Everdure FLINDERS, NORFOLK II, KIMBERLEY, DAINTREE Assembly, Operation & Maintenance Instructions

Page 1

STYLE, GRILLED TO PERFECTION

ASSEMBLY, OPERATION

& MAINTENANCE INSTRUCTIONS

FOR EVERDURE 4 BURNER GAS BARBECUES

Models Included:

KIMBERLEY

FLINDERS

NORFOLK II

DAINTREE

KIMBERLEY

Page 2

STYLE, GRILLED TO PERFECTION

ASSEMBLY, OPERATION AND MAINTENANCE INSTRUCTIONS

FOR EVERDURE 4 BURNER GAS BARBECUE RANGE

FLINDERS, NORFOLK II, DAINTREE & KIMBERLEY OUTDOOR BARBECUES

CONTENTS

SECTION PAGE NO.

General Safety Instructions ……………… 3

Appliance Details ………………………… 4

Gas Connections …………………………. 4

Outdoor Installation Guide ……………… 5

Operating Instructions …………………… 6

Lighting Procedure ……………………….. 6

Cooking …………………………………… 7

Cleaning And Storage …………………… 8

Troubleshooting ………………………….. 9

Maintenance ………………………………. 9

Assembly Instructions …………………….. 10-28

Barbecue Accessories ……………………. 29

NG Conversion & Installation ………….. 30-31

Exploded Component Diagrams ……..... 32-33

It is important that you retain these instructions, proof of purchase as well as

other important documents about this product for future reference.

Due to continual product development, Everdure reserves the right to alter

specifications or appearances without notice.

Dispose of packaging responsibly – recycle where facilities are available.

2

Page 3

STYLE, GRILLED TO PERFECTION

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT: Read the assembly instruction section and safety precautions of this booklet carefully before

removing the contents of this carton. If you are unsure about anything regarding your

barbecue, please contact your Service Centre before operating the appliance.

1. This barbecue and wok burner is for OUTDOOR USE ONLY. This appliance must NOT be used indoors.

2. Ensure that all gas connections are tight before operating this appliance (refer to leak testing procedure in this

manual). Always check for leaks when a gas cylinder is replaced or reconnected. The manifold is supplied with a

temporary plastic cap over the thread for the wok burner hose. This MUST be removed and the wok burner hose

attached. Failure to connect the wok burner will result in a gas leak.

3. Unsupervised children or pets should not be near a barbecue while cooking or during warm up or cool down.

Ensure children or pets are kept a distance well away from the barbecue whilst it is in use. Ensure that young

children do not play with the appliance. This appliance is not intended for use by young children or infirm persons.

4. Particular care must be taken when removing the fat tray. Hot fats can cause serious injury.

5. Turn all gas valves off including cylinder after use. Do not allow build up of unburned gas.

6. Do not use this appliance for any purpose other than what it is intended for.

7. Do not move this barbecue while in use as accessible parts may be very hot. Ensure that your barbecue is in a level

position and the wheels are locked when the barbecue is in place to minimize movement of your barbecue. This

barbecue is not designed for fixed installation – do not remove castors from appliance.

8. People with flammable clothing such as nylon etc. should keep well away from the barbecue when it is operating.

9. Never leave burners on high for more than 10 minutes unless actually cooking.

10. Always check for leaks when a gas cylinder is replaced or reconnected.

11. In case of fat fire turn cylinder off. Fat drip trays should be cleaned and checked before using the barbecue.

Regular cleaning should reduce the build up of fat and food residues which is combustible and can result in a fat

fire. Fat fires can be prevented with diligence in cleaning your fat tray. Damage as a result of fat fire is not

covered by your warranty and voids it. Do not use sand, fat absorbents or kitty litter in the fat tray; line the fat tray

with aluminium foil for easy cleaning.

12. For your safety and enjoyment, read all operating instructions before lighting.

13. Ensure that the product has adequate clearance from combustible materials. The appliance is designed so that

heat will not affect the trolley. All combustible materials must be kept more than 250mm from the sides of the

trolley and more than 1500mm above the cooking surface of the barbecue.

14. If the burner makes a hissing sound when lit, it may be burning inside. Turn the burner off, allow it to cool, and

then try ignition again. Keep your barbecue protected against strong wind – if this cannot be avoided, always

check that the burners remain alight if operating the barbecue in windy conditions.

15. When the wok burner is in use or is still hot, the lid must not be placed in the closed position.

16. Do not carry out any servicing on the gas manifold of the barbecue yourself – this must only be done by authorised

technicians.

17. We recommend that you regularly maintain your barbecue and keep it in good condition. This can be achieved by

following the cleaning and maintenance suggestions in this booklet.

18. This appliance is not suitable for mounting in a movable vehicle (boat, trailer etc). The appliance should be on a

solid surface (ground, concrete etc) when in use.

19. Do not use or store this appliance in areas of high salt content (a marine environment) or an area with caustic

fumes or liquids (such as a domestic pool), as these chemicals can cause the appliance materials to deteriorate

(and void the warranty). Regular cleaning and covering with an Everdure barbecue cover can help can help to

reduce this.

DO NOT OPERATE THIS APPLIANCE BEFORE READING THE INSTRUCTION BOOKLET

DO NOT PLACE ARTICLES ON OR AGAINST THIS APPLIANCE

DO NOT STORE CHEMICALS OR FLAMMABLE MATERIALS OR SPRAY AEROSOLS NEAR

THIS APPLIANCE

DO NOT OPERATE THIS APPLIANCE INDOORS

DO NOT ENCLOSE THIS APPLIANCE

3

Page 4

STYLE, GRILLED TO PERFECTION

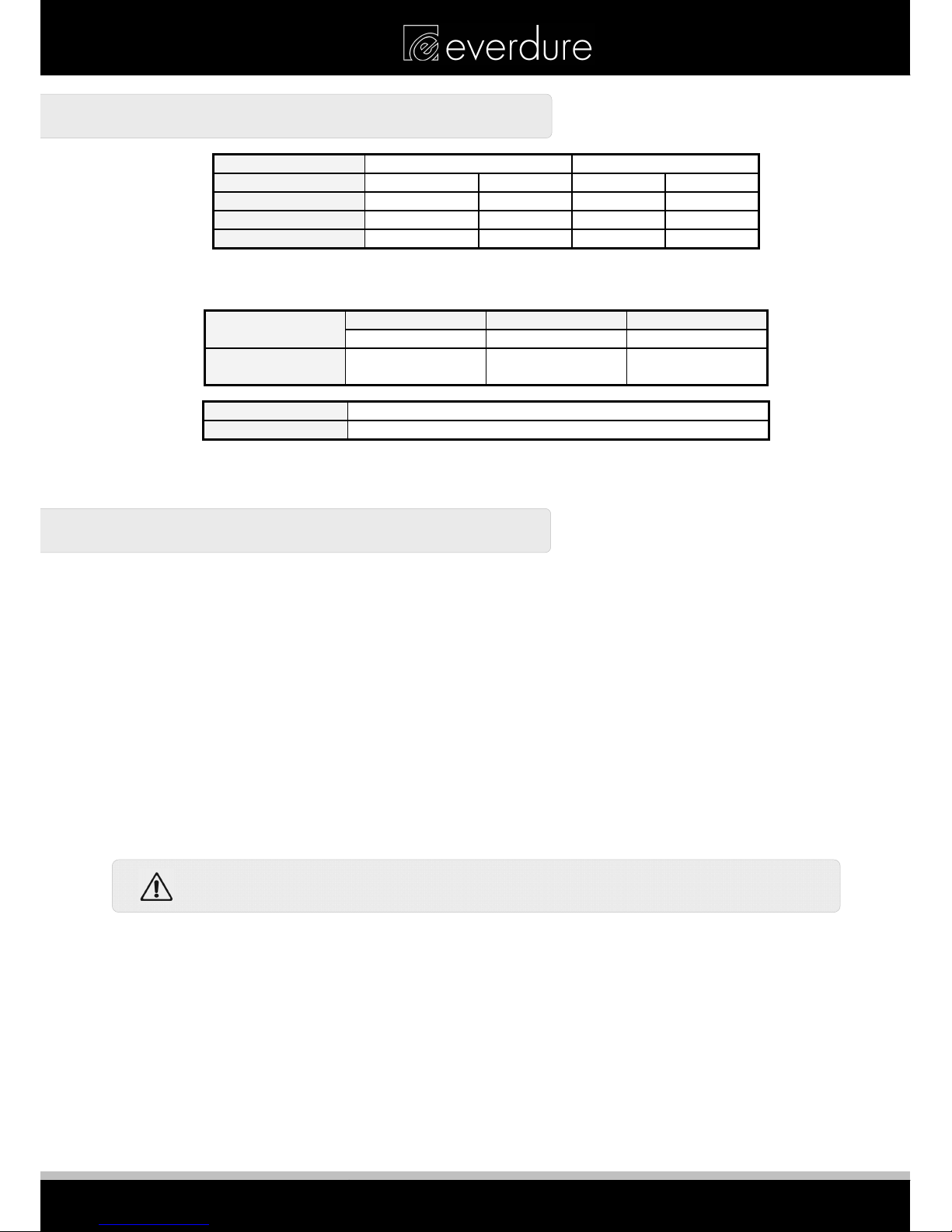

APPLIANCE DETAILS

MAIN BARBECUE

SIDE BURNER

Gas Type: Propane

N.G

Propane

N.G.

