Everlast series 2000 Owner's Manual And Installation Manual

EVERLAST MANUAL 15-8-2008.indd 1 20/8/08 10:35:05 AM

EVERLAST MANUAL 16pp.indd 1 9/07/10 11:02 AM

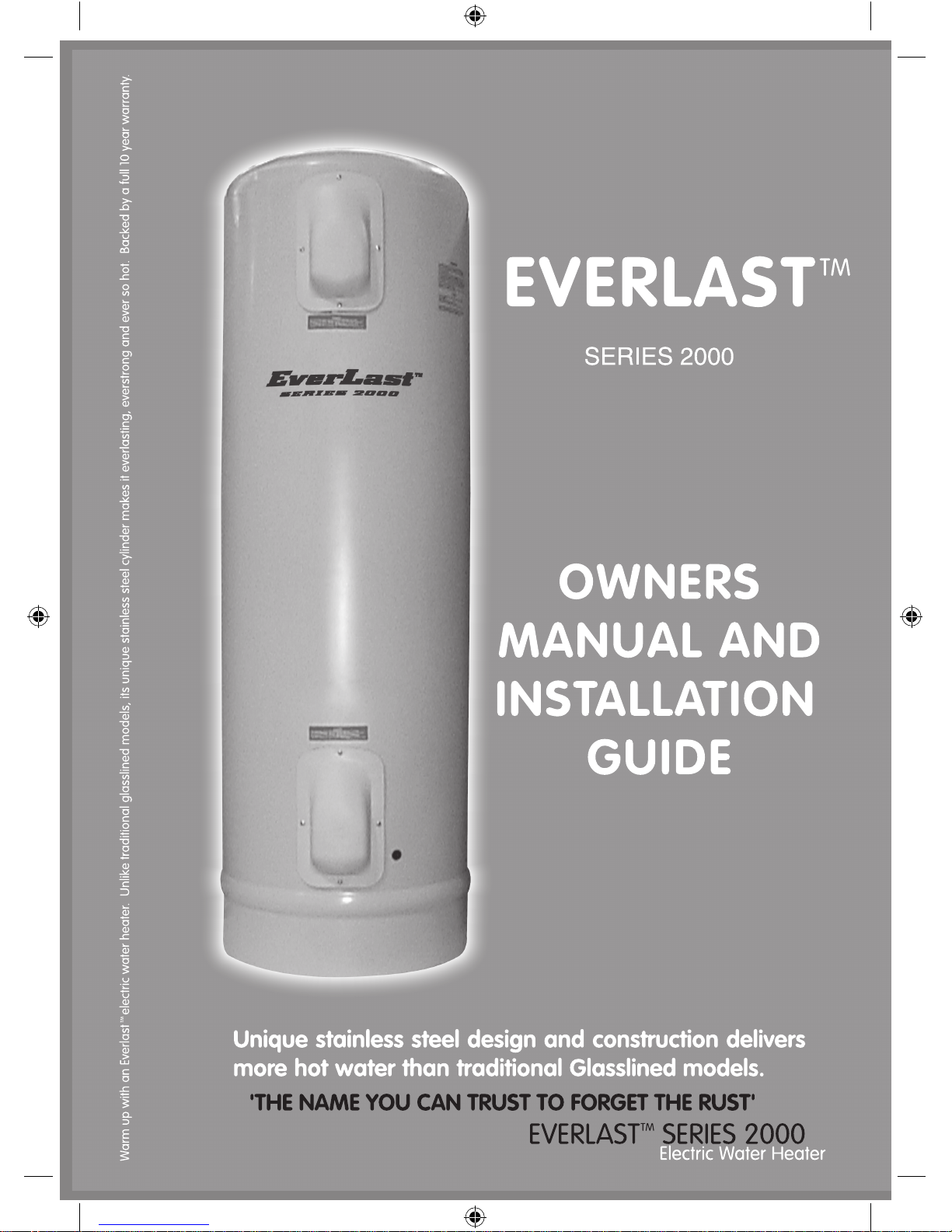

EVERLAST™ - SERIES 2000

Information regarding your EVERLAST™ Series 2000, Electric

Water Heater.

