Evergreen Solar ES-C-70-fa5, ES-C-120-fa2, ES-C-110-fa2, ES-C-80-fa5, ES-C-115-fa4 Safety, Installation, And Operation Manual

...

ELECTRICAL EQUIPMENT — CHECK WITH YOUR INSTALLER

Evergreen Solar ES-C Series photovoltaic (PV, solar electric) panels are designed to produce DC electrical energy from light. This manual contains

important safety, installation and operating information with which you should be familiar before using Evergreen Solar ES-C Series panels.

This Manual is valid in North America only

(ETL listed; conforms to UL Standard 1703)

3190157

ES-C Series Photovoltaic Panels

Safety, Installation and Operation Manual

Limited Warranty

Copyright © 2009 Evergreen Solar, Inc.

General Information

• All installation and safety instructions should be understood before attempting to install, wire, operate and maintain

the panel.

• When installing, observe all local, regional, national and international statutory regulations, guidelines, norms and

code requirements.

• Installation or maintenance should only be performed by qualied professionals.

• Panels produce voltage even when not connected to an electrical circuit or load. Panels produce nearly full voltage

when exposed to as little as 5% of full sunlight, and both electrical current and power increase with light intensity.

• Panels can produce higher output than the rated specications.

• Industry standard rated specications are made at conditions of 1000W/m2 irradiance and 25°C (77ºF) solar cell

temperature. Colder temperatures can substantially increase voltage and power.

• Ensure that panels are only subjected to ambient temperatures in the range -40 to +80°C (-40 to +176°F).

• Reection from snow, water or other surfaces can increase light and therefore increase both the current and power

generated by the panel.

• Do not articially concentrate light on the panel.

• Panels are intended for outdoors, land-based applications only. Panels are not intended for indoor use.

• Excluded applications also include, but are not limited to, installations where panels come into contact with salt

water or where likely to become partially or wholly submerged in fresh or salt water, examples of which include

boats, docks and buoys.

• Use only equipment, connectors, wiring and support frames suitable for use in a solar electric system.

• Follow all safety precautions of other used components.

• Each panel is marked with a serial number, including the date of manufacture and the manufacturing location.

Example: XXxxYYYYMMDDzzzzzzz

- XX = country code (49 for Germany, 01 for US, 86 for China)

- xx = manufacturing building code, can be 01 or higher

- YYYY = year, MM = month, DD = day

- zzzzzzz = serial number

Handling Safety

• Do not use the junction box to hold or transport the panel.

• Do not stand or step on the panel.

• Do not drop panel or allow objects to fall on panel.

• Do not damage or scratch the rear surface of the panel.

• Avoid setting the panel down hard on any surface, particularly when placing it on a corner.

• Do not disassemble, modify or adapt the panel or remove any part or labeling installed by Evergreen Solar.

Doing so will void the warranty.

• Do not drill holes in the frame or glass of the panel. Doing so will void the warranty.

• Do not apply paint or adhesive to the rear surface of the panel.

• Never leave a panel unsupported or unsecured.

• Panels are constructed with tempered glass, but must still be handled with care.

• A panel with broken glass or torn back-skin cannot be repaired and must not be used since contact with any

panel surface or the frame can produce electrical shock.

• Broken or damaged panels must be handled carefully and disposed of properly. Broken glass can be sharp and

cause injury if not handled with the appropriate protective equipment.

• Work only under dry conditions, and use only dry tools. Do not handle panels when they are wet unless wearing

the appropriate protective equipment.

• When storing un-connected panels outside for any length of time, always cover panels which have the glass

facing down to stop water collecting inside the panel and causing damage to exposed connectors.

1

Installation Safety

• Keep children away from the system and panels when installing.

• Do not carry out installation work when there are strong winds.

• When installing panels above ground, avoid any possible falling or other safety hazards by following appropriate

safety practices and using required safety equipment.

• Solar electric panels have no on/off switch. Panels can be rendered inoperative only be removing them from

light, or by fully covering their front surface with an opaque material, or by working with panels face down on

a smooth, at surface.

