Everest EMGR5, EMGR8, EMGR10(B), EMGR20, EMGR24(B) EMSGR33 User Manual

...

Glass Door Merchandisers &

Chromatography Refrigerators

Owner’s Manual

EMGR5, EMGR8, EMGR10(B), EMGR20,

EMGR24(B) EMSGR33, EMSGR48, EMSGR69

EMGR33(B), EMGR48(B), EMGR69(B)

EMSGR24C, EMSGR33C, EMSGR48C,

EMSGR69C, EMGR33C, EMGR48C, EMGR69C

www.EVERESTref.com

Glass Door Merchandisers &

Chromatography Refrigerators

EMGR5 EMGR8 EMGR10(B) EMGR20 EMGR24(B) EMSGR33 EMSGR48 EMSGR69

EMGR33(B) EMGR48(B) EMGR69(B) EMGR24C EMSGR33C EMSGR48C EMSGR69C

EMGR33C EMGR48C EMGR69C

Contents

1. Hydrocarbon Guidelines 1

2. Installation Instructions 3

3. General Safety 7

4. Electrical Safety 8

5. Chromatography Features 9

6. Operation 10

7. Care and Maintenance 15

8. Door Reversal Instructions 20

9. Troubleshooting Guide 23

10. Warranty Information 25

Everest Owner’s Manual

Hydrocarbon Guidelines

1. Hydrocarbon Guidelines

This section applies to R290 Hydrocarbon units only. To identify the refrigerant type, see the data plate

in the cabinet interior.

WARNING - THIS UNIT USES R290, A HYDROCARBON, PROPANE REFRIGERANT THAT IS

ENVIRONMENTALLY FRIENDLY BUT IS ALSO HIGHLY FLAMMABLE AND EXPLOSIVE. PLEASE READ

THIS MANUAL CAREFULLY AND FOLLOW ALL SAFETY PRECAUTIONS CONTAINED HEREIN TO

AVOID THE RISK OF FIRE OR EXPLOSION. FAILURE TO FOLLOW THE SAFETY PRECAUTIONS MAY

RESULT IN SERIOUS INJURY OR DEATH, AND/OR PROPERTY DAMAGE.

DANGER - Risk of fire or explosion. Flammable refrigerant used. Do not use mechanical devices or

other means to accelerate the defrosting process. Do not puncture refrigerant tubing.

DANGER - Risk of fire or explosion. Flammable refrigerant used. To be repaired only by trained service

personnel. Do not puncture refrigerant tubing.

CAUTION - Risk of fire or explosion. Flammable refrigerant used. Consult Service Manual or Owner’s

Manual before attempting to install or service this product. All safety precautions must be followed.

CAUTION - Risk of fire or explosion. Dispose of properly in accordance with federal or local

regulations. Flammable refrigerant used.

CAUTION - Risk of fire or explosion due to puncture of refrigerant tubing; follow handling instructions

carefully. Flammable refrigerant used.

1

Hydrocarbon Guidelines

Propane (R290) is highly approved for use as a refrigerant in commercial, self-contained units in the US under limited

use conditions. It can only be used in new equipment. Backfitting or modifications of old equipment are not allowed. It

must be charged in a strictly limited volume of up to 150 grams (5.3 oz) per refrigeration circuit. Even though this is a

small amount, it still presents a fire or explosion hazard if it leaks out of parts that hold refrigerant. When it comes in

contact with air, a flammable propane-air mixture can be created and easily ignited by electrical sparks, open flames

or hot surfaces. The risk is higher in small, confined, poorly ventilated spaces. Propane will settle at lower zones

because it is heavier than air. To reduce these risks, observe the following precautions

• Avoid installation of unit in areas with open flames or in general vicinity of open flames or high surface

temperatures.

• Avoid unit installation in small, confined spaces. Ensure ample ventilation at all times. Keep all exhaust vents

free of any blockage or obstruction.

• Do not rely on smell to detect potential leaks of propane refrigerant. Propane refrigerant is a high purity

propane gas and does not contain odourants or stenching agents. These additives are typically used in fuel-

grade propane and natural gas in order to give them a distinctive smell which makes it easier to detect leaks.

• General service and repairs must be performed in well-ventilated areas. General service and repairs must be

performed only by professionals authorized by Everest Refrigeration.

• Component shall be replaced with Everest-issued, like components to minimize the risk of possible ignition

resulting from incompatible parts or improper repairs.

