Everlasting BAKING CAB FL, BAKING CAB FB, BAKING TAB FL, BAKING TAB FB Use And Maintenance Manual

Page 1

Use and maintenance manual

REFRIGERATED CABINET

REFRIGERATED TABLE

RETARDER-PROOFER

DOUGH-RETARDER

Rev.10-6

Page 2

ENGLISH

Thank you for choosing this product.

Please read the warnings contained in this manual carefully, as they provide important information

regarding safe operation and maintenance.

Make sure to keep this manual for any future reference by the various operators.

In some parts of the manual, the symbol appears, indicating an important warning that must

be observed for safety purposes.

CHAPTER 1 BOUNDARY CHARACTERISTICS OF OPERATION

The retarder-proofer/dough retarder refrigerated cabinet and refrigerated table have been designed

and built to operate in optimal conditions at temperatures of up to +10°C and +38°C, with adequate

air circulation. In places with characteristics that are different from the requirements, the stated

performance cannot be guaranteed.

The supply voltage must be 230V +/- 10% 50Hz as standard, or as indicated on the EC label.

The retarder-proofer/dough retarder refrigerated cabinet and refrigerated table may only be used

within the temperature limits specified by the manufacturer; to identify the correct operating range,

read the letters after the last digit of the model shown on the CE label and compare it with the table

below:

Series Temperature

BAKING CAB FL -10° +40°C / 55÷95% U.R.

BAKING CAB FB -10° +40°C

BAKING TAB FL -5° +40°C / 55÷95% U.R.

BAKING TAB FB -5° +40°C

The retarder-proofer/dough retarder refrigerated cabinet and refrigerated table complies with the

European directives as described in detail in the Annex “EC Declaration of Conformity”.

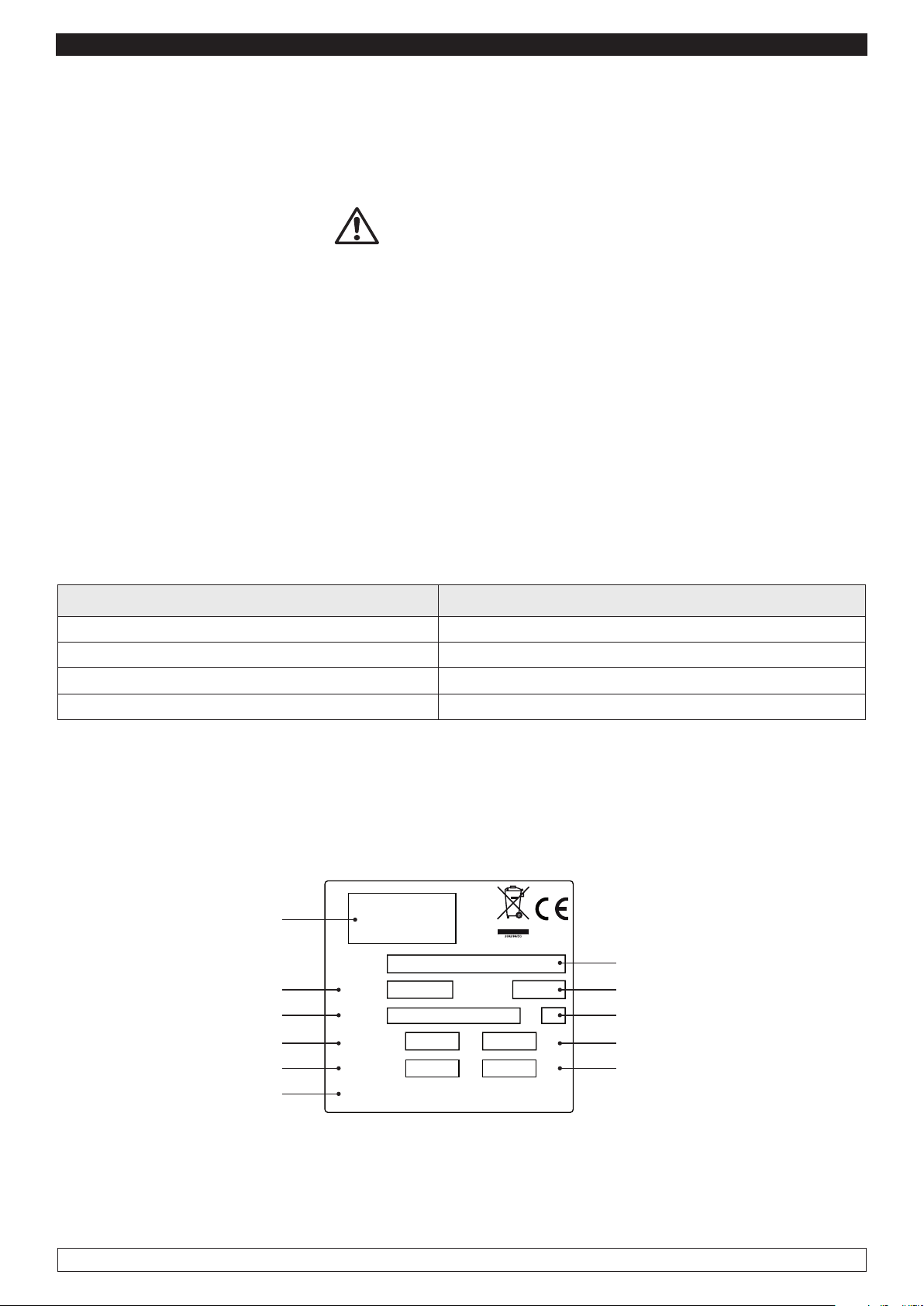

The data are reported on the EC label placed in the retarder-proofer/dough retarder refrigerated

cabinet and refrigerated table, inside the engine compartment.

Manufacturing Company

Code article

Operating voltage

Power consumption

Cooling capacity

Type of coolant

Modello

Model

Cod.Art

Code

Tensione

Tension

Assorbimento

Absorption

Gas

Gaz

IP20, CLASS 1

Matricola

Ser. Number

A

CL.

Kw

Kg

Model

Registration Number

Climate class

Electrical power

Quantity of coolant

The manufacturer declines any liability for improper use of the retarder-proofer/dough retarder

refrigerated cabinet and refrigerated table as well as use that could not have been reasonably

foreseen, and for all operations performed on it that disregard the instructions in the manual.

1

Page 3

ENGLISH

The main general safety standards are listed below:

- Do not use or place electrical devices inside the refrigerated compartments if they are not of the

type recommended by the manufacturer

- Do not touch the the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table

with damp or wet hands or feet

- Do notuse the the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table barefoot

- Do not insert screwdrivers or other objects between the guards or moving parts

- Do not pull the power cord to unplug the the retarder-proofer/dough retarder refrigerated cabinet

and refrigerated table from the electricity network

- The retarder-proofer/dough retarder refrigerated cabinet and refrigerated table are not intended to

be used by persons (including children) with physical or mental problems, or lack of experience and

knowledge, unless they are controlled or instructed in using the unit by a person responsible for their

safety. Children must be supervised to ensure that they do not play with the appliance.

- before carrying out any cleaning or maintenance, disconnect the refrigerated cabinet from the mains

power supply by turning off the main switch and pulling the plug

- in the event of failure and/or malfunction of the the retarder-proofer/dough retarder refrigerated

cabinet and refrigerated table, turn it off and to refrain from any attempt to repair or intervene directly.

It is necessary to exclusively contact a qualified technician.

The retarder-proofer/dough retarder refrigerated cabinet and refrigerated table are composed of a

modular monocoque coated with different materials and insulated with polyurethane foam of density

42 kg/m3.

In the design and construction, all measures have been adopted to ensure the retarder-proofer/dough

retarder refrigerated cabinet and refrigerated table comply with safety and hygiene requirements,

such as: rounded interior corners, deep drawing with drain on the outside for the condensate liquids,

no rough surfaces, fixed guards on moving or dangerous parts.

The products must be stored in observance of the load limits given in the table, in order to ensure

an efficient circulation of air inside the refrigerated cabinet.

Load limits expressed in Kg.

Grille 400x600 20

Sheet Metal Baking Trays 800x600 10

Sheet Metal Baking Trays 400x600 8

The installation must be performed exclusively by a qualified technician

1.1 It is prohibited to remove the guards and safety devices

It is absolutely forbidden to remove safety guards.

The manufacturer disclaims any liability for accidents due to failure to comply with this obligation.

1.2 Information on emergency operations in the event of fire

- disconnect the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table from the

electrical outlet or cut off the main power supply

- do not use water jets

- use dry chemical or CO2 extinguishers

2

Page 4

ENGLISH

A

L

C

O

O

L

CHAPTER 2 CLEANING

Since the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table will be used to

store food, cleaning is necessary for hygiene and health protection purposes.

The cleaning of the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table have

already been carried out at the factory. It is suggested, however, to carry out an additional cleaning

of the internal parts before use, making sure that the power cord is unplugged.

2.1 Cleaning the interior and exterior cabinet

For this purpose the following are indicated

- the cleaning products: water and mild, non-abrasive detergents. DO NOT USE SOLVENTS AND

THINNERS

- methods for cleaning: wash the interior and exterior parts with warm water and mild soap or with a

cloth or sponge with suitable products

- disinfection: avoid substances that can alter the organoleptic characteristics of the food

- rinsing: cloth or sponge soaked in warm water. DO NOT USE WATER JETS

- frequency: weekly is recommended, the user can set different frequencies depending on the type

of food being stored.

REMARK : Clean frequently the door seals.

Some preserved products could release some enzymes that could damage

the seals causing its quick deterioration.

For the cleaning, use only specific products for this purposes, available also

on request on our sales network.

2.2 Cleaning the condenser

The efficiency of

the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table

is

compromised by the clogging of the condenser, therefore it is necessary to clean it on a monthly basis.

Before carrying out this operation, switch off

and refrigerated table

unplug the power cord and proceed as follows:

Retarder-proofer/dough retarder refrigerated cabinet and refrigerated table

the retarder-proofer/dough retarder refrigerated cabinet

- open the front

control panel by unscrewing the screws and making it rotate on the hinges located below.

Retarder-proofer/dough retarder refrigerated cabinet and refrigerated table -

safe ladder and go directly to the condenser placed on top of

the retarder-proofer/dough retarder

climb up on a

refrigerated cabinet and refrigerated table

Fig.1

With the aid of a jet of air or dry brush, eliminate, in a vertical movement (Fig.

1), the dust and lint deposited on the fins. In the case of greasy deposits, we

recommend using a brush moistened with special cleaning agents.

When the operation is completed, restart

refrigerated cabinet and refrigerated table

the retarder-proofer/dough retarder

During this operation, use the following personal protective equipment: goggles, respiratory

protection mask, chemically resistant gloves (gasoline-alcohol).

3

Page 5

ENGLISH

CHAPTER 3 PERIODIC CHECKS TO BE CARRIED OUT

IMPORTANT: The following are the points or units of the retarder-proofer/dough retarder

refrigerated cabinet and refrigerated table that require periodic checks:

- integrity and efficiency of door seals

- integrity of the grilles in contact with food

- integrity of the fixing hinges of the doors

- integrity of the power cord

3.1 PRECAUTIONS IN CASE OF LONG PERIODS OF INACTIVITY

A long period of inactivity is defined as a stoppage of more than 15 days.

It is necessary to proceed as follows:

- switch off the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table and

disconnect it from the power supply

- carry out a thorough cleaning of the interior cabinet, shelves, trays, guides and supports, paying

special attention to critical points such as the joints and magnetic gaskets, as indicated in Chapter 2.

- leave the door partly open to prevent air stagnation and residual humidity

CHAPTER 4 PREVENTIVE MAINTENANCE

4.1 Restarting after a long period of inactivity

Restarting after long inactivity is an event that requires preventive maintenance.

It is necessary to perform a thorough cleaning as described in chapter 2.

4.2 Control of the warning and control devices

We recommend that you contact your dealer for a service or maintenance contract that includes:

- cleaning of the condenser

- verification of the coolant load

- verification of the full cycle operation

- electrical safety

CHAPTER 5 EXTRAORDINARY MAINTENANCE AND REPAIR

All maintenance activities that have not been described in previous chapters are considered

“Extraordinary Maintenance.” Extraordinary maintenance and repair are tasks reserved exclusively

to the specialist personnel authorized by the manufacturer.

No liability is accepted for actions carried out by the user, by unauthorized personnel, or with the use

of non-original replacement parts.