• When working with panels in light, follow all applicable regulation regarding working with live electrical

equipment.

• Do not touch electrical terminals or the ends of any wire while the panel is exposed to light or while installing

the panel.

• Do not wear metallic jewelry while performing mechanical or electrical installation.

• Never open electrical connections or unplug connectors while the circuit is under load.

• Contact with electrically active parts of the panels, such as terminals, can result in burns, sparks and lethal

shock whether the panel is connected or disconnected.

• Always use insulated tools and rubber gloves that are approved for working on electrical installations.

Fire Safety

• Refer to your local authority for guidelines and requirements for building or structural re safety.

• The roof construction and installation may affect the re safety of a building; improper installation may contribute

to hazards in the event of re.

• For roof application, the panels should be mounted over a re resistant covering rated for the application.

• It may be necessary to use components such as earth ground fault circuit breakers, fuses and circuit breakers.

• Do not use panels near equipment or locations where ammable gases can be generated or can collect.

Electrical Installation –General Recommendations

• Avoid all electrical hazards when installing, wiring, operating and maintaining a panel.

• If the total DC system voltage exceeds 100V, the system must be installed, commissioned and maintained by a

qualied professional.

• Contact with a DC voltage 30V or more is potentially hazardous.

• Do not use panels of different electrical or physical congurations in the same system.

• The maximum open circuit voltage of the system must not be greater than the specied maximum system voltage

for the panel.

• When reverse currents can exceed the value of the maximum protective fuse marked on the back of the panel,

a properly rated and certied over-current device (fuse or circuit breaker) must be connected in series with each

panel or string of panels.

• The rating of the over-current device shall not exceed the value of the maximum protective fuse marked on the

back of the panel.

• Panels with a suspected electrical problem should be returned to Evergreen Solar for inspection and possible

repair or replacement as per the warranty conditions provided by Evergreen Solar.

Panel Wiring – Cables and Bypass Diodes Installation

• ES-C panels come with a conduit ready junction box designed to be used with standard wiring, watertight strain

relief ttings and conduit connections.

• To open the junction box, loosen the two captive screws in the cover. The cover is designed to remain open

during wiring and cannot be removed from the panel.

• The junction box has a gasket that ensures the waterproof integrity. Check that the gasket is in the right position

before securing the junction box. Do not over-tighten the cover screws.

