EVERLIGHT ELECTRONICS CO.,LTD.

Technical Data Sheet

Infrared Remote-control Receiver Module

Features

‧High shielding against electric field disturbance.

‧Circular lens to improve the receive characteristic.

‧Line-up for various center carrier frequencies.

‧Low voltage and low power consumption.

‧High immunity against ambient light.

‧Photodiode with integrated circuit.

‧TTL and CMOS compatibility.

‧Top-received SMD.

‧Suitable burst length ≧

‧This product itself will remain within RoHS compliant version.

‧Pb free.

‧ External dimensions 5.3(L)*2.9(W)*3.65(H)mm.

10 pulses/burst.

Descriptions

The device is a miniature SMD type infrared remote

control system receiver that has been developed and

designed by utilizing the most updated IC technology. The

PIN diode and preamplifier are assembled on PCB, the

epoxy package is designed as an IR filter. The demodulated

output signal can directly be decoded by a microprocessor.

Applications

1. Light detecting portion of remote control

․AV instruments such as Audio, TV, VCR, CD, MD, etc.

․Home appliances such as Air-conditioner, Fan , etc.

․The other equipments with wireless remote control.

․CATV set top boxes

․Multi-media Equipment

Device Selection Guide

IRM-H538/TR2

PART MATERIAL COLOR

Chip Silicon ---

Package Epoxy Black

Metal case SPCC Silver white

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 1 Page: 1 of 12

Device No

:

DMO-538-400 Prepared date:11-24-2006 Prepared by:Cindy Lin

EVERLIGHT ELECTRONICS CO.,LTD.