• Do not modify, re-appropriate or remove any functional part(s) from the unit.

• Handle the unit with care to avoid any damage.

• Practice safety guidelines when transporting the unit. Consult with your local Department of Transportation for

requirements in moving flammable gasses.

2

Installation Instructions

2. Installation Instructions

This section applies to all Everest products. Correct installation ensures proper performance and

longevity of your appliance. Professional installation by a trained refrigeration technician and

electrician is recommended. Warranty is void if the following guidelines are not met.

1. Inspect for any freight damage upon delivery

of the unit. If damage is detected, immediately

report it to an Everest representative. Everest is

not responsible for damage that occurs during

shipment.

2. Keep the unit upright at all times. The

compressor contains oil, refrigerant, lubricants,

and various chemicals. When tilted, these fluids

may shift and travel to sections where they

don’t naturally occur. This will lead to system

contamination and compressor failure.

3. Some units require caster installation for

proper performance. Visit our website at www.

everestref.com and enter your product’s model

number in the search field to determine its

caster requirements.

4. Do not place your hands under the unit when

moving it to avoid injury from sharp edges,

protruding parts or weight impact.

5. Select a location with good air ventilation.

Poor ventilation rapidly increases ambient

temperature. High ambient temperatures

exceeding 86°F (30°C) promote excessive

compressor activity in order to maintain the

desired cabinet temperature. This will result in

decreased performance, advanced component

failure and the risk of fire.

6. Select a location away from heat-generating

equipment such as stoves, ovens, etc. Heat

sources rapidly increase the temperature of the

immediate vicinity. High temperatures exceeding

86°F (30°C) promote excessive compressor

activity in order to maintain the desired cabinet

temperature. This will result in decreased

performance, advanced component failure, and

the risk of fire.

7. A distance of 6” is required for backside clearance.

This ensures proper ventilation and prevents

overheating which can lead to advanced component

failure and the risk of fire.

8. Select a location with a hard, leveled surface.

Use a leveling tool on the unit to ensure proper

alignment. Proper door function and condensate

removal is dependent on accurate balance. Install

the front leg stabilizers for units that come standard

with it to ensure proper door functions and unit

stability.

9. Select a location close to an electrical wall outlet

to ensure direct connection without the use of

extension cords.

10. Select a location away from severe moisture

conditions. This may compromise the unit’s electrical

components and lead to electrical shocks or the risk

of fire.

11. Select a location that will not expose the unit

to extremely dusty conditions. Environments with

high dust and debris content will significantly hasten

condenser coil blockage and will result in decreased

performance, advanced component failure and the

risk of fire.

12. Do not build an enclosure or cabinet around the

unit. This will restrict air ventilation resulting in elevated

compressor activity, decreased performance, advanced

component failure and the risk of fire.

13. The unit is not intended for use in food trucks.

Limited space, lack of ventilation, and ambient

temperatures exceeding 86°F (30°C) typical to this

setting will result in elevated compressor activity,

decreased performance, advanced component failure,

and the risk of fire.

14. The unit is intended for indoor use only.

Outdoor use will cause a decrease in performance,

advanced component failure and the risk of fire.

