Everlast PowerTig 200EX, PowerTig200LX, PowerTig 250EX, PowerTig250DX, PowerTig250LX Operator's Manual

...

1

EVERLAST

Power TIG ® Series

Tig (GTAW) and mma (smaw)

Welders

Operator ’ s Manual for PowerTig® AC/DC Welders

Includes Power i-Tig® DC Models

Safety, Setup and General Use Guide

Rev. 1 0518-09

2

Thank you for purchasing an everlast product. We appreciate your patronage and hope that you will enjoy

years of use from our product.

Please go directly to the Everlast website to register

your unit and receive your warranty information.

Your unit registration is important should any information such as product updates or recalls be issued.

It is also important so that we may track your satisfaction with Everlast products and services. If you

are unable to register by website, contact Everlast directly through the consumer department at the main

number. Your unit will be registered and warrantee

will be issued and in full effect.

3

Serial number: __________________________

Model number: ____________________________

Date of Purchase___________________________

EVERLAST

Contact Information

Everlast consumer satisfaction email: sales@everlastwelders.com

Everlast Website: everlastwelders.com

Everlast Technical Support: Support@everlastwelders.com

Main toll free number: 1-877-755 WELD ( 9353 ) 9am—5pm PST M-F

11am-4pm PST Sat.

FAX: 1-650-588-8817

NOTES:

4

Table of contents

Section……………………………………………….Page

General ...……………………………………………

Safety Precautions..……………………………….

Introduction and Specifications…………………

Know Your Machine………………………………..

2.1 Panel Face and Functions……………………

2.2 Lower Panel and functions….………………

Getting Started……………………………………..

3.1 General Guidelines……………………………

3.2 Shielding Gas Selection………………………

3.3 Regulator/Flow meter Selection……………

3.4 Regulator Connection………………………...

3.5 Regulator Adjustment………………………..

3.6 Machine Setup………………………………….

3.7 Tungsten Selection……………………………

3.8 TIG Torch………………………………………..

3.9 TIG Welding Principles and Guide…………

3.13 MMA (Stick Welding)…………………………

Trouble Shooting……………………………………

5

6

9

19

19

22

23

23

23

23

23

23

24

24

26

26

28

30

5

Everlast is dedicated to providing you with the best possible equipment and

service to meet the demanding jobs that you have. We want to go beyond delivering a satisfactory product to you. That is the reason we offer technical support to assist you with your needs should an occasion occur. With proper use

and care your product should deliver years of trouble free service.

Safe operation and proper maintenance is your responsibility.

We have compiled this operator’s manual, to instruct you in basic safety, op-

eration and maintenance of your Everlast product to give you the best possible

experience. Much of welding and cutting is based upon experience and common sense. As thorough as this welding manual may be, it is no substitute for

either. Exercise extreme caution and care in all activities related to welding or

cutting. Your safety, health and even life depends upon it. While accidents are

never planned, preventing an accident requires careful planning.

Please carefully read this manual before you operate your Everlast unit. This

manual is not only for the use of the machine, but to assist in obtaining the

best performance out of your unit. Do not operate the unit until you have read

this manual and you are thoroughly familiar with the safe operation of the unit.

If you feel you need more information please contact Everlast Support.

The warranty does not cover improper use, maintenance or consumables. Do

not attempt to alter or defeat any piece or part of your unit, particularly any

safety device. Keep all shields and covers in place during unit operation should

an unlikely failure of internal components result in the possible presence of

sparks and explosions. If a failure occurs, discontinue further use until malfunctioning parts or accessories have been repaired or replaced by qualified

personnel.

Note on High Frequency electromagnetic disturbances:

Certain welding and cutting processes generate High Frequency (HF) waves.

These waves may disturb sensitive electronic equipment such as televisions,

radios, computers, cell phones, and related equipment. High Frequency may

also interfere with fluorescent lights. Consult with an electrician if disturbance is noted. Sometimes, improper wire routing or poor shielding may be

the cause.

HF can interfere with pacemakers. See EMF warnings in following safety section for further information. Always consult your physician before entering an

area known to have welding or cutting equipment if you have a pacemaker.

General

6

SAFETY PRECAUTIONS

These safety precautions are for protection of safety and health. Failure to

follow these guidelines may result in serious injury or death. Be careful to

read and follow all cautions and warnings. Protect yourself and others.