2Valid from 1st September 2009 / IMW-ES-C_US_010909_ETL

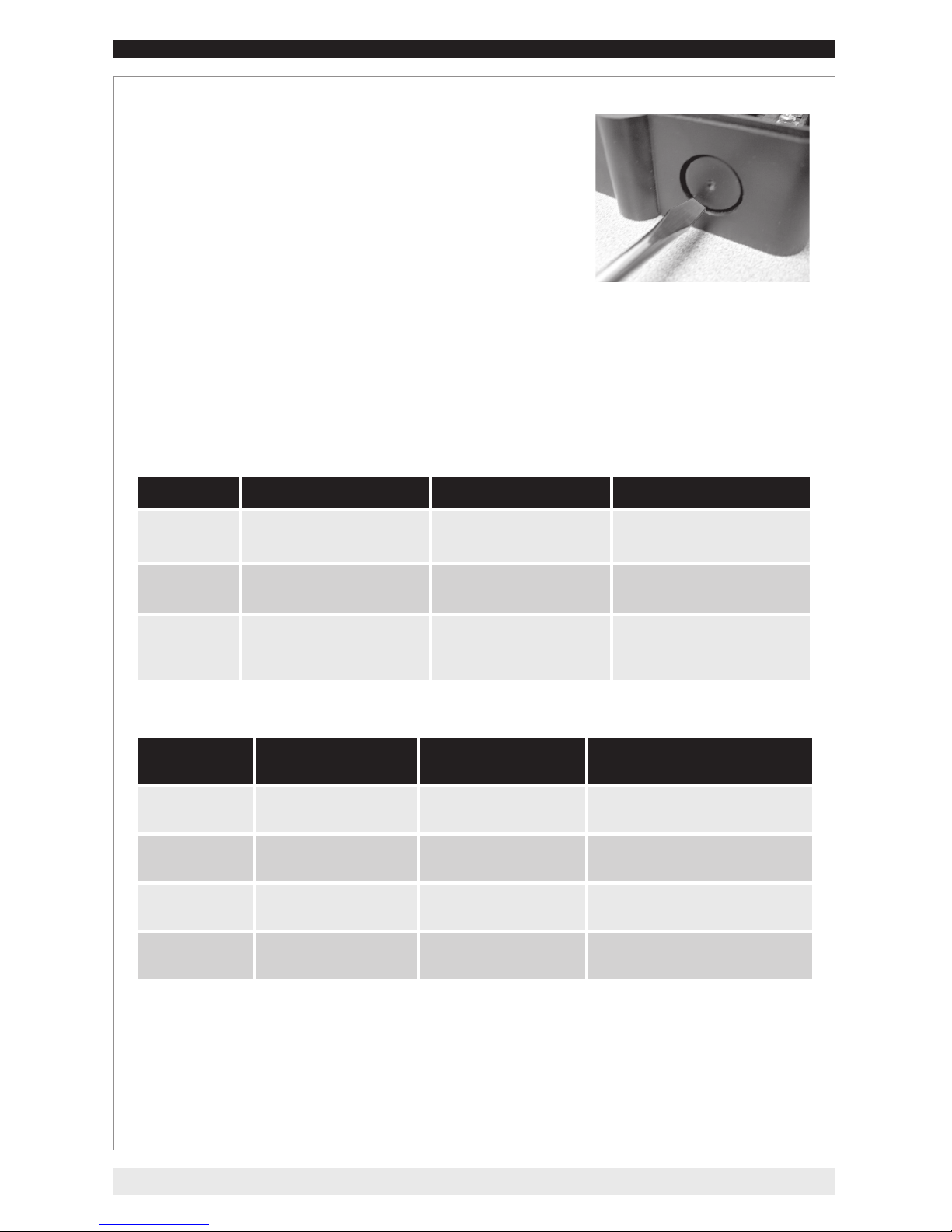

• The junction has four (4) ½” knockouts; two (2) on the bottom and

one on each side. Use a tool such as a at screwdriver to remove

the knockouts. Remove only the required knockouts by hitting the

perimeter and not the center as shown in Figure 1.

• It is not recommended to run wires through the knockouts without

using a watertight strain relief or conduit.

• Use the appropriate ½” PG or NPT watertight cable strain relief

depending on your installation and the cable diameter. Table 2 shows

some of the ½” NPT options.

• Knockouts are designed to attach to any standard ½” rigid or exible

conduit.

• Steel or nylon lock nuts can be used. Make sure lock nuts are properly tightened to avoid ingress of humidity or

water inside the junction box.

• Cables used to wire ES-C panels may be single or two conductors, from 14 AWG up to 10 AWG gauge.

• For cables exposed outdoors, use only sunlight resistant cables rated for 90ºC and wet locations. Table 1 shows

the outdoor sunlight resistant cable options.

• For cables installed in conduit, types THWN-2, RHW-2 and XHHW-2 are recommended.

Wire Type Insulation (Jacket) Characteristics Watertight Strain Relief

USE-2 XLP/XLPE cross-linked

polyethylene

Underground

service entrance

1

/2” NPT with 1 or 2 round

holes. Steel or nylon lock nut.

TC (Tray) Thermoplastic (PVC, Nylon).

XLP/XLPE for conductors.

2-conductor,

direct burial

1

/2” NPT with 1 oval hole.

Steel or nylon lock nut.

PV Wire XLP/XLPE cross-linked

polyethylene

Thicker jacket per UL4703

Ungrounded arrays,

Transformerless inverters.

1

/2” NPT with 1 round hole.