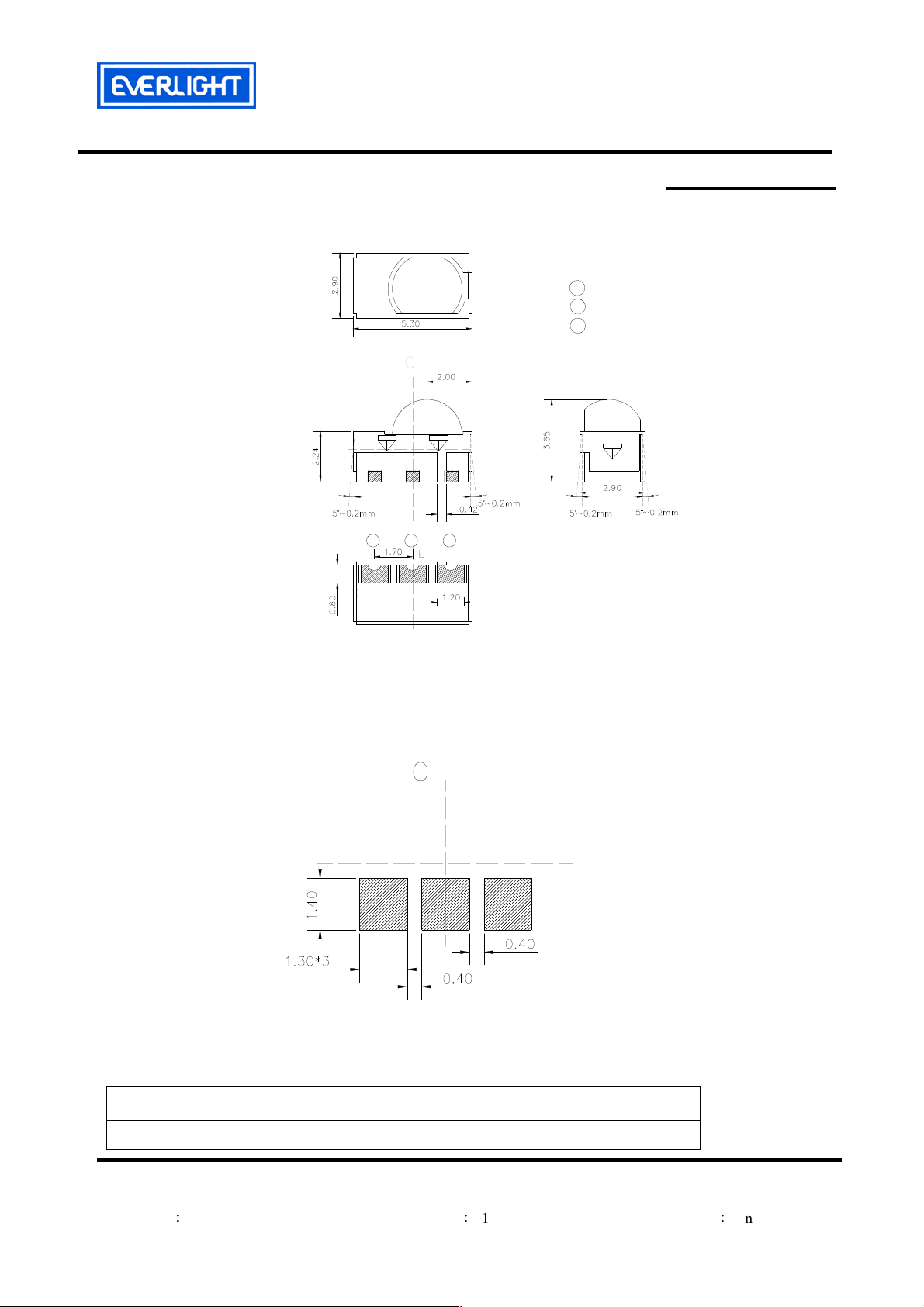

Package Dimensions

Notes::::1.All dimensions are in millimeters.

1

IRM-H538/TR2

Pin Function

1 :V

out

2 :V

cc

3 :GND

3

2

2.Tolerances unless dimensions ±0.2mm.

Soldering patterns

The following soldering patterns are recommended for reflow-soldering :

Unit: mm

Available Types For Different Carrier Frequencies

Type Carrier Frequencies (Typ)

IRM-H538/TR2 38 kHz

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 1 Page: 2 of 12

Device No

:

DMO-538-400 Prepared date:11-24-2006 Prepared by:Cindy Lin

EVERLIGHT ELECTRONICS CO.,LTD.

