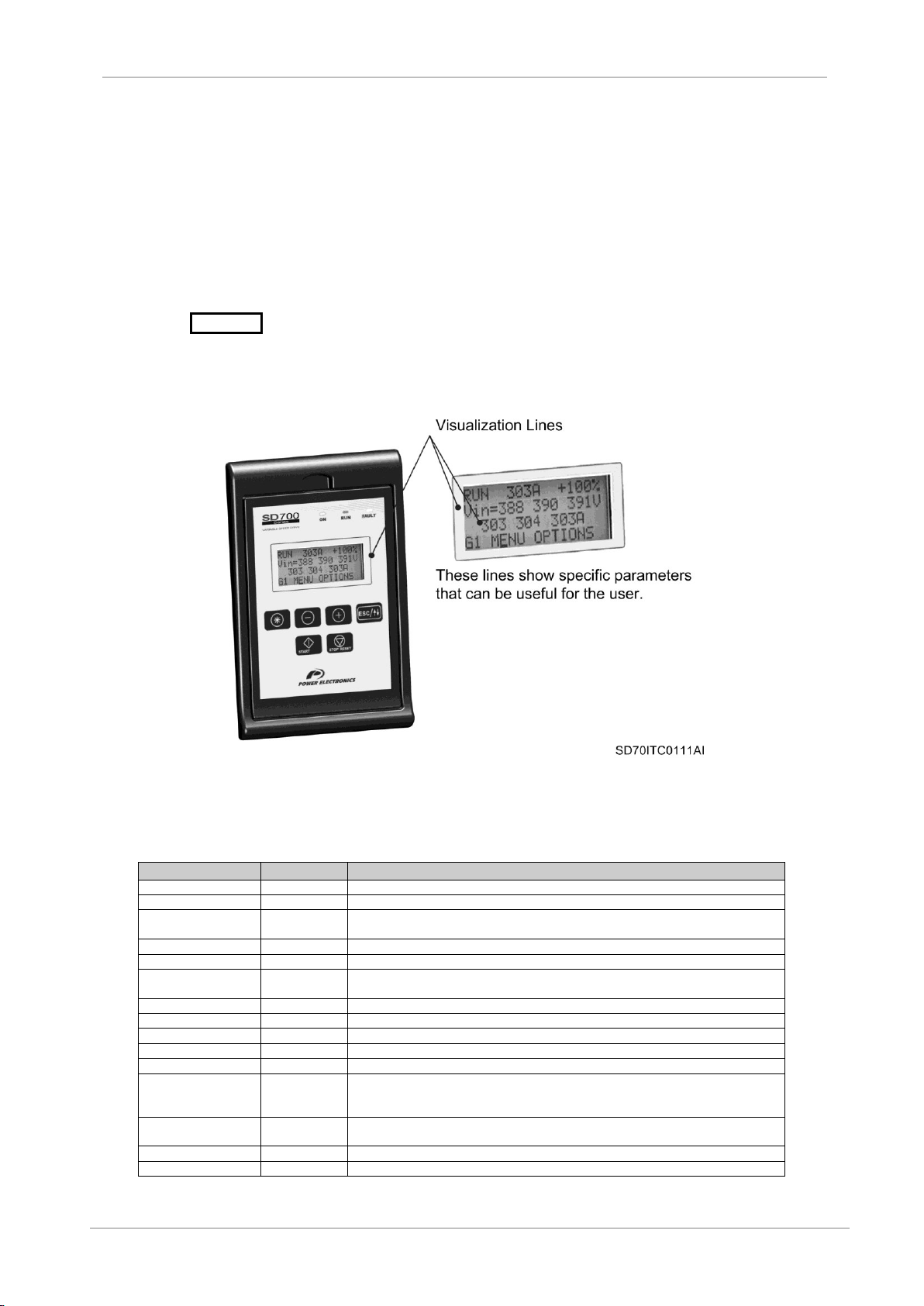

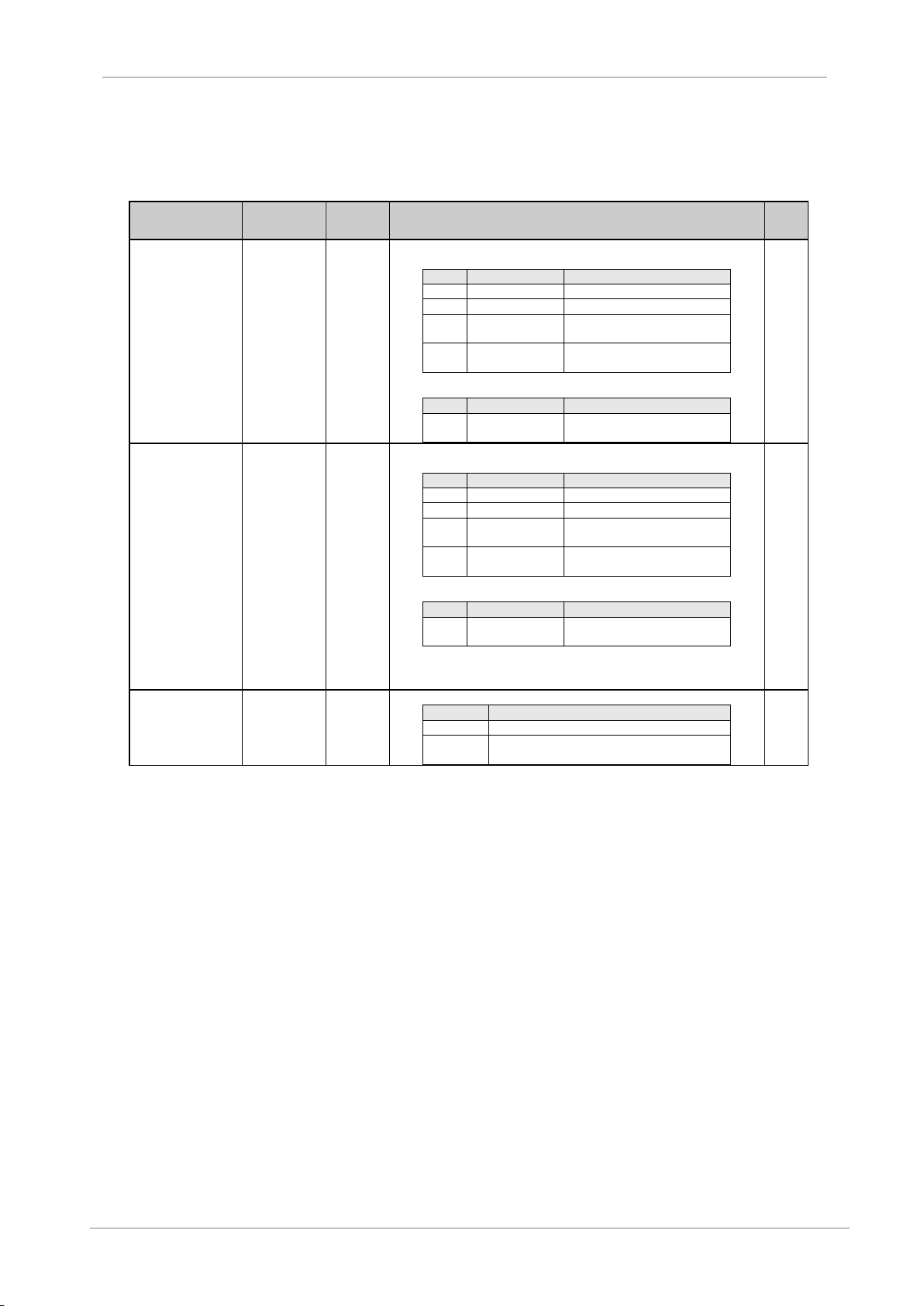

3. VISUALISATION AND STATUS

PARAMETERS. GROUP G0

These parameters constantly indicate the input signal status and dynamic parameter status of the

SD700FR. Visualization lines are the second and the third lines. The user can select the parameter to be

displayed in each line from the different visualization options.

To select a display parameter you should move to the cursor to the second or third line. For this, you need

to press ESC /

located on the second or third line you can navigate like the programming line (line 4) and select the

desired parameter to be displayed. Once selected these parameters are saved into memory. These

parameters are then displayed on lines 2 and 3 whenever the drive is powered up.

Thanks to these lines user can display desired parameters and obtain additional information easily.

key for approx two seconds. The cursor moves from one line to the next. Once

Figure 3.1 Visualization Lines Description

3.1. Parameters SV.1 – Motor Visualisation

POWER ELECTRONICS

SD700FR SERIES

VISUALIZATION AND STATUS PARAMETERS. GROUP G0

17

Screen

Units

Description

390 390 390V

V

It shows the input instantaneous voltage applied to the drive (RS, ST, RT).