Welding and cutting processes produce high levels of ultraviolet (UV) radiation that

can cause severe skin burn and damage. There are other potential hazards involved

with welding such as severe burns and respiratory related illnesses. Therefore observe the following to minimize potential accidents and injury:

Use appropriate safety glasses with wrap around shields while in the work area, even

under welding helmets to protect your eyes from flying sparks and debris. When chipping slag or grinding, goggles and face shields may be required.

When welding or cutting, always use an approved shielding device, with the correct

shade of filter installed. Always use a welding helmet in good condition. Discard any

broken or cracked filters or helmets. Using broken or cracked filters or helmets can

cause severe eye injury and burn. Filter shades of no less than shade 5 for cutting

and no less than shade 9 for welding are highly recommended. Shades greater than 9

may be required for high amperage welds. Keep filter lenses clean and clear for maximum visibility. It is also advisable to consult with your eye doctor should you wear

contacts for corrective vision before you wear them while welding.

Do not allow personnel to watch or observe the welding or cutting operation unless

fully protected by a filter screen, protective curtains or equivalent protective equipment. If no protection is available, exclude them from the work area. Even brief exposure to the rays from the welding arc can damage unprotected eyes.

Always wear hearing protection because welding and cutting can be extremely noisy.

Ear protection is necessary to prevent hearing loss. Even prolonged low levels of

noise has been known to create long term hearing damage. Hearing protection also

further protects against hot sparks and debris from entering the ear canal and doing

harm.

Always wear personal protective clothing. Flame proof clothing is required at all

times. Sparks and hot metal can lodge in pockets, hems and cuffs. Make sure loose

clothing is tucked in neatly. Leather aprons and jackets are recommended. Suitable

welding jackets and coats may be purchased made from fire proof material from

welding supply stores. Discard any burned or frayed clothing. Keep clothing away

from oil, grease and flammable liquids.

Leather boots or steel toed leather boots with rubber bottoms are required for adequate foot protection. Canvas, polyester and other man made materials often found

in shoes will either burn or melt. Rubber or other non conductive soles are necessary

to help protect from electrical shock.

Flame proof and insulated gauntlet gloves are required whether welding or cutting or

handling metal. Simple work gloves for the garden or chore work are not sufficient.

Gauntlet type welding gloves are available from your local welding supply companies.

Never attempt to weld with out gloves. Welding with out gloves can result in serious

burns and electrical shock. If your hand or body parts comes into contact with the

arc of a plasma cutter or welder, instant and serious burns will occur. Proper hand

protection is required at all times when working with welding or cutting machines!

7

SAFETY PRECAUTIONS

continued

WARNING! Persons with pacemakers should not weld, cut or be in the welding area

until they consult with their physician. Some pacemakers are sensitive to EMF radiation

and could severely malfunction while welding or while being in the vicinity of someone

welding. Serious injury or death may occur!

Welding and plasma cutting processes generate electro-magnetic fields and radiation.

While the effects of EMF radiation are not known, it is suspected that there may be

some harm from long term exposure to electromagnetic fields. Therefore, certain precautions should be taken to minimize exposure:

Lay welding leads and lines neatly away from the body.

Never coil cables around the body.

Secure cables with tape if necessary to keep from the body.

Keep all cables and leads on the same side the body.

Never stand between cables or leads.

Keep as far away from the power source (welder) as possible while welding.

Never stand between the ground clamp and the torch.

Keep the ground clamp grounded as close to the weld or cut as possible.

Welding and cutting processes pose certain inhalation risks. Be sure to follow any

guidelines from your chosen consumable and electrode suppliers regarding possible

need for respiratory equipment while welding or cutting. Always weld with adequate

ventilation. Never weld in closed rooms or confined spaces. Fumes and gases released while welding or cutting may be poisonous. Take precautions at all times.

Any burning of the eyes, nose or throat are signs that you need to increase ventilation.

Stop immediately and relocate work if necessary until adequate ventilation is obtained.

Stop work completely and seek medical help if irritation and discomfort persists.

WARNING! Do not weld on galvanized steel, stainless steel, beryllium, titanium, cop-

per, cadmium, lead or zinc without proper respiratory equipment and or ventilation.