Burner Pressure: 2.75 kPa

0.95 kPa

2.75 kPa

0.95 kPa

Injector Diameter: Ø1.10 mm

Ø1.80 mm Ø1.10 mm Ø1.80 mm

Heat Input: 60 MJ/ h

r

60 MJ/ h

r

16

MJ/ h

r

16 MJ/ hr

Note: The size of the injector diameter is stamped on one of the hexagon faces (e.g. ‘180’ for

Ø1.80mm injector).

Front 55mm x Full width of fat tra

y

Rear 100mm x Full width of fat tra

y

Combustion air is admitted at the underside at the front and rear of the combustion chamber.

GAS CONNECTIONS

FOR PROPANE CYLINDER CONNECTION

1. To achieve the optimum performance from your Everdure Barbecue, an approved gas cylinder (POL

fitting) of 9kg capacity must be used.

2. Connect the cylinder to the barbecue, via the hose and regulator. Firmly tighten joints, but do not over-

tighten. Take care not to damage the regulator fitting. Check that ALL Barbecue and Wok Burner valves

are in the Off position before opening the gas cylinder.

NOTE: Only one gas cylinder should be stored inside the trolley at any one time.

LEAK TESTING

1. Make sure gas control knobs are Off and turn the cylinder valve On.

2. Check for leaking joints by brushing with solution of half-liquid detergent and half water. If a leak is

present, bubbles will appear (or you may hear a hissing sound). Retightening connections can generally

repair a leaking joint. You must also check the gas hose and connection at the gas cylinder. If a leak

cannot be resolved, do not proceed.

DO NOT USE NAKED FLAME FOR LOCATING GAS LEAKS.

IF A LEAK PERSISTS CALL AN AUTHORISED GAS FITTER.

LOCAL AUTHORITY REQUIREMENTS

Check Gas Type and specifications plate on the left-hand side of the barbecue. All gas fitting work, service

and repairs can only be performed by an authorized person in accordance with AS 5601 & your local gas

regulations.

NATURAL GAS

All barbecues are supplied for use with propane gas. For natural gas usage, a conversion kit must be

purchased and installed by a gas fitter or Everdure Service Technician. Please see the separate NG

conversion and installation instruction at the end of this instruction manual for details.

Barbecue only

LENGTH (mm)

W

IDTH (mm)

HEIGHT (mm)

905

590

230

Barbecue and

Trolley

1575 600 1240

4

Page 5

STYLE, GRILLED TO PERFECTION

OUTDOOR INSTALLATION GUIDE

This Appliance shall only be used in an above ground open-air situation with natural ventilation, without

stagnant areas, where gas leakage and products of combustion are rapidly dispersed by wind and natural

convection.

This appliance must not be used indoors. Do not use your barbecue in garages, porches, sheds or other

enclosed areas. The barbecue is not intended to be installed in or used on recreational vehicles (e.g. boats,

camping vans) and should not be placed close to or under any surfaces that will burn or are sensitive to heat.

Do not block/obstruct the flow of air and combustion around the barbecue housing while in use.

Any enclosure in which the appliance is used shall comply with one of the following:

An enclosure with walls on all sides, but at least one permanent opening at ground level and no

overhead cover.

Within a partial enclosure that includes an overhead cover and no more than two walls

Within a partial enclosure that includes an overhead cover and more than two walls, the following

shall apply-

(i) at least 25% of the total wall area is completely open: and

(ii) at least 30% of the remaining wall area is open and unrestricted.

In the case of balconies, at least 20% of the total of the side, back and front wall areas shall be and remain

open and unrestricted.

OUTDOOR AREA – EXAMPLE 1

Both ends open

OUTDOOR AREA – EXAMPLE 2

Open side at

least 25% of

total wall area

30% or more in total of the

remaining wall area is open and

unrestricted.

30% or more in total of the

remaining wall area is open and

unrestricted.

Open side at

least 25% of

total wall area

OUTDOOR AREA

–

EXAMPLE 3

5

Page 6

STYLE, GRILLED TO PERFECTION

OPERATING INSTRUCTIONS

GAS TYPE AND CONSUMPTION

The barbecues are designed to operate on Propane and NG Gas (gas type must be specified at time of

purchase). Gas consumption, Pressure and Injector Orifice size are shown on the Data Plate found on the

left-hand side of the barbecue (see segment on locating your serial number in the warranty section).

GAS CONTROL KNOBS (BARBECUES AND WOK BURNERS)

The gas control knob locks in both the Off and High positions. By depressing the knob and turning anticlockwise, gas flow will gradually increase until the High position is reached. Continue turning in this

direction and gas flow will decrease until a simmer level is reached at Low. To turn gas flow off the gas

control knob must be turned clockwise from Low, depressed at High and turned until the Off position is

reached.

VAPOURISER

Prior to using the barbecue, ensure the vapouriser is in the correct position below the grill plate.

NON-VITREOUS ENAMEL CAST IRON HOT PLATES & GRILL PLATES

Prior to using the barbecue, it’s advisable to cure the cooking surface. Wash the hot plate and grill plate,

then cover with olive or vegetable oil, light all burners and leave on until oil is absorbed, then wipe with a dry

cloth. To prolong the life of your cooking plates, please follow the maintenance procedures outlined in this

instruction manual.

FAT TRAY

Prior to use check that the fat tray is clean and lined with aluminium foil.

UNDER NO CIRCUMSTANCES MUST SAND, KITTY LITTER OR FAT ABSORBENTS BE USED IN THE FAT TRAY

LIGHTING PROCEDURE

Read all operating instructions before lighting.

Open roasting hood before lighting.

Make sure all gas control knobs are in the ‘Off’ position and open cylinder

valve or connect natural gas.

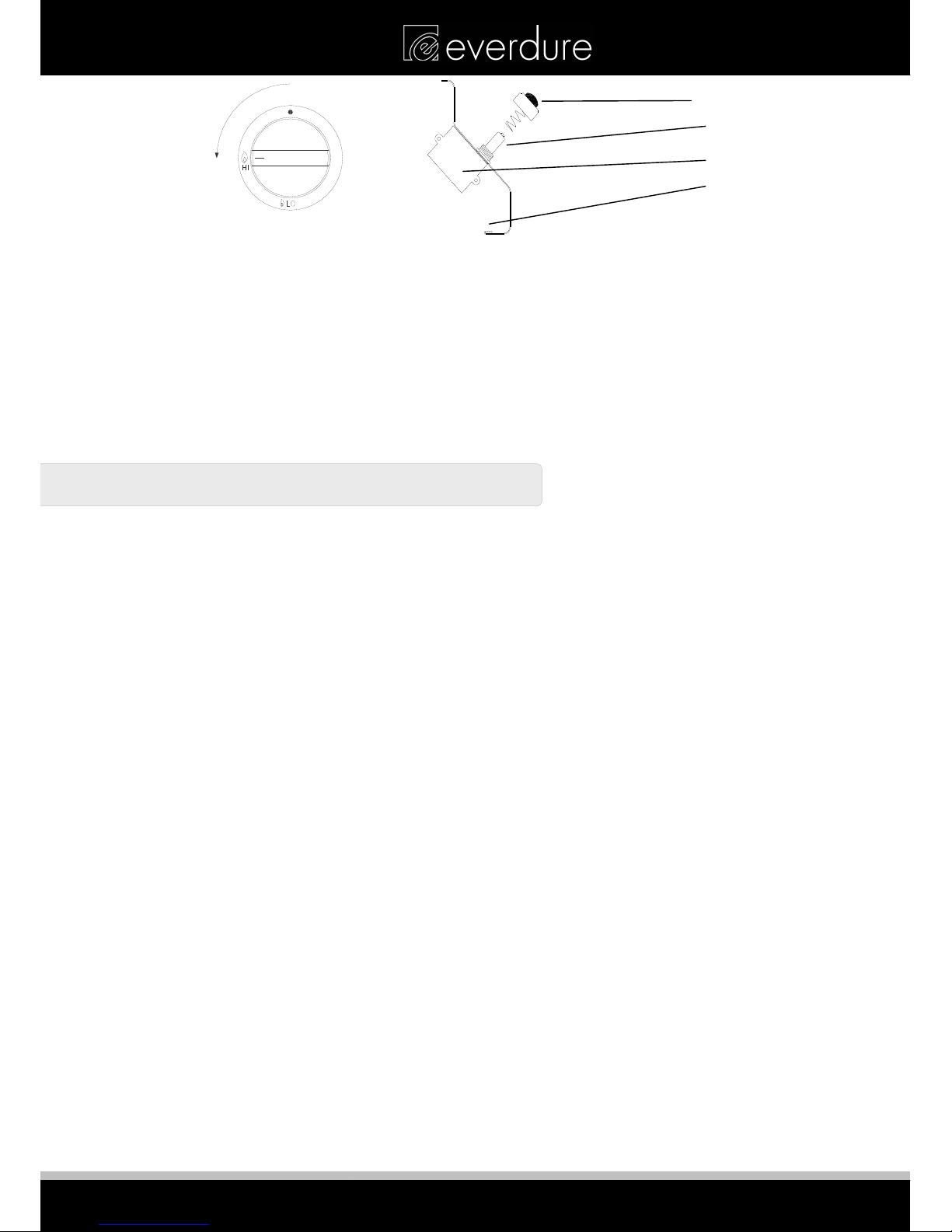

LIGHTING THE BARBECUE USING THE ELECTRONIC IGNITION

The Everdure 4 burner barbecue has 1 battery operated igniter to operate the appliance. The sparker ignites

the second burner in from the right hand side. The remaining burners are ignited by a cross over channel.

