Page 1

EVERLIGHT ELECTRONICS CO.,LTD.

Technical Data Sheet

High Power LED – 1W

Features

z Feature of the device: small package with high efficiency

z View angle: 130°.

z High light flux output: more than 34lm@350mA.

z ESD protection.

z Soldering methods: Hot bar soldering

z Grouping parameter: total luminous flux, dominant

wavelength.

z Optical efficiency: 38 lm/W.

z Thermal resistance (junction to lead): 15 K/W.

z The product itself will remain within RoHS compliant

version.

Applications

z TFT LCD display backlight

z Decorative and entertainment illumination

z Signal and symbol luminaries for orientation marker

lights (e.g. steps, exit ways, etc.)

z Exterior and interior automotive illumination

EHP-A08L/SUR01-P01

Materials

Items Description

Housing black body Heat resistant polymer

Encapsulating Resin Silicone resin

Lens Heat resistant clear polymer

Electrodes Ag plating copper alloy

Die attach Silver paste

Chip AlGaInP

Everlight Electronics Co., Ltd. http://www.everlight.com Rev. 3.0 Page: 1 of 11

Device No. :

DSE-8L1-002 Prepared date: Nov 17, 2006 Prepared by: Anita Chen

Page 2

Dimensions

EVERLIGHT ELECTRONICS CO.,LTD.

EHP-A08L/SUR01-P01

Notes: 1. Dimensions are in millimeters

2. Tolerances unless dimensions ±0.25mm

Everlight Electronics Co., Ltd. http://www.everlight.com Rev. 3.0 Page: 2 of 11

Device No. : DSE-8L1-002 Prepared date: Nov 17, 2006 Prepared by: Anita Chen

Page 3

EVERLIGHT ELECTRONICS CO.,LTD.

EHP-A08L/SUR01-P01

Maximum Ratings (T

Ambient

=25ºC)

Parameter Symbol Rating Unit

Operating Temperature

Storage Temperature

Junction temperature

Forward Current

Power Dissipation

Junction to heat-sink thermal resistance

T

opr

T

stg

T

j

I

F

P

d

R

th

-40 ~ +100 ºC

-40 ~ +100 ºC

125 ºC

500 mA

1.5 W

15 K/W

Electro-Optical Characteristics (T

Parameter Bin Symbol Min Typ. Max Unit Condition

J1 23 ---- 27

Luminous Flux

(1)

J2 27 ---- 33

Ф

Ambient

v

=25ºC)

lm

Viewing Angle

(2)

J3

----

2θ

1/2

33 ---- 39

---- 130 ---- deg

U2 2.05 ---- 2.35

Forward Voltage

(3)

U3 2.35 ---- 2.65

U4

V

F

2.65 ---- 2.95

R3 610 ---- 615

R4 615 ---- 620

Wavelength

(4)

R5 620 ---- 625

R6

Note. 1. Luminous flux measurement tolerance : ±10%

2. 2θ

3. Forward Voltage measurement tolerance : ±0.1V

4. Wavelength measurement tolerance : ±1nm

is the off axis angle from lamp centerline where the luminous intensity is 1/2 of the peak value.

1/2

λ

d

625 ---- 630

V

nm

=350mA

I

F

Everlight Electronics Co., Ltd. http://www.everlight.com Rev. 3.0 Page: 3 of 11

Device No. : DSE-8L1-002 Prepared date: Nov 17, 2006 Prepared by: Anita Chen

Page 4

EVERLIGHT ELECTRONICS CO.,LTD.