WARNING! This product when used for welding or cutting produces fumes and

gases which contains chemicals known to the State of California to cause birth defects and in some cases cancer. (California Safety and Health Code §25249.5

et seq

.)

WARNING! Do not weld or cut around Chlorinated solvents or degreasing areas.

Release of Phosgene gas can be deadly. Consider all chemicals to have potential

deadly results if welded on or near metal containing residual amounts of chemicals.

Keep all cylinders upright and chained to a wall or appropriate holding pen. Certain

regulations regarding high pressure cylinders can be obtained from OSHA or local

regulatory agency. Consult also with your welding supply company in your area for

further recommendations. The regulatory changes are frequent so keep informed.

All cylinders have a potential explosion hazard. When not in use, keep capped and

closed. Store chained so that overturn is not likely. Transporting cylinders incorrectly

can lead to an explosion. Do not attempt to adapt regulators to fit cylinders. Do not

use faulty regulators. Do not allow cylinders to come into contact with work piece or

work. Do not weld or strike arcs on cylinders. Keep cylinders away from direct heat,

flame and sparks.

8

SAFETY PRECAUTIONS

continued

WARNING! Electrical shock can kill. Make sure all electrical equipment is properly

grounded. Do not use frayed, cut or otherwise damaged cables and leads. Do not

stand, lean or rest on ground clamp. Do not stand in water or damp areas while welding or cutting. Keep work surface dry. Do not use welder or plasma cutter in the rain

or in extremely humid conditions. Use dry rubber soled shoes and dry gloves when

welding or cutting to insulate against electrical shock. Turn machine on or off only

with gloved hand. Keep all parts of the body insulated from work, and work tables.

Keep away from direct contact with skin against work. If tight or close quarters necessitates standing or resting on work piece, insulate with dry boards and rubber

mats designed to insulate the body from direct contact.

All work cables, leads, and hoses pose trip hazards. Be aware of their location and

make sure all personnel in area are advised of their location. Taping or securing cables with appropriate restraints can help reduce trips and falls.

WARNING! Fire and explosions are real risks while welding or cutting. Always keep

fire extinguishers close by and additionally a water hose or bucket of sand. Periodically check work area for smoldering embers or smoke. It is a good idea to have

someone help watch for possible fires while you are welding. Sparks and hot metal

may travel a long distance. They may go into cracks in walls and floors and start a fire

that would not be immediately visible. Here are some things you can do to reduce the

possibility of fire or explosion:

Keep all combustible materials including rags and spare clothing away from area.

Keep all flammable fuels and liquids stored separately from work area.

Visually inspect work area when job is completed for the slightest traces of smoke

or embers.

If welding or cutting outside, make sure you are in a cleared off area, free from

dry tender and debris that might start a forest or grass fire.

Do not weld on tanks, drums or barrels that are closed, pressurized or anything

that held flammable liquid or material.

Metal is hot after welding or cutting! Always use gloves and or tongs when handling

hot pieces of metal. Remember to place hot metal on fire-proof surfaces after handling. Serious burns and injury can result if material is improperly handled.

WARNING! Faulty or poorly maintained equipment can cause injury or death.

Proper maintenance is your responsibility. Make sure all equipment is properly maintained and serviced by qualified personnel. Do not abuse or misuse equipment.

Keep all covers in place. A faulty machine may shoot sparks or may have exploding

parts. Touching uncovered parts inside machine can cause discharge of high

amounts of electricity. Do not allow employees to operate poorly serviced equipment.

Always check condition of equipment thoroughly before start up. Disconnect unit

from power source before any service attempt is made and for long term storage or

electrical storms.

Further information can be obtained from The American Welding Society (AWS) that

relates directly to safe welding and plasma cutting. Additionally, your local welding

supply company may have additional pamphlets available concerning their products.

Do not operate machinery until your are comfortable with proper operation and are

able to assume inherent risks of cutting or welding.