Before attempting to light the barbecue, please ensure that a battery has been placed in the battery operated

igniter. To check for, and replace a battery, the black and silver cap requires removing. The cap is removed

by turning in an anti – clockwise direction. A battery can then be placed into the box and the cap replaced.

The barbecue can then be lit by the following procedure:

1. Turn the burner gas control knob to the ‘High’ position on the second burner from the right.

2. Hold down the igniter button until the burner ignites. If the burner does not light within 10 seconds, turn

gas control knob off and allow the unburned gas to dissipate before attempting ignition again. If

ignition continues to fail refer to the “Trouble Shooting” section.

3. To achieve ignition on the remaining burners turn either of the burner gas control knobs next to the lit

burner to ‘High’, and the burner will ignite from the first burner.

6

Page 7

STYLE, GRILLED TO PERFECTION

LIGHTING THE WOK BURNER USING THE ELECTRONIC IGNITION

The Wok Burner also has a 1 battery operated igniter situated at the front of the Wok Burner servery, which has

the same battery replacement procedure as the barbecue igniter. To ignite the Wok Burner, press and hold the

wok burner igniter button down, so that sparks can be seen at the brass burner. Press the gas control knob in and

turn to the High position. When the gas ignites, release the igniter button. If the burner fails to light, turn the gas

control knob to the Off position, let the gas dissipate for five minutes, and then re-try. If ignition continues to fail

refer to the “Trouble shooting” section.

MANUAL IGNITION

To light the barbecue manually, the fat tray is removed. Any burner can then be lit by a match from below. Once

lit, the fat tray is replaced in position.

COOKING

COOKING WITH YOUR BARBECUE PLATES

A fairly protected location is desirable for pleasant and efficient cooking. Try to keep the barbecue sheltered

from strong winds as this will drastically reduce cooking efficiency. Check frequently that the burners remain

alight when used in conditions of strong wind.

FOR VITREOUS & NON VITREOUS ENAMEL COOKING SURFACES

After ignition, run the barbecue for 10 minutes with the burners on high, to heat up the cooking area. A little

cooking fat (or oil) on the cooking surfaces will prevent sticking. Immediately after adding the oil, place items

onto the cooking surfaces. NOTE: When cooking on vitreous enamel surfaces, please ensure that metallic or

sharp objects are NOT used. Damage to plates and grills due to the use of metallic or sharp objects will not be

covered under warranty. It is recommended to use silicone cooking utensils as these are both hygienic and

withstand high temperatures.

FOR STAINLESS STEEL COOKING SURFACES

Approximately 30 minutes to 1 hour before cooking, all chilled, raw food items should be removed from the

refrigerator, as room temperature food will have a shorter cooking time and minimize warping of the stainless

steel hot plate. After ignition, run the barbecue for 5 minutes with the burners on high, to heat the cooking area

to the ideal cooking temperature (between 145-160ºC). Once this temperature has been reached, apply a small

amount of oil to both the hot plate and grill plate. Everdure recommends the use of Canola oil, or oils with a

high smoke point (such as Sunflower or Safflower). Immediately after adding the oil, place items onto the

cooking surfaces.

Turn burners down a little when full heat is not required and to LOW when not cooking. Cooking time for a

20mm thick steak cooked to medium on the char grill is approximately 15 minutes (7.5 minutes per side) with

the burners on high.

During cooking, fat and scrapings will drip through to the fat tray. Do not allow excess fat to build up in the fat

tray. Clean the fat tray and replace the aluminium foil before use.

COOKING USING THE HOOD

Open the hood and remove the solid plate and flame tamer. Place the grill in the centre position of the barbecue.

With the roasting hood open, ignite the burners and turn to Hi. Close the roasting hood and allow 10 minutes for

pre cooking time, or until the internal temperature reaches approximately 180°C. During the 10 minutes, the roast

can be prepared. Place 2cms of water into a domestic oven proof roasting tin of maximum size 40cm x 30cm x

5cms deep. Place a suitably sized rack into the roasting tin. Place the item to be cooked centrally onto the rack, so

Black & Silver cap

Batter

y

Ignition box

Fascia Panel

–

Side View

Turn knob

anti-clockwise

to “Hi”

7

Page 8

STYLE, GRILLED TO PERFECTION

that any surplus fat and grease will drip into the water. The water will also keep the food moist during the cooking

process. After the pre heat time is complete, open the roasting hood and place the roasting tin centrally onto the

grill plate. Turn the centre 2 burners off and close the roasting hood. The highest setting for the duration of the

cooking is with both outer burners on high, but the temperature can be fine tuned by adjusting the outer burners

up and down to give the ideal cooking temperature. Naturally the degree of heat required will very much depend

on the weather conditions at the time of cooking. A similar set-up can be used when using a rotisserie, making

sure that oil and fat cannot drip directly onto the burners.

A guide for roasting beef is to allow 30 to 50 minutes cooking time per kilogram for rare and well done

respectively. It is recommended that for evenness, the item being cooked is turned over at approximately half way

through the cooking time. Ensure that the centre burners remain Off, leaving only the two outside burners on Hi

during the cooking process. This is most important as severe overheating and spoilt food will result if the two

central burners are left on Hi. This is a general guide for roasting only – please check www.everdure.com for any

updated cooking guides.

AFTER COOKING

1. When finished, make sure burner control knobs are turned OFF.

2. TURN OFF THE GAS SUPPLY AT THE CYLINDER.

3. After cooking and whilst the barbecue is still warm, remove scraps from the grill with a scraper.

4. Excess fat and meat scraps can be scraped off the vapouriser by removing the grill to gain access.

WARNING: Some surfaces may still be hot – please use protective gloves.

5. Clean the fat tray and replace the aluminium foil after or before each use of the appliance.

6. Once the barbecue is cool close the roasting hood and wipe off any fat splatter from the trolley with a clean

rag.

CLEANING & STORAGE

CLEANING

Before cleaning, ensure the appliance has cooled and is safe to touch. Painted surfaces can be cleaned using a

mild household detergent or cleaner and a clean cloth (do not use scourers or harsh detergents). It is advisable

to test cleaners on a small section of the appliance first. The brass burner and spill bowl of the wok burner can

be cleaned by removing the trivet. NEVER use paint thinners or similar solvents for cleaning and NEVER pour

cold water over hot surfaces. Over time, stainless steel will be affected by “tea staining” or “bronzing” (brown

discoloration of stainless steel). This can be reduced by washing the surface with mild detergent and warm

water, followed by rinsing with clean cold water. Dry the surface afterwards.

For vitreous enamel and stainless steel cooking surfaces only: Starting from cold, pre-heat the cooking surfaces

for 5 minutes (do not overheat, as this can make them difficult to clean). During this 5 minutes, carefully remove

any excess oil with paper towels or a cotton rag. After the 5 minutes warm up, turn off the burners, and carefully

clean with soapy water and a mild scourer, rinsing the scourer occasionally. Finish by cleaning with a damp

paper towel or damp cotton cloth.

WARNING! The surfaces of the plates will be hot. Please ensure protective gloves are worn.

STORAGE

When the appliance is not in use, the cylinder valve must be turned OFF, the appliance and the cylinder together

must be stored outdoors in a well ventilated area. However it is permissible to store the appliance (but not the

cylinder) indoors. Ensure a small amount of fat or oil is on the barbecue plates to prevent rust.

WARNING: STORE CYLINDER IN A WELL VENTILATED AREA OUT OF REACH OF CHILDREN

When the gas cylinder is disconnected, replace the plug or cap on the valve outlet.

For extended storage it is suggested that the primary air port of the burners be covered against the penetration

of insects or vermin. Spiders and small insects can spin webs or nest in the burner rails/tubes, which could lead

to obstruction in the gas and air flow, resulting in a fire in an around the burner rails/tubes. This type of fire is

called a flash-back and can cause serious damage to your barbecue and create an unsafe operating condition.

To prevent this, regularly inspect and clean the burners. A barbecue cover can be placed over the appliance for

extra protection, and to reduce this.

8

Page 9

STYLE, GRILLED TO PERFECTION

TROUBLESHOOTING

Burner will not ignite when using the igniter:

Cylinder valve is not on Turn cylinder valve on

Cylinder is empty Replace with a full cylinder

Igniter button is not working Check battery.

Igniter is not sparking Remove plate and visually check ignition box for a spark. Check that

the cable is not broken or disconnected. Also check the alignment of

the sparker. If there is no spark, contact Everdure Service.

Injector is blocked Clean injector with a toothbrush. Do not drill out or use wire. Do not

remove injector. Contact Everdure Service.

Burner flame is erratic:

Burner is blocked Remove burner and check for obstruction

Flame is burning inside

burner (hissing sound)

Turn off burner, allow to cool and re-ignite (page 3)

Regulator is faulty Contact Everdure Service.

Injector is partially blocked Clean injector with a toothbrush. Do not drill out or use wire. Do not

remove injector. Contact Everdure Service.

Gas is leaking from connections:

Connections are loose Tighten loose connections (do not over-tighten) and leak test under

pressure with soapy water solution (page 4)

Hose has deteriorated Replace hose (page 9)

Gas valve is faulty Contact Everdure Service.

Threads are damaged Contact Everdure Service.

MAINTENANCE

It is recommended that, at the commencement of each barbecue season, the following maintenance be

conducted.

BURNER

1. Remove the burner and inspect the port holes, primary air inlet and mixing throat for any signs of

blockage. Clean out with compressed air or a length of wire if necessary.