3

Installation Instructions

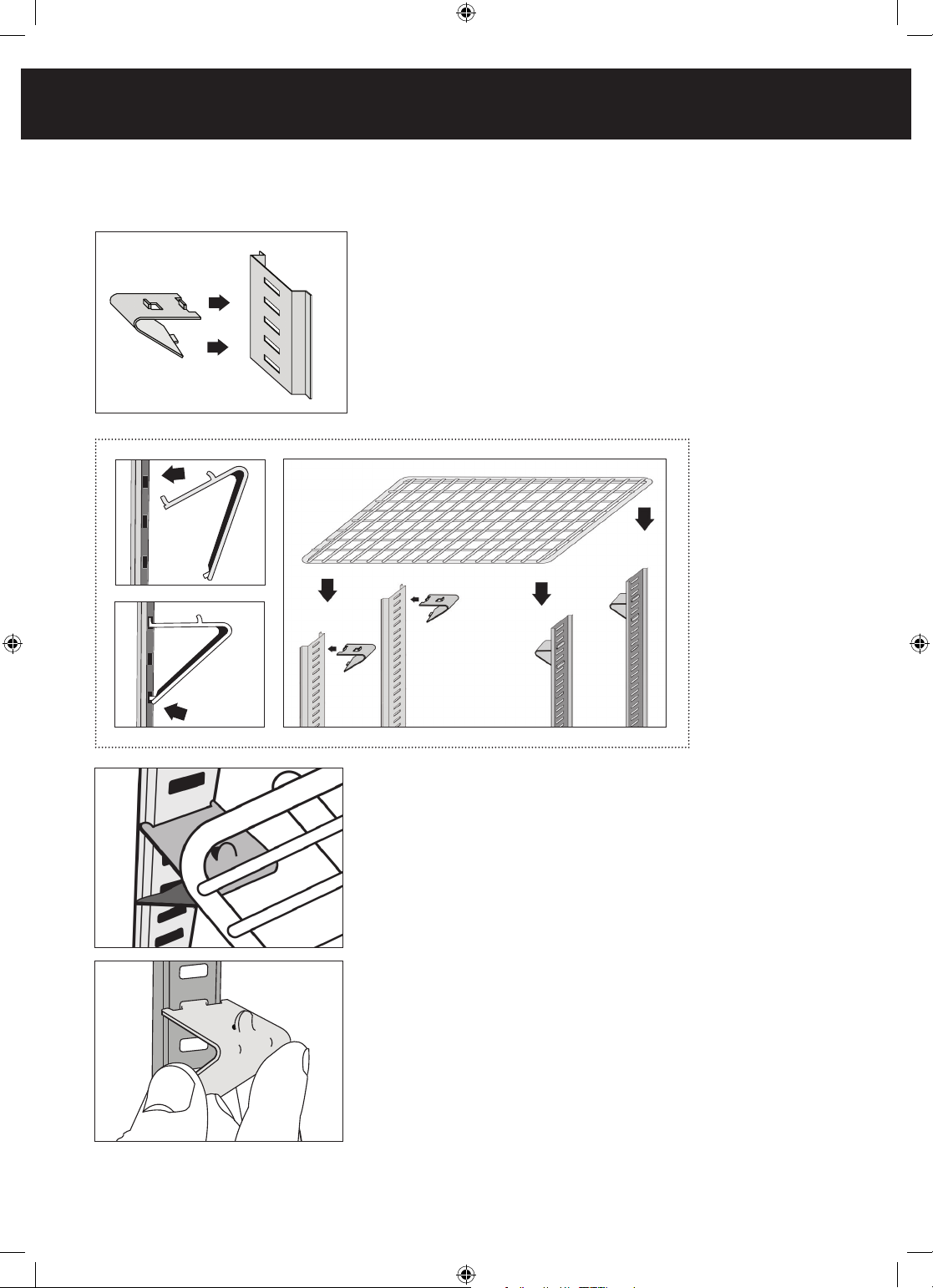

Shelf Installation

Some models come standard with shelves, shelf clips and notched pilasters. Each shelf requires

four clips.

1. Attach the shelf clips onto the pilasters by inserting its top

hook into a pilaster notch followed by the bottom hook. Do

not use pliers or other crimping tools to modify the shape of

the shelf clips. This will result in shelf mounting instability.

2. Place shelves on the shelf clips making sure all corners are

mounted securely and evenly with identical distance from the

unit’s floor and up. Always lay the back of each shelf down on

the rear clips before the front.

3. When removing a shelf, unmount the shelf from the shelf

clips. To detach the shelf clip from the pilaster, tilt up the shelf

clip until the bottom hook clears, followed by the top hook.