Steel or nylon lock nut.

Table 1. Sunlight 90ºC Wet Resistant Cables.

Manufacturer Part Number

(Black & Gray)

Opening

(Cable range)

Cable Type Fit

Hummel CD16NS-01 &

CD16NS-02

One oval, 0.24” x 0.55” TC (Tray) AWG #14/2,

12/2 &10/2

Hummel CD13NR-BK &

CD13NR-GY

One round, 0.2” to 0.35”Ø PV Wire AWG #14,12 &10

USE-2 AWG #14,12 & 10

Hummel CD13N4-BK &

CD13N4-GY

Two round, 0.2” Ø USE-2 AWG #14,12 & 10

Heyco 3231 & 3232 One round, 0.17” to

0.45ӯ

PV Wire AWG #14,12 &10

USE-2 AWG #14,12 & 10

Table 2. Watertight Strain Reliefs

• The panel contains factory installed bypass diodes located inside the junction box. These diodes are designed

to protect the panel against partial shading conditions and should not be removed.

• Diodes can be easy replaced in the eld if necessary. Use only Super Barrier type diodes SBR10U45SD1, 45V,

10A or equivalent. Diodes should be installed as shown in Figure 2.

Copyright © 2009 Evergreen Solar, Inc.3

Figure 1. Knockout Removal

4Valid from 1st September 2009 / IMW-ES-C_US_010909_ETL

Figure 2. Junction Box Components

• ES-C series panels are factory wired for 12V nominal operation and are not intended to be recongured for other

voltages.

• The electrical connection block has three (3) double screw terminals; positive (+), negative (-) and spare. It is

recommended that the top screws of the terminals be reserved for the bypass diodes, and the output wiring be

connected only to the bottom screws. Junction box components are described in Figure 2.

• Match the polarities of cables and terminals when making the connections; failure to do so may result in damage

to the panel.

• The Spare terminal can be used to wire arrays at different voltage congurations. Figure 3. Shows examples of

the standard 12, 24 and 48 V congurations.

Figure 3. Wiring Examples

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

RED

12 V (2 PARALLEL)

24 V (2 SERIES)

48 V (4 SERIES)

Copyright © 2009 Evergreen Solar, Inc.5

Grounding

• Panel frames should be connected to an earth ground for safety and protection from lightning.

• The panel frame is provided with grounding holes that accommodate self-tapping screws. If grounding holes

are utilized, a #10-32 stainless steel thread cutting screw is required.

• The following specic grounding methods utilizing thread cutting screws have been successfully tested with

ES-C panels to the UL1703 standard. This does not prohibit the use of other methods, providing that the

applicable codes and standards are met.

Device Part No. Material Bonding Method to Frame

ILSCO

lay-in lug

Tyco

lay-in lug

GBL-4DBT

SolKip

1954381-1

Tin plated

copper

Copper alloy

plated with tin

over nickel

• 10-32 cutting screw at grounding hole locations.

• The use of a nut is required behind the screw to create a

positive means of attachment to the frame.

Cutting

screw with

3 washers

(2 cupped,

1 star)

N/A

Stainless steel

• 10-32 cutting screw at grounding hole locations.

• The use of a nut is required behind the screw to create a

positive means of attachment to the frame.

• The grounding wire must be placed between 2 cupped

washers and around the 10-32 cutting screw.

• A star washer is required between the panel frame and the

cupped washer to ensure that the frame anodized layer is

penetrated.

• Evergreen panels can also be grounded using third party grounding washers or clip devices provided the

devices are listed and identied for grounding the metallic frames of PV panels and the devices are installed in

accordance with the manufacturers specied instructions.

Mechanical Installation

• Panels should be mounted to maximize direct exposure to sunlight and to eliminate or minimize shadowing.

• Even partial shadowing can substantially reduce panel and system output.

• Panels must be securely fastened using support frames or mounting kits specialized for PV applications.

• Panels may be mounted at any angle from vertical to horizontal orientation.