2. Wire brush the outside of the burner to remove rust and dirt.

3. Replace the burner.

GAS SUPPLY

1. Inspect the gas supply hose for any deterioration and replace it if necessary.

2. Test the gas circuit for leaks and remedy any found.

TROLLEY

1. Check all fasteners for tightness and re tighten where necessary to ensure rigidity of the structure.

2. Wipe over barbecue trolley with a clean cloth.

9

Page 10

STYLE, GRILLED TO PERFECTION

ASSEMBLY INSTRUCTIONS

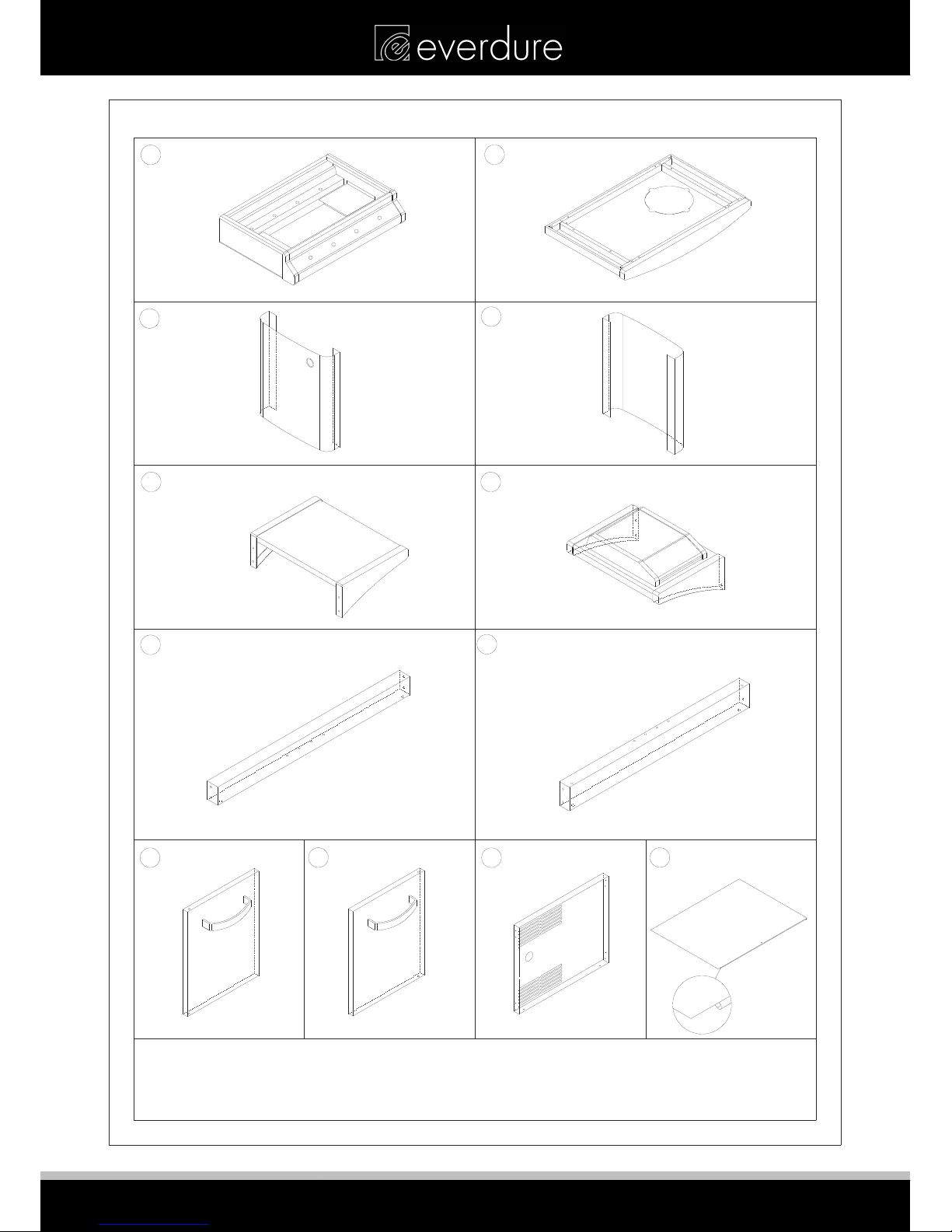

PARTS LIST

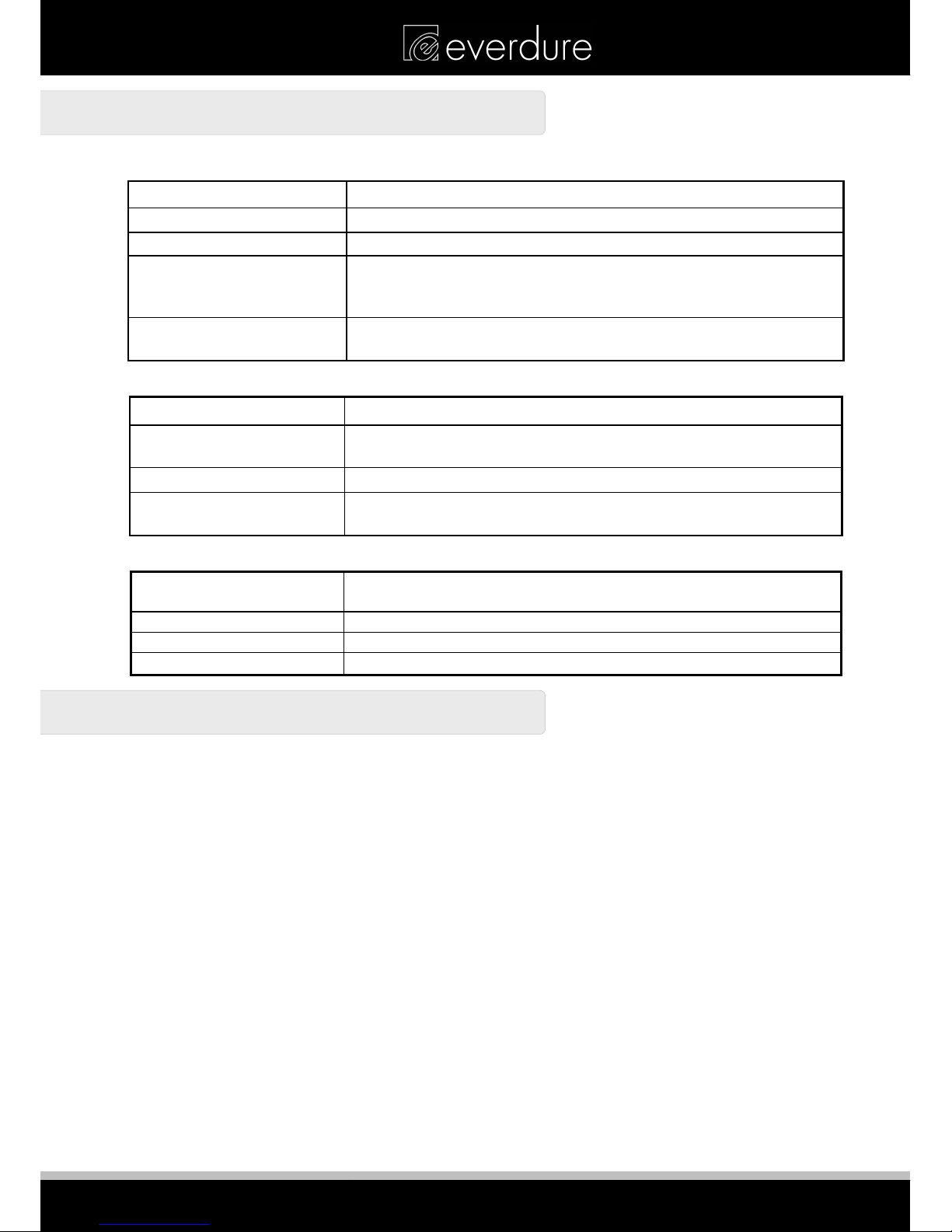

Barbecue Chassis Carton: Cooking Plates Pack: Burner Pack:

Barbecue Chassis Hot Plate 4 x Burners

Fat Tray Grill Plate

Gas Hose & Regulator (Propane only) Vapouriser

Cross-over Tube

Steel Trolley Carton: (Not built in models) Roasting Hood Carton:

Trolley Base Roasting Hood

Trolley Frame Fastener Pack

4 x Castors Assembly Instructions

Wok Burner

Fastener Pack

Remove all components from the cartons and carefully check against Parts List. Make sure you thoroughly

inspect parts before assembly and do not assemble or operate a barbecue that appears damaged. Some

assembly will require the use of a Phillips Drive screwdriver. When connecting the hose and adaptor to the

gas inlet you will require a 17mm and a 19mm Spanner or an adjustable Wrench.

NOTE: Check ‘Gas Type’ and specification plate on left-hand side of barbecue.

BARBECUE ASSEMBLY (see fig N and fig O for completed diagrams)

1. Remove the fat tray from the barbecue and place to one side until required at instruction N.

2. Firstly, build the barbecue trolley assembly following the instructions A - L.

3. Place and fit roasting hood onto barbecue as shown instruction M.

4. For barbecue assembly, follow the instruction N.

5. Fit the 4 burners to the valves and place the ‘R’ clips through the burners to secure in the location.

6. Fit the vapouriser to the right hand side of the barbecue, with the raised portions facing up.

7. Place both the hot plate and grill plate as shown in instruction N. The grill plate should be positioned

above the vapouriser on the right hand side.

8. Line the fat tray with aluminium foil and slide the fat tray in position. Do not fill the fat tray with sand or

kitty litter.