Inp Vol = 390V

V

It shows the average input voltage to the drive.

50.0 50.0 50.0Hz

Hz

It shows the frequency of the input voltage to the drive.

Bus vol = 540V

VDC

It shows DC Link voltage of the drive.

IGBT Temp =+23ºC

ºC

It shows the temperature measured at the power stage of the drive output.

Drive Temp =+26ºC

ºC

It shows the temperature measured inside the electronics chamber of the drive.

Screen

Units

Description

ANLG IN1 = +0.0V

V or mA

It shows the value of Analogue Input 1.

AIN1 Refr = +0.00%

% bottom scale

AI1

It shows the value or the PID reference proportional to Analogue Input 1 in percentage.

AIN1 S = +0.00l/s

Engineering

units

It shows the value of sensor 1 associated to the Analogue Input 1.

ANLG IN2 = +0.0V

V or mA

It shows the value of the Analogue Input 2.

AIN2 Refr = +0.00%

% bottom scale

AI2

It shows the value or the PID reference proportional to the Analogue Input 2 signal.

AIN 2 S = +0.00Bar

Engineering

units

It shows the value of sensor 2 associated to the Analogue Input 2.

ANL OUT1 = +4.0mA

V or mA

It shows the value of Analogue Output 1.

AOUT1 Refer = +0.0%

% associated

magnitude

It shows the magnitude value associated to the Analogue Output 1 (speed, current ...).

ANL OUT2 = +4.0mA

V or mA

It shows the value of Analogue Output 2.

AOUT2 Refer = +0.0%

% associated

magnitude

It shows the magnitude value associated to the Analogue Output 2 (speed, current ...).

DI: 000000 0

-

It shows whether the Digital Inputs are activated or not, from DI1 to DI6. The final is another

input which shows the status of the motor PTC signal.

X: Active.

0: Not Active.

Relays 1-3: X0X

-

It shows whether the output relays are activated or not.

X: Active.

0: Not Active.

Speed M = +0.000m/s

Depending on

config.

It shows the speed of the motor in engineering units. Pressing key you can access to the

following sub-parameters of configuration:

Screen

Range

Description

Scale ftr=1

0.001 10

To set the ratio factor between motor speed and

machine speed.

Units Ma=m/s

m/s

m/m

cm/s

cm/m

v/s

v/m

It allows selection of the units to be displayed

Units

Description

m/s

Meters / second

m/m

Meters / minute

cm/s

Centimetres / second

cm/m

Centimetres / minute

v/s

Turns / second

v/m

Turns / minute

Note: They both are settable during run.

Modbus Traffic=0

0 / X

“X” will be displayed if Modbus communication exists through RS232 or RS485 user port.

Furthermore, “X” will blink at constant frequency while communication is active.

After half second is elapsed without communication, “O” will be displayed.

Display_traffi = 0

-

It shows if the display is connected.

Screen

Description

0

The display is not connected.

1

The display is connected.

3.2. Parameters SV.2 – Drive Visualisation

3.3. Parameters SV.3 – Visualisation

SD700FR SERIES

POWER ELECTRONICS

18

VISUALIZATION AND STATUS PARAMETERS. GROUP G0

Screen

Units

Description

Actual Fault = 00

-

It shows the present code fault. See fault history G13.

Drive Curr = 170A

A

It shows the drive rated current (maximum current of the equipment at 50ºC).

Drive Volt = 400V

V

It shows the drive rated voltage.

S/W

-

It shows the software version installed into the equipment.

H/W y.y

-

It shows the hardware version of the equipment.

PID R% = +0.0%

% feedback

range

It shows the reference value in PID mode of the equipment standard program.

PID F% = +0.0%

% AI used as

feedback

It shows the feedback value in PID mode of the equipment standard program.

PID Error = +0.0%

% feedback

range

It shows the error value in PID mode that means the difference between the reference value

and the real value of the system feedback signal.

Comparators: 000

-

It shows if comparators are activated or not.

X: Active / 0: Not Active.

FLT.STAT.=NO FLT

NO FLT

---

It shows if the equipment is in faulty status.

If the equipment is in faulty status, it shows the status of the drive before the fault is

produced; when there is not fault, it shows ‘NO FLT’.

Fault Diag.=N

N

Y

When it is set to ‘Y’ (YES), the parameters of groups ‘SV.1 Motor Visualization’ and ‘SV.2

Drive Visualization’ are hold with the last values at the moment of the last fault is produced.

If the user sets the parameter to ‘N’ (NO), or after 135 seconds are elapsed, the parameters

will show the actual values again. The hold values are saved in memory until next fault will be

produced, even if the input power of the drive is lost.

Screen

Units

Description

Local Sp = +100%

% motor speed

It shows the speed reference value in local mode (introduced by keypad). See G3.3 parameter

for additional data.

PID Local = +100%

% feedback

It allows user to select the PID reference in local mode. See G6.2 parameter for additional

data.

Mref 1 = +10.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 1. See G14.1 parameter for

additional data.

Mref 2 = +20.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 2. See G14.2 parameter for

additional data.

Mref 3 = +30.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 3. See G14.3 parameter for

additional data.

Mref 4 = +40.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 4. See G14.4 parameter for

additional data.

Mref 5 = +50.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 5. See G14.5 parameter for

additional data.

Mref 6 = +60.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 6. See G14.6 parameter for

additional data.

Mref 7 = +70.0%

% motor speed

It allows user to set the speed value assigned to Multi-reference 7. See G14.7 parameter for

additional data.

Inch Spd1 = 0.00%

% motor speed

It allows user to set the step frequency 1 value. See G15.1 for additional data.

Inch Spd2 = 0.00%

% motor speed

It allows user to set the step frequency 2 value. See G15.2 for additional data.

Inch Spd3 = 0.00%

% motor speed

It allows user to set the step frequency 3 value. See G15.1 and 2 for additional data.

3.4. Parameters SV.4 – Internal Visualisation

3.5. Parameters SV.5 – Programmable Parameters

This group is not only a display group. Some parameters such as speed, pressure and inch speeds

can be adjusted in this group. These parameters are also available in their corresponding parameter

groups. This is a simple way to allow user adjustment of basic parameters without entering the main

programming groups.

POWER ELECTRONICS

SD700FR SERIES

VISUALIZATION AND STATUS PARAMETERS. GROUP G0

19

Screen

Units

Description

TOT= d h

Days and Hours

It shows the total time during which the drive is running (RUN).

PAR= d h

Days and Hours

It shows the partial time during which the drive is running (RUN).

CLEAR PARTIAL=N

-

It allows resetting the counter of partial time for running status (RUN).

MOTOR ENERGY

kWh/MWh/GWh

Shows the drive energy consumption in motor mode operation.

REGEN. ENERGY

kWh/MWh/GWh

Shows the regenerated energy in regeneration mode operation.

RSET PRTL ENRG

Y/N

The user is able to reset the partial energy counters.

Screen

Units

Description

Pow in

kW

It shows the input power.

IR & IS & IT

A

It shows the currents per phase.

R. Phi Cos

-

It shows the input cos PHI or Displacement Power Factor (DPF).

Rec T IGBT

ºC

It shows the maximum temperature of rectifier’s IGBT.

PLL frq

Hz

It shows the internal PLL frequency.

THDi

%

It shows the input current distortion (THDi).

Screen

Units

Description

DIAGNOSTIC STATUS

-

This screen is a logger that shows the different events detected in the drive. When there are

no events detected, the screen will show DIAGNOSTIC: OK. The distribution boards identify

and inform about the module that provoques the different events, distinguishing between

inverter and rectifier sides. The format that the message is shown is like following:

Mx y WARN

Where each of meaning is:

- Mx: number of module the warning has raised (example M1, M2...)

- y: bridge where is placed the warning; R for rectifier and I for inverter

- WARN: name of the warning raised

The different events detected are:

- Desaturation faults. Identifies the IGBT in fault.

Ex: M3 I DESAT 2+ (The second leg high IGBT of the module 3 inverter side is

in desaturation fault).

- Fan fault. Identifies the fan.

Ex: M1 R FAULT FAN 2 (There are some problem in the fan 2 of module 1).

- LCL Temperature.

Ex: M10 R TEMP LCL (The LCL thermal relay of the module 10 has faulted).

- Fan power supply.

Ex: M5 R FAN PO SUP (The feedback of the module 5 power supply has

faulted).

- Communication fault.

Ex: M6 I TOUT CAN (The inverter bridge diagnostic of module 6 is not

communicating).

- ID repeated. Some diagnostic board have the same ID. Normally, when this

warning appears, another warning by timeout raises.