4

Installation Instructions

Product Load Level & Shelf Placement

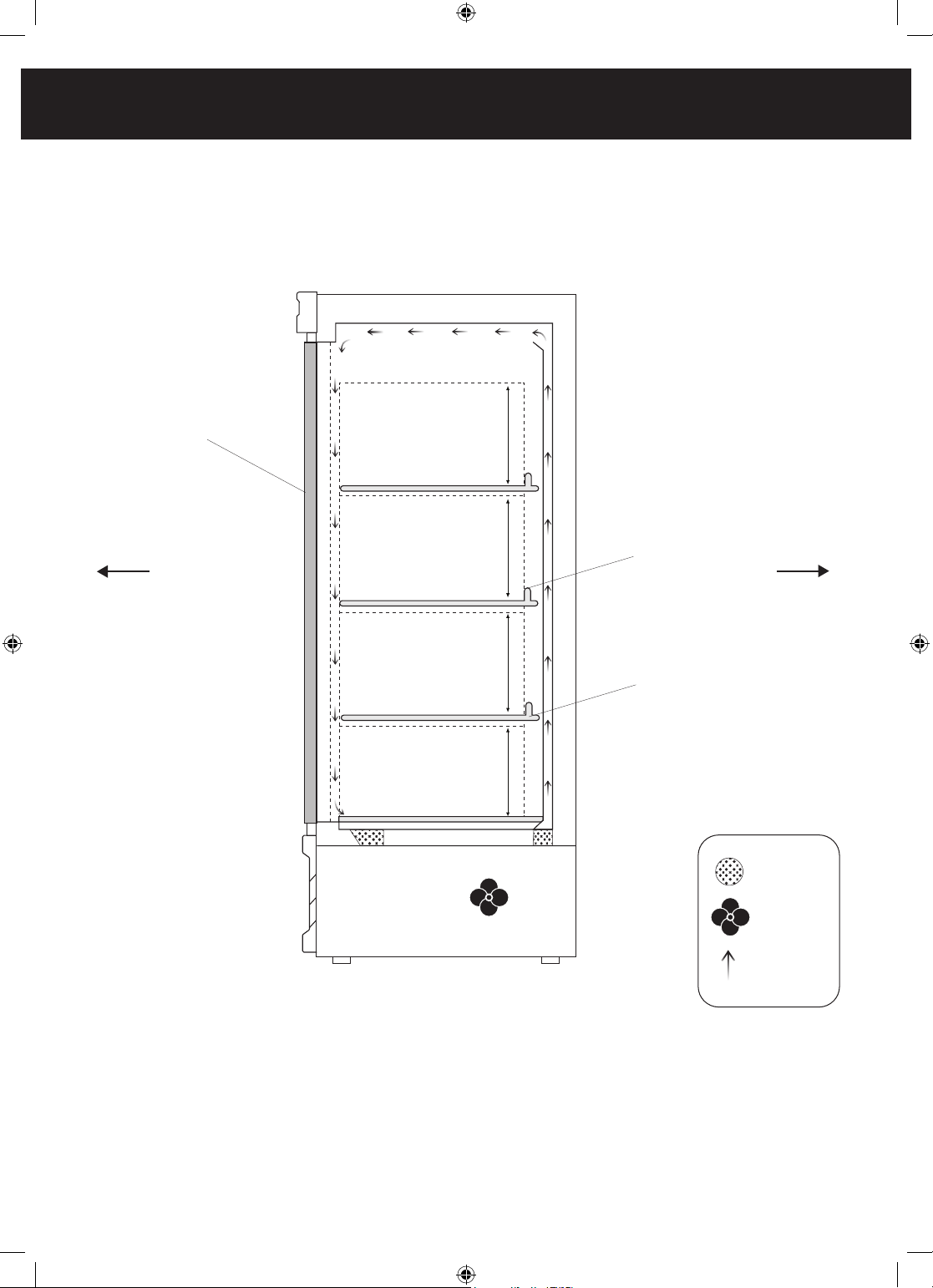

Product Load Level for EM Series (Sliding Door Models)

Glass Sliding Door

Front

Load Level 10”

Load Level 10”

Load Level 10”

Load Level 10”