For all service and assembly enquiries call:

In Australia: 1300 766 066

In New Zealand: (09) 415 6000

Refer to the warranty card regarding your product details prior to calling.

10

Page 11

STYLE, GRILLED TO PERFECTION

RIGHT HAND DOOR

4 BURNER TROLLEY COMPONENTS

TOP DOOR INFILL PANEL

FROSTED GLASS

DOORS ARE

NOTE: KIMBERLEY

9

LEFT HAND DOOR

7

NO : NORFOLK

10

LEFT HAND

BARBECUE CARCASS

5

3

1

R/H SERVERY

CABINET TOP

DA : DAINTREEKI : KIMBERLEY

LARGE INFILL PANEL

BOTTOM DOOR INFILL PANEL

11

8

12

SIDE BURNER SERVERY

Note: Hole in

base for Propane

models only

x1

x1

x1

NO

KI

RIGHT HAND

4

6

TROLLEY BASE

2

DA

KI

NO

DAx1x1

x1 x1

x1x1DA

NO

KI

KI

NO

DAx1x1

x1

x1DA

x1KI

x1

NO

FROSTED GLASSDOORS ARE

NOTE: KIMBERLEY

LEGEND

TROLLEY SIDE

TROLLEY SIDE

x1FL

FL

x1

FL x1

FL x1

FL x1

x1

x1

x1

NO

KI

DA

FL x1

x1

x1

x1

NO

KI

DA

FL x1

x1

x1

x1

NO

KI

DA

FL

x1

x1

x1

x1

NO

KI

DA

FL

x1

x1

x1

x1

NO

KI

DA

FL x1

x1

x1

x1

NO

KI

DA

FL x1

x1

x1

x1

NO

KI

DA

FL

x1

FL : FLINDERS

11

Page 12

STYLE, GRILLED TO PERFECTION

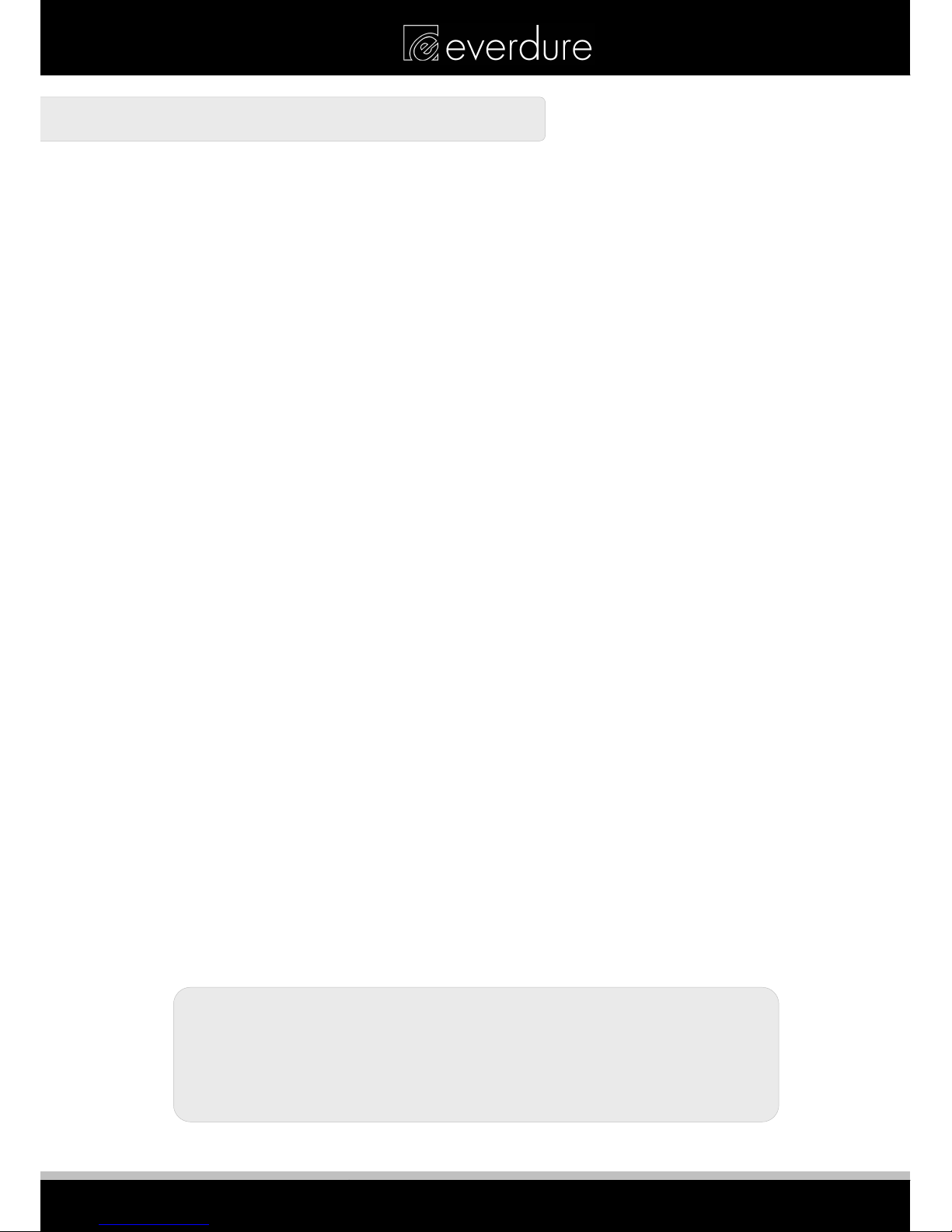

'L' BRACKET

4 BURNER FASTENER COMPONENTS

MAGNETIC CATCH

FIBRE WASHER

25

22

5mm DIAMETER WASHER

KI

NO

DA

x4

x4

x4

x8

x8

x8

NO

DA

KI

23

26

KI

NO

DA

x28

x32

x28

M5 NUT

M6 x 50 BOLT

18

13

M5 x 12 SCREW

x4

x4

x4

NO

DA

KI

19

M6 NUT

NO

DAKIx4

x4

x4

x4

x4

x4

NO

DA

FL

KI

14

NO

DA

KI

x4

x4

x4

CASTOR

6mm DIAMETER WASHER

KI x2

24

27

NO

DA

KIx4x4

x4

x4

x4

x4

KI

NO

DA

ST3.5x10 SCREW

ST3.5x10 SCREW

15

NO

DA

KI

x8

x8

x8

17

x1

x1

x1

NO

DA

KI

NO

DA

KI

x44

x44

x48

16

M5 x 20 SCREW

21

x24

x24

x28

NO

DA

KI

DOOR HINGE SPACER

M5 LOCK NUT

20

x4

x4

x4

NO

DA

KI

x4

FL

x44 FL

x4

FL

x8

FL

x1

FL

x24

FL x4

FL x4

FL x4

FL x8

FL

x28

FL x4

FL x4

FL x4

12

Page 13

STYLE, GRILLED TO PERFECTION

4 BURNER HOOD COMPONENTS

FIBRE WASHER

31

x4

x4

x4

NO

DA

KI

M5 NUT

30

M5 x 20 COUNTERSUNK SCREW

x4

x4

x4

NO

DA

KI

29

NO

DA

KI

x4

x4

x4

28

HOOD

x1

x1

x1

NO

DA

KI

x1FL

FL

x4

FL

x4

FL

x4

13

Page 14

STYLE, GRILLED TO PERFECTION

LOCATED IN THE FRAME. SEE DIAGRAMS ABOVE FOR DETAILS.

5. REPEAT ALL OF THE ABOVE FOR THE REMAINING 3 CASTORS.

4. ATTACH THE CASTOR TO THE FRAME USING 3 x M5 SCREWS (PART 14) UNTIL FULLY TIGHTENED.

3. ALIGN HOLES IN THE CASTOR PLATE TO THE CORRESPONDING HOLES OF THE NUTSERTS WHICH ARE

2. PLACE A CASTOR (PART 27) ONTO THE BASE FRAME AS SHOWN.

1. PLACE TROLLEY BASE (PART 2) UPSIDE DOWN, AS SHOWN IN THE DIAGRAM ABOVE.

FITTING OF THE CASTORS TO THE BASE ASSEMBLY

VIEW OF NUTSERTS

A

FITTED CASTOR

FINAL VIEW OF

2

14

FRONT

14

14

27

FLINDERS, NORFOLK, DAINTREE & KIMBERLEY TROLLEY ASSEMBLY

14

Page 15

STYLE, GRILLED TO PERFECTION

FLINDERS, NORFOLK, DAINTREE & KIMBERLEY TROLLEY ASSEMBLY

THE HOLES OF THE PANEL WITH THE BASE ASSEMBLY. FOLLOW STEPS 3 & 4 FOR ATTACHING THE PANEL.

6. TO ATTACH THE BOTTOM DOOR INFILL PANEL (PART 8), PLACE THE PART INTO THE POSITION SHOWN. ALIGN

5. REPEAT STEPS 3 & 4 TO SECURE THE LARGE INFILL PANEL.

4. ATTACH 1 x 6mm DIAMETER WASHER (PART 24) AND 1 x M6 NUT (PART 19) TO THE BOLT AND FULLY

PANEL, AND THROUGH THE BASE ASSEMBLY.

3. ATTACH THE PANEL BY PLACING 1 x M6 BOLT (PART 13) THROUGH ONE HOLE IN THE LARGE INFILL

PANEL AND THE BASE PLATE.