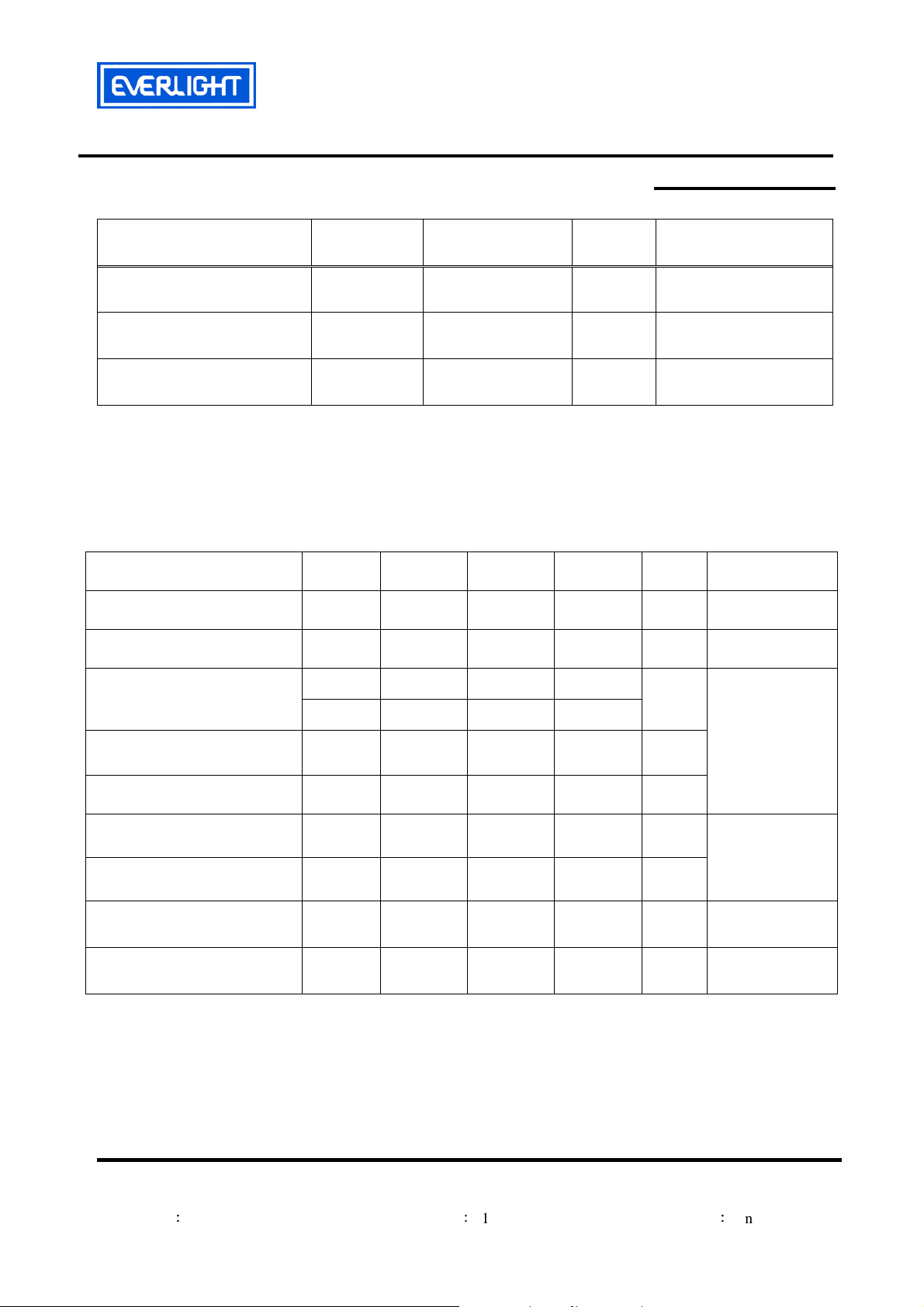

Absolute Maximum Ratings (Ta=25℃℃℃℃)

Parameter Symbol Rating Unit

Supply Voltage Vcc

Operating Temperature Topr

Storage Temperature Tstg

0~6

-25 ~ +85

-40 ~ +85

V

℃

℃

Recommended Operating Condition

Supply Voltage Rating: Vcc 2.7V to 5.5V

Electro-Optical Characteristics (Ta=25℃℃℃℃, and Vcc=3.0V)

Parameter Symbol

Supply Current Icc

MIN. TYP. MAX. Unit

--- --- 1.2

IRM-H538/TR2

Notice

Condition

mA No signal input

Peak Wavelength

Reception Distance

Half Angle(Horizontal)

Half Angle(Vertical)

High Level Pulse Width TH

Low Level Pulse Width TL

High Level Output Voltage

Low Level Output Voltage

Notes:

*1:The ray receiving surface at a vertex and relation to the ray axis in the range of θ= 0° and θ=45°.

*2:A range from 30cm to the arrival distance. Average value of 50 pulses.

λp

L0

L45

Θh

Θv

VH

VL

--- 940 ---

8 --- ---

5 --- ---

--- 45 ---

--- 45 ---

400 --- 800

400 --- 800

2.7 --- ---

--- 0.2 0.5

nm

m

deg

deg

μs

μs

V

V

At the ray axis

*1

At the ray axis

*2

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 1 Page: 3 of 12

Device No

:

DMO-538-400 Prepared date:11-24-2006 Prepared by:Cindy Lin

EVERLIGHT ELECTRONICS CO.,LTD.