Ex: M8 I ID REPEAT (There more than one distribution boards selected as the

module 8 of the inverter side).

- Temperature warning. The IGBT temperature is too high or the thermal probe

is not connected correctly. Identifies the IGBT in warning.

Ex: M3 R TMP IGBT3 (The IGBT 3 of the module 3 of the rectifier side presents

a temperature warning).

Module X (X

corresponds with the

number of modules of

the equipment)

ºC

These screens show all the IGBTs temperatures of the whole drive. There will be as screens

as the number of modules. Once entered in the module subgroup, the temperature of the six

IGBTs is available. The first screen shows the three rectifier temperatures (R 25 26 24C) and

the second shows the inverter ones (I 24 24 23C).

3.6. Parameters SV.6 – Registers

This group includes several registers of general information about the drive use. Therefore, we can

visualize a total and partial counter for running time (RUN).

3.7. Parameters SV.7 – Rectifier

This group includes several registers of general information about the rectifier bridge.

3.8. Parameters SV.9 – DIAGNOSTIC

This group includes several registers of general information about the rectifier bridge.

SD700FR SERIES

POWER ELECTRONICS

20

DESCRIPTION OF PROGRAMMING PARAMETERS

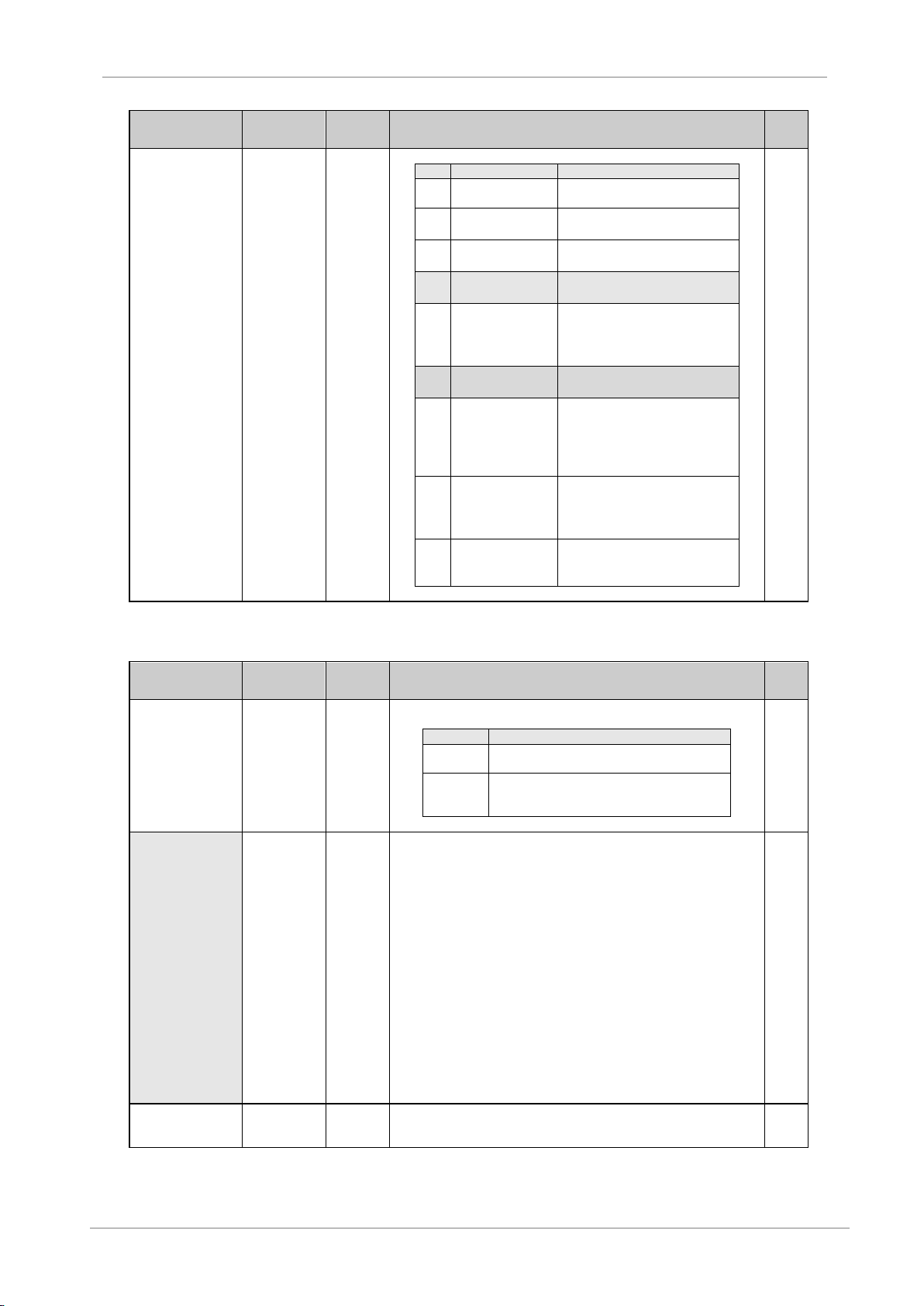

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

1 LOCK PARMTRS=0

G1.1 / Parameter

lock

0 – 2

It allows user to lock SD700FR parameters totally or partially. To lock you have to

introduce a password in G1.2.

OPT

DESCRIPTION

FUNCTION

0

NO

Parameter lock is not active.

1

PARTIAL LOCK

All of parameters are locked

except for G1.1, G1.2, G3.3 and

G6.2 (PID reference).

2

TOTAL LOCK

Only G1.1 and G1.2 can be

modified.

YES

2 PASSWORD_=OFF

G1.2 / Access

password

OFF,

0000 – 9999

It allows user to introduce a password to lock parameters and avoid unauthorized

changes in the programming.

If in G1.1 'Parameter lock ', option '1 or 2' has been chosen, then this parameter

appears automatically.

Unlock: In G1.1 = 1 or 2 set to '0 NO'. 2 PASSWORD_?OFF will be displayed.

YES

3 PSW ERR=XXXX

G1.2b / Unlock

password

recovery

0000 – 9999

To recover the password the following formula can be used:

Unlock password = (XXXX/2)-3.

YES

4 LANG=ESPANOL

G1.4 / Language

selection

ENGLISH

ESPANOL

DEUTSCH

PORTUGE

It allows selection of the user language.