• Care must be taken to avoid low tilt angles which may cause dirt to build-up on the glass against the

frame edge.

• Dirt build-up on the surface of the panel can cause active solar cells to be shaded and electrical

performance to be impaired.

• Contact Evergreen Solar for more information regarding minimum recommended tilt angles for specific

panel products.

• For roof mounted systems, provide adequate rear ventilation under a panel for cooling (100mm: 4 in. gap

minimum).

• Clearance of 7mm:¼ in or more between panels is required to allow for thermal expansion of the frames.

• Always keep the back surface of the panel free from any foreign objects or structural elements which could

come into contact with the panel, especially when the panel is under mechanical load.

• Ensure panels are not subjected to wind or snow loads in excess of the maximum permissible loads and are

not subjected to excessive forces due to thermal expansion of the support structure.

• Evergreen Solar permits several different mounting methods. The permissible mounting methods and

maximum permissible wind and snow loads are detailed in the Mounting Guide available from Evergreen

Solar (ETL listed version).

Valid from 1st September 2009 / IMW-ES-C_US_010909_ETL

6

• For permission to use mounting methods not described in the Mounting Guide (ETL listed version), please

consult Evergreen Solar. Failure to do so will void the warranty and panecertication.

• Always follow the mounting equipment vendors’ installation instructions in addition to the instructions found

in the Mounting Guide (ETL listed version). In cases where the vendors’ instructions are more stringent

than those detailed in the Mounting Guide (ETL listed version), the vendors’ instructions shall apply.

• In cases where the maximum permissible loading determined by the mounting equipment vendor is less

than the maximum permissible load stated in the Mounting Guide (ETL listed version), the maximum loads

determined by the vendor should always be used.

• The maximum permissible loads apply to uniformly distributed wind or snow loading. Care should be taken to

avoid mounting panels in areas that are prone to drifting snow, icicle and/or ice dam formation.

Operation and Maintenance

• No routine maintenance is required. However it is advisable to perform periodic inspection of the panels for

damage to glass, back-skin, frame, junction box or external electrical connections.

• Check electrical connections for loose connections and corrosion.

• PV panels can operate effectively without ever being washed, although removal of dirt from the front glass

can increase output.

• Water can be used for regular washing or rinsing of the front glass to remove dust, dirt or other deposits.

• To remove ingrained dirt, the glass can be washed with a micro-ber cloth and ethanol or a conventional

glass cleanser.

• No aggressive and abrasive cleansers or chemicals should ever be used on the front glass. No alkali based

chemicals should be used, including ammonia based solutions.

• Always wear rubber gloves for electrical insulation whilst maintaining, washing or cleaning panels.

Underwriters Laboratories and Canadian Standard ULC/ORD-C1703-01 Information

• Under normal conditions, a photovoltaic panel is likely to experience conditions that produce more current

and/or voltage than reported at Standard Test Conditions. Accordingly, the values of Isc and Voc marked on

this panel should be multiplied by a factor of 1.25 when determining component voltage ratings, conductor

capacities, fuse sizes, and size of controls connected to the PV output.

• Refer to section 690-8 of the National Electric Code (NEC) for an additional multiplying factor of 125% (80%

de-rating) which may be applicable.

• Conductor recommendations: Single conductor cable, type USE-2 (non-conduit) or PV-WIRE, 14AWG

(2.5mm²) minimum.

• For compliance with Canadian Standard ULC/ORD-C1703-1, the installation shall be in accordance with CSA

C22.1, Safety Standard for Electrical Installations, Canadian Electrical Code, Part 1.

Disclaimer of Liability

Since the use of this Safety, Installation and Operation Manual and the conditions or methods of installation,

operation, use and maintenance of the panel are beyond Evergreen Solar control, Evergreen Solar does not

assume responsibility and expressly disclaims liability for loss, damage, injury or expense arising out of or in any

connected with such installation, operation, use or maintenance of the panel.

Evergreen Solar assumes no responsibility for any infringement of patents or other rights of third parties that may

result from use of the panel. No license is granted by implication or otherwise under any patent or patent rights.