9

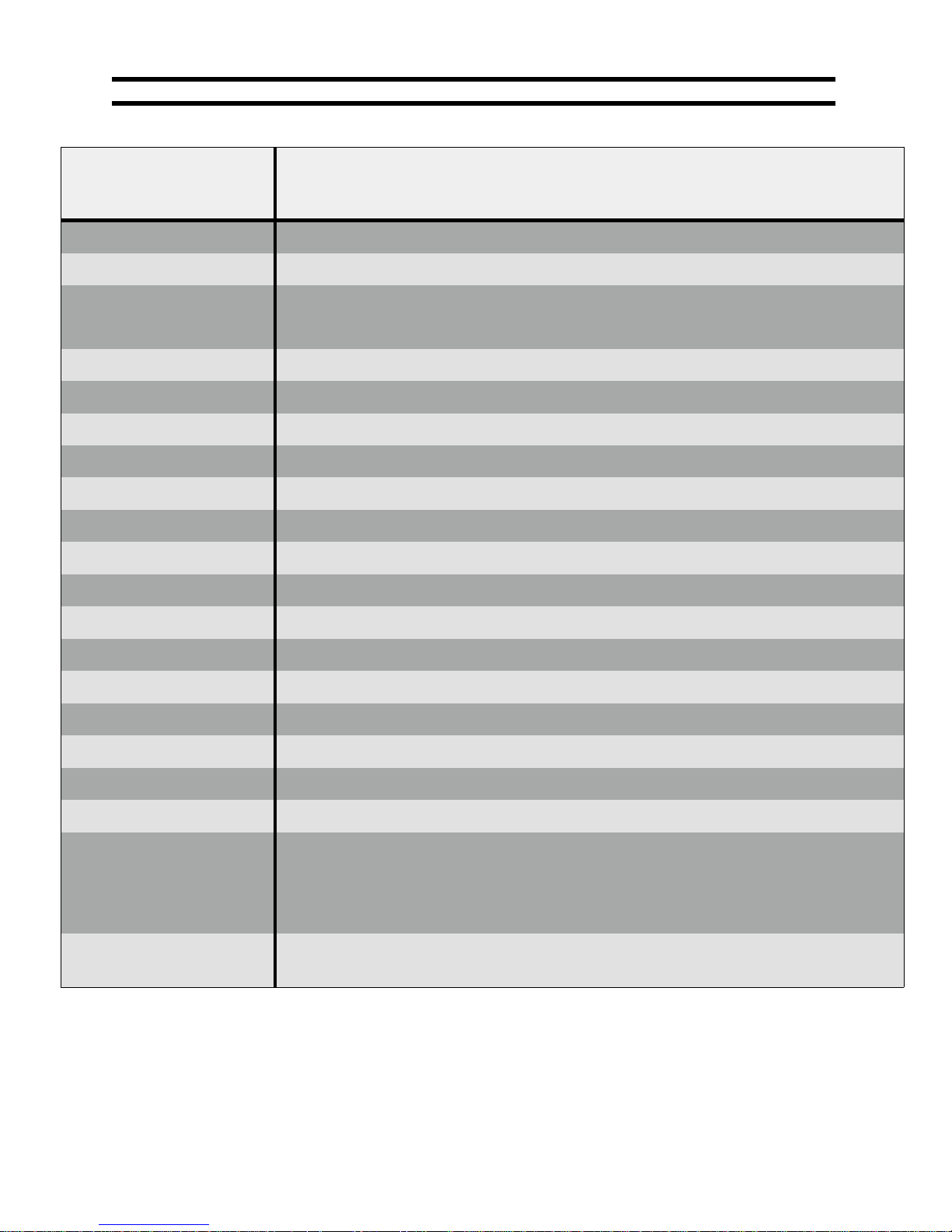

Product Feature Comparison

Introduction and Specifications Section 1

Product Features EX Series

200/250

LX Series

200/250

DX Series

200/250

I-Tig

200/250

315 DX

Over Current Warning

• • • • •

High Frequency Start

• • • • •

High Frequency AC

(Aluminum)

• • • •

Pulse Frequency Control

• • • • •

Pulse Ratio (Width)

• • • • •

Base /Peak Ratio

• • • • * • *

Arc Force Control (Dig)

• •

Tig and Stick (SMAW)

• • • • •

AC Frequency Control

• • • •

AC Balance Control

• • • •

4t/2t Remote

• • • • •

Spot Timer

•

Pre-Gas Flow Timer

•

Post-Flow Timer

• • • •** •

Start Current (initial)

•

Up Slope Timer

• • • •

Down Slope Timer

• • • • •

Crater Current (Final)

•

Voltage

220-240 V

1ph (200)

1-3ph (250)

220/240 V

1ph

(200/250)

220/240 V

1ph

(200/250)

220-240V

(200) 1ph

110/220V

(250) 1ph

220/240V

3 ph only

Duty Cycle @ Rated Amps

60% 60% 35% 35%(200)

60% (250)

35%

*Base/Peak Ratio is controlled by setting independent Base

Amp and Peak Amp controls.