4

Page 6

ENGLISH

CHAPTER 6 TROUBLESHOOTING

Problems may occur, in

the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table

identified as shown in the table:

TROUBLE DESCRIPTION POSSIBLE CAUSES HOW TO REPAIR IT

the retarder-proofer/dough retarder

refrigerated cabinet and refrigerated

table do not turn on

the refrigeration unit does not start the set temperature has been reached set new temperature

the refrigeration unit runs continuously but does not reach the set

temperature

the refrigeration unit does not stop at

the set temperature

no power supply check the plug, socket, fuses, line

other fuses, line

defrosting in progress

control panel failed contact technical support

other contact technical support

location is too hot aerate more

condenser is dirty clean the condenser

insufficient coolant contact technical support

stop the condenser fan contact technical support

insufficient sealing of doors check the seals / provision of goods

evaporator completely frosted manual defrosting

other contact technical support

command panel failed contact technical support

Pr1 temperature sensor failed contact technical support

wait until the end of cycle / turn power off

and on again

misuse see chapter 1.

block of ice on the evaporator

accumulation of water or ice in the

drip tray

defrost heater fault contact technical support

defrost probe Pr2 damaged contact technical support

drain clogged clean the pipette and the drain

Cabinet/table are not levelled check levelling

CHAPTER 7 INSTRUCTIONS FOR REQUESTING ASSISTANCE

For any technical problem, and any requests for assistance or service, you must exclusively contact

your own dealer with the code and the registration number described on the label of technical data

applied on the equipment

CHAPTER 8 SAFETY AND ACCIDENT PREVENTION

The retarder-proofer/dough retarder refrigerated cabinet and refrigerated table have been built with

suitable measures to ensure the safety and health of the user.

The following are the measures taken to protect against mechanical risks:

- stability: The retarder-proofer/dough retarder refrigerated cabinet and refrigerated table , even with

the grilles removed, have been designed and built in such a way that under the intended operating

conditions, its stability is suitable for use without risk of overturning, falling or unexpected movement

- surfaces, edges, corners: the accessible parts of the retarder-proofer/dough retarder refrigerated

cabinet and refrigerated table are, within the limits allowed by their functions, free of sharp angles

and sharp edges, as well as rough surfaces likely to cause injury

- moving parts: were designed, constructed and arranged to avoid risks. Certain parts are equipped

with fixed guards so as to prevent risks of contact which may result in injury

5

Page 7

ENGLISH

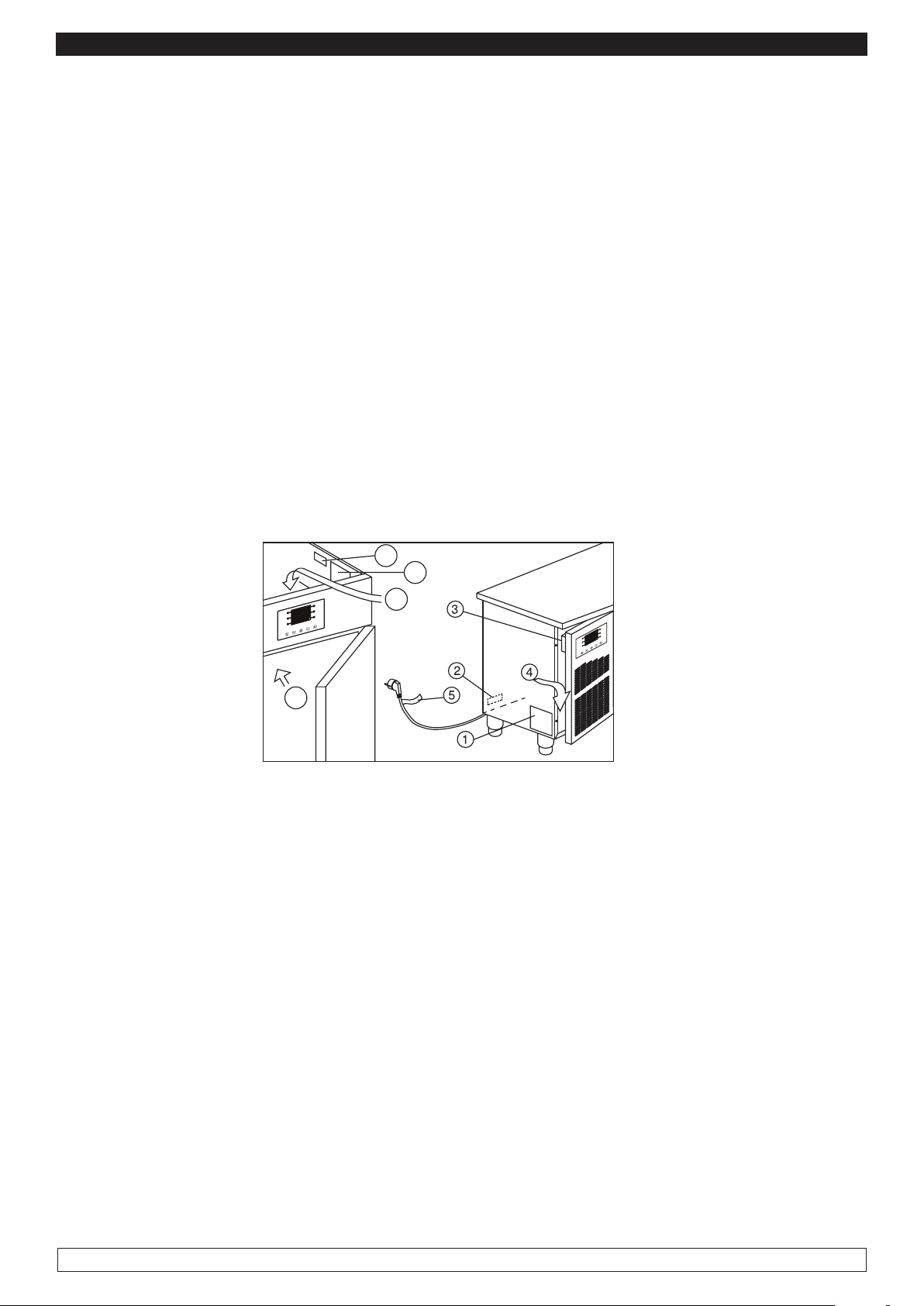

2

The following are the measures taken to protect against other risks:

- electricity: The the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table

have been designed, built and equipped so as to prevent risks from electricity, in accordance with

the specific legislation in force

- noise: The retarder-proofer/dough retarder refrigerated cabinet and refrigerated table have been

designed and built in such a way that risks resulting from the emission of airborne noise are reduced

to the minimum level

8.1 safety devices adopted (Fig. 2) :

- Do not remove the labels applied at the inner edge of the engine compartment, showing the technical

specifications (1) and the instructions for grounding (2)

- Do not remove the label applied on the evaporator guard and near the electrical wiring inside the

engine compartment, which warns the user to turn off the power supply before working on the unit (3)

- Do not remove the labels applied inside the engine compartment, indicating grounding (4)

- Do not remove the label applied on the power cord, indicating the type of power supply (5)

The manufacturer declines any responsibility for the safety of the the retarder-proofer/dough retarder

refrigerated cabinet and refrigerated table if this were to happen.

1

4

3

Fig.2

8.2 Indications for optimal operation

- do not block the air vents of the engine compartment

- do not insert foods or liquids that are still hot

- place the foodstuffs on the appropriate shelves or containers. Do not place them directly on the

bottom, or leaning against the walls, doors or fixed guards

- close the doors carefully

- always keep the defrost water drain hole clear of obstructions

- limit, to the extent possible, the frequency and duration of door opening. Each opening causes a

change in the internal temperature

- perform periodically current maintenance (see chapter 3)

In case of interruption or failure of the power supply circuit, prevent the opening of the doors in order

to maintain a uniform temperature inside the retarder-proofer/dough retarder refrigerated cabinet

and refrigerated table.

If the problem persists longer than a few hours it is recommended to move the material to a suitable

place.

6

Page 8

ENGLISH

USEFUL SUGGESTIONS

Before starting a RETARDER-PROOFING cycle it is advisable to pre-cool the empty cell at -5 ° C,

thus allowing more effective action of the Retarder-proofing action during the introduction of the

product (see par.10.6 p. 29)

For cycles longer than 48 H increase yeast of 0.5% speeding as possible the loading phase of the

product.

Do not bake the product once it has been taken out from the retarder proofer, leave at least 10

minutes at room temperature in order to avoid an excess of moisture in the surface that could cause

defects in the crust formation during cooking.

The possible bubbles formation on the bread is not synonymous of failure in the system, the cause

is almost always due to a problem of bread: dough too soft, too cold, low-quality flour, too much

moisture in the leavening phase, the oven is too hot, excess of cooking steam, etc

Avoid too high temperatures along with too short times during LEAVENING and PROVING, thermal

shock should cause problems to gluten and yeast damaging the quality of the finished product.

In the case of products that require periods of storage longer than 72H is advisable to use special

temperature blast chiller (see our catalogues) designed to bring the inside part of bread in the shortest

time to a temperature of -20 ° C thus allowing to keep the original organoleptic quality comparing it

to the fresh product.

Even the storage phase must take place in a special cold room who keeps constantly t -20 ° C.

PRELIMINARY NOTES

The control panel provides full control for retarder-proofer cabinets or tables for confectionery and

bakery, through the automatic management of the complete retarder-proofing cycle Example

START

MACHINE

COOLING

-5° / -10 °C

--- % r.H.

4-6 ore

STORAGE

-2° / +2 °C

--- % r.H.

changeable time

PROOFING

+10° / +13 °C

70 - 80 % r.H.

1 - 5 ore

LEAVENING

+25° / +30 °C

85 - 90 % r.H.

2 - 4 ore

END

CYCLE

STOP

MACHINE

DELAYED

BAKING

INF+25° / +30 °C

85 - 90 % r.H.

no limit of time

7

Page 9

ENGLISH

AUTOMATIC CYCLE

An automatic retarded proofing process consists of 5 steps providing different temperatures, relative

humidity, fans speed and different duration which are carried out in sequence as follows:

1. COOLING Phase

The block phase is the first phase of the automatic cycle.

► Temperature adjustment : ACTIVE AND ADJUSTABLE

► Duration (Hours/Minutes): ADJUSTABLE

► Fan speed : AUTOMATIC

2. PRESERVATION Phase

The preservation phase is the second phase of the automatic cycle.

► Temperature adjustement: ACTIVE AND ADJUSTABLE

► Duration : (Hours-Minutes): AUTOMATIC

► Fan speed : AUTOMATIC

The duration of this phase is automatically calculated by the controller on the basis of the duration

of the cooling , the proofing and the leavening processes as well as the day and the time the end of

the dough leavening process is required to stop.

3. PROOFING Phase

The proofing phase is the third phase of the automatic cycle.

►

Temperature adjustement : ACTIVE AND ADJUSTABLE

►

Humidity Adjustment : ACTIVE AND ADJUSTABLE

►

Duration (Hours-Minutes): ADJUSTABLE

►

Fan speed : AUTOMATIC

4. LEAVENING Phase

The leavening phase is the fourth phase of the automatic cycle.

►

Temperature adjustement : ACTIVE AND ADJUSTABLE

►

Humidity adjustment : ACTIVE AND ADJUSTABLE

►

Duration (Hours-Minutes): ADJUSTABLE

►

Fan speed : AUTOMATIC

5. DELAYED BAKING Phase

The delayed baking phase is the fifth phase of the automatic cycle.

The delayed baking phase may be either enabled or disabled both during the cycle setting and also

during a processing cycle by the final user.

► Temperature adjustment :ACTIVE AND ADJUSTABLE

► Humidity adjustement : ACTIVE AND ADJUSTABLE

► Fan speed : AUTOMATIC

► Duration (Hours-Minutes): The duration of this phase is virtually infinite , that is : it only stops when

you interrupt the cycle by pressing the stop button for 3 seconds.

MANUAL CYCLES

MANUAL COOLING PROCESS : (equivalent to storage but with infinite duration)

HEATING MANUAL PROCESS : (equivalent to a never-ending leavening process)

Besides the automatic and manual cycles management, the controller also provides you to control

other functions such as :

- Cell pre-cooling management system

- “Delayed baking” activation/deactivation management system

- 10 User’s Programmes management

- 10 Favourite Programmes management

- Connection to RICS (remote management – supervisory control) and RS485

- Onboard USB Host port management for PROGRAMMES download/upload , PARAMETERS

download/upload and HACCP data download.