2. PLACE THE LARGE INFILL PANEL (PART 11) INTO POSITION AND ALIGN THE HOLES OF THE LARGE INFILL

1. PLACE THE BARBECUE TROLLEY BASE IN IT'S UPRIGHT POSITION AS SHOWN.

FITTING OF INFILL PANELS TO THE BASE ASSEMBLY

TIGHTEN.

B

REAR PANEL FITTED

FINAL VIEW SHOWING

8

19

24

13

11

15

Page 16

STYLE, GRILLED TO PERFECTION

6. FULLY TIGHTEN THE SCREWS NUTS AND WASHERS.

THIS WILL GIVE THE DESIRED CURVE ON THE PANEL.

DURING THIS STAGE, SOME PRESSURE WILL BE REQUIRED ON THE TROLLEY SIDE PANEL TO ALIGN THE HOLES.

ATTACHMENT OF TROLLEY SIDE PANELS

(NOTE: LEAVE THE BARBECUE IN THE UPSIDE DOWN POSITION FOR THE NEXT PART OF ASSEMBLY)

7. REPEAT ALL OF THE ABOVE STEPS FOR THE OTHER TROLLEY SIDE PANEL (PART 3 OR 4).

TROLLEY SIDE PANEL.

5. REPEAT STEPS 3 & 4 FOR THE THREE REMAINING HOLES TO COMPLETE THE ATTACHMENT OF THE

4. ATTACH 1 x 5mm DIAMETER WASHER (PART 23) AND 1 x M5 NUT (PART 18) ONTO THE SCREW. DO NOT FULLY

HOLES OF THE BARBECUE CARCASS AND THROUGH THE HOLE OF THE TROLLEY SIDE PANEL.

3. PLACE 1 x FIBRE WASHER (PART 22) ONTO 1 x M5 SCREW (PART 14). PLACE THE SCREW THROUGH ONE OF THE

HOLES OF THE BARBECUE CARCASS.

2. ALIGN THE HOLES AT ONE END OF ONE TROLLEY SIDE PANEL (PART 3 OR 4) WITH THE CORRESPONDING

1. PLACE THE BARBECUE CARCASS (PART 1) UPSIDE DOWN AS SHOWN ABOVE.

TIGHTEN AT THIS STAGE.

C

STAGE OF ASSEMBLY

IS UPSIDE DOWN FOR THIS

NOTE: THE BARBECUE CARCASS

THE SIDE BURNER HOSE

NOTE: PLEASE ENSURE THE HOLE FOR

IS TO THIS SIDE

BARBECUE

FRONT OF

1

14

14

22

22

3

4

23

23

18

18

FLINDERS, NORFOLK, DAINTREE & KIMBERLEY TROLLEY ASSEMBLY

16

Page 17

STYLE, GRILLED TO PERFECTION

NOTE: DO NOT FULLY TIGHTEN THESE SCREWS AT THIS STAGE.

6. REPEAT STEPS 3 TO 5 FOR THE REMAINING 3 POSITIONS.

5. ATTACH 1 x 5mm DIAMETER WASHER (PART 23) & 1 x M5 NUT (PART 18) ONTO THE SCREW.

CORRESPONDING HOLE OF THE TROLLEY SIDE PANEL.

4. PLACE 1 x M5 SCREW (PART 14) THROUGH THE HOLE OF THE INFILL PANEL AND THROUGH THE

3. ALIGN THE HOLES OF THE INFILL PANEL WITH THE HOLES IN THE TROLLEY SIDES.

2. PLACE THE INFILL PANEL INTO THE POSITION SHOWN IN THE ABOVE DIAGRAM.

IS UPSIDE DOWN.

1. THE TOP DOOR INFILL PANEL (PART 7) CAN BE ATTACHED TO THE TROLLEY SIDES, WHILE THE BARBECUE

ATTACHING TOP DOOR INFILL PANEL

FLINDERS, NORFOLK, DAINTREE & KIMBERLEY TROLLEY ASSEMBLY

D

14

7

14

23

23

18

18

17

Page 18

STYLE, GRILLED TO PERFECTION

4. REPEAT THE ABOVE STEPS FOR THE OTHER POSITIONS AS SHOWN ABOVE.

3. PLACE 1 x 5mm DIAMETER WASHER (PART 23) AND 1 x M5 NUT (PART 18) ONTO THE M5 SCREW AND

CORRESPONDING HOLE OF THE TROLLEY SIDE PANEL (PART 3 OR 4).

2. PLACE 1 X M5 SCREW (PART 14) THROUGH A HOLE IN ONE OF THE INFILL PANELS AND THROUGH THE

1. GENTLY LOWER THE BARBECUE ASSEMBLY ONTO THE BASE AS SHOWN ABOVE.

ATTACHING THE BARBECUE TO THE BASE ASSEMBLY

FLINDERS, NORFOLK, DAINTREE & KIMBERLEY TROLLEY ASSEMBLY

FULLY TIGHTEN.

E

FROM THE FRONT. SEE DIAGRAM.

WHEN LOOKING AT THE BARBECUE

BASE IS TO THE LEFT HAND SIDE,

THAT THE LARGE HOLE IN THE

NOTE: FOR PROPANE BARBECUES, ENSURE

AND BOTTOM DOOR INFILL PANEL

ATTACHMENT OF TROLLEY SIDE

ENLARGED VIEW FOR

14

14

14

18

23

23

18

14

23

23

18

18

18

Page 19

STYLE, GRILLED TO PERFECTION

4. FOR FLINDERS, NORFOLK & DAINTREE BARBECUES SEE PAGE 22 FOR NEXT INSTRUCTION.

3. FULLY TIGHTEN THE SCREWS. REPEAT FOR THE REMAINING 3 CATCHES.

2. ATTACH THE CATCH BY USING 2 x ST3.5x10 SCREWS (PART 16) AND A PHILLIPS HEAD SCREW DRIVER.

1. PLACE 1 x MAGNETIC CATCH (PART 25) INTO POSITION AS SHOWN ABOVE.

FITTING OF THE MAGNETIC CATCHES TO THE CABINET

FLINDERS, NORFOLK, DAINTREE & KIMBERLEY TROLLEY ASSEMBLY

F

FOR FITTING THE MAGNETIC CATCHES

ENLARGED VIEW OF HOLES

16

16

16

25

25

16

19

Page 20

STYLE, GRILLED TO PERFECTION

6. REPEAT ALL OF THE ABOVE STEPS FOR THE OTHER TROLLEY SIDE PANEL.

5. ATTACH 1 x 5mm DIAMETER WASHER (PART 23) & 1 x M5 NUT (PART 18) TO THE SCREW AND

THROUGH THE HOLE OF THE 'L' BRACKET (PART 26).

4. PLACE 1 x M5 SCREW (PART 14) THROUGH THE HOLE OF THE TROLLEY SIDE PANEL AND

3. ATTACH 1 x 5mm DIAMETER WASHER (PART 23) & 1 x M5 NUT (PART 18) TO THE SCREW AND

THROUGH THE HOLE OF THE TROLLEY BASE PANEL.

2. PLACE 1 x M5 SCREW (PART 14) THROUGH THE HOLE OF THE 'L' BRACKET (PART 26) AND

1. ALIGN THE HOLES IN THE 'L' BRACKET (PART 26) WITH THE HOLES IN THE TROLLEY BASE.

FITTING OF THE 'L' BRACKETS

KIMBERLEY TROLLEY ASSEMBLY

FULLY TIGHTEN.

FULLY TIGHTEN.

G

OF THE 'L' BRACKETS AND FASTENERS

ENLARGED VIEW TO SHOW FINAL ATTACHMENT

18

23

14

18

23

14

26

20

Page 21

STYLE, GRILLED TO PERFECTION

KIMBERLEY TROLLEY ASSEMBLY

H

ATTACHMENT OF THE DOORS TO THE CABINET

9. SEE PAGE 23 FOR THE NEXT INSTRUCTION FOR KIMBERLEY TROLLEYS.

VIEW "A"

9

10

ENLARGED VIEW TO SHOW

INFILL PANEL ROTATED

FINAL ASSEMBLED

VIEW

20

23

21

15

20

23

21

15

1. TAKE THE LEFT HAND DOOR (PART 9 WITH GLASS) AND ALIGN THE HOLE IN THE BOTTOM DOOR INFILL PANEL.

3. PUSH A 12MM x M5 SCREW (PART 15) THROUGH THE HOLE IN THE BOTTOM OF THE DOOR, THROUGH THE

SPACER AND THROUGH THE HOLE IN THE BOTTOM INFILL PANEL.

4. PLACE 1 x M5 WASHER (PART 23) AND 1 x M5 LOCK NUT (PART 20) ONTO THE M5 SCREW AND TIGHTEN.

2. PLACE A DOOR HINGE SPACER (PART 21) BETWEEN THE DOOR AND THE INFILL PANEL.

5. FOR THE DOOR TOP, CAREFULLY PLACE A DOOR HINGE SPACER BETWEEN THE DOOR AND THE TOP INFILL

PANEL. NOTE: IF IT IS A TIGHT FIT, ROTATE THE PANEL SLIGHTLY (SEE VIEW "A" ABOVE).

6. PUSH A 12MM x M5 SCREW (PART 15) THROUGH THE HOLE IN THE TOP OF THE DOOR, THROUGH THE

SPACER AND THROUGH THE HOLE IN THE TOP INFILL PANEL. NOTE: THE PANEL CAN NOW BE ROTATED BACK.

7. PLACE 1 x M5 WASHER (PART 23) AND 1 x M5 LOCK NUT (PART 20) ONTO THE M5 SCREW BUT DON'T TIGHTEN.

8. REPEAT STEPS 1-7 FOR THE RIGHT HAND DOOR (PART 10 WITH GLASS). FULLY TIGHTEN ALL OF THE NUTS AND

SCREWS ON THE DOOR TOPS AND THE TOP INFILL PANEL.