NO

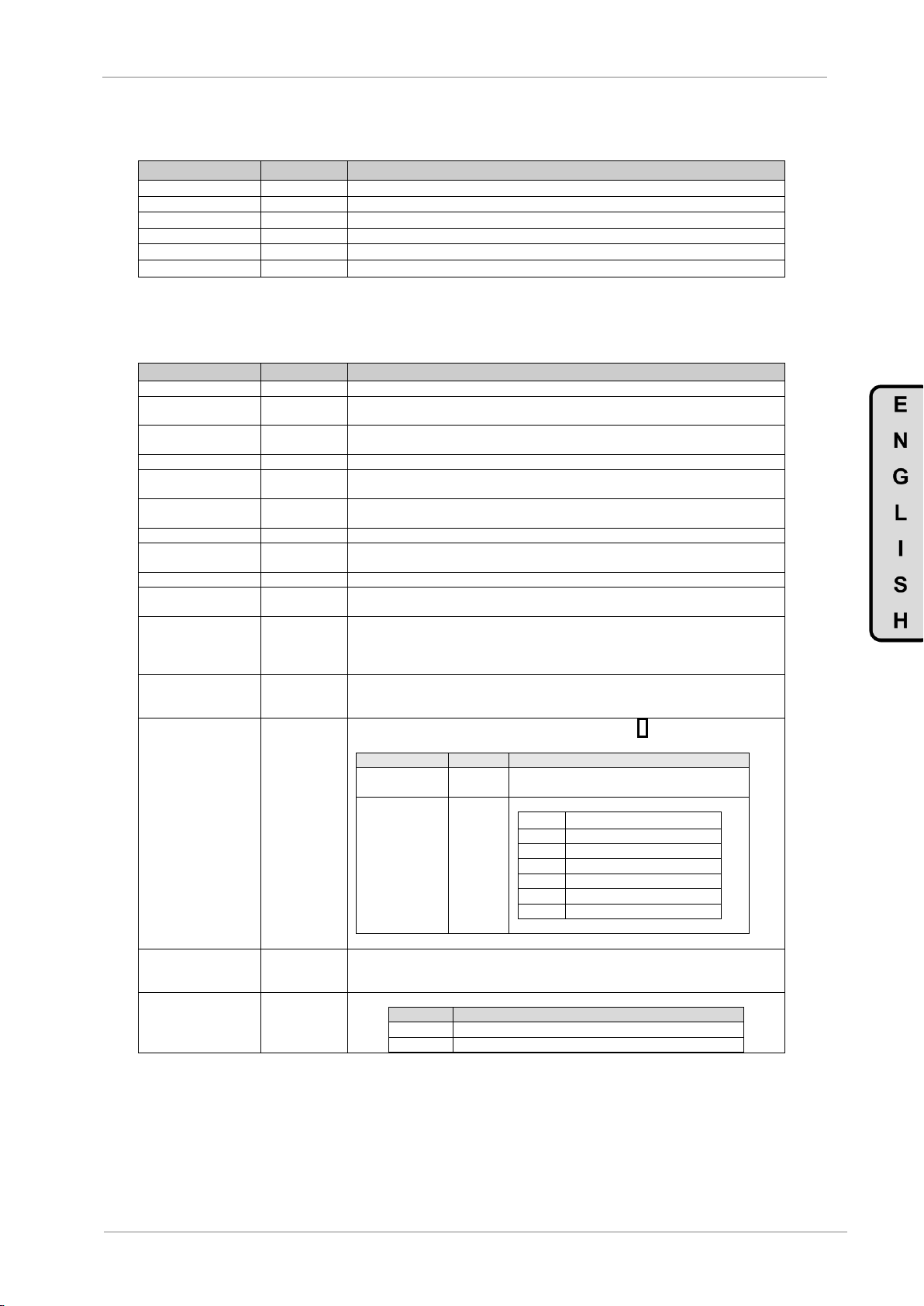

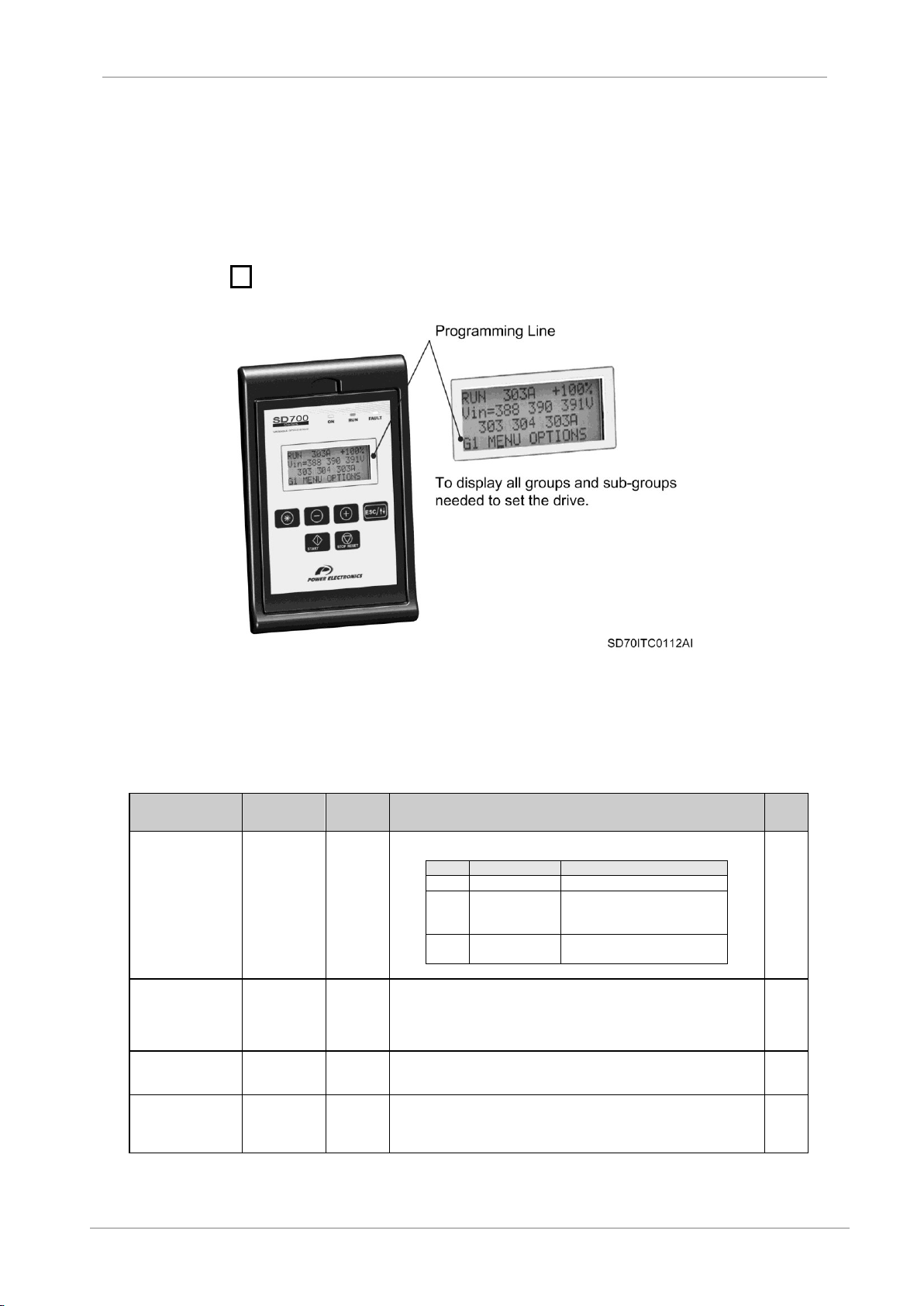

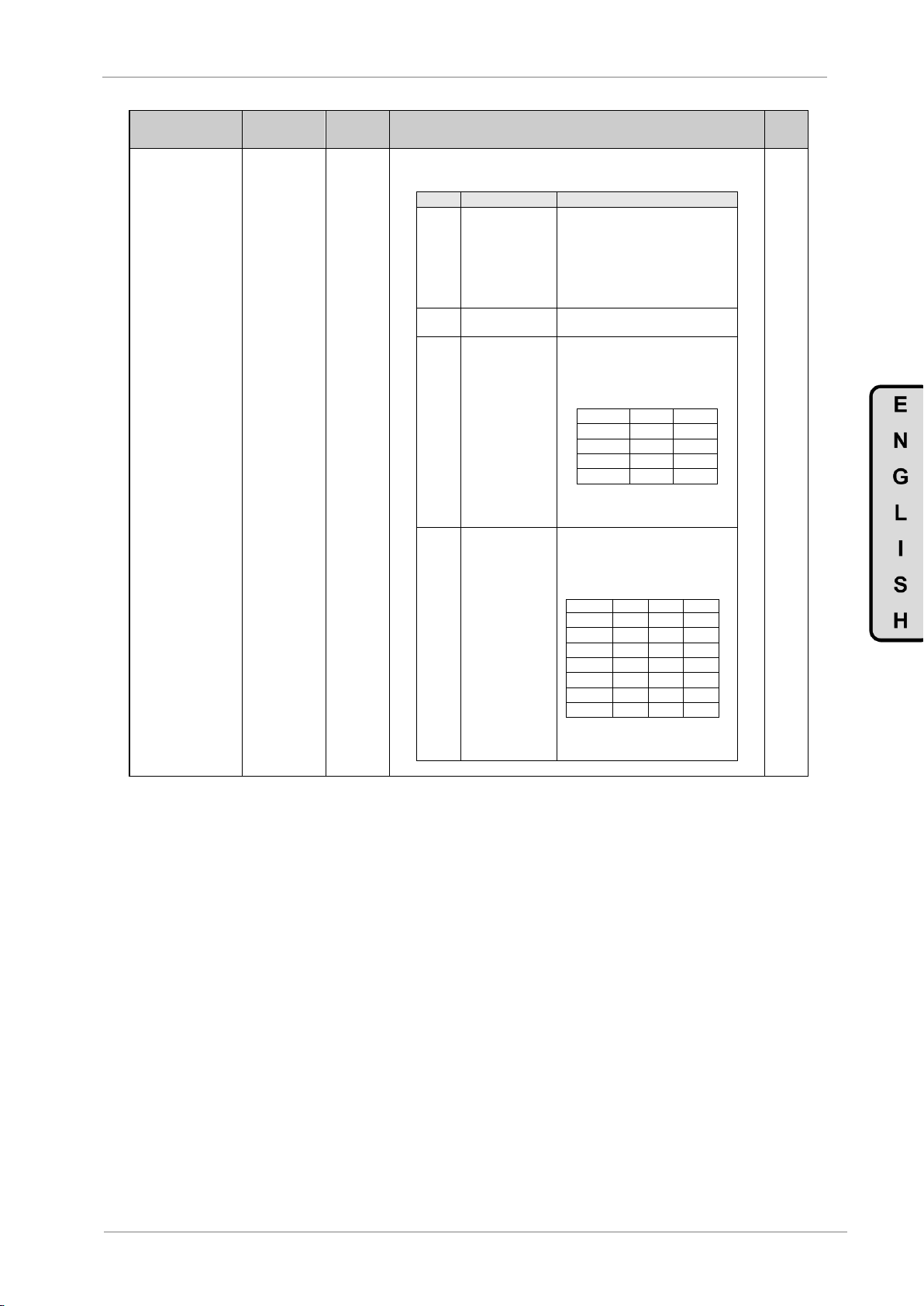

4. DESCRIPTION OF PROGRAMMING

PARAMETERS

The different parameters of the SD700FR are displayed in the alphanumeric LCD. These parameters are

organized in groups (G1, G2, G3, …). To access to the parameters or sub-groups which are in a lower

level, press the

either a numerical value or a list of possible options.