The information in this Manual is based on Evergreen Solar knowledge and experience and is believed to be

reliable; but such information including product specications (without limitations) and suggestions do not

constitute a warranty, expressed or implied. Evergreen Solar reserves the right to make changes to the product,

specications or this Manual without prior notice.

Note: This document may be provided in multiple languages. If there is a conflict among versions, the

English language version dominates.

7 Copyright © 2009 Evergreen Solar, Inc.

Electrical Specifications at STC*

ES-C-70

-fa5

ES-C-80

-fa5

ES-C-110

-fa2

ES-C-120

-fa2

ES-C-115

-fa4

ES-C-125

-fa4

Pmp (W) 70 80 110 120 115 125

Pptc** (W) 63.0 72.2 99.1 108.3 103.7 112.9

V

mp (V) 17.50 18.23 16.75 17.27 17.92 18.36

Imp (A) 4.00 4.39 6.57 6.95 6.42 6.81

V

oc (V) 21.70 22.51 20.92 21.34 22.30 22.63

Isc (A) 4.56 4.78 7.33 7.62 7.15 7.37

Electrical Specifications at NOCT***

ES-C-70

-fa5

ES-C-80

-fa5

ES-C-110

-fa2

ES-C-120

-fa2

ES-C-115

-fa4

ES-C-125

-fa4

P

mp (W) 51.2 58.6 80.5 87.8 84.2 91.5

Vmp (V) 16.01 16.68 15.33 15.80 16.40 16.80

Imp (A) 3.20 3.51 5.26 5.56 5.14 5.45

V

oc (V) 19.86 20.60 19.14 19.53 20.40 20.71

Isc (A) 3.65 3.82 5.86 6.10 5.72 5.90

T

NOCT (°C) 45.4 45.4 45.4 45.4 45.4 45.4

*At Standard Test Conditions: 1000W/m2, 25°C cell temperature, AM 1.5 spectrum. Minimum specied power rating is 5% below Pmp for all products;

other specications are +/-10% of measured values per ASTM E 892. Specications subject to change without notice. Warranty details available on request.

**At PTC (PV-USA Test Conditions): 1000 W/m

2

, 20°C ambient temperature, 1m/s wind speed.

*** At Nominal Operating Cell Temperature Conditions: 800W/m

2

, 20°C ambient temperature, wind velocity 1m/s, AM 1.5 spectrum.

The relative reduction of panel efciency at 200W/m

2

irradiance in relation to 1000W/m2 both at 25°C cell temperature and spectrum AM 1.5 is 0%.

ES-C-70, 80 -fa5 ES-C-110, 120 -fa2 ES-C-115, 125 -fa4

Individual Cell Size 150 x 50 mm 150 x 80 mm 150 x 77 mm

Number of Cells 76 72 76

Bypass Diodes 2 x Type Super Barrier SBR10U45SD1, 45V, 10A

Max. Series Fuse/

Max. Reverse Current

8A 15A 15A

UL Rated System Voltage 600V DC Maximum

Temperature Coefficients

g P

mp

-0.43 (%/°C)

b V

mp

-0.40 (%/°C)

a I

mp

-0.03 (%/°C)

b V

oc

-0.31 (%/°C)

a I

sc

+0.05 (%/°C)

DRAINAGE HOLES MOUNTING HOLES GROUNDING HOLES

22.44

24.07

12x ø .24 FRAME

DRAINAGE HOLES

(NOT TO BE USED

FOR MOUNTING)

10x

ø.26

MOUNTING

HOLES

FOR

¼" BOLTS

PANEL DATA &

SAFETY LABEL

PANEL

SERIAL

NUMBER

4x

ø.16

GROUNDING

HOLES

JUNCTION

BOX

5.20

9.90

1.60

2.24

5.38

25.67 ±.06

FRAME ID LABEL

2x ø.16 ±.00 GROUNDING HOLES

(1 NEARSIDE, 1 FARSIDE)