A

A

r

Typical Electro-Optical Characteristics Curves

EHP-A08L/SUR01-P01

1.0

Relative Spectral Distribution,

=350mA, T

I

F

Ambient

=25ºC

0.8

0.6

0.4

0.2

Relative Luminous Intensity (%)

0.0

500 600 700 800

1.6

1.4

1.2

1.0

0.8

0.6

Relative Luminous Intensity vs Forward

Current, T

mbient

=25ºC

0.4

Relative Luminous Intensity

0.2

0.0

0 50 100 150 200 250 300 350 400 450 500 550

Forward Current (mA)

Forward Voltage vs Forward Current,

mbient

=25ºC

Forward Current (mA)Wavelength (nm)

T

2.5

2.4

2.3

2.2

2.1

2.0

Forward Voltage (Volt)

1.9

1.8

0 100 200 300 400 500

Forward Current Derating Curve,

ating based on T

De

400

350

300

250

200

JMAX

=125°C

Forward Current (mA)

150

100

020406080100

Ambient Temperature (οC)

Everlight Electronics Co., Ltd. http://www.everlight.com Rev. 3.0 Page: 4 of 11

Device No. : DSE-8L1-002 Prepared date: Nov 17, 2006 Prepared by: Anita Chen

Page 5

EVERLIGHT ELECTRONICS CO.,LTD.

Typical Representative Spatial Radiation Pattern

EHP-A08L/SUR01-P01

Everlight Electronics Co., Ltd. http://www.everlight.com Rev. 3.0 Page: 5 of 11

Device No. : DSE-8L1-002 Prepared date: Nov 17, 2006 Prepared by: Anita Chen

Page 6

EVERLIGHT ELECTRONICS CO.,LTD.