See the information below for the whole parameter list and possible options of configuration.

key. When you have accessed the desired parameter, this parameter will be shown as

Figure 4.1 Detail of Programming Line.

4.1. Group 1 – G1: Options Menu

POWER ELECTRONICS

SD700FR SERIES

DESCRIPTION OF PROGRAMMING PARAMETERS

21

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

5 INITIALISE=0

G1.5 / Parameter

initialize

0 – 5

It allows selection of the parameters that we desire to initialize back to the factory

default value.

OPT.

DESCRIPTION

FUNCTION

0

NO INIT

None of parameters is initialized.

1

USR PRMTR

User parameters are only

initialized.

2

MTR PRMTR

Motor data are only initialized.

3

ALL PRMTR

All parameters of the drive are

initialized.

4

INIT_SOFT

Newly added parameter values

are initialized.

5

INIT_PARTIAL

All parameters of the drive are

initialized except communication

parameters.

NO

6 SHORT Menu=NO

G1.6 / To hide

some

configuration

menus

NO

YES

If it is active, then configuration menus will not be accessible. Only visible G1

OPTIONS MENU, G10 LIMITS, and Display groups.

NO

7 PROG= STANDARD

G1.7 / Program

activation

STANDARD

PUMP

MACRO for

VYSTA

programs

It allows selection additional functionalities. If PUMP is selected, then extended

functionality for pumping control G25 will appear as available.

The group G25 will be hidden if the pump program is not active. Furthermore,

there are not available any configuration options related to pump control included

in other parameters.

Once selected the pump program, a character will appear in the upper line of the

display, beside the drive status, indicating constantly that the pump program is

active. The letter “b” in Spanish and the letter “p” for English / German.

The most of parameters relative to the pump control are located in Group 25,

excepting those setting relatives to inputs and outputs that can be found in groups

G4 and G7.

Additionally there are some visualization screens included in visualization groups

SV.5 and SV.8.

For additional information, see the ‘Pump Application Manual’ for the SD700.

NO

SV 1.8 Visual

The programming line becomes a visualization line.

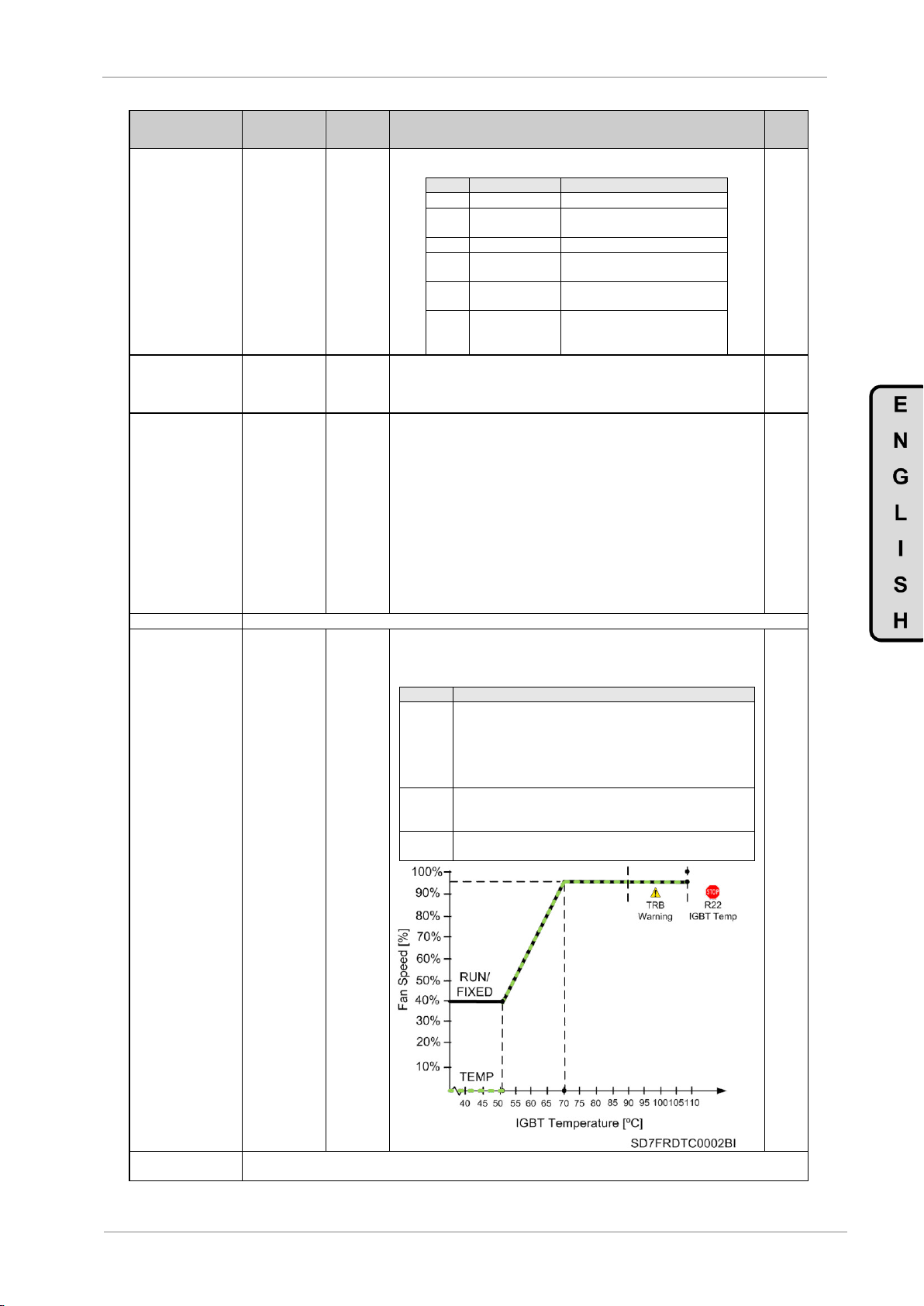

11 FAN CTRL=RUN

G1.11 / Drive fan

control mode

RUN

TEMP

FIXE

It allows selecting the operation mode for drive fans. The SD700FR integrates a

VSD system that varies the cooling flow depending on the IGBT temperature. All

control modes respect the following speed vs temperature curve.

OPTION

FUNCTION

RUN

Start command connect the fans at the minimum speed 40%.

Then fan’s speed will vary depending on the rectifier’s IGBT

temperature. The fans will stop 3 minutes after the rectifier

bridge stopping.

Note: Rectifier bridge stops after the sum of the deceleration

ramp time and the Delay IGBT off time.

TEMP

The fans’ speed depends on the rectifiers IGBT temperature.

The fans will be connected when the temperature is above

51ºC and stopped when the temperature is below 51ºC.

FIXED

Starts the fans following the speed curve even if the equipment

is not running.

YES

14 SER GRP PWD =

OFF

Group reserved for the technical service and qualified personnel of Power Electronics

SD700FR SERIES

POWER ELECTRONICS

22

DESCRIPTION OF PROGRAMMING PARAMETERS

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

UPLOAD=N

G1.10.1 / Saves

the parameters

of the drive to the

display.

N

Y

When adjusting this value to Yes, the copy of parameters to the display starts,

saving the configuration of the drive.

A screen will appear showing the uploading progress:

UPLOADING…100%

When this process is over, the progress screen will automatically return to the

main screen, set by default to No.

Note: In order to carry out the parameter load correctly, the user should firstly

configure the digital inputs concerning ‘STOP’ functions before any other function.

YES

DOWNLOAD=N

G1.10.2 / Saves

the parameters

of the display to

the drive.

N

Y

When adjusting this value to Yes, the copy of parameters stored in the display to

the drive will start modifying and programming the parameters of this new drive.