2.24

0.29

21.46

20.28

12.60

2.76

2.24

42.90 ±.06

1.60

0.67

2x ø.16 ±.00

GROUNDING HOLES

(1 NEARSIDE, 1 FARSIDE)

1.60

TYP

1.60 TYP

Mechanical Specifications

ES-C-70, 80 - fa5

All dimensions in inches; Weight: 19 lbs. (8.6 kg)

Valid from 1st September 2009 / IMW-ES-C_US_010909_ETL

8

Evergreen Solar - Photovoltaic Panels Limited Warranty

Limited Warrant y: Materials or Workmanship

Evergreen Solar warrants the panels to be free from defects in materials or workman-ship under normal application, installation, use, and

service conditions. The panels must be installed according to the latest Safety, Installation and Operation Manual provided by Evergreen

Solar otherwise this warranty will be void. If the product fails to conform to this warranty, then, for a period ending sixty (60) months

from date of sale to the original consumer purchaser, Evergreen Solar will, at its option, either repair or replace the product or refund the

purchase price. The repair, replacement, or refund remedy shall be the sole and exclusive remedy provided under this warranty.

DRAINAGE HOLES MOUNTING HOLES GROUNDING HOLES

22.44

24.07

PA NEL DATA &

SAFETY LABEL

12x ø .24 FRAME

DRAINAGE HOLES

(NOT TO BE USED

FOR MOUNTING)

10x

ø

.26

MOUNTING

HOLES

FOR

1

/4” BOLTS

PA NEL

SERIAL

NUMBER

JUNCTION

BOX

9.90

1.60

2.24

FRAME ID LABEL

2x ø .16 ±00 GROUNDING HOLES

(1 NEARSIDE, 1 FARSIDE)

25.67 ±0.6

2.24

.29

1.60 TYP

5.20

4x ø .16

GROUNDING

HOLES

1.60 TYP

5.38

62.40±.06

1.60

.67

30.00

12.60

2.76

2.24

2x ø .16 ±00

GROUNDING HOLES

(1 NEARSIDE, 1 FARSIDE)

31.20

ES-C- 110, 120 – fa2, 115, 125 – fa4

All dimensions in inches; Weight: 27 lbs. (12.3 kg)

Mechanical Specifications

9 Copyright © 2009 Evergreen Solar, Inc.

Worldwide Headquarters

Evergreen Solar Inc.

138 Bartlett Street

Marlboro, MA 01752 USA

T: +1 508.357.2221 | F: +1 508.229.0747

info@evergreensolar.com

Customer Service - Americas and Asia

Evergreen Solar Inc.

138 Bartlett Street

Marlboro, MA 01752 USA

T: +1 508.357.2221 | F: +1 508.229.0747

sales@evergreensolar.com

www.evergreensolar.com

SAP Ref. 301253 SM-0043

Limited Warrant y: Power Output

Evergreen Solar warrants for a period of ten (10) years from the date of sale to the original consumer purchaser that the power rating

at Standard Test Conditions will remain at 90% or greater of Evergreen Solar’s Minimum Specied Power Rating. Evergreen Solar

further warrants for a period of twenty-ve (25) years from the date of sale to the original consumer purchaser that the power rating at

Standard Test Conditions will remain at 80% or greater of Evergreen Solar’s Minimum Specied Power Rating.

Evergreen Solar will, at its option, repair or replace the product, refund the purchase price, or provide the purchaser with additional

panels to make up lost power, provided that such degradation is determined to be due to defects in materials or workmanship under

normal installation, application, and use. The panels must be installed according to the latest Safety, Installation and Operation Manual

provided by Evergreen Solar otherwise this warranty will be void. The relevant Minimum Specied Power Rating is dened in Evergreen

Solar’s product data sheet at the time of shipment. Standard Test Conditions are irradiance of 1000 W/m

2

, 25° C cell temperature,

and AM 1.5 light spectrum.