21

Page 22

STYLE, GRILLED TO PERFECTION

1. TAKE THE LEFT HAND DOOR (PART 9) AND ALIGN THE HOLE IN THE BOTTOM DOOR INFILL PANEL.

3. PUSH A 12MM x M5 SCREW (PART 15) THROUGH THE HOLE IN THE BOTTOM OF THE DOOR, THROUGH THE

SPACER AND THROUGH THE HOLE IN THE BOTTOM INFILL PANEL.

4. PLACE 1 x M5 WASHER (PART 23) AND 1 x M5 LOCK NUT (PART 20) ONTO THE M5 SCREW AND TIGHTEN.

VIEW "A"

ATTACHMENT OF THE DOORS TO THE CABINET

FLINDERS, NORFOLK & DAINTREE TROLLEY ASSEMBLY

I

9

10

ENLARGED VIEW TO SHOW

INFILL PANEL ROTATED

FINAL ASSEMBLED

VIEW

2. PLACE A DOOR HINGE SPACER (PART 21) BETWEEN THE DOOR AND THE INFILL PANEL.

20

23

21

15

20

23

21

15

5. FOR THE DOOR TOP, CAREFULLY PLACE A DOOR HINGE SPACER BETWEEN THE DOOR AND THE TOP INFILL

PANEL. NOTE: IF IT IS A TIGHT FIT, ROTATE THE PANEL SLIGHTLY (SEE VIEW "A" ABOVE).

6. PUSH A 12MM x M5 SCREW (PART 15) THROUGH THE HOLE IN THE TOP OF THE DOOR, THROUGH THE

SPACER AND THROUGH THE HOLE IN THE TOP INFILL PANEL. NOTE: THE PANEL CAN NOW BE ROTATED BACK.

7. PLACE 1 x M5 WASHER (PART 23) AND 1 x M5 LOCK NUT (PART 20) ONTO THE M5 SCREW BUT DON'T TIGHTEN.

8. REPEAT STEPS 1-7 FOR THE RIGHT HAND DOOR (PART 10). FULLY TIGHTEN ALL OF THE NUTS AND SCREWS

ON THE DOOR TOPS AND THE TOP INFILL PANEL.

22

Page 23

STYLE, GRILLED TO PERFECTION

6. REPEAT ALL OF THE ABOVE STEPS FOR THE LEFT HAND SERVERY WITH WOK BURNER.

5. AFTER ATTACHING, FULLY TIGHTEN ALL FOUR OF THE SCREWS.

WITH TWO MORE M5 SCREWS (PART 14).

4. ALIGN THE REMAINING TWO HOLES WITH THE NUTSERTS IN THE BARBECUE CARCASS. ATTACH

3. REPEAT THIS STEP FOR THE TOP HOLE AT THE REAR END OF THE SERVERY.

AND SCREW IT INTO THE NUTSERT. DO NOT FULLY TIGHTEN.

2. PLACE 1 x M5 SCREW (PART 14) THROUGH THE TOP HOLE AT THE FRONT OF THE SERVERY,

SEE ENLARGED VIEW.

1. ALIGN THE HOLES IN THE SERVERY (PART 5) WITH THE NUTSERTS IN THE BARBECUE CARCASS.

FITTING OF THE SERVERIES

FLINDERS, NORFOLK, DAINTREE & KIMBERLEY TROLLEY ASSEMBLY

J

THE BARBECUE CARCASS

FITTING OF SERVERIES TO

14

6

14

14

14

5

NOTE: FOLLOW THE INSTRUCTIONS SUPPLIED WITH THE WOK BURNER AND INSTRUCTION K

FOR GAS CONNECTION AND TESTING.

23

Page 24

STYLE, GRILLED TO PERFECTION

2. PROPANE CONNECTION: ATTACH THE SMALL WOK BURNER HOSE TO THE BBQ MANIFOLD (SEE ABOVE)

CONNECTING THE GAS SUPPLY TO THE WOK BURNER

1. CHECK THE GAS TYPE OF THE WOK BURNER (LABEL ON BOTTOM OF WOK BURNER SERVERY) MATCHES

THAT OF THE BBQ.

FLINDERS, NORFOLK, DAINTREE & KIMBERLEY TROLLEY ASSEMBLY

K

WOK BURNER GAS SUPPLY HOSE

CONNECTION TO BBQ MANIFOLD

IS DONE FROM INSIDE THE TROLLEY

HOLE IN TROLLEY SIDE FOR HOSE

GAS SUPPLY HOSE AND

REGULATOR

THROUGH THE HOLE IN THE LEFT HAND TROLLEY SIDE PANEL. CONNECT GAS HOSE AND REGULATOR

TO THE GAS CYLINDER (SEE PAGE 4 FOR OTHER INSTALLATION AND LEAK TEST INSTRUCTIONS).

3. NG CONNECTION: ALL GAS FITTING WORK, SERVICE AND REPAIRS CAN ONLY BE PERFORMED BY AN

AUTHORISED PERSON IN ACCORDANCE WITH AS5601 / AG601 AND LOCAL GAS REGULATIONS.

INSTRUCTIONS FOR AUTHORISED PERSON: FIT SMALL WOK BURNER HOSE TO BBQ MANIFOLD (SEE PAGE 4

FOR OTHER INSTALLATION AND LEAK TESTING INSTRUCTIONS).

24

Page 25

STYLE, GRILLED TO PERFECTION

2. ALIGN THE HOLE IN THE CABINET TOP (PART 12) WITH THE HOLE IN THE LARGE INFILL PANEL (PART 11)

TO THE REAR INFILL PANEL (PART 11). FULLY TIGHTEN THE SCREW.

3. PLACE 1 x ST3.5x10 SCREW (PART 17) THROUGH THE HOLE OF THE CABINET TOP (PART 12) AND ATTACH IT

ATTACHING THE CABINET TOP TO THE TROLLEY

1. PLACE THE CABINET TOP (PART 12) ONTO THE BARBECUE CARCASS ENSURING THAT THE SAFETY EDGES

ARE FACING DOWN. SEE VIEW 'A' ABOVE FOR DETAILS.

FLINDERS, NORFOLK, DAINTREE & KIMBERLEY TROLLEY ASSEMBLY

L

VIEW 'A'

11

12

17

25

Page 26

STYLE, GRILLED TO PERFECTION

2. PLACE THE HOOD ASSEMBLY (PART 28) ON TOP OF THE BARBECUE SO THAT THE TABS IN THE REAR HOOD

SIDES LINE UP WITH THE HOLES ALONG THE INNER EDGES OF THE BARBECUE. TAKE CARE NOT TO DAMAGE

3. PLACE 1 x M5 SCREW THROUGH THE HOLE OF A REAR HOOD SIDE TAB, FIX A FIBRE WASHER, AND LOOSELY FIT

ATTACHING THE HOOD TO THE BARBECUE

1. THE HOOD CARTON CONTAINS IT'S OWN HARDWARE PACK, CONSISTING OF FOUR M5 NUTS (PART 30),

FOUR M5 x 20 SCREWS (PART 29) AND FOUR FIBRE WASHERS (PART 31).

FLINDERS, NORFOLK, DAINTREE & KIMBERLEY HOOD ASSEMBLY

M

EITHER COMPONENT.

A M5 NUT. REPEAT FOR ALL FOUR HOLES, THEN FULLY TIGHTEN ALL THE NUTS.

4. CHECK THAT THE HOOD OPENS AND CLOSES CORRECTLY BEFORE USE.

28

29

29

30

31

5. NOTE: THE HOOD PANEL OF SOME MODELS WILL HAVE A GLASS WINDOW. TAKE CARE NOT TO DAMAGE.

26

Page 27

STYLE, GRILLED TO PERFECTION

FLINDERS, NORFOLK, DAINTREE & KIMBERLEY BARBECUE ASSEMBLY

N

NOTE: THE HOOD, SERVERIES AND DOORS ARE NOT SHOWN FOR CLARITY.

HOT PLATE

GRILL PLATE

BURNERS

'R' CLIPS

CROSS-OVER TUBES

VAPOURISER (RAISED

PORTIONS FACING UP)

BARBECUE CHASSIS

FAT TRAY

GAS CYLINDER AND HOSE.

CYLINDER IS PLACED IN

LOCATING HOLE IN TROLLEY

BASE (NOT APPLICABLE FOR

NG MODELS).

FOR PROPANE GAS:

GAS HOSE IS CONNECTED TO

THE MANIFOLD INSIDE THE

TROLLEY CABINET AS SHOWN.

27

Page 28

STYLE, GRILLED TO PERFECTION

FLINDERS, NORFOLK, DAINTREE & KIMBERLEY COMPLETE BARBECUE ASSEMBLY

O

NOTE: THE HOOD IS NOT SHOWN FOR CLARITY.

NOTE: THE KIMBERLEY HAS FROSTED GLASS DOORS.

28

Page 29

STYLE, GRILLED TO PERFECTION

EVERDURE BARBECUE ACCESSORIES (OPTIONAL)

Everdure also offers a comprehensive range of essential barbecue accessories - everything that you need to

turn your barbecue into a complete outdoor cooking system and also to prolong the use of your product.

Visit www.everdure.com for regular product updates.

EVERDURE BARBECUE COVERS

EVERDURE BARBECUE ROTISSERIE

EVERDURE BARBECUE TOOLS

Everdure barbecue tool sets are ergonomically designed to allow ease of use. Visit www.everdure.com for

more details.