A screen will appear showing the downloading progress:

DOWNLOADING…100%

When this process is over, the progress screen will automatically change to the

main screen, set by default to No.

Note: When using the Pump Applications. Before downloading parameters from

the display, the parameter [G1.7] must be set as ‘PUMP’.

NO

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

1 MTR CUR=00.00A (*)

MOTOR CURRENT

G2.1 / Motor

rated current

1 – 9999A

It allows setting of the motor rated current according to its nameplate.

NO

2 MTR VOLT=400V

MOTOR VOLTAGE

G2.2 / Motor

rated voltage

220 – 999V

It allows setting of the motor rated voltage according to its nameplate.

YES

3 MTR PWR=00.0Kw

(*)

MOTOR POWER

G2.3 / Motor

rated power

0 – 6500kW

It allows setting of the motor rated power according to its nameplate.

NO

4 MTR RPM=1450

MOTOR SPEED(rpm)

G2.4 / Motor rpm

0 –

24000rpm

It allows setting of the motor rated speed according to its nameplate.

NO

5 MTR PFA=0.84

MTR POWER FACTOR

G2.5 / Cosine

Phi

0 to 0.99

It allows setting of motor cosine Phi according its nameplate.

NO

6 MTR FRQ=50Hz

MOTOR FREQUENCY

G2.6 / Motor

rated frequency

0 – 100Hz

It allows setting of the motor rated frequency according to its nameplate.

NO

7 MTR COOLN=63%

MOTOR COOLING

G2.7 / Motor

cooling at zero

speed

OFF,

5 – 100%

It provides adjustment of sensitive of the motor thermal model based on actual

motor cooling.

The following settings can be taken as reference:

Submersible pumps and non-deflagrating motor 5%

Self-cool motor 63%

Forced-cool motor 100%

Note: If the drive is working at low speeds for a long time and several trips caused

by motor thermal model are produced even though the motor was not hot then this

value can be increased slightly to avoid further tripping.

Note: If it is set to 'OFF', thermal model will be deactivated.

Note: This protection estimates the temperature in the motor. To guarantee the

motor protection, it is recommended to use the motor sensor (PTC).

NO

4.1.1. Subgroup 1.10 – S1.10: Eloader (EEPROM Charger)

4.2. Group 2 – G2: Motor Nameplate Data

This value depends on the drive rated current.

Note: If all of these values are not entered correctly, the SD700FR will not operate correctly. When the motor nameplate

offers multiple configuration possibilities, as in case of the start-delta motor connection, ensure the correct data is

entered for the appropriate configuration.

POWER ELECTRONICS

SD700FR SERIES

DESCRIPTION OF PROGRAMMING PARAMETERS

23

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

1 REF1 SPD=LOCAL

G3.1 / Reference

source 1 of

speed

NONE

AI1

AI2

AI1+AI2

FIB_1

LOCAL

MREF

PMOT

PID

COMMS

FIB_2

It allows selecting the source 1 or 2 for the speed reference.

OPTION

FUNCTION

NONE

Reference source 1 has not been selected.

AI1

Reference will be introduced through the

Analogue Input 1.

AI2

Reference will be introduced through the

Analogue Input 2.

AI1+AI2

Reference will be the sum of the signals

introduced through the Analogue Inputs 1 and 2.

LOCAL

Reference will be given by keypad and will be set

in ‘G3.3'Local Speed Reference'.

MREF

Multi-Reference. Different references activated by

the digital inputs. It will be necessary to configure

the digital inputs. See ‘S4.1 Digital Inputs’.

PMOT

Motorized potentiometer with or without reference

memory.

PID

It will take as reference the value set in the

parameters of the PID function.

COMMS

The reference will be introduced through the

communications.

If the parameter G20.0.1 is set as OFC, the following options are shown too.

OPTION

FUNCTION

FIB_1

The drive speed reference will be the same as the

master current speed

FIB_2

The drive speed reference will be the master motor

current speed (%)

YES

2 REF2 SPD=LOCAL

G3.2 / Reference

source 2 of

speed

YES

3 LOCAL SP=+100%

LOCAL SPEED

G3.3 / Local

Speed

Reference

-250 to

+250%

Allows the user to set the motor speed value if the reference source for speed has

been set to 'LOCAL'.

YES

4 REF1 TQ = LOCAL

G3.4 / Torque

Source reference

1

NONE

AI1

AI2

AI1+AI2

FIB_1

LOCAL

MREF

PID

COMMS

FIB_2

Allows selecting supply 1 or supplying 2 of the torque reference.

OPTION

FUNTION

NONE

The supply reference 1 has not been selected.

AI1

The reference will be introduced through the

analogue input 1.

AI2

The reference will be introduced through the

analogue input 2.

AI1+AI2

The reference will be the addition of the signals

introduced through the Analogue Inputs 1 and 2.

RESER

Reserved

LOCAL

The reference will be introduced through

keyboard and will be adjusted in G3.3 “Local

Speed Reference”.

MREF

Multi-reference. Different activated references by

digital inputs. Digital inputs have to be configured.

See S4.1 Digital Inputs.

PID

Will assume as reference the value adjusted in

the parameters of the PID.

If the parameter G20.0.1 is set as OFC, the following options are shown too.

OPTION

FUNCTION

FIB_1

The drive torque reference will be the same as the

master current speed

FIB_2

The drive torque reference will be the master motor

current torque (%)

YES

5 REF2 TQ = NONE

G3.5 / Torque

supply reference

2

YES

6TQ_LOCAL = +100%

G3.6/ Local

Torque reference

-250 to

+250%

Allows the user to set the torque value of the motor if the torque reference source

has been adjusted to “LOCAL”.

YES

4.3. Group 3 – G3: References

SD700FR SERIES

POWER ELECTRONICS

24

DESCRIPTION OF PROGRAMMING PARAMETERS

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

1 CNTROL MODE1=1

G4.1.1 / Main

Control Mode

0 – 4

It allows user to set the control mode for the drive commands (Start/Stop, Reset,

...).

OPT

DESCRIPTION

FUNCTION

0

NONE

Control mode 1 is not operative.

1

LOCAL

Drive control is done by keypad.

2

REMOTE

Drive controlled through control

terminals.

3

SERIAL COMMS

Drive controlled through

communication bus.

If the parameter G20.0.1 is set as OFC, the following options are shown too:

OPT

DESCRIPTION

FUNCTION

4

FIBER

Drive controlled through optical

fiber

NO

2 CNTROL MODE2=2

G4.1.2 /

Alternative

Control Mode

0 – 4

It allows user to set the secondary control mode for the drive commands

(Start/Stop, Reset, ...).

OPT

DESCRIPTION

FUNCTION

0

NONE

Control mode 2 is not operative.

1

LOCAL

Drive control is done by keypad.

2

REMOTE

Drive controlled through control

terminals.

3

SERIAL COMMS

Drive controlled through

communication bus.

If the parameter G20.0.1 is set as OFC, the following options are shown too:

OPT

DESCRIPTION

FUNCTION

4

FIBER

Drive controlled through optical

fiber

Note: Control mode 2 will be activated through digital inputs exclusively. To use

this set one of the digital inputs to '17 CONTROL 2'. When this input is

activated, auxiliary control mode will be activated.

NO

3 RESET MODE=Y

G4.1.3 / Reset

from keypad

N

Y

It allows user to reset faults from the keypad unit (LOCAL).

OPTION

FUNCTION

N=NO

It is not possible to reset from the keypad unit.

Y=YES

The drive can be reset via the reset button on the

keypad unit.

YES

4.4. Group 4 – G4: Inputs

4.4.1. Subgroup 4.1 – S4.1: Digital Inputs

POWER ELECTRONICS

SD700FR SERIES

DESCRIPTION OF PROGRAMMING PARAMETERS

25

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

4 DIGIT I MODE=1

G4.1.4 /

Selection of

Digital Inputs

configuration

0 – 5

It allows user to configure the digital inputs for different functions. All the options

described below will program to all the digital inputs simultaneously, except for

option '1 All Programmable', which allows to configure their in a separate way.

OPT

DESCRIPTION

FUNCTION

0

3 WIRES

'Start/Stop and Reset' by terminals.

DI1 = 01 Start (NO)

DI2 = 04 Stop 1-Reset (NC)

DI3 = 03 Stop 2-Reset (NC)

DI4 = 15 Reference 2 (NO)

DI5 = 10 Speed Inversion (NO)

DI6 = 17 Control 2 (NO)

1

ALL

PROGRAMMABLE

Inputs configuration individually by

user. See G4.1.5 to G4.1.10.

2

MREF 2 WIRES

Digital inputs 5 and 6 are

programmed as multiple references

(of speed or PID references) for up

to 4 preset speeds. The remaining

inputs are user programmable.