8

Page 10

ENGLISH

6

9

10

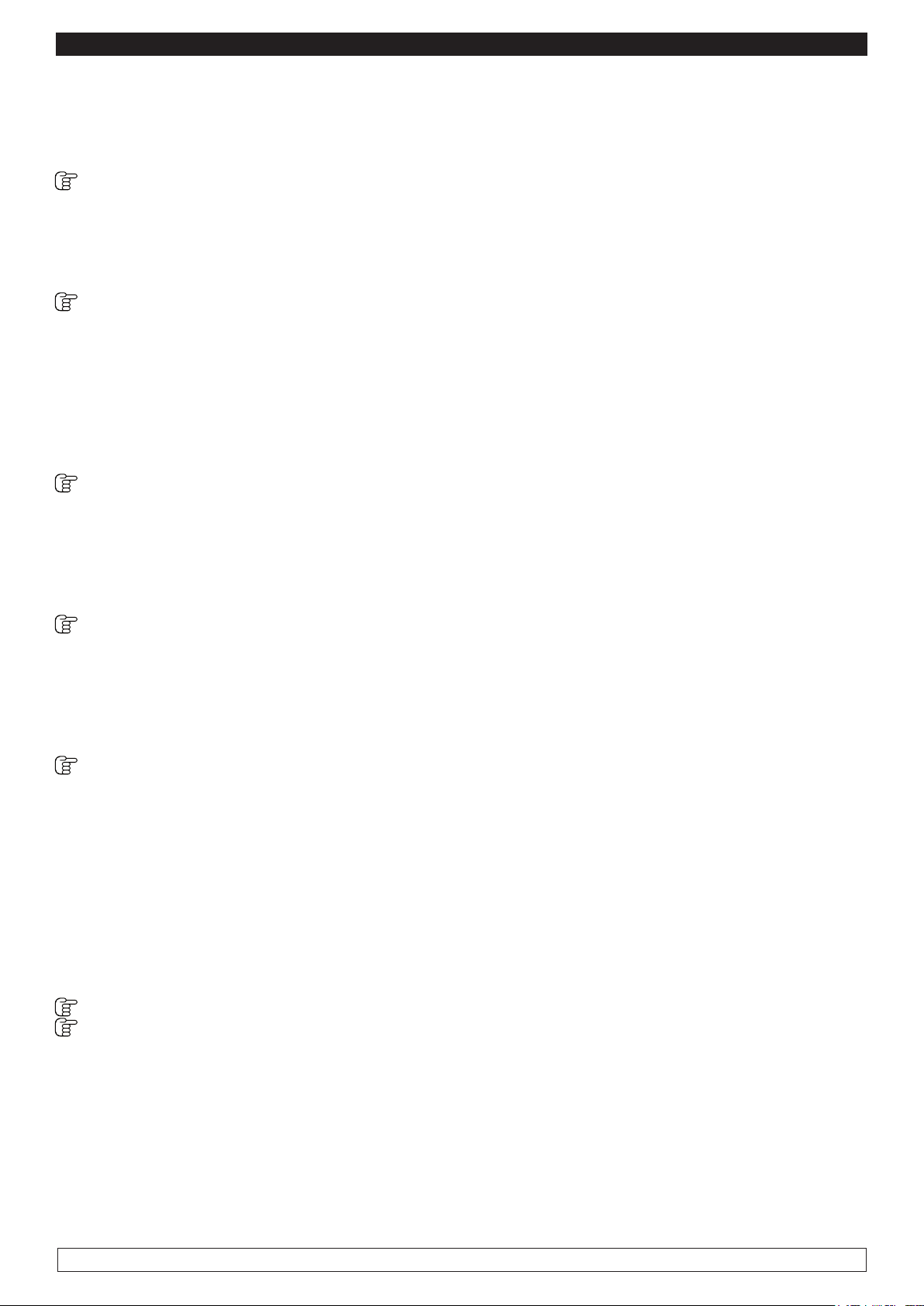

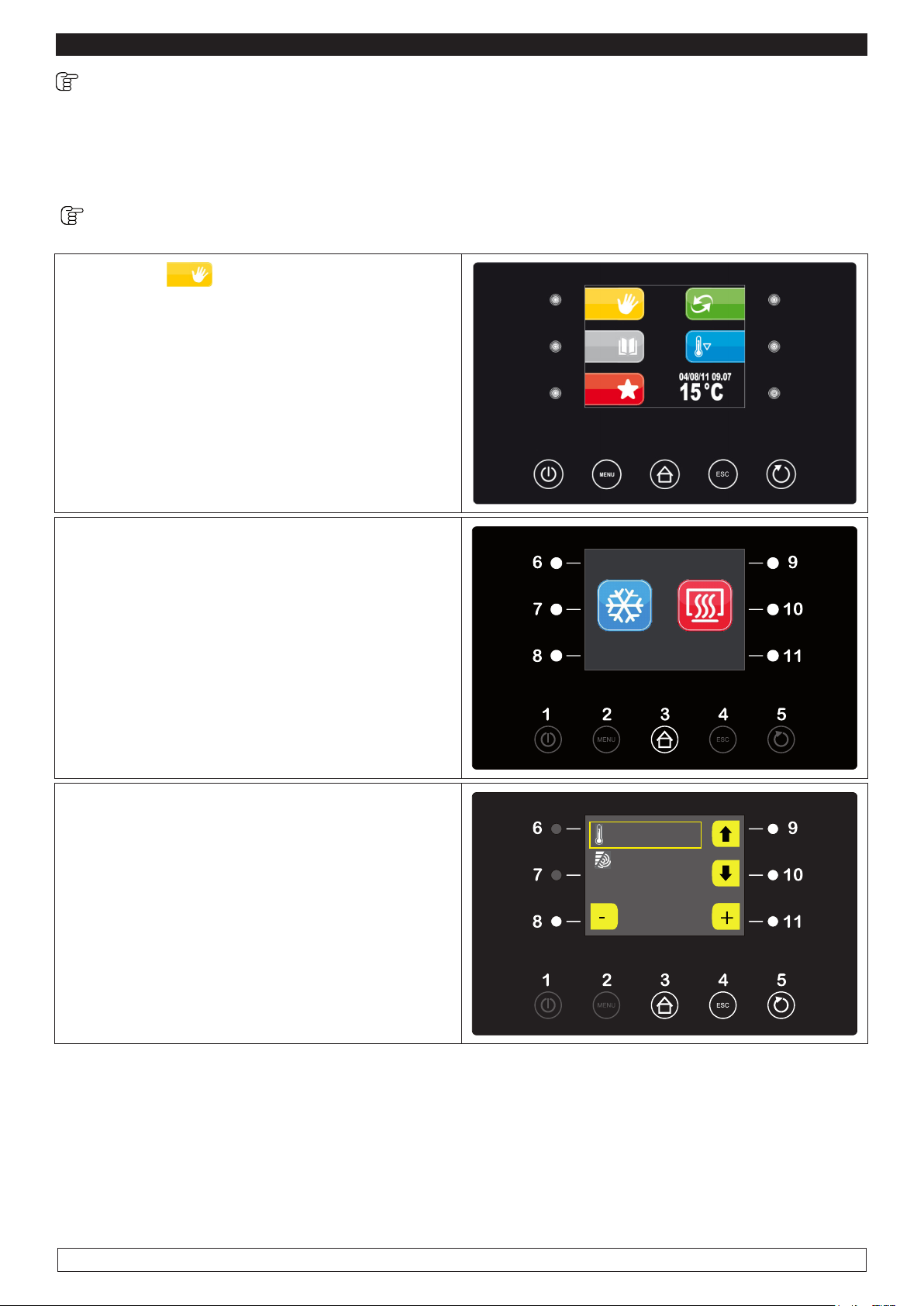

CHAPTER 9 CONTROLS

Description of control Panel:

The Control Panel consists of a digital capacitive-type temperature controller for coldness with colour

3,5” TFT supplied with user-friendly icons:

7

8

12345

The Control Panel is supplied with the following buttons:

1

2

3

ON / OFF It allows to change the controller’s status

MENU It allows to open the pop-up window containing the options for the current screen

HOME It allows to go back to the pre-selection screen at any time, cancelling any pro-

cessing selected programme.

11

ESC

4

5

6

7

8

9

10

11

ESC It allows to go back to the previous page at any time, cancelling any processing

selected programme.

START / STOP It allows to start/stop a working cycle, either manual or automatic or

auxiliary.

MANUAL KEY It allows to select a MANUAL working cycle

PROGRAMMES KEY It allows to select and/or change automatic retarded proofing

processes stored in memory.

FAVOURITE KEY It allows to recall the last 10 cycles performed promptly.

AUTOMATIC KEY It allows the selection, the setting and the implementation of a com-

plete automatic retarded proofing process.

PRE-COOLING KEY It allows the implementation of a cell pre-cooling cycle.

INTERACTIVE SELECTION KEY It allows to select the menu options

9

Page 11

ENGLISH

Active keys are the backlit keys only.

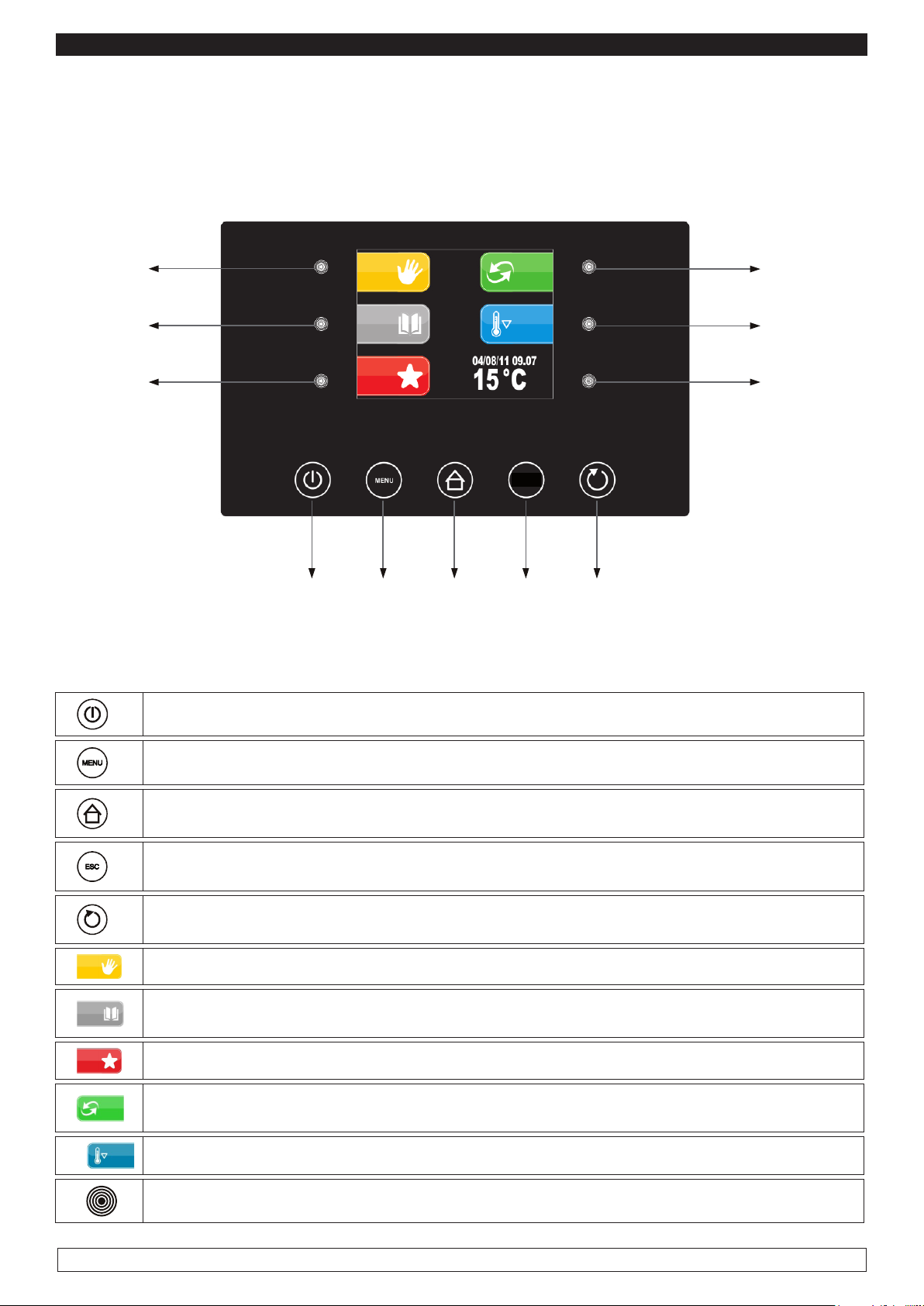

9.2 INSTRUCTIONS FOR USE

9.2.1 Starting process

Before starting the Retarder-Proofer Cabinet you need to check if the electrical connections have

been made according to what stated in Chapter 14.