IRM-H538/TR2

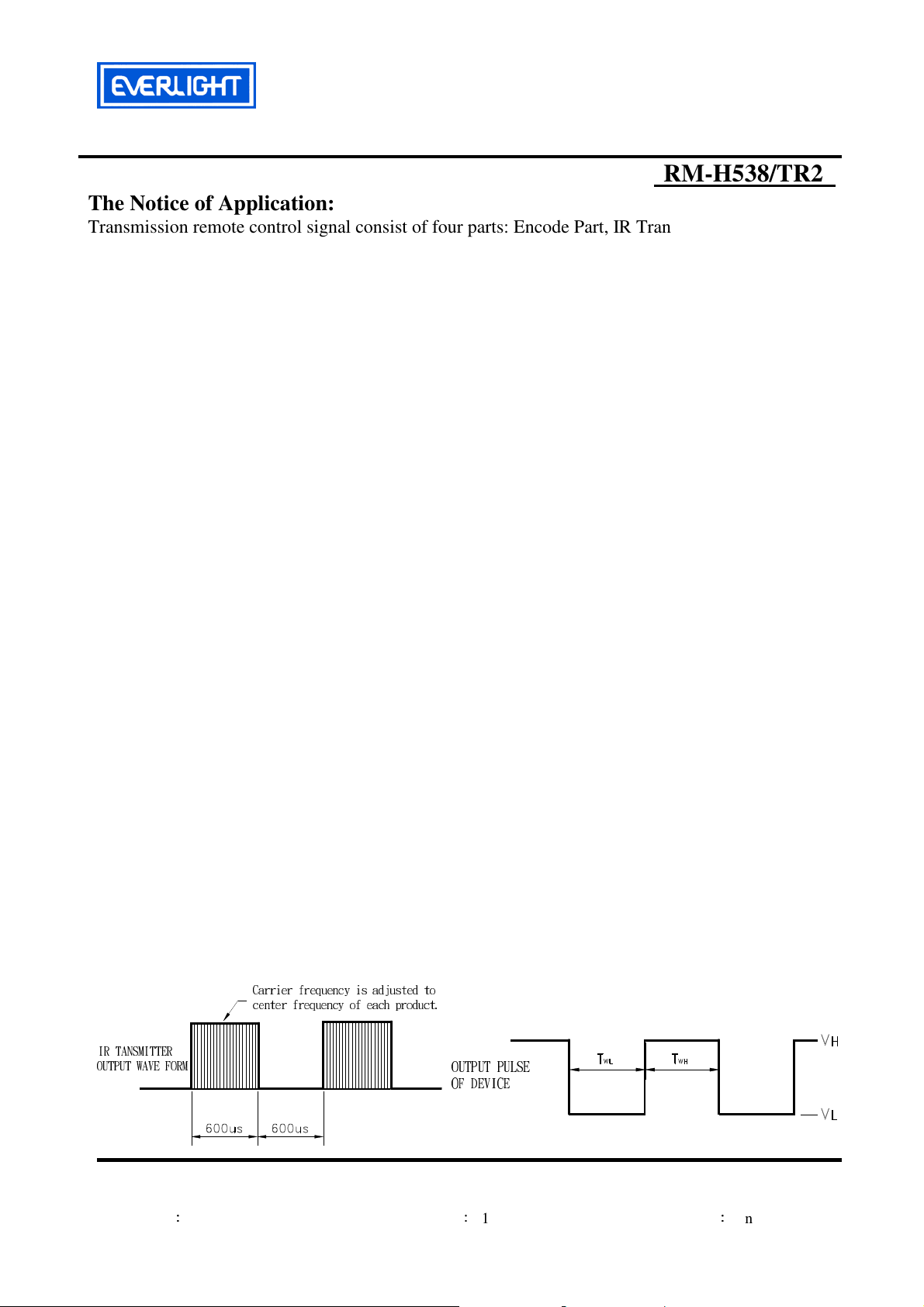

The Notice of Application:

Transmission remote control signal consist of four parts: Encode Part, IR Transmitter Source, IRM

device, Decode Part

1. When IRM-H538 code select frequency, it need to well understand the center system of

encode part.

2. Strong or weak light of IR Transmitter can affect distance of transmission.

3. Minimum Burst Length T

4. It needs to ensure the translation range of decode part if it is applied to the pulse-width range.

If the above items hardly assure of its application, it’ll cause NG(no good) message from the edge of

signal.

Test Method::::

The specified electro-optical characteristics is satisfied under the following

Conditions at the controllable distance.

Measurement place

A place that is nothing of extreme light reflected in the room.

External light

Project the light of ordinary white fluorescent lamps which are not high

Frequency lamps and must be less then 10 Lux at the module surface.

(Ee≦10Lux)

Standard transmitter

A transmitter whose output is so adjusted as to Vo=400mVp-p and the output

Wave form shown in Fig.-1.According to the measurement method shown in

Fig.-2 the standard transmitter is specified.