Limitations and Conditions

The remedy set forth in these limited warranties shall be the sole and exclusive remedy provided under the extended term warranty, unless

otherwise agreed by Evergreen Solar in writing. In Germany, these limited warranties are neither a “guarantee of the quality” of the panel

pursuant to §443 BGB (German Civil Code) nor are they an “acceptance of a guarantee” pursuant to §276 BGB.

The limited warranties set forth herein do not apply to any panel which in Evergreen Solar’s sole judgement has been subjected to misuse,

neglect, or accident; has been damaged through abuse, alteration, improper installation or application, or negligence in use, storage,

transportation, or handling; has not been installed in accordance with the latest Safety, Installation and Operation Manual provided by

Evergreen Solar or has in any way been tampered with or repaired by anyone other than Evergreen Solar or its authorized agent.

The limited warranties do not cover costs associated with panel installation, removal, testing, packaging, transportation, or reinstallation;

other costs associated with obtaining warranty service; or costs, lost revenues, or lost prots associated with the performance or

nonperformance of defective panels.

Any panels repaired or replaced by Evergreen Solar under a warranty claim shall be covered by the same warranties and original term

as the rst product purchased under said claim. The term shall not be prolonged or reset from the date of sale to the original consumer

purchaser. Any replaced parts or products become the property of Evergreen Solar.

These limited warranties apply only to the rst end-user purchaser of the panels or to any subsequent owners of the original building or site

where the panels were rst installed. The limited warranties set forth herein are expressly in lieu of and exclude all other express or implied

warranties, including but not limited to warranties of merchantability and of tness for particular purpose, use, or application and all other

obligations or liabilities on the part of Evergreen Solar, unless such other warranties, obligations, or liabilities are expressly agreed to in

writing signed and approved by Evergreen Solar.

Evergreen Solar shall have no responsibility or liability whatsoever for damage or injury to persons or property, or for other loss or injury

resulting from any cause whatsoever arising out of or related to the product, including, without limitation, any defects in the panel, or from use

or installation. Under no circumstances shall Evergreen Solar be liable for incidental, consequential, or special damages, howsoever caused.

Evergreen Solar’s aggregate liability, if any, in damages or otherwise, shall not exceed the payment, if any, received by seller for the unit

of product or service furnished or to be furnished, as the case may be, which is the subject of claim or dispute. Some jurisdictions do not

allow limitations on implied warranties or the exclusion or limitation of damages, so the above limitations or exclusions may not apply to

you.

If a part, provision, or clause of terms and conditions of sale, or the application thereof to any person or circumstance is held invalid,

void, or unenforceable, such holding shall not affect and leave all other parts, provisions, clauses, or applications of terms and conditions

remaining, and to this end the terms and conditions shall be treated as severable.

This warranty gives you specic legal rights; and you may also have other rights that vary from state to state and country to country.

Neither party shall be in any way responsible or liable to the other party, or to any third party, arising out of nonperformance or delay in

performance of the terms and conditions of sale due to acts of God, war, riot, strikes, unavailability of suitable and sufcient labor, and any

unforeseen event beyond its control, including, without limitations, any technological or physical event or condition which is not reasonably

known or understood at the time of sale.

Any claim or dispute regarding these warranties shall be governed by and construed in accordance with the laws of the State of New York (US ).

Obtaining Warranty Performance

If you feel you have a claim covered by warranty, you must promptly notify the dealer who sold you the panel of the claim. The dealer will

give advice handling the claim. If further assistance is required, write Evergreen Solar for instructions.

The customer must submit a written claim, including adequate documentation of panel purchase, serial number, and product failure.

Evergreen Solar will determine in its sole judgment the adequacy of such claim. Evergreen Solar may require that product subject to a

claim be returned to the factory, at the customer’s expense. If product is determined to be defective and is replaced but is not returned to

Evergreen Solar, then the customer must submit adequate evidence that such product has been destroyed or recycled.

Note: This document may be provided in multiple languages. If there is a conflic t among versions, the English language version

dominates.

Loading...

Loading...