LOADING...

► Connect the machine to the power supply: the display will switch on completely for 10’’, then

it shall be on the “STAND-BY” status.

Starting / switching-off : Start the panel by pressing the ON/OFF touch button (1)

1

ESC

► If the power cut has caused clock error , the display will directly show the clock setting

screen.

PLEASE NOTE:

the control panel shall not verify whether the inserted date is correct, it is up

to the user to set it properly. (Par. 9.2.2)

► While the machine is ON, the display will show the date, the present time, the cell temperature

and all the functions which may be selected.

- Press the ON / OFF key (1) to switch off.

10

Page 12

ENGLISH

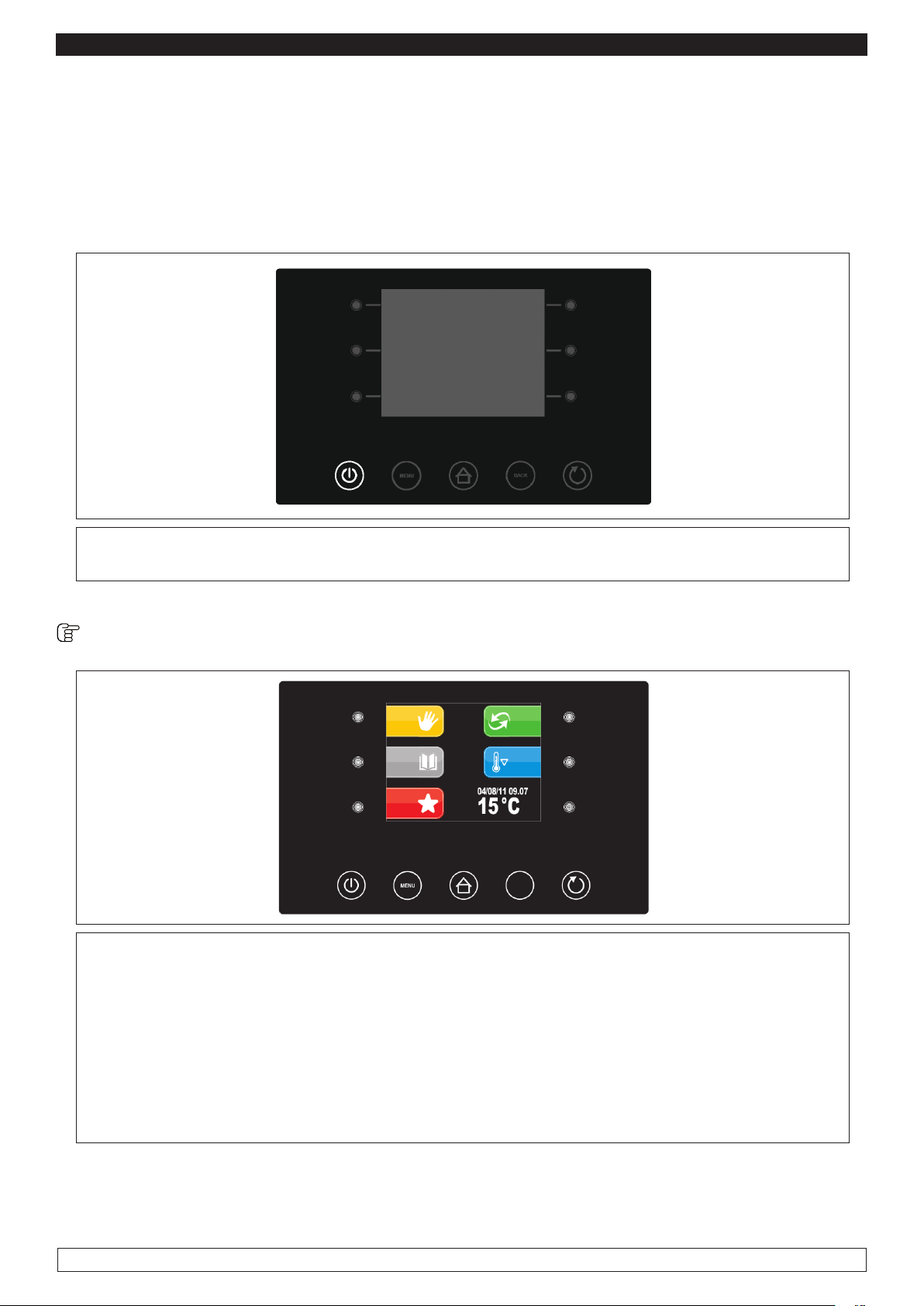

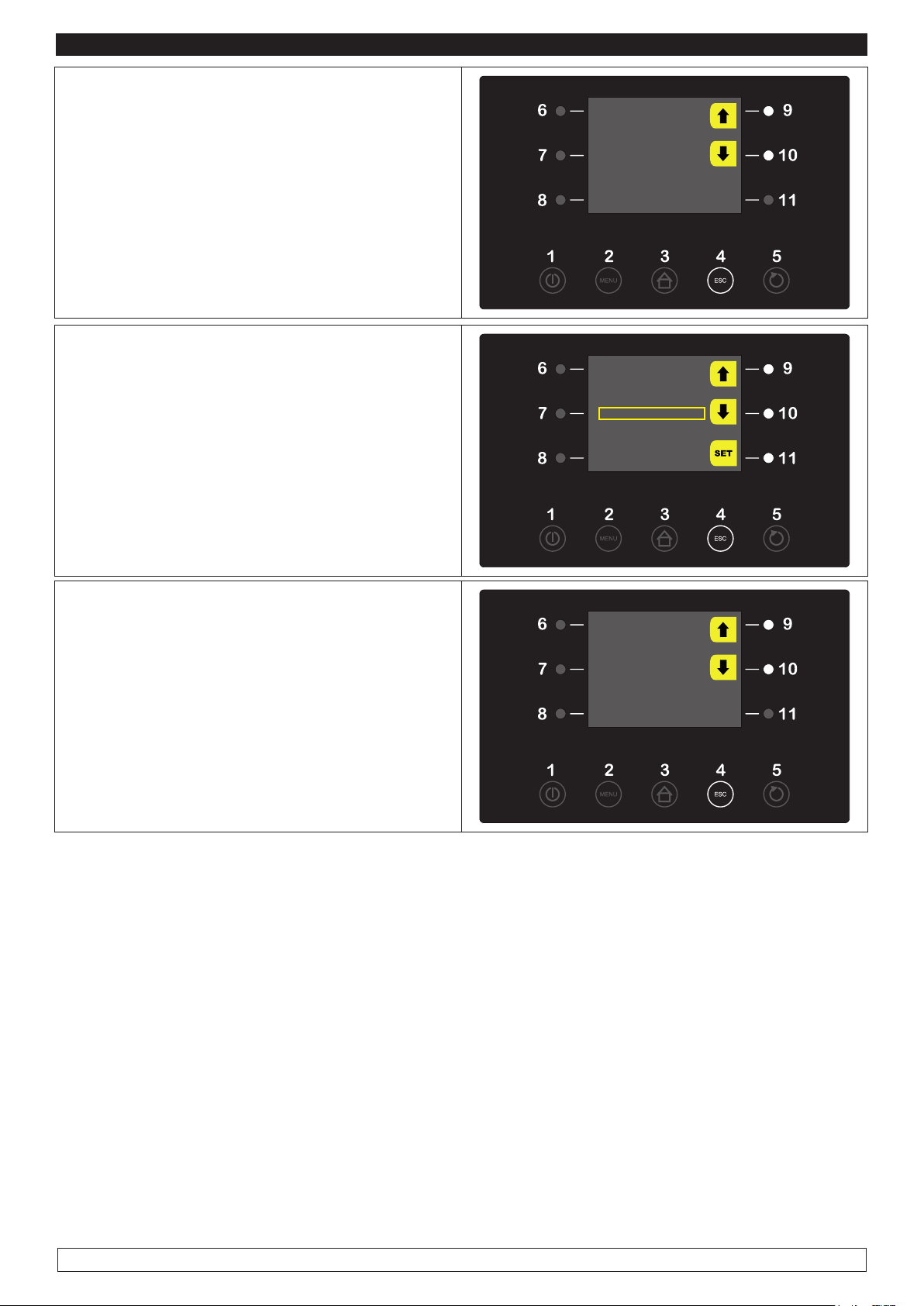

9.2.2 Clock setting: set date and present time

The first operation to be carried out is setting the clock to the present time as follows:

► Press the MENU key (2) ,

2

ESC

► Select with the UP-DOWN keys (9-10) the

menu date and time options then confirm by

pressing the SET key (11)

OPTIONS

LIGHT

22/12/14 18:15

MANUAL DEFROST

ALARM LIST

INTERNAL VALUES

SERVICE

► Press the - and + keys (8-11) to adjust the date

then confirm by pressing the SET key (9)

► The adjustment of Month, Year , Hours and

Minutes will be automatically carried out in sequence.

► Press the - and + keys (8-11) to change the

inserted data.

► Press the SET key (9) to confirm the inserted

data.

22 / 12 / 14

18:15

22 / 12 / 14

18:15

►

When the operation is completed either press the ESC key (4) or do not work for 60 seconds.

11

Page 13

ENGLISH

9.2.3 Language setting

Proceed as follows:

► Press the MENU key (2),

► Select with the UP-DOWN keys (9-10) the

menu SERVICE item and press the SET key (11)

2

ESC

OPTIONS

LIGHT

22/12/14 18:15

MANUAL DEFROST

ALARM LIST

INTERNAL VALUES

SERVICE

► Select with the UP-DOWN keys (9-10) the

menu LANGUAGES item then press the SET

key (11)

►

Select with UP-DOWN keys (9-10) the desired

LANGUAGE

►

Press the SET key (11) to confirm

SERVICE

LANGUAGES

HISTORICAL DATA

INTERNAL SETTING

SERVICE

ITALIANO

ENGLISH

FRANCAIS

DEUTSCH

ESPANOL

►

When the operation is completed either press the ESC button (4) or do not work for 60 seconds.

12

Page 14

ENGLISH

CHAPTER 10 OPERATION

Main menu

In the pre-setting page there is the list of the available functions as well as the following data: date,

time and cell internal temperature.

ESC

The 5 “interactive” keys allow you to select:

MANUAL CYCLES: i.e. the selection, the setting-up and the implementation of a manual

cooling or heating cycle.

STORED PROGRAMMES: i.e. the selection and/or the adjustement of automatic retarded

proofing processes stored in memory.

FAVOURITE PROGRAMS: i.e. the prompt recalling of the last 10 performed cycles

AUTOMATICI CYCLES: i.e. the selection, the setting-up and the implementation of a complete

automatic retarded proofing process.

CELL PRE-COOLING PROGRAMME: i.e. The implementation of the cell pre-cooling cycle.