EHP-A08L/SUR01-P01

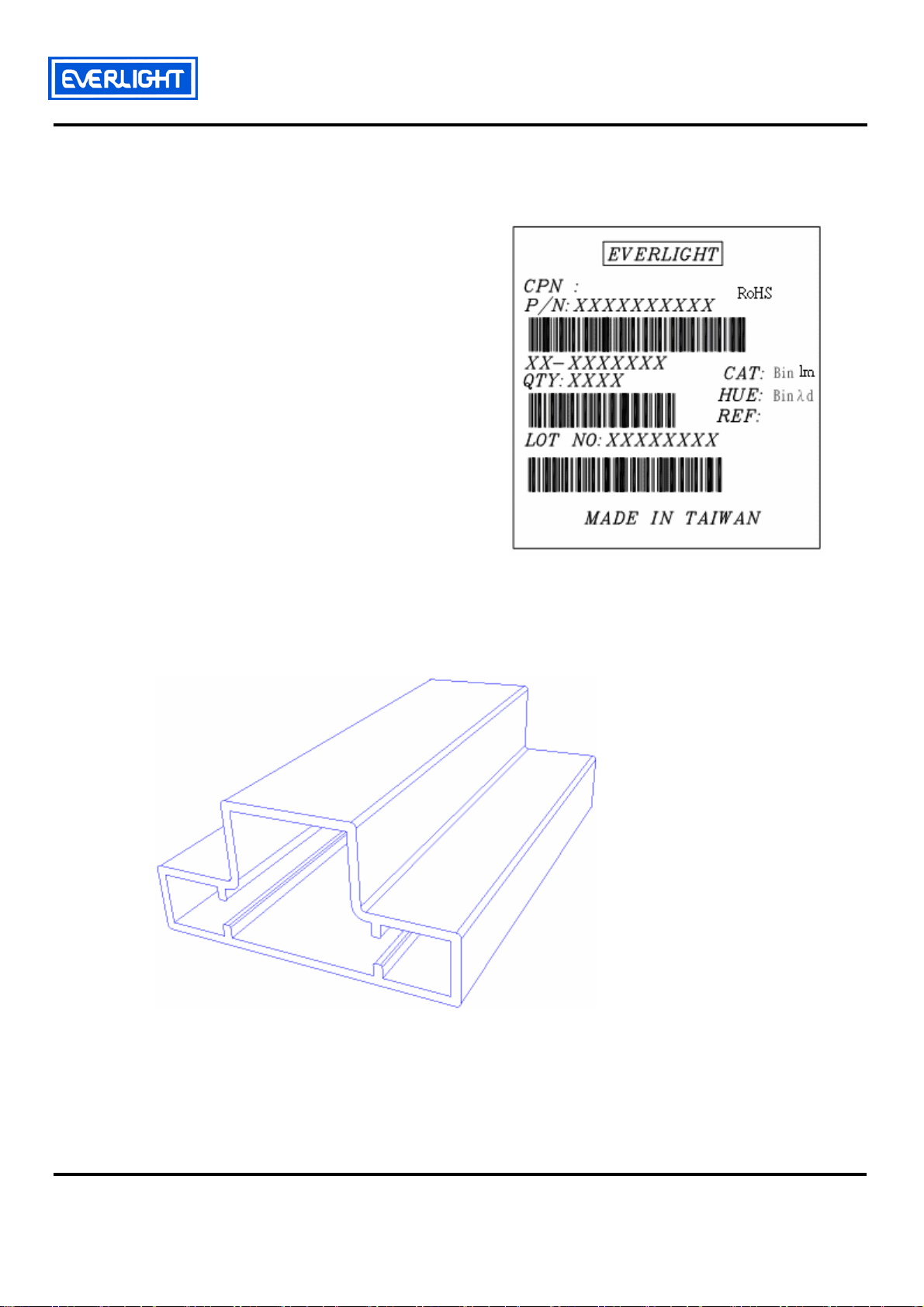

Label explanation

CPN: Customer’s Production Number

P/N : Production Number

QTY: Packing Quantity

CAT: Ranks

HUE: Peak Wavelength

REF: Reference

LOT No: Lot Number

MADE IN TAIWAN: Production Place

Tube Packing Specifications

1. Tube

Everlight Electronics Co., Ltd. http://www.everlight.com Rev. 3.0 Page: 6 of 11

Device No. : DSE-8L1-002 Prepared date: Nov 17, 2006 Prepared by: Anita Chen

Page 7

2. Inner Carton

3. Outside Carton

EVERLIGHT ELECTRONICS CO.,LTD.

EHP-A08L/SUR01-P01

z Packing Quanity

1. 60 Pcs / Per Tube

2. 20 Tubes / Inner Carton

3. 12 Inner Cartons / Outside Carton

Everlight Electronics Co., Ltd. http://www.everlight.com Rev. 3.0 Page: 7 of 11

Device No. : DSE-8L1-002 Prepared date: Nov 17, 2006 Prepared by: Anita Chen

Page 8

EVERLIGHT ELECTRONICS CO.,LTD.

EHP-A08L/SUR01-P01

Reliability Test Items and Results

Stress Test Stress Condition Stress Duration

Solderability

Resistance to Solder Heat

Thermal Shock

Temperature Cycle

High Temperature/Humidity

Reverse Bias

High Temperature/Humidity

Operation

High Temperature Storage Ta=110℃ 1000hours

Low Temperature Storage Ta=-40℃ 1000hours

Intermittent operational Life

Ta=85℃ , RH=60%, IF=225mA

Tsol=230℃, 5sec

Tsol=260℃, 10sec, 6min

H:+110℃ 20min.

'∫ 10sec.

'L:- 40℃ 20min.

H:+100℃ 30min.

'∫ 5min.

'L:- 40℃ 30min.

Ta=85℃ , RH=85%

Ta=25℃, IF=1000mA

30mS on/ 2500mS off

1 times

3 times

500 Cycles

1000 Cycles

1000hours

1000hours

1000hours

High Temperature Operation

Life #1

High Temperature Operation

Life #2

High Temperature Operation

Life #3

Low Temperature Operation

Life

Power Temperature Cycle

ESD Human Body Model 2000V, Interval:0.5sec 3 times

ESD Machine Model 200V, Interval:0.5sec 3 times

*lm: BRIGHTNESS ATTENUATE DIFFERENCE(1000hrs)<50%

*VF: FORWARD VOLTAGE DIFFERENCE<20%

Ta=55℃, IF=350mA 1000hours

Ta=85℃, IF=225mA 1000hours

Ta=100℃, IF=150mA 1000hours

Ta=-40℃, IF=350mA 1000hours

H:+85℃ 15min.