** Post Flow is controlled by selecting preset switch.

10

Introduction and Specifications Section 1

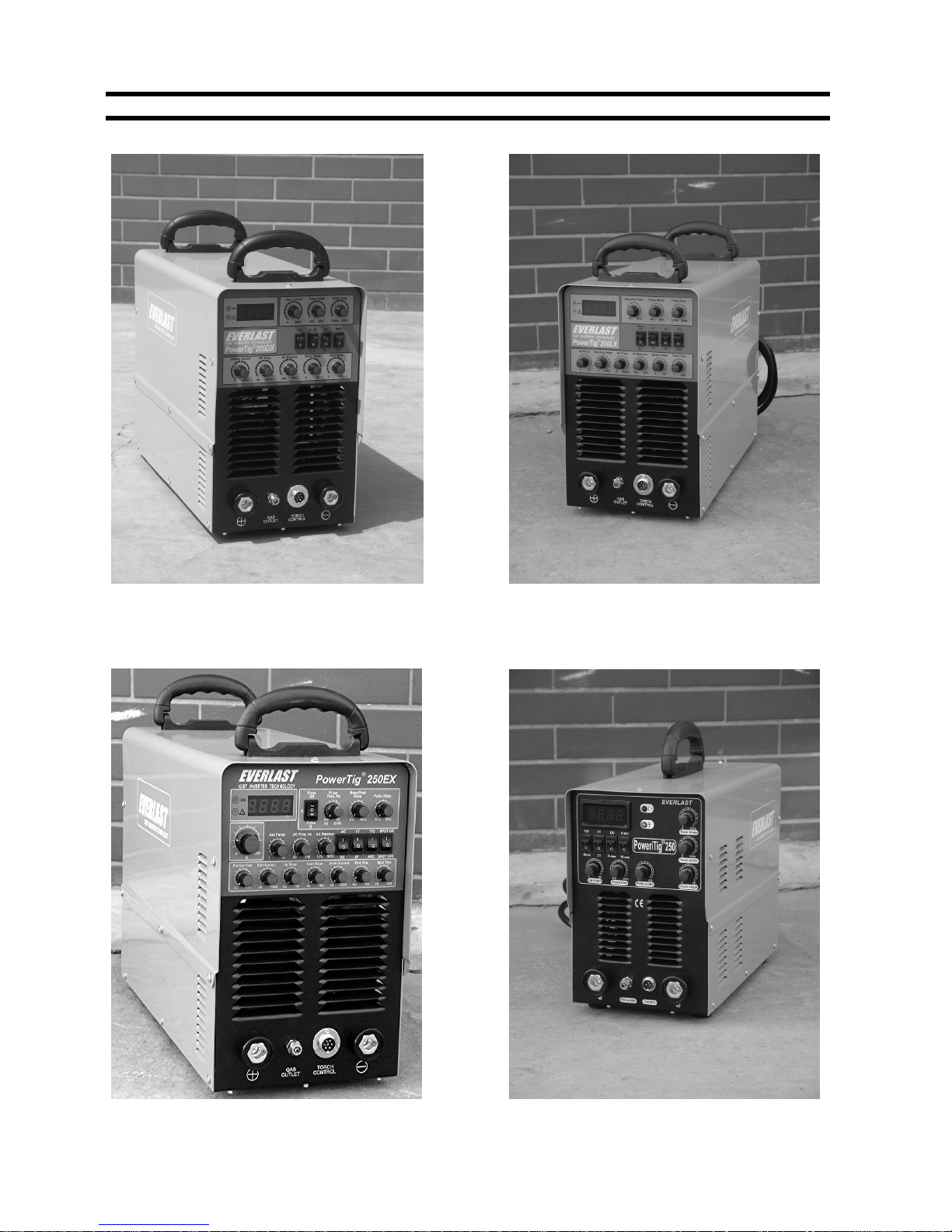

PowerTig DX, LX and EX Models, I-Tig Models

PowerTig DX Series

PowerTig LX Series

PowerTig EX Series Power I-Tig Series

Loading...

Loading...