The 5 “Navigate” keys allow you to scroll to the desired menu and to activate the different working

cycles:

ON/OFF

MENU

HOME

ESC

START/STOP

13

Page 15

ENGLISH

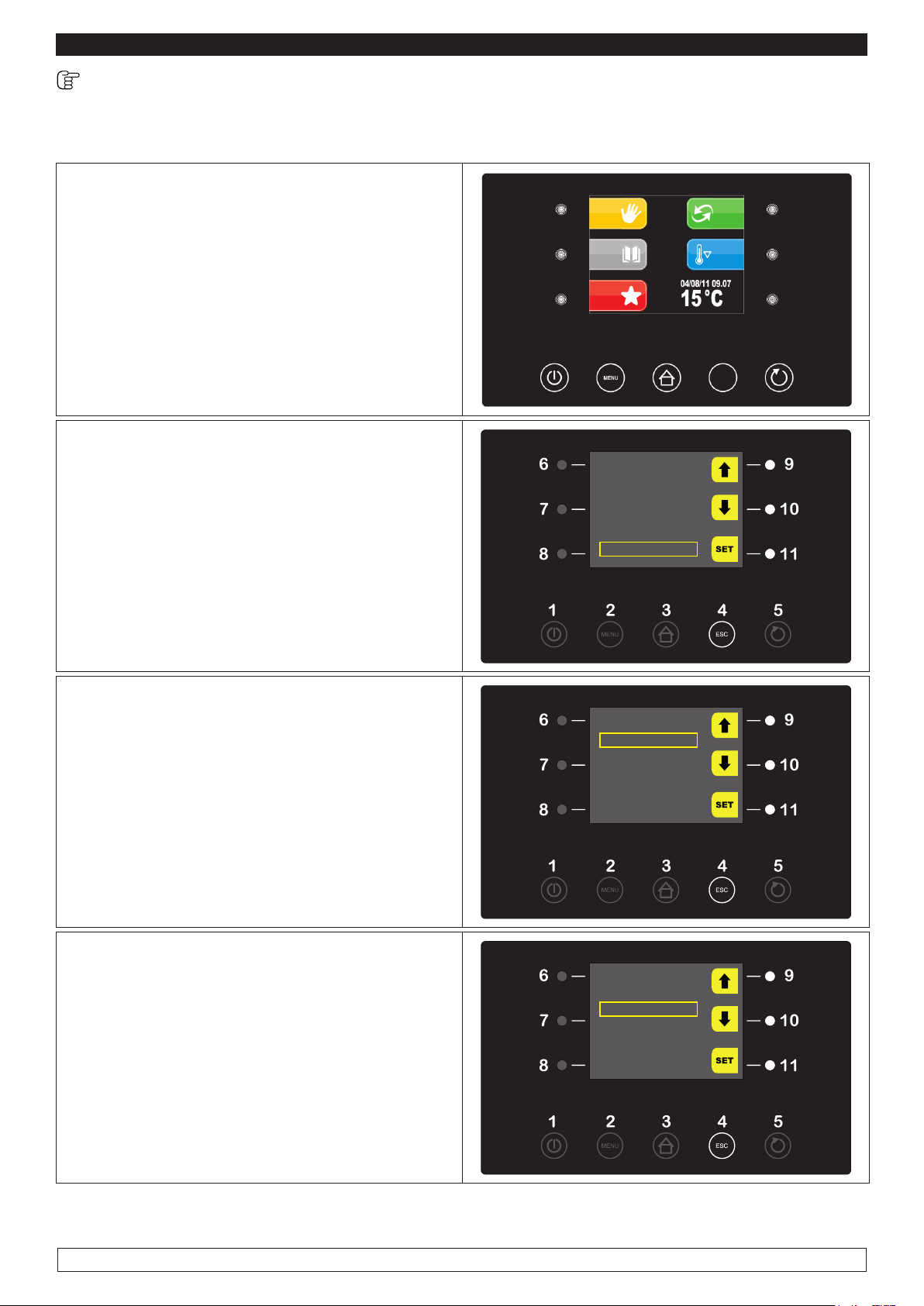

10.1 Setting-up and implementation of a MANUAL COOLING or HEATING cycle

From this menu you may select all the phases needed to carry out a manual COOLING or HEATING

cycle.

10.2 Setting up and running a cycle REFRIGERATION MANUAL:

► Press key MANUAL (6)

6

► Press one of the three left keys (6-7-8) to per-

form the MANUAL COOLING cycle

► Press the - and + keys (8-11) to adjust the CO-

OLING temperature

► Press the START/STOP key (5) to start the MA-

NUAL COOLING cycle

PLEASE NOTE: The fans speed adjustment function is disabled as it is automatically set.

Refrigeration Heating

12 °C

100%

14

Page 16

ENGLISH

You may view the following list of OPTIONS by pressing the MENU key (2) during a MANUAL

COOLING cycle:

- SETPOINT

- ALARMS LIST

- INTERNAL VALUES

- MANUAL DEFROSTING (not to be carried out if not necessary)

- LIGHT

► To visualize the defined SETPOINT during a

working MANUAL COOLING cycle, press the

MENU key (2), select with the UP-DOWN keys

(9-10) the SETPOINT function and press the SET

key (11)

OPTIONS

SETPOINT

ALARM LIST

INTERNAL VALUES

MANUAL DEFROST

LIGHT

15:14 07/01/15

► To modify the defined SETPOINT press the -

and + keys (8-11)

► When the operation is over either press the ESC

button (4) to go back to the OPTIONS menu

PLEASE NOTE: The fans speed adjustment function is disabled as it is automatically set.

►

To display the ALARMS LIST during a working

MANUAL COOLING cycle, press the MENU key (2)

►Select with the UP-DOWN keys (9-10) the

ALARMS LIST item and press the SET key (11)

12 °C

100%

OPTIONS

SETPOINT

ALARM LIST

INTERNAL VALUES

MANUAL DEFROST

LIGHT

15:14 07/01/15

15

Page 17

ENGLISH

►The screen will display the current alarms list

► Press the UP-DOWN keys (9-10) to scroll throu-

gh the alarms, if the alarm is ON it is active, if it is

OFF it is not active.

► When the operation is over either press the ESC

key (4) to go back to the OPTIONS

► To view the INTERNAL VALUES during a wor-

king MANUAL COOLING cycle press the MENU

key (2)

► Press the UP-DOWN keys (9-10) to select the

INTERNAL VALUES then press the SET key (11)

ALARM LIST

Error Pr1 OFF

Error Pr2 OFF

Error Pr3 OFF

Error Pr4 OFF

Error AH OFF

Error PD OFF

OPTIONS

SETPOINT

ALARM LIST

INTERNAL VALUES

MANUAL DEFROST

LIGHT

15:14 07/01/15

► The screen will display the INTERNAL VALUES list.

► Press the UP-DOWN keys (9-10) to scroll throu-

gh the INTERNAL VALUES

► When the operation is over either press the ESC

INTERNAL VALUES

Temp cell 15°C

Humidity 40%

Temp Evap 27°C

Temp Cond - - -

Door OFF

High Pres OFF

key (4) to go back to the OPTIONS menu

PLEASE NOTE: The MANUAL DEFROSTING menu is activated only if the evaporator

temperature is lower than the final defrost end temperature.

To cancel the MANUAL COOLING cycle press the START/STOP button (5) for two consecutive

times. The display will go back to the Home screen.

16

Page 18

ENGLISH

10.3 Setting-up and implementation of a MANUAL HEATING cycle:

► Press Key MANUAL (6)

6

► Press one of the three right keys (9-10-11) to

execute a MANUAL HEATING cycle

► Press the UP-DOWN keys (9-10) and select

the TEMPERATURE parameters. Press the and + keys (8-11) to modify its value

► Press the UP-DOWN keys (9-10) and select

the HUMIDITY parameters . Press the - and +

keys (8-11) to modify its value

► Press the START/STOP key (5) to start a MA-

NUAL HEATING cycle

PLEASE NOTE: The fans speed adjustment function is disabled as it is automatically set.

Refrigeration Heating

25 °C

80 %rH

100 %

► Once the MANUAL HEATING cycle is working,

the following screen shall be displayed.

Heating

26 °C

39 %rH

17

Page 19

ENGLISH

► You may view the following list of OPTIONS by pressing the MENU key (2) during a MANUAL HE-

ATING cycle:

- SETPOINT

- ALARMS LIST

- INTERNAL VALUES

- LIGHT

► Press the MENU key (2) to display the

SETPOINT during a working MANUAL HEATING

cycle.

► Select with the UP-DOWN keys (9-10) the

SETPOINT function then press the SET key (11)

OPTIONS

SETPOINT

ALARM LIST

INTERNAL VALUES

LIGHT

► To modify the defined TEMPERATURE value

press the – and + keys (8-11)

► Press the UP-DOWN keys (9-10) and select the

HUMIDITY parameters. Press the - and + keys

(8-11) to modify its value.

► When the operation is over either press the

ESC button (4) to go back to the OPTIONS menu

PLEASE NOTE: The fans speed adjustment function is disabled during all the process steps as it

is automatically set.

► To display the ALARMS LIST during a working

MANUAL HEATING cycle press the MENU key

(2).

► Select with the UP-DOWN keys (9-10) the

ALARMS LIST item then press the SET key (11).

25 °C

80 %rH

100 %

OPTIONS

SETPOINT

ALARM LIST

INTERNAL VALUES

LIGHT

18

Page 20

ENGLISH

► The display will show the current alarms list

► Press the UP-DOWN keys (9-10) to scroll throu-

gh the alarms list, if an alarm is ON it is active.

► When the operation is over either press the ESC

key (4) to go back to the OPTIONS menu

► Press the MENU key (2) to display the INTER-

NAL VALUES during a working MANUAL HEATING cycle.

► Press the UP-DOWN keys (9-10) to select the

INTERNAL VALUES then press the SET key (11)

ALARM LIST

Error Pr1 OFF

Error Pr2 OFF

Error Pr3 OFF

Error Pr4 OFF

Error AH OFF

Error PD OFF

OPTIONS

SETPOINT

ALARM LIST

INTERNAL VALUES

LIGHT

► The screen will display the list of INTERNAL VALUES

► Press the UP-DOWN keys (9-10) to scroll throu-

gh the INTERNAL VALUES, the temperatures

and the relays status for the unit running will be

displayed. Such values cannot be modified.

► When the operation is over either press the

INTERNAL VALUES

Temp cell 15°C

Humidity 40%

Temp Evap 27°C

Temp Cond - - -

Door OFF

High Pres OFF

ESC key (4) to go back to the OPTIONS menu or

do not work for 60 seconds.

To cancel a MANUAL HEATING cycle press the START/STOP button (5) for two consecutive

times. The display will go back to the Home screen.

19

Page 21

ENGLISH

10.4 Setting-up and implementation of an AUTOMATIC cycle :

The selection of the AUTOMATIC menu allows you to set up a complete retarded proofing process.

► Press key AUTOMATIC (9)

9

► Press the + button or the minus button to set

the end of cycle time

► Press SET (9) to confirm the hour and move

to change minutes after modification

► push the key SET (9) again to confirm the

time of the end of the cycle and move to the

next screen

The screen shows the day and time for end of

stroke and four selection options

-Hourly (7) time slot +24 +48 +72

-Clock (10)

-Pencil (8)

-Save data (11)

END CYCLE TIME CHANGE

END CYCLE

MON 30/12/13 12:00

Hourly -time slot (7) +24 +48 +72 by pushing

it delays the end time 24h 48h 72h cycle or

leaving unchanged the end time cycle and the

fermolievitazione program:

-Watch (10) Pushing it back to set the time for

the end of cycle

END CYCLE

MON 30/12/13 12:00

20

Page 22

ENGLISH

► Press key (8) to set up the AUTOMATIC

starting cycle parameters.

► Press the SET key (10) to modify the parame-

ters relative to the first “BLOCK” phase of the

automatic RETARDED PROOFING CYCLE.

- Temperature

- Duration

PHASE 1

-5 °C

04:32 h:m

100 %

PHASE 1

-5 °C

04:32 h:m

100 %

PLEASE NOTE: The fans speed adjustment fun-

ction is disabled as it is automatically set.

► Press the - and + keys (8-11) to modify the values

► Press the SET key (10) to confirm

► When the operation is over press the UP key

(9) to proceed to the next step

►

Press the SET key (10) to modify the parameters

relative to the second “PRESERVATION” phase of

the automatic RETARDED PROOFING cycle.

- Temperature

PHASE 1

-5 °C

04:32 h:m

100 %

PHASE 2

-5 °C

100 %

► Press the – and + keys (8-11) to modify the

TEMPERATURE values

► Press the SET key (10) to confirm

► When the operation is over press the UP key

(9) to proceed to the next step

PLEASE NOTE: The fans speed adjustment

function is disabled as it is automatically set

21

Page 23

ENGLISH

► Press the SET key (10) to modify the parame-

ters relative to the third “PROOFING” phase of

the automatic RETARDED PROOFING cycle.

- Temperature

- Humidity

- Duration

► Press the - and + keys (8-11) to modify values

► Press the SET key (10) to confirm

► When the operation is over press the UP key

(9) to proceed to the next step

PLEASE NOTE: The fans speed adjustment

function is disabled as it is automatically set .

► Press the SET key (10) to modify the parame-

ters relative to the fourth “LEAVENING” phase

of the automatic RETARDED PROOFING cycle.

- Temperature

- Humidity

- Duration

PHASE 3

3 °C

100 %

02:00 h:m

100 %

PHASE 4

28 °C

100 %

02:00 h:m

100 %

► Press the – and + keys (8-11) to modify values

► Press the SET keys (10) to confirm

► When the operation is over press the UP key

(9) to proceed to the next step

PLEASE NOTE: The fans speed adjustment

function is disabled as it is automatically set.

PLEASE NOTE : to skip one or more single step you should set its duration at 00:00 h:m

► Press the SET key (10) to modify the para-

meters relative to the fifth “DELAYED BAKING”

phase of the automatic RETARDED PROOFING

cycle.