PARM

DI5

DI6

G14.4 0 0

G14.5 0 X

G14.6 X 0

G14.7 X X

Note: It is necessary to set G3.1

REF1 SPD=MREF or G3.2 REF2

SPD=MREF.

3

MREF 3 WIRES

Digital inputs 4, 5 and 6 are

programmed as multiple references

(of speed or PID references) for up

to 7 preset speeds. The remaining

inputs are user programmable.

PARM

DI4

DI5

DI6

G14.1 0 0 X G14.2 0 X

0

G14.3 0 X

X

G14.4 X 0 0 G14.5 X 0

X

G14.6 X X

0

G14.7 X X

X

Note: It is necessary to set G3.1

REF1 SPD=MREF or G3.2 REF2

SPD=MREF.

Note: See following page.

NO

SD700FR SERIES

POWER ELECTRONICS

26

DESCRIPTION OF PROGRAMMING PARAMETERS

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

4 DIGIT I MODE=1

G4.1.4 /

Selection of

Digital Inputs

configuration

0 – 5

Note: Coming from the previous page.

OPT

DESCRIPTION

FUNCTION

4

MOTORIZED

POT

It assigns the up and down

reference function for two of the

digital inputs.

DI5 = Up (NO contact)

DI6 = Down (NC contact)

Reference limits will be the

speed limits set in 'G10 LIMITS'.

Programming a change ramp is

possible at:

G5.7 PMT ACL1=3%/s

G5.8 PMT DCL1=3%/s

G5.9 PMT ACL2=1%/s

G5.10 PMT DCL2=1%/s

G5.11 PMOT BRK=OFF

Note: In this mode, the reference

set by potentiometer will be

memorized even if the motor is

stopped and also in the case of a

power loss.

5

ERASAB POT

It operates in the same way as

option 4, but when the motor is

stopped or a power loss occurs,

the reference will not be

memorized. In this case the

minimum reference value set in

G10.1 or G10.3 will be the

default speed. This will happen

when the limit is above zero, if

the limit is equal or below zero,

the default speed will be zero.

Caution: Digital input configuration changes their settings automatically.

Make sure there is not a hazard due to accidental motor starting that can cause

property damage or personal injury.

NO

Pumps program activation, in G1.7 PROG = PUMP, requires the following considerations:

There is some configuration options available when the pump program is active, which can be set in the same way that

the options available in the standard program.

Nevertheless, when the pump program is active, the drive will assume that only the configurable options from 50 to 75

(for G4.1.5 to G4.1.10) can be set, without taking into consideration the setting on parameter ‘G4.1.4 DIGIT I MODE’,

which means a block setting.

All that means that the user will configure the pump program freely, according to his requirements, selecting the correct

functionality and protections. For a correct programming of the digital inputs when the pump program is active, there is

additional information in ‘Pump Application Manual’, where information about Pump Control (G25) is included.

Note: Selection of the pump program will set all the Digital Inputs to mode ‘00 – un used’. If re-programming is needed,

it will be necessary to configure their functionality in a separate way again. So it guarantees a safety installation

operation, avoiding that hardware external to the equipment can cause any kind of damage.

Note: The digital outputs will also be affected due to pump control activation.

To select one auxiliary pump it is necessary to act in the following way:

o Set any free digital input to options ‘52 FIX PUMP1 FLT’, ‘53 FIX PUMP2 FLT’, ‘54 FIX PUMP3

FLT’, ‘55 FIX PUMP4 FLT’ or ‘56 FIX PUMP5 FLT’

o To enable the control of the pump in the corresponding screen G25.9.1, G25.9.2, G25.9.3, G25.9.4

and G25.9.5 respectively.

To remove this pump configuration and release the relay for another use, the user should:

o Disable the control of the pump in the corresponding screen G25.9.1, G25.9.2, G25.9.3, G25.9.4 or

G25.9.5 respectively.

POWER ELECTRONICS

SD700FR SERIES

DESCRIPTION OF PROGRAMMING PARAMETERS

27

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

5 DIGITL IN 1=06

G4.1.5 / Multi-

function Digital

Input 1

configuration

00 – 75

It allows user to configure the digital inputs for individual use.

OPT

DESCRIPTION

FUNCTION

00

NO USE

Input is disabled.

01

START

‘Start’ command from a normally

open push button (NO). First, It is

necessary to configure another

input as a ‘Stop’ command from a

normally closed contact (NC).

02

STOP1

‘Stop’ command from a normally

closed push button. Stop mode is

adjusted in G7.1 STOP 1. (NC)

03

STOP2-RESET

‘Stop’ command from a normally

closed pushbutton. Stop mode is

adjusted in G7.2 STOP 2. Activation

of the input in this mode also acts

as a ‘Reset’ signal. (NC)

04

STOP1-RESET

‘Stop’ command from a normally

closed pushbutton. Stop mode is

adjusted in G7.1 STOP 1. Activation

of the input in this mode also acts a

‘Reset’ signal. (NC)

05

START/STOP

It allows start when closed and stop

when open (2 wires start / stop).

(NO)

06

STARTRST/STOP

It allows start when closed and stop

when open (2 wires start / stop).

Activation of this input also acts a

fault reset. (NO)

07

RESET

‘Reset’ signal by push button. (NC).

See Note.

08

START +

INCH1

‘Start’ command and inch speed 1

when closed. Inch speed is

programmed in G15.1 INCH1. (NO)

09

START +

INCH2

‘Start’ command and inch speed 2

when closed. Inch speed is

programmed in G15.2 INCH2. (NO)

[1]

.

10

INV SPEED

It causes deceleration of the motor

until motor is stopped, and inverts

the rotation direction. (NO)

[2]

.

11

RESERVE

Reserved for future use.

12

RESERVE

Reserved for future use.

13

INV INCHS

It inverts the fixed speed reference

set in G15.1, G15.2 or G15.3. (NO)

[2]

.

14

ACC/DEC 2

It active acceleration and

deceleration ramps are enabled.

Alternative acceleration and

deceleration rates are programmed

in G5.3 and G5.4. (NO)

15

REFERENCE 2

It allows selection of the alternative

speed reference as programmed in

G3.2. (NO)

16

RESERVE

Reserved for future use.

17

CONTROL 2

It activates the alternative control

mode as programmed in G4.1.2. (NO)

18

START/STP –

RST

Like the option 06, but ‘Reset’ signal

will be activated after the drive is

stopped. (NO)

19

STOP (2)

‘Stop’ command from a normally

closed pushbutton. Stop mode is

adjusted in G7.2 STOP 2. (NC)

20

SPEED LIMIT 2

It will change to the alternative

speed limits as programmed in

G10.3 and G10.4. (NO).

Note: See following page.

NO

6 DIGITL IN 2=00

G4.1.6 / Multi-

function Digital

Input 2

configuration

00 – 75

7 DIGITL IN 3=00

G4.1.7 / Multi-

function Digital

Input 3

configuration

00 – 75

8 DIGITL IN 4=00

G4.1.8 / Multi-

function Digital

Input 4

configuration

00 – 75

9 DIGITL IN 5=00

G4.1.9 / Multi-

function Digital

Input 5

configuration

00 – 75

Note: The user can choose this option independently of the selected program (STANDARD or PUMP) and the used

control mode (LOCAL, REMOTE, SERIAL COMMS).

[1]

If two inputs set to options '08 START + INCH1' and '09 START + INCH2' are activated at the same time the

combination of 'START + INCH3' programmed in G15.3 INCH3 is enabled.

[2]

Rotation inversion in 'G10.11 INVERSION ?=Y' must be enabled.

SD700FR SERIES

POWER ELECTRONICS

28

DESCRIPTION OF PROGRAMMING PARAMETERS

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

10 DIGITL IN6=17

G4.1.10 / Multi-

function Digital

Input 6

configuration

00 – 75

Note: Coming from the previous page.

OPT

DESCRIPTION

FUNCTION

21

DC BRAKE

It activates or deactivates dynamic

brake unit. (NO)

22

START MODE 2

To select the alternative starting

mode (Ramp / Spin) (NO)

23

CURRENT LIMI2

To select the alternative current

limit. (NO)

24

EXTERN EMERGE

To generate the fault ‘F56

EMERGEN.STOP’. (NC). See Note.

25

FREMAQ FLT

It is an emergency stop which

indicates fault in the freemaq filter

(NC). Drive will trip by fault 78 TMP

FREEMAQ.

26

SPEED/TORQUE

(*)

Switchs between speed mode (NO)

and torque mode (NC)

27

STRT/STOP + INV

Start/Stop + rotation reversal. Start

the equipment with this digital input

means starting in the opposite

direction of the reference speed

sign.