To extend the life of your barbecue and trolley

and to keep it looking great, we recommend

using the Everdure Weatherproof Cover.

Main Features:

-

Cibatex APS treatment – a special agent

that reduces photodegradation to offer

the best protection against the harsh

Australian outdoor elements

-

100% Waterproof

-

UV Stable Fabric – reduces fading

-

Polyester Oxford-PVC backed fabric

-

Model No. AC4BVC-10

Everdure barbecue hoods are designed to fit a 240 volt rotisserie, which will allow you to cook

your favourite meats.

Main Features:

-

Full Stainless Steel rod and rotisserie forks (adjustable and lockable)

-

240 Volts

-

Slow rotation to allow even cooking

-

Model No. AC4ROUB10

29

Page 30

STYLE, GRILLED TO PERFECTION

NATURAL GAS CONVERSION & INSTALLATION

NG CONVERSIONS CAN ONLY BE DONE BY AN AUTHORISED PERSON.

FOR BBQS SUPPLIED WITH TROLLEYS, THE BBQ IS NOT DESIGNED FOR FIXED

INSTALLATION – DO NOT REMOVE CASTORS.

IMPORTANT – FOR THE CONSUMER & INSTALLER

1. CHECK WITH EVERDURE

Not all Everdure barbecues are certified for conversion to NG. If in doubt, contact us on 1300 766 066 in Australia, or

(09) 415 6000 in New Zealand.

2. LOCAL AUTHORITY REQUIREMENTS

All gas fitting work, service and repairs should only be performed by an authorised person in accordance to AS5601 and your local

gas regulations. If you are unsure who this is, please contact us.

3. CHECK THE CONVERSION KIT IS CORRECT FOR YOUR BBQ, AND THAT ALL PARTS ARE PRESENT

Many of the Everdure NG conversion kits are common for a number of different models. Check the table below for your model

barbecue, and only use the parts listed for that model. Using the incorrect gas injectors on an Everdure BBQ can invalidate the

warranty.

PARTS LIST:

ITEM DESCRIPTION

ITEM CODE

QUANTITY

Classic 4

burner, Classic

Esee 4 burner

Wok burner gas valve injector

(Ø1.8mm)

BBA0336 1

BBQ gas valve injector

(Ø1.8mm)

BBA0336 4

Natural gas label BBA0840 2

Manifold inlet adaptor (NG)

3/8”x1/2”BSP

DCC0390 1

Natural gas regulator SHA0410 1

Natural gas stainless steel

hose

DCA0425 1

Nylon bush TMA0340 -

IMPORTANT – FOR THE INSTALLER

1. Remove the burners from the BBQ (by removing the clip at the back of each burner).

2. Remove the injector from each gas valve using a spanner & replace with an Ø1.8mm injector, taking care not to over-tighten the new

injector.

3. Replace each burner and secure by replacing the clips.

4. Unscrew the wok burner gas valve from the underside of the wok servery.

5. Remove the injector from the wok burner gas valve using a spanner & replace with an Ø1.8mm injector, taking care not to over-tighten

the new injector. Check the data label or instruction manual for injector size, or ring Everdure Service with the serial number to confirm

injector size.

6. Screw the wok burner gas valve back into place under the wok servery, making sure the gas valve is correctly allocated in the throat of the

burner.

7. Remove the Propane hose and regulator from the BBQ manifold inlet.

8. Add a small amount of approved sealant to the manifold’s 3/8”BSP thread and screw on the NG inlet adaptor until tight.

9. Add a small amount of approved sealant to the inlet adaptor’s ½” BSPT thread and screw on the supplied regulator (note that the arrow

on the regulator should be pointing to the adaptor).

10 Add a small amount of approved sealant to the hose’s ½” BSPT thread and screw onto the other end of the regulator.

11. Cover the existing “propane” label with the supplied “Natural gas” label.

12. If there is already an Ø45mm hole in the trolley rear panel (without a safety edge), check that a nylon bush is fitted to stop the hose

being damaged. Run the hose through the hole. If no hole is present, drill an Ø45mm hole in the trolley rear panel, centred 50mm in

from the side & 220mm from the base on the vented side. Place a nylon bush in the hole & run the hose out through it.

13. Connect a manometer to the regulator. Turn off all valves & connect the gas hose to the natural gas supply. Leak test as per the

instructions (tighten any joints which leak & replace any faulty parts). Light all BBQ burners, set them all to high and adjust the pressure

(using the adjustment screw on the regulator) to 0.95kPa.

14. The installer must instruct the consumer on the safe & correct operation of the BBQ and hand over all operating instructions.

30

Page 31

STYLE, GRILLED TO PERFECTION

IMPORTANT – FOR THE CONSUMER & INSTALLER

Once the barbecue has been converted to natural gas, a tether kit must be fixed to the rear panel of the barbecue trolley (this

kit is not needed for the built-in models). This must then be connected to a point near or on the gas outlet (bayonet point) at

the wall.

Note: The tether kit is designed only to warn the barbecue operator that the natural gas hose is connected and may become

under stress. The strength of the chain is such that it will not support the weight of a toppling barbecue, or a barbecue forced

out of position. The manufacturer takes no responsibility for any damage done to a barbecue of the surrounding area if the

tether kit is broken.

1. Take the round link of the tether kit chain and place the supplied M5 screw through it. Push the screw through the Ø7mm hole (to the

side of the NG hose hole) and fix in place with the supplied M5 self-locking nut (see diagram below).

2. If convenient, wrap the hook end of the chain around the bayonet point and fix in place with the hook (disregard parts 3 (eyelet) and 4

(wall plug)).

3. If tether kit cannot be fixed directly to the bayonet point, fix the eyelet into the wall (using the wall plug if necessary), and hook the

tether kit hook onto that.

4. Check that the chain goes taunt before the NG hose does when moving the barbecue in all directions.

5. The hook should only be unhitched when the NG hose is to be disconnected from the bayonet point.

6 burner model shown.

31

Page 32

STYLE, GRILLED TO PERFECTION

EXPLODED COMPONENT DIAGRAMS

REF DESCRIPTION

QTY USED

PER BBQ

4 BURNER

1.00 HOOD HANDLE 1

2.00 TEMPERATURE GAUGE 1

3.00 FRONT HOOD ASSY 1

4.00 HOOD HINGE BOLT 2

5.00 REAR HOOD no lighting panel 1

5.10 HOOD HARDWARE KIT 1

6.00 LIGHTING PANEL 0

7.00 GLOBE 20W 12V AC 0

8.00 GLASS COVER - LIGHT 0

9.00 WARMING RACK 1

10.00 HOT PLATE 1

11.00 GRILL PLATE 1

12.00 FLAME TAMER 1

13.00 LOCKING CLIP (rail burner) 4

14.00 RAIL BURNER 4

15.00 FAT TRAY 1

16.00 FAT TRAY HANDLE 1

17.00 CROSSOVER PANEL 1

18.00 CARCUSS / BODY 1

19.00 WIRING - LIGHT SWITCH 0

20.00 FACIA ASS'Y 1

21.00 GAS VALVE (includes injector) 4

21.10 INJECTOR 5

22.00 SINGLE POINT IGNITION BOX 2

23.00 ELECTRODE & SHROUD 1

24.00 FACIA PANEL 1

25.00 BEZEL 5

26.00 LIGHT SWITCH 0

27.00 KNOB 4

28.00 IGNITION BUTTON 2

29.00 LPG HOSE & REGULATOR 1

32

Page 33

STYLE, GRILLED TO PERFECTION

REF DESCRIPTION

QTY USED

PER BBQ

4 BURNER

30.00 WOK LID 1

31.00 TRIVET WOK 1

32.00 BRASS RING BURNER 1

33.00 WOK/LEFT HAND SERVERY no lid 1

34.00 WOK KNOB & BEZEL 1

35.00 ELECTRODE SPRING & CLIP 1

36.00 WOK HOSE 1

37.00 RIGHT HAND SIDE SEVERY 1

38.00 TOP TROLLEY PANEL 1

39.00 SCREW IN WIRING 0

40.00 TRANSFORMER 0

41.00 REAR TROLLEY PANEL 1

42.00 RIGHT HAND SIDE TROLLEY PANEL

1

43.00 LEFT HAND SIDE TROLLEY PANEL 1

44.00 TOP INFILL TROLLEY PANEL 1

45.00 MAGNET 4

46.00 TROLLEY DOOR 2

47.00 DOOR HANDLE 2

48.00 BOTTOM INFILL TROLLEY PANEL 1

49.00 TROLLEY BASE PLATE ASSY 1

50.00 CASTOR WHEEL 4

51.00 HARDWARE KIT 1

52.00 DOOR HARDWARE KIT 1

33

Page 34

STYLE, GRILLED TO PERFECTION

NOTES

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

34

Page 35

STYLE, GRILLED TO PERFECTION

NOTES

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

___________________________________________________________________

Other Products Available from Everdure (visit www.everdure.com for more details):

Gas Heaters Electric Heaters

Gas Radiant Ceramic Tower and Personal Heaters

Heaters

35

Page 36

STYLE, GRILLED TO PERFECTION

A division of Shriro Australia Pty Ltd

104 Vanessa St Kingsgrove NSW 2208

In Australia: 1300 766 066

www.everdure.com

IM Ref: DCG 0480 08/2015/06FC

FOR OUTDOOR USE ONLY

STYLE. GRILLED TO PERFECTION

Loading...

Loading...