Congratulations for choosing an Everlast™ Water Heater. The unit has been

manufactured to Australian Standards AS 1056.1 and AS/NZS 60335.2.21,

and incorporates a STAINLESS STEEL CYLINDER produced from marine

grade stainless steel and which is covered by a 10 year warranty as per the

enclosed warranty conditions. The stainless steel cylinder gives longevity

of service and also less maintenance because there is no sacrificial anode.

The Everlast™ Series 2000 Electric Water Heater will provide continuous hot

water for many years to come.

1 Features of your Everlast™ Water Heater

The Everlast™ Series 2000 is an electric storage water heater that

can be heated using standard or “off peak” electricity. Your electricity supply

authority can provide you with information in relation to the “off peak” tariff

applicable to your particular location.

The Everlast™ Series 2000 incorporates the latest aspects of design and

material selection including :

• Marine Grade stainless steel cylinder,

• Control of thermal stratification,

• Dual Positive Domed Cylinder resulting in optimum location of

element(s), water supply and delivery and flushing-through of

suspended solids.

• Highest level of insulation due to the use of a polymeric external

casing combined with thick polyurethane insulation.

The Everlast™ Series 2000 heats potable water in the storage

cylinder by one or more immersion elements (depending upon model).

A thermostatically controlled electric element in the bottom of the

cylinder can be connected to normal or “Off Peak” power supply. A

second optional booster in the top half of the cylinder ( in twin element

models ) is used to add additional hot water as required. The heated water

rises up the cylinder by natural convection to the top where it is ready for use.

As hot water leaves the storage cylinder, it is replaced by cold water, which

enters at the bottom of the cylinder.

Everlast™ recommends flushing the water heater at regular intervals as

advised by your licensed plumber, and to assist this operation, the cold water

inlet has a large opening for flushing any built up solids that have escaped

the line strainer.

EVERLAST MANUAL 16pp.indd 2 9/07/10 11:02 AM

Hot Water Safety

In accordance with Australian Standard AS 3500.4, it is recommended

that where required a temperature control device or mixing valve be

fitted between the water heater and bathroom and ensuites to reduce the risk

of scalding. This is achieved by controlling water temperature to below 50

degrees C.

This appliance is not intended for use by young children or infirm persons

unless they have been adequately supervised by a responsible person to

ensure that they can use the appliance safely. Young children should be

supervised to ensure that they do not play with the appliance.

Pressure and temperature relief valve (P&T)

The Everlast™ Series 2000 is fitted with an 850 kPa P&T valve, which is

located on the side of the water heater and is essential for its safe operation.

We recommend you operate the easing lever on the P&T valve once every 6

months. It is important you raise and lower the lever gently. The P&T valve is

designed to allow small quantities of hot water to discharge during heating to

allow for hot water expansion. The P&T valve discharge should be directed

away by a downwards oriented discharge pipe which is protected by location

from possible frost restriction. This pipe must be left open to atmosphere and

suitably located to not become blocked.

Should a continuous discharge occur, we recommend that you consult your

licensed plumber as this may indicate a defective P&T valve, defective

thermostat, or abnormal high mains water pressure and that a pressure

limiting valve has not been fitted during installation.

Everlast ™ recommends that a 500 kPa pressure reducing valve be fitted at

time of installation. (refer to the water heater label and Mains Water Supply

in Section 2). This is an Installation Warranty condition. (refer to Warranty).

The valve should be installed in the Cold Water Inlet Piping as shown in the

schematic adjacent to Fig 2.

2 Installation, almost anywhere !

Most electric hot water heaters require a sacrificial anode inside the

cylinder, however, anodes are not necessary with a stainless steel

storage cylinder. As anode replacement is not required, headroom above

the cylinder only needs to accommodate convenient installation rather than

the one metre or more required to remove/replace the anode. Low eaves ?