'∫ 5min.

'L:- 40℃ 15min.

IF=225mA,2min on/off

1000cycles

Everlight Electronics Co., Ltd. http://www.everlight.com Rev. 3.0 Page: 8 of 11

Device No. : DSE-8L1-002 Prepared date: Nov 17, 2006 Prepared by: Anita Chen

Page 9

EVERLIGHT ELECTRONICS CO.,LTD.

EHP-A08L/SUR01-P01

Precautions For Use

1. Over-current-proof

Though EHP-A08 has conducted ESD protection mechanism, customer must not use the device in

reverse and should apply resistors for extra protection. Otherwise slight voltage shift may cause

enormous current change and burn out failure would happen.

2. Storage

i. Do not open moisture proof bag before the products are ready to use.

ii. Before opening the package, the LEDs should be kept at 30℃ or less and 90%RH or less.

iii. The LEDs should be used within a year.

iv. After opening the package, the LEDs should be kept at 30℃ or less and 70%RH or less.

v. The LEDs should be used within 168 hours (7 days) after opening the package.

vi. If the moisture absorbent material (silicone gel) has faded away or the LEDs have exceeded the

storage time, baking treatment should be performed using the following conditions.

vii. Pre-curing treatment : 60±5℃ for 24 hours.

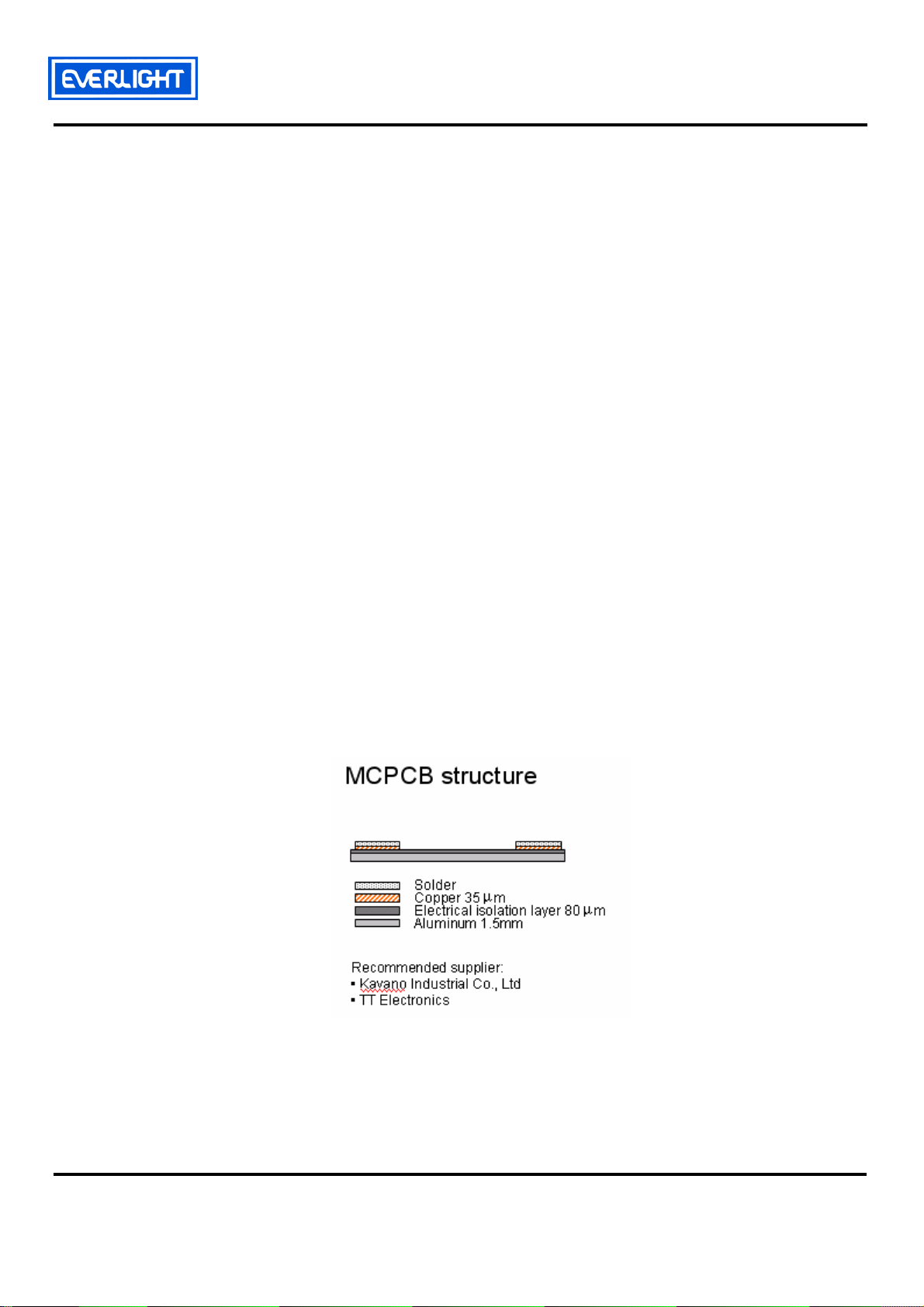

3. Thermal Management

i. For maintaining the high flux output and achieving reliability, EHP-A08 series LED package should

be mounted on a metal core printed circuit board (MCPCB) with proper thermal connection to

dissipate approximately 1W of thermal energy under 350mA operation.

ii. Special thermal designs are also recommended to take in outer heat sink design, such as FR4 PCB

on Aluminum with thermal vias or FPC on Aluminum with thermal conductive adhesive, etc.