- Delay baking

PHASE 5

SI

13 °C

85 % rH

100 %

- Temperature

- Humidity

► Press the – and + keys (8-11) to modify values

► Press the SET button (10) to confirm

PLEASE NOTE: The fans speed adjustment

function is disabled as it is automatically set.

► When all the programming phases of the AUTOMATIC CYCLE have been completed, press the

UP key (9) to review the set values of the different cycle steps.

22

Page 24

ENGLISH

► To save the new set cycle press the ESC key (4)

► Press the SAVE DATA button (11)

► Press the DOWN key (9) to save the program-

me with a name already existing in the list then

press the SAVE key (10) or save the programme

with a new name by pressing the SAVE AS key

(11)

END CYCLE

MON 30/12/13 12:00

PROGRAMS

P01 BREAD 100G

P02 BREAD 300G

P03 BREAD 500G

P04 <free>

P05 <free>

P06 <free>

P07 <free>

To save the programme with a new name:

BREAD 100G------

► Press the direction keys (6-7-9-10) to select

the letters

► Press the SET key (11) to confirm

► Press the DEL key (8) to cancel

► Select END to confirm and save the name of

A B C D E F G H I J K

M N O P Q R S T U V

Y Z 0 1 2 3 4 5 6 7 8 9

. , ; : ! ? % / * - + (

) ‘ (SPACE) (END)

the programme

Each recalled cycle always suggests the time with which the program has been saved

► Press the START/STOP keys (5) to view the

schedules of the end phase

► Press the START/STOP keys (5) again to start

the automatic cycle

END OF PHASES TIME

Phase 1 THU 08/01/15 h 13:47

Phase 1 THU 08/01/15 h 13:47

Phase 1 THU 08/01/15 h 13:47

Phase 1 THU 08/01/15 h 13:47

23

Page 25

ENGLISH

► The display will show the status of the current

PHASE, the end-of-cycle date and the temperature.

END CYCLE THU 08/01 17:47

► To deactivate the DELAYED BAKING phase

press the (8) key

PHASE 1

25 °C

At the end of the program the machine stops automatically in STAND-BY

During the implementation of an AUTOMATIC CYCLE press the MENU key (2) to view the following

options:

- SETPOINT

- ALARMS LIST

- INTERNAL VALUES

- END-OF-PHASE TIME

- MANUAL DEFROSTING

- LIGHT

► Press the MENU key (2) to modify the

SETPOINT during a working AUTOMATIC

CYCLE and select with the UP-DOWN keys (9-

10) the SETPOINT item then press the SET key

(11)

OPTIONS

SETPOINT

ALARM LIST

INTERNAL VALUES

END OF PHASES TIME

MANUAL DEFROST

LIGHT

15:14 07/01/15

► Press the – and + keys (8-11) to modify the de-

fined SETPOINT

► Press the 9 button to move to the next phase

► When the operation is over either press the ESC

key (4) to go back to the OPTIONS menu

PLEASE NOTE: The fans speed adjustment functon is disabled as it is automatically set.

24

PHASE 1

-5 °C

04:32 h:m

100 %

Page 26

ENGLISH

► Press the MENU key (2) to view the ALARMS

LIST during a working AUTOMATIC CYCLE.

► Select with the UP-DOWN keys (9-10) the

ALARMS LIST item then press the SET key (11)

► The display will show the alarms list (active

alarms are identied with ON)

► Press the UP-DOWN keys (9-10) to scroll throu-

gh the alarms

► When the operation is over either press the

ESC key (4) to go back to the OPTIONS menu or

do not work for 60 seconds.

OPTIONS

SETPOINT

ALARM LIST

INTERNAL VALUES

END OF PHASES TIME

MANUAL DEFROST

LIGHT

15:14 07/01/15

ALARM LIST

Error Pr1 OFF

Error Pr2 OFF

Error Pr3 OFF

Error Pr4 OFF

Error AH OFF

Error PD OFF

► Press the MENU key (2) to display the INTER-

NAL VALUES during a running AUTOMATIC

CYCLE

► Press the UP-DOWN keys (9-10) to select the

INTERNAL VALUES then press the SET key (11)

► The display will show the list of the INTERNAL

VALUES

► Press the UP-DOWN keys (9-10) to scroll down

the INTERNAL VALUES

► When the operation is over either press the

ESC key (4) to go back to the OPTIONS menu or

do not work for 60 seconds.

OPTIONS

SETPOINT

ALARM LIST

INTERNAL VALUES

END OF PHASES TIME

MANUAL DEFROST

LIGHT

15:14 07/01/15

INTERNAL VALUES

Temp cell 15°C

Humidity 40%

Temp Evap 27°C

Temp Cond - - -

Door OFF

High Pres OFF

25

Page 27

ENGLISH

► Press the MENU key (2) to view the END-OF-

PHASES TIME during a running AUTOMATIC

CYCLE.

► Press the UP-DOWN keys (9-10) to select the

END-OF-PHASES TIME then press the SET key

(11)

► The display will show the list of the END-OF-

PHASES TIME

OPTIONS

SETPOINT

ALARM LIST

INTERNAL VALUES

END OF PHASES TIME

MANUAL DEFROST

LIGHT

15:14 07/01/15

END OF PHASES TIME

► When the operation is over either press the

ESC key (4) to go back to the OPTIONS menu or

Phase 1 THU 08/01/15 h 13:47

Phase 1 THU 08/01/15 h 13:47

Phase 1 THU 08/01/15 h 13:47

Phase 1 THU 08/01/15 h 13:47

do not work for 60 seconds.

To cancel the AUTOMATIC cycle press the START/STOP button (5) for two consecutive

times. The display will go back to the Home screen.

26

Page 28

ENGLISH

10.5 PROGRAMS:

The PROGRAMS menu allows you to select a retarded proong cycle among the 10 available

programme locations.

► Press key PROGRAMS (7)

7

► Press the UP-DOWN keys (9-10) to scroll down

the list

► Press the SET key (11) to select the desired

program.

► Press the START/STOP key (5) to start the se-

lected program or

PROGRAMS

P01 BREAD 100G

P02 BREAD 300G

P03 BREAD 500G

P04 <free>

P05 <free>

P06 <free>

P07 <free>

► Press the CHANGE VALUES key (8) to modify

the SETs of the different phases (see Par. 10.4

page 20)

The screen shows the day and time for end of

stroke and four selection options

-Hourly (7) time slot +24 +48 +72

-Clock (10)

-Pencil (8)

-Save data (11)

► Press the START/STOP key (5) twice to start

the selected program

► The display will show the current status of the

running PHASE , the current end-of-cycle date

and the temperature.

► Press the (8) key to deactivate the DELAYED

BAKING phase. The same options of the AUTOMATIC CYCLE will be available by pressing

the MENU key (2) during the running of a PROGRAM (Chapter10.4 page 20)

END CYCLE

MON 30/12/13 12:00

END CYCLE THU 08/01 17:47

PHASE 1

25 °C

27

Page 29

ENGLISH

► Retarded proong process already stored

As an example it has been stored 3 programs : Bread 100 gr., Bread 300 gr., Bread 500 gr.

P01 - Bread 100 gr.

PHASE 1 PHASE 2 PHASE 3 PHASE 4 PHASE 5

COOLING STORAGE PROOFING LEAVENING DELAYED BAKING

Temperature -5 2 16 28 22

Humidity NOT ACTIVATED NOT ACTIVATED 80% 80% 75%

Time 03:30 (hh:mm) AUTOMATIC 03:00 (hh:mm) 2:00 (hh:mm) INFINITE

Fan speed 100% 100% 100% 100% 100%

P02 - Bread 300 gr.

PHASE 1 PHASE 2 PHASE 3 PHASE 4 PHASE 5

COOLING STORAGE PROOFING LEAVENING DELAYED BAKING

Temperature -5 0 16 28 22

Humidity NOT ACTIVATED NOT ACTIVATED 80% 80% 75%

Time 04:00 (hh:mm) AUTOMATIC 03:30 (hh:mm) 02:30 (hh:mm) INFINITE

Fan speed 100% 100% 100% 100% 100%

P03 - Bread 500 gr.

PHASE 1 PHASE 2 PHASE 3 PHASE 4 PHASE 5

COOLING STORAGE PROOFING LEAVENING DELAYED BAKING

Temperature -6 -2 16 28 22

Humidity NOT ACTIVATED NOT ACTIVATED 80% 80% 75%

Time 04:30 (hh:mm) AUTOMATIC 04:00 (hh:mm) 03:00 (hh:mm) INFINITE

Fan speed 100% 100% 100% 100% 100%

The remaining 7 positions, on 10 available are personalised directly by the customer himself.

28

Page 30

ENGLISH

10.6 PRE-COOLING CYCLE:

The purpose of the pre-cooling cycle is to lead the cell to a defined temperature before selecting and

starting a retarded proofing cycle.

Once the pre-cooling temperature is reached , the buzzer sounds in an intermittent manner indicating

that the machine is ready to perform a cycle.

The pre-cooling cycle goes on running until the START/STOP key is pressed or up to the starting of

an automatic or manual cycle.

► Press key PRE-COOLING (10)

10

► Press the - and + keys (8-11) to modify the

temperature

► Press the START/STOP key (5) to start the

PRE-COOLING cycle

► The display will show a flashing white triangle

on the PRE-COOLING icon (10)

The cycle may last until you start a program. When

the defined temperature is reached an acoustic signal will sound.

► To cancel the PRE-COOLING cycle hold the

START/STOP key (5) pressed for more than 5 seconds.

Pre-cooling

-5 °C

Start

10

5

29

Page 31

ENGLISH

10.7 FAVOURITE RUNNING CYCLES :

This menu allows you to recall the favourite running cycles promptly, i.e. the last 10 implemented

cycles.

► Press key FAVOURITES (8)

8

► Press the UP-DOWN keys (9-10) to scroll down

the list of favourite programs

► Press the SET key (11) to select a favourite

program

FAVOURITES

F01 BREAD 100GM

F03 ---

F04 ---

F05 ---

F06 ---

F07 ---

F08 --

► If necessary, press the CHANGE VALUES key

(8) to modify the SETs of the different phases (see

Par. 10.4 page 20)

END CYCLE

MON 30/12/13 12:00

The screen shows the day and time for end of

stroke and four selection options

-Hourly (7) time slot +24 +48 +72

-Clock (10)

-Pencil (8)

-Save data (11)

► Press the START/STOP key (5) twice to start

the selected program.

The management of the cycle will be the same as

the setting of an automatic cycle

To cancel the cycle hold the START/STOP button (5) for two consecutive times.. The display

will go back to the Home screen.

30

Page 32

ENGLISH

10.8 ALARMS

This page allows you to enter the ALARMS menu .

► Premere key MENU (2),

► Select with UP-DOWN keys (9-10) ALARMS

LIST item then press the SET key (11)

2

OPTIONS

LIGHT

22/12/14 18:15

MANUAL DEFROST

ALARM LIST

INTERNAL VALUES

SERVICE

► Press the UP-DOWN keys (9-10) to scroll

through the alarms list .

Active alarms will be identified with ON

► Either press the ESC key (4) to terminate or do

not work for 60 seconds.

ALARM LIST

Error Pr1 OFF

Error Pr2 OFF

Error Pr3 OFF

Error Pr4 OFF

Error AH OFF

Error PD OFF

Error CSd OFF

31

Page 33

List of alarms which may occur:

ENGLISH

ALARM

Pr1 Cell probe error • Cell probe fails • Replace probe

Pr2 Evaporator probe error • Evaporator probe fails • Replace probe

Pr3 Condenser probe error • Disabled • Disabled

Pr4 Humidity probe error • Humidity probe is faulty • Replace the probe

AH

PD

CSd Blocked Compressor alarm • Disabled • Disabled

COH Blocked Compressor alarm • Disabled • Disabled

rtc Internal clock error

Maximum temperature

alarm

Poup-Down

compressor alarm

DESCRIPTION CAUSE SOLUTION

• Cell probe is faulty

• Control unit is faulty

• Cooling system is faulty

• Disabled • Disabled

• The device has not worked

for a long period

• Control unit is faulty

• Service

• Service

• Service

• Switch on the device

and set the date again

• Service

CtH

ErC

ErL

PF

id Open door alarm

HP High pressure alarm • Disabled • Disabled

LP Low pressure alarm • Disabled • Disabled

Compressor thermal

protector

No compatibility between

interface and control modu-

No communication between

interface and control module

Interruption of power supply

to the machine

• Disabled • Disabled

• Firmware of setting - instrument

is not compatible

• Interface connection is either

incorrect or faulty

• Power failure may have

occurred

• The door has been kept open

• Service

• Check proper

connection

• Press any key to cancel

the alarm

• Close the door

32

Page 34

ENGLISH

10.9 MANUAL DEFROSTING

To start a MANUAL DEFROSTING cycle proceed as follows.