No problem for Everlast™.

The Everlast™ Series 2000 may be used either indoors or outdoors and

should be installed by and located in accordance with your licensed plumbers

recommendation, but usually close to the outlet where there is the greatest

usage of hot water. Installation must comply with Australian Standard AS

3500.4 and any local authority regulations.

EVERLAST MANUAL 16pp.indd 3 9/07/10 11:02 AM

In accordance with AS/NZS 60335 CI.7, the following recommendations

are made in regard to both internal and external installation.

The Minimum space to be provided for Internal installation is 600 mm x 600

mm. The installation may be freestanding on the floor/sub-floor structure in

the enclosed area.

The clearance required needs to be adequate for service/replacement of cold

water inlet piping devices, PTR valve and tempering valves (where fitted),

elements and thermostats. This may be facilitated by correct orientation of the

cover positions when installing. There are no operational clearance limitations

to surrounding structure. PTR valve removal requires approximately 150 mm

for withdrawal.

Building-in acceptable provided that removable panels are able to facilitate

Unit replacement without major alteration to piping or to structural elements.

It is recommended to provide 25 mm hardwood slats under the unit to allow

free air movement and also a vent grille if the unit is to be fully built-in. This

will ensure that any moisture discharge from PTR drain pipe is evaporated if

directed to safety tray drain point.

Combustible Material

It is recommended to not place combustible material on or adjacent to the

water heater.

Internal Installation Safe Tray

For internal (indoor) installations, a safe tray is recommended in

accordance with Australian Standard AS 3500.4 clause 4.4, and as shown

in Figure 1. This is necessary to prevent damage associated with water loss

during element replacement.

External Installation Plinth

For external installation a plinth or concrete base pad is recommended in

accordance with Australian Standard AS 3500.4 clause 4.5.3. as shown

in Figure 2. Whilst this is necessary to ensure that the sheetmetal base of

conventional water heaters does not corrode; wet conditions do not effect the

Everlast™ polymeric casing which is corrosion proof. A base pad is optional

and will ensure even support. There is no need for any external weather

protection for your Everlast™ Series 2000 water heater.

Mains Power supply connections

Electrical work must be carried out by a licenced tradesman and in accordance

with AS 3000 SAA Wiring Rules. The circuit isolation and Fixed Appliance

regulations of the Wiring Rules Sec 4.3.9 shall be complied in regard to

connection to Supply and circuit isolatiom. Refer to Electrical Connection for

appliance to wiring connection and disconnection.

EVERLAST MANUAL 16pp.indd 4 9/07/10 11:02 AM

Mains water supply

As mains pressure commonly exceeds 500 – 550 kPa, a pressure limiting

valve should be installed set to 500 kPa maximum. Note: In some States a

cold water expansion valve must be installed by regulation. This valve must

be set at 700 kPa maximum.

As shown in figure 1 and 2, an approved isolating valve, line strainer and

union are recommended between the cold water supply main and the cold

water inlet of the Everlast™ Series 2000 water heater. Plumbing compliance

(safety) regulations require the installation of the supplied Non Return Valve

to ensure that the appliance does not empty during normal use or interrupted

water supply.

The Everlast™ Series 2000 water heater is designed to ensure total drainage

for flushing if required. It is recommended that a drain cock be installed on

the cold water inlet pipe adjacent to the heater to facilitate flushing annually in

poor water quality areas.

Hot water connection should be as shown in figure 1 and 2. It is recommended

that hot water outlet pipes are fully insulated withweatherproof insulation, and

that the hot water outlet pipe is slightly curved or stepped down adjacent to the

water heater outlet to provide a positive heat trap and avoid thermal siphoning

from the heater.

EVERLAST MANUAL 16pp.indd 5 9/07/10 11:02 AM

NON STANDARD INSTALLATIONS

The installation diagrams on the following pages refer to standard domestic

connections / installs.

For Solar and Commercial applications please refer to the relative system

suppliers connection / installation instructions.

Loading...

Loading...