Airflow Guard

Shelf

Rear

Air Vent

Fan

Airflow

Side View

5

Installation Instructions

Product Load Level & Shelf Placement

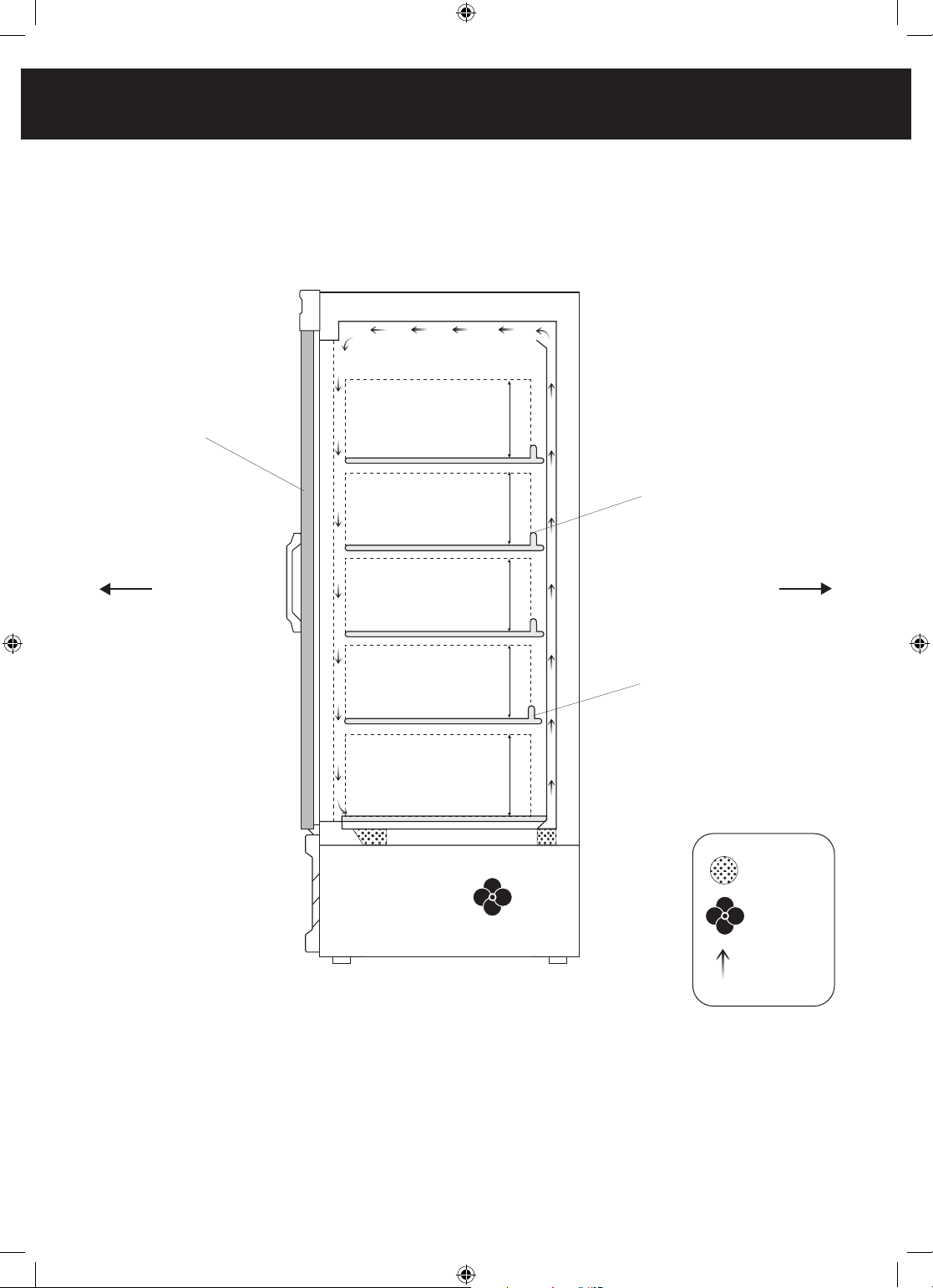

Product Load Level for EM Series (Swing Door Models)

Glass Swing Door

Front

Load Level 10”

Airflow Guard

Load Level 10”

Rear

Load Level 10”

Shelf

Load Level 10”

Load Level 10”

Air Vent

Fan

Airflow

Side View

6

General Safety

3. General Safety

This section applies to all Everest products. Use your appliance according to its designed function as

specified in this Owner’s Manual. Warranty is void if the following guidelines are not met.

• Before the unit is used, it must be installed and connected according to the installation instructions provided

in this manual.

• Remove all packaging material and protective vinyl covering from the unit before it is used. These items are

flammable and can lead to a fire.

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of the unit. Do not store

combustible or explosive items and substances such as aerosol cans in or around the vicinity of the unit.

• Do not place objects on or around the exhaust vents of the unit. This can cause overheating which may lead

to a fire or explosion. Objects may also fall when opening and closing doors which may lead to serious injury.

• Do not climb, stand or hang on the shelves, doors, or drawers of the unit. This can damage the unit and lead

to serious injury.

• Do not touch the freezer interior if your hands are wet or damp. This may lead to freezer burn or cause your

skin to stick to the cold surface.

• If you suspect a refrigerant leak or a compromised refrigeration system, disconnect the unit and contact

Everest Refrigeration immediately.

• When disposing the unit, remove all doors and shelves to avoid any risk of injury or entrapment. Ensure that

the refrigerant in the condensing unit is properly disposed of by a qualified refrigeration technician according to

governmental codes, requirements and regulations.

7

Loading...

Loading...