► Premere the key MENU (2),

► Select with the UP-DOWN keys (9-10) the MA-

NUAL DEFROSTING item then press the SET

key (11)

The defrosting cycle will start if the evaporator

temperature is lower than the defined value for

the defrosting completition, only

2

OPTIONS

LIGHT

22/12/14 18:15

MANUAL DEFROST

ALARM LIST

INTERNAL VALUES

SERVICE

► The display will go back to the Home screen

where the defrost icon relative to the MANUAL

DEFROSTING cycle running will appear in the

center of the picture display.

33

Page 35

ENGLISH

10.10 INTERNAL LIGHT SWITCHING-ON ( for cabinets supplied with glass door only)

To switch on the internal light proceed as follows.

► Press key MENU (2),

2

► Select with the UP-DOWN keys (9-10) the

LIGHT item then press the SET key (11)

The machine internal LIGHT will switch on.

Press the SET key (11) to switch off the light

OPTIONS

LIGHT

22/12/14 18:15

MANUAL DEFROST

ALARM LIST

INTERNAL VALUES

SERVICE

It is possible to switch on the internal LIGHT at any time even when the machine is running by

pressing the MENU key (2) and repeating the above procedure.

34

Page 36

ENGLISH

10.11 Detailed description of the icons relative to the Controllers Status

During the implementation of a cycle (either Manual or Automatic) the status of the main controllers

shall be displayed by means of icons.

► White ON : compressor is activated

► Yellow ON: compressor activation is required

► OFF : compressor is not active

► ON : heating is activated

► OFF: heating is not active

► ON : humidification is activated

► OFF : humidification is not active

► ON : dehumidification is activated

► OFF : dehumidificazione is not active

Buzzer silencing

Press and release any key when the buzzer is sounding.

Alarms

When an alarm signal occurs a pop-up window opens stating the current alarm code. The buzzer

sounds in an intermittent manner until you press any key silencing the buzzer and making the popup window disappear.

The icon indicating the current alarm is still present on the screen

35

Page 37

ENGLISH

10.12 USB Host Port

By inserting a USB stick you may have the possibility to carry out the following operations:

► Download the data relative to the cycles performed on the USB stick (historical records)

► Download the saved parameters onto the USB stick (service)

► Download the saved programs onto the USB stick (service)

► Upload the parameters contained in the USB stick (service)

► Upload the programs contained in the USB stick (service)

10.13 Download of data relative to the cycles performed on the USB stick (historical

records)

It allows to record the data relative to the performed cycles onto the USB stick and view them on

any PC by means of Excel computer program.

► If ON put the card in STAND-BY mode by

pressing the ON/OFF key (1)

► Insert the USB stick into the USB host port

► Select with the UP-DOWN keys (9-10) the

DOWNLOAD HISTORY menu then press the

SET key (11)

DOWNLOAD HISTORY

DOWNLOAD PARAMETERS

DOWNLOAD PROGRAMS

UPLOAD PARAMETERS

UPLOAD PROGRAMS

USB

► Select with the – and + keys (8-11) date and

time

► Press the SET key (9) to confirm

► Press the START/STOP key (5) to download

data relative to performed cycles onto the USB

stick.

► When the operation is over take out the USB

stick. This option saves a text file (CSV) onto the

USB stick that may be displayed on any type of

PC fitted with EXCEL program

SELECT

DATE AND TIME

09 / 01 / 15

13.44

USB

DOWNLOAD HYSTORY

END

REMOVE KEY

The download le will be a CSV format, i.e. it can be simply open with a double click by any computer

tted with Excel program.

36

Page 38

ENGLISH

The recorded les have a sequential number accordingly with the number of times they have been

unloaded.

In this way the name of le could change in “log00n00001.csv”, “log00n00002.csv”, etc.

All collected data will be automatically entered in tabular form on a Excel sheet, separated into

columns and rows. You can then obtain tables and graphs (see example) depending on your needs.

EVFTFT618

°C °C %

12/03/2015 14.00 Start 19 19 44

State cycle In progress

Type of cycle Manual

Number of phase Heating

Defrost cycle Off

Status compressor Off

State light Off

State humidier Off

State dehumidier Off

State defrosting Off

State desistance Off

State steam generator Off

12/03/2015 14.02 Event 20 20 44

High Press. alarm Present

12/03/2015 14.03 Event 20 20 44

High Press. alarm Not present

12/03/2015 14.05 sampling 20 20 44

12/03/2015 14.08 event 20 20 43

High Press. alarm Present

12/03/2015 14.08 event 20 20 43

High Press. alarm Not present

12/03/2015 14.09 Event 20 20 43

Thermal probe Present

12/03/2015 14.09 Event 20 20 43

Thermal probe Not present

12/03/2015 14.10 Sampling 20 20 42

12/03/2015 14.11 Stop 20 20 42

12/03/2015 14.11 Start 20 20 42

State cycle In progress

Type of cycle Automatic

Number of Phase Phase 1

12/03/2015 14.16 Sampling 21 21 43

12/03/2015 14.16 Stop 21 21 43

Cell

probe

Evaporator

probe

Umidity

probe

CHAPTER 10 NOISE LEVEL

The noise threshold of the retarder-proofer/dough retarder refrigerated cabinet and refrigerated

table is lower than 70 dB (A).

CHAPTER 11 MATERIALS AND FLUID USED

The materials in contact or which may come into contact with foodstuffs comply with the relevant

directives.

The retarder-proofer/dough retarder refrigerated cabinet and refrigerated table have been

designed and built in such a way that these materials can be cleaned before each use.

The coolants used R404A/R290 conform to the relevant provisions of law (see Table 1).

R404A is a fluorinated gas covered by the Kyoto Protocol with a GWP potential of 3300

The symbol indicates that this product must not be treated as household waste.

To prevent potential negative consequences for the environment and human health, make sure that

this product is properly disposed of and recycled.

For more information regarding the disposal and recycling of this product, please contact your

Distributor, after sale Service, or waste treatment Service.

37

Page 39

ENGLISH

CHAPTER 13 TRANSPORT AND HANDLING

The transport and handling of the retarder-proofer/dough retarder refrigerated cabinet and

refrigerated table must only be done while maintaining the vertical position, observing the markings

on the packaging.

The manufacturer disclaims any liability for problems resulting from transport performed

under conditions other than those specified above.

The accessories of the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table

(guides, grilles, trays, remote condensing unit with pipes) are packaged separately and placed inside

the unit.

The retarder-proofer/dough retarder refrigerated cabinet and refrigerated table are mounted on a

wooden base with screws and packaged with polyethylene, carton, crate or boxes.

Regarding the disposal of the packaging it is necessary to refer to current regulations in your country.

The movement of the retarder-proofer/dough retarder refrigerated cabinet and refrigerated

table shall be performed using a fork lift or pallet trucks equipped with suitable forks (length of at

least 2/3 of the unit).

The dimensions and masses of the retarder-proofer/dough retarder refrigerated cabinet and refrigerated

table packed are shown in Table 1.

The limits of stackability and the centre of gravity are indicated on the label of the package.

13.1 Positioning operations

Since the incorrect positioning of the retarder-proofer/dough retarder refrigerated cabinet and

refrigerated table can cause damage to the same, jeopardizing its proper functioning and cause risks

to the personnel, the installer must comply with the following general rules:

- position the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table keeping a

minimum distance of 3 cm from any wall

- the environment must be sufciently ventilated

- position the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table away from

heat sources

- avoid exposure to direct sunlight

- remove the polyethylene, cardboard or wood packaging

38

Page 40

ENGLISH

Polyethylene is dangerous for children

- remove any accessories with external connections

Removing the wooden base (g. 4) : tilt the retarder-proofer/dough retarder refrigerated cabinet and

refrigerated table sideways and unscrew the two self-tapping screws (cabinet solely) , lift the retarderproofer/dough retarder refrigerated cabinet and refrigerated table and remove the base.

Fig.4

use protective gloves when handling the wooden packaging and the wooden base.

The presence of splinters may cause damage to your hands

- remove the PVC lm applied as a protection to the outer surfaces of he retarder-proofer/dough

retarder refrigerated cabinet and refrigerated table

- position the retarder-proofer/dough retarder refrigerated cabinet and refrigerated table using a level

with possible adjustment of the feet of the metal base (Fig. 5 )

Fig.5

- position the grille holding guide fails in the holes of the racks (Fig. 6 )

39

Fig.6

Page 41

ENGLISH

- insert the grilles for food in the special guides

- insert the condensate water drain pan into the special guide rails already xed under the retarder-

proofer/dough retarder table REM.

13.2 Retarder-proofer/dough retarder refrigerated cabinet and refrigerated table REM ( Fig. 7 )

Fig.7

- position the retarder-proofer/dough retarder table REM as described above (Fig. 5)

- prepare the two tubes that come out of the retarder-proofer/dough retarder table and cabinet REM

(refer to the technical sheet of the equipment) for the connection to the respective pipes

- connect the pipes of the condensing unit to the pipes of the retarder-proofer/dough retarder table

- create a vacuum and then carry out the loading of the coolant

- make the electrical connection of the retarder-proofer/dough retarder table and cabinet to the

condensing unit

- perform a functional test to verify the correct gas charge.

CHAPTER 14 ELECTRICAL WIRING AND CONNECTIONS

The electrical system and connection must be carried out by qualified personnel. Before installation,

measure the impedance of the network, the impedance value for the connection to the network must

not exceed 0.075 ohm.

For safety reasons you must follow these guidelines:

- verify that the sizing of the electrical system is suitable for the power consumption of the retarderproofer/dough retarder table and cabinet and that it provides for a differential switch (circuit breaker)

- in case of incompatibility between the outlet and the plug of the retarder-proofer/dough retarder

table and cabinet, replace the outlet with another of a suitable type provided that it is in accordance

with regulations

- do not insert adapters and/or reductions (Fig. 8)

Fig.8

The power cord has the connection type “Y” and it can be replaced exclusively by the

manufacturer or authorized technical service

40

Page 42

ENGLISH

It is essential to correctly connect the retarder-proofer/dough retarder table and cabinet to an

efcient earthing system carried out as specied by the applicable provisions of law.

14.1 Connection to the water supply (retarder-proofer solely)

All models of retarder-proofer/dough retarder refrigerated table and refrigerated cabinet need to

be connected to a water supply to perform the functions of management and control of humidity.

The connection to water supply must be made according to the manufacturer’s instructions and by

professionally qualied personnel. The tting of 3/4 for the connection to the water supply is located

in the condensing unit of the retarder-proofer cabinets, in the rear, close to the housing of the power

supply cable at an height from the ground of cm 190. This unit must only be supplied with cold water,

not distilled or demineralized.

The operating pressure should be between 0.1 and 0.5 MPA. Between the water network and the

load connection of the equipment 3/4 should be installed a tap to interrupt the passage of water in

case of need. In the case the water is hard it is advisable to install a water softener, the presence of

solids such as sand can be eliminated by installing a mechanical lter to be inspected and cleaned

periodically.

CHAPTER 15 INSTALLATION OPERATIONS

It is important, in order to prevent errors and accidents, to perform a series of checks before starting

up the the retarder-proofer/dough retarder table and cabinet in order to identify any damage incurred

during transport, handling and connection.

Checks to be performed:

- check the integrity of the power cord (it must not have suffered abrasions or cuts)

- check the solidity of the legs, door hinges, shelf supports

- check the integrity of the internal and external parts (pipes, heating elements, fans, electrical

components, etc.) and their xing

- check that the seals of the doors and drawers have not been damaged (cuts or abrasions) and

close with an airtight seal

- check the integrity of the pipes and ttings (REM)

CHAPTER 16 REINSTALLATION

It is necessary to comply with the following procedure:

- disconnect the power cord from the power outlet

- the handling should be carried out as described in chapter 13

- for a new placement and connection, please refer to par. 13.1

- for the REM models proceed to the possible recovery of the coolant gas in accordance with the

regulations in force in your country

41

Page 43

ATTENTION!

INSTRUCTIONS RESERVED SOLELY TO TECHNICAL

PERSONNELL

Users are adviced that any work performed by non-technical staff or

unauthorized personnel will produce the voiding of the warranty rules.

42

Page 44

PARAMETER MODIFICATION DISPLAYING

It allows to access the setup parameters of the

Control Panel.

