Everest UL 2703 Assembly Instructions Manual

ASSEMBLY INSTRUCTIONS

RESIDENTIAL ROOF SOLUTIONS

CROSSRAIL SHARED RAIL SYSTEM

UL 2703 Listed System

USA

TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY REGULATIONS

MATERIALS REQUIRED

BONDING AND GROUNDING

MODULE COMPATIBILITY

FIRE RATING

ASSEMBLY

TERMS AND CONDITIONS

2

3

4

6

7

8

9

15

ENGINEERING STRENGTH IS AT OUR CORE

With sophisticated product innovations and a deep customer focus, Everest Solar is the engineering leader for all your mounting

system needs. We are the US division of K2 Systems, one of Europe’s market leaders with more than 5.0 GW installed.

We offer proven product solutions and innovative designs. Wind tunnel testing along with advanced structural and electrical

validation to facilitate permitting, design and installation. Our designs result in cost competitive racking systems with dedicated

support that will position you to win more projects.

We partner with our customers and suppliers for the long-term. High quality materials and cutting edge designs provide a

durable, yet functional system. Our product line is comprised of a few, coordinated components that lower the cost of materials,

and simplify installation, saving you time and money. All backed by German engineering, a long track record of quality and a

company that is here to stay.

Thank you for choosing Everest Solar Systems for your Solar PV Project.

Table of Contents

2 | 15

GENERAL SAFETY INSTRUCTIONS

Everest Solar Systems’ General Assembly Instructions must be followed to maintain the exclusive, limited product warranty.

You can access these instructions at Everest‘s Technical Info Page:

http://everest-solarsystems.com/en-US/technical-product-information or by contacting us directly.

In general, the following applies:

T Systems should be installed by experienced contractors licensed and qualified to perform the work with professional

workmanship and quality.

T Before installation, Contractor must verify that the system meets all applicable laws, regulations, ordinances, and codes.

Contractor shall verify that the roof or other structures to which the system is being attached are capable of carrying the

system loads. For information about the dead loads of the various system components, Contractor should review the Everest

Technical information page at http://everest-solarsystems.com/en-US/technical-product-information or contact us

directly.

T Contractor is solely responsible for work safety and accident prevention regulations and corresponding standards and

regulations of the applicable occupational safety and health agency are followed, including:

T Safety clothing is worn such as safety helmets, work shoes, and gloves.

T Where required, Contractor should use fall protection, scaffolding with arrestor equipment and other approved methods for

worker safety.

T Contractor shall verify that they are using the most current instructions by downloading the latest version from our website or

contacting our office directly.

T Module manufacturer installation guides must be followed. Please use approved electrical bonding and grounding

components that are required by the local or national codes and AHJ.

T A copy of these instructions must be on site, and read and understood by all workers during installation.

T In the event our general installation and assembly instructions are not followed, or that not all system components and

assemblies are used according to these instructions, or that components are used which were not obtained from us, Everest

Solar Systems is not liable for any resulting defects and damages, and the exclusive, limited warranty will be void.

T The exclusive, limited product warranty shall apply only if all instructions are strictly adhered to and the system is correctly

installed. Everest Solar Systems disclaims any and all warranties, expressed or implied, including without limitation any

warranties of merchantability and fitness for a particular purpose other than as set forth in the exclusive, limited warranty in

the terms and conditions of sale, which can be viewed under on our website:

http://everest-solarsystems.com/en-US/technical-product-information

T The dismantling of the system should be in reverse order of these assembly instructions.

Safety Regulations

3 | 15

n

Shared Rail for Pitched Roof:

T UL 2703 Listed

T Fast, simple installation

T No drilling, no bonding jumpers

T Pre-assembled universal module clamps with

integrated bonding

T Robust bonding rail splices

T Low part count

T Also compatible with tile roofs using commonly

available roof hooks

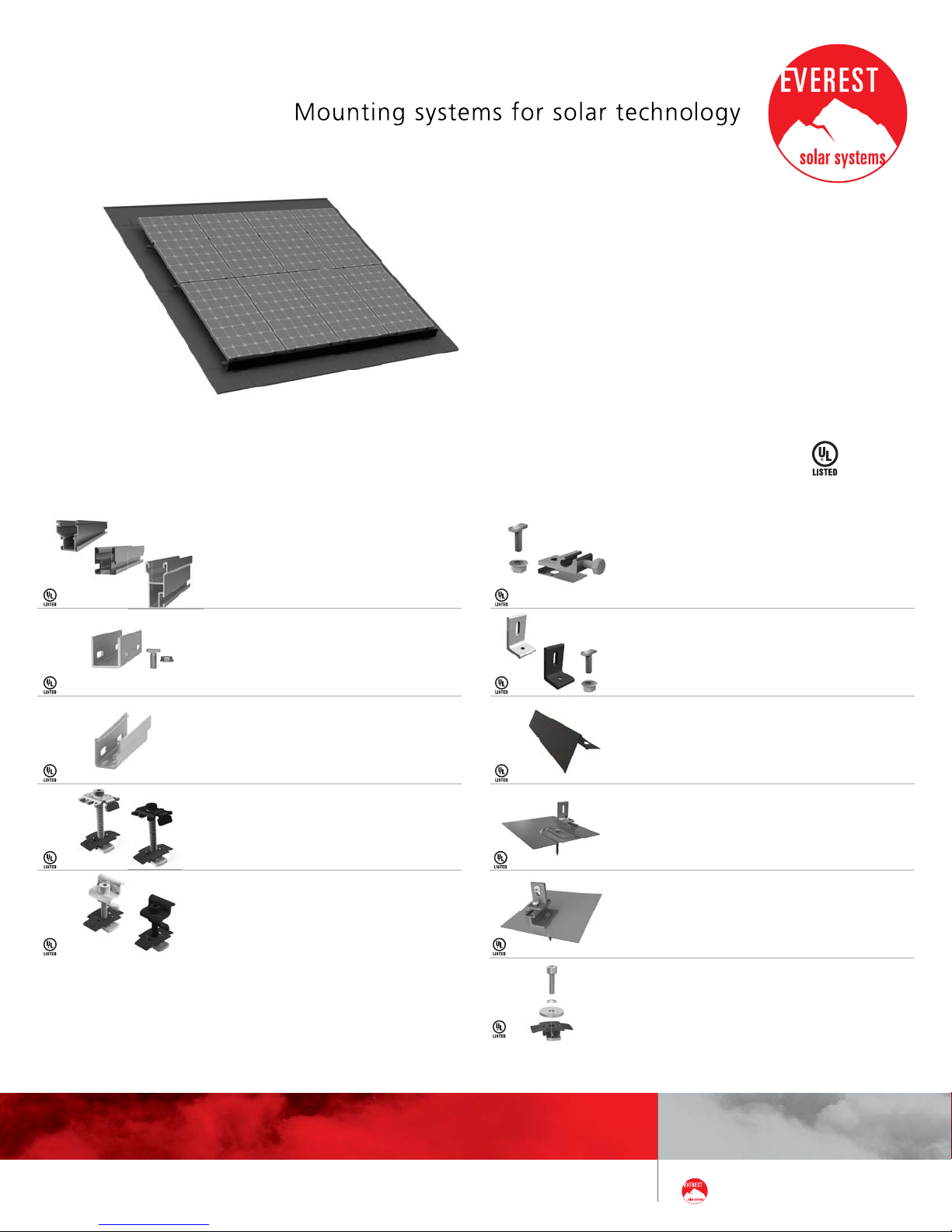

UL 2703 LISTED COMPONENTS

All components evaluated under UL 2703 and encompassed within Everest Solar System’s UL 2703 Listing shown below

If you seek a UL Listed System, only the parts shown on this page are acceptable.

CrossRail 48-S/48/80

Material: aluminum

Fi

Finish: mill, dark anodized

Rail Connector Set

Material: aluminum

Finish: mill, dark anodized

Hardware: stainless steel

1

Structural Rail Connector Set

CR 48-S

Material: aluminum

Hardware: stainless steel

CrossRail Mid Clamp UL2703+ Set

Material: stainless steel

Finish: silver, dark

CrossRail End Clamp Set

Material: stainless steel

Finish: silver, dark

1

Burndy WEEB Lug 8.0 + Hardware

4

Or Burndy WEEB Lug 10.3 + Hardware

WEEB Lug Material: tin plated copper

Hardware: stainless steel

L-Foot with Hardware

Material: aluminum

Finish: mill, dark anodized

Hardware: stainless steel

2

Optional: Array Skirt

Material: aluminum

Finish: dark anodized

Hardware: stainless steel

1

EverFlash eComp with Slider Kit

Material: aluminum, stainless steel

Finish: silver

EverFlash qComp with Slider Kit

Material: aluminum, stainless steel

Finish: silver

Optional: Micro Inverter and Optimizer

Mounting Kit

Material: stainless steel

1,3

1

Dark anodized rail must use Bonding T-Bolt and Bonding MK3 hardware.

2

Use standard L-foot with third-party roof attachments and EverFlash L-foot with EverFlash Comp Flashing.

3

The inverter hardware kit is not intended to replace the micro inverter ground and has only been evaluated to attach to the rail.

4

For certain jurisdictions, this item is regarded as a single-use item for a UL 2703 Listed System.