iii. Sufficient thermal management must be conducted, or the die junction temperature will be over the

limit under large electronic driving and LED lifetime will decrease critically.

Everlight Electronics Co., Ltd. http://www.everlight.com Rev. 3.0 Page: 9 of 11

Device No. : DSE-8L1-002 Prepared date: Nov 17, 2006 Prepared by: Anita Chen

Page 10

EVERLIGHT ELECTRONICS CO.,LTD.

4. Assembly process flow

EHP-A08L/SUR01-P01

Handling Indications:Do not handle the EHP-A08 by the lens at any time during the assembly process.

This can cause damage to the optical surfaces or may dislocate the lens if excessive force is applied.

5. Soldering Iron

i. For prototype builds or small series production runs it is possible to place and solder the LED by

hand.

ii. Dispensing thermal conductive glue or grease on the substrates and follow its curing spec. Press

LED housing to closely connect LED and substrate.

Everlight Electronics Co., Ltd. http://www.everlight.com Rev. 3.0 Page: 10 of 11

Device No. : DSE-8L1-002 Prepared date: Nov 17, 2006 Prepared by: Anita Chen

Page 11

EVERLIGHT ELECTRONICS CO.,LTD.

EHP-A08L/SUR01-P01

iii. It is recommended to hand solder the leads with a solder tip temperature of 280°C for less than 3

seconds within once in less than the soldering iron capacity 25W. Leave two seconds and more

intervals, and do soldering of each terminal.

iv. Be careful because the damage of the product is often started at the time of the hand solder.

Everlight Electronics Co., Ltd. http://www.everlight.com Rev. 3.0 Page: 11 of 11

Device No. : DSE-8L1-002 Prepared date: Nov 17, 2006 Prepared by: Anita Chen

Loading...

Loading...