► Press the MENU key (2).

► Select with the UP-DOWN keys (9-10) the

“SERVICE” menu item then press the SET key

(11)

2

OPTIONS

22/12/14 18:15

MANUAL DEFROST

ALARM LIST

INTERNAL VALUES

SERVICE

► Select with the UP-DOWN keys (9-10) the

“INTERNAL SETUP” menu item then press the

SET key (11)

► Enter the Password* (-19) with the – and +

keys (8-11) then press the SET key (9)

SERVICE

LANGUAGES

HISTORICAL DATA

INTERNAL SETTING

PASSWORD

PA -19

43

Page 45

► Select with the UP-DOWN keys (9-10) the

menu item then press the – and + keys (8-11) to

modify values.

► Either press the ESC key (4) to exit or do not

work for 60 seconds.

ALARM LIST DISPLAYING

Proceed as stated at Paragraph 10.8 to display the alarms list.

PARAMETERS

CA1

CA2

CA3

CA4

P0

P2

1

0

0° C

0° C

0° C

%

44

Page 46

RETARDER PROOFER CABINETS/TABLES AND DOUGH-RETARDER PARAMETERS

Par. Min. Mas. Unit Dough

CA1 ¬25 25 °C 0 0

CA2 ¬25 25 °C 0 0

CA3 ¬25 25 °C 0 0

CA4 ¬25 25 %r.H. 0 0

P0 0 1 ¬¬¬¬ 1 1

P2 0 1 ¬¬¬¬ 0 0

P3 0 1 ¬¬¬¬ 1 1

P4 0 1 ¬¬¬¬ 0 0

P5 0 60 Min 60 60

P6 0 2 ¬¬¬¬ 1 1

P7 0 P8 %r.H. 0 0

P8 P7 100 %r.H. 100 100

P9 0 250 ds 5 5

Par. Min. Mas. Unit Dough

rC0 1 15 °C 2 2

rC1 ¬99 rC2 °C ¬-10 -10

rC2 rC2 99 °C 20 20

rC3 0 10 °C 1 1

rC4 0 10 °C 1 1

rC5 0 10 °C 1 1

rC6 ¬99 99 °C -5 -5

Par. Min. Mas. Unit Dough

rH0 1 15 °C 2 2

rH1 ¬99 rH2 °C 0 0

rH2 rH2 99 °C 40 40

rH3 0 10 °C 1 1

rH4 0 10 °C 1 1

rH5 0 10 °C 1 1

rH6 1 600 sec 60 60

rH7 1 600 sec 60 60

rr0 1 10 ¬¬¬¬ 1 1

rr1 1 rr2 % 100 100

rr2 rr1 rr3 % 1 1

rr3 rr2 rr4 % 1 1

rr4 rr3 100 % 1 1

rr5 rr4 rr6 % ¬¬¬¬- rr6 rr5 rr7 % ¬¬¬¬- rr7 rr6 rr8 % ¬¬¬¬- rr8 rr7 rr9 % ¬¬¬¬- rr9 rr8 rr10 % ¬¬¬¬- -

rr10 rr9 100 % ¬¬¬¬- -

rL0 1 10 ¬¬¬¬ 1 1

rL1 1 rL2 % 100 100

rL2 rL1 rL3 % 1 1

rL3 rL2 rL4 % 1 1

rL4 rL3 100 % 1 1

rL5 rL4 rL6 % ¬¬¬¬- rL6 rL5 rL7 % ¬¬¬¬- rL7 rL6 rL8 % ¬¬¬¬- rL8 rL7 rL9 % ¬¬¬¬- rL9 rL8 rL10 % ¬¬¬¬- -

rL10 rL9 100 % ¬¬¬¬- -

Par. Min. Mas. Unit Dough

rU0 0 1 ¬¬¬¬ 1 0

rU1 ¬99 99 °C 7 7

Retarder-Proofer

Retarder-Proofer

Retarder-Proofer

Retarder-Proofer

Analog inputs

Offset cell probe

Offset evaporator probe

offset condenser probe

offset humidity probe

Type of probe 0 = PTC 1 = NTC

Temperature unit of measure 0 = °C 1 = °F

Enabling of evaporator probe 0 = disabled 1 = enabled

Enabling of condenser probe 0 = disabled 1 = enabled

duration of a power failure while a higher cycle which is signaled by the power failure

alarm

Reserved

Lower limit of humidity transducer calibration range (equal to 4mA)

Higher limit of humidity transducer calibration range (equal to 20mA)

Delayed visualisation of the temperature variation detected by probes

Cold Regulator

Variation of the rC3, rC4, rC5 parameters

Minimum setpoint that can be set for the block phases, the preservation and the manual

cooling operations

Maximum setpoint that can be set for the block phases, the preservation and the manual

cooling operations

Values of cold neutral zone for the block phase, the preservation and the manual cooling

operations

Values of cold neutral zone for the proong , the leavening and the manual heating

operations

Values of cold neutral zone for the delayed baking phase

precooling setpoint

Hot Regulator

Variations of the rH3, rH4, rH5 parameters

Minimum setpoint that can be set for the proong phase, the leavening , the delayed

baking and the manual heating operations

Maximum setpoint that can be set for the proong phase, the leavening, the delayed

baking and the manual heating operations

Value of warm neutral zone for the block phases, the preservation and the manual heating operation

Value of warm neutral zone for the proong phases, the leavening and the manual heating operation

Value of warm neutral zone for the delayed baking phase

Cycle time for the starting of the heating resistors in case warmth is required (see also

rH7)

Switch-on time for the heating resistors within the limit of the cycle time stated at rH6

Number of adjustment pitches during the proong phase

Percentage increase 1° proong step (compared to 100% total)

Percentage increase 2° proong step (compared to 100% total)

Percentage increase 3° proong step (compared to 100% total)

Percentage increase 4° proong step (compared to 100%)

Percentage increase 5° proong step (compared to 100%)

Percentage increase 6° proong step (compared to 100%)

Percentage increase 7° proong step (compared to 100%)

Percentage increase 8° proong step (compared to 100%)

Percentage increase 9° proong step (compared to 100%)

Percentage increase 10° proong step (compared to 100%)

Number of resistors adjustment pitches during the leavening phase

Percentage increase 1° leavening step (compared to 100%)

Percentage increase 2° leavening step (compared to 100%)

Percentage increase 3° leavening step (compared to 100%)

Percentage increase 4° leavening step (compared to 100%)

Percentage increase 5° leavening step (compared to 100%)

Percentage increase 6° leavening step (compared to 100%)

Percentage increase 7° leavening step (compared to 100%)

Percentage increase 8° leavening step (compared to 100%)

Percentage increase 9° leavening step (compared to 100%)

Percentage increase 10° leavening step (compared to 100%)

Humidity Regulator

Humidity management mode : 0 = with humidity probe 1 = time cycles based on the set

percentange

minima temperatura in cella al di sotto della quale il controllo umidicazione/deumidicazione viene inibito

45

Page 47

rU2 1 600 sec 60 60

rU3 1 600 sec 60 60

rU4 0 1 ¬¬¬¬ 0 0

rU5 1 100 %r.H. 5 5

rU6 0 100 %r.H. 5 5

rU7 0 255 sec 10 10

rU8 1 100 %r.H. 5 5

rU9 0 100 %r.H. 5 5

rU1 0 0 50 %r.H. 10 10

rU1 1 0 255 s 60 60

rU1 2 0 1 ¬¬¬¬ 1 1

rU1 3 0 100 ¬¬¬¬ 100 100

Par. Min. Mas. Unit Dough

Retarder-Proofer

C0 0 240 min 0 0

C1 0 240 min 0 0

C2 0 240 min 5 5

C3 0 240 s 0 0

C4 0 240 min 0 0

C6 0 199 °C 60 60

C7 0 199 °C 65 65

C8 0 15 min 1 1

Par. Min. Mas. Unit Dough

Retarder-Proofer

d0 0 99 h 6 6

d1 0 1 ¬¬¬¬ 0 0

d2 ¬99 99 °C 8 8

d3 0 99 min 30 30

d5 0 99 min 0 0

d7 0 15 min 2 2

d15 0 99 min 0 0

Par. Min. Mas. Unit Dough

Retarder-Proofer

A1 0 99 °C 50 50

A2 0 1 ¬¬¬¬ 1 1

Par. Min. Mas. Unit Dough

Retarder-Proofer

F0 0 1 ¬¬¬¬ 1 1

F1 0 1 ¬¬¬¬ 0 0

F2 0 1 ¬¬¬¬ 1 1

F3 0 1 ¬¬¬¬ 1 1

F4 0 1 ¬¬¬¬ 1 1

F10 0 100 % 100 100

F11 0 100 % 100 100

F12 0 15 m 1 1

F13 0 250 s 0 0

F14 1 600 sec 0 0

F15 1 600 sec 0 0

F16 0 99 °C 40 40

F17 0 240 s 5 5

F18 0 240 s 5 5

F19 0 100 % 100 100

F20 0 100 % 100 100

F21 0 100 % 100 100

Cycle time for the starting of the humidier (only for rU0 = 1, see also uU3)

Humidier starting time within the cycle time uU2 to obtain 100% humidity inside cell

(only for rU0 = 1, see also rU2)

Enabling of humidication/dehumidication control during the block phases, the preservation and the manual cooling operations

Variations of dehumidifcation

Value of dehumidifcation neutral zone

Duration of dehumidication attempt with pumpdown-type solenoid valve

Variations of humidication

Value of humidication neutral zone

Value of humidication proportional band

Cycle time to adjust humidication proportional band

Time base for cycle time to adjust humidication proportional band 0 = seconds 1 =

minutes

Maximum humidity set

Compressor protection

Compressor delayed starting in respect of unit starting

Minimum lapse of time between two compressor starting operations

Minimum duration of compressor switching-off

Minimum duration of compressor switching-on

Duration of forced compressor starting at the beginning of the proong phases, the leavening and the delayed baking operations

Condenser temperature above which the overheated compressor alarm is activated

(code “COH”)

Condenser temperature above which the blocked compressor alarm is activated (code

“CSd”)

Blocked compressor delayed alarm (code “CSd”)

Defrosting

Defrost interval 0 = defrost at intervals will never be activated

Type of defrost 0 = elettrical (during defrosting the compressor will be switched-off, the

defrost output will be activated and the evaporator fan will be switched-off) 1 = with hot

gas defrosting (during defrosting the compressor will be switched-on, the defrost output

will be activated and the evaporator fan will be switched-off)

End-of-defrost temperature (evaporator temperature); see also the d3 parameter

If the P3 parameter is set to 0, duration of defrost if the P3 parameter is set to 1, maximum defrost duration ; see also the d2 parameter, 0 = defrost will never be activated

Delayed defrost in respect of the starting of the preservation phase/manual cooling operation 0 = defrost wll be activated after the time set with paramenter d0 is over

Duration of dripping (during dripping the compressor and the evaporator fan are

switched-off and the defrost output will be deactivated)

Minimum duration of the compressor starting when the defrosting operation is activated

to let it be started (if the d1 parameter is set to 1 only)

Temperature alarms

Evaporator temperature above which the evaporator high temperature alarm will be activated (code “AH”); see also the A2 parameter

Enabling of evaporator high temperature alarm (code “AH”) 1 = yes

Condenser and evaporator fan

Evaporator fan activity during the block phase 0 = parallel operation with compressor 1

= continuous operation

Evaporator fan activity during the preservation , cooling and precooling phases 0 = parallel operation with compressor 1 = continuous operation

Evaporator fan activity during the proong phase 0 = parallel operation with main utilities

1 = continuous operation

Evaporator fan activity during the leavening and heating phases 0 = parallel operation

with main utilities 1 = continuous operation

Evaporator fan activity during the delayed baking phase 0 = parallel operation with main

utilities 1 = continuous operation

Fans speed during precooling phase

Fans speed during dehumidication phase

Fans stop after dripping phase

Delayed evaporator fan switching-off from main utilities off

Evaporator fan cycle time, if set to 0, the cyclical switching-on of the evaporator will be

deactivated

Evaporator fan switching-on time within the F14 cycle time

Condenser temperature above which the condenser fan will be switched-on even if the

compressor is switched-off

Delayed switching-off of the condenser fan from the compressor switching-off (active if

the condenser probe is disabled, only)

Delayed evaporator fan switching-on from the closing of the door, i.e. from the deactivation of the micro door input

Minimum speed of the evaporator fan that can be set

Maximum speed of the evaporator fan that can be set

Start-up wind speed of the evaporator fan

46

Page 48

F22 1 10 s 10 10