Materials Required

4 | 15

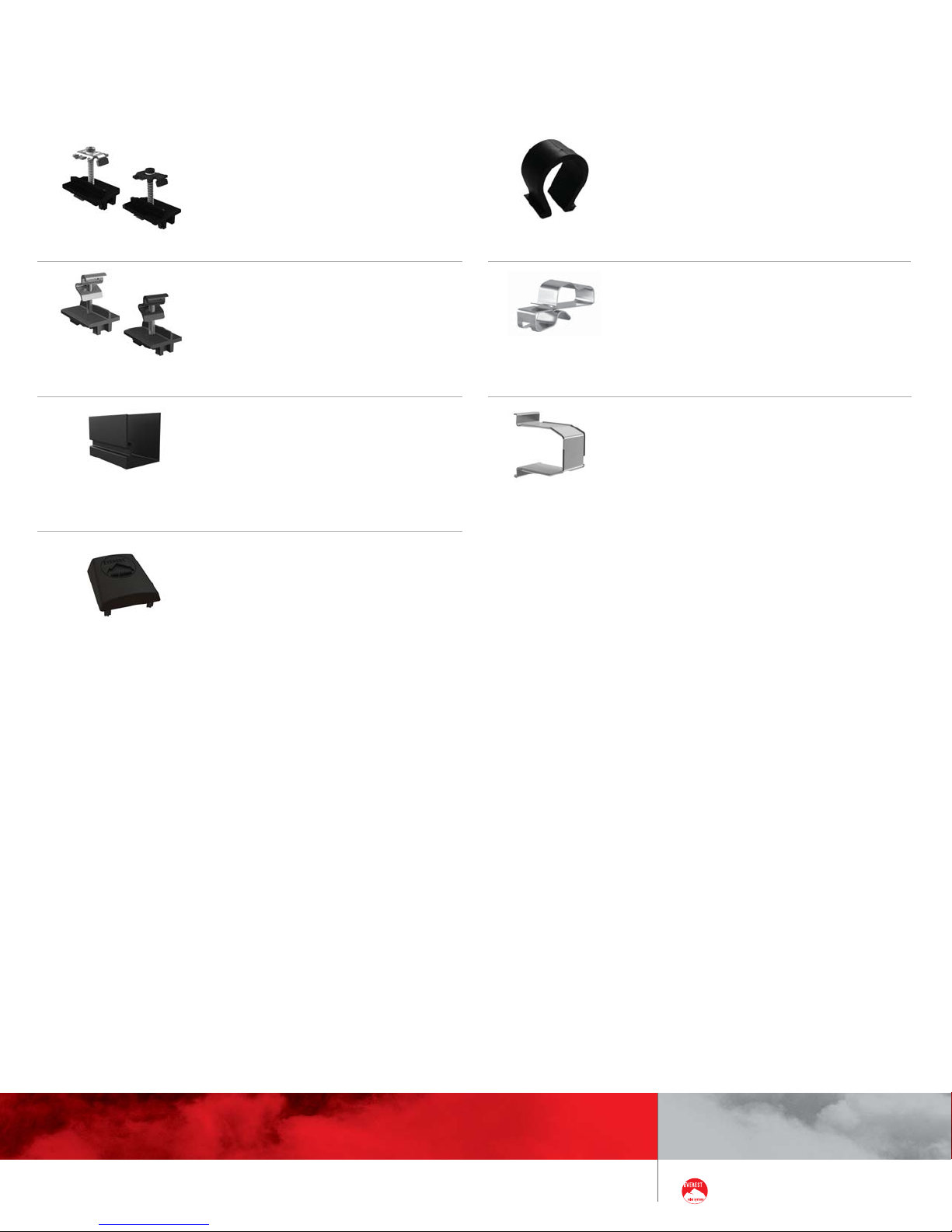

NON-UL LISTED COMPONENTS

Components in this section were not evaluated by UL for bonding

Shared Rail UL2703+ Mid Clamp

with AddOn

Material: stainless steel, glass fiber reinforced

polymide

Finish: mill, black oxide

Hardware: stainless steel

Shared Rail End Clamp with AddOn

Material: stainless steal, glass fiber reinforced

polymide

Finish: mill, black oxide

Hardware: stainless steel

CrossRail Sleeve 3”, Black

Material: UV Rated PVC

Finish: dark

Optional: End Cap for CrossRail

48-S/48/80

CrossRail 48-S End Cap shown

Material: glass fiber reinforced polyamide

Optional: External Omega Cable Clip

Material: polyamide, black

Optional: HEYClip SunRunner Cable

Clip SS, S6404

Material: stainless steel

Optional: Burndy Omega Clip

Material: 304 stainless steel

TOOLS AND TORQUE SPECIFICATIONS REQUIRED

Everest Solar Systems are designed to make installation easy and fast. The basic tools required to assemble the parts are listed below as a guide.

TOOLS REQUIRED

T Torque wrench (0 – 50 ft-lb)

T Cordless Drill (non-impact)

T 13mm Deep Socket

T 15mm Deep Socket

T 6mm Allen Drive (for M8 Allen Bolt)

T 1/2” Socket (for lag bolt)

T Measuring Tape

T String Line

Tools and materials for the installation of third party items such as roof attachment products, roof covering and sealing products or items used for

bonding and grounding are not listed here. Please refer to the instructions of those third party products.

TORQUE SPECIFICATIONS

T M10 T-Bolts: 25.8 ft-lb (35 Nm)

T WEEB Lug 10.3: 15 ft-lb (20.3 Nm)

T M8 T-Bolts: 10 ft-lb (13.5 Nm)

T Climber Set:

M8 Allen Bolts: 11.8 ft-lb (16 Nm)

T Mid Clamp UL2703+

M8 Allen Bolts: 12 ft-lb (16.3 Nm)

T All other clamps:

M8 Allen Bolts: 10.3 ft-lb (14 Nm)

Materials and Tools Required

5 | 15

Loading...

Loading...