28

Dig Ouput FB

(NC) drive works normally, but, in

OPEN state, when the [G8.1.35]

expires, drive will trip by fault 55.

See parameter G8.1.34.

.

40

U.STOP

It stops the drive regardless of

control mode & program selection

configured (NO).

Parameters 70 and 75 available with the pump software.

NO

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

1 SENSOR 1 ?=N

G4.2.1 / To

enable sensor of

Analogue Input 1

N

Y

It allows user to configure analogue input 1 for use with a sensor and activates the

parameters which are necessary to set it up. See G4.2.2 up to G4.2.7.

OPTION

FUNCTION

N=NO

The analogue input will remain scaled in default

units (%).

Y=YES

The analogue input and any variables relating to

the analogue input will be configured in the

engineering units selected in G4.2.2.

NO

2 SENSOR 1=l/s

[3]

G4.2.2 /

Selection of

sensor 1 units

%

l/s

m³/s

l/m

m³/m

l/h

m³/h

m/s

m/m

m/h

Bar

kPa

Psi

m

ºC

ºF

ºK

Hz

rpm

It allows selection of different units of measurement for analogue input 1

according to the sensor that is used.

If this parameter is modified, the minimum and maximum values of the sensor

range must be adjusted to ensure correct configuration. Therefore, the following

set values should be checked:

'G4.2.5 Smi1=+0.0l/s' Minimum range of sensor.

'G4.2.7 Sma1=+10.0l/s' Maximum range of sensor.

NO

3 AIN1 FORMAT=V

G4.2.3 /

Analogue Input 1

format

V

mA

It allows configuration of the analogue input 1 format for either a voltage or current

signal. Set according to the sensor that will be used.

NO

4.4.2. Subgroup 4.2 – S4.2: Analogue Input 1

POWER ELECTRONICS

SD700FR SERIES

DESCRIPTION OF PROGRAMMING PARAMETERS

29

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

4 INmin1=+0V

AIN1 LOW RANGE

G4.2.4 /

Minimum range

of Analogue

Input 1

-10V to G4.2.6

+0mA to

G4.2.6

It determines the minimum voltage or current value for analogue input 1. Set

according to the characteristics of the sensor that will be connected.

YES

5 Smi1=+0.0l/s

[3]

SENS1 LOW RANGE

G4.2.5 /

Minimum range

of sensor 1

-3200 to

G4.2.7

Engineering

units

It sets the minimum units value of the sensor connected to analogue input 1. This

value should also correspond to the minimum voltage or current level of the

sensor set in 'G4.2.4 INmin1'.

Note: This value should be checked if the units are changed in 'G4.2.2 SENSOR

1'. It will be set to operate in open loop and close loop.

YES

6 INmax1=+10V

AIN1 HIGH RANGE

G4.2.6 /

Maximum range

of Analogue

Input 1

G4.2.4 to

+10V

G4.2.4 to

+20mA

It determines the maximum voltage or current value for analogue input 1. Set

according to the characteristics of the sensor that will be connected.

YES

7 Sma1=+10.0l/s

[3]

SENS1 HIGH RANGE

G4.2.7 /

Maximum range

of sensor 1

G4.2.5 to

+3200

Engineering

units

It sets the maximum units value of the sensor connected to analogue input 1. This

value should also correspond to the maximum voltage or current level of the

sensor set in 'G4.2.6 INmax1'.

Note: This value should be checked if the units are changed in 'G4.2.2 SENSOR

1'. For this, it is necessary to set this value in open loop and close loop

configurations.

YES

8 SPD LO1=+0%

SPD LO RNG AIN1

G4.2.8 / Speed

for the

minimum range

of Analogue

Input 1

-250% to

G4.2.9

It allows scaling of the speed reference to correspond with the minimum range of

the analogue input 1 as set in 'G4.2.4 INmin1'.

The value is a percentage of the motor rated speed.

YES

9 SPD HI1=+100%

SPD HIG RNG AIN1

G4.2.9 / Speed

for the

maximum range

Analogue Input

1

G4.2.8 to

+250%

It allows scaling of the speed reference to correspond with the maximum range of

the analogue input 1 as set in 'G4.2.6 INmax1'.

The value is a percentage of the motor rated speed.

YES

14 AIN1 LOSS=N

G4.2.14 /

Protection for

Analogue Input

1 loss

N

Y

To set the drive stop mode when a loss of the analogue input 1 signal occurs.

OPTION

FUNCTION

N=NO

Function disabled.

Y=YES

When the analogue input level decreases down

to zero value, sensor will be considered damaged

and the drive will stop generating a fault 'F42

AIN1 LOSS'.

YES

15 1_Z BAND=OFF

AIN1 ZERO BAND

G4.2.15 / Zero

band filter for

Analogue Input

1

OFF = 0.0,

0.1 to 2.0%

Filtering of analogue input 1 signal. Setting this value we can filter analogue input

1 to avoid possible electrical noise preventing the analogue reading a zero value.

YES

16 FILTER1=OFF

AIN1 STABIL FILT

G4.2.16 / Low

Pass filter for

Analogue Input

1

OFF = 0.0,

0.1 to 20.0%

It allows filtering the Analogue Input 1 signal. Setting the value of this time

constant we can eliminate possible instabilities in the value of the same ones due

to noise, wiring faults, etc.

Note: When applying a Low Pass filter to any analogue signal, a delay time in the

own signal is generated. This delay time is the value of the configured time

constant approximately.

YES

Note: The user can choose this option independently of the selected program (STÁNDARD or PUMP) or the control

mode used (LOCAL, REMOTE, and SERIAL COMMS).

[3]

Available only when 'G4.2.1 SENSOR 1 = Y'.

SD700FR SERIES

POWER ELECTRONICS

30

DESCRIPTION OF PROGRAMMING PARAMETERS

Parameter /

Default Value

Name /

Description

Range

Function

Set on

RUN

1 SENSOR 2 ?=N

G4.3.1 / Sensor

of Analogue

Input 2 enable

N

Y

It allows user to configure analogue input 2 for use with a sensor and activates the

parameters which are necessary to set it up. See G4.3.2 up to G4.3.7.

OPTION

FUNCTION

N=NO

The analogue input will remained scaled in

defaults units (%).

Y=YES

The analogue input and any variables relating to

the analogue input will be configured in the

engineering units selected in G4.3.2.

NO

2 SENSOR 2=Bar

[4]

G4.3.2 /

Selection of

sensor 2 units

%

l/s

m³/s

l/m

m³/m

l/h

m³/h

m/s

m/m

m/h

Bar

kPa

Psi

m

ºC

ºF

ºK

Hz

rpm

It allows selection of different units of measurement for the analogue input 2

according to the sensor that is used.

If this parameter is modified, the minimum and maximum values of the sensor

range must be adjusted to ensure correct configuration. Therefore, the following

set values should be checked:

'G4.3.5 Smi2=+0.0Bar' Minimum range of sensor.

'G4.3.7 Sma2=+10.0Bar' Maximum range of sensor.

NO

3 AIN2 FORMAT=mA

G4.3.3 /

Analogue Input

2 format

V

mA

It allows configuration of the analogue input 2 format for either a voltage or current

signal. Set according to the sensor that will be used.

NO

4 INmin2=+4mA

AIN2 LOW RANGE

G4.3.4 /

Minimum range

of Analogue

Input 2

-10V to

G4.3.6

+0mA to

G4.3.6

It determines the minimum voltage or current value for analogue input 2. Set

according to the characteristics of the sensor that will be connected.

YES

5 Smi2=+0.0Bar[4]

SENS2 LOW RANGE

G4.3.5 /

Minimum range

of sensor 2

-3200 to

G4.3.7

Engineering

units

It sets the minimum units value of the sensor connected to the analogue input 2.

This value should also correspond to the minimum voltage or current level of the

sensor set in 'G4.3.4 INmin2'.

Note: This value should be checked if the units are changed in 'G4.3.2 SENSOR

2'. It will be set to operate in open loop and close loop.

YES

6 INmax2=+20mA

AIN2 HIGH RANGE

G4.3.6 /

Maximum range

of Analogue

Input 2

G4.3.4 to

+10V

G4.3.4 to

+20mA

It determines the maximum voltage or current value for the analogue input 2. Set

according to the characteristics of the sensor that will be connected.

YES

7 Sma2=+10.0Bar

[4]

SENS2 HIGH RANGE

G4.3.7 /

Maximum range

of sensor 2

G4.3.5 to

+3200

Engineering

units

It sets the maximum units value of the sensor connected to the analogue input 2.

This value should also correspond to the maximum voltage or current level of the