However , the infrared photodiode to be used for the transmitter should be

λp=940nm,∆λ=50nm. Also, photodiode is used of PD438B(Vr=5V).

(Standard light / Light source temperature 2856°K).

Measuring system

According to the measuring system shown in Fig.-3

Fig.-1 Transmitter Wave Form D.U.T output Pulse

IR TANSMITTER

OUTPUT WAVE FORM

Carrier frequency is adjusted to

center frequency of each product.

burst

(number of pulses per burst) : 10 cycles

OUTPUT PULSE

OF DEVICE

Duty=0.5

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 1 Page: 4 of 12

Device No

:

DMO-538-400 Prepared date:11-24-2006 Prepared by:Cindy Lin

EVERLIGHT ELECTRONICS CO.,LTD.

IRM-H538/TR2

Fig.-2 Measuring Method Fig.-3 Measuring System

Standard Transmitter

Block Diagram:

20cm

10k

+5.0± 0.1V

10uF

k

0

0

1

Oscilloscope

Vout

Standard Transmitter

Vs

Input CGA & filter Demodulator

L: Transmission Distance

θ

θ

D.U.T

θ: Angle Of Horizontal & Vertical Direction

OUT

GND

OUT IN

Vcc

Vout

µC

Oscillator AGC/ATC & digital control

Carrier frequency f0

Modulated IR signal

min 10 pulses

GND

Application Circuit:

RC Filter should be connected closely between Vcc pin and GND pin.

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 1 Page: 5 of 12

Device No

:

DMO-538-400 Prepared date:11-24-2006 Prepared by:Cindy Lin

EVERLIGHT ELECTRONICS CO.,LTD.

Typical Electro-Optical Characteristics Curves

Fig.-4 Relative Spectral Sensitivity vs.

Wavelength

Fig.-5 Relative Transmission Distance vs.

Direction

IRM-H538/TR2

θ

Fig.-6 Output Pulse Length vs. Arrival Distance Fig.-7 Arrival Distance vs. Supply Voltage

µ

10

8

6

4

2

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 1 Page: 6 of 12

Device No

:

DMO-538-400 Prepared date:11-24-2006 Prepared by:Cindy Lin

EVERLIGHT ELECTRONICS CO.,LTD.

IRM-H538/TR2

Typical Electro-Optical Characteristics Curves

Fig.-8 Relative Transmission Distance

vs. Center Carrier Frequency

Fig.-9 Arrival Distance vs. Ambient Temperature

8

6

4

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 1 Page: 7 of 12

Device No

:

DMO-538-400 Prepared date:11-24-2006 Prepared by:Cindy Lin

EVERLIGHT ELECTRONICS CO.,LTD.

1000hrs

IRM-H538/TR2

Reliability Test Item And Condition

The reliability of products shall be satisfied with items listed below.

Confidence level:90%

LTPD:10%

Reflow Terms: JEDEC Level 4 Specification

Drying; Temp.:125℃ 24hrs Moisture 30℃ / 60% RH 96hrs Reflow Temp.: 260℃±5℃

10sec, 3 times

Note:

1. Not sooner than 15 minutes and not longer than 4 hours after removal from the

temperature/humidity chamber.

2. The time between reflow shall be 5 minutes minimum and 60 minutes maximum.

Test Items Test Conditions

Failure Judgement

Criteria

Samples(n)

Defective(c)

Temperature cycle

High temperature test

Low temperature

storage

High temperature

High humidity

1 cycle:-25℃ +85℃

(30min)(5min)(30min)

300 cycle test

Temp:+85℃

Vcc:5V

Temp:-40℃

1000hrs

Ta:85℃,RH:85%

1000hrs

L0≦ L×0.8

L45≦ L×0.8

L: Lower

specification limit

*Icc : Operate

Current (mA)

Variation≦±20%:

n=76,c=0

n=76,c=0

n=76,c=0

n=76,c=0

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 1 Page: 8 of 12

Device No

:

DMO-538-400 Prepared date:11-24-2006 Prepared by:Cindy Lin

EVERLIGHT ELECTRONICS CO.,LTD.

IRM-H538/TR2

Recommended method of storage

Dry box storage is recommended as soon as the aluminum bag has been opened prevent

moisture absorption. The following conditions should be observed, if dry boxes are not available:

Storage temperature 10℃ to 30℃

Storage humidity ≦60%RH max.

After more than 72 hours under these conditions moisture content will be too high for

Reflow soldering:

In case of moisture absorption, the devices will recover to former condition by drying

under the following condition:

192 hours at 40℃+5℃/-0℃ and 5%RH (dry air / nitrogen) or

96 hours at 60℃+5℃ and < 5%RH for all device containers or

24 hours at 125℃+5℃ not suitable for reel or tubes.

ESD Precaution

Proper storage and handing procedures should be followed to prevent ESD damage to

the devices especially when they are removed from the Anti-static bag. Electro-Static Sensitive

Devices warning labels are on the packing.

Recommended Solder Profile

1~5°C/sec

60sec. Max.

Above. 220°C

1~5°C/sec.

Pre-heating

180~200°C

120sec.Max.

Notice:

(1) Reflow soldering should not be done more than two times.

(2) When soldering, do not put stress on the IRM-H538/TR1 Series devices during heating.

(3) After soldering, do not warp the circuit board.

260°C Max.

10sec Max.

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 1 Page: 9 of 12

Device No

:

DMO-538-400 Prepared date:11-24-2006 Prepared by:Cindy Lin

EVERLIGHT ELECTRONICS CO.,LTD.

IRM-H538/TR2

Soldering Iron

seconds within once in less than the soldering iron capacity 25W. Leave two seconds and more

intervals, and do soldering of each terminal. Be careful because the damage of the product is often

started at the time of the hand solder.

Repairing

Repair should not be done after the Devices have been soldered. When repairing is

unavoidable, a double-head soldering iron should be used (as below figure). It should be confirmed

beforehand whether the characteristics of the Devices will or will not be damaged by repairing.

Each terminal is to go to the tip of soldering iron temperature less than 350℃ for 3

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 1 Page: 10 of 12

Device No

:

DMO-538-400 Prepared date:11-24-2006 Prepared by:Cindy Lin

EVERLIGHT ELECTRONICS CO.,LTD.

IRM-H538/TR2

Packing Quantity Specification

1. 2000 PCS/1 Reel

2. 5 Reel /1Carton

Carrier Tape Dimensions: Loaded quantity 2000 PCS per reel

Progressive Direction

Cover Trap

Packing process

Bar Code Label

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 1 Page: 11 of 12

Device No

:

DMO-538-400 Prepared date:11-24-2006 Prepared by:Cindy Lin

EVERLIGHT ELECTRONICS CO.,LTD.

IRM-H538/TR2

Label Form Specification

CPN: Customer’s Production Number

P/N : Production Number

QTY: Packing Quantity

CAT: None

HUE: None

REF: Reference

LOT No: Lot Number

MADE IN TAIWAN: Production Place

Notes

1. Above specification may be changed without notice. EVERLIGHT will reserve authority on

material change for above specification.

2. When using this product, please observe the absolute maximum ratings and the instructions

for using outlined in these specification sheets. EVERLIGHT assumes no responsibility for

any damage resulting from use of the product which does not comply with the absolute

maximum ratings and the instructions included in these specification sheets.

3. These specification sheets include materials protected under copyright of EVERLIGHT

corporation. Please don’t reproduce or cause anyone to reproduce them without

EVERLIGHT’s consent.

EVERLIGHT ELECTRONICS CO., LTD. Tel: 886-2-2267-2000, 2267-9936

Office: No 25, Lane 76, Sec 3, Chung Yang Rd, Fax: 886-2267-6244, 2267-6189, 2267-6306

Tucheng, Taipei 236, Taiwan, R.O.C http:\\www.everlight.com

Everlight Electronics Co., Ltd. http:\\www.everlight.com Rev 1 Page: 12 of 12

Device No

:

DMO-538-400 Prepared date:11-24-2006 Prepared by:Cindy Lin

